Page 1

TECHNICAL

*

MANUAL

LSI53C896

PCI to Dual Channel

Ultra2 SCSI

Multifunction Controller

Version 3.2

April 2001

®

Page 2

This document contains proprietary information of LSI Logic Corporation. The

*

information contained herein is not to be used by or disclosed to third parties

without the express written permission of an officer of LSI Logic Corporation.

LSI Logic products are not intended for use in life-support appliances, devices,

or systems. Use of any LSI Logic product in such applications without written

consent of the appropriate LSI Logic officer is prohibited.

Document DB14-000083-03, Fourth Edition (April 2001)

This document describes the LSI Logic LSI53C896 PCI to Dual Channel Ultra2

SCSI Multifunction Controller and will remain the official reference source for all

revisions/releases of this product until rescinded by an update.

To receive product literature, visit us at http://www.lsilogic.com.

LSI Logic Corporation reserves the right to make changes to any products herein

at any time without notice. LSI Logic does not assume any responsibility or

liability arising out of the application or use of any product described herein,

except as expressly agreed to in writing by LSI Logic; nor does the purchase or

use of a product from LSI Logic convey a license under any patent rights,

copyrights, trademark rights, or any other of the intellectual property rights of

LSI Logic or third parties.

Ultra SCSI is the term used by the SCSI Trade Association (STA) to describe

Fast-20 SCSI, as documented in the SCSI-3 Fast-20 Parallel Interface standard,

X3.277-199X.

Ultra2 SCSI is the term used by the SCSI Trade Association (STA) to describe

Fast-40 SCSI, as documented in the SCSI Parallel Interface–2 standard, (SPI–2)

X3T10/1142D.

Copyright © 1998–2001 by LSI Logic Corporation. All rights reserved.

TRADEMARK ACKNOWLEDGMENT

The LSI Logic logo design, TolerANT, LVDlink, and SCRIPTS are registered

trademarks or trademarks of LSI Logic Corporation. All other brand and product

names may be trademarks of their respective companies.

ii

Page 3

Audience

*

Organization

Preface

This book is the primary reference and technical manual for the LSI Logic

Corporation LSI53C896 PCI to Dual Channel Ultra2 SCSI Multifunction

Controller. It contains a complete functional description for the product

and includes complete physical and electrical specifications.

This document was prepared for system designers and programmers

who are using this device to design an Ultra2 SCSI port for PCI-based

personal computers, workstations, servers or embedded applications.

This document has the following chapters and appendixes:

• Chapter 1, Introduction, describes the general information about the

LSI53C896.

• Chapter 2, Functional Description, describes the main functional

areas of the chip in more detail, including the interfaces to the SCSI

bus and external memory.

• Chapter 3, Signal Descriptions, contains the pin diagram and signal

descriptions.

• Chapter 4, Registers, describes each bit in the operating registers,

and is organized by register address.

• Chapter 5, SCSI SCRIPTS Instruction Set, defines all of the SCSI

SCRIPTS instructions that are supported by the LSI53C896.

• Chapter 6, Specifications, contains the electrical characteristics and

AC timing diagrams.

• Appendix A, Register Summary, is a register summary.

Preface iii

Page 4

• Appendix B, External Memory Interface Diagram Examples,

*

Related Publications

For background information, please contact:

ANSI

11 West 42nd Street

New York, NY 10036

(212) 642-4900

Ask for document number X3.131-199X (SCSI-2)

Global Engineering Documents

15 Inverness Way East

Englewood, CO 80112

(800) 854-7179 or (303) 397-7956 (outside U.S.) FAX (303) 397-2740

Ask for document number X3.131-1994 (SCSI-2); X3.253

(SCSI-3 Parallel Interface)

ENDL Publications

14426 Black Walnut Court

Saratoga, CA 95070

(408) 867-6642

Document names: SCSI Bench Reference, SCSI Encyclopedia, SCSI

Tutor

contains several example interface drawings for connecting the

LSI53C896 to external ROMs.

Prentice Hall

113 Sylvan Avenue

Englewood Cliffs, NJ 07632

(800) 947-7700

Ask for document number ISBN 0-13-796855-8, SCSI: Understanding

the Small Computer System Interface

LSI Logic World Wide Web Home Page

www.lsilogic.com

SCSI SCRIPTS™ Processors Programming Guide, Version 2.2,

Order Number S14044.A

iv Preface

Page 5

PCI Special Interest Group

*

2575 N. E. Katherine

Hillsboro, OR 97214

(800) 433-5177; (503) 693-6232 (International); FAX (503) 693-8344

Conventions Used in This Manual

The word assert means to drive a signal true or active. The word

deassert means to drive a signal false or inactive.

Hexadecimal numbers are indicated by the prefix “0x” —for example,

0x32CF. Binary numbers are indicated by the prefix “0b” —for example,

0b0011.0010.1100.1111.

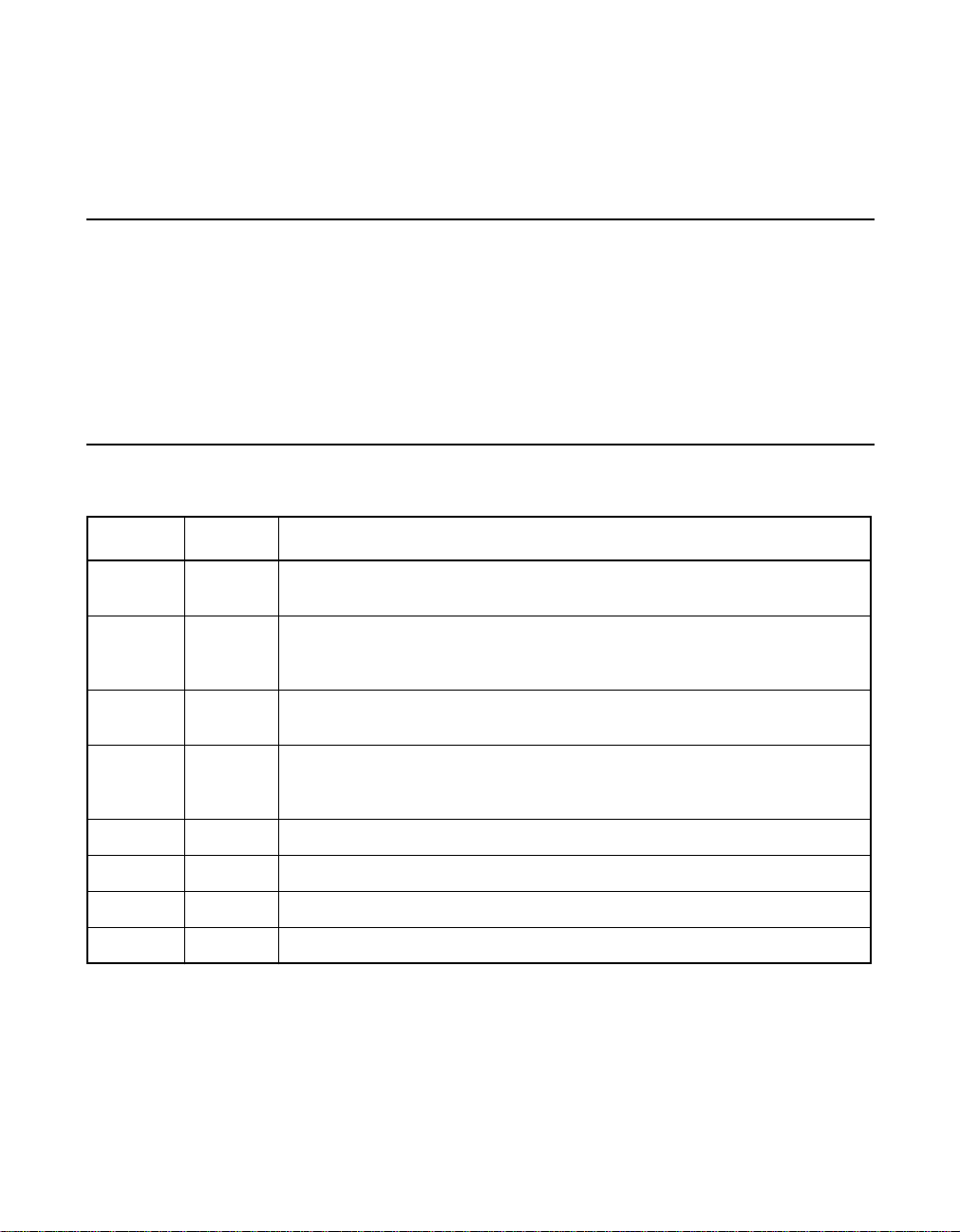

Revision Record

Revision Date Remarks

0.5 7/97 Advanced Information Data. Contains Signal Descriptions, Registers, and

0.6 10/22/97 First Draft. Added Introduction, Functional Description, SCSI SCRIPTS

1.0 3/11/98 Changes throughout to reflect manual review process and preproduction

2.0 1/18/99 Miscellaneous changes/corrections to reflect product qualification. A table

2.1 4/12/99 Miscellaneous cosmetic/format changes.

3.0 11/99 Final version.

3.1 1/01 All product names changed from SYM to LSI.

3.2 4/01 Changes made to Chapter 6 to DC Characteristics.

Mechanical Drawings.

Instruction Set, Electrical Characteristics, Register Summary, and External

Memory Interface Diagram Examples.

chip revisions.

showing LSI53C896 internal pull-up and pull-downs has been added to

Chapter 3.

Preface v

Page 6

vi Preface

*

Page 7

Contents

*

Chapter 1 Introduction

1.1 General Description 1-1

1.1.1 New Features in the LSI53C896 1-3

1.2 Benefits of Ultra2 SCSI 1-4

1.3 Benefits of LVDlink 1-4

1.4 TolerANT®Technology 1-5

1.5 LSI53C896 Benefits Summary 1-6

1.5.1 SCSI Performance 1-6

1.5.2 PCI Performance 1-7

1.5.3 Integration 1-8

1.5.4 Ease of Use 1-8

1.5.5 Flexibility 1-8

1.5.6 Reliability 1-9

1.5.7 Testability 1-10

Chapter 2 Functional Description

2.1 PCI Functional Description 2-2

2.1.1 PCI Addressing 2-3

2.1.2 PCI Bus Commands and Functions Supported 2-4

2.1.3 Internal Arbiter 2-11

2.1.4 PCI Cache Mode 2-11

2.2 SCSI Functional Description 2-19

2.2.1 SCRIPTS Processor 2-20

2.2.2 Internal SCRIPTS RAM 2-21

2.2.3 64-Bit Addressing in SCRIPTS 2-22

2.2.4 Hardware Control of SCSI Activity LED 2-22

2.2.5 Designing an Ultra2 SCSI System 2-23

2.2.6 Prefetching SCRIPTS Instructions 2-24

2.2.7 Opcode Fetch Burst Capability 2-25

Contents vii

Page 8

2.2.8 Load/Store Instructions 2-26

*

2.2.9 JTAG Boundary Scan Testing 2-26

2.2.10 SCSI Loopback Mode 2-27

2.2.11 Parity Options 2-27

2.2.12 DMA FIFO 2-30

2.2.13 SCSI Bus Interface 2-35

2.2.14 Select/Reselect During Selection/Reselection 2-40

2.2.15 Synchronous Operation 2-40

2.2.16 Interrupt Handling 2-43

2.2.17 Interrupt Routing 2-50

2.2.18 Chained Block Moves 2-52

2.3 Parallel ROM Interface 2-56

2.4 Serial EEPROM Interface 2-58

2.4.1 Default Download Mode 2-58

2.4.2 No Download Mode 2-59

2.5 Power Management 2-59

2.5.1 Power State D0 2-60

2.5.2 Power State D1 2-61

2.5.3 Power State D2 2-61

2.5.4 Power State D3 2-61

Chapter 3 Signal Descriptions

3.1 Internal Pull-ups on LSI53C896 Signals 3-4

3.2 PCI Bus Interface Signals 3-5

3.2.1 System Signals 3-5

3.2.2 Address and Data Signals 3-6

3.2.3 Interface Control Signals 3-7

3.2.4 Arbitration Signals 3-8

3.2.5 Error Reporting Signals 3-9

3.2.6 Interrupt Signals 3-10

3.2.7 SCSI Function A GPIO Signals 3-11

3.2.8 SCSI Function B GPIO Signals 3-12

3.3 SCSI Bus Interface Signals 3-13

3.3.1 SCSI Function A Signals 3-13

3.3.2 SCSI Function B Signals 3-16

3.4 Flash ROM and Memory Interface Signals 3-19

3.5 Test Interface Signals 3-20

viii Contents

Page 9

3.6 Power and Ground Signals 3-21

*

3.7 MAD Bus Programming 3-22

Chapter 4 Registers

4.1 PCI Configuration Registers 4-1

4.2 SCSI Registers 4-19

4.3 64-Bit SCRIPTS Selectors 4-107

4.4 Phase Mismatch Jump Registers 4-111

Chapter 5 SCSI SCRIPTS Instruction Set

5.1 SCSI SCRIPTS 5-1

5.1.1 Sample Operation 5-3

5.2 Block Move Instructions 5-4

5.2.1 First Dword 5-5

5.2.2 Second Dword 5-14

5.2.3 Third Dword 5-14

5.3 I/O Instructions 5-15

5.3.1 First Dword 5-15

5.3.2 Second Dword 5-22

5.4 Read/Write Instructions 5-23

5.4.1 First Dword 5-23

5.4.2 Second Dword 5-24

5.4.3 Read-Modify-Write Cycles 5-24

5.4.4 Move To/From SFBR Cycles 5-24

5.5 Transfer Control Instructions 5-26

5.5.1 First Dword 5-27

5.5.2 Second Dword 5-33

5.5.3 Third Dword 5-33

5.6 Memory Move Instructions 5-34

5.6.1 First Dword 5-35

5.6.2 Read/Write System Memory from a SCRIPTS 5-35

5.6.3 Second Dword 5-36

5.6.4 Third Dword 5-37

5.7 Load/Store Instructions 5-37

5.7.1 First Dword 5-38

5.7.2 Second Dword 5-40

Contents ix

Page 10

Chapter 6 Specifications

*

6.1 DC Characteristics 6-1

6.2 TolerANT Technology Electrical Characteristics 6-8

6.3 AC Characteristics 6-11

6.4 PCI and External Memory Interface Timing Diagrams 6-14

6.4.1 Target Timing 6-15

6.4.2 Initiator Timing 6-22

6.4.3 External Memory Timing 6-39

6.5 SCSI Timing Diagrams 6-60

6.6 Package Drawings 6-67

Appendix A Register Summary

Appendix B External Memory Interface Diagram Examples

Index

Customer Feedback

Figures

1.1 Typical LSI53C896 System Application 1-2

1.2 Typical LSI53C896 Board Application 1-3

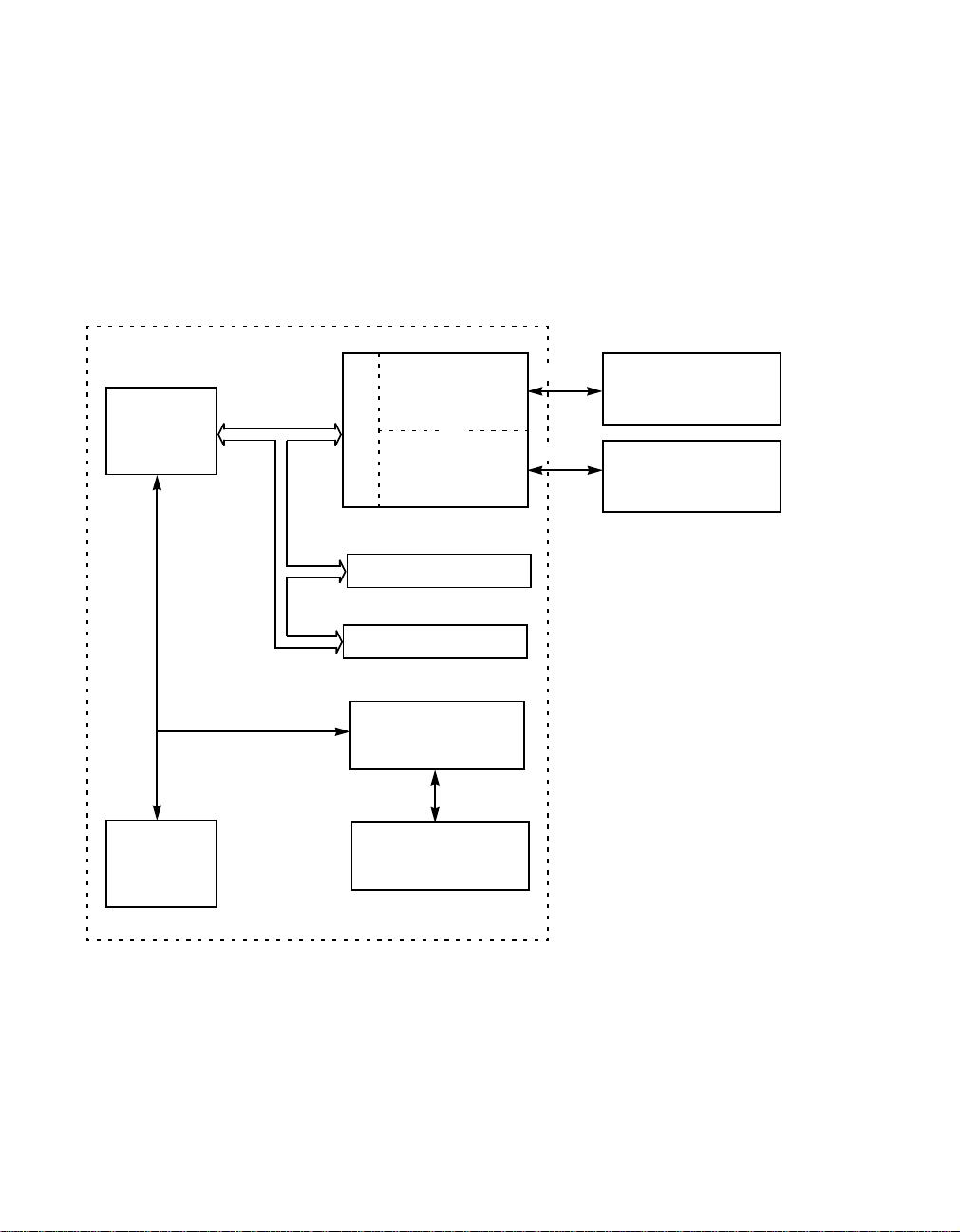

2.1 LSI53C896 Block Diagram 2-2

2.2 Parity Checking/Generation 2-30

2.3 DMA FIFO Sections 2-31

2.4 LSI53C896 Host Interface SCSI Data Paths 2-32

2.5 8-Bit HVD Wiring Diagram for Ultra SCSI 2-37

2.6 Regulated Termination for Ultra2 SCSI 2-39

2.7 Determining the Synchronous Transfer Rate 2-41

2.8 Interrupt Routing Hardware Using the LSI53C896 2-51

2.9 Block Move and Chained Block Move Instructions 2-53

3.1 LSI53C896 Functional Signal Grouping 3-2

5.1 SCRIPTS Overview 5-4

5.2 Block Move Instruction - First Dword 5-5

5.3 Block Move Instruction - Second Dword 5-14

x Contents

Page 11

5.4 Block Move Instruction - Third Dword 5-14

*

5.5 First 32-Bit Word of the I/O Instruction 5-15

5.6 Second 32-Bit Word of the I/O Instruction 5-22

5.7 Read/Write Instruction - First Dword 5-23

5.8 Read/Write Instruction - Second Dword 5-24

5.9 Transfer Control Instructions - First Dword 5-27

5.10 Transfer Control Instructions - Second Dword 5-33

5.11 Transfer Control Instructions - Third Dword 5-33

5.12 Memory Move Instructions - First Dword 5-35

5.13 Memory Move Instructions - Second Dword 5-36

5.14 Memory Move Instructions - Third Dword 5-37

5.15 Load/Store Instruction - First Dword 5-38

5.16 Load/Store Instructions - Second Dword 5-40

6.1 LVD Driver 6-3

6.2 LVD Receiver 6-4

6.3 Rise and Fall Time Test Condition 6-9

6.4 SCSI Input Filtering 6-9

6.5 Hysteresis of SCSI Receivers 6-10

6.6 Input Current as a Function of Input Voltage 6-10

6.7 Output Current as a Function of Output Voltage 6-11

6.8 External Clock 6-12

6.9 Reset Input 6-13

6.10 Interrupt Output 6-14

6.11 PCI Configuration Register Read 6-16

6.12 PCI Configuration Register Write 6-17

6.13 Operating Registers/SCRIPTS RAM Read, 32-Bit 6-18

6.14 Operating Register/SCRIPTS RAM Read, 64-Bit 6-19

6.15 Operating Register/SCRIPTS RAM Write, 32-Bit 6-20

6.16 Operating Register/SCRIPTS RAM Write, 64-Bit 6-21

6.17 Nonburst Opcode Fetch, 32-Bit Address and Data 6-23

6.18 Burst Opcode Fetch, 32-Bit Address and Data 6-25

6.19 Back to Back Read, 32-Bit Address and Data 6-27

6.20 Back to Back Write, 32-Bit Address and Data 6-29

6.21 Burst Read, 32-Bit Address and Data 6-31

6.22 Burst Read, 64-Bit Address and Data 6-33

6.23 Burst Write, 32-Bit Address and Data 6-35

6.24 Burst Write, 64-Bit Address and Data 6-37

6.25 External Memory Read 6-40

Contents xi

Page 12

6.26 External Memory Write 6-44

*

6.27 Normal/Fast Memory (≥ 128 Kbytes) Single Byte

Access Read Cycle 6-46

6.28 Normal/Fast Memory (≥ 128 Kbytes) Single Byte

Access Write Cycle 6-48

6.29 Normal/Fast Memory (≥ 128 Kbytes) Multiple Byte

Access Read Cycle 6-50

6.30 Normal/Fast Memory (≥ 128 Kbytes) Multiple Byte

Access Write Cycle 6-52

6.31 Slow Memory (≥ 128 Kbytes) Read Cycle 6-54

6.32 Slow Memory (≥ 128 Kbytes) Write Cycle 6-56

6.33 ≤ 64 Kbytes ROM Read Cycle 6-58

6.34 ≤ 64 Kbytes ROM Write Cycle 6-59

6.35 Initiator Asynchronous Send 6-60

6.36 Initiator Asynchronous Receive 6-61

6.37 Target Asynchronous Send 6-61

6.38 Target Asynchronous Receive 6-62

6.39 Initiator and Target Synchronous Transfer 6-66

6.40 LSI53C896 329 BGA (Bottom View) 6-70

6.41 LSI53C896 329 BGA Mechanical Drawing 6-71

B.1 16 Kbyte Interface with 200 ns Memory B-1

B.2 64 Kbyte Interface with 150 ns Memory B-2

B.3 128, 256, 512 Kbyte or 1 Mbyte Interface with

150 ns Memory B-3

B.4 512 Kbyte Interface with 150 ns Memory B-4

Tables

2.1 PCI Bus Commands and Encoding Types for the

LSI53C896 2-5

2.2 PCI Cache Mode Alignment 2-14

2.3 Bits Used for Parity Control and Generation 2-28

2.4 SCSI Parity Control 2-29

2.5 SCSI Parity Errors and Interrupts 2-29

2.6 HVD Signals 2-36

2.7 Parallel ROM Support 2-57

2.8 Mode A Serial EEPROM Data Format 2-59

2.9 Power States 2-60

3.1 LSI53C896 Internal Pull-ups and Pull-downs 3-4

xii Contents

Page 13

3.2 System Signals 3-5

*

3.3 Address and Data Signals 3-6

3.4 Interface Control Signals 3-7

3.5 Arbitration Signals 3-8

3.6 Error Reporting Signals 3-9

3.7 Interrupt Signals 3-10

3.8 SCSI Function A GPIO Signals 3-11

3.9 SCSI Function B GPIO Signals 3-12

3.10 SCSI Bus Interface Signals 3-13

3.11 SCSI Function A Signals 3-14

3.12 SCSI Function A_SCTRL Signals 3-15

3.13 SCSI Function B Signals 3-16

3.14 SCSI Function B_SCRTL Signals 3-18

3.15 Flash ROM and Memory Interface Signals 3-19

3.16 Test Interface Signals 3-20

3.17 Power and Ground Signals 3-21

3.18 Decode of MAD[3:1] Pins 3-23

4.1 PCI Configuration Register Map 4-2

4.2 SCSI Register Map 4-20

4.3 Examples of Synchronous Transfer Periods and

Rates for SCSI-1 4-34

4.4 Example Transfer Periods and Rates for Fast SCSI-2,

Ultra, and Ultra2 4-35

4.5 Maximum Synchronous Offset 4-36

4.6 SCSI Synchronous Data FIFO Word Count 4-46

5.1 Read/Write Instructions 5-25

6.1 Absolute Maximum Stress Ratings 6-2

6.2 Operating Conditions 6-2

6.3 LVD Driver SCSI Signals—SD[15:0], SDP[1:0], SREQ/,

SREQ2/, SACK/, SACK2/, SMSG/, SIO/, SCD/, SATN/,

SBSY/, SSEL/, SRST/ 6-3

6.4 LVD Receiver SCSI Signals—SD[15:0], SDP[1:0],

SREQ/, SREQ2/, SACK/, SACK2/, SMSG/, SIO/,

SCD/, SATN/, SBSY/, SSEL/, SRST/ 6-3

6.5 A and B DIFFSENS SCSI Signals 6-4

6.6 Input Capacitance 6-4

6.7 Bidirectional Signals—GPIO0_FETCH/,

GPIO1_MASTER/, GPIO2, GPIO3, GPIO4, MAD[7:0] 6-5

Contents xiii

Page 14

6.8 Output Signals—MAS/[1:0], MCE/, MOE/_TESTOUT,

*

MWE/, TDO 6-5

6.9 Bidirectional Signals—AD[63:0], C_BE[7:0]/, FRAME/,

IRDY/, TRDY/, DEVSEL/, STOP/, PERR/, PAR, PAR64,

REQ64/, ACK64/ 6-6

6.10 Input Signals—CLK, GNT/, IDSEL, INT_DIR, RST/,

SCLK, TCK, TDI, TEST_HSC, TEST_RST/, TMS 6-6

6.11 Output Signals—INTA, INTB, ALT_INTA, ALT_INTB,

REQ/ 6-7

6.12 Output Signal—SERR/ 6-7

6.13 TolerANT Technology Electrical Characteristics for SE

SCSI Signals 6-8

6.14 External Clock 6-12

6.15 Reset Input 6-13

6.16 Interrupt Output 6-14

6.17 PCI Configuration Register Read 6-16

6.18 PCI Configuration Register Write 6-17

6.19 Operating Register/SCRIPTS RAM Read, 32-Bit 6-18

6.20 Operating Register/SCRIPTS RAM Read, 64-Bit 6-19

6.21 Operating Register/SCRIPTS RAM Write, 32-Bit 6-20

6.22 Operating Register/SCRIPTS RAM Write, 64-Bit 6-21

6.23 Nonburst Opcode Fetch, 32-Bit Address and Data 6-22

6.24 Burst Opcode Fetch, 32-Bit Address and Data 6-24

6.25 Back to Back Read, 32-Bit Address and Data 6-26

6.26 Back to Back Write, 32-Bit Address and Data 6-28

6.27 Burst Read, 32-Bit Address and Data 6-30

6.28 Burst Read, 64-Bit Address and Data 6-32

6.29 Burst Write, 32-Bit Address and Data 6-34

6.30 Burst Write, 64-Bit Address and Data 6-36

6.31 External Memory Read 6-39

6.32 External Memory Write 6-43

6.33 Normal/Fast Memory (≥ 128 Kbytes) Single Byte

Access Read Cycle 6-46

6.34 Normal/Fast Memory (≥ 128 Kbytes) Single Byte

Access Write Cycle 6-48

6.35 Slow Memory (≥ 128 Kbytes) Read Cycle 6-54

6.36 Slow Memory (≥ 128 Kbytes) Write Cycle 6-56

6.37 ≤ 64 Kbytes ROM Read Cycle 6-58

xiv Contents

Page 15

6.38 ≤ 64 Kbytes ROM Write Cycle 6-59

*

6.39 Initiator Asynchronous Send 6-60

6.40 Initiator Asynchronous Receive 6-61

6.41 Target Asynchronous Send 6-61

6.42 Target Asynchronous Receive 6-62

6.43 SCSI-1 Transfers (SE 5.0 Mbytes) 6-63

6.44 SCSI-1 Transfers (Differential 4.17 Mbytes) 6-63

6.45 SCSI-2 Fast Transfers 10.0 Mbytes (8-Bit Transfers) or

20.0 Mbytes (16-Bit Transfers) 40 MHz Clock 6-64

6.46 SCSI-2 Fast Transfers 10.0 Mbytes (8-Bit Transfers) or

20.0 Mbytes (16-Bit Transfers) 50 MHz Clock 6-64

6.47 Ultra SCSI SE Transfers 20.0 Mbytes (8-Bit Transfers)

or 40.0 Mbytes (16-Bit Transfers) Quadrupled 40 MHz

Clock 6-65

6.48 Ultra SCSI HVD Transfers 20.0 Mbytes (8-Bit Transfers)

or 40.0 Mbytes (16-Bit Transfers) 80 MHz Clock 6-65

6.49 Ultra2 SCSI Transfers 40.0 Mbyte (8-Bit Transfers) or

80.0 Mbyte (16-Bit Transfers) Quadrupled 40 MHz Clock 6-66

6.50 Signal Names and BGA Position 6-68

6.51 Signal Names by BGA Position 6-69

A.1 LSI53C896 Register Map A-1

Contents xv

Page 16

xvi Contents

*

Page 17

Chapter 1

*

Introduction

This chapter provides a general overview of the LSI53C896 PCI to Dual

Channel Ultra2 SCSI Multifunction Controller. The chapter contains the

following sections:

• Section 1.1, “General Description”

• Section 1.2, “Benefits of Ultra2 SCSI”

• Section 1.3, “Benefits of L VDlink”

• Section 1.4, “TolerANT

• Section 1.5, “LSI53C896 Benefits Summary”

1.1 General Description

®

Technology”

The LSI53C896 brings Ultra2 SCSI performance to host adapter,

workstation, and general computer designs, making it easy to add a

high-performance SCSI bus to any PCI system. It supports Ultra2 SCSI

transfer rates and allows increased SCSI connectivity and cable length

with Low Voltage Differential (LVD) signaling for SCSI devices.

The LSI53C896 has a local memory bus for local storage of the device’s

BIOS ROM in flash memory or standard EPROMs. The LSI53C896

supports programming of local flash memory for updates to BIOS. The

chip is packaged in a 329 Ball Grid Array (BGA) package. System

diagrams showing the connections of the LSI53C896 with an external

ROM or flash memory are shown in Appendix B, “External Memory

Interface Diagram Examples. ”

LVDlink™ technology is the LSI Logic implementation of LVD. LVDlink

transceivers allow the LSI53C896 to perform either Single-Ended (SE) or

LVD transfers, and support external High Voltage Differential (HVD)

transceivers. The LSI53C896 integrates a high-performance SCSI core,

a 64-bit PCI bus master DMA core, and the LSI Logic SCSI SCRIPTS™

LSI53C896 PCI to Dual Channel Ultra2 SCSI Multifunction Controller 1-1

Page 18

processor to meet the flexibility requirements of SCSI-3 and Ultra2 SCSI

*

standards. It is designed to implement multithreaded I/O algorithms with

a minimum of processor intervention, solving the protocol overhead

problems of previous intelligent and nonintelligent adapter designs.

Figure 1.1 illustrates a typical LSI53C896 system and Figure 1.2

illustrates a typical LSI53C896 board application.

Figure 1.1 Typical LSI53C896 System Application

PCI Bus

Interface

Controller

Processor Bus

Central

Processing

Unit

(CPU)

Typical PCI Computer

System Architecture

LSI53C896 PCI

to Wide Ultra2 SCSI

Function A

and

LSI53C896 PCI

to Wide Ultra2 SCSI

Function B

One PCI Bus Load

PCI Graphic Accelerator

PCI Fast Ethernet

Memory

Controller

Memory

SCSI Bus

SCSI Bus

Fixed Disk, Optical Disk,

Printer, Tape, and Other

Peripherals

Fixed Disk, Optical Disk,

Printer, Tape, and Other

Peripherals

1-2 Introduction

Page 19

Figure 1.2 Typical LSI53C896 Board Application

*

SCSI Data,

Function A

68 Pin

Wide SCSI

Connector

Function B

68 Pin

Wide SCSI

Connector

Parity, and

Control Signals

LSI53C896

64-Bit PCI

SCSI Data,

Parity, and

Control Signals

PCI Address, Data, Parity and Control Signals

Dual Channel SCSI

to

Controller

PCI Interface

1.1.1 New Features in the LSI53C896

The LSI53C896 is functionally similar to the LSI53C876 PCI to Dual

Channel SCSI Multifunction Controller, with added support for Ultra2

SCSI. Some software enhancements, and the use of LVD, are needed to

enable the chip to transfer data at Ultra2 SCSI transfer rates.

Memory

Address/Data

Bus

A_GPIO/[1:0]

B_GPIO/[1:0]

Memory Control

Block

Flash EEPROM

Serial EEPROM

Function A

Serial EEPROM

Function B

• 64-bit PCI Interface.

• Able to handle SCSI phase mismatches in SCRIPTS without

interrupting the CPU.

• Two wide Ultra2 SCSI channels in a single package.

• Separate 8 Kbyte internal SCRIPTS RAMs.

• JTAG boundary scanning.

• RAID ready alternative interrupt signaling.

• PC99 Power Management - including automatic download of

Subsystem Vendor ID and Subsystem ID, and PCI power

management levels D0, D1, D2, and D3.

General Description 1-3

Page 20

• Improved PCI Caching design - improves PCI bus efficiency.

*

• Load/Store data transferred to or from SCRIPTS RAM internal to

chip.

• Hardware control of SCSI activity LED.

• Optional 944 byte DMA FIFO supports large block transfers at Ultra2

SCSI speeds. The default FIFO size of 112 bytes is also supported.

• 32-bit ISTAT registers (Interrupt Status Zero (ISTAT0), Interrupt Status

One (ISTAT1), Mailbox Zero (MBOX0), and Mailbox One (MBOX1)).

1.2 Benefits of Ultra2 SCSI

Ultra2 SCSI is an extension of the SPI-2 draft standard that allows faster

synchronous SCSI transfer rates and defines a new physical layer, LVD

SCSI, that provides an incremental evolution from SCSI-2 and Ultra

SCSI. When enabled, Ultra2 SCSI performs 40 mega transfers per

second, which results in approximately double the synchronous transfer

rates of Ultra SCSI. The LSI53C896 can perform 16-bit, Ultra2 SCSI

synchronous transfers as fast as 80 Mbytes/s on each channel for a total

bandwidth of 160 Mbytes/s. This advantage is most noticeable in heavily

loaded systems, or large block size applications such as video

on-demand and image processing.

An advantage of Ultra2 SCSI is that it significantly improves SCSI

bandwidth while preserving existing hardware and software investments.

The primary software changes required are to enable the chip to perform

synchronous negotiations for Ultra2 SCSI rates, and to enable the clock

quadrupler. Ultra2 SCSI uses the same connectors as Ultra SCSI, but

can operate with longer cables and more devices on the bus. Chapter 2,

“Functional Description,” contains more information on migrating an Ultra

SCSI design to an Ultra2 SCSI design.

1.3 Benefits of LVDlink

The LSI53C896 supports LVD for SCSI, a signaling technology that

increases the reliability of SCSI data transfers over longer distances than

are supported by SE SCSI. The low current output of LVD allows the I/O

transceivers to be integrated directly onto the chip. LVD provides the

1-4 Introduction

Page 21

reliability of HVD SCSI without the added cost of external differential

*

transceivers. Ultra2 SCSI with LVD allows a longer SCSI cable and more

devices on the bus, with the same cables defined in the SCSI-3 Parallel

Interface standard for Fast-20 (Ultra SCSI). LVD provides a long-term

migration path to even faster SCSI transfer rates without compromising

signal integrity, cable length, or connectivity.

For backward compatibility to existing SE devices, the LSI53C896

features universal LVDlink transceivers that can support LVD SCSI, SE,

and HVD modes. The LVDlink technology also supports HVD signaling

in legacy systems, when external transceivers are connected to the

LSI53C896. This allows the LSI53C896 to be used in both legacy and

Ultra2 SCSI applications.

1.4 TolerANT®Technology

The LSI53C896 features TolerANT technology, which includes active

negation on the SCSI drivers and input signal filtering on the SCSI

receivers. Active negation causes the SCSI Request, Acknowledge,

Data, and Parity signals to be actively driven HIGH rather than passively

pulled up by terminators. Active negation is enabled by setting bit 7 in

the SCSI T est Three (STEST3) register.

TolerANT receiver technology improves data integrity in unreliable

cabling environments, where other devices would be subject to data

corruption. TolerANT receivers filter the SCSI bus signals to eliminate

unwanted transitions, without the long signal delay associated with

RC-type input filters. This improved driver and receiver technology helps

eliminate double clocking of data, the single biggest reliability issue with

SCSI operations. TolerANT input signal filtering is a built-in feature of the

LSI53C896 and all LSI Logic fast SCSI, Ultra SCSI, and Ultra2 SCSI

devices.

The benefits of TolerANT technology include increased immunity to noise

when the signal is going HIGH, better performance due to balanced duty

cycles, and improvedfast SCSI transfer rates.Inaddition,TolerANT SCSI

devices do not cause glitches on the SCSI bus at power-up or

power-down, so other devices on the bus are also protected from data

corruption. When it is used with the LVDlink transceivers, TolerANT

technology provides excellent signal quality and data reliability in real

TolerANT®Technology 1-5

Page 22

world cabling environments. TolerANT technology is compatible with both

*

the Alternative One and Alternative Two termination schemes proposed

by the American National Standards Institute.

1.5 LSI53C896 Benefits Summary

This section provides an overview of the LSI53C896 features and

benefits. It contains information on SCSI Performance, PCI Performance,

Integration, Ease of Use, Flexibility, Reliability, and Testability.

1.5.1 SCSI Performance

• Has integrated LVDlink universal transceivers which:

– Support SE, LVD, and HVD signals (with external transceivers).

– Allow greater device connectivity and longer cable length.

– LVDlink transceivers save the cost of external differential

transceivers.

– Supports a long-term performance migration path.

• With a 944 byte FIFO, the chip can efficiently burst up to 512 bytes

across the PCI bus.

• Two separate SCSI channels on one chip.

• Performs wide, Ultra2 SCSI synchronous transfers as fast as

80 Mbytes/s on each SCSI channel for a total of 160 Mbytes/s.

• Can handle phase mismatches in SCRIPTS without interrupting the

system processor.

• On-chip SCSI clock quadrupler allows the chip to achieve Ultra2

SCSI transfer rates with an input frequency of 40 MHz.

• Includes 8 Kbytes of internal RAM for SCRIPTS instruction storage

for each SCSI channel.

• 31 levels of SCSI synchronous offset.

• Supports variable block size and scatter/gather data transfers.

• Performs sustained memory-to-memory DMA transfers to

approximately 100 Mbytes/s.

• Minimizes SCSI I/O start latency.

1-6 Introduction

Page 23

• Performs complex bus sequences without interrupts, including

*

restoring data pointers.

• Reduces ISR overhead through a unique interrupt status reporting

method.

• Load/Store SCRIPTS instructions increase performance of data

transfers to and from the chip registers without using PCI cycles.

• SCRIPTS support of 64-bit addressing.

• Supports target disconnect and later reconnect with no interrupt to

the system processor.

• Supports multithreaded I/O algorithms in SCSI SCRIPTS with fast

I/O context switching.

• Expanded Register Move instruction supports additional arithmetic

capability.

1.5.2 PCI Performance

• Complies with the PCI 2.1 specification.

• 64-bit or 32-bit 33 MHz PCI interface.

– Dual Address Cycle (DAC) can be generated for all SCRIPTS.

– True PCI Multifunction Device - presents one electrical load to

the PCI Bus.

• Bursts 2/4, 4/8, 8/16, 16/32, 32/64, or 64/128 Qword/Dword transfers

across the PCI bus.

• Supports 64-bit or 32-bit word data bursts with variable burst lengths.

• Prefetches up to 8 Dwords of SCRIPTS instructions.

• Bursts SCRIPTS opcode fetches across the PCI bus.

• Performs zero wait-state bus master data bursts up to 264 Mbytes/s

(@ 33 MHz).

• Supports PCI Cache Line Size register.

• Supports PCI Write and Invalidate, Read Line, and Read Multiple

commands.

• Complies with PCI Bus Power Management Specification

Revision 1.1.

LSI53C896 Benefits Summary 1-7

Page 24

1.5.3 Integration

*

• Dual channel Ultra2 SCSI PCI Multifunction controller.

• Integrated LVD transceivers.

• Full 64-bit or 32-bit PCI DMA bus master.

• Can be used as a third-party PCI bus DMA controller by using

• Integrated SCRIPTS processor.

1.5.4 Ease of Use

• Up to one megabyte of add-in memory support for BIOS and

• Direct PCI to SCSI connection.

• Reduced SCSI development effort.

• Compiler-compatible with existing LSI53C7XX and LSI53C8XX

• Direct connection to PCI and SCSI SE, LVD and HVD (needs

• Development tools and sample SCSI SCRIPTS available.

Memory-to-Memory Move instructions.

SCRIPTS storage.

family SCRIPTS.

external transceivers).

• Maskable and pollable interrupts.

• Wide SCSI, A or P cable, and up to 15 devices per SCSI channel

supported.

• Three programmable SCSI timers: Select/Reselect,

Handshake-to-Handshake, and General Purpose. The time-out

period is programmable from 100 µs to greater than 25.6 seconds.

• Software for PC-based operating system support.

• Support for relative jumps.

• SCSI Selected As ID bits for responding with multiple IDs.

1.5.5 Flexibility

• Universal LVD transceivers are backward compatible with SE or HVD

devices.

• High level programming interface (SCSI SCRIPTS).

1-8 Introduction

Page 25

1.5.6 Reliability

*

• Programs local and bus flash memory.

• Selectable 112 or 944 byte DMA FIFO for backward compatibility.

• Tailored SCSI sequences execute from main system RAM or internal

SCRIPTS RAM.

• Flexible programming interface to tune I/O performance or to adapt

to unique SCSI devices.

• Support for changes in the logical I/O interface definition.

• Low level access to all registers and all SCSI bus signals.

• Fetch, Master, and Memory Access control pins.

• Separate SCSI and system clocks.

• SCSI clock quadrupler bits enable Ultra2 SCSI transfer rates with a

40 MHz SCSI clock input.

• Selectable IRQ pin disable bit.

• Ability to route system clock to SCSI clock.

• Compatible with 3.3 V and 5 V PCI.

• 2 kV ESD protection on SCSI signals.

• Protection against bus reflections due to impedance mismatches.

• Controlled bus assertion times (reduces RFI, improves reliability,and

eases FCC certification).

• Latch-up protection greater than 150 mA.

• Voltage feed-through protection (minimum leakage current through

SCSI pads).

• More than 25% of pins are power and ground.

• Power and ground isolation of I/O pads and internal chip logic.

• TolerANT technology provides:

– Active negation of SCSI Data, Parity, Request, and Acknowledge

signals for improved fast SCSI transfer rates.

– Input signal filtering on SCSI receivers improves data integrity,

even in noisy cabling environments.

LSI53C896 Benefits Summary 1-9

Page 26

1.5.7 Testability

*

• All SCSI signals accessible through programmed I/O.

• SCSI loopback diagnostics.

• SCSI bus signal continuity checking.

• Support for single step mode operation.

• JTAG boundary scan.

1-10 Introduction

Page 27

Chapter 2

*

Functional Description

Chapter 2 is divided into the following sections:

• Section 2.1, “PCI Functional Description”

• Section 2.2, “SCSI Functional Description”

• Section 2.3, “Parallel ROM Interface”

• Section 2.4, “Serial EEPROM Interface”

• Section 2.5, “Power Management”

The LSI53C896 is composed of the following modules:

• 64-bit PCI Interface.

• Two independent PCI-to-Wide Ultra2 SCSI Controllers.

• ROM/Flash Memory Controller.

• Serial EEPROM Controller.

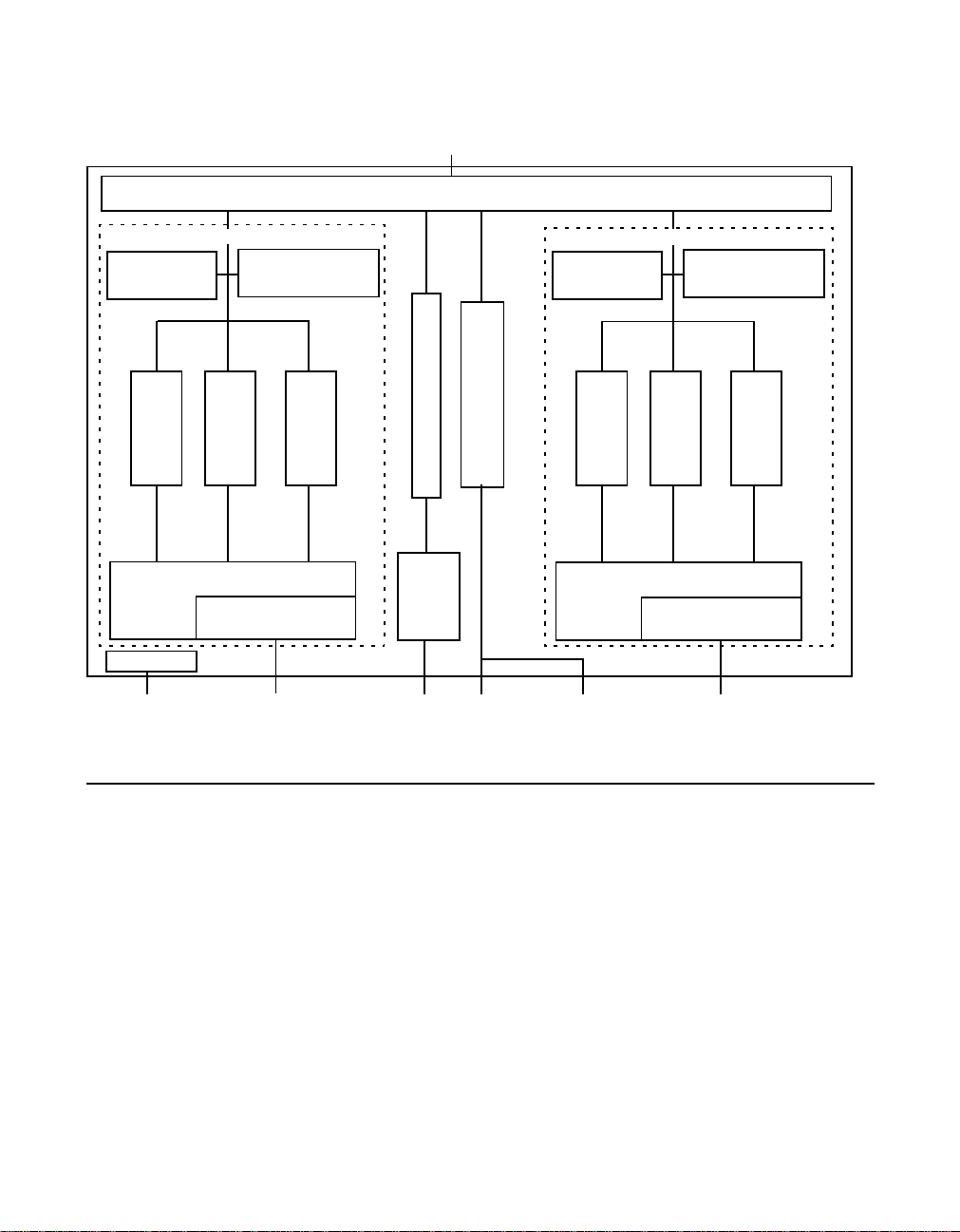

Figure 2.1 illustrates the relationship between these modules.

LSI53C896 PCI to Dual Channel Ultra2 SCSI Multifunction Controller 2-1

Page 28

Figure 2.1 LSI53C896 Block Diagram

*

64-Bit PCI Interface, PCI Configuration Registers (2 sets)

PCI Bus

Wide Ultra2 SCSI Controller

8 Kbyte

SCRIPTS RAM

944 Byte

DMA FIFO

SCSI FIFO and SCSI Control Block

JTAG

JTAG

Bus

8 Dword SCRIPTS

Prefetch Buffer

Registers

Processor

SCSI SCRIPTS

Universal TolerANT

Drivers and Receivers

SCSI Function A

Wide Ultra2

SCSI Bus

Operating

Local

Memory

ROM/Flash

Memory

Bus

ROM/Flash Memory Control

Bus

2-Wire Serial

EEPROM Bus

(Function A)

SCRIPTS RAM

and Autoconfiguration

Serial EEPROM Controller

Wide Ultra2 SCSI Controller

8 Kbyte

Registers

Operating

SCSI FIFO and SCSI Control Block

2-Wire Serial

EEPROM Bus

(Function B)

8 Dword SCRIPTS

Prefetch Buffer

Processor

SCSI SCRIPTS

Universal TolerANT

Drivers and Receivers

SCSI Function B

Wide Ultra2

SCSI Bus

944 Byte

DMA FIFO

2.1 PCI Functional Description

The LSI53C896 implements two PCI-to-Wide Ultra2 SCSI controllers in

a single package. This configuration presents only one load to the PCI

bus and uses one REQ/ - GNT/ pair to arbitrate for PCI bus mastership.

However, separate interrupt signals are generated for SCSI Function A

and SCSI Function B.

2-2 Functional Description

Page 29

2.1.1 PCI Addressing

*

There are three physical PCI-defined address spaces:

• PCI Configuration Space.

• I/O Space for operating registers.

• Memory Space for operating registers.

2.1.1.1 Configuration Space

The host processor uses this configuration space to initialize the

LSI53C896. Two independent sets of configuration space registers are

defined, one set for each SCSI function. The Configuration registers are

accessible only by system BIOS during PCI configuration cycles. Each

configuration space is a contiguous 256 X 8-bit set of addresses.

Decoding C_BE[3:0]/ determines if a PCI cycle is intended to access the

configuration register space. The IDSEL bus signal is a “chip select” that

allows access to the configuration register space only. A configuration

read/write cycle without IDSEL is ignored. The eight lower order address

bits (AD[7:0]) are used to select a specific 8-bit register. Since the

LSI53C896 is a PCI multifunction device, bits AD[10:8] decode either

SCSI Function A Configuration register (AD[10:8] = 0b000) or SCSI

Function B Configuration register (AD[10:8] = 0b001).

At initialization time, each PCI device is assigned a base address (in the

case of the LSI53C896, the upper 24 bits of the address are selected)

for memory accesses and I/O accesses. On every access, the

LSI53C896 compares its assigned base addresses with the value on the

Address/Data bus during the PCI address phase. If there is a match of

the upper 24 bits, the access is for the LSI53C896 and the low-order

eight bits define the register to be accessed. A decode of C_BE[3:0]/

determines which registers and what type of access is to be performed.

2.1.1.2 I/O Space

The PCI specification defines I/O space as a contiguous 32-bit I/O

address that is shared by all system resources, including the LSI53C896.

Base Address Register Zero (I/O) determines which 256-byte I/O area

this device occupies.

PCI Functional Description 2-3

Page 30

2.1.1.3 Memory Space

*

The PCI specification defines memory space as a contiguous 64-bit

memory address that is shared by all system resources, including the

LSI53C896. Base Address Register One (MEMORY) determines which

1 Kbyte memory area this device occupies. Each SCSI function uses a

8 Kbyte SCRIPTS RAM memory space.Base Address Register Two

(SCRIPTS RAM) determines the 8 Kbyte memory area the SCRIPTS

RAM occupies.

2.1.2 PCI Bus Commands and Functions Supported

Bus commands indicate to the target the type of transaction the master

is requesting. Bus commands are encoded on the C_BE[3:0]/ lines

during the address phase. PCI bus commands and encoding types

appear in Table 2.1.

2-4 Functional Description

Page 31

Table 2.1 PCI Bus Commands and Encoding Types for the LSI53C896

*

C_BE[3:0]/ Command Type Supported as Master Supported as Slave

0000 Interrupt Acknowledge No No

0001 Special Cycle No No

0010 I/O Read Yes Yes

0011 I/O Write Yes Yes

0100 Reserved N/A N/A

0101 Reserved N/A N/A

0110 Memory Read Yes Yes

0111 Memory Write Yes Yes

1000 Reserved N/A N/A

1001 Reserved N/A N/A

1010 Configuration Read No Yes

1011 Configuration Write No Yes

1100 Memory Read Multiple Yes

1

Yes (defaults to 0110)

1101 DAC Yes Yes

1110 Memory Read Line Yes

1111 Memory Write and Invalidate Yes

1. See the DMA Mode (DMODE) register.

2. See the Chip Test Three (CTEST3) register.

1

2

Yes (defaults to 0110)

Yes (defaults to 0111)

2.1.2.1 Interrupt Acknowledge Command

The LSI53C896 does not respond to this command as a slave and it

never generates this command as a master.

2.1.2.2 Special Cycle Command

The LSI53C896 does not respond to this command as a slave and it

never generates this command as a master.

PCI Functional Description 2-5

Page 32

2.1.2.3 I/O Read Command

*

The I/O Read command reads data from an agent mapped in the I/O

address space. When decoding I/O cycles, the LSI53C896 decodes the

lower 32 address bits and ignores the upper 32 address bits.

2.1.2.4 I/O Write Command

The I/O Write command writes data to an agent mapped in the I/O

address space. When decoding I/O cycles, the LSI53C896 decodes the

lower 32 address bits and ignores the upper 32 address bits.

2.1.2.5 Reserved Command

The LSI53C896 does not respond to this command as a slave and it

never generates this command as a master.

2.1.2.6 Memory Read Command

The Memory Read command reads data from an agent mapped in the

Memory Address Space. The target is free to do an anticipatory read for

this command only if it can guarantee that such a read has no side

effects.

2.1.2.7 Memory Write Command

The Memory Write command writes data to an agent mapped in the

Memory Address Space. When the target returns “ready”, it assumes

responsibility for the coherency (which includes ordering) of the subject

data.

2.1.2.8 Configuration Read Command

The Configuration Read command reads the configuration space of each

agent. An agent is selected during a configuration access when its

IDSEL signal is asserted and AD[1:0] are 0b00. During the address

phase of a configuration cycle AD[7:2] addresses one of the 64 Dword

registers (where byte enables address the bytes within each Dword) in

the configuration space of each device. AD[63:11] are logical don’t cares

to the selected agent. AD[10:8] indicate which device of a multifunction

agent is being addressed.

2-6 Functional Description

Page 33

2.1.2.9 Configuration Write Command

*

The Configuration Write command transfers data to the configuration

space of each agent. An agent is selected when its IDSEL signal is

asserted and AD[1:0] are 0b00. During the address phase of a

configuration cycle, the AD[7:2] lines address the 64 Dword registers

(where byte enables address the bytes within each Dword) in the

configuration space of each device. AD[63:11] are logical don’t cares to

the selected agent. AD[10:8] indicate which device of a multifunction

agent is addressed.

2.1.2.10 Memory Read Multiple Command

This command is identical to the Memory Read command except that it

additionally indicates that the master may intend to fetch more than one

cache line before disconnecting. The LSI53C896 supports PCI Memory

Read Multiple functionality and issues Memory Read Multiple commands

on the PCI bus when the Read Multiple mode is enabled. This mode is

enabled by setting bit 2 (ERMP) of the DMA Mode (DMODE) register. If

cache mode is enabled, a Memory Read Multiple command is issued on

all read cycles, except opcode fetches, when the following conditions are

met:

• The CLSE bit (Cache Line Size Enable, bit 7, DMA Control (DCNTL)

register) and the ERMP bit (Enable Read Multiple, bit 2, DMA Mode

(DMODE) register) are set.

• The Cache Line Size register for each function contains a legal burst

size value (2, 4, 8, 16, 32, or 64) and that value is less than or equal

to the DMODE burst size.

• The transfer will cross a cache line boundary.

When these conditions are met, the chip issues a Memory Read Multiple

command instead of a Memory Read during all PCI read cycles.

PCI Functional Description 2-7

Page 34

Burst Size Selection – The Read Multiple command reads in multiple

*

cache lines of data in a single bus ownership. The number of cache lines

to read is a multiple of the cache line size specified in Revision 2.1 of

the PCI specification. The logic selects the largest multiple of the cache

line size based on the amount of data to transfer, with the maximum

allowableburstsize determined from the DMA Mode (DMODE) burst size

bits, and the Chip Test Five (CTEST5), bit 2.

2.1.2.11 DAC Command

The LSI53C896 performs DACs when 64-bit addressing is required. See

PCI specification 2.1. If any of the selector registers contain a nonzero

value, a DAC will be generated.

2.1.2.12 Memory Read Line Command

This command is identical to the Memory Read command, except that it

additionally indicates that the master intends to fetch a complete cache

line. This command is intended for use with bulksequentialdatatransfers

where the memory system and the requesting master might gain some

performance advantage by reading to a cache line boundary rather than

a single memory cycle. The Read Line function in the LSI53C896 takes

advantage of the PCI 2.1 specification regarding issuing of this

command.

If the cache mode is disabled, Read Line commands will not be issued.

If the cache mode is enabled, a Read Line command is issued on all

read cycles, except nonprefetch opcode fetches, when the following

conditions are met:

• The CLSE (Cache Line Size Enable, bit 7, of the DMA Control

(DCNTL) register) and ERL (Enable Read Line, bit 3, of the DMA

Mode (DMODE) register) bits are set.

• The Cache Line Size register for each function must contain a legal

burst size value in Dwords (2, 4, 8, 16, 32, 64, or 128) and that value

is less than or equal to the DMODE burst size.

• The transfer will cross a Dword boundary but not a cache line

boundary.

2-8 Functional Description

Page 35

When these conditions are met, the chip issues a Read Line command

*

instead of a Memory Read during all PCI read cycles. Otherwise, it

issues a normal Memory Read command.

Read Multiple with Read Line Enabled – When both the Read

Multiple and Read Line modes are enabled, the Read Line command is

not issued if the above conditions are met. Instead, a Read Multiple

command is issued, even though the conditions for Read Line are met.

If the Read Multiple mode is enabled and the Read Line mode is

disabled, Read Multiple commands are issued if the Read Multiple

conditions are met.

2.1.2.13 Memory Write and Invalidate Command

The Memory Write and Invalidate command is identical to the Memory

Write command, except that it additionally guarantees a minimum

transfer of one complete cache line. That is, the master intends to write

all bytes within the addressed cache line in a single PCI transaction

unless interrupted by the target. This command requires implementation

of the PCI Cache Line Size register at address 0x0C in PCI configuration

space. The LSI53C896 enables Memory Write and Invalidate cycles

when bit 0 (WRIE) in the Chip Test Three (CTEST3) register and bit 4

(WIE) in the PCI Command register are set. When the following

conditions are met, Memory Write and Invalidate commands are issued:

• The CLSE bit (Cache Line Size Enable, bit 7, of the DMA Control

(DCNTL) register), WRIE bit (Write and Invalidate Enable, bit 0, of

the Chip Test Three (CTEST3) register), and PCI configuration

Command register, bit 4 are set.

• The Cache Line Size register for each function contains a legal burst

size value in Dwords (2, 4, 8, 16, 32, 64, or 128) and that value is

less than or equal to the DMA Mode (DMODE) burst size.

• The chip has enough bytes in the DMA FIFO to complete at least

one full cache line burst.

• The chip is aligned to a cache line boundary.

When these conditions are met, the LSI53C896 issues a Write and

Invalidate command instead of a Memory Write command during all PCI

write cycles.

PCI Functional Description 2-9

Page 36

Multiple Cache Line Transfers – The Memory Write and Invalidate

*

command can write multiple cache lines of data in a single bus

ownership. The chip issues a burst transfer as soon as it reaches a

cache line boundary. The size of the transfer is not automatically the

cache line size, but rather a multiple of the cache line size specified in

Revision 2.1 of the PCI specification. The logic selects the largest

multiple of the cache line size based on the amount of data to transfer,

with the maximum allowable burst size determined from the DMA Mode

(DMODE) burst size bits, and Chip Test Five (CTEST5), bit 2. If multiple

cache line size transfers are not desired, set the DMODE burst size to

exactly the cache line size and the chip only issues single cache line

transfers.

After each data transfer, the chip re-evaluates the burst size based on

the amount of remaining data to transfer and again selects the highest

possible multiple of the cache line size, and no larger than the DMA

Mode (DMODE) burst size. The most likely scenario of this scheme is

that the chip selects the DMODE burst size after alignment, and issues

bursts of this size. The burst size is, in effect, throttled down toward the

end of a long Memory Move or Block Move transfer until only the cache

line size burst size is left. The chip finishes the transfer with this burst

size.

Latency – In accordance with the PCI specification, the latency timer is

ignored when issuing a Memory Write and Invalidate command such that

when a latency time-out occurs, the LSI53C896 continues to transfer up

to a cache line boundary. At that point, the chip relinquishes the bus, and

finishes the transfer at a later time using another bus ownership. If the

chip is transferring multiple cache lines it continues to transfer until the

next cache boundary is reached.

PCI Target Retry – During a Memory Write and Invalidate transfer, if the

target device issues a retry (STOP with no TRDY/, indicating that no data

was transferred), the chip relinquishes the bus and immediately tries to

finish the transfer on another bus ownership. The chip issues another

Memory Write and Invalidate command on the next ownership, in

accordance with the PCI specification.

PCI Target Disconnect – During a Memory Write and Invalidate

transfer, if the target device issues a disconnect the LSI53C896

relinquishes the bus and immediately tries to finish the transfer on

2-10 Functional Description

Page 37

another bus ownership. The chip does not issue another Memory Write

*

and Invalidate command on the next ownership unless the address is

aligned.

2.1.3 Internal Arbiter

The PCI to SCSI controller uses a single REQ/ - GNT/ signal pair to

arbitrate for access to the PCI bus. An internal arbiter circuit allows the

different bus mastering functions resident in the chip to arbitrate among

themselves for the privilege of arbitrating for PCI bus access. There are

two independent bus mastering functions inside the LSI53C896, one for

each of the SCSI functions.

The internal arbiter uses a round robin arbitration scheme to decide

which internal bus mastering function may arbitrate for access to the PCI

bus. This ensures that no function is starved for access to the PCI bus.

2.1.4 PCI Cache Mode

The LSI53C896 supports the PCI specification for an 8-bit Cache Line

Size register located in the PCI configuration space. The Cache Line

Size register provides the ability to sense and react to nonaligned

addresses corresponding to cache line boundaries. In conjunction with

the Cache Line Size register, the PCI commands Memory Read Line,

Memory Read Multiple, Memory Write and Invalidate are each software

enabled or disabled to allow the user full flexibility in using these

commands.

2.1.4.1 Enabling Cache Mode

For the cache logic to be enabled to issue PCI cache commands

(Memory Read Line, Memory Read Multiple, and Memory Write and

Invalidate) on any given PCI master operation the following conditions

must be met:

• The Cache Line Size Enable bit in the DMA Control (DCNTL) register

must be set.

• The PCI Cache Line Size register must contain a valid binary cache

size, i.e. 2, 4, 8, 16, 32, 64, or 128 Dwords. Only these values are

considered valid cache sizes.

PCI Functional Description 2-11

Page 38

• The programmed burst size (in Dwords) must be equal to or greater

*

than the cache line size register. The DMA Mode (DMODE) register

bits [7:6] and the Chip Test Five (CTEST5) register bit 2 are the burst

length bits.

• The part must be doing a PCI Master transfer. The following PCI

Master transactions do not utilize the PCI cache logic and thus no

PCI cache commands will be issued during these types of cycles: a

nonprefetch SCRIPTS fetch, a Load/Store data transfer, a data flush

operation. All other types of PCI Master transactions will utilize the

PCI cache logic.

The above four conditions must be met for the cache logic to control the

type of PCI cache command that is issued, along with any alignment that

may be necessary during write operations. If these conditions are not

met for any given PCI Master transaction, a Memory Read or Memory

Write will be issued and no cache write alignment will be done.

2.1.4.2 Issuing Cache Commands

In order to issue each type of PCI cache command, the corresponding

enable bit must be set (2 bits in the case of Memory Write and

Invalidate).

• To issue Memory Read Line commands, set the Memory Read Line

enable bit in the DMA Mode (DMODE) register.

• To issue Memory Read Multiple commands, set the Read Multiple

enable bit in the DMA Mode (DMODE) register.

• To issue Memory Write and Invalidate commands, set the Write and

Invalidate enables in both the Chip Test Three (CTEST3) and the

PCI configuration Command registers.

If the corresponding cache command that is to be issued is not enabled

then the cache logic will fall back to the next command enabled, i.e., if

Memory Read Multiple is not enabled and Memory Read Lines are, read

lines will be issued in place of read multiples. If no cache commands are

enabled, cache write alignment will still occur but no cache commands

will be issued, only memory reads and memory writes will be issued.

2-12 Functional Description

Page 39

2.1.4.3 Memory Read Caching

*

Which type of Memory Read command gets issued depends on the

starting location of the transfer and the number of bytes to be transferred.

During reads, no cache alignment is done (this is not required nor

optimal per PCI 2.1 specification) and reads will always be either a

programmed burst length in size, as set in the DMA Mode (DMODE) and

Chip Test Three (CTEST3) registers. In the case of a transfer which is

smaller than the burst length, all bytes for that transfer will be read in one

PCI burst transaction. If the transfer will cross a Dword boundary

(A[1:0] = 0b00) a Memory Read Line command is issued. When the

transfer will cross a cache boundary (depends on the cache line size

programmed into the PCI configuration register), a Memory Read

Multiple command is issued. If a transfer will not cross a Dword or cache

boundary or if cache mode is not enabled a Memory Read command is

issued.

2.1.4.4 Memory Write Caching

Writes will be aligned in a single burst transfer to get to a cache

boundary. At that point, Memory Write and Invalidate commands will be

issued and will continue at the burst length programmed into the DMA

Mode (DMODE) register. Memory Write and Invalidate commands are

issued as long as the remaining byte count is greater than the Memory

Write and Invalidate threshold. When the byte count goes below this

threshold, a single Memory Write burst will be issued to complete the

transfer. The general pattern for PCI writes will is:

• A single Memory Write to align to a cache boundary.

• Multiple Memory Write and Invalidates.

• A single data residual Memory Write to complete the transfer.

Table 2.2 describes PCI cache mode alignment.

PCI Functional Description 2-13

Page 40

Table 2.2 PCI Cache Mode Alignment

*

Host Memory

A 0x00

B 0x04

0x08

C 0x0C

D 0x10

0x14

0x18

0x1C

E 0x20

0x24

0x28

0x2C

F 0x30

0x34

0x38

0x3C

G 0x40

0x44

0x48

0x4C

H 0x50

0x54

0x58

0x5C

0x60

2-14 Functional Description

Page 41

2.1.4.5 Examples:

*

The examples in this section employ the following abbreviations:

MR = Memory Read, MRL = Memory Read Line, MRM = Memory Read

Multiple, MW = Memory Write, MWI = Memory Write and Invalidate.

Read Example 1 –

Burst = 4 Dwords, Cache Line Size = 4 Dwords:

AtoB: MRL (6 bytes)

AtoC: MRL (13 bytes)

AtoD: MRL (15 bytes)

CtoD: MRM (5 bytes)

CtoE: MRM (15 bytes)

DtoF: MRL (15 bytes)

AtoH: MRL (15 bytes)

AtoG: MRL (15 bytes)

MR (2 bytes)

MRM (6 bytes)

MRL (16 bytes)

MR (1 byte)

MRL (16 bytes)

MRL (16 bytes)

MRL (16 bytes)

MRL (16 bytes)

MR (2 bytes)

MRL (16 bytes)

MRL (16 bytes)

MRL (16 bytes)

MR (3 bytes)

PCI Functional Description 2-15

Page 42

Read Example 2 –

*

Burst = 8 Dwords, Cache Line Size = 4 Dwords:

AtoB: MRL (6 bytes)

AtoC: MRL (13 bytes)

AtoD: MRM (17 bytes)

CtoD: MRM (5 bytes)

CtoE: MRM (21 bytes)

DtoF: MRM (31 bytes)

AtoH: MRM (31 bytes)

AtoG: MRM (31 bytes)

MR (1 byte)

MRM (32 bytes)

MRM (18 bytes)

MRM (32 bytes)

MR (3 bytes)

Read Example 3 –

Burst = 16 Dwords, Cache Line Size = 8 Dwords:

AtoB: MRL (6 bytes)

AtoC: MRL (13 bytes)

AtoD: MRL (17 bytes)

CtoD: MRL (5 bytes)

CtoE: MRM (21 bytes)

DtoF: MRM (32 bytes)

AtoH: MRM (63 bytes)

MRL (16 bytes)

MRM (2 bytes)

AtoG: MRM (63 bytes)

2-16 Functional Description

MR (3 bytes)

Page 43

Write Example 1 –

*

Burst = 4 Dwords, Cache Line Size = 4 Dwords:

AtoB: MW (6 bytes)

AtoC: MW (13 bytes)

AtoD: MW (17 bytes)

CtoD: MW (5 bytes)

CtoE: MW (3 bytes)

DtoF: MW (15 bytes)

AtoH: MW (15 bytes)

AtoG: MW (15 bytes)

MWI (16 bytes)

MW (2 bytes)

MWI (16 bytes)

MW (1 byte)

MWI (16 bytes)

MWI (16 bytes)

MWI (16 bytes)

MWI (16 bytes)

MW (2 bytes)

MWI (16 bytes)

MWI (16 bytes)

MWI (16 bytes)

MW (3 bytes)

PCI Functional Description 2-17

Page 44

Write Example 2 –

*

Burst = 8 Dwords, Cache Line Size = 4 Dwords:

AtoB: MW (6 bytes)

AtoC: MW (13 bytes)

AtoD: MW (17 bytes)

CtoD: MW (5 bytes)

CtoE: MW (3 bytes)

DtoF: MW (15 bytes)

AtoH: MW (15 bytes)

AtoG: MW (15 bytes)

MWI (16 bytes)

MW (2 bytes)

MWI (16 bytes)

MW (1 byte)

MWI (32 bytes)

MWI (32 bytes)

MW (2 bytes)

MWI (32 bytes)

MWI (16 bytes)

MW (3 bytes)

2-18 Functional Description

Page 45

Write Example 3 –

*

Burst = 16 Dwords, Cache Line Size = 8 Dwords:

AtoB: MW (6 bytes)

AtoC: MW (13 bytes)

AtoD: MW (17 bytes)

CtoD: MW (5 bytes)

CtoE: MW (21 bytes)

DtoF: MW (32 bytes)

AtoH: MW (15 bytes)

AtoG: MW (15 bytes)

MWI (64 bytes)

MW (2 bytes)

MWI (32 bytes)

MW (18 bytes)

2.1.4.6 Memory-to-Memory Moves

Memory-to-Memory Moves also support PCI cache commands, as

described above, with one limitation: Memory Write and Invalidate on

Memory-to-Memory Move writes are only supported if the source and

destination address are quad word aligned. If the source and destination

are not quad word aligned, that is, Source address[2:0] == Destination

Address[2:0], write aligning is not performed and no Memory Write and

Invalidate commands are issued. The LSI53C896 is little endian only.

2.2 SCSI Functional Description

The LSI53C896 provides two Ultra2 SCSI controllers on a single chip.

Each Ultra2 SCSI controller provides a SCSI function that supports an

8-bit or 16-bit bus. Each controller supports Wide Ultra2 SCSI

synchronous transfer rates up to 80 Mbytes/s on a LVD SCSI bus. SCSI

functions can be programmed with SCSI SCRIPTS, making it easy to

“fine tune” the system for specific mass storage devices or Ultra2 SCSI

requirements.

SCSI Functional Description 2-19

Page 46

The LSI53C896 offers low level register access or a high-level control

*

interface. Like first generation SCSI devices, the LSI53C896 is accessed

as a register-oriented device. The ability to sample and/or assert any

signal on the SCSI bus is used in error recovery and diagnostic

procedures. In support of SCSI loopback diagnostics, each SCSI function

may perform a self-selection and operate as both an initiator and a

target.

The LSI53C896 is controlled by the integrated SCRIPTS processor

through a high-level logical interface. Commands controlling the SCSI

functions are fetched out of the main host memory or local memory.

These commands instruct the SCSI functions to Select, Reselect,

Disconnect, Wait for a Disconnect, Transfer Information, Change Bus

Phases and, in general, implement all aspects of the SCSI protocol. The

SCRIPTS processor is a special high-speed processor optimized for

SCSI protocol.

2.2.1 SCRIPTS Processor

The SCSI SCRIPTS processor allows both DMA and SCSI commands

to be fetched from host memory or internal SCRIPTS RAM. Algorithms

written in SCSI SCRIPTS control the actions of the SCSI and DMA

cores. The SCRIPTS processor executes complex SCSI bus sequences

independently of the host CPU.

Algorithms may be designed to tune SCSI bus performance, to adjust to

new bus devicetypes(suchasscanners,communicationgateways, etc.),

or to incorporate changes in the SCSI-2 or SCSI-3 logical bus definitions

without sacrificing I/O performance. SCSI SCRIPTS are hardware

independent, so they can be used interchangeably on any host or CPU

system bus. SCSI SCRIPTS also handle conditions such as Phase

Mismatch.

2.2.1.1 Phase Mismatch Handling in SCRIPTS

The LSI53C896 can handle phase mismatches due to drive disconnects

without needing to interrupt the processor. The primary goal of this logic

is to completely eliminate the need for CPU intervention during an I/O

disconnect/reselect sequence.

2-20 Functional Description

Page 47

Storing the appropriate information to later restart the I/O can be done

*

through SCRIPTS, eliminating the need for processor intervention during

an I/O disconnect/reselect sequence. Calculations are performed such

that the appropriate information is available to SCRIPTS so that an I/O

state can be properly stored for restart later.

The Phase Mismatch Jump logic powers up disabled and must be

enabled by setting the Phase Mismatch Jump Enable bit (ENPMJ, bit 7

in the Chip Control 0 (CCNTL0) register).

Utilizing the information supplied in the Phase Mismatch Jump Address

1 (PMJAD1) and Phase Mismatch Jump Address 2 (PMJAD2) registers,

described in Chapter 4, “Registers,” allows all overhead involved in a

disconnect/reselect sequence to be handled with a modest amount of

SCRIPTS instructions.

2.2.2 Internal SCRIPTS RAM

The LSI53C896 has 8 Kbytes (2048 x 32 bits) of internal, general

purpose RAM for each SCSI function. The RAM is designed for

SCRIPTS program storage, but is not limited to this type of information.

When the chip fetchesSCRIPTSinstructions or Table Indirect information

from the internal RAM, these fetches remain internal to the chip and do

not use the PCI bus. Other types of access to the RAM by the chip,

except Load/Store, use the PCI bus as if they were external accesses.

The SCRIPTS RAM powers up enabled by default.

The RAM can be relocated by the PCI system BIOS anywhere in the

64-bit address space. Base Address Register Two (SCRIPTS RAM) in

the PCI configuration space contains the base address of the internal

RAM. To simplify loading of the SCRIPTS instructions, the base address

of the RAM appears in the Scratch Register B (SCRATCHB) register

when bit 3 of the Chip Test Two (CTEST2) register is set. The upper

32 bits of a 64-bit base address will be in the SCRIPTS Fetch Selector

(SFS) register. The RAM is byte accessible from the PCI bus and is

visible to any bus mastering device on the bus. External accesses to the

RAM (by the CPU) follow the same timing sequence as a standard slave

register access, except that the required target wait-states drop from

5to3.

SCSI Functional Description 2-21

Page 48

A complete set of development tools is available for writing custom

*

drivers with SCSI SCRIPTS. For more information on the SCSI SCRIPTS

instructions supported by the LSI53C896, see Chapter 5, “SCSI

SCRIPTS Instruction Set.”

2.2.3 64-Bit Addressing in SCRIPTS

The LSI53C896 has a 64-bit PCI interface which provides 64-bit address

and data capability in the initiator mode. The chip can also respond to

64-bit addressing in the target mode.

DACs can be generated for all SCRIPTS operations. There are six

selector registers which hold the upper Dword of a 64-bit address. All but

one of these is static and requires manual loading using a CPU access,

a Load/Store instruction, or a memory move instruction. One of the

selector registers is dynamic and is used during 64-bit direct block moves

only. All selectors will default to zero, meaning the LSI53C896 will

power-up in a state where only Single Address Cycles (SACs) will be

generated. When any of the selector registers are written to a nonzero

value, DACs will be generated.

Direct, table indirect and indirect block moves, Memory-to-Memory

Moves, Load/Stores and jumps are all instructions with 64-bit address

capability.

Crossing the 4 Gbyte boundary on any one SCRIPTS operation is not

permitted and software needs to take care that any given SCRIPTS

operation will not cross the 4 Gbyte boundary.

2.2.4 Hardware Control of SCSI Activity LED

The LSI53C896 has the ability to control a LED through the GPIO_0 pin

to indicate that it is connected to the SCSI bus. Formerly this function

was done by a software driver.

When bit 5 (LED_CNTL) in the General Purpose Pin Control (GPCNTL)

register is set and bit 6 (Fetch Enable) in the GPCNTL register is cleared

and the LSI53C896 is not performing an EEPROM autodownload, then

bit 3 (CON) in the Interrupt Status Zero (ISTAT0) register will be

presented at the GPIO_0 pin.

2-22 Functional Description

Page 49

The CON (Connected) bit in Interrupt Status Zero (ISTAT0) will be set

*

anytime the LSI53C896 is connected to the SCSI bus either as an

initiator or a target. This will happen after the LSI53C896 has

successfully completed a selection or when it has successfully

responded to a selection or reselection. It will also be set when the

LSI53C896 wins arbitration in low level mode.

2.2.5 Designing an Ultra2 SCSI System

Since Ultra2 SCSI is based on existing SCSI standards, it can use

existing driver programs as long as the software is able to negotiate for

Ultra2 SCSI synchronous transfer rates. Additional software

modifications may be needed to take advantage of the new features in

the LSI53C896.

In the area of hardware, LVD SCSI is required to achieve Ultra2 SCSI

transfer rates and to support the longer cable and additional devices on

the bus. All devices on the bus must have LVD SCSI capabilities to

guarantee Ultra2 SCSI transfer rates. Foradditional information on Ultra2

SCSI, refer to the SPI-2 working document which is available from the

SCSI BBS referenced at the beginning of this manual. Chapter 6,

“Specifications,” contains Ultra2 SCSI timing information. In addition to

the guidelines in the draft standard, make the following software and

hardware adjustments to accommodate Ultra2 SCSI transfers:

• Set the Ultra Enable bit to enable Ultra2 SCSI transfers.

• Set the TolerANT Enable bit, bit 7 in the SCSI Test Three (STEST3)

register, whenever the Ultra Enable bit is set.

• Do not extend the SREQ/SACK filtering period with the SCSI Test

Two (STEST2) register bit 1. When the Ultra Enable bit is set, the

filtering period will be fixed at 8 ns for Ultra2 SCSI or 15 ns for Ultra

SCSI, regardless of the value of the SREQ/SACK filtering bit.

• Use the SCSI clock quadrupler.

2.2.5.1 Using the SCSI Clock Quadrupler

The LSI53C896 can quadruple the frequency of a 40 MHz SCSI clock,

allowing the system to perform Ultra2 SCSI transfers. This option is user

selectable with bit settings in the SCSI Test One (STEST1), SCSI Test

SCSI Functional Description 2-23

Page 50

Three (STEST3), and SCSI Control Three (SCNTL3) registers. At

*

power-on or reset, the quadrupler is disabled and powered down. Follow

these steps to use the clock quadrupler:

1. Set the SCLK Quadrupler Enable bit (SCSI Test One (STEST1)

register, bit 3).

2. Poll bit 5 of the SCSI Test Four (STEST4) register. The LSI53C896

sets this bit as soon as it locks in the 160 MHz frequency. The

frequency lockin takes approximately 100 microseconds.

3. Halt the SCSI clock by setting the Halt SCSI Clock bit (SCSI Test

Three (STEST3) register, bit 5).

4. Set the clock conversion factor using the SCF and CCF fields in the

SCSI Control Three (SCNTL3) register.

5. Set the SCLK Quadrupler Select bit (SCSI Test One (STEST1), bit 2).

6. Clear the Halt SCSI Clock bit.

2.2.6 Prefetching SCRIPTS Instructions

When enabled by setting the Prefetch Enable bit (bit 5) in the DMA

Control (DCNTL) register, the prefetch logic in the LSI53C896 fetches

8 Dwords of instruction. The prefetch logic automatically determines the

maximum burst size that it can perform, based on the burst length as

determined by the values in the DMA Mode (DMODE) register. If the unit

cannot perform bursts of at least four Dwords, it disables itself. While the

chip is prefetching SCRIPTS instructions, it will use PCI cache

commands Memory Read Line, and Memory Read Multiple, if PCI

caching is enabled.

Note: This feature is only useful when fetching SCRIPTS

instructions from main memory. Due to the short access

time of SCRIPTS RAM, prefetching is not necessary when

fetching instructions from this memory.

The LSI53C896 may flush the contents of the prefetch unit under certain

conditions to ensure that the chip always operates from the most current

version of the SCRIPTS instruction. When one of these conditions

applies, the contents of the prefetch unit are automatically flushed.

• On every Memory Move instruction. The Memory Move instruction is

often used to place modified code directly into memory. To make

sure that the chip executes all recent modifications, the prefetch unit

2-24 Functional Description

Page 51

flushes its contents and loads the modified code every time an

*

instruction is issued. To avoid inadvertently flushing the prefetch unit

contents, use the No Flush option for all Memory Move operations

that do not modify code within the next 8 Dwords. For more

information on this instruction refer to Chapter 5, “SCSI SCRIPTS

Instruction Set.”

• On every Store instruction. The Store instruction may also be used

to place modified code directly into memory. To avoid inadvertently

flushing the prefetch unit contents use the No Flush option for all

Store operations that do not modify code within the next 8 Dwords.

• On every write to the DMA SCRIPTS Pointer (DSP) register.

• On all Transfer Control instructions when the transfer conditions are

met. This is necessary because the next instruction to execute is not

the sequential next instruction in the prefetch unit.

• When the Prefetch Flush bit (DMA Control (DCNTL) register, bit 6)

is set. The unit flushes whenever this bit is set. The bit is

self-clearing.

2.2.7 Opcode Fetch Burst Capability

Setting the Burst Opcode Fetch Enable bit (bit 1) in the DMA Mode

(DMODE) register (0x38) causes the LSI53C896 to burst in the first two

Dwords of all instruction fetches. If the instruction is a Memory-toMemory Move, the third Dword is accessed in a separate ownership. If

the instruction is an Indirect Type, the additional Dword is accessed in a

subsequent bus ownership. If the instruction is a table indirect Block

Move, the chip uses two accesses to obtain the four Dwords required, in

two bursts of two Dwords each.

Note: This feature is only useful if Prefetching is disabled.

This feature is only useful if fetching SCRIPTS instructions

from main memory. Due to the short access time of

SCRIPTS RAM, burst opcode fetching is not necessary

when fetching instructions from this memory.

SCSI Functional Description 2-25

Page 52

2.2.8 Load/Store Instructions

*

The LSI53C896 supports the Load/Store instruction type, which

simplifies the movement of data between memory and the internal chip

registers. It also enables the chip to transfer bytes to addresses relative

to the Data Structure Address (DSA) register. Load/Store data transfers

to or from the SCRIPTS RAM will remain internal to the chip and will not

generate PCI bus cycles. While a Load/Store to or from SCRIPTS RAM

is occurring, any external PCI slave cycles that occur will be retried on

the PCI bus. This feature can be disabled by setting the DILS bit in the

Chip Control 0 (CCNTL0) register. For more information on the

Load/Store instructions refer to Chapter 5, “SCSI SCRIPTS Instruction

Set.”

2.2.9 JTAG Boundary Scan Testing

The LSI53C896 includes support for JTAG boundary scan testing in

accordance with the IEEE 1149.1 specification with one exception, which

is explained in this section. This device accepts all required boundary

scan instructions including the optional CLAMP, HIGH-Z, and IDCODE

instructions.

The LSI53C896 uses an 8-bit instruction register to support all boundary

scan instructions. The data registers included in the device are the

Boundary Data register, the IDCODE register, and the Bypass register.

This device can handle a 10 MHz TCK frequency for TDO and TDI.

Due to design constraints, the RST/ pin (system reset) always 3-states

the SCSI pins when it is asserted. Boundary scan logic does not control

this action, and this is not compliant with the specification. There are two

solutions that resolve this issue:

1. Use the RST/ pin as a boundary scan compliance pin. When the pin

is deasserted, the device is boundary scan compliant and when

asserted, the device is noncompliant. To maintain compliance the

RST/ pin must be driven HIGH.

2. When RST/ is asserted during boundary scan testing the expected

output on the SCSI pins must be the HIGH-Z condition, and not what