BRUSHLESS DC MOTOR COMMUTATOR/CONTROLLER

FEATURES:

• Speed Control by Pulse Width Modulation (PWM)

of low-side drivers only.

• Open or closed loop motor speed control.

• +5 to +28 Volt operation (Vss - VDD).

• Externally selectable input to output code for 60°,

120°, 240°, or 300° electrical sensor spacing.

• Three or four phase operation.

• Analog Speed control.

• Forward/Reverse control.

• Output Enable control.

• Positive Static Braking.

• Overcurrent Sensing.

• Six outputs drive switching bridge directly.

DESCRIPTION:

The LS7362 is a monolithic, ion implanted MOS circuit designed to generate the signals necessary to control a three

phase or four phase brushless DC motor. It is the basic

building block of a brushless DC motor controller. The circuit responds to changes at the SENSE inputs, originating

at the motor position sensors, to provide electronic commutation of the motor windings. Pulse width modulation

(PWM) of low-side drivers for motor speed control is accomplished through either the ENABLE input or through

the V TRIP input (Analog Speed control) in conjunction with

the OSCILLATOR input. Overcurrent circuitry is provided

to protect the windings, associated drivers and power supply. The LS7362 circuitry causes the external output drivers to switch off immediately upon sensing the overcurrent

condition, and on again only when the overcurrent condition disappears and the positive edge of either the ENABLE input or the sawtooth OSCILLATOR occurs. This limits the overcurrent sense cycling to the chopping rate of the

ENABLE input or the sawtooth OSCILLATOR. A positive

braking feature is provided to effect rapid deceleration. The

LS7362 is designed for driving Bipolar and Field Effect

Transistors. Because only low-side drivers are pulse width

modulated, the LS7362 is ideally suited in situations where

the integrated circuit interfaces with level converters to

drive high voltage brushless DC motors. By pulse width

modulating the low-side drivers only, the switch losses in

the level conversion circuitry for the high-side drivers is

minimized. Figure 1 indicates how the level conversion is

accomplished.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

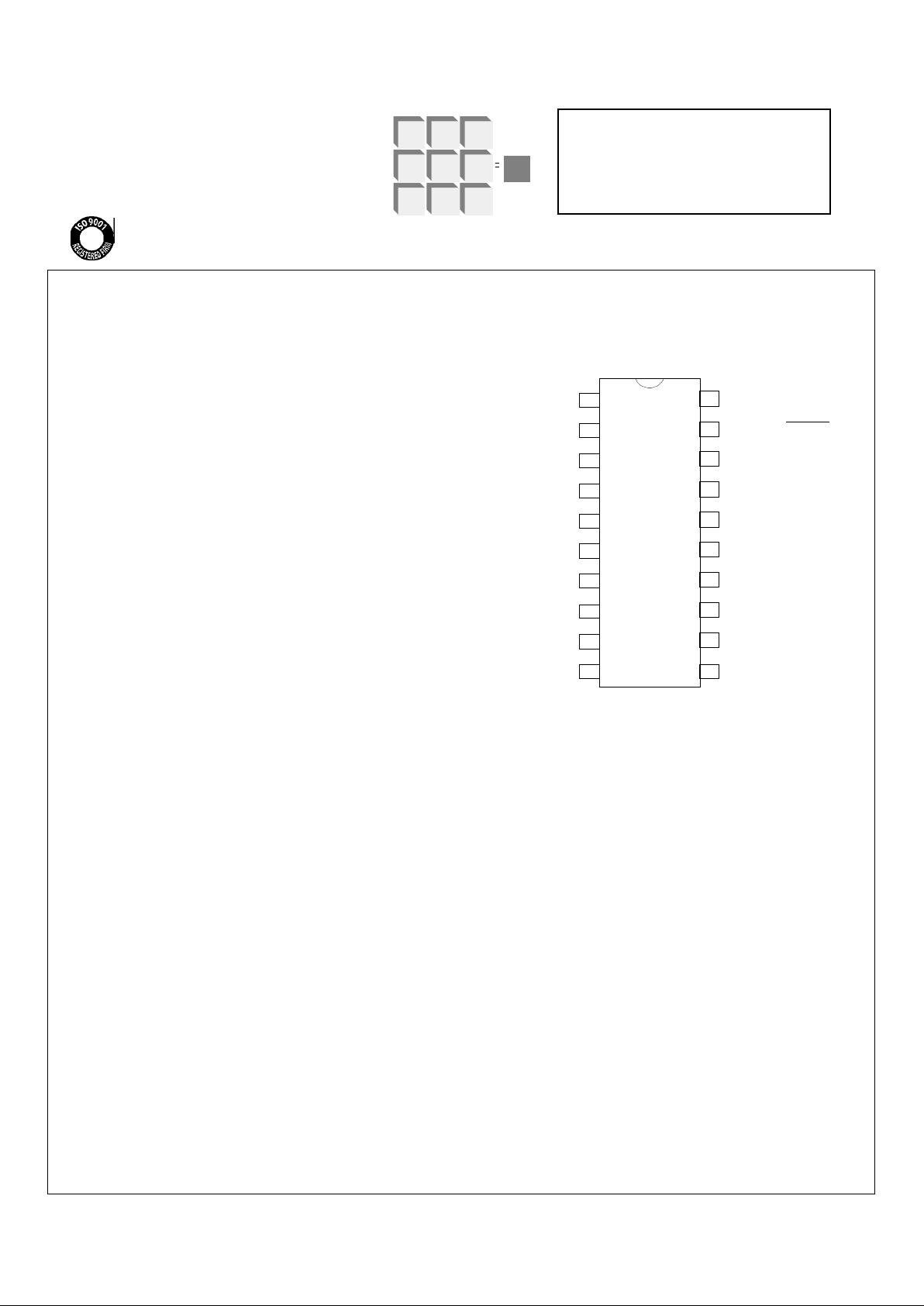

LSI

CS1

OUT 1

OUT 2

OUT 3

OUT 4

COMMON

OUT 5

OUT 6

BRAKE

ENABLE

CS2

FORWARD/REVERSE

VDD (-V)

S3

S2

S1

OSCILLATOR

V TRIP

OVERCURRENT SENSE

VSS (+V)

LS7362

CONNECTION DIAGRAM - TOP VIEW

STANDARD 20 PIN PLASTIC DIP

The COMMON, Pin 5, is tied to the positive supply rail

and LS7362 Outputs 1, 2, and 3 are used to drive level

converters Q101, Q102 and Q103 respectively. Only the

motor top side drivers consisting of Q107, Q108 and

Q109 which are connected to the motor power supply,

VM, will be subject to the high speed switching currents

that flow through the motor. The level converters are

turned on and off at the slower commutation rate.

INPUT/OUTPUT DESCRIPTION:

COMMUTATION SELECTS (Pins 1, 20)

These inputs are used to select the proper sequence of

outputs based on the electrical separation of the motor

position sensors. With both inputs low (logic zero), the

sequence is adjusted for 60° electrical separation, with

CS2 high and CS1 low 120° separation sequence is selected, with CS1 high and CS2 low 240° separation sequence is selected and with CS1 and CS2 high the 300°

separation sequence is selected. Note that in all cases

the external output drivers are disabled for invalid

SENSE input codes. Internal pull down resistors are provided at Pins 1 and 20 causing a logic zero when these

pins are left open.

September 1999

7362-041100-1

LSI/CSI

LSI Computer Systems, Inc. 1235 Walt Whitman Road, Melville, NY 11747 (631) 271-0400 FAX (631) 271-0405

LS7362

• LS7362 (DIP); LS7362-S (SOIC);

LS7362-TS (TSSOP) - See Connection Diagram

U

L

®

A3800

FORWARD/REVERSE (Pin 19)

This pin acts to modify the input to output sequence such

that when brought from high to low or low to high the direction of rotation will reverse. An internal pull up resistor is

provided at Pin 19 causing a logic one when left open.

SENSE INPUTS (Pins 15, 16, 17)

These inputs provide control of the output commutation

sequence as shown in Table III. S1, S2, S3 originate in

the position sensors of the motor and must sequence in

cycle code order. Hall switch "pull-up" resistors are provided at Pins 15, 16 and 17. The positive supply of the

Hall devices should be common to the chip Vss.

BRAKE (Pin 9)

A high level applied to this input unconditionally turns off

outputs 1, 2 and 3 and turns on outputs 4,5 and 6 (See

Figure 1). Transistors Q101, Q102 and Q103 cut off causing Q107, Q108 and Q109 to cut off and transistors Q104,

Q105 and Q106 turn on, shorting the windings together,

The BRAKE has priority over all other inputs. An internal

pull down resistor is provided at Pin 9 causing no braking

when left open. (Center- tapped motor configuration requires a power supply disconnect transistor controlled by

the BRAKE signal - See Figure 3.)

ENABLE (Pin 10)

A high level on this input permits the output to sequence

as in Table III, while a low disables all external output drivers. An internal "pull up" resistor is provided at Pin 10,

enabling when left open. Positive edges at this input will

reset the overcurrent flip-flop.

OVERCURRENT SENSE (Pin 12)

This input provides the user a way of protecting the motor

winding, drivers and power supply from an overload

condition. The user provides a fractional ohm resistor

between the negative supply and the common emitters of

the NPN drivers. This point is connected to one end of a

potentiometer (e.g. 100K ohms), the other end of which is

connected to the positive supply. The wiper pickoff is

adjusted so that all outputs are disabled for currents greater than the limit. The action of the input is to disable all

external output drivers. When BRAKE exists, OVERCURRENT SENSE will be overridden. The overcurrent

circuitry latches the overcurrent condition. The latch may

be reset by the positive edge of either the sawtooth OSCILLATOR or the ENABLE input. When using the ENABLE input as a chopped input, the OSCILLATOR pin

should be held at VSS. When the ENABLE input is held

high, the OSCILLATOR must be used to reset the overcurrent latch.

V TRIP (Pin 13)

This pin is used in conjunction with the sawtooth oscillator

provided on the circuit. When the voltage level applied to

V TRIP is more negative than the waveform at the OSCILLATOR pin, the low-side drivers will be enabled. When

V TRIP is more positive than the sawtooth OSCILLATOR

waveform the low-side drivers are disabled.

The sawtooth waveform at the OSCILLATOR pin typically varies from .4 Vss to Vss-2 Volts (assuming VDD is at ground potential). The purpose of the V TRIP input in conjunction with the

OSCILLATOR is to provide variable speed adjustment for the

motor by means of PWM of the low-side drivers.

OSCILLATOR (Pin 14)

A reisistor and capacitor connected to this pin (See Fig. 6) provide the timing components for a sawtooth OSCILLATOR. The

signal generated is used in conjunction with V TRIP to provide

PWM for variable speed applications and to reset the overcurrent condition.

OUTPUTS 1, 2, 3 (Pins 2, 3, 4)

These open drain outputs are enabled as shown in Table III and

provide base current when the COMMON (Pin 5) is tied to Vss.

These outputs provide commutation only for the high-side drivers. They are not pulse width modulated to control speed.

OUTPUT 4, 5, 6 (PINS 6, 7, 8)

These open drain outputs are enabled as in Table III and

provide base current to NPN transistors when the COMMON is

tied to Vss. They provide commutation and are pulse width

modulated to provide speed control.

COMMON (Pin 5)

The COMMON is connected to Vss for driving low-side drivers

and high-side level converters.

Vss (Pin 11) Supply voltage positive terminal.

VDD (Pin 18) Supply voltage negative terminal.

TYPICAL CIRCUIT OPERATION:

Figure 1 indicates an application using bipolar power transistors. The oscillator is used for motor speed control as explained under VTRIP. Only low-side drive transistors are pulse

width modulated during speed control. The outputs turn on

in pairs (See Table III). For example, two separate paths are

turned on when Q8 and Q4 are on. One path is from the positive supply through Q8, R1 and the base emitter junction of

Q101. The second is from the positive supply through Q4, R14,

the base emitter junction of Q105 and the fractional ohm resistor to ground. The current in the first path is determined by

the power supply voltage, the impedance of Q8, the value of

R1 and the voltage drop across the base-emitter junction of

Q101 (0.7 Volts for a single transistor or 1.4 Volts for a Darlington Transistor). The current in the second path is determined

by the power supply voltage, the impedance of Q4, the value of

R14 and the voltage drop across the base-emitter junction of

Q105. Table I provides the recommended value for R1; R2,

R3, R13, R14, and R15 are the same value.

Figure 2 indicates an application where Power FETS are used.

The nominal power supply for the LS7362 in this configuration

is 15 Volts so that the low side N channel Power FET drivers

will have 15 Volts of gate drive. Resistors R13, R14 and R15

serve to discharge the gate capacitance during FET turn-off.

The high-side P-channel FET drivers use 15 Volt Zener diodes

Z1, Z2 and Z3 to limit the gate drive. Resistors R8, R10 and

R12 are the gate capacitance discharge resistors. Table II indicates the minimum value of R13 (=R14=R15) needed as a

function of output drive voltage for the low-side drivers.

7362-110292-2

MAXIMUM RATINGS:

PARAMETER SYMBOL VALUE UNIT

Storage Temperature TSTG -65 to +150 °C

Operating Temperature

1. Plastic TA -25 to +70 °C

2. Ceramic TA -55 to +125 °C

Voltage (any pin to Vss) VMAX -30 to +.5 Volts

DC ELECTRICAL CHARACTERISTICS:

(All Voltages Referenced to VDD)

SYMBOL MIN TYP MAX UNIT

Supply Voltage VSS 5 - 28 Volts

Supply Current

(Excluding Outputs) IDD - 4.5 6 mA

Input Specifications:

BRAKE, ENABLE, CS1, CS2 RIN - 150 - KΩ

S1, S2, S3, FORWARD/REVERSE

Voltage (Logic "1") VIH VSS-1.5 - VSS Volts

(Logic "0") VIL 0 - VSS-4.0 Volts

OVERCURRENT SENSE (See Note)

Voltage (Logic "1") VIH (VSS/2)+.25 - VSS Volts

(Logic "0") VIL 0 - (VSS/2)-.25 Volts

Oscillator:

Frequency Range Fosc 0 1/RC 100 kHz

External Resistor Range Rosc 22 - 1000 kΩ

NOTE: Theoretical switching point of the OVERCURRENT SENSE input is one half of the power supply determined by an internal bias

network in manufacturing. Tolerances cause the switching point to vary plus or minus .25 Volts. After manufacture, the switching point

remains fixed within 10 mV over time and temperature. The input switching sensivity is a maximum of 50mV. There is no hysteresis on

the OVERCURRENT SENSE input.

TABLE I

OUTPUT CURRENT LIMITING RESISTOR SELECTION TABLE

POWER OUTPUT CURRENT

SUPPLY

(VOLTS) 20 15 10 7.5 5 2.5 mA

6 ** ** ** ** ** 2.0

9 ** ** ** .94 1.6 3.2

12 .35 .53 .88 1.2 2.1 4.0

15 .54 .76 1.2 1.7 2.6 5.3 Resistance

18 * 1.0 1.6 2.1 3.2 6.5 (kΩ)

21 * * 1.9 2.5 3.8 7.7

24 * * 2.2 2.9 4.4 9.0

28 * * * 3.5 5.3 10.3

*causes excessive power dissipation

**exceeds max current possible for this voltage

TABLE II

For Power Supply 5-28 Volts

R13 (K ohms) Output Voltage

10 Vss -0.5

5.1 Vss -1.0

2.7 Vss -2.0

TABLE III

OUTPUT COMMUTATION SEQUENCE

THREE PHASE OPERATION

SEQUENCE SELECT CS1 CS2 CS1 CS2 CS1 CS2 CS1 CS2 FORWARD/REVERSE=1 FORWARD/REVERSE=0

0 0 0 1 1 0 1 1

ELECTRICAL SEPARATION (-60°-) (-120°-) (-240°-) (-300°-) OUTPUTS DRIVERS OUTPUTS DRIVERS

SENSE INPUTS S1 S2 S3 S1 S2 S3 S1 S2 S3 S1 S2 S3 ENABLED A B C ENABLED A B C

0 0 0 0 0 1 0 1 0 0 1 1 O1, O5 + - Off O2, O4 - + Off

1 0 0 1 0 1 1 1 0 1 1 1 O3, O5 Off - + O2, O6 Off + -

1 1 0 1 0 0 1 0 0 1 1 0 O3, O4 - Off + O1, O6 + Off 1 1 1 1 1 0 1 0 1 1 0 0 O2, O4 - + Off O1, O5 + - Off

0 1 1 0 1 0 0 0 1 0 0 0 O2, O6 Off + - O3, O5 Off - +

0 0 1 0 1 1 0 1 1 0 0 1 O1, O6 + Off - O3, O4 - Off +

0 1 0 0 0 0 0 0 0 0 1 0 ALL DISABLED ALL DISABLED

1 0 1 1 1 1 1 1 1 1 0 1 ALL DISABLED ALL DISABLED

The OVERCURRENT input (BRAKE low) enables external output drivers in normal sequence when more negative than Vss/2 and disables

all external output drivers when more positive than Vss/2. The OVERCURRENT is sensed continuously, and sets a flip flop which is reset

by the rising edge of the ENABLE input or the sawtooth OSCILLATOR. (See description under OVERCURRENT SENSE.)

7362-110292-3

6

12

Output

Encoder

7

8

5

4

3

2

Q106

Q105

Q104

A

L1

B

L2

L3

R13

R14

R15

Q6

Q7Q8

Q3

Q4Q5

BRAKE

11

Fractional

Ohm

Resistor

TO OVERCURRENT

ADJUSTMENT

Vss

Vss

O4

O5

O6

O3

O2

O1

M

O

T

O

R

FIGURE 1. BIPOLAR THREE PHASE OUTPUT DRIVER CIRCUITRY

C

Q107 Q108

Q109

R16

R17 R18

R4 R5 R6

Q101

Q102

Q103

R8

R7

R10

R9

R12

R11

R1

R2

R3

VM

6

12

Output

Encoder

7

8

5

4

3

2

A

L1

B

L2

L3

Q6Q7Q8

Q3Q4Q5

BRAKE

11

Fractional

Ohm

Resistor

TO OVERCURRENT

ADJUSTMENT

Vss

Vss

O4

O5

O6

O3

O2

O1

M

O

T

O

R

FIGURE 2. POWER FET THREE PHASE OUTPUT DRIVER CIRCUITRY

C

R13

R14

R15

R4 R5 R6

Q101

Q102

Q103

R8

R7

R10

R9

R12

R11

R1

R2

R3

VM

Z3

Z2

Z1

Q104

Q105

Q106

Q107

Q108

Q109

7362-101992-4

Vss

+

13

V TRIP

EXT. OSCILLATOR

R6

R2

C1

S1

R1

15

Vss

C3

Vss

R3

R4

R5

D1

C2

Vss

R8

LS7362

FROM MOTOR

POSITION

SENSOR

14

C4

R7

FIGURE 5

CLOSED-LOOP SPEED CONTROLLER

A closed loop system can be configured by differentiating

one of the motor position sense inputs and integrating only

the negative pulses to form a DC voltage that is applied to

the inverting input of an op-amp. The non-inverting input

voltage is adjusted with a potentiometer until the resultant

voltage at V TRIP causes the motor to run at desired speed.

The R2-C1 differentiator, the R3-D1 negative pulse transmitter and the R4-C2 integrator form a frequency to voltage

converter. An increase in motor speed above the desired

speed causes V TRIP to increase which lowers the duty cycle modulation of the oscillator and the resultant motor

speed. A decrease in speed lowers V TRIP and raises the

duty cycle modulation and the resultant motor speed. For

proper operation, both R5 and R6 should be greater than

R4, and R4 in turn should be greater than both R2 and R3.

Also the R4-C2 time constant should be greater than the

R2-C1 time constant. C3 may be added across R6 for

additional V TRIP smoothing.

BRAKE

MOTOR

SUPPLY

Vss

O6

8

5

COMMON

BRAKE

INPUT

7

O4

6

9

O5

LS7362

FIGURE 3.

SINGLE-ENDED

DRIVER CIRCUIT

This configuration requires only

one base current limiting resistor

connected from the COMMON

pin to Vss.

FORWARD

REVERSE

IN914

2.2K

Inputs form SG1731

or UC1637

F/R

LS7362

ENABLE

19

10

FIGURE 4. PRECISION CONTROL

BRUSHLESS DC MOTOR DRIVE

For controlled acceleration and deceleration of motors

in the forward or reverse directions, a motor control

pulse width modulator circuit such as the SG1731 or

UC1637 can be interfaced with the LS7362.

The logical OR gate made up of the resistor-diode network permits the LS7362 to be enabled when either the

forward or reverse input is high. By applying the forward

input directly to Pin 19, the motor can only operate in the

forward direction when the forward input is high and only

in the reverse direction when the reverse input is high.

Motor direction is determined by relative pulse widths of

the forward and reverse inputs while acceleration or

deceleration is determined by variations of these widths.

The information included herein is believed to be

accurate and reliable. However, LSI Computer Systems,

Inc. assumes no responsibilities for inaccuracies, nor for

any infringements of patent rights of others which may

result from its use.

7362-101992-5

OUTPUT

DRIVERS

OUTPUT

ENCODER

INPUT

DECODER

R

Q

S

SAWTOOTH

OSCILLATOR

+

+

POSITIVE

EDGE

DETECTOR

COMMUTATION

SEQUENCE

SELECT LOGIC

LOW-SIDE

DRIVERS

HIGH-SIDE

DRIVERS

5

6

8

11

VDD18

VSS

GND

COMMON

4

+V

1

20

19

15

16

17

9

10

12

13

14

≈30KHz

CS1

CS2

FWD/REV

S1

S2

S3

BRAKE

ENABLE

OVERCURRENT

SENSE

V TRIP

.001µF

33K

+V

+V

FIGURE 6. LS7362 BLOCK DIAGRAM

R

R

+V

2

3

4

5

6

7

O1

O2

O3

O4

O5

O6

-

Loading...

Loading...