Page 1

Drive Module

Site Preparation Guide

DF1153-E1, First Edition

Page 2

This document contains proprietary information of LSI Logic Corporation. The

information contained herein is not to be used by or disclosed to third parties without the

express written permission of an officer of LSI Logic Corporation. Any product(s)

described herein is/are a licensed product of LSI Logic Corporation.

Document DF1153-E1, First Edition. March 2001

This document describes models E3300, FC-1 10x, FC-1 14x, E2400 10x, and E2400 14x of

LSI Logic Corporation’s drive modules and command modules and will remain the official

reference source for all revisions/releases of this product until rescinded by an update.

It is the policy of LSI Logic to improve products as new technology, components, software,

and firmware become available. LSI Logic Corporation reserves the right to make changes

to any products her ein at any time without notice. All features, functions, and operations

described herein may not be marketed by LSI Logic in all parts of the world. In some

instances, photographs and figures are of equipment prototypes. Therefore, before using

this document, consult you LSI Logic representative for information that is applicable and

current. LSI LOGIC DOES NOT ASSUME ANY RESPONSIBILITY OR LIABILITY FOR

THE USE OF ANY PRODUCT(S) DESCRIBED HEREIN EXCEPT AS EXPRESSLY

AGREED TO IN WRITING BY LSI LOGIC. The purchase of use of an LSI Logic product

does not convey a license under any patent, copyright, trademark, or other intellectual

property right of LSI Logic or third parties.

Copyright © 2001. LSI Logic Corporation. All rights reserved.

Trademark Acknowledgments

LSI Logic and the LSI Logic logo are registered trademarks of LSI Logic Corporation.

Adobe, Acrobat, and Acrobat Reader are either register ed trademarks or trademarks of

Adobe Systems Incorporated. All other brand and product names may be trademarks of

their respective companies.

Page 3

Federal Communications Commission (FCC) Radio

Frequency Interfere nce Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a commercial installation. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the interference at

his own expense.

LSI Logic Corporation is not responsible for any radio or television interference caused by

unauthorized modification of this equipment or the substitution or attachment of

connecting cables and equipment other than those specified by LSI Logic Corporation. It is

the user’s responsibility to correct interference caused by such unauthorized modification,

substitution, or attachment.

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la classé A respecte toutes les exigences du Règlement sure le

matèriel brouilleur du Canada.

Drive Module Site Preparation Guide i

Page 4

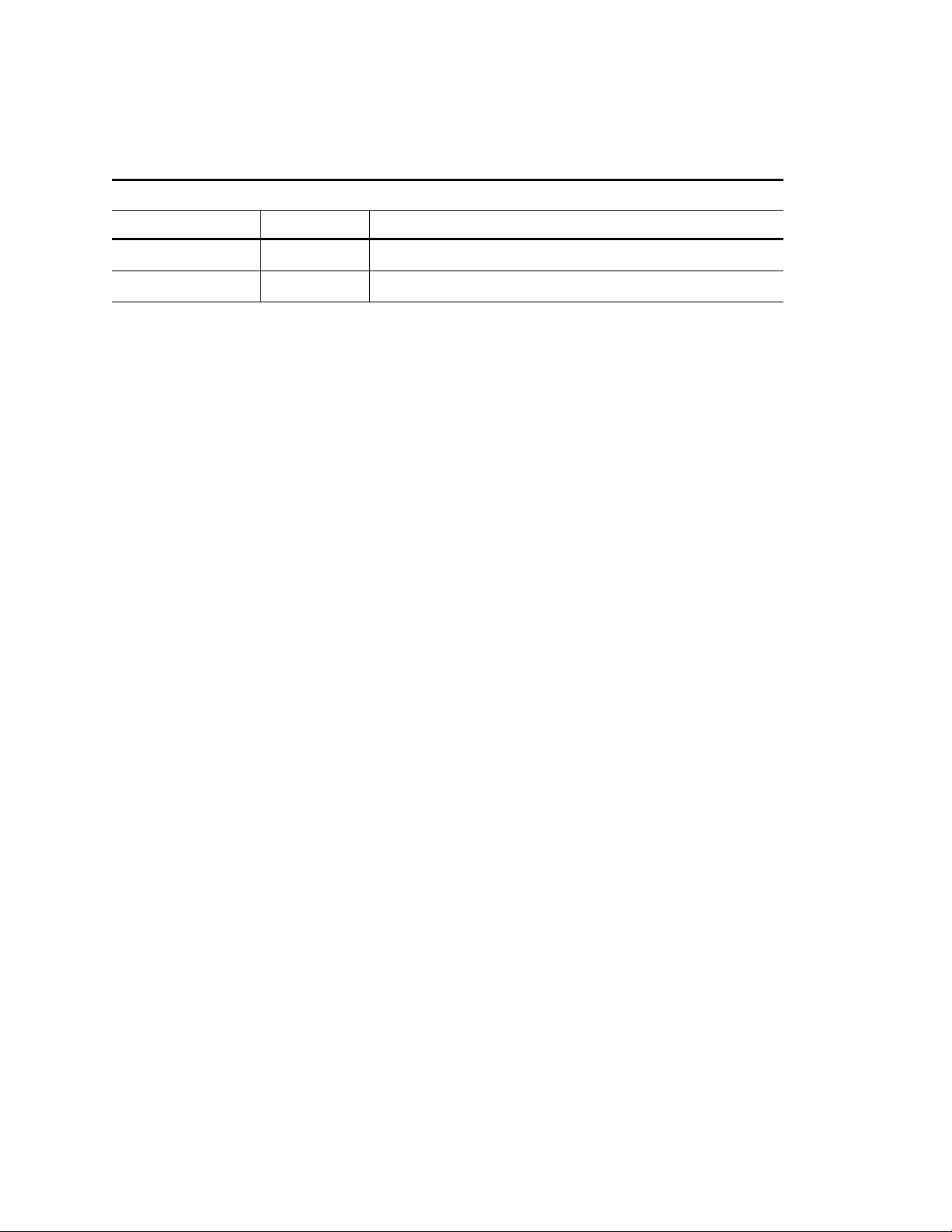

Revision Record

Edition or Revision Date Affected Pages/Remarks

First Edition March 20 01 New Book

Part Number: DF1153-E1

ii Drive Module Site Preparation Guide

Page 5

Contents

About This Book ..............................................................................................................................1

Intended Readers .......................................................................................................................1

Content and Organization .........................................................................................................2

Terminology Used in This Book ............................................................................................... 2

Documentation Set ..........................................................................................................................4

General Documentation ............................................................................................................ 4

Hardware Documentation ..................................... ...................................................................4

Software Documentation ........................................................................................................... 4

Preparatory Tasks ............................................................................................................................5

Tools and Equipment You May Need ......................................................................................5

Area Requirements ..........................................................................................................................6

Weights .......................................................................................................................................6

Dimensions ...............................................................................................................................12

Airflow ......................................................................................................................................16

Environmental Requirements .................................................... ................................................... 17

Site Wiring Requirements ............. ................................................................................................19

Site Wiring and Voltages .........................................................................................................19

Drive Module Power Requirements .............................................................................................21

E3300 Drive Module ................................................................................................................21

Power Connections ............................................................................................................21

Power Cord Routing ...........................................................................................................22

FC-1 10x Drive Module and E2400 10x Command Module ................................................23

Power Cord Routing ...........................................................................................................24

FC-1 14x Drive Module and E2400 14x Command Module ................................................25

Power Cord Routing ...........................................................................................................26

Drive Module Site Preparation Guide iii

Page 6

Drive Module Cable Requirements ...............................................................................................27

E3300 Interface Cables .............................................................................................................27

SCSI Terminators ................................................................................................................27

FC-1 10x, E2400 10x, FC-1 14x, and E2400 14x Interface Cables .........................................28

iv Drive Module Site Preparation Guide

Page 7

List of Figures

1 E3300 Drive Module Dimensions .............................................................................................13

2 FC-1 10x Drive Module and E2400 10x Command Module Dimensions ..............................14

3 FC-1 14x Drive Module and E2400 14x Command Module Dimensions ..............................15

4 Drive Module or E2400 Command Module Airflow ...............................................................16

5 Redundant AC Power Connections to Rackmount Controller and Drive Modules ..............24

6 Redundant AC Power Connections to Rackmount Controller and Drive Modules ..............26

Drive Module Site Preparation Guide v

Page 8

List of Tables

1 Unique Terminology and Concepts .............................................................................................3

2 E3300 Drive Module Weight Table ..................................................................... .........................7

3 FC-1 10x Dr ive Module Weight Table ..................................................................... ....................8

4 E2400 10x Command Module Weight Table ..............................................................................9

5 FC-1 14x Dr ive Module Weight Table ..................................................................... ..................10

6 E2400 14x Command Module Weight Table ............................................................................11

7 Shipping Carton Dimensions .....................................................................................................15

8 Drive Module and E2400 Command Module Environmental Requiremen ts ........................17

9 Drive Module and E2400 Command Module Heat Dissipation .................................. ............18

10 Drive Module and E2400 Command Module Site Wiring Voltages ......................................20

11 E3300 Power Requirements ......................................................................................................21

12 FC-1 10x and E2400 10x Power Requirements ....................................... ................................23

13 FC-1 14x and E2400 14x Power Requirements ....................................... ................................25

14 SCSI Drive Interface Cables ......................................................................................................27

15 Fibre Channel Host and Drive Interface Cables ......................................................................28

vi Drive Module Site Preparat ion Guide

Page 9

About This Book

This book provides technical specifications and information you will need to prepare a site

before installing the following hardware:

E3300 Drive Module containing up to ten drives and one low-voltage-differential- to-

•

single-ended environmental services monitor (LVD-SE ESM),

E3300 Drive Module containing up to ten drives and one LVD-LVD ESM

•

FC-1 10x Drive Module containing up to ten drives and one or two Fibre-Channel-to-

•

Fibre-Channel (FC-FC) ESMs

a

E2400 10x Command Module containing up to ten drives and one or two 2772

•

controllers

FC-1 14x Drive Module containing up to fourteen drives and one or two FC-FC ESMs

•

E2400 14x Command Module containing up to fourteen drives and one or two 2772

•

controllers

Intended Readers

This book is intended for end users, system operators, system administrators, and service

technicians who are responsible for preparing and installing hardware. Readers should

understand the following technologies:

Redundant array of independent disk (RAID)

•

Small computer systems interface (SCSI)

•

Fibre Channel

•

Drive Module Site Preparation Guide 1

Page 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Content and Organization

Site preparation information covered in this book includes:

Area requirements – drive module and E2400 command module weight, dimensions,

•

and airflow to help you determine installation, service, and operating floor space

requirements

Environmental requirements – temperature, humidity , and altitude ranges to help you

•

determine heating and air conditioning requirements

Power requir emen ts – drive module E2400 command module voltages and power

•

requirements to help you prepare the site wiring

Interface requirements – interface cable types and lengths to help you determine which

•

cables to order

Terminology Used in This Book

The following table contains a list of terminology and de finitions that are unique to the

products supported in this documentations set. For additional information on

terminol ogy and concepts, see Understanding SANtricity™ Storage Manager Concepts

Guide for Version 7.10.

2 Drive Module Site Preparation Guide

Page 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . About This Book

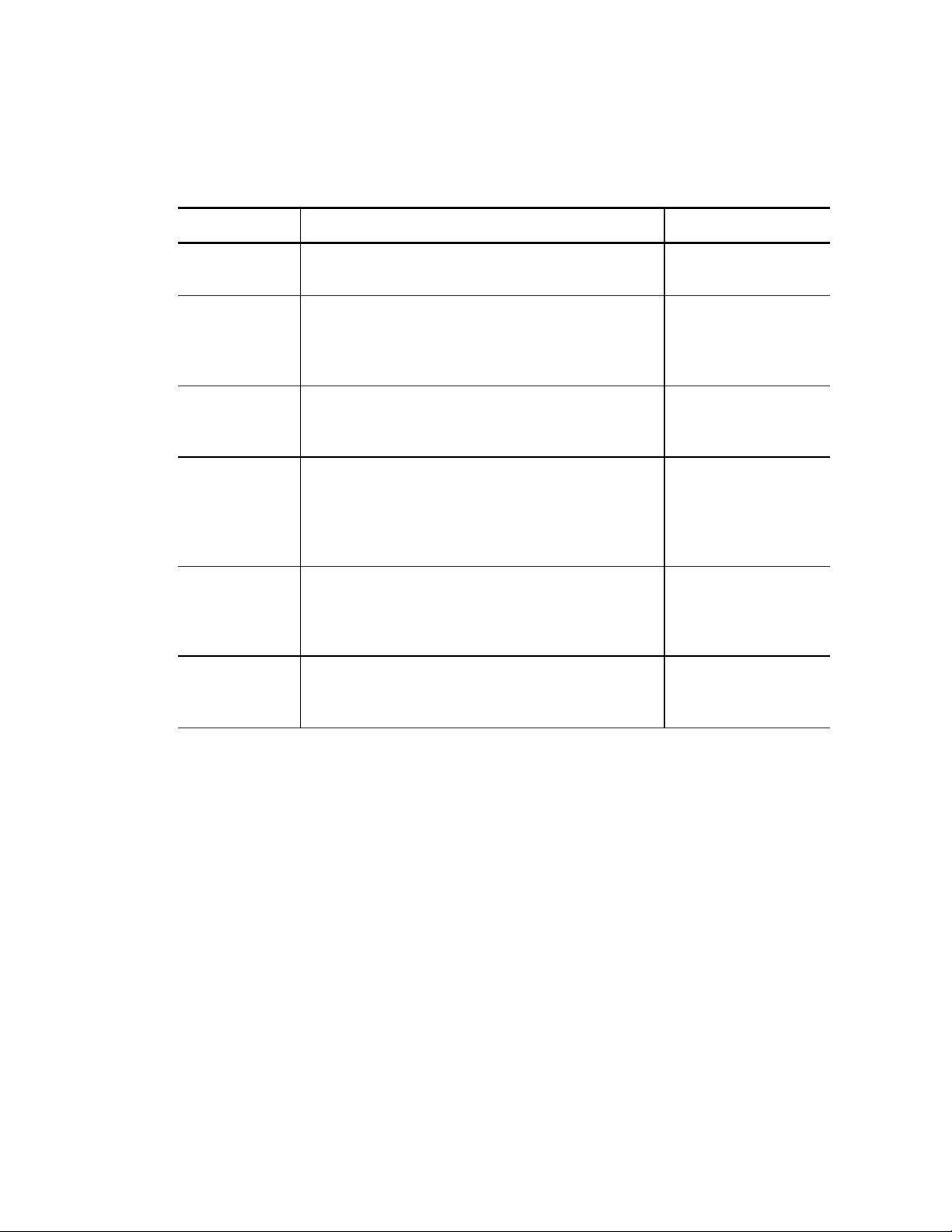

Table 1 Unique Terminology and Concepts

Term Definition Usage Examples

canister

command

module

drive module

ESM

GBIC

light

Po rt able, removable contain e r for component s . Also

known as CRU.

Compact unit that contains one or two controllers,

power supplies, and fans. Note: The E2400 command

module also contains disk drives. Also known as

controller module or controller tray.

Compact unit that contains disk drives, power supplies,

one or two ESMs, an d fans. Also known as drive tray or

expansion drive module.

Environmental Services Monitor. Interface board that

provides interface connections between the drive

modules and the SCSI bus, and environmental

information about the drive module to the host. Also

known as ESM CRU, ECC, or env iro nmental card.

Gigabit interface converter. A device used in Fibre

Channel networks to convert copper fibre signals to

fiber optic and v ice versa.

Lights that glow or b lin k to indicate either a normal

operating statu s o r hardware error. Also kn own as LE Ds.

controller canister

command module

drive module

ESM canister

copper GBIC mini hub

copper GBIC module

optical GBIC min ihub

optical GBIC module

indicator light

Power l ight

Fault light

Drive Module Site Preparation Guide 3

Page 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Documentation Set

The Drive Module Site Preparation Guide is part of a documentation set that provides

planning, installation, operation, and servicing information for SANtricity™ Storage

Manager software, command modules (E3300, E4400), drive modules (E3300, FC-1 10x,

FC-1 14x) and command modules (E2400 10x, E2400 14x). The documentation set

includes:

General Documentation

Roadmap.pdf file contains descriptions of and hyperlinks to the Adobe® Portable

•

Document Format (PDF) files that are stored on the software compact disk (CD). PDFs

are electronic versions of this document set.

Product Release Notes for SANtricity™ Storage Manager contains im portant i nformati on

•

about the CD contents, known restrictions and workarounds, and last minute updates

to the product documentation. This guide is shipped in printed form only.

Hardware Documen tation

Command Module Site Preparation Guide contains site requirements and other

•

technical information for preparing the building for a command module installation.

Command Module and Drive Module Installation Guide contains step-by-step

•

instructions for installing deskside and rackmount command modules, drive modules,

and E2400 command modules, including switch setting information and cabling

routing examples.

Command Module User Guide contains model specifications and step-by-step

•

instructions for operating, upgrading, maintaining, and servicing the command

module and its components.

Drive Module User Guide contains model specifications and step-by-step instructions

•

for operating, upgrading, maintaining, and servicing the drive module, E2400

command modules, and their components.

Software Documentation

Storage System Planning Guide contains technical information and planning worksheets

•

to help you prepare for software installation.

SANtricity™ Storage Manager Installation Guide for Version 7.10 contains step-by-step

•

instructions for installing and upgrading the storage management software.

Understanding SANtricity™ Storage Manager Concepts Guide for Version 7.10 contains

•

explanations of the storage management software terminology, concepts and features.

4 Drive Module Site Preparation Guide

Page 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preparatory Tasks

Preparatory Tasks

Before starting the installation process, you should complete the following tasks:

Make sure that the installation site meets all area, environmental, and power

•

requirements discussed in this book.

Order all necessary equipment and kits, including:

•

Hosts and host adapters

•

Interface cables

•

Mounting hardware and blank panel kits (for rackmount installations only)

•

Install all applicable hosts, host adapters, and command modules.

•

If you are preparing a rackmount installation, move the rackmount cabinet to its final

•

location and install all optional equipment (support rails, panels, command modules,

etc.). Route all power and auxiliary cables in the cabinet.

Attach t he interface cables t o th e a pp ro p riate command modu le s and route them to th e

•

area in which you intend to install the drive modules.

Tools and Equip ment You May Need

To complete the installation procedure, you need the following items:

Two power cords (shipped with unit)

•

Screwdrivers and wrenches (various sizes)

•

Antistatic protection (such as a grounded wrist strap)

•

Interface cables, terminators, and tie wraps

•

Mounting hardware (for rackmount installations only)

•

Table or cart (optional)

•

Storage management software (to configure the disk array)

•

Drive Module Site Preparation Guide 5

Page 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Area Requirements

The floor space at the installation site must provide:

Enough stability to support the weight of the drive module or E2400 command

•

module, and associated equipment (see "Weights" on this page)

Sufficient space to install, operate, and service the drive module or E2400 command

•

module (see "Dimensions" on page 12 and "Airflow" on page 16)

Weights

The drive module’s or E2400 command module’s total weight depends on the number of

components installed in the chassis. Refer to the following weight tables for information

on each model:

E3300 drive module – see Table 2 on page 7

•

FC-1 10x drive module – see Table 3 on page 8

•

E2400 10x command module – see Table 4 on page 9

•

FC-1 14x drive module – see Table 5 on page 10

•

E2400 14x command module – see Table 6 on page 11

•

6 Drive Module Site Preparation Guide

Page 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Area Requirements

Table 2 E3300 Drive Module Weight Table

Unit

Drive Module, deskside,

Low Profile (LP) 18 GB or 36 GB drives

Drive Module, deskside,

Half Height (HH) 36 GB or 73 GB drives

Drive Module, rackmount,

LP 18 GB and 36 GB drives

Drive Module, rackmount,

HH 36 GB or 73 GB drives

Maximum

46.4 kg (102.1 lb) 25.95 kg (57.04 lb) 59.0 kg (130.1 lb)

49.66 kg (109.5 lb) 25.91 kg (57.04 lb) 62.4 kg (137.5 lb)

34.6 kg (76.2 lb) 10.18 kg (23.74 lb) 47.3 kg (104.3 lb)

37.9 kg (83.6 lb) 14.15 kg (31.14 lb) 50.7 kg (111.7 lb)

Weight

1

Unit

Empty2 Unit

Weight

LP Drive, 18 GB or 36 GB 1.06 kg (2.34 lb)

HH Drive, 36 GB or 73 GB 1.4 kg (3.08 lb)

ESM 2.77 kg (6.1 lb)

Not Applicable

Power Supply 2.3 kg (5.0 lb)

Fan 1.0 kg (2.3 lb)

1

Maximum weight equals a drive module with all canisters installed (ful ly loade d) .

2

Empty weight equals a drive module chassis with all canisters removed.

3

Shipping weight equals the maximum we ig ht of the drive module, plus all shipping materials .

Shipping3

Weight

Drive Module Site Preparation Guide 7

Page 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3 FC-1 10x Drive Module Weight Table

Unit

Drive Module, deskside,

LP 18 GB or 36 GB drives

Drive Module, deskside,

HH 36 GB or 73 GB drives

Drive Module, rackmount,

LP 18 GB and 36 GB drives

Drive Module, rackmount,

HH 36 GB or 73 GB drives

Maximum Unit

Weight

1

44.5 kg (98.0 lb) 23.6 kg (52.0 lb) 59.0 kg (130.0 lb)

47.8 kg (105.0 lb) 23.6 kg (52.0 lb) 62.4 kg (137.0 lb)

38.3 kg (84.4 lb) 12.7 kg (28.0 lb) 43.5 kg (96.0 lb)

41.7 kg (92.0 lb) 12.7 kg (28.0 lb) 47.0 kg (103.6 lb)

Empty Unit

Weight

2

Shipping

Weight

LP Drive, 18 GB or 36 GB 1.06 kg (2.34 lb)

HH Drive, 36 GB or 73 GB 1.4 kg (3.08 lb)

ESM 1.7 kg (3.8 lb)

Power Supply 2.3 kg (5.0 lb)

Fan 1.0 kg (2.3 lb)

1

Maximum weight equals a drive module with all canisters installed (ful ly loade d) .

2

Empty weight equals a drive module chassis with all canisters removed.

3

Shipping weight equals the maximum we ig ht of the drive module, plus all shipping material.

3

8 Drive Module Site Preparation Guide

Page 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Area Requirements

Table 4 E2400 10x Command Module Weight Table

Unit

Command Module, deskside,

LP 18 GB or 36 GB drives

Command Module, deskside,

HH 36 GB or 73 GB drives

Command Module, rackmount,

LP 18 GB and 36 GB drives

Command Module, rackmount,

HH 36 GB or 73 GB drives

Maximum Unit

Weight

1

45.0 kg (99.2 lb) 23.6 kg (52.0 lb) 59.0 kg(1 30.1 lb)

48.6 kg (107.2 lb) 23.6 kg (52.0 lb) 62.6 kg (138.1 lb)

38.9 kg (86.4 lb) 17.8 kg(39. 2 lb) 44.1 kg (98.0 lb)

42.3 kg (94.0 lb) 17.8 kg (39.2 lb) 47.5 kg (105 .6 lb)

Empty Unit

Weight

2

Shipping

Weight

LP Drive, 18 GB or 36 GB 1.06 kg (2.34 lb)

HH Drive, 36 GB or 73 GB 1.4 kg (3.08 lb)

Controller 2.2 kg (4.8 lb)

Power Supply 2.3 kg (5.0 lb)

Fan 1.0 kg (2.3 lb)

1

Maximum weight equals a command module with all canisters installed (fully loade d) .

2

Empty weight equals a command module chassis with all canisters removed.

3

Shipping weight equals the maximum weight of the command module, plus all shipping materials.

3

Drive Module Site Preparation Guide 9

Page 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5 FC-1 14x Drive Module Weight Table

Unit

Drive Module, rackmount,

Maximum Unit

Weight

1

40.02 kg (87.12 lb) 46.94 kg (103.92 lb)

Drive-Ready

Unit Weight

Shipping

2

Weight

LP 18 GB and 36 GB drives

30.5 kg (66.4 lb) 37.44 kg (83.2 lb)

LP Drive, 18 GB or 36 GB 1.0 kg (2.2 lb)

LP Drive, Blank Canisters 0.32 kg (0.72 lb)

ESM 1.67 kg (3.7 lb)

Power Supply 2.49 kg (5.5 lb)

Fan 1.0 kg (2.2 lb)

1

Maximum weight equals a drive module with all canisters in stalled (fully loaded).

2

Drive-ready weight equals a drive module chassis with blank (empty) drive canis ters and all

remaining canisters installed.

3

Shipping weight equals the maximu m o r drive-ready weight of the drive module, plus all shippi ng

material.

3

10 Drive Module Site Preparation Guide

Page 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Area Requirements

Table 6 E2400 14x Command Module Weight Table

Unit

Command Module, deskside,

LP 18 GB or 36 GB drives

Command Module, rackmount,

LP 18 GB and 36 GB drives

Maximum Unit

Weight

1

45.0 kg (99.2 lb) 23.6 kg (52.0 lb) 59.0 kg(1 30.1 lb)

40.95 kg (90.5 lb) 15.11 kg (33.54 lb) 47.25 kg (105.0 lb)

Empty Unit

Weight

2

Shipping

Weight

LP Drive, 18 GB or 36 GB 1.06 kg (2.34 lb)

Controller 2.2 kg (4.8 lb)

Power Supply 2.3 kg (5.0 lb)

Fan 1.0 kg (2.3 lb)

1

Maximum weight equals a command module with all canisters installed (fully loade d) .

2

Empty weight equals a command module chassis with all canisters removed.

3

Shipping weight equals the maximum weight of the command module, plus all shipping materials.

3

Drive Module Site Preparation Guide 11

Page 20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions

Refer to one of the following figures for dimensional measurements of each model of the

drive module, E2400 command module, and shipping cartons:

E3300 drive module – see Figure 1 on page 13

•

FC-1 10x drive module – see Figure 2 on page 14

•

E2400 10x command module – see Figure 2 on page 14

•

E2400 14x command module – see Figure 3 on page 15

•

FC-1 14x drive module – see Figure 3 on page 15

•

Shipping cartons – see Table 7 on page 15

•

12 Drive Module Site Preparation Guide

Page 21

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Area Requirements

16.61 cm (6.54 in.)

52.68 cm (20.74 in.)

67.49 cm (26.57 in.)

57.5 cm (22.63 in.)

13.18 cm (5.2 in.)

48.0 cm (18.9 in.)

Note: Front panel thickness is 1.59 cm (0.625 in.)

Figure 1 E3300 Drive Module Dimensions

44.7 cm (17.6 in.)

12.9 cm (5.08 in.)

55.91 cm (22.005 in.)

Drive Module Site Preparation Guide 13

Page 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.6 cm (6.5 in.)

52.7 cm (20.7 in.)

13.18 cm (5.2 in.)

Figure 2 FC-1 10x Drive Module and E2400 10x Command Module Dimensions

56.0 cm (22.0 in.)

44.7 cm (17.6 in.)

12.9 cm (5.08 in.)

55.91 cm (22.005 in.)

48.0 cm (18.9 in.)

1.59 cm (0.625 in.)

14 Drive Module Site Preparation Guide

Page 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Area Requirements

13.23 cm

(5.21 in.)

59.74 cm (23.52 in.)

17.60 cm (44.70 in.)

12.9 cm

(5.08 in.)

56.13 cm (22.1 in.)

18.97 cm (48.18 in.)

3.63 cm (1.43 in.)

Figure 3 FC-1 14x Drive Module and E2400 14x Command Module Dimensions

Table 7 Shipping Carton Dimensions

Unit Carton Height Carton Width Carton Depth

E3300 Deskside and Rackmount 38.1 cm (15.0 in.) 61.4 (24.0 in.) 83.2 cm (32.7 in.)

FC-1 10x Deskside and Rackmount 38.1 cm (15.0 in.) 61.4 (24.0 in.) 83.2 cm (32.7 in.)

E2400 10x Deskside and Rackmount 38.1 cm (15.0 in.) 61.4 (24.0 in.) 83.2 cm (32.7 in.)

FC-1 14x Rackmount 44.45 cm (17.5 in.) 62.23 (24.5 in.) 74.93 cm (29.5 in.)

E2400 14x Rackmount 44.45 cm (17.5 in.) 62.23 (24.5 in.) 74.93 cm (29.5 in.)

Drive Module Site Preparation Guide 15

Page 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Airflow

Figure 4 shows the airflow direction through a drive module or E2400 command module.

Allow at least 2 feet of clearance in front of and behind the drive module for proper

ventilation.

Deskside

Back

Front

Rackmount

Figure 4 Drive Module or E2400 Command Module Airflow

16 Drive Module Site Preparation Guide

Page 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Environmental Requirements

Environmental Requirements

Table 8 Drive Module and E2400 Command Module Environmental Requirements

Element Unit of Measure

Optimum

Operating Range

Temperature

Storage Ra nge

Transit Range

Operating Range

Temperature

Change

Storage Ra nge

(Max. Allowed)

Transit Range

Operating Range 20% to 80% 20% to 80%

Storage Ran ge 10% to 90% 10% to 90%

Relative Humidity

(No Con den sa t ion )

Transit R ange 5% to 95% 5% to 95%

Max. Dew Point

Max. Gradient 10% per hour 10% per hour

E3300 and FC-1 10x

Requirement

º

C (72º F) 22º C (72º F)

22

º

C to 40º C (50º F to 104º F) 10º C to 40º C (50º F to 104º F)

10

º

C to 50º C (14º F to 120º F) -10º C to 50º C (14º F to 120º F)

-10

º

C to 60º

-40

º

(-40

F to 140º F)

º

C (18º F) per hour 10º C (18º F) per hour

10

º

C (27º F) per hour 15º C (27º F) per hour

15

º

C (36º F) per hour 20º C (36º F) per hour

20

º

26

C (79º F) 26º C (79º F)

FC-1 14x and E2400 14x

Requirement

º

C to 60º C

-40

º

(-40

F to 140º F)

Sound Power 6.0 bels 6.0 bels

Sound

Sound Pressure 60 dBA 60 dBA

Operating Range

Altitude

1

Storage Ra nge

Transit Range

1

If you plan to operate the drive module or E2400 command module at altitudes between 1000 m (3280 ft.)

and 3000 m (9850 ft.), lower the environmental temperature 1.7

30.5 m (100 ft.) below sea level

3000 m (9840 ft.) above sea level

30.5 m (100 ft.) below sea level

3000 m (9840 ft.) above sea level

30.5 m (100 ft.) below sea level

12,000 m (40,000 ft.) above sea level

º

C (3.3º F) for every 1000 m (3280 ft.)

above sea level.

Drive Module Site Preparation Guide 17

Page 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9 Drive Module and E2400 Command Module Heat Dissipation

Unit

Heat Dissipation

LP 18 GB and 36 GB Drives

Heat Dissipation

HH 36 GB and 73 GB Drives

E3300 673.0 Btu/hr (0.199 kVA or 197.0 W) 826.0 Btu/hr (0.244 kVA or 241.0 W)

FC-1 10x 1036.0 Btu/hr (0.31 kVA or 303.0 W) 1070.0 Btu/hr (0.33 kVA or 313.0 W)

E2400 10x 1187.0 Btu/hr (0.35 kVA or 347.0 W) 1221.0 Btu/hr (0.37 kVA or 357.0 W)

18 Drive Module Site Preparation Guide

Page 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Site Wiring Requirements

Site Wiring Requirements

Review the following information when preparing the drive module or E2400 command

module installation site.

Earth ground – The unit must be properly grounded, including an earth ground

•

conductor on the AC power source.

Circuit overloading – Make sure the power circuits and associated circuit breakers in

•

the cabinet and building provide sufficient power and overload protection. To prevent

possible damage to the unit, isolate its power source from large switching loads (such as

air conditioning motors).

Po wer interruptions – The drive module or E2400 command module will withstand

•

the following applied voltage interruptions:

Input transient: 50% of nominal voltage

•

Duration: one half cycle

•

Minimum f requency: once every 10 seconds

•

Power failures – Once power is restored after a complete power failure, the unit

•

automatically performs a power-up recovery sequence without operator intervention.

Site Wiring and Voltages

The drive modules and E2400 command module use wide-ranging, redundant power

supplies that automatically match voltages to the AC power source. They are a 120 /220

VAC, 50/60 Hz units that meet standard voltage requirements for both domestic (USA)

and international (outside USA) operation. They use standard industrial wiring with a

line-to-neutral or line-to-line power connections (Table 10).

Drive Module Site Preparation Guide 19

Page 28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10 Drive Module and E2400 Command Module Site Wiring Voltages

Input Power

Single-Phase

Line-to-Neutral

Single-Phase,

Line-to-Line

50 Hz 60 HZ

Nominal Minimum Maximum Nominal Minimum Maximum

100 90 107 100 90 107

127 114 136 120 104 127

220 198 235

230 207 246

240 216 264

200 180 214 200 180 214

208 180 220

240 208 264

20 Drive Module Site Preparation Guide

Page 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drive Module Power Requirements

Drive Module Power Requirements

E3300 Drive Module

The AC power source must provide the correct voltage, current, and frequency specified

on the manufacturer’s nameplate. Internal AC power units for rackmount cabinets must

be able to handle the power requirements for this unit (Table 11).

Table 11 E3300 Power Requirements

Item Unit of Measure Requirement

Circuit Breaker 3.0 A (slow-bl ow fuse per power sup pl y )

USA International

Nominal Voltage 90 to 136 VAC 198 to 257 VAC

Drive Module AC

Power

Maximum Oper ating Current 3 .2 A

Frequency 50/60 Hz 50/60 Hz

Idle Current 2.9 A

Maximum Surg e Current 4.5 A

1

1

1

1.3 A

1.5 A

2.1 A

1

1

1

Power Connections

The drive module uses two AC power cords (one for each power supply). In order to meet

power r e qu ir emen ts and ma inta in power redundancy, you must con n ect the dri v e mo du le

to either 90-136 VAC or 198-257 VAC, 15 A circuits as described below.

Redundant power, 90-136 V – Connect as follows:

•

If three or less drive modules are connected to a command module, use two 90-136

•

V, 15 A circuits. Connect one power supply from each drive module to one circuit

and the other power supplies to the second circuit.

If more than three drive modules are connected to a command module, use four

•

90-136 V, 15 A circuits. Connect one half of the drive modules to two circuits and

the remaining drive modules to the other two circuits. Make sure that each drive

module connects to two different circuits (one per power supply).

Redunda nt po wer, 198-257 V – Use two 198 V-257 V, 15 A circuits. Connect one power

•

supply from each drive module to one circuit and the other power supply to the second

circuit.

Drive Module Site Preparation Guide 21

Page 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Routing

Some rackmount cabinets have two AC distribution boxes. Each AC distribution box has

its own power cord. Because of limited space inside the cabinet, it may be easier to connect

and route power cords before installing the support rails and command module. You may

connect power to a command module in a rackmount cabinet in three ways:

Redundant power to cabinet and drive module – Connect the AC boxes in the cabinet

•

to two, independent, external power sources. Connect one power cord from each drive

module to each AC box in the cabinet.

Redundant power to cabinet; non-redundant to drive module – Connect the AC boxes

•

in the cabinet to two, independent, external power sources. Connect both power cords

from the drive module to one AC box in the rackmount cabinet.

Non-redundant power to cabin e t and drive module – Connect both AC boxes in the

•

cabinet to a single power source. Connect both power cords from the drive module to

one or both AC boxes in the rackmount cabinet.

22 Drive Module Site Preparation Guide

Page 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drive Module Power Requirements

FC-1 10x Drive Module and E2400 10x Command Module

The AC power source must provide the correct voltage, current, and frequency specified

on the manufacturer’s nameplate. Internal AC power units for rackmount cabinets must

be able to handle the power requirements for these units (Table 12).

Table 12 FC-1 10x and E2400 10x Power Requirements

Item Unit of Measure Requirement

Circuit Breaker 3.0 A (slow-bl ow fuse per power sup pl y )

USA International

Nominal Voltage 90 to 136 VAC 198 to 264 VAC

Drive Module and

Command Module

AC Pow er

Frequency 50/60 Hz 50/60 Hz

Idle Current 3.39 A 1.45 A

Maximum Oper ating Current 3.53 A 1.50 A

Maximum Surge Current (10-

drive s p i n up)

5.19 A 2.10 A

Drive Module Site Preparation Guide 23

Page 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Routing

The drive module and command module use two AC power cords (one for each power

supply). You must have an independent AC power source for each power supply in the

drive module and command module in order to maintain redundancy. This applies to

both deskside and rackmount models.

Some rackmount cabinets have two AC distribution boxes. Each AC distribution box has

its own power cord. To ensure red undancy, connect the AC boxes in the cabinet to two

independent power sources. Then, connect one power cord from each drive module or

command module to each AC box in the cabinet (Figure 5). Beca use o f limite d spac e insi de

the cabinet, it may be easi er to co nnect and ro ute pow er co rds befor e installing the support

rails and drive module (or command module).

Drive Module

Power Supplies

Command

Module Power

AC Distribution

Boxes

Figure 5 Redundant AC Power Connections to Rackmount Controller and Drive Modules

24 Drive Module Site Preparation Guide

Page 33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drive Module Power Requirements

FC-1 14x Drive Module and E2400 14x Command Module

The AC power source must provide the correct voltage, current, and frequency specified

on the manufacturer’s nameplate. Internal AC power units for rackmount cabinets must

be able to handle the p ower requirements for these units (Table 13).

Table 13 FC-1 14x and E2400 14x Power Requirements

Item Unit of Measure Requirement

Circuit Breaker 3.0 A (slow-bl ow fuse per power sup pl y )

USA International

Drive Module and

Command Module

AC Pow er

Nominal Voltage 90 to 136 VAC 198 to 264 VAC

Frequency 50/60 Hz 50/60 Hz

Drive Module Site Preparation Guide 25

Page 34

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Routing

The drive module and command module use two AC power cords (one for each power

supply). You must have an independent AC power source for each power supply in the

drive module and command module in order to maintain redundancy. This applies to

both deskside and rackmount models.

Some rackmount cabinets have two AC distribution boxes. Each AC distribution box has

its own power cord. To ensure red undancy, connect the AC boxes in the cabinet to two

independent power sources. Then, connect one power cord from each drive module or

command module to each AC box in the cabinet (Figure 5). Beca use o f limite d spac e insi de

the cabinet, it may be easi er to co nnect and ro ute pow er co rds befor e installing the support

rails and drive module (or command module).

Drive Module

Power Supplies

Command

Module Power

AC Distribution

Boxes

Figure 6 Redundant AC Power Connections to Rackmount Controller and Drive Modules

26 Drive Module Site Preparation Guide

Page 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Drive Module Cable Requirements

Drive Module Cable Requirements

E3300 Interface Cables

The E3300 drive module has two SCSI connectors. To connect the drive module to a

SYM1000E command module, you must use 68-pin, VHDCI (very high density cable

interface) LVD, Ultra SCSI-2 cables.

The maximum length for any SCSI, 68-pin HD cable is 25 m (82 ft.) or 12 m (39 ft.) for

VHDCI cable. The total length includes both internal and external cabling. The SCSI

cabling inside this drive module is approximately 0.1 m (4 in.) for the host bus. Table 14

lists the SCSI cables that you can use on this drive module.

Table 14 SCSI Drive Interface Cables

Order Infor mation

Cable Description

Part

Number

Length

1.0 meter

1.5 meter

3.0 meter

8 meter

LVD, Ultra SCSI-2 cable with 68-pin, VHDCI connector

SCSI

Terminators

006-1086595

006-1086596

006-1086597

006-1086598

If yo u are installing the dri v e m od ul e as the last d evice o n a SC SI b us, y o u m us t i nst all a 1 6bit terminator on the OUT connector. Every drive module shipped from the factory

includes 16-bit terminators.

Drive Module Site Preparation Guide 27

Page 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FC-1 10x, E2400 10x, FC-1 14x, and E2400 14x Interface Cables

The drive modules and command modules support Fibre Channel connections to the

command modules. They have four gigabit interface converter (GBIC) connectors, two on

each ESM or controller. The connectors may be fiber optic or copper. The type of

connector depends on what type of drive interface you ordered and what type of cable you

are using to attach the drive module or command module to the command module.

If you ordered optical GBIC connectors, you will need fiber optic cable. If you ordered

copper GBIC connectors, you will need copper wire cable. Table 15 lists the types and

lengths of cable available from your local dealer.

Table 15 Fibre Channel Host and Drive Interface Cables

Descriptions Order Information

Cable Data Size

Fiber optic, multi-mode,

50 micrometer, shortwave

laser

Copper wire, sh ielded,

twisted pair, electrical

signal

Transfer

Speed

100 MB/sec 1062.5 Mbaud

100 MB/sec 1062.5 Mbaud

Range

Up to 0.5

kilometer

Up to 30

meters

Part

Number

006-108667 2 2 met e r

006-108641 6 3 met e r

006-108667 3 5 met e r

006-1086417 10 meter

006-108668 2 2 met e r

006-108667 2 3 met e r

006-108648 3 5 met e r

006-1086473 10 meter

Length

28 Drive Module Site Preparation Guide

Page 37

A

AC power cords

E2400 10x

E2400 14x 26

E3300 21

E4400 24

FC-1 14x 26

AC power requirements

E2400 10x

E3300 21

E4400 23

FC-1 14x 25

airflow 16

amperage requirements

E2400 10x

E2400 14x 25

E3300 21

E4400 23

FC-1 14x 25

24

23

23

B

bels, sound power 17

C

cable

drive interface

E2400 10x

E2400 14x 28

E3300 27

E4400 28

FC-1 14x 28

Fibre Channel 27, 28

28

host interface

E2400 10x

E3300 27

E4400 28

FC-1 14x 28

length

fiber optic and copper

SCSI 27

circuit breaker 19, 21, 23, 25

controller

E2400 10x

E2400 14x 11

copper wire cable

length

order information 27, 28

current. See electrical

27, 28

28

9

D

data transfer rates

copper wire

fiber optic 28

dew point 17

dimensions

E2400 10x

E2400 14x 15

E3300 13

E4400 14

FC-1 14x 15

domestic voltages

E2400 10x

E2400 14x 19

E3300 19

E4400 19

FC-1 14x 19

28

14

19

Index

27, 28

Drive Module Site Preparation Gui de Index-1

Page 38

drive

cable connectors

28

weight

E2400 10x

9

E2400 14x 11

E3300 7

E4400 8

FC-1 14x 10

drive interface cables

E2400 10x

28

E4400 28

FC-1 14x 28

drive interface cablesE3300 27

drive module

electrical overload protection

installation 5

E

earth ground 19

electrical

circuit breakers

copper wire 28

current 21, 23, 25

earth ground 19

frequency 21, 23, 25

operating current 21, 23

overload protection 19

power requirements

E2400 10x

E2400 14x 25

E3300 21

E4400 23

FC-1 14x 25

single-phase wiring 20

site wiring

E2400 10x

E2400 14x 19

E3300 19

E4400 19

FC-1 14x 19

voltage interruptions 19

voltage requirements 21, 23, 25

environmental card

E3300

7

E4400 8

FC-1 14x 10

19, 21, 23, 25

23

19

19

E2400 10x

airflow

16

circuit breaker type 23

dimension 14

interface cables 28

noise level 17

operating and surge current 23

power cords 24

power requirements 23

weight 9

wiring for 19

E2400 14x

airflow

16

circuit breaker type 25

dimension 15

noise level 17

power cords 26

weight 11

wiring for 19

E3300

airflow

16

circuit breaker type 21

dimension 13

interface cables 27

noise level 17

operating and surge current 21

power cords 21, 22

power requirements 21

voltage specifications 21

weight 7

wiring for 19

E4400

airflow

16

circuit breaker type 23

dimension 14

interface cables 28

noise level 17

operating and surge current 23

power cords 24

power requirements 23

voltage specifications 23, 25

weight 8

wiring for 19

Index-2 Drive Module Site Preparation Guide

Page 39

F

fan

E2400 10x

E2400 14x 11

E3300 7

E4400 8

FC-1 14x 10

FC-1 14x

airflow

circuit breaker type 25

dimension 15

interface cables 28

noise level 17

power cords 26

power requirements 25

weight 10

wiring for 19

fiber optic cabl e

length

order information 27, 28

Fibre Channel cable 27, 28

fuse requirements 21, 23, 25

9

16

27, 28

installation

host adapters

5

preparation tasks 5

interface cables

drive

E2400 10x

E2400 14x 28

E3300 27

E4400 28

FC-1 14x 28

host

E2400 10x

E2400 14x 28

E3300 27

E4400 28

FC-1 14x 28

international voltages

E2400 10x

19

E2400 14x 19

E3300 19

E4400 19

FC-1 14x 19

28

28

G

gradient (humidity) 17

ground wiring 19

H

host adapter 5

host interface cables

E2400 10x

28

E2400 14x 28

E3300 27

E4400 28

FC-1 14x 28

I

idle current

E2400 10x

E3300 21

E4400 23

input transient 19

23

L

length

Fibre Channel cables

SCSI cables 27

M

multi-mode 28

N

noise level

E2400 10x

17

E2400 14x 17

E3300 17

E4400 17

FC-1 14x 17

O

operating current

E2400 10x

E3300 21

E4400 23

23

27, 28

Drive Module Site Preparation Gui de Index-3

Page 40

P

power

connections

E2400 14x

26

E3300 21

E4400 22, 24

FC-1 14x 26

interruptions 19

overload protection 19

redundancy

E2400 10x

24

E2400 14x 26

E3300 21, 22

E4400 24

FC-1 14x 26

power cord

E2400 10x

24

E2400 14x 26

E3300 22

E4400 24

FC-1 14x 26

number of 21

power supply

E2400 10x

9

E2400 14x 11

E3300 7

E4400 8

FC-1 14x 10

preparing command module for installation 5

pressure (sound) 17

R

rackmount

power connections

routing power cords

E2400 10x

E2400 14x 26

E3300 22

E4400 24

FC-1 14x 26

redundant power

E2400 10x

E2400 14x 26

E3300 21, 22

E4400 24

FC-1 14x 26

24

22, 24, 26

24

S

SCSI bus 27

SCSI cables

maximum length

27

shortwave laser 28

single-phase wiring 20

sound 17

specifications

airflow

16

copper wire cable 28

E2400 10x

dimension

14

site wiring 19

voltages 23

E2400 14x

dimension

15

site wiring 19

voltage 25

E3300

dimensions

13

site wiring 19

voltages 21

E4400

dimension

14

Fibre Channel cable 28

site wiring 19

voltages 23

FC-1 14x

dimension

15

site wiring 19

voltages 25

sound pressure and power 17

surge current

E2400 10x

23

E3300 21

E4400 23

T

temperature change 17

terminator

types of

27

tools needed for installation 5

U

Ultra SCSI cable 27

Index-4 Drive Module Site Preparation Guide

Page 41

V

VHDCI (very high density cable interface) 27

voltage

E2400 10x

19, 23

E2400 14x 19, 25

E3300 19, 21

E4400 19, 23, 25

FC-1 14x 19, 25

W

weight

E2400 10x

E2400 14x 11

E3300 7

E4400 8

FC-1 14x 10

table of 8, 10

wiring

earth ground

single-phase 20

9

19

Drive Module Site Preparation Gui de Index-5

Page 42

Index-6 Drive Module Site Preparation Guide

Loading...

Loading...