Page 1

Job: ________________________

Item: _______________________

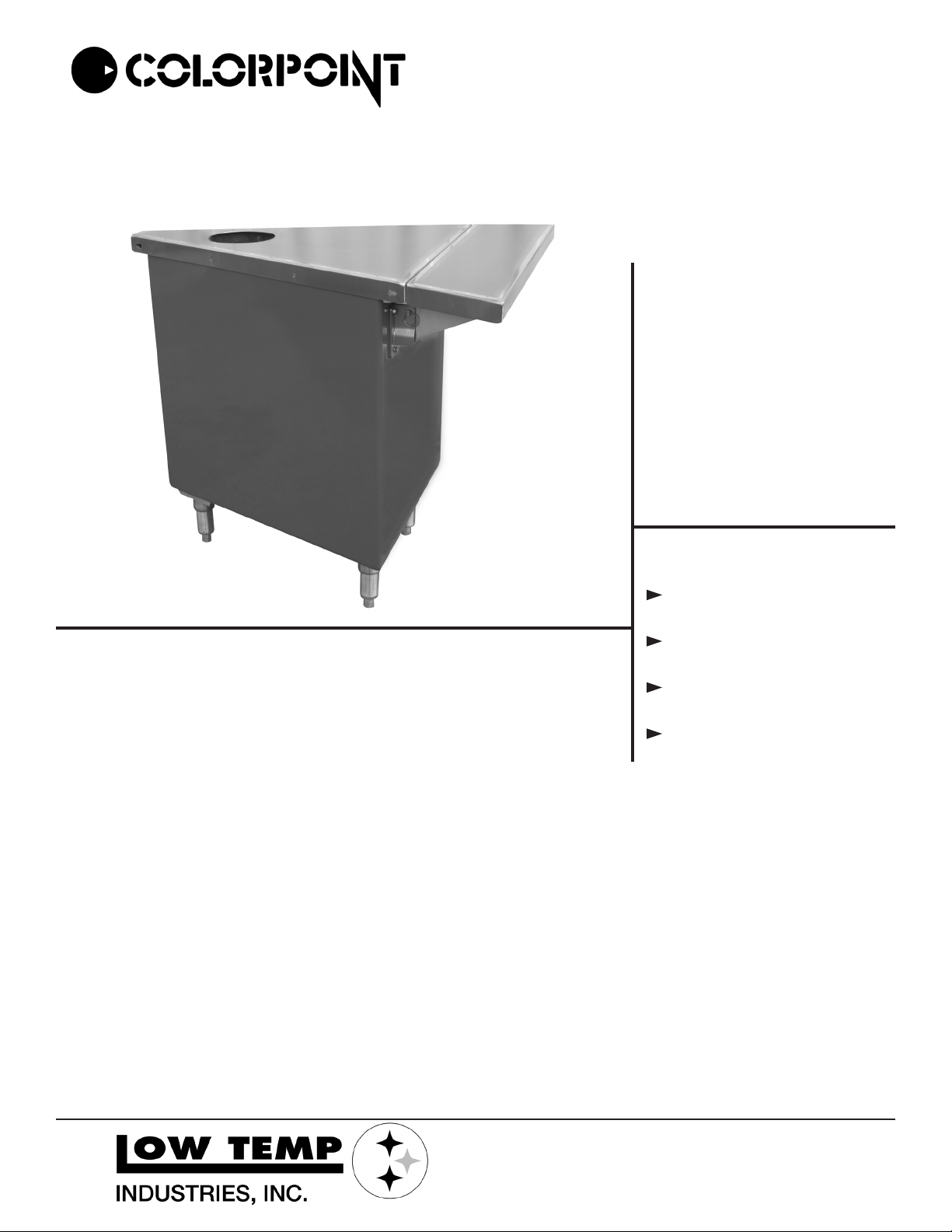

Solid Top 45° Wedge Filler Unit

ST-W

shown with optional

cutting board, top cut-out,

and stainless steel legs

Quantity: ___________________

Model

❑ ST-W

Benefits:

Upgrade directional flow in

serving lines

Standard Features

✔ 14 gauge stainless steel top with #7 hi-lite edges

✔ 4” swivel casters with brakes

Optional Features (specify)

❑ (A) Tray slide, stainless, solid V ridge

❑ (B) Tray slide, stainless, flat surface

❑ (D) Cutting board, 8” wide stainless steel

❑ (E) Cutting board, 8” wide Richlite

®

composite

❑ (AA) Cam operated line-up locks

❑ (SS) Stainless steel legs

❑ 5” swivel casters

❑ Cutouts, specify_____________

❑ Special Height, specify_____________

Molded fiberglass body to

match line-up

Makes a perfect 45° turn in

any serving line

Sanitary, easy to clean de-

sign

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

13

Page 2

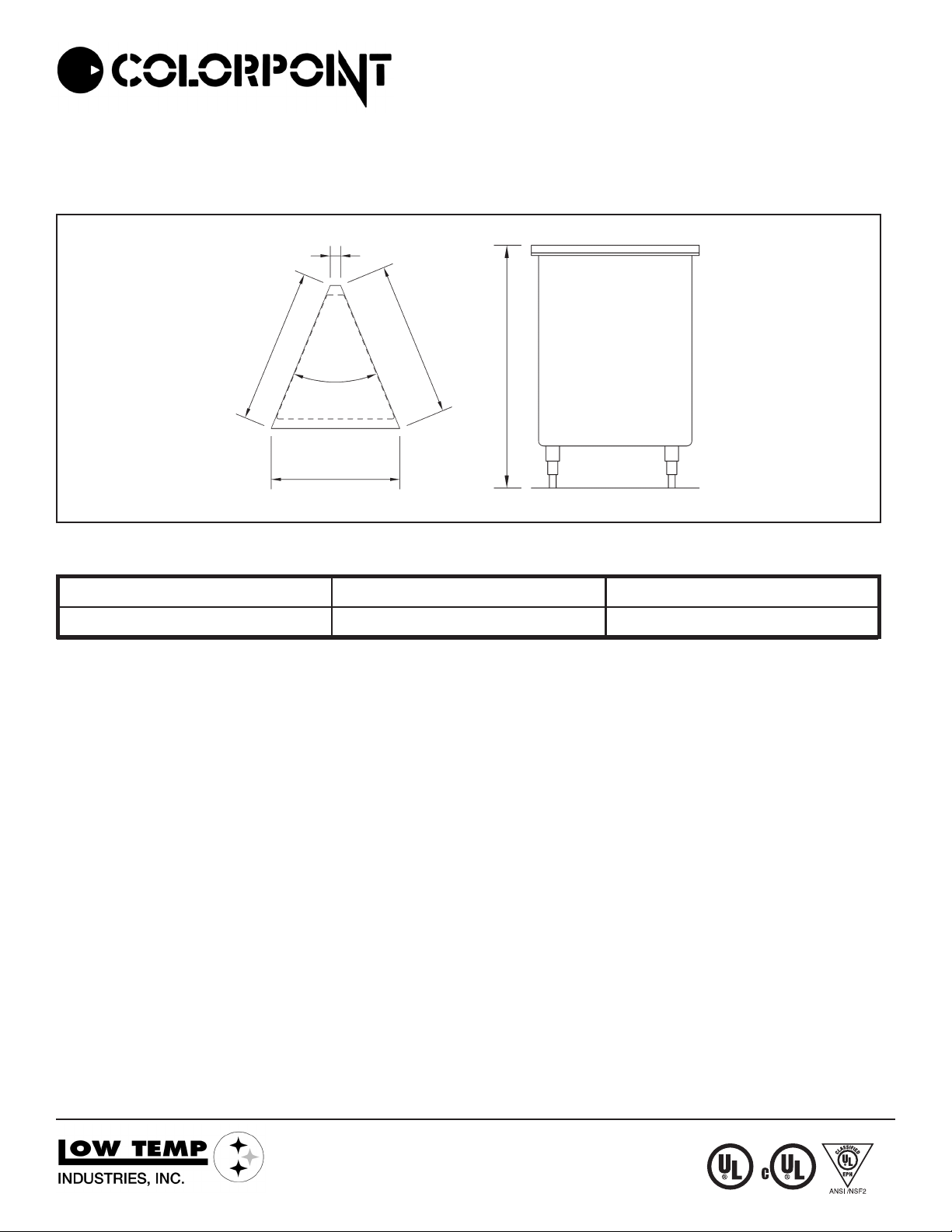

Solid Top 45° Wedge Filler Unit

2”

30”

30”

45°

15

24

/16”

Plan View End View

36”

Job: ____________________________

Item: ___________________________

Quantity: _______________________

Model L x W x H Approx. Ship Weight

General Specifications

TOP: Top to be 30” wide and fabricated

from a minimum of 14 ga. stainless steel

with square turndown on all sides and corners fully welded, ground and polished. Top

to have #4 satin finish and with all edges

having a #7 hi-lite finish.

BODY: Body to be seamless molded fiberglass (F.R.P.) with smooth exterior surfaces

and rounded corners. To be constructed

by a hand lay-up process with four layers

of 1.5 oz continuous strand fiberglass mat,

ST-W 25” x 30” x 36” 175 lbs.

plus a 24 oz layer of woven roving on the

bottom for added strength. Fiberglass to

be flame retardant per specification ASTM

E-162 having a flame spread of 25 or

less. Body interior to be reinforced at each

end with 4” wide, 12 gauge galvanized

channels welded to form integral “U” frame

for maximum stress relief.

CASTERS: 4” diameter, ball bearing, swivel type casters to be non-marking and with

brakes on all wheels. Casters to be mounted

thru two 12 gauge channels for extra rigidity.

We reserve the right to change specifications and product design without notice. Such revisions

do not entitle the buyer to corresponding changes, improvements, additions or replacement for

previously purchased equipment.

All equipment to be built in accordance with the Underwriters Laboratories. Inc. and the National

Sanitation Foundation, Inc. standards and shall bear the Underwriters Laboratories, Inc. listing

label for safety and the Underwriters Laboratories classification label for sanitation.

04/2007

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

U.L. SanitationClassified to NSF Standards

Loading...

Loading...