Page 1

Temp-est Aire® Cold Food Well Drop-In

Project: _____________________

Item: _______________________

Quantity: ___________________

Model Pans

❑ DI-2025TA 2

❑ DI-2037TA 3

❑ DI-2050TA 4

❑ DI-2063TA 5

❑ DI-2075TA 6

Temp-est Aire

Patent No. 5,388,429

®

Performance

LTI’s Temp-est Aire® Cold Food Well Drop-In was developed to hold

product in open pans at a temp. of 40 degrees F or less, while in

an ambient temp. of up to 86 degrees F.

The patented design features a refrigeration system that utilizes

convection air to produce a circulating “cold air zone” around

the full area of the insert pan. The system maintains critical

temperatures without risk of freezing.

Product must be pre-chilled to a temperature below 40 degrees F,

and kept at a level

proper cooling.

Our “drop-In” configuration provides a self-contained unit that

allows for easy installation in any counter, serving line, cart or

table.

Meets NSF7 requirements with pans flush with countertop.

1

/

” below the top of the storage pan to ensure

2

Standard Features

✔ Full sealing gasket

✔ Pan dividers

✔ 6’ cord and plug

✔ 120V, 60, 1PH

✔ T-Turn down edge

Optional Features

(specify)

❑ Small pan divider bars

❑ Hugged edge

(denote “H” in suffix)

❑ Skirt mounted control

adapter (must specify)

❑ Other voltage, phase, cycle

(specify ___________________)

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

U.L. SanitationClassified to NSF Standards

Page 2

Temp-est Aire® Cold Food Well Drop-In

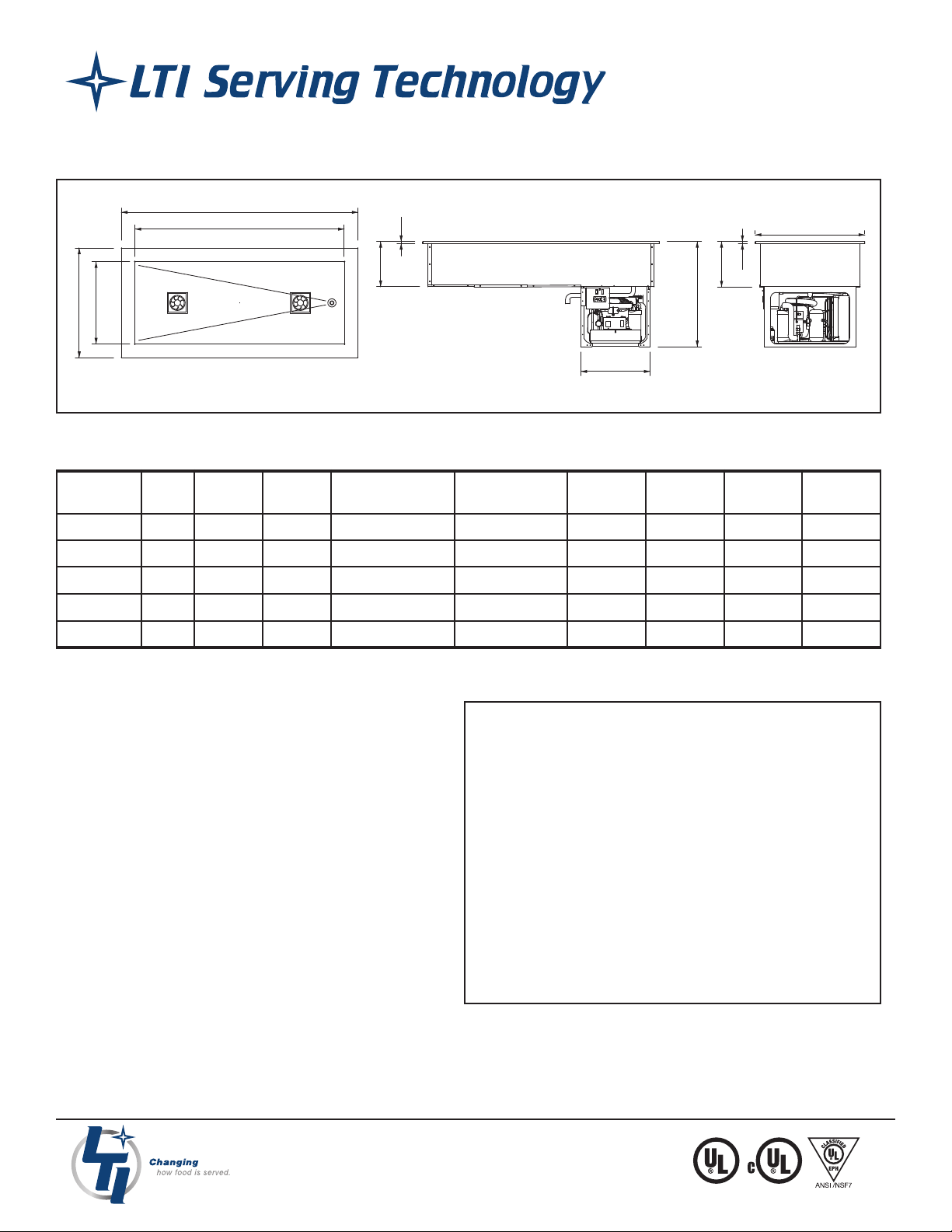

26 - 3/4”

11”

26 - 3/4”

20”

L

L1

1/2”

11”

11”

26 - 3/4”

L

L1

1/2”

Project: _________________________

Item: ___________________________

Quantity: _______________________

26 - 3/4”

1/2”

20”

TA Cold Food Well Drop-Ins have an interior well depth of 9 inches to accomodate a maximum of 6 inch deep

food pan. A three inch gap between food pan and cooling fans must be maintained for proper operation.

16 - 7/8”

18 - 7/8”

25 - 3/4”

Technical Specifications

Amps NEMA

Model Pans L L’ Cut-out size H.P. Volts Fans (120V) Plug

DI-2025TA 2 32 1/4” 24 3/4” 25 1/8” x 29 7/8” 1/3 120V/1 1 7.6 5-15

7

DI-2037TA 3 45” 37

3

DI-2050TA 4 57

DI-2063TA 5 70

*DI-2075TA 6 83

* Wider compressor housing required

/4” 51” 25 1/8” x 55 7/8” 1/3 120V/1 2 8.5 5-15

1

/2” 64” 25 1/8” x 68 7/8” 1/3 120V/1 2 8.5 5-15

1

/4” 77” 25 1/8” x 81 7/8” 1/3 120V/1 3 12 5-15

/8” 25 1/8” x 42 7/8” 1/3 120V/1 1 7.6 5-15

Specifications

Top perimeter frame to be constructed of 14 gauge

stainless steel, welded, ground and polished with a thermal break provided between the top and refrigerated interior. Interior pan to be 18 gauge stainless steel, fully

welded, ground and polished with a 3/4” open drain. To

be fully insulated with a 11/2” to 2” urethane insulation.

The exterior jacket to be constructed of heavy gauge galvanized steel.

Refrigeration system to be hermetically sealed compressor operating on R-507 (HFC) refrigerant and will include

the Temp-est Aire circulating cold air system. Thermostatic

control will clear the cooling surface of frost on every

cycle. All switches and controls to be fully accessible.

Provide with cord and plug.

Units to be UL listed and shall bear the UL classified

EPH label for sanitation meeting all NSF7 requirements.

NOTE: To ensure proper operation, adequate

airflow must be provided.

www.lowtempind.com • colorpoint@lowtempind.com

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

Approval/Submittal (signature required)

Model #__________________

Flange Edge Detail:Turned (T)______ Hugged(H)______

(T)= ½” 90° turn down (H)= 14 gauge thickness

Voltage __________

Compressor standard location is right end (from control side).

Adherence to LTI installation instructions is required.

Failure to do so may void the warranty.

Signature ___________________________Date__________

We reserve the right to change specifications and product design without notice. Such revisions

do not entitle the buyer to corresponding changes, improvements, additions or replacement for

previously purchased equipment.

All equipment to be built in accordance with the Underwriters Laboratories. Inc. and the National

Sanitation Foundation, Inc. standards and shall bear the Underwriters Laboratories, Inc. listing

label for safety and the Underwriters Laboratories classification label for sanitation.

U.L. SanitationClassified to NSF Standards

01/2013

Loading...

Loading...