Page 1

Job: ________________________

Item: _______________________

Hinged Lid Milk Carton Dispenser

CTAM-7

Quantity: ___________________

Models

length

❑ CTAM-5 50 3/8”

❑ CTAM-66 66 3/8”

❑ CTAM-7 74 3/8”

Benefits:

Large capacity of half pint

cartons

Durable and easy to clean

Standard Features

✔ 14 gauge stainless steel tops

✔ Insulated stainless steel hinged doors

✔ Molded fiberglass body

✔ Self-leveling dispensers

✔ 6 stainless steel trays per compartment

✔ Welded stainless steel interior

✔ 4” swivel casters

Optional Features (specify)

❑ (A) Tray slide, stainless, solid V ridge

❑ (B) Tray slide, stainless, flat surface

❑ (D) Cutting board, stainless

❑ (AA) Cam operated line-up locks

❑ (DD) Convenience outlet, flush mount

❑ (EE) Convenience outlet, pedistal mount

❑ (FF) End drop shelf, stainless

❑ (GG) Lid Locks

❑ (SS) Stainless steel legs

❑ (TT) Wrap-around bumper

❑ (**) Stainless or laminate body construction (specify)

❑ 5” swivel casters

❑ Optional height (specify ______________)

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

Easy mobility

Cartons kept at easy-to-reach

height

Performance

These Heavy Duty, versatile units are designed to maintain proper holding temperatures with a forced air finned coil system.

They provide fast, efficient product access

through hinged, insulated stainless steel lids

that help maintain approved temperatures.

P.O. Box 795 • Jonesboro, GA 30237

22

Page 2

Hinged Lid Milk Carton Dispenser

”

2

/

1

1

30”

length

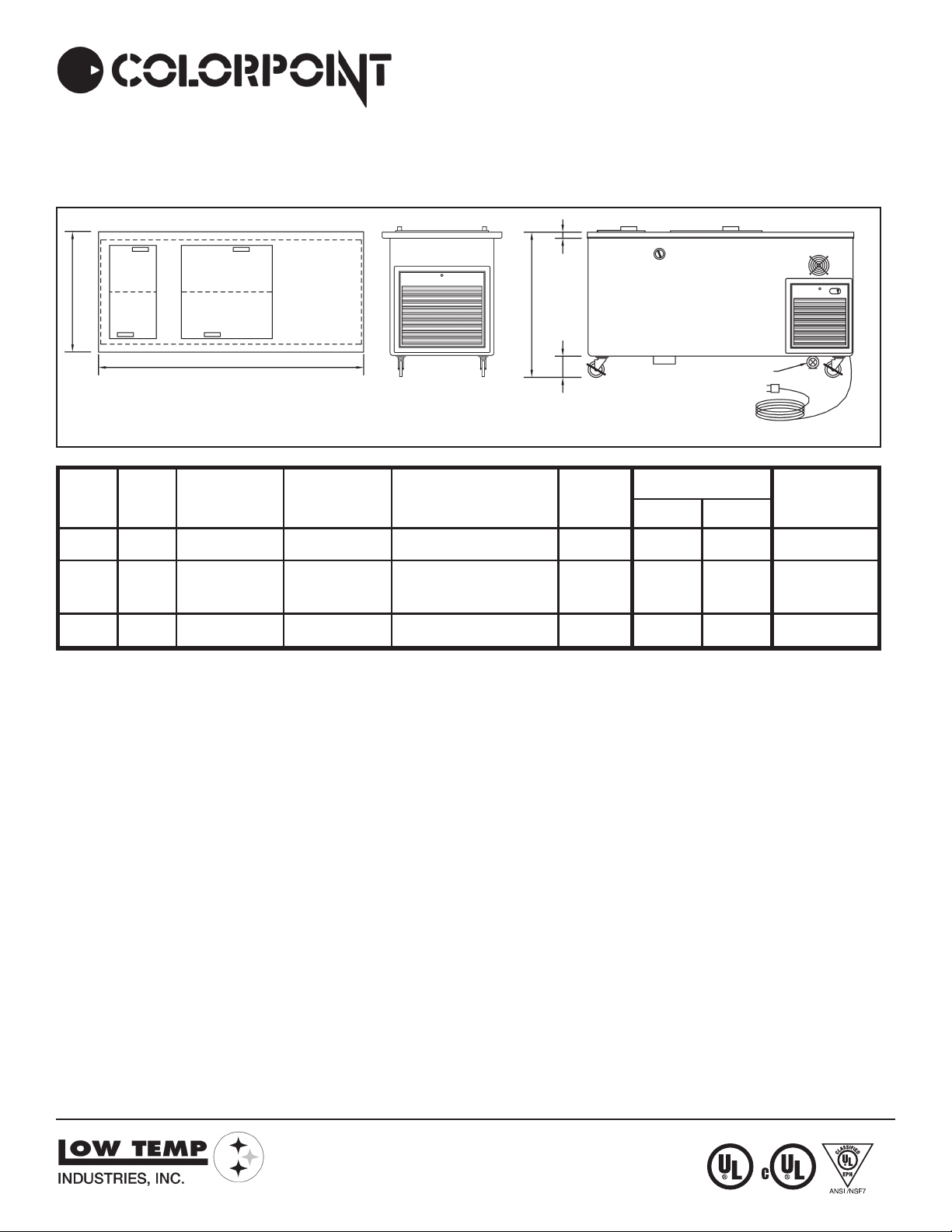

Plan View End View Elevation View

36”

”

4

/

1

5

Job: ____________________________

Item: ___________________________

Quantity: _______________________

Drain Valve

Model Length Tray Size Top Opening using

CTAM-5 50

CTAM-66 66

one - 20x20

CTAM-7 74

General Specifications

Body: Body to be seamless molded fiberglass (F.R.P.) with

smooth exterior surfaces and rounded corners. To be constructed

by a hand lay-up process with four layers of 1.5 oz continuous

strand fiberglass mat, plus a 24 oz layer of woven roving on

the bottom for added strength. Fiberglass to be flame retardant

per specification ASTM E-162 having a flame spread of 25 or

less. Body interior to be reinforced at each end with 4” wide, 12

gauge galvanized channels welded to form integral “U” frame for

maximum stress relief.

Top: Top to be 30” wide and fabricated from 14 ga. stainless

steel with square turndown on all sides and corners fully welded,

ground and polished. Top to have #4 satin finish and all edges

having #7 hi-lite finish.

Refrigerated Dispenser: Unit shall have a welded stainless

steel watertight interior liner with 2” of urethane foam insulation

and full perimeter breaker strips at the top. 1” brass drain shall

extend to a shut off valve below the fiberglass body. An interior

box temperature of 38 degrees shall be maintained by a finned

tube forced air coil with accessible thermostatic expansion valve,

and shall include an installed condensate evaporator. Openings

will be fitted high impact plastic throat liner and hinged insulated

stainless steel lids.

Each opening shall contain a stainless steel self-leveling dis

3

/8” one - 20x20 1 384

one - 10x20

3

/8”

3

/8” two - 20x20 3 768

2 576

-

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

120V/1 phase

Capacity

1

/2 pt cartons Comp. Amps Plug Ship Weight

1

/4 H.P. 10.2 5-15P 325 lbs.

1

/4 H.P. 10.2 5-15P 460 lbs.

1

/3 H.P. 10.6 5-15P 515 lbs.

penser. Dispensing mechanism shall be constructed with automatic self-leveling elevators, enclosed in a stainless steel housing.

The lowerator mechanisms shall be field adjustable without the use

of tools and be connected to a removable heavy gauge stainless steel carrier. Each compartment to be furnished with six (6)

removable divider trays.

Compressor Housing: Cross flow ventilated compartment to

have two stainless steel exterior frames complete with removable

stainless steel louvers.

Condensing Unit: Unit to contain a fully hermetic system using

R-22 refrigerant, with all necessary controls for proper operation.

System to be hooked-up, tested in the factory and made ready to

plug in on the job.

Casters: 4” diameter, ball bearing, swivel type casters to be

non-marking and with brakes on all wheels. Casters are mounted

with exterior and interior bracing for maximum stress relief.

We reserve the right to change specifications and product design without notice. Such revisions

do not entitle the buyer to corresponding changes, improvements, additions or replacement for

previously purchased equipment.

All equipment to be built in accordance with the Underwriters Laboratories. Inc. and the National

Sanitation Foundation, Inc. standards and shall bear the Underwriters Laboratories, Inc. listing

label for safety and the Underwriters Laboratories classification label for sanitation.

03/2007

U.L. SanitationClassified to NSF Standards

Loading...

Loading...