Page 1

Job: ________________________

Item: _______________________

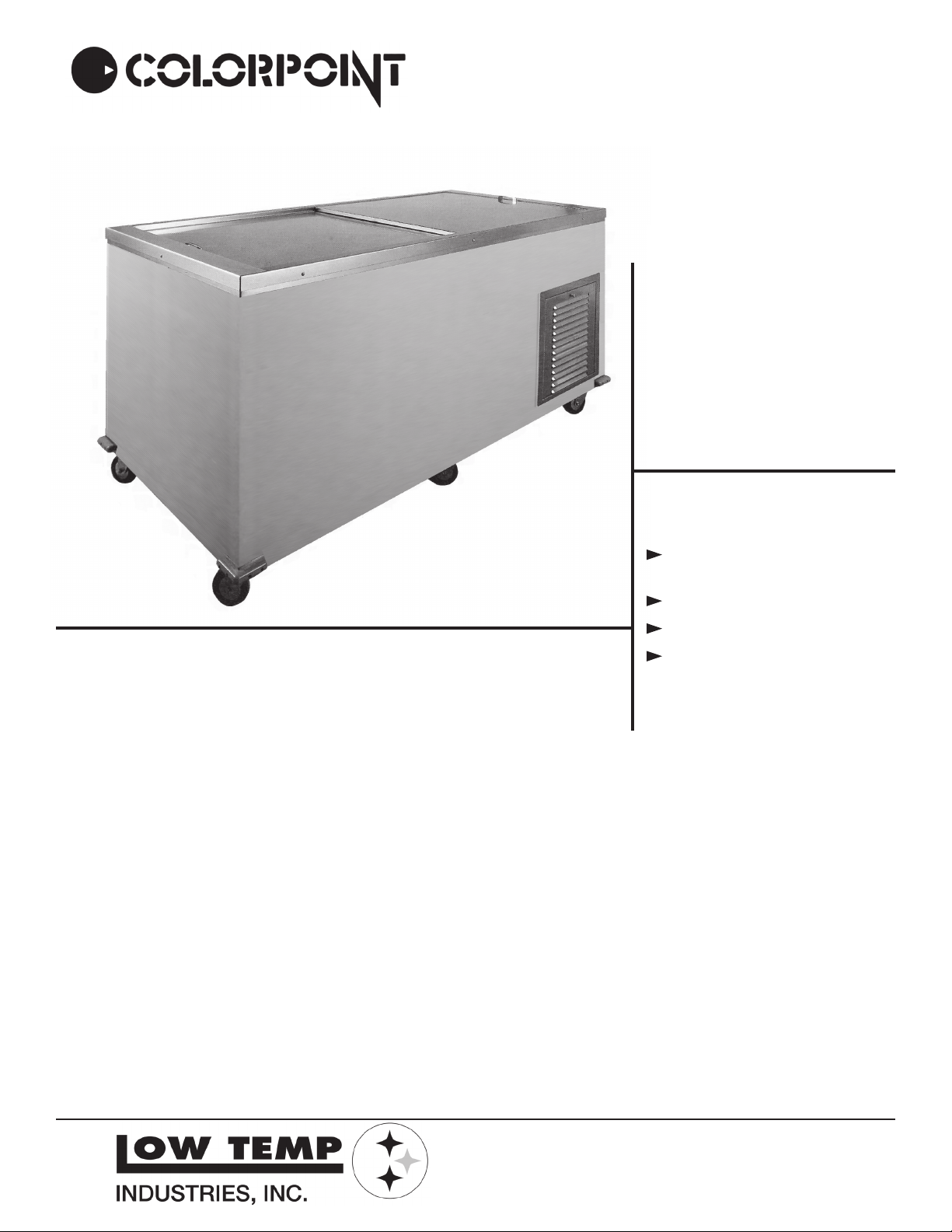

Sliding Top Milk Case Dispenser

CPM-1314

shown with optional corner bumpers

Standard Features

✔ 14 gauge stainless steel tops

✔ Insulated stainless steel sliding doors

✔ Molded fiberglass body

✔ Self-leveling crate dispensers

✔ Dispensers adjustable without tools

✔ Welded stainless steel interior

✔ Heavy duty crate supports

✔ 4” swivel casters

Optional Features (specify)

❑ (A) Tray slide, stainless, solid V ridge

❑ (B) Tray slide, stainless, flat surface

❑ (D) Cutting board, stainless

❑ (AA) Cam operated line-up locks

❑ (FF) End drop shelf, stainless

❑ (GG) Lid Locks

❑ (SS) Stainless steel legs

❑ (TT) Wrap-around bumper

❑ (**) Stainless or laminate body construction (specify)

❑ 5” swivel casters

❑ Reduced height (min. 33” w/4” casters; 34” w/5” casters)

Performance

These Heavy Duty, versatile units are

designed to maintain proper holding

temperatures and provide fast, efficient

loading and rapid product delivery. Full

sized sliding stainless steel doors provide

easy access and help maintain approved

temperatures.

Quantity: ___________________

Models

length

❑ CPM 1306 39 3/4”

❑ CPM 1310 57”

❑ CPM 1314 75 3/4”

Benefits:

Holds crates, no re-loading

necessary

Durable and easy to clean

Easy mobility

Crates maintained at easy-to-

reach height

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

21

Page 2

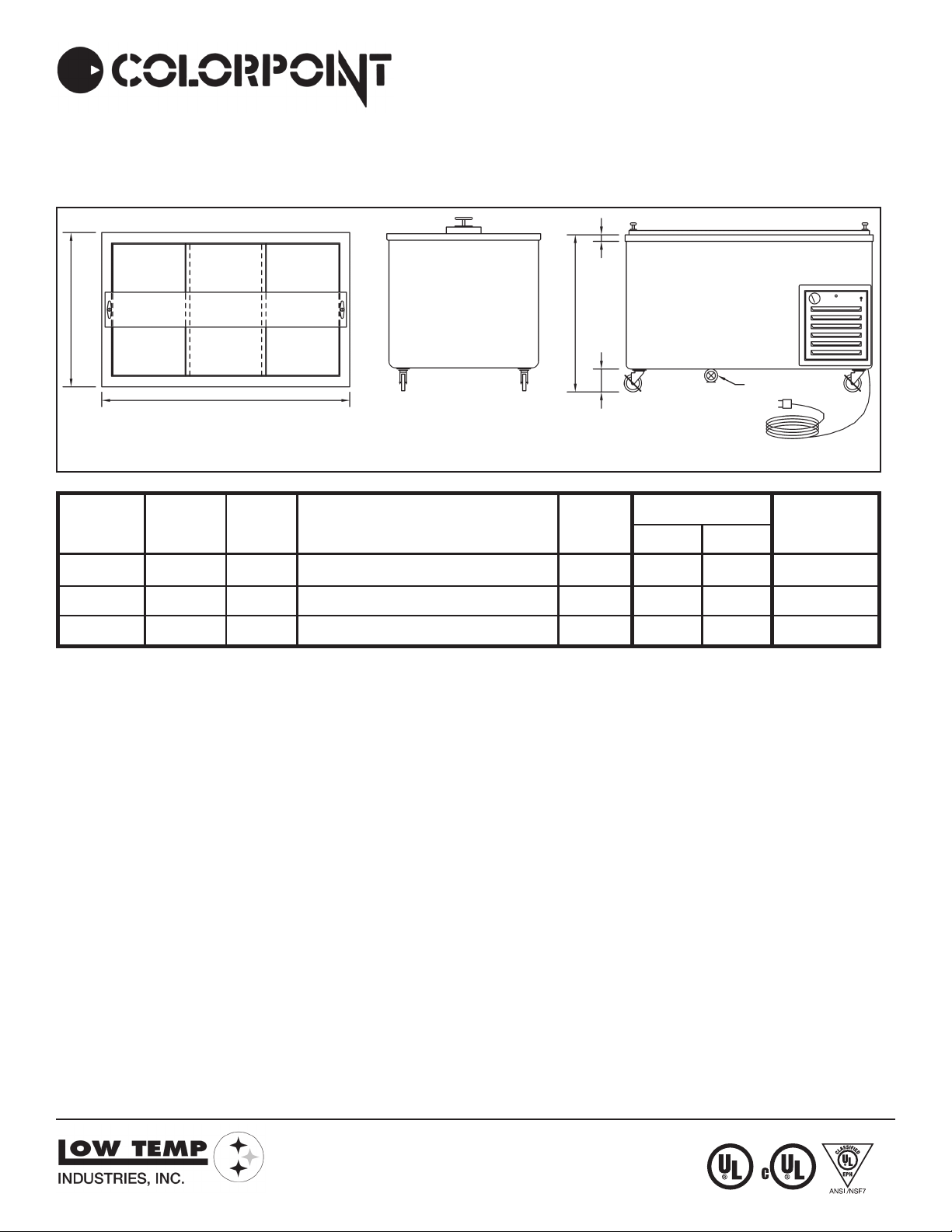

Sliding Top Milk Case Dispenser

”

2

/

1

36”

1

”

4

/

1

5

”

8

/

3

35

Plan View End View Elevation View

Model shown with optinal lid locks.

length

Job: ____________________________

Item: ___________________________

Quantity: _______________________

Drain Valve

Model Length Dairy Cases

CPM 1306 39

3

/4” 6 288

Capacity - using

1

/2 pt cartons @ 48/case Comp. Amps Plug Ship Weight

CPM 1310 57” 10 480

CPM 1314 75

General Specifications

Body: Body to be seamless molded fiberglass (F.R.P.)

with smooth exterior surfaces and rounded corners. To be

constructed by a hand lay-up process with four layers of

1.5 oz continuous strand fiberglass mat, plus a 24 oz layer

of woven roving on the bottom for added strength. Fiberglass to be flame retardant per specification ASTM E-162

having a flame spread of 25 or less. Body interior to be

reinforced at each end with 4” wide, 12 gauge galvanized

channels welded to form integral “U” frame for maximum

stress relief.

Refrigerated interior to be a welded steel cabinet with a

water tight liner, fully insulated and with a 1” brass drain

extended below the body to a shut off valve.

Top and Lids: Top to be 14 ga. stainless steel with

square turndown on all sides and corners fully welded,

ground and polished. To have #4 satin finish and all edges

to have #7 hi-lite finish. Interior top to turn down into opening and complete with integral ledges to support sliding

lids. Lids shall be 18 ga. stainless steel double pan construction complete with stainless steel hand pulls. Cabinet

and lids are full insulated with urethane insulation.

3

/4” 14 672

P.O. Box 795 • Jonesboro, GA 30237

Tel: 770.478.8803 • Fax: 770.471.3715

www.lowtempind.com • colorpoint@lowtempind.com

120V/1 phase

1

/4 H.P. 6.7 5-15P 375 lbs.

1

/4 H.P. 6.7 5-15P 515 lbs.

1

/3 H.P. 7.1 5-15P 595 lbs.

Self-leveling system: Each milk crate to be held at

proper height by two stainless steel self-leveling mechanisms, field adjustable without tools, and a removable

stainless steel carrier. (Area above compressor will not be

self-leveling.)

Refrigeration system: A temperature of 38 degrees F

shall be maintained by a cold wall evaporator system, with

an accessible expansion valve. The condensing unit shall

be a fully hermetic system using R-22 refrigerant, with all

necessary controls.

Casters: 4” diameter, ball bearing, swivel type casters to

be non-marking and with brakes on all wheels. Casters to

be mounted thru two 12 gauge channels for extra rigidity.

We reserve the right to change specifications and product design without notice. Such revisions

do not entitle the buyer to corresponding changes, improvements, additions or replacement for

previously purchased equipment.

All equipment to be built in accordance with the Underwriters Laboratories. Inc. and the National

Sanitation Foundation, Inc. standards and shall bear the Underwriters Laboratories, Inc. listing

label for safety and the Underwriters Laboratories classification label for sanitation.

03/2007

U.L. SanitationClassified to NSF Standards

Loading...

Loading...