Page 1

HDS Series

Installation manual

Page 2

Preface

Disclaimer

As Navico is continuously improving this product, we retain the right to make changes to the

product at any time which may not be reected in this version of the manual. Please contact

your nearest distributor if you require any further assistance.

It is the owner’s sole responsibility to install and use the instrument and transducers in a

manner that will not cause accidents, personal injury or property damage. The user of this

product is solely responsible for observing safe boating practices.

NAVICO HOLDING AS AND ITS SUBSIDIARIES, BRANCHES AND AFFILIATES

DISCLAIM ALL LIABILITY FOR ANY USE OF THIS PRODUCT IN A WAY THAT MAY

CAUSE ACCIDENTS, DAMAGE OR THAT MAY VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user guides and other

information relating to the product (Documentation) may be translated to, or has been

translated from, another language (Translation). In the event of any conict between any

Translation of the Documentation, the English language version of the Documentation will be

the ofcial version of the Documentation.

This manual represents the product as at the time of printing. Navico Holding AS and its

subsidiaries, branches and afliates reserve the right to make changes to specications

without notice.

Copyright

Copyright © 2010 Navico Holding AS.

Feedback from you

Your feedback is important and helps Navico ensure that this manual is a valuable resource

for all marine technicians. E-mail your comments or suggestions about this manual to the

following address: tech.writing@navico.com

Warranty

• The warranty card is supplied as a separate document.

• It is shipped with the product registration card.

• In case of any queries, refer to the brand web site of your display or system.

www.lowrance.com

1

Page 3

Declaration of Conformity

GB

FI

NL

FR

SE

DK

DE

GR

IT

ES

PT

Hereby, Navico Holding AS declares that this HDS is in compliance

with the essential requirements and other relevant provisions of Directive

1999/5/EC.

Navico Holding AS vakuuttaa täten että HDS tyyppinen laite on

direktiivin 1999/5/EY oleellisten vaatimusten ja sitä koskevien

direktiivin muiden ehtojen mukainen.

Hierbij verklaart Navico Holding AS dat het toestel HDS in

overeenstemming is met de essentiële eisen en de andere relevante

bepalingen van richtlijn 1999/5/EG.

Par la présente, Navico Holding AS déclare que ce HDS est conforme

aux exigences essentielles et aux autres dispositions de la directive

1999/5/CE qui lui sont applicables.

Härmed intygar Navico Holding AS att denna HDS står i

verensstämmelse med de väsentliga egenskapskrav och övriga relevanta

bestämmelser som framgår av direktiv 1999/5/EG.

Undertegnede Navico Holding AS erklærer herved, at følgende udstyr

HDS overholder de væsentlige krav og øvrige relevante krav i direktiv

1999/5/ EF.

Hiermit erklärt Navico Holding AS, dass sich dieses SE8, in

Übereinstimmung mit den grundlegenden Anforderungen und den

anderen relevanten Vorschriften der Richtlinie 1999/5/EG bendet.

(BMWi)

Με την παρουσα Navico Holding AS δηλωνει οτι HDS συμμορφωνεται

προς τις ουσιωδεις απαιτησεις και τις λοιπες σχετικες διαταξεις της

οδηγιας 1999/5/ΕΚ.

Con la presente Navico Holding AS dichiara che questo HDS è

conforme ai requisiti essenziali ed alle altre disposizioni pertinenti

stabilite dalla direttiva 1999/5/CE.

Por medio de la presente Navico Holding AS declara que el HDS cumple

con los requisitos esenciales y cualesquiera otras disposiciones aplicables

o exigibles de la Directiva 1999/5/CE.

Navico Holding AS declara que este HDS está conforme com os

requisitos essenciais e outras provisões da Directiva 1999/5/CE.

The equipment named in this declaration, is intended for use in international waters as well as

coastal sea areas administered by countries of the E.U. and E.E.A. A full Declaration can be

obtained from www.lowrance.com

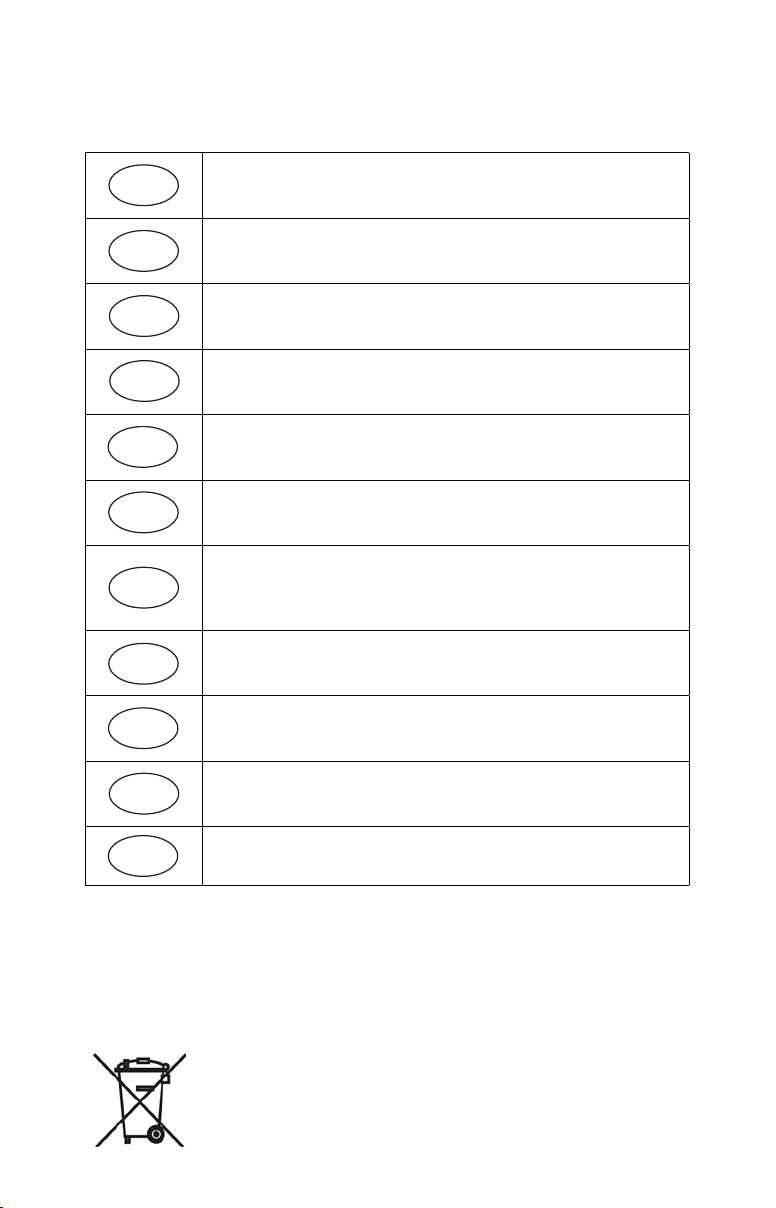

Disposal

Waste Electrical and Electronic Equipment (WEEE) The use of the WEEE

Symbol indicates that this product may not be treated as household waste.

By ensuring this product is disposed of correctly, you will help protect the

environment. For more detailed information about the recycling of this

product, please contact your local authority, your household waste disposal

service provider or the shop where you purchased the product.

2

Page 4

Contents

Preface .....................................................................................................1

Declaration of Conformity .............................................................................................2

Disposal .........................................................................................................................2

Introduction ........................................................................................... .5

About this Manual .........................................................................................................5

Important Safety and Warning Information ...................................................................5

Check the Parts ..............................................................................................................6

Overview ........................................................................................................................7

Display Installation ................................................................................9

Mounting location ..........................................................................................................9

Panel Mount ...................................................................................................................11

Bracket Mount ...............................................................................................................12

Transducer Installation .........................................................................14

Recommended Tools and Supplies ................................................................................14

Skimmer Installation Instructions ..................................................................................15

System Architecture ...............................................................................28

Wiring the HDS ..................................................................................... .29

Wiring Guidelines ..........................................................................................................29

Power/Data Cable ..........................................................................................................30

NMEA 0183 Wiring Table .............................................................................................31

NMEA 0183 wiring ......................................................................................................31

NMEA 2000 wiring .......................................................................................................32

Ethernet ..........................................................................................................................33

HDS-8 & HDS-10 Data Bridging ..................................................................................34

Single Station .................................................................................................................35

Dual & Multi Station .....................................................................................................36

Connecting HD Radar ....................................................................................................37

Connecting BR24 Radar ...............................................................................................38

Commissioning Check List ............................................................................................39

Sonar ..............................................................................................................................41

3

Page 5

Dimensional Drawings .......................................................................... .43

HDS5 .............................................................................................................................43

HDS7 .............................................................................................................................44

HDS8 .............................................................................................................................45

HDS10 ...........................................................................................................................46

NMEA Information ................................................................................47

NMEA 2000 PGN List ...................................................................................................47

Supported NMEA 0183 sentences .................................................................................49

4

Page 6

Introduction

About this Manual

• This manual is a reference guide for installing a Lowrance HDS System.

• The information in this manual at the time of printing is correct to the best of our

knowledge. Navico can not be liable for any inaccuracies or missing information.

• Due to the constant improvement of Navico’s products. Navico cannot be liable for

changes between the product and the manual. Refer to www.lowrance.com for

the latest manuals and addendum’s.

Important Safety and Warning Information

Please read carefully before use.

When navigating the vessel, use the Lowrance HDS system only as a

navigational aid. Proper navigation of the vessel is the sole responsibility of the

vessel operator.

The electronic chart used by the HDS System is an aid to navigation only and

is designed to supplement, not replace, ofcial government charts. Only ofcial

government charts supplemented by notices to mariners contain the information

required for safe and prudent navigation. Always supplement the electronic

information provided by the Lowrance HDS with other plotting sources such

as observations, depth soundings, radar and hand compass bearings. Should the

information not agree, the discrepancy must be resolved before proceeding any

further.

Never operate the HDS in Simulate Mode while you are underway. It is the

user’s responsibility to ensure that Simulate Mode is used only in safe situations

such as when you are moored in a marina.

The Global Positioning System (GPS) is operated by the US Government which

is solely responsible for its operation, accuracy and maintenance. The GPS

system is subject to changes which could affect the accuracy and performance

of all GPS equipment anywhere in the world.

The accuracy of the Sonar depth display can be limited by many factors,

including the type of transducer, the location of the transducer, and water

conditions. Ensure that the transducer is installed correctly and the Sonar is used

correctly.

HDS units intended for sale and operation in the America’s region DO NOT

include full functionality outside of the America’s, dened as 30 degrees west

longitude and 180 degrees west longitude. Units are restricted to operate in

English language only with imperial (non-metric) units only.

For full use around the globe an International unit must be purchased from

outside of the America’s region.

5

Page 7

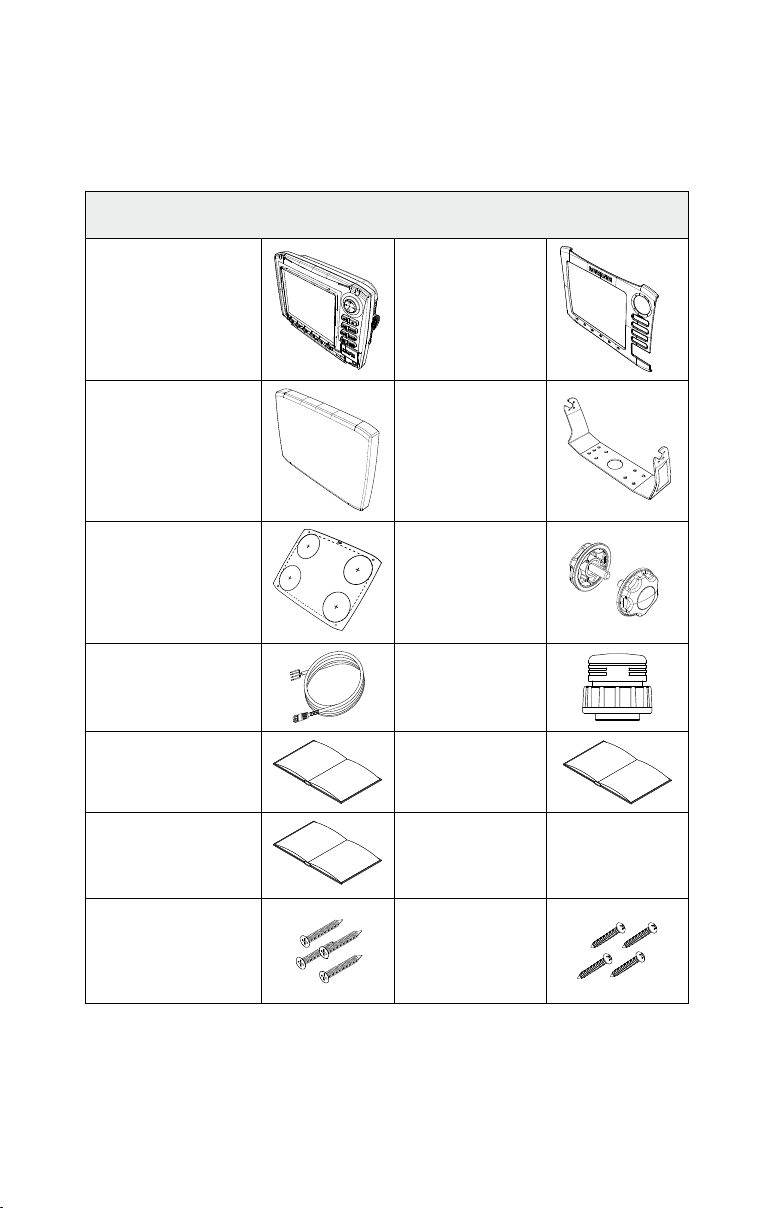

Check the Parts

ISO 30 Degree with Perspective

HDS Head Unit

Models: 5”, 7”, 8”

or 10”

Packaged Parts List

HDS Bezel

HDS Dust Cover

HDS Cut-out

Template

HDS

Power/Data Cable

HDS

Installation Manual

HDS

Quick start guide

HDS

4 x SCREW #10

3/4 PAN HEAD SS

SELFTAP

HDS Mounting

Bracket

HDS Bracket Knobs

HDS

Connector Caps

HDS

Operation Manual

HDS

4 x SCREW NO.

6X1.5 PANHEAD

PHILLIPS TP1

6

Page 8

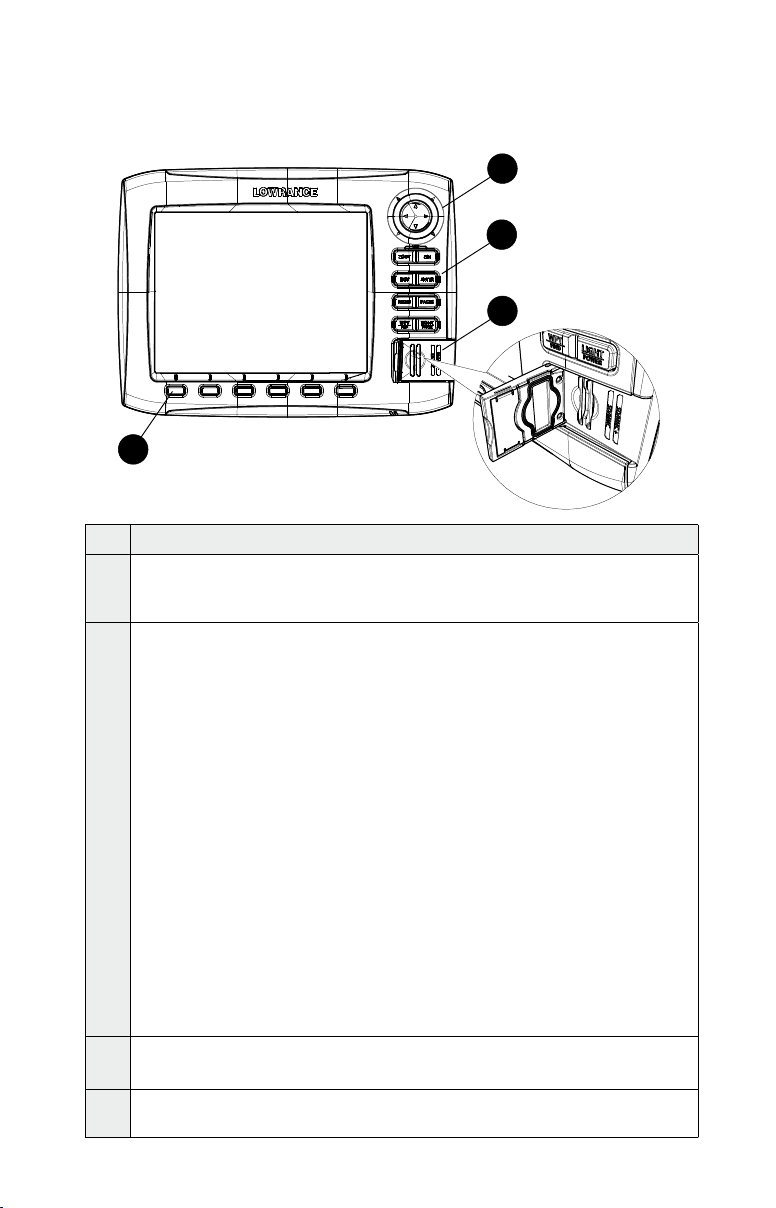

Overview

4

3

2

1

Key Description

CURSOR CONTROL: Move the cursor, scroll through menus, adjust

1

features, view sonar/GPS history. 8 & 10 models also have a y wheel to aid

scrolling.

CONTROL KEYS

ZOUT:

Zoom out to see more of the map with less detail

ZIN: Zoom in to see less of the map with more detail.

Pressing ZOUT & ZIN at the same time will activate Man Overboard mode.

ENTER: Finalize menu selections; shortcut key for functions like saving a

waypoint at cursor position.

2

MENU: Opens Content & Settings menu.

LIGHT/POWER: Controls backlight level & turns the unit on/off.

EXIT: Cancels entries, closes menus & windows; toggles between cursor position

and chart location on Chart page.

PAGES: Press to open Pages menu; press and hold to select the active panel of the

display.

WPT/FIND: Saves a waypoint at current position; accesses searching tools.

3

MMC/SD Card slot: Insert MMC/SD and high-detail mapping cards here.

SOFT KEYS: Controls commonly used features and functions. Only available on

4

8 & 10” units.

7

Page 9

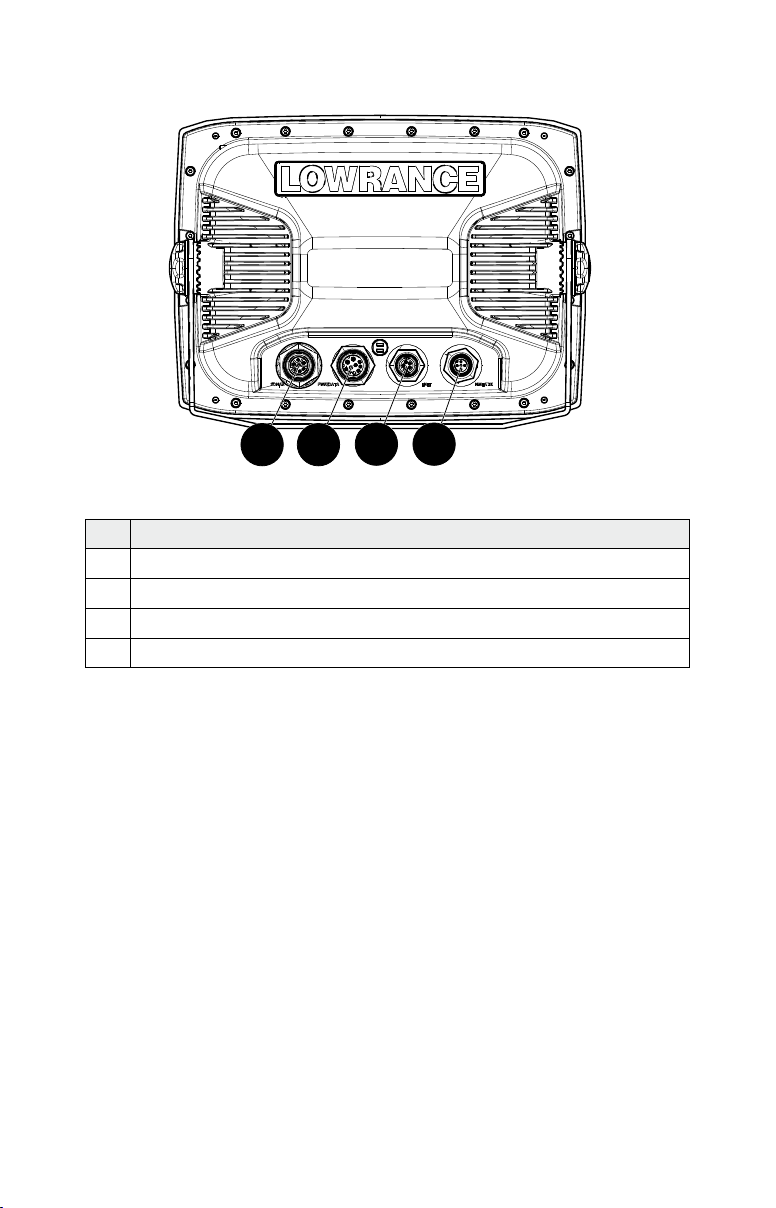

2

3 4

1

Key Description

1 Sonar (Not available on HDS5M, 7M, 8M or 10M units)

2 Power/Data

3 ENET (Ethernet)

4 NMEA2K (NMEA2000) Network

8

Page 10

Display Installation

Mounting location

Choose the mounting locations carefully before you drill or cut. The display should be

mounted so that the operator can easily use the controls and clearly see the display screen.

Be sure to leave a direct path for all of the cables. The display screen is high-contrast and antireective, and is viewable in direct sunlight, but for best results install the display out of direct

sunlight. The chosen location should have minimal glare from windows or bright objects.

Ensure that any holes cut are in a safe position and will not weaken the boat’s structure. If in

doubt, consult a qualied marine electronics installer.

The mounting location should be at least 100 mm (4”) away from the compass, at least 300

mm (12”) away from any radio transmitter and at least 1.2 m (4 ft) away from any antenna.

Before cutting a hole in a panel, make sure that there are no hidden electrical wires or other

parts behind the panel.

Do not mount any part where it could be used as a hand hold, where it might be submerged or

where it will interfere with the operation, launching or retrieving of the boat.

If bracket mounting, chose a at area where the display will not be subjected to excessive

vibration.

Leave sufcient clearance space behind the display to connect all relevant cables.

Good ventilation is required behind the mounting panel. Poor ventilation may cause the

display to overheat. The display is designed to operate in temperatures from -15° C to +55° C

(+5° F to +131° F).

For overall width and height requirements, please see the drawings at the back of this manual.

9

Page 11

Bezel Removal

1: To removing the bezel from the 5 and 7-inch models the card slot door must be open

2: To remove the bezel use a at head screwdriver.

3: Insert screwdriver into the bezel release slots and pry out and away from the unit. The

bottom of the bezel will release from the unit. Push up to release the top bezel catches.

For 8 and 10-inch models

1: While pulling the lower left or right corner of the bezel toward the outside of the unit

2: Push up towards the top of the unit to release the top bezel catches.

Note: All models have four adhesive strips behind the bezel. These strips should be kept free

of dust and other foreign material when the bezel is not attached to the unit.

10

Page 12

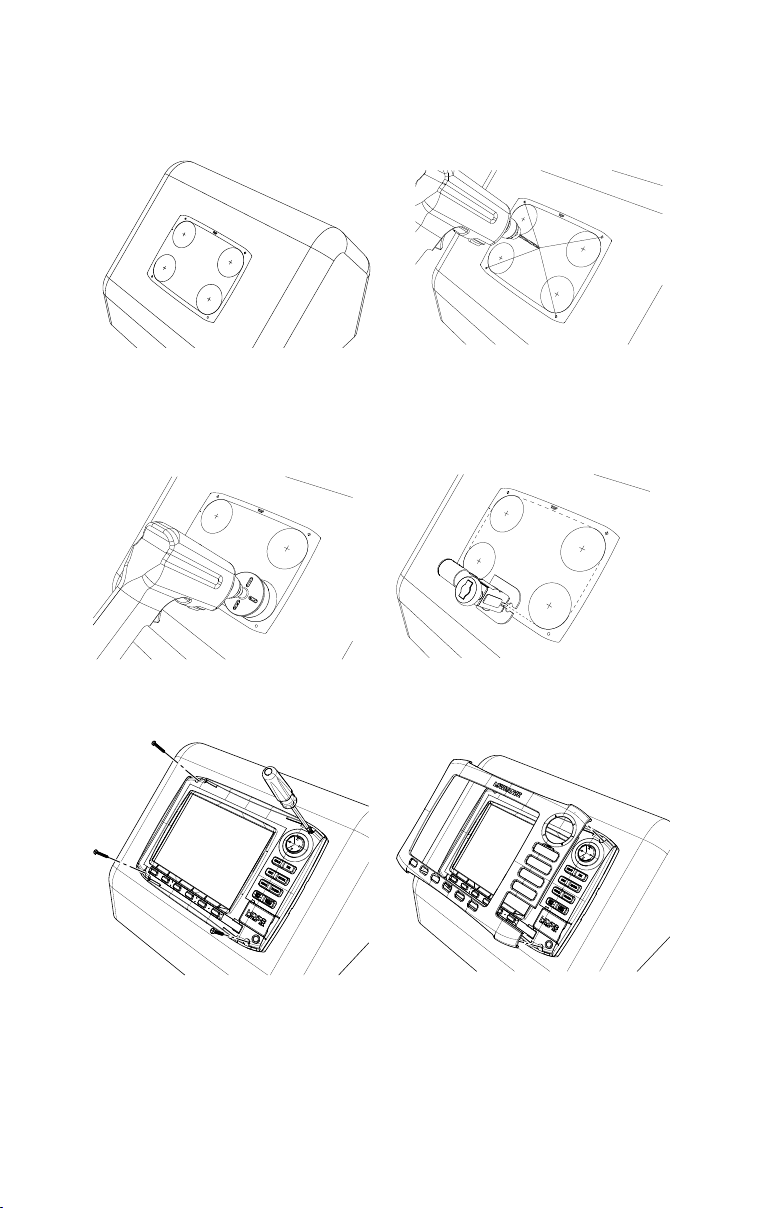

Panel Mount

1: Attach the ush mounting template

to the selected mounting position

using adhesive tape.

3: Use a hole saw to cut the four corner

radius

2: Drill pilot holes for the four hole saw

cuts and for the four self tapping

screws used to secure the display.

4: Cut along the dotted line and remove

the shaded area.

5: Connect all cables to the rear of

the unit before placing the unit

into the console. Secure using the four

provided #6-20 x 1-1/2” screws

6: To nish off the installation rmly

clip the front bezel in place

11

Page 13

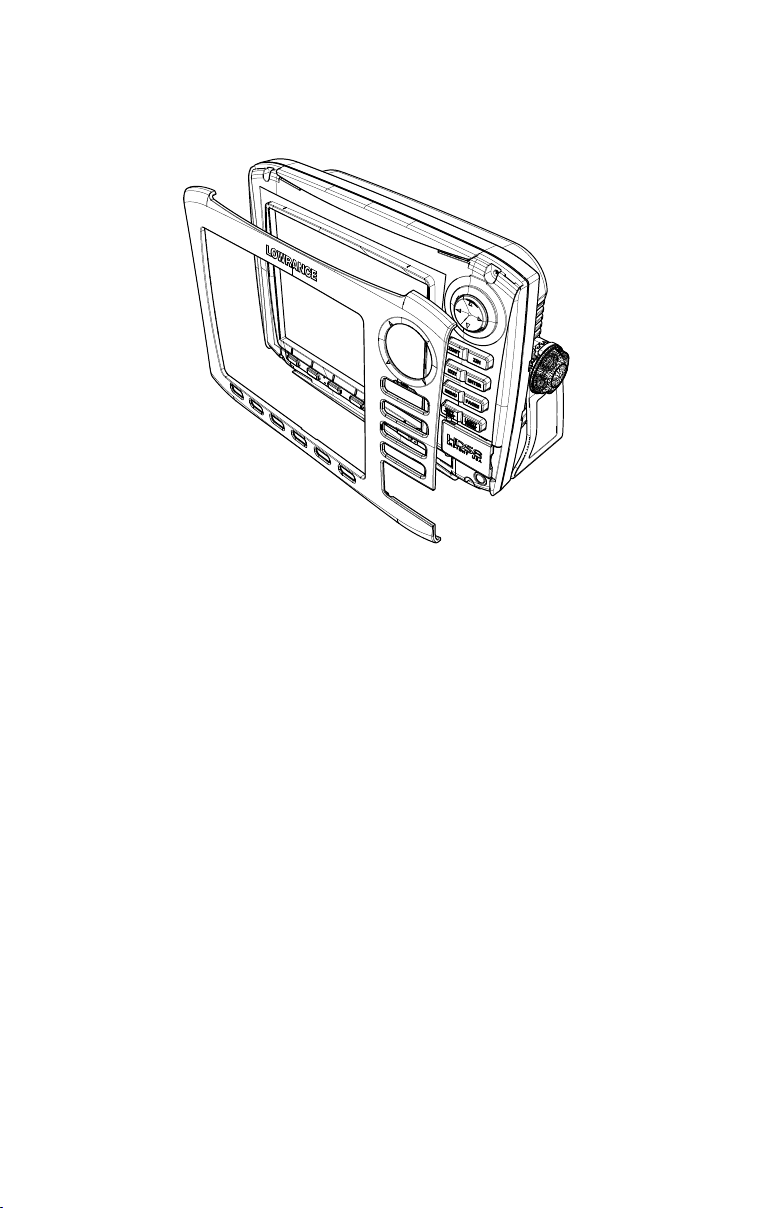

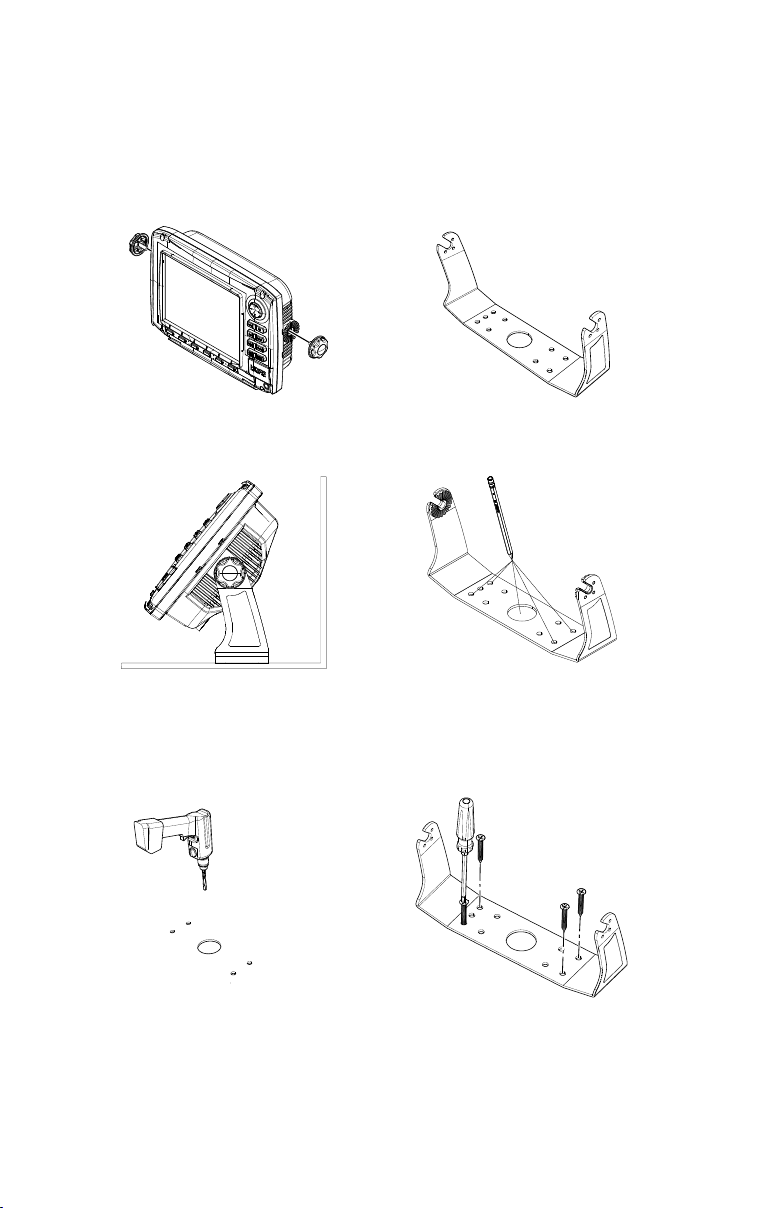

Bracket Mount

An alternative to ush mounting the HDS display is to bracket mount the unit. This method

has the advantage that the display can be easily removed when not in use and may be tilted to

achieve the best possible viewing angle.

1: Loosely screw securing knobs to the

Display unit.

3: Make sure the display can be

adjusted to the correct angle without

interfering with the surrounding.

Allow space for cables attached to

the rear of the unit

2: Temporarily mount the display unit

in the bracket

4: Remove the display unit and use the

mounting bracket as a template to

mark the four positions of the screw

holes and optional center cable hole.

5: Drill a pilot hole for the four screws

and an optional hole large enough

for the cables to emerge from.

6: Secure the bracket to the surface

7: Connect the cables.

12

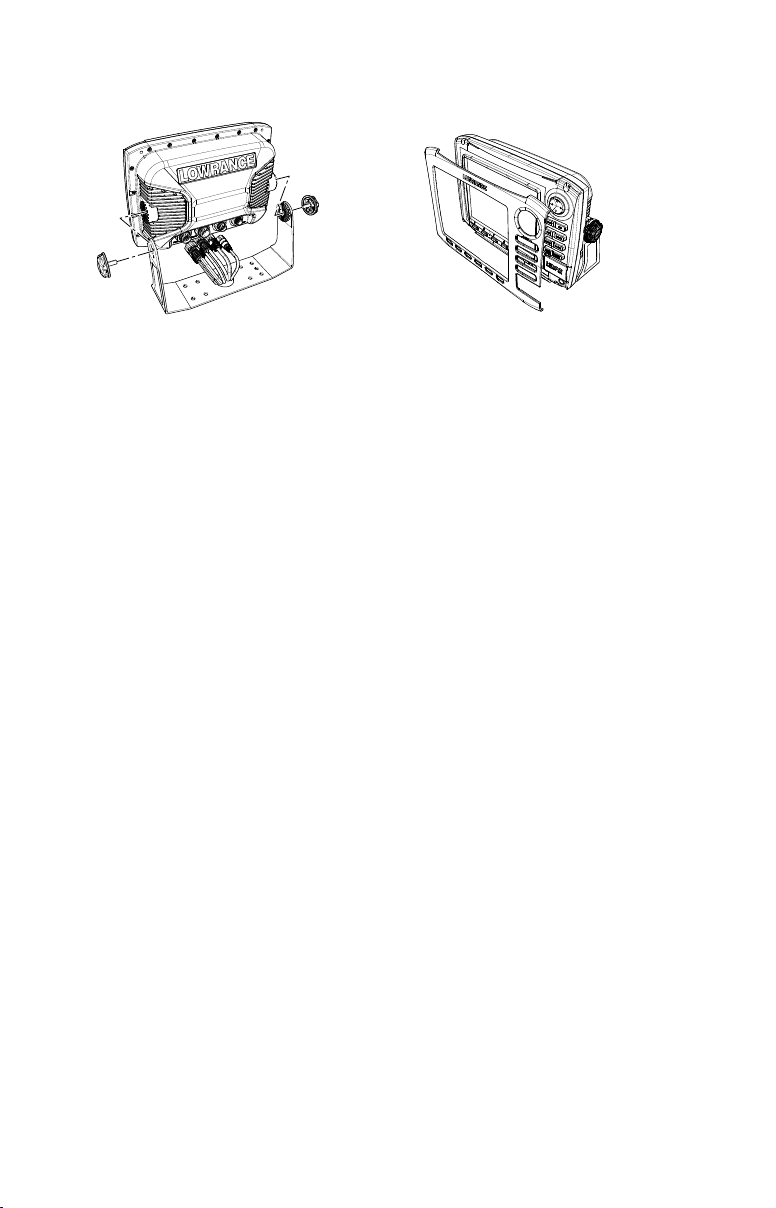

Page 14

8: Slide the display into the mounting

bracket and secure in place with the

bracket knobs.

9: Attach the bezel. Firmly clip the

front bezel in place.

13

Page 15

Transducer Installation

Recommended Tools and Supplies

Tools and Supplies (not included)

If you plan to route the transducer cable through the transom, you will need either a 1” drill

bit or a 5/8” drill bit depending on the size of the transducer cable connector. Each transom

mount requires a high quality, marine grade above- or below-waterline sealant/adhesive

compound. The following installations also call for these recommended tools and supplies.

One-piece Bracket Transom Installation

Tools: two adjustable wrenches or socket wrench, drill, #29 (0.136”) drill bit, screwdriver.

Supplies: none.

Two-piece Bracket Transom Installation

Tools: two adjustable wrenches or socket wrench, drill, #20 (0.161”) drill bit, screwdriver.

Supplies: four, 1” long, #12 stainless steel wood screws.

TMB-S Bracket Trolling Motor Installation

Tools: two adjustable wrenches or socket wrench, screwdriver. Supplies: plastic cable ties.

Skimmer Transducer Shoot-through Hull Installation

Supplies: alcohol wipes, 60 and 160 grit sandpaper, and marine grade above- or below-

waterline epoxy adhesive.

Pod Transducer Shoot-through Hull Installation

Supplies: alcohol wipes, 60 and 160 grit sandpaper, and marine grade above- or below-

waterline epoxy adhesive.

14

Page 16

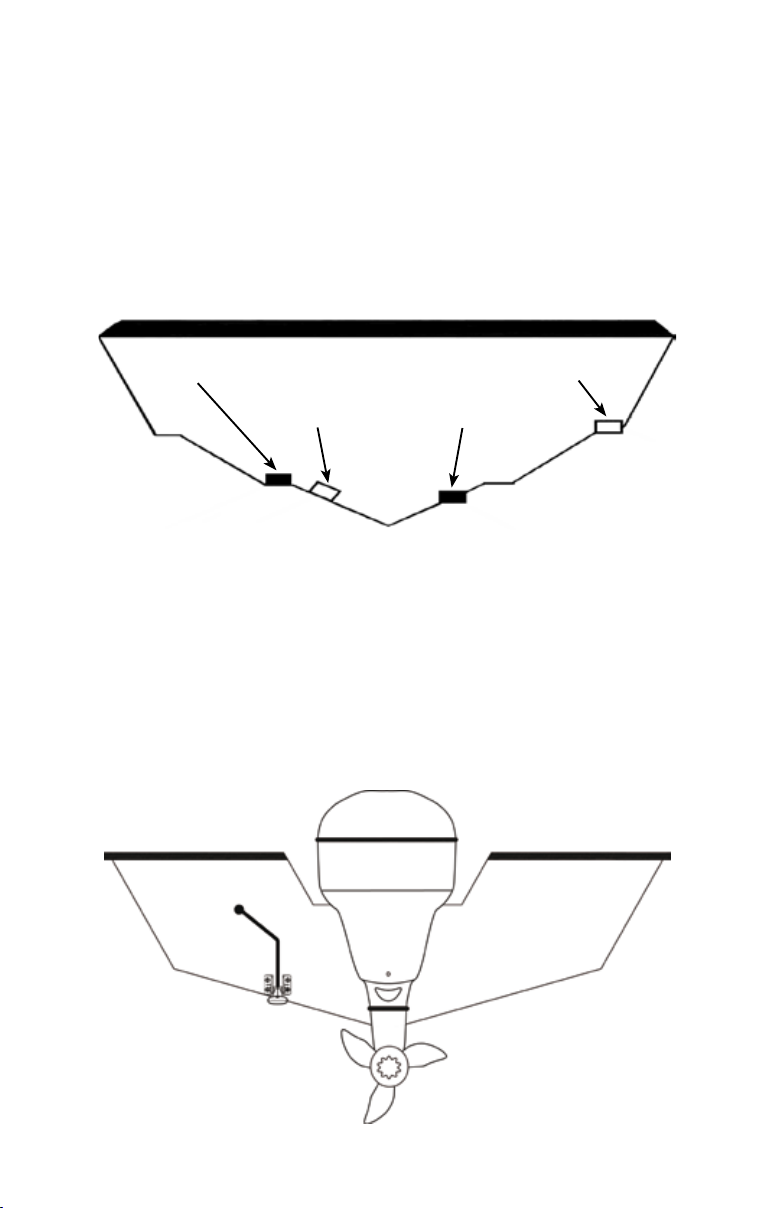

Skimmer Installation Instructions

Transducer location and installation is one of the most critical steps in sonar installation.

Select a transducer location

To function properly the Skimmer transducer must be in the water at all times and in a

location that has a smooth ow of water when the boat is moving.

Good location

Poor location

Good location

Poor location

Note: Aluminum boats with strakes or ribs on the hull can create large amounts of

turbulence at higher speeds. A good transducer location on these types of boats is between the

ribs closest to the engine.

If the transducer is not placed in a smooth ow of water, interference caused by bubbles and

turbulence may show on-screen in the form of random lines or dots. The unit also could lose

bottom signal when the boat is on plane.

Note: When mounting the transducer, make sure it does not interfere with the hauling of the

boat.

Do not mount the transducer

closer than approximately one

foot from the engine’s lower

unit. This will prevent cavitation

interference from the prop.

15

Page 17

Aligning Ratchets on Transducer bracket

Aligning ratchets on one-piece bracket:

The one-piece bracket assembly includes two black plastic ratchets. The ratchets are used to

align the transducer with the boat hull. Each ratchet has the letters A-E molded into it.

1: Insert the ratchets in the bracket with the

Ratchet

Bracket

letter "A" aligned with the dot stamped on the

outside of the transducer bracket, as shown in

the following series of diagrams.

Align dot and

letter "A".

2: Slide the transducer in the

bracket and temporarily

slide the bolt through the

transducer bracket, as

shown in the image at

right.

Transom

3: Hold the transducer assembly against the

transom. Look at the transducer from the

side.Try to adjust the transducer so its face

is parallel to the ground. If it does, then the

"A" position is correct.

If the transducer will not adjust with its face parallel to the ground, remove the transducer and

ratchets from the bracket. Reinsert the ratchets into the bracket, this time with the letter “B”

aligned with the dot stamped in the bracket.

Reassemble the transducer and bracket and place it against the transom. Again, check to see if

the transducer will adjust so its face is parallel with the ground. Repeat this process until the

transducers face will adjust so that it is parallel with the ground.

16

Page 18

Aligning ratchets on two-piece bracket

The two-piece bracket includes four black plastic ratchets. The ratchets are

used to align the transducer with the boat hull. Each ratchet has the letters A-F

molded into it.

If the transducer will not adjust with its face parallel to the ground.

1: Place two of the ratchets

in each side of the bracket

with the letter "A" aligned with

the alignment mark molded

Alignment mark

into each bracket.

2: Now place the other two

Bracket

ratchets on the transducer with

the letter "A" aligned in the

12 o'clock position on the

transducer stem.

3: Slide the transducer in the bracket

and temporarily slide the bolt through

the transducer bracket.

4: Hold the transducer assembly

against the transom. Look at

he transducer from the side. Try

to adjust the transducer so its

face is parallel to the ground.

If it does, then the

"A" position is correct.

Ratchet

Transom

5: Remove the transducer and ratchets

from the bracket. Reinsert the ratchets

into the bracket, this time with the

letter “B” aligned with the dot stamped

in the bracket. Reassemble the

transducer and bracket and place it against the transom. Again, check to see if the

transducer will adjust so its face is parallel with the ground. Repeat this process until the

transducers face will adjust so that it is parallel with the ground.

17

Page 19

Assembling the Transducer bracket

After determining the correct position for the ratchets, loosely assemble the transducer and

bracket assembly as shown in one of the two diagrams below.

One-piece bracket assembly

Metal washer

Lock nut

Rubber washers

Ratchets

Note:

Do not tighten the transducer bracket assembly until you have aligned the transducer

and bracket on the transom.

Two-piece bracket assembly

Ratchets

Bolt

Small at

washer

Metal washer

Bolt

Large at

washer

Lock nut

Thick rubber

washer

Note:

Do not tighten the transducer bracket assembly until you have aligned the transducer

and bracket on the transom.

18

Page 20

Aligning and Attaching the Transducer

Adjust the transducer so that its "face" is parallel with the ground and its center line is even

with the bottom of the boat hull.

Transducer bracket

mounted too low.

Transom Transom

Transducer bracket

mounted too high.

Bottom of hull.Bottom of hull.

Note: When mounting the transducer to the transom, there are two extremes you should

avoid, rst, do not let the edge of the mounting bracket extend below the bottom of the hull,

left image, above. Second, do not let the bottom of the transducer rise above the bottom of

the hull, right image, above.

The center line of the transducer

should be level with the bottom of

the boat hull and its "face" parallel

with the ground.

Transom

Transducer face

Do not over tighten

the transducer bracket

lock nut. If you do,

the transducer may not

"kick-up" if it strikes an

object in the water.

Bottom of hull.

For single frequency

transducers, with a

one-piece bracket,

assemble it with the

cable passing over the

bolt and through the

bracket, as shown here.

19

Page 21

1: Hold the transducer and bracket

assembly against the transom.

When the transducer and bracket

are properly aligned mark its

position on the hull.

2: Drill the mounting holes for the

transducer bracket. For the one piece bracket use a #29 bit (for

the #10 screws). For the two-piece

bracket use a #20 bit (for the #12

screws).

Note: Use the provided screws to secure the transducer assembly to the transom.

Be sure to use a below-waterline

marine grade sealant on all of the

transducer bracket screw holes.

When mounting a Skimmer

transducer to a boat with a veehull,

make sure the transducer center

line is aligned to the bottom of the

boat hull, as shown here.

Water line

Clamp the transducer cable to the

transom near the transducer. This

will help keep the cable secure.

If you drill a hole in the transom for

the transducer cable, make sure it

is located above the waterline. Seal

the hole with an above- or belowwaterline marine grade sealant.

20

Page 22

If you drill a hole in the transom for the transducer cable, make sure it is located above

the waterline. Seal the hole with an above or below waterline marine grade sealant. Route

the transducer cable to the sonar unit. Make sure to leave some slack in the cable near the

transducer.

Use caution when routing the transducer cable near other wiring and cables. If you need to

drill a hole in the transom to pass the connector through, the hole size will depend on the

connector on the end of the transducer’s cable.

Make a test run to determine the results

At times you may need to adjust the transducer higher or lower. The slots in the mounting

brackets allow you to loosen the screws and slide the transducer up or down.

Improper transducer

angles

Partial sonar

sh arches

Full sonar sh arch

If the sonar screen is displaying partial sh arches, as shown in the previous top two images,

the transducer could be at an improper angle. Check the transducer and make sure its face is

parallel with the bottom, as shown in the bottom example. If you frequently lose bottom signal

lock the transducer may be coming out of the water as the boat crosses waves or wakes.

Move the transducer a little lower in the water to see if that improves sonar performance.

When shing around underwater structure the transducer may be kicked up from object

strikes. If the transducer is being kicked up too often, try moving it a little higher for more

protection.

Transducer face parallel

with the bottom.

21

Page 23

TMB-S Trolling Motor Bracket Installation

Note: The TMB-S bracket is designed for one-piece bracket transducers only.

The TMB-S trolling motor bracket (Part No. 51-45) is an optional accessory and is available

through LEI Extras at www.lei-extras.com.

The TMB-S bracket is used to attach a one-piece bracket transducer to a trolling motor. If you

regularly sh in water with a lot of underwater structure, such as rocks, stumps and trees, you

may consider using a Pod transducer for trolling motor installation. Pod transducers cannot be

“kicked up” by underwater structure.

Internal tooth washer

Bolt

Using the components supplied with the TMB-S bracket (adjustable strap, internal tooth

washer and plastic bracket) attach it to the transducer as shown in the diagram above.

Adjustable strap

Plastic bracket

Lock nut

Flat washer

Route the transducer cable

along the trolling motor

shaft. Use plastic ties (not

included) to secure the

cable to the shaft.

Slide the adjustable strap through the plastic bracket as shown above, left, then slip the strap

around the trolling motor as shown in the image, at right. Position the transducer so its “face”

is pointing straight down when the trolling motor is in the water. Tighten the adjustable strap

securely to the trolling motor. Make sure there is enough slack in the transducer cable for the

trolling motor to turn freely.

22

Page 24

Skimmer Transducer Shoot-thru-hull Installation

Before attempting any installation on boats with otation material sandwiched within the hull,

consult the boat manufacturer. In a shoot-thru-hull installation the transducer is epoxied to the

inside of the boat hull.

WARNING: Do not remove any material from the inner hull. Careless grinding or cutting

on the hull could damage the integrity of the hull. Contact the boat dealer or manufacturer to

conrm hull specications.

Transducer

Transducer epoxied

to hull.

Epoxy

Hull

Note: The previous image shows a Skimmer transducer epoxied to a at, solid portion of the

boat hull near the transom. The circled image is a close-up view of the transducer epoxied to

the hull.

On vee hulls try to place the transducer

where the dead rise is 10° or less.

Note: While you can epoxy a Skimmer transducer to the inside of a boat hull, we

recommend using a Pod transducer for this type of installation. Use care when mounting a

transducer inside a boat hull. Once epoxied into position, the transducer can be very difcult

to remove.

23

Page 25

A transducer can not shoot through wood or metal hulls. Wood and metal hulls require either

a transom mount or "thru-hull" installation. For shoot-thru-hull applications many boat hulls

have a at keel pad that offers a good transducer mounting surface.

If you are using a Skimmer transducer versus a Pod transducer for this installation, make sure

the Skimmer transducer is oriented so the nose of the transducer is facing the bow (front) of

the boat. Also, if the transducer has a built in temp sensor, it will only show the temperature of

the hull, not the water temp.

Before you epoxy the transducer to the hull, make sure the area is clean, dry and free of oil or

grease. The surface of the hull must be at so the entire transducer face is in contact with the

hull. Also, make sure the cable is long enough to reach the sonar unit.

1: Sand face of

transducer

and bottom

of hull.

2.: Apply

epoxy to the

face of

transducer

and bottom

of hull.

3: Epoxy transducer to hull.

Epoxy

Hull

To bow

Apply pressure to hold the transducer in place while the epoxy sets. Be careful not to move

the transducer while the epoxy is setting. Allow the epoxy to set before moving the boat.

When nished, the face of the transducer should be parallel with the hull with a minimum

amount of epoxy between the hull and transducer. After the epoxy has set, route the transducer

cable to the sonar unit.

Sand both the inside surface of the hull,

where the transducer is to be epoxied,

and the face of the transducer.

Start with a rougher grit sandpaper, such

as 60 grit, and nish with a smoother

grit, such as 160 grit, sandpaper. Sand

the inside surface of the hull until it is

smooth to the touch.

The sanded area should be about 1-1/2

times the diameter of the transducer.

After sanding, clean the hull and face of

the transducer with an alcohol wipe to

remove any sandpaper grit and dust.

Apply a thin layer of epoxy (about

1-16" or 1.5 mm) on the face of the

transducer and the sanded area on the

hull. Make sure there are no air pockets

in the epoxy layers.

Press the transducer into the epoxy,

twisting and turning it to force any air

bubbles out from under the transducer

face. Stop pressing when it bottoms out

on the hull.

24

Page 26

Pod Transducer Installation Instructions

The following instructions explain how to install a Pod transducer inside a hull or on a trolling

motor. Read the following instructions carefully before attempting any installation. Use

extreme care when mounting a transducer inside a boat hull. Once epoxied into position, the

transducer can be very difcult to remove.

Note: Transducer location and installation is one of the most critical steps in sonar

installation.

Pod Transducer shoot-thru-hull installation

Before attempting any installation on boats with otation material sandwiched within the hull,

consult the boat manufacturer.

WARNING: Do not remove any material from the inner hull. Careless grinding or cutting

could damage the integrity of the hull. Contact the boat dealer or manufacturer to conrm hull

specications.

A transducer can not shoot through wood or metal hulls. Wood and metal hulls require either

a transom mount or “thru-hull” installation. For shoot-thru-hull applications many boat hulls

have a at keel pad that offers a good transducer mounting surface.

Transducer

Transducer epoxied to hull.

Epoxy

Hull

Note: The previous image shows a Pod transducer epoxied to a at, solid portion of the boat

hull near the transom. The transducer should be installed as close to the transom as possible,

close to the center line.

Before you epoxy the transducer to the hull, make sure the area is clean, dry and free of oil or

grease. The surface of the hull must be at so the entire transducer face is in contact with the

hull. Also, make sure the cable is long enough to reach the sonar unit before the transducer is

epoxied into place.

25

Page 27

On vee hulls try to place the transducer where

the deadrise is 10° or less.

1: Sand

face of

transducer

and bottom

of hull.

2: Apply

epoxy to

face of

transducer

and bottom

of hull.

Sand both the inside surface of the hull, where

the transducer is to be epoxied, and the face of

the transducer.

You may want to start with a rougher grit

sandpaper, such as 60 grit, and nish with a

smoother grit, such as 160 grit, sandpaper.

Sand the inside surface of the hull until it is

smooth to the touch.

The sanded area should be about 1-1/2 times

the diameter of the transducer. After sanding,

clean the hull and face of the transducer with

an alcohol wipe to remove any sandpaper grit

and dust.

Apply a thin layer of epoxy (about 1-16" or

1.5 mm) on the face of the transducer and the

sanded area on the hull. Make sure there are

no air pockets in the epoxy layers.

3: Epoxy transducer to hull.

Epoxy

Hull

Note: After the epoxy has set, route

the transducer cable to the sonar unit.

Press the transducer into the epoxy, twisting

and turning it to force any air bubbles out

from under the transducer face. Stop pressing

when it bottoms out on the hull.

Apply pressure to hold the transducer in place

while the epoxy sets. Be careful not to move

the transducer while the epoxy is setting.

Allow the epoxy to set before moving the

boat.

When nished, the face of the transducer

should be parallel with the hull with a

minimum amount of epoxy between the hull

and transducer.

26

Page 28

Pod Transducer Trolling Motor Installation

The top of the transducer is curved to t the contour of the trolling

motor.

You will need a hose clamp large enough to t over the

trolling motor. The hose clamp is NOT included with the Pod

transducer.

Before you attach the transducer to the trolling motor, make sure there is enough

slack in the transducer cable for the trolling motor to turn freely.

1: Slide the hose

clamp through the Pod

transducer brackets, as

shown below.

2: Slip the clamp around the trolling motor, as shown

below. Tighten the hose clamp securely to

the trolling motor.

Note: The transducer should be mounted ahead of the trolling motor n. Position the

transducer to so its face is pointing straight down when the trolling motor is in the water.

Cable ties Cable ties

Hose

clamp

Hose

clamp

Transducer

Route the transducer cable along the trolling motor shaft. Use plastic ties (not included) to

secure the cable to the shaft.

27

Page 29

System Architecture

This section explains how the HDS connects to other devices as part of a system. The

HDS has a highly scalable system architecture. A system can consist of a basic stand alone

shnder or chart plotter, or expand to a networked, multi-display system connected to a wide

range of accessories.

Networking, Data Interfacing

The HDS display can connect to other devices in the system by Ethernet, NMEA 2000 or

NMEA 0183.

Ethernet: (NETWORK Ports)

HDS uses an Ethernet network for the transfer of high bandwidth data between other HDS

displays and from network modules such as Radar and weather modules.

Each HDS display has an Ethernet network port.

Ethernet does not transfer navigation data such as position, heading etc. This is handled either

by NMEA 0183 or NMEA 2000. However navigation and display settings are synchronized

over Ethernet.

NMEA 2000

NMEA 2000 is an industry standard for marine communications for transfer of navigation

data such as wind, Position, AIS, etc between all NMEA 2000 devices on a network.

NMEA 2000 is lower bandwidth than the Ethernet network, but is 50 times faster than NMEA

0183

NMEA 0183

NMEA 0183 is a point to point connection using RS422 or RS232 protocol.

HDS5” & 7” displays have one NMEA 0183 port enabling them to output to one NMEA 0183

“Listener” and receive from one NMEA 0183 “Talker”, (RS422)

HDS8” & 10” displays have two NMEA 0183 ports enabling them to output to two NMEA

0183 “Listeners” and receive from two NMEA 0183 “Talkers” This can be congured to

either 1 x RS422 port or 2x RS232,

Note: The Baud rate setting for transmit and receive is xed for each port. ie. 38400 in,

38400 out.

28

Page 30

Wiring the HDS

Wiring Guidelines

Most installation problems are caused by shortcuts taken with system cables. When wiring the

HDS follow the guidelines below.

Don’t do this Do this

Don’t make sharp bends in the cables Do make drip and service loops

Don’t run cables in a way that allows water

to ow down into the connectors

Don’t route the data cables in areas adjacent

to radar, transmitter, or large current

carrying cables

Before starting the installation, be sure to turn electrical power off. If power is

left on or turned on during the installation, re, electrical shock, or other serious

injury may occur. Be sure that the voltage of the power supply is compatible

with the HDS display.

The HDS has a voltage rating of 10-19V DC.

The red wire should always be connected to (+) DC V using a fuse or thermal

breaker (10 Amp)

Do tie-wrap all cables to keep them secure

Do leave room at the back to install and

remove cables

29

Page 31

Power/Data Cable

12 V DC

Red (FUSE)

Black

Yellow

(Accessory Wake Up)

+

_

Yellow TX (+)

Data cable (5 wire)Power (3 wire)

NMEA0183 Wiring

RS-422 All HDS Units

Alternative NMEA0183 Wiring

RS-232 HDS 8 & HDS 10

Com 1

Power / Data cable

BLUE TX (-)

Orange (RX+)

Green (RX-)

Shield (ground)

Yellow (TX)

Com 1

Common

BLUE (TX)

Orange (RX)

Green (RX-)

Shield (ground)

Com 2

The power cable from each device contains a yellow wire. The yellow wire is the accessory

wake up line. Connect the yellow wires together. When the accessory wake up line is used to

connect units with the accessory wake up feature, you can power up certain connected devices

from one location, including StructureScan and expansion ports.

The Data cable wires are used for the NMEA 0183 and RS-422 hook up; also, RS-232 and

RS-422 for HDS-8 and HDS-10 models.

30

Page 32

NMEA 0183 Wiring Table

RS-422

HDS Device

Green RX (-) Transmit (-)

Orange RX (+) Transmit (+)

Shield (Ground) Ground

Yellow TX (+) Receive (+)

Blue TX (-) Receive (-)

RS-232 HDS-8 & 10 Only — (COM 1)

HDS Device

Yellow TX Receive

Orange RX Transmit

Shield (Ground) Ground

RS-232 HDS-8 & 10 Only — (COM 1)

HDS Device

Blue TX Receive

Green RX Transmit

Shield (Ground) Ground

NMEA 0183 wiring

HDS-5 & HDS-7 Data Cable

To exchange NMEA 0183 data, the HDS-5 and HDS-7 units have a NMEA 0183 version 2.0

(RS-422) communication port. Serial Communications Port one can be used to transmit or

receive NMEA format data. The ve wires for the serial communications ports (Data cable)

are combined with the Power cable to form the Power/Data cable.

HDS-8 & HDS-10 Data Cable

To exchange NMEA 0183 data, the HDS-8 and HDS-10 units have either one NMEA0183

version 2.0 (RS-422) communication port, or two NMEA 0183 (RS-232) communication

ports. The ve wires for the serial communications ports (Data cable) are combined with the

Power cable to form the Power/Data cable.

31

Page 33

NMEA 2000 wiring

All NMEA 2000 systems must consist of 12V power, two (2) 120 Ohm terminators (one on

each end of the network), T joiners and NMEA 2000 Devices.

Lowrance offers a NMEA 2000 starter kit (000-0124-69) that includes two (2) terminators,

two (2) T connectors, one (1) 2ft extension/drop cable, one (1) 15ft extension cable and one

(1) power node.

32

Page 34

Ethernet

1

5

4

3

2

The HDS system uses an Ethernet network to interconnect high bandwidth devices such as

other HDS displays, radar and sonar. Each HDS display has one network port with 5 pin

connector. Ethernet network has orange connectors that are retained by a bayonet type locking

collar.

If more than two network devices need to be connected, use the optional Network Expansion

Port (NEP). which will allow for the connection of up to ve ethernet devices or a

StructureScan module which will allow for the connection of up to three ethernet devices.

Ethernet connector

Pin Function

1 TX +

2 TX -

3 RX +

4 RX -

5 GND

The Ethernet connection carries sonar, Structurescan and radar data between two or more

displays. Sonar data (water,speed, depth and temperature) is bridged onto the Ethernet bus.

Sonar data is only bridged if network sonar is turned on. Below is an example of sonar data

being shared between two displays.

33

Page 35

HDS-8 & HDS-10 Data Bridging

Power / Data cable

Power / Data cable

NMEA 2K

NMEA 2K Network NMEA 2K Network

HDS HDS

NMEA 2K

Yellow TX (+)

NMEA0183 Talker NMEA0183 Listner

BLUE TX (-)

Orange (RX+)

Green (RX-)

Shield (ground)

Yellow TX (+)

BLUE TX (-)

Orange (RX+)

Green (RX-)

Shield (ground)

0183 0183

N2K N2K

A

B

C

Supported NMEA0183 sentences entering the system are bridged (converted) to NMEA2000

and distributed on the Lowrance backbone for all other displays to use.

Certain NMEA2000 PGNs (messages/sentences) are bridged across to NMEA0183 to be

available as an output from any HDS display.

Refer to the NMEA 0183 table in the back of this manual to view bridgable sentences.

34

Page 36

Single Station

10 - 17 V DC

Red (FUSE)

Black

Y

ellow

+

_

Blue

No Connect

Single station configuration possibilities

Supplied

with display

Optional

accessory

HDS Display

POWER

NMEA0183

Wake up wire

Used to turn on

accessories

Power/Data Cable

NMEA2000

OR

RADAR

StructureScan

LSS-1*

BR24 BroadBand Radar

Pulse Radar

LRA-1800 or LRA-2400

Sirius Weather Module

LWX-1

LNK/ACT

NMEA2000 Devices

LGC-4000 GPS Receiver

Temperature Sensor

Fluid Level Sensor

Fuel Flow Sensor

Pressure Sensor

Heading Sensor/Compass

Engine Interface

SonicHub Audio Server

LMF Gauges

VHF Radio

12v

* Radar interface box not included

with US version of BR24

RS-422

HDS Device

Green RX (-) Transmit (-)

Orange RX (+) Transmit (+)

Shield (ground) Ground

Yellow TX (+) Receive (+)

Blue TX (-) Receive (-)

RS-232 HDS-8/10 only

HDS Device

Orange RX Transmit

Shield (ground) Ground

Yellow TX Receive

Blue TX Receive

GroundShield (ground)

Com 1

Com 2

Green RX Transmit

HDS Device

Skimmer

transducer included

with most HDS

LOWRANCE StructureScan™

*To use more than one Ethernet

accessory you need either a LSS-1

StructureScan module or a NEP-2

Expansion port.

35

Page 37

Dual & Multi Station

NMEA0183

Power/Data Cable

RS-422

HDS Device

Green RX (-) Transmit (-)

Orange RX (+) Transmit (+)

Shield (ground) Ground

Yellow TX (+) Receive (+)

Blue TX (-) Receive (-)

RS-232 HDS-8/10 only

HDS Device

Orange RX Transmit

Shield (ground) Ground

Yellow TX Receive

Blue TX Receive

GroundShield (ground)

Com 1

Com 2

Green RX Transmit

HDS Device

Supplied

with display

Optional

accessory

Dual station configuration possibilities

OR

BR24 BroadBand Radar

Pulse Radar

LRA-1800 or LRA-2400

* Radar interface box not included

with US version of BR24

NMEA2000

12v

Sirius Weather

Module

LWX-1

StructureScan

LSS-1*

LNK/ACT

LOWRANCE StructureScan™

LNK/ACT

Network Expansion

Port

NEP-2

NMEA2000 Devices

LGC-4000 GPS Receiver

Temperature Sensor

Fluid Level Sensor

Fuel Flow Sensor

Pressure Sensor

Heading Sensor/Compass

Engine Interface

SonicHub Audio Server

LMF Gauges

VHF Radio

Network Expansion Port -2

36

Page 38

Connecting HD Radar

12 V DC ONLY

+

_

B

C

D

D

E

G

G

LL

J

KK

H

I

A

Ethernet

Scanner

HEADING In

F

Key Description

A

B

HDS Display.

LRA1800 &LRA2400 HD radar system for HDS. Includes parts C,D and E. 2kw &

4 kW Radome.

C

Scanner cable. 15 m (50 ft) An Optional 20 m (65ft) cable is available

D

HD Radar Processor

E

Ethernet cable RJ45 (male/male). Available in 2, 5 and 10 m, (6.5, 16.5 & 33 ft)

F

Ethernet Adapter cable. Yellow 5 pin (Male) to RJ45 (female) 2 m (6 ft). The HD

radar can be connected directly to HDS or via a Network Expansion Port (H).

G

HDS and Radar Power. Make sure a fuse is used. See radar installation manual for

radar fuse size

H

Optional NEP (Network Expansion port) (000-0132-031)

For Chart overlay or MARPA the following are required:

I

AT10HD Fast heading NMEA2000 to NMEA0183 converter. (24006694)

J

RC42 Compass (Heading)

K

SimNet to NMEA2000 adapter kit (000-0127-45)

L

NMEA 2000 Backbone

37

Page 39

Connecting BR24 Radar

+

_

D

F

F

J J

G

I I

H

A

E

B

C

D

Power

Scanner cable

SimNet

Network

Key Description

A HDS Display.

B BR24 BroadBand™ Radar system for HDS. Includes parts B, C and D (not included

in US) and E (2 m 6ft)

C Scanner cable. 10 m (33 ft) : Optional 20 m (65 ft) and 30 m (98 ft).

D RI10 Radar interface box (Used with MARPA) (Not included with US version)

E Ethernet cable. BR24 comes with a 2 m (6.5 ft) 5 pin cable and a RJ45 cable (US

F Power control bus: In this case BR24 is connected to Power Control Bus. BR24 is

G RC42 Compass

H LSS1 - StructureScan black box

I SimNet drop cable: (0.3 m 1ft, 2 m 6ft or 5 m 15ft ) The RI10 interface box and

J SimNet to NMEA2000 adapter kit (000-0127-45)

K NMEA2000 Backbone

only) The BR24 can be connected directly to HDS or via a Network Expansion Port

(G)

turned on when the HDS is powered on. Note the yellow wire must be connected to

either the power control bus or to 12 V DC supply)

HDS are connected to the NMEA2000 backbone. BR24 requires heading at 10 hz

to calculate MARPA

38

Page 40

Commissioning Check List

Commissioning your system will improve the functionality and operation of your unit.

The following pages will give you an overview of the minimum settings we recommend you

set up before you start operating your HDS.

Please refer to the HDS operations guide for more information on how to change these

settings.

Language

Select the language used on menus and dialog boxes. The default language is English.

Units

Select which unit type you would like the HDS to display data in.

Time

Change local time to offset differences in time zone and to select the way time and date will

be displayed.

Note: The time and date will automatically set itself via the internal GPS antenna upon

initial startup, or reset.

Data Source

An advanced feature that allows you to use data from a network data source or data from a

sensor connected to your unit.

If, for example, you do not want to use your unit’s internal GPS antenna, you could use an

external GPS antenna connected to an ethernet or NMEA 2000 network.

Sonar Setup

To ensure proper sonar operation you need to select the proper transducer from the sonar

installation menu. This helps the HDS determine what settings and features will be available

in order to properly work with your transducer. To do this press Menu-Menu-InstallationTransducer type- then select the appropriate transducer.

The HDS comes with either a 83/200kHz HST-WSBL, 50/200kHz HST-DFSBL, or if you

purchased a unit with no transducer select the appropriate one off of the drop down list.

The next step to ensure that your sonar is set up properly is to select the appropriate shing

mode for the depth of water you operate in and the type of shing that you are doing. These

shing modes set the HDS to use different ping speeds, bottom search ranges and color pallets

to optimize it for your type of shing.

39

Page 41

Selecting a Fishing Mode

Fishing modes enhance the performance of your unit by providing preset packages of sonar

settings geared to specic shing conditions.

To select a shing mode: Press Menu twice. Select Sonar and press enter. Highlight Fishing

Mode and press enter. Select the desired shing mode and press enter.

Fishing Mode Depth Settings Palette

General Use ≤1,000 ft 50% Ping speed

Shallow Water ≤ 60 ft 75% Ping speed

Fresh Water ≤ 400 ft 50% Ping speed

Deep Water ≥ 1,000 ft 50% Ping speed Deep Blue

Slow Trolling ≤ 400 ft 50% Ping speed

Fast Trolling ≤ 400 ft Lower chart speed

Clear Water ≤ 400 ft 50% Ping speed

Brackish

Water

≤ 400 ft

Higher ASP;

Lower chart speed

Bottom brown/ blue

background

bottom brown/white

background

bottom brown/white

background

Bottom brown/white

background

Bottom brown/white

background

Bottom brown/white

background

Bottom brown/blue

background

Entering Letters in Text Boxes

This unit has some features and functions that may require you to enter data in a text box.

To enter data in a text box:

Highlight the text box and press ENTER. A keyboard will appear on the screen.

Use the keypad to highlight the rst character and press ENTER. Repeat this step until all

characters have been entered. Highlight OK and press enter.

Datum

A model of the earth’s surface based on a network of surveyed ground features (points). This

unit’s default datum is WGRS-84.

Coord System

Controls the coordinate system used when position coordinates are entered and displayed.

40

Page 42

Magnetic Variation

A B C

Converts magnetic north data to true north, increasing the accuracy of navigation information.

The Magnetic Variance Auto setting, automatically converts magnetic north to true north.

Note: When using manual mode, you will have to input the magnetic variance.

Satellites

Monitors the location of satellites in view and the quality of the unit’s satellite lock-on. The

Satellite page has two display options.

The Satellite screen displays a circular graphic that shows where satellites are located and a

bar graph that monitors the strength of satellites within range of your unit. Your unit is locked

on to satellites shown with blue bars.

Sonar

Depth offset

Is a value that can be entered to make the depth on the Sonar page represent either depth

below the transducer or depth below the surface.

The depth offset can be found via Menu, Settings, Sonar, Installation.

A: Depth below Keel value: Is the distance from transducer to the keel.

Enter a negative value.

B: Depth Below Transducer: no offset required.

C: Depth Below Surface (waterline) value: Is the distance from transducer to the surface.

Enter a positive value.

41

Page 43

Water speed off set

Water speed calibration is used to adjust the speed value from the paddle wheel to match

the actual speed. This can be measured either from the GPS speed over ground (SOG) or by

timing the boat over a known distance. Water speed calibration should be performed with as

little wind and current movement as possible.

Select Auto correct to match water speed to ground speed

Manual calculation. If in average the water speed reads 8.5 knots and SOG records 10 knots.

Increase the offset to 117%. The calculation is:

Difference in speed

Paddle wheel speed

If water speed is lower than SOG then increase the calibration value.

Default is 100 % with ability to calibrate to +/-20%.

x 100.

42

Page 44

Dimensional Drawings

184 mm (7.24")

145.4 mm (5.72")

151.8 mm (5.97")

30 mm (1.18") 58 mm (2.28")

56.9 mm (2.24")

HDS5

43

Page 45

HDS7

223 mm (8.78")

163.9 mm (6.45")

196.9 mm (7.75")

30.79 mm (1.21")

57.5 mm (2.26")

60 mm (2.36")

44

Page 46

HDS8

1

1

269 mm (10.59")

197.2 mm (7.76")

205.9 mm (8.11")

31.4 mm (1.24")

61 mm (2.4")

64 mm (2.52")

45

Page 47

HDS10

311.8 mm (12.28")

34.3 mm (1.35")

229.3 mm (9.03")

64 mm (2.52")

58 mm (2.28")

224.9 mm (8.85")

46

Page 48

NMEA Information

NMEA 2000 PGN List

NMEA 2000 PGN Transmit

126208 ISO Command Group Function

126992 System Time

126996 Product Info

127237 Heading/Track Control

127250 Vessel Heading

127258 Magnetic Variation

128259 Speed, Water referenced

128267 Water Depth

128275 DistanceLog

129025 Position, Rapid Update

129026 COG & SOG, Rapid Update

129029 GNSS Position Data

129283 Cross Track Error

129284 Navigation Data

129539 GNSS DOPs

129540 GNSS Sats in View

130074 Route and WP Service - WP List

- WP Name & Position

130306 Wind Data

130310 Environmental Parameters

130311 Environmental Parameters

130312 Temperature

130577 Direction Data

61184 Parameter Request/Command

130840 Data User Group Conguration

130845 Parameter Handle

130850 Event Command

65287 Congure Temperature IHDScts

65289 Trim Tab IHDSct Calibration

65290 Paddle Wheel Speed

Conguration

65292 Clear Fluid Level Warnings

65293 LGC-2000 Conguration

130818 Reprogram Data

130819 Request Reprogram

130828 Set Serial Number

130831 Suzuki Engine and Storage

Device Cong

130835 Set Engine And Tank

Conguration

130836 Fluid Level IHDSct

Conguration

130837 Fuel Flow Turbine Conguration

130839 Pressure IHDSct Conguration

130845 “Weather and Fish Prediction and

Barometric Pressure History”

130850 Evinrude Engine Warnings

47

Page 49

NMEA 2000 PGN Receive

59392 ISO Acknowledgement

59904 ISO Request

60928 ISO Address Claim

60928 ISO Address Claim

126208 ISO Command Group Function

126992 System Time

126996 Product Info

127237 Heading/Track Control

127245 Rudder

127250 Vessel Heading

127251 Rate of Turn

127257 Attitude

127258 Magnetic Variation

127488 Engine Parameters, Rapid Update

127489 Engine Parameters, Dynamic

127493 Transmission Parameters,

Dynamic

127505 Fluid Level

127508 Battery Status

128259 Speed, Water referenced

128267 Water Depth

128275 DistanceLog

129025 Position, Rapid Update

129026 COG & SOG, Rapid Update

129029 GNSS Position Data

129033 Time & Date

129038 AIS Class A Position Report

129039 AIS Class B Position Report

129040 AIS Class B Extended Position

Report

129283 Cross Track Error

129284 Navigation Data

129539 GNSS DOPs

129540 GNSS Sats in View

129794 AIS Class A Static and Voyage

Related Data

129801 AIS Addressed Safety Related

Message

129802 AIS Safety Related Broadcast

Message

129808 DSC Call Information

130074 Route and WP Service - WP List

WP Name & Position

130306 Wind Data

130310 Environmental Parameters

130311 Environmental Parameters

130312 Temperature

130313 Humidity

130314 Actual Pressure

130576 Small Craft Status

130577 Direction Data

61184 Parameter Request/Command

65323 Data User Group Request

65325 Reprogram Status

65341 Autopilot Mode

65480 Autopilot Mode

130840 Data User Group Conguration

130842 SimNet DSC Message

130845 Parameter Handle

130850 Event Command

130851 Event Reply

65285 Temperature with Instance

65292 Clear Fluid Level Warnings

65293 LGC-2000 Conguration

130817 Product Info

130820 Reprogram Status

130831 Suzuki Engine and Storage

Device Cong

130832 Fuel Used - High Resolution

130834 Engine and Tank Conguration

130835 Set Engine And Tank

Conguration

130838 Fluid Level Warning

130839 Pressure IHDSct Conguration

130843 Sonar Status, Frequency and DSP

Voltage

48

Page 50

Supported NMEA 0183 sentences

TX / RX GPS

Receive GGA GLL GSA GSV VTG ZDA

Transmit GGA GLL GSA GSV VTG ZDA

Navigation

Receive RMC

Transmit AAM APB BOD BWC BWR RMC RMB XTE

Echo

Receive DBT DPT MTW VLW VHW

Transmit DBT DPT MTW VLW VHW

Compass

Receive HDG HDT HDM

Transmit HDG

Wind

Receive MWV MWD

Transmit MWV

AIS / DSC

Receive DSC DSE VDM

Transmit TLL TTM These are only out put sentences

AIS sentences are not bridged

MARPA

49

Page 51

Page 52

Visit our website:

www.lowrance.com

*988-10043-001*

© Copyright 2011

All Rights Reserved

Navico Holding AS

Loading...

Loading...