Lowell RRD-14 Specifications

Model: RRD-series

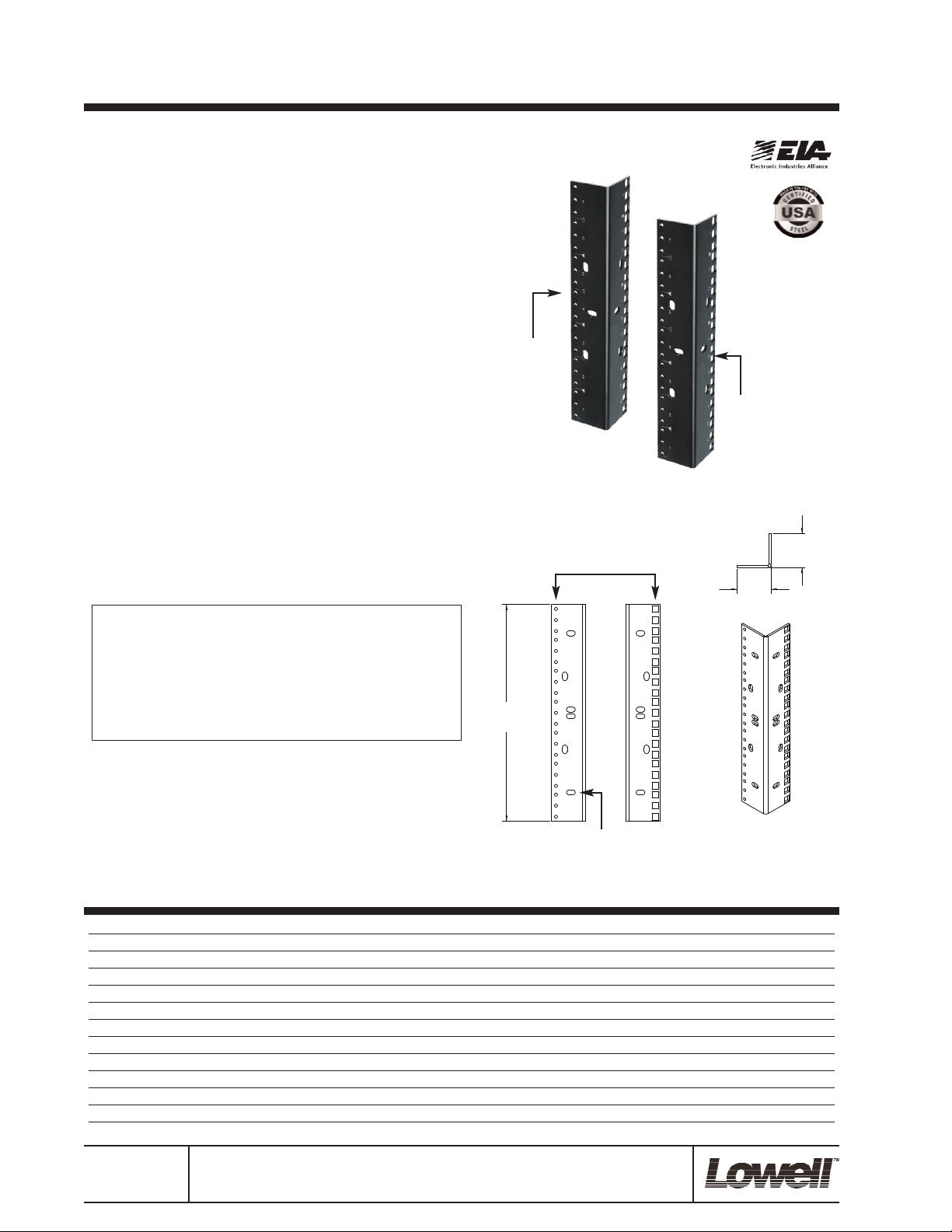

A

1

.938

1.937

Rack Railswith Dual-hole pattern

escription:

D

The RRD-series of reversible mounting rails were designed to accommodate different types of hardware on a single rail. The dual-

ole pattern rails are tapped on one side (to accept threaded

h

10-32 screws) and square-punched on the other side (to accept

12-24, 6mm, or 10-32 hardware with cage nuts). The rails also

feature a printed scale showing rack unit increments to facilitate

set-up. The easy-to-read rack units and symbols for 1U and 2U

loading patterns are printed on both the tapped and punched side

of each rail. The 1U position should always be placed at the bottom of the rack to facilitate consistent loading of equipment. The

flip side of the rail (tapped or punched) can be used to mount rack

accessories or to manage wires and cables. Rails are made from

sturdy 11-gauge steel and have a black powder epoxy finish.

Features:

• Rails include fixed hole positions to secure the rail during

transportation or on the job site when forward/backward movement of rails (and loaded equipment) is not desired.

• 11-gauge steel

• Black powder epoxy finish

• Made in the USA with 100% certified US steel

• For use with Lowell rack models LER, LER-F, LGR, LSER,

LSER-F, LSGR, LPR, LPPR, and LWR.

• Sold in pairs

Tapped holes will

accept 10-32

screws.

Typical EIA spacing.

Square punched holes

will accept 12-24, 6mm

or 10-32 hardware with

cage nuts.

1.938"

1.937"

Note: If a full size rail is not needed for racks 24U or taller (e.g.

extra support is only needed for equipment at the top or bottom of the rack), order rack rail model no. RRD-21. This short

rail is unique in that its hole pattern is designed to align not

only with 21U racks but also with the top or bottom of taller

racks. This provides an economical way to support the rear of

rackmounted equipment when a full size rail is not needed.

“A”

A & E Specifications:

Additional mounting rails for the rack shall be Lowell Model No.

________. The rails shall be fabricated from 11-gauge steel and

have a black powder epoxy finish. Each rail shall measure ___

rack units and be tapped on one side to accept threaded 10-32

screws and square-punched on the other side to accept 12-24,

Position of inner rounds and obrounds

will vary depending on overall rail height.

6mm or 10-32 hardware with cage nuts. The rails shall also feature a printed scale showing rack unit increments.

Model No. Description Former No. Overall H (RU)* Overall H (in.) Overall H (mm) Pkg Qty

RRD-7 Rack Rails with Dual-hole pattern L212-12 7 12.25 311 1-pr.

RRD-10 Rack Rails with Dual-hole pattern L212-17 10 17.50 445 1-pr.

RRD-12 Rack Rails with Dual-hole pattern L212-21 12 21.00 533 1-pr.

RRD-14 Rack Rails with Dual-hole pattern L212-24 14 24.50 622 1-pr.

RRD-16 Rack Rails with Dual-hole pattern L212-28 16 28.00 711 1-pr.

RRD-18 Rack Rails with Dual-hole pattern ---- 18 31.50 800 1-pr.

RRD-21 Rack Rails with Dual-hole pattern L212-36 21 36.75 933 1-pr.

RRD-24 Rack Rails with Dual-hole pattern L212-42 24 42.00 1067 1-pr.

RRD-35 Rack Rails with Dual-hole pattern L212-61 35 61.25 1556 1-pr.

RRD-40 Rack Rails with Dual-hole pattern L212-70 40 70.00 1778 1-pr.

RRD-44 Rack Rails with Dual-hole pattern L212-77 44 77.00 1956 1-pr.

*One rack unit = 1.75"

Spec. No. 1030

(rev. 02.07.12)

pg. 1 of 1

©2012 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069. Phone–800.325.9660

Fax—636.257.6606. Lowell makes every effort to provide accurate information while reserving the right to

change specifications and/or improve manufacturing methods without notification. (lowellmfg.com)

Loading...

Loading...