Lowell LUH-15TI User Manual

Model: LUH-15TI (for intercom use)

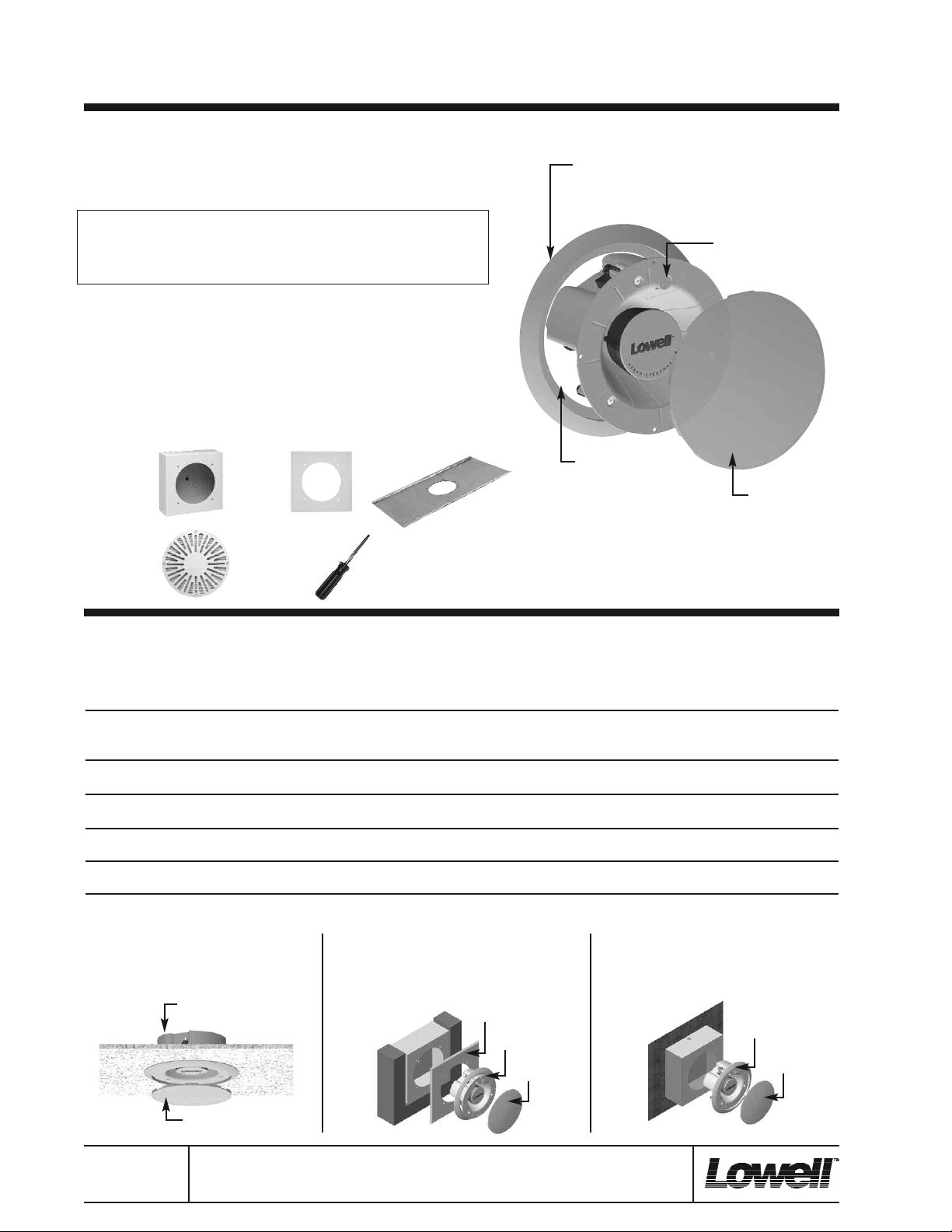

INSTRUCTIONS: UNIHORN®LUH-15TI

The UNIHORN®(model LUH-15TI for intercom use) is designed to mount

indoors or outdoors in either recessed or surface-mount applications. It can

be mounted with or without the trim ring and press-fit grille (included). In-

tallation should conform to all Federal, state and local codes and should

s

only be made by qualified service personnel.

Note: The LUH-15TI is designed for use in a talkback intercom system

and DOES NOT include a DC blocking capacitor that would be required

for speaker line supervision in a life safety system. See model LUH-15T

for life safety use.

UNIHORN

• Aluminum re-entrant horn with 70V/25V transformer (LUH-15TI)

• Aluminum trim ring: 9.6" dia. with 7.25" center cutout.

• Press-fit aluminum grille.

Tools Needed: (not included)

• Screwdrivers and tools for electrical connections.

Optional Accessories: (order separately)

®

Carton Includes: (1 ea.)

Trim ring ships with horn. It

can be discarded for installations

that do not use the press-fit

aluminum grille.

Transformer settings on

horn can be adjusted

front or rear.

LUH-BOX:

stainless steel

backbox (10.5"

sq. x 4"D)

LUH-VRG:

cast-aluminum

vandal-resistant

grille (9.6" dia.)

LUH-TP:

trim plate

(11.5" sq.)

HRP832: spannerhead screwdriver

for use with 8-32

spanner screws.

LUH-TBAR:

tile bridge

Inside diameter of trim

ring (7.25") can be used

as a cutout template.

Press-fit

aluminum grille.

Installation Methods / Accessories: the UNIHORN®can be mounted with or without the trim ring and press-fit grille. In addition, the horn features

standard screw holes that will fit the optional LUH-VRG vandal-resistant grille or any standard 8" (screw-type) speaker grille. The LUH-VRG installs

with spanner-head screws and screwdriver. Standard grilles screw-mount to the UNIHORN

®

and fit various backboxes. See individual product spec

sheets for more information on standard 8" speaker grilles and backboxes.

Installation Method Grille Backbox / Trim Plate T-bridge

Open Installation No grille N/A N/A

Press-fit aluminum grille* N/A N/A

LUH-VRG vandal-resistant grille* N/A N/A

Drywall Press-fit aluminum grille No backbox N/A

LUH-VRG vandal-resistant grille No backbox N/A

Lay-in Tile Ceiling Press-fit aluminum grille No backbox LUH-TBAR**

LUH-VRG vandal-resistant grille No backbox LUH-TBAR**

Masonry Press-fit aluminum grille LUH-BOX (recessed) + LUH-TP trim plate N/A

LUH-VRG vandal-resistant grille LUH-BOX (recessed) + LUH-TP trim plate N/A

Surface-mount Press-fit aluminum grille LUH-BOX (surface) N/A

LUH-VRG vandal-resistant grille LUH-BOX (surface) N/A

*Tighten dog ears to hold trim ring in place. **T-bridge is recommended for acoustic tile ceilings.

Lay-in Tile Ceiling or Drywall: horn with trim

ring clamps to ceiling (tile bridge is recommended

for acoustic tile). Grille press-fits to horn assembly. No visible screws.

Clamp horn with trim

ring to ceiling.

Press-fit grille to horn.

No. i-201

(rev. 02.15.11)

pg. 1 of 2

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069. Phone–800.325.9660 Fax—

636.257.6606. Lowell makes every effort to provide accurate information while reserving the right to change

specifications and/or improve manufacturing methods without notification. (lowellmfg.com)

Masonry: 10.5" sq. x 4"D stainless steel backbox

mounts into masonry wall. LUH-TP trim plate screws to

backbox. Horn with trim ring clamps to trim plate (trim

ring covers screws). Grille press-fits to horn assembly.

Recess-mount

LUH-BOX to

masonry wall.

Screw LUH-TP trim

plate to backbox.

Clamp horn with

trim ring to plate.

Press-fit

grille to horn.

Surface-mount: 10.5" sq. x 4"D stainless steel

backbox surface-mounts to wall. Horn with trim ring

clamps to box (ring covers unused screw holes).

Grille press-fits to horn assembly.

Surface-mount

LUH-BOX

to wall.

Clamp horn with

trim ring to box.

Press-fit

grille to horn.

Model: LUH-15TI (for intercom use)

INSTRUCTIONS: UNIHORN®LUH-15TI

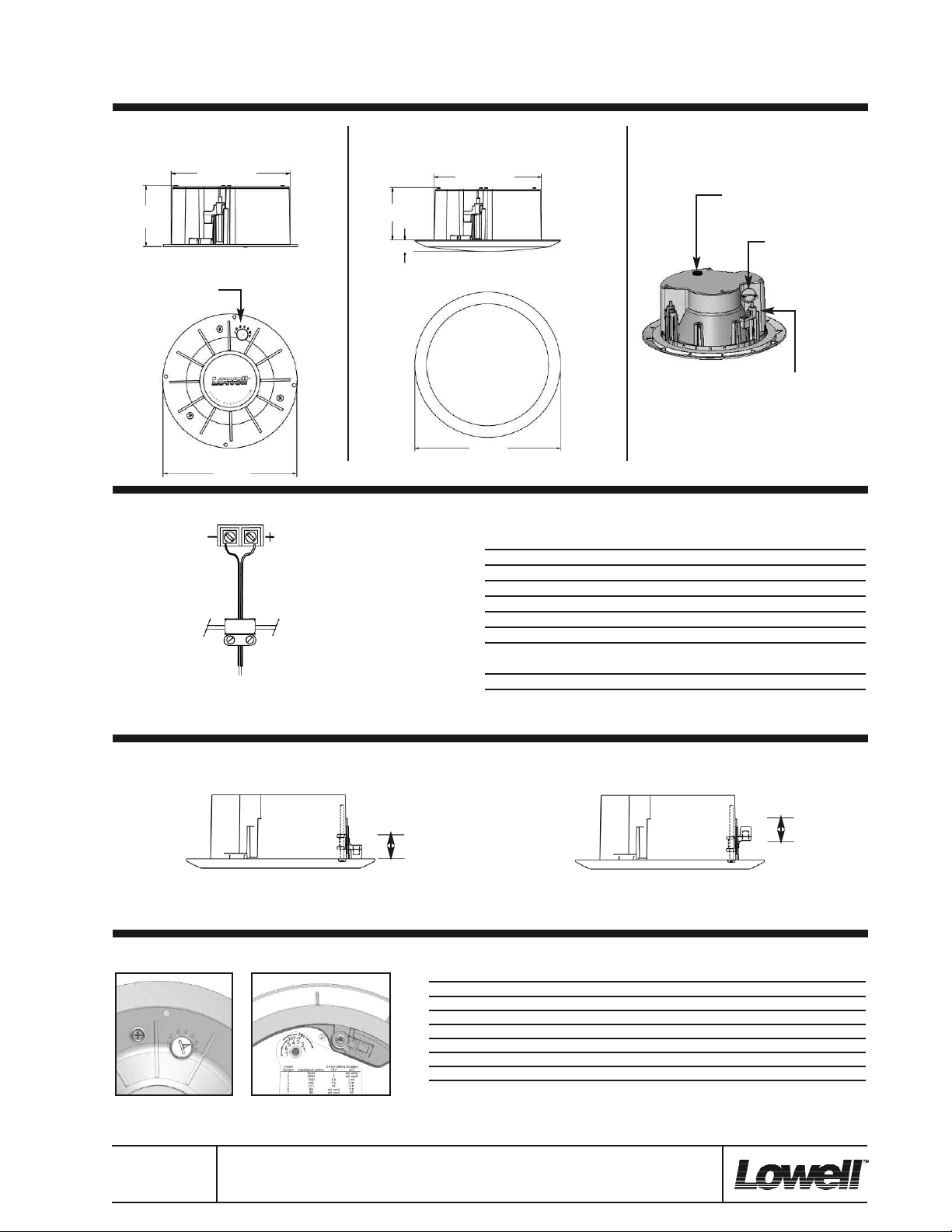

HORN ASSEMBLY

without trim ring/grille

.72"

3

Transformer is

adjustable on

front and rear.

Connections:

Model LUH-15TI ships ready for

hookup with a 2-conductor cable

exiting through a rear cable clamp.

7.1" housing

7.25" cutout

8.0"

Black

White stripe

HORN ASSEMBLY

with trim ring/grille.

7.1" housing

7.25" cutout

3.3"

.77"

0

Installed depth is less with the trim ring/grille as the

trim ring overlaps and extends beyond horn face.

9.6"

Specifications:

Model No. LUH-15TI

Power Rating: 15W

Frequency Response: 740Hz - 7.4kHz +/- 6dB

Dispersion: 80˚

SPL: 105dB 1W/1M, 101dB 15W/10-ft., 106dB 15W/10-ft.*

Calculated Max SPL: 116.8dB 15W/1M

Impedance: OHMS: 5000, 2500, 1300, 666, 333, 89, 45

Power Taps: 25V@ .48, .94, 1.8, 7.5, 15W

Size: 7.1" rear dia., 8" face dia., 3.72"D, 9.6" dia. grille

* 3dB increment rating with a sweep sine-wave signal source flat weight SPL meter.

REAR CONNECTION

Rear-access transformer

taps are protected by a

rubber plug.

Two-wire connection

secures through a

metal clamp.

Three adjustable

clamps swing out

to provide laborsaving installation.

70V@ .9, 1.8, 3.8, 7.5, 15W

Mounting Clamps: LUH-15TI ships with screwdriver-adjustable clamps.

CLAMPS (as shipped): The out-of-box position of clamps

will accept depths of 0–1.5" (approx).

Transformer Settings:

Switch Watts@ SPL@10ft. Watts@ SPL @10-ft

Position Impedance 70V 70V 25V 25V

1 5000 0.9 94dB* NOT USED --2 2500 1.8 97dB* NOT USED --3 1300 3.8 100dB* 0.48 91dB*

4 666 7.5 103dB* 0.94 94dB*

5 333 15 106dB* 1.8 97dB*

6 89 DO NOT USE** --- 7.5 102dB*

7 45 DO NOT USE** --- 15 105dB*

* 3dB increment rating with a sweep sine-wave signal source flat weight SPL meter.

Transformer adjustment

from front.

No. i-201

(rev. 02.15.11)

pg. 2 of 2

Transformer adjustment from

rear (under rubber plug).

** Note switch positions 6 and 7 ARE NOT USED on 70V applications. They exceed the

capacity of the driver and transformer and could damage or destroy the driver and/or amplifier.

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069. Phone–800.325.9660 Fax—

636.257.6606. Lowell makes every effort to provide accurate information while reserving the right to change

specifications and/or improve manufacturing methods without notification. (lowellmfg.com)

CLAMPS (reversed): The clamp position can be reversed by

installer to accept depths of 1"–2.125" (approx).

Loading...

Loading...