Lowell LUH-15T User Manual

Model: LUH-15T

INSTRUCTIONS: UNIHORN®LUH-15T

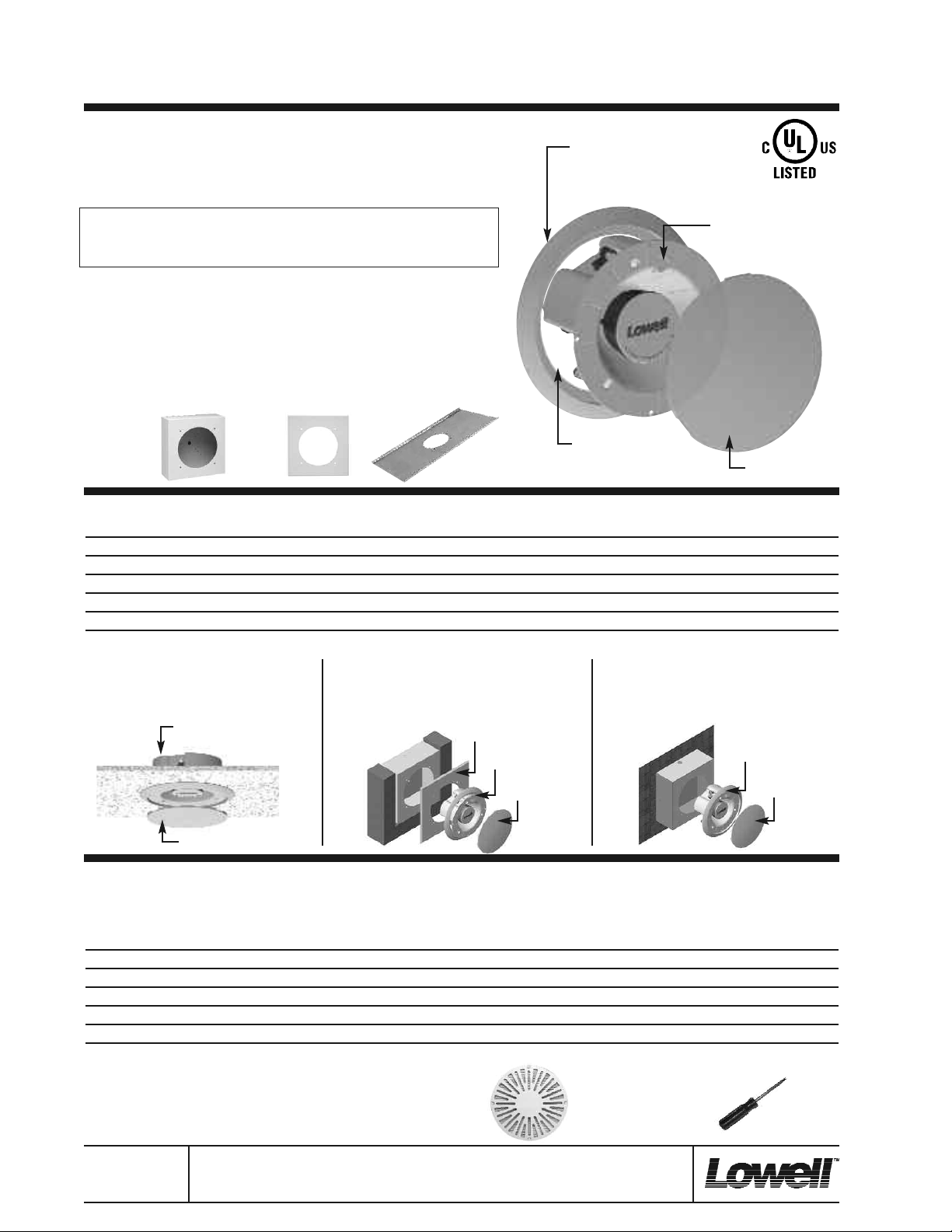

The UL Listed, universal-use UNIHORN®(model LUH-15T) is designed to

mount indoors or outdoors in either recessed or surface-mount applications.

It can be mounted with or without the trim ring and press-fit grille (included).

Installation should conform to all Federal, state and local codes and should

only be made by qualified service personnel.

Trim ring ships with horn. It

can be discarded for installations

that do not use the press-fit

aluminum grille.

NOTE: The LUH-15T includes a DC blocking capacitor that is required for

speaker line supervision in a life safety system, and therefore cannot be

used for a talkback intercom system. See model LUH-15TI for intercom use.

Transformer settings on

horn can be adjusted

front or rear.

UNIHORN®Carton Includes: (1 ea.)

• Aluminum re-entrant horn with 70V/25V transformer (LUH-15T).

• Aluminum trim ring: 9.6" dia. with 7.25" center cutout.

• Press-fit aluminum grille.

Tools Needed: (not included)

• Screwdrivers and tools for electrical connections.

Optional Accessories: (order separately)

LUH-BOX:

stainless steel

backbox (10.5"

sq. x 4"D)

LUH-TP:

trim plate

(11.5" sq.)

LUH-TBAR:

tile bridge

Inside diameter of trim

ring (7.25") can be used

as a cutout template.

Press-fit

aluminum grille.

UL Approved Installation Methods / Accessories:

Installation Method Grille Backbox / Trim Plate T-bridge

Open Installation Press-fit aluminum grille* OR no grille N/A N/A

Drywall Press-fit aluminum grille No backbox N/A

Lay-in Tile Ceiling Press-fit aluminum grille No backbox LUH-TBAR**

Masonry Press-fit aluminum grille LUH-BOX (recessed) + LUH-TP trim plate N/A

Surface-mount Press-fit aluminum grille LUH-BOX (surface) N/A

*Tighten dog ears to hold trim ring in place. **T-bridge is recommended for acoustic tile ceilings.

Lay-in Tile Ceiling or Drywall: horn with trim

ring clamps to ceiling (tile bridge is recommended

for acoustic tile). Grille press-fits to horn assembly. No visible screws.

Clamp horn with trim

ring to ceiling.

Masonry: 10.5" sq. x 4"D stainless steel backbox

mounts into masonry wall. LUH-TP trim plate screws to

backbox. Horn with trim ring clamps to trim plate (trim

ring covers screws). Grille press-fits to horn assembly.

Recess-mount

LUH-BOX to

masonry wall.

Screw LUH-TP trim

plate to backbox.

Clamp horn with

trim ring to plate.

Press-fit

grille to horn.

Surface-mount: 10.5" sq. x 4"D stainless steel

backbox surface-mounts to wall. Horn with trim ring

clamps to box (ring covers unused screw holes).

Grille press-fits to horn assembly.

Surface-mount

LUH-BOX

to wall.

Clamp horn with

trim ring to box.

Press-fit

grille to horn.

horn.

to

-fit grille

ress

P

Other Installation Accessories (not evaluated or approved by UL): the UNIHORN®also features standard screw holes that fit the LUH-VRG

vandal-resistant grille or any standard 8" speaker grille; however, these options have not been evaluated by UL. The LUH-VRG installs with spannerhead screws and screwdriver. Standard grilles screw-mount to the UNIHORN®and fit various backboxes. See individual product spec sheets for more

information on standard 8" speaker grilles and backboxes.

Installation Method Grille Backbox / Trim Plate T-bridge

Open Installation LUH-VRG vandal-resistant grille* OR no grille N/A N/A

Drywall LUH-VRG vandal-resistant grille No backbox N/A

Lay-in Tile Ceiling LUH-VRG vandal-resistant grille No backbox LUH-TBAR**

Masonry LUH-VRG vandal-resistant grille LUH-BOX (recessed) + LUH-TP trim plate N/A

Surface-mount LUH-VRG vandal-resistant grille LUH-BOX (surface) N/A

*Tighten dog ears to hold trim ring in place. **T-bridge is recommended for acoustic tile ceilings.

Optional Accessories: (order separately)

No. i-200

(rev. 02.15.11)

pg. 1 of 2

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069. Phone–800.325.9660 Fax—

636.257.6606. Lowell makes every effort to provide accurate information while reserving the right to change

specifications and/or improve manufacturing methods without notification. (lowellmfg.com)

LUH-VRG: cast-aluminum

vandal-resistant grille (9.6" dia.)

HRP832: spanner-head

screwdriver for use with

8-32 spanner screws.

Model: LUH-15T

INSTRUCTIONS: UNIHORN®LUH-15T

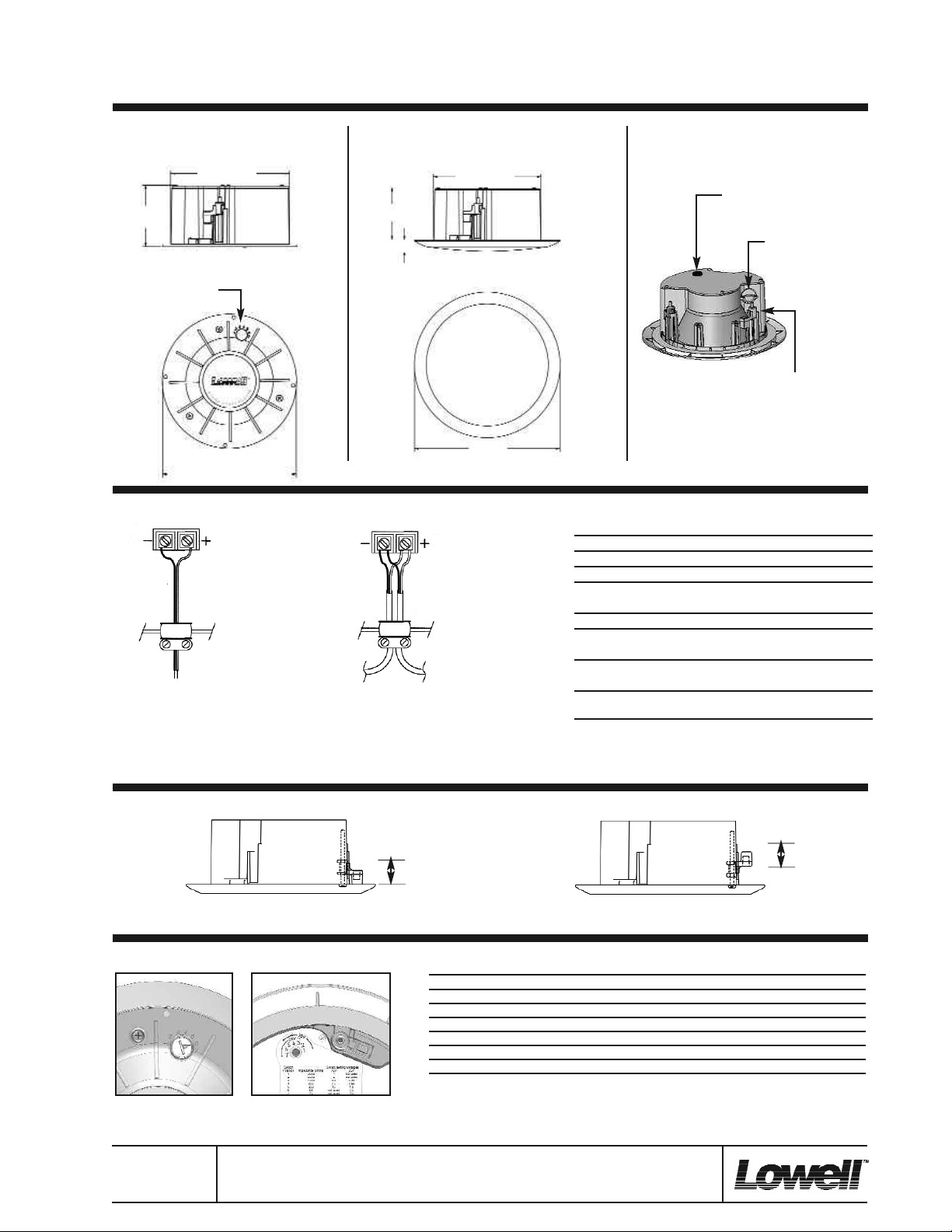

HORN ASSEMBLY

without trim ring/grille

7.1" housing

7.25" cutout

.72"

3

Transformer is

adjustable on

front and rear.

8.0"

Connections:

hite stripe

W

lack

B

Model LUH-15T ships ready for

hookup with a 2-conductor cable

exiting through a rear cable clamp.

HORN ASSEMBLY

with trim ring/grille.

7.1" housing

7.25" cutout

3.3"

.77"

0

Installed depth is less with the trim ring/grille as the

trim ring overlaps and extends beyond horn face.

9.6"

rom previous

F

speaker or amplifier.

For supervised system applications, the LUH-15T is equipped

with an internal series connected 250V DC blocking capacitor (10

uf NP) with maximum supervisory voltage of 100VDC. Connections for supervised systems typically utilize an “in/out” wiring

scheme to maintain supervision on all wiring external to the loudspeaker connections. Requires removal of rear cover to access

loudspeaker terminals.

To next speaker or

end-of-line resistor.

REAR CONNECTION

Rear-access transformer

taps are protected by a

rubber plug.

Two-wire connection

secures through a

metal clamp.

Specifications:

Model No. LUH-15T

Power Rating: 15W

Frequency Response: 740Hz - 7.4kHz +/- 6dB

Dispersion: 80˚

SPL: 105dB 1W/1M, 101dB 15W/10-ft.*,

106dB 15W/10-ft.**

Calculated Max SPL: 116.8dB 15W/1M

Impedance: OHMS: 5000, 2500, 1300, 666, 333,

89, 45

Power Taps: 25V@ .48, .94, 1.8, 7.5, 15W

70V@ .9, 1.8, 3.8, 7.5, 15W

Size: 7.1" rear dia., 8" face dia., 3.72"D,

* UL measured A weighted reverberant room sound power output

** 3dB increment rating with a sweep sine-wave signal source - flat weight SPL meter.

9.6" dia. grille

Three adjustable

clamps swing out

to provide laborsaving installation.

Mounting Clamps: LUH-15T ships with screwdriver-adjustable clamps.

CLAMPS (as shipped): The out-of-box position of clamps will

accept depths of 0–1.5" (approx).

Transformer Settings:

Transformer adjustment

from front.

No. i-200

(rev. 02.15.11)

pg. 2 of 2

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069. Phone–800.325.9660 Fax—

636.257.6606. Lowell makes every effort to provide accurate information while reserving the right to change

specifications and/or improve manufacturing methods without notification. (lowellmfg.com)

Transformer adjustment from

rear (under rubber plug).

Switch Watts@ SPL@10ft. Watts@ SPL @10-ft

Position Impedance 70V 70V 25V 25V

1 5000 0.9 90dB†94dB* NOT USED --2 2500 1.8 94dB

3 1300 3.8 97dB

4 666 7.5 99dB

5 333 15 101dB

6 89 DO NOT USE** --- 7.5 99dB

7 45 DO NOT USE** --- 15 101dB

* 3dB increment rating with a sweep sine-wave signal source flat weight SPL meter.

** Note switch positions 6 and 7 ARE NOT USED on 70V applications. They exceed the

capacity of the driver and transformer and could damage or destroy the driver and/or amplifier.

† UL measured A weighted reverberant room sound power output.

CLAMPS (reversed): The clamp position can be reversed by

installer to accept depths of 1"–2.125" (approx).

†

97dB* NOT USED ---

†

100dB* 0.48 86dB

†

103dB* 0.94 91dB

†

106dB* 1.8 93dB

†

91dB*

†

94dB*

†

97dB*

†

102dB*

†

105dB*

Loading...

Loading...