Lowell LPTR4-2123 Specifications

Manufacturing Company — Since 1947

LPTR-series (23"D, 4-slide)

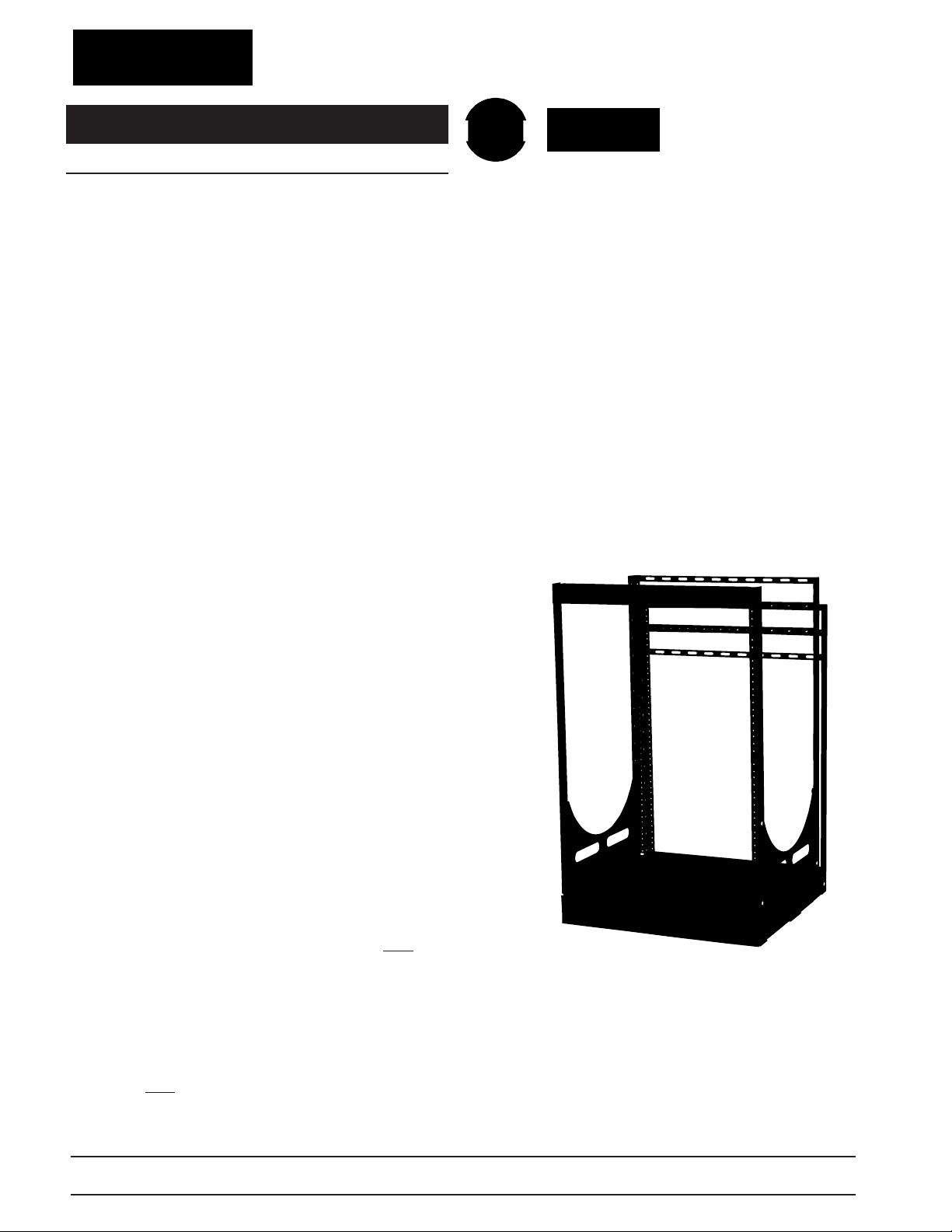

Lowell Pull & Turn Rack

Description:

Lowell's Pull & Turn Rack for built-in wall and millwork applications features a turntable on four, heavy-duty slides for smooth

pullout access to rackmounted equipment. Load capacity is 300

lbs. Sturdy system is engineered for efficient on-site installation

and packaged unassembled in two cartons so that the bottom

base (with slides and integral turntable) along with two rear corner

post rails and three cable lacing bars can be sent ahead to the

job site and installed in a boxed wall opening or cabinet. The second carton contains the rack base, front and rear posts, side stiffeners, front vent panel and three lacing bars to assemble the rack

for pre-loading and testing of equipment in the shop - a real benefit for corporate boardroom and training facility installations.

The bottom base installs using (8) screws and may be mounted

flush or recessed up to 2” into a boxed wall or cabinetry to allow

for equipment protrusions. The removable rack base, with or without mounted equipment, easily docks and secures to the bottom

base using two screws on the front and rear frame (no wing nuts

under the rack). When all equipment is in place and wired, the

assembly is secured in fixed position with two screws through a

perforated front security panel. To facilitate wiring and servicing

of rack equipment, the security panel may be removed; allowing

the rack to be pulled out smoothly from the wall or millwork on

the heavy-duty slides. A convenient pushbutton lock and release,

accessible in the center front of the bottom base, allows the rack

to rotate 60º and 90º on the turntable. Note the rack must be fully

forward to rotate with adequate clearance. If it is recessed up to

2” it will not rotate the full 90

the pushbutton to return the rack to its front-facing position, push

it back into the wall and re-install the front security panel. Components are manufactured from certified US steel and finished in

smooth black powder epoxy. Choose models with panel space of

10, 12, 16 or 21RU. All provide 23” useable depth (23.22” overall).

Features:

• Bottom base with turntable and 4 heavy-duty slides for

300 lb. load

• Removable rack base

• 6 corner-post rails (10-32) and 2-side stiffeners

• Cable lacing panels (6)

• Front security panel, perforated

• Black powder epoxy finish

0

. When servicing is complete, use

A&E Specifications:

The rack for built-in applications shall be Lowell LPTR4-series

Model ________. It shall be 19.13”W and 23.23”D with 23” useable depth. Panel space shall be ______ (10RU, 12RU, 16RU,

21RU). The rack shall include four heavy duty slides and a

turntable base allowing it to pull out and rotate 60

rack shall be unassembled and ship in two cartons to facilitate job

site installation of the bottom base and shop mounting and testing

of the equipment. The rack system shall include cable management panels and be capable of supporting a 300 lb. load. It shall

be manufactured from certified US steel and finished in smooth

black powder epoxy.

o

and 90o. The

To Service Installed Rack:

1. Remove the bottom security panel (2 screws). Note

: if security panel is not used, the rack should be locked using two

screws in the panel location.

2. Pull the rack fully forward to clear the opening.

3. Locate the pushbutton in the center of the base.

4. Depress the pushbutton in the center of the base to release

the turntable, allowing it to rotate to 60

5) Depress the pushbutton again to rotate the rack to the 90

o

right or left.

o

position. Note: the 90oposition is recommended when tying

off cords and cables to rear lacing panels as it ensures adequate length at maximum turn radius.

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069 USA. Ph–800.325.9660 or 636.257.3400. Fax—888.456.9355 or 636.257.6606. Lowellmfg.com

Lowell makes every effort to provide accurate information while reserving the right to change specifications and/or improve manufacturing methods without notification.

Spec #1037 (rev. 08.09.10) Page 1 of 2

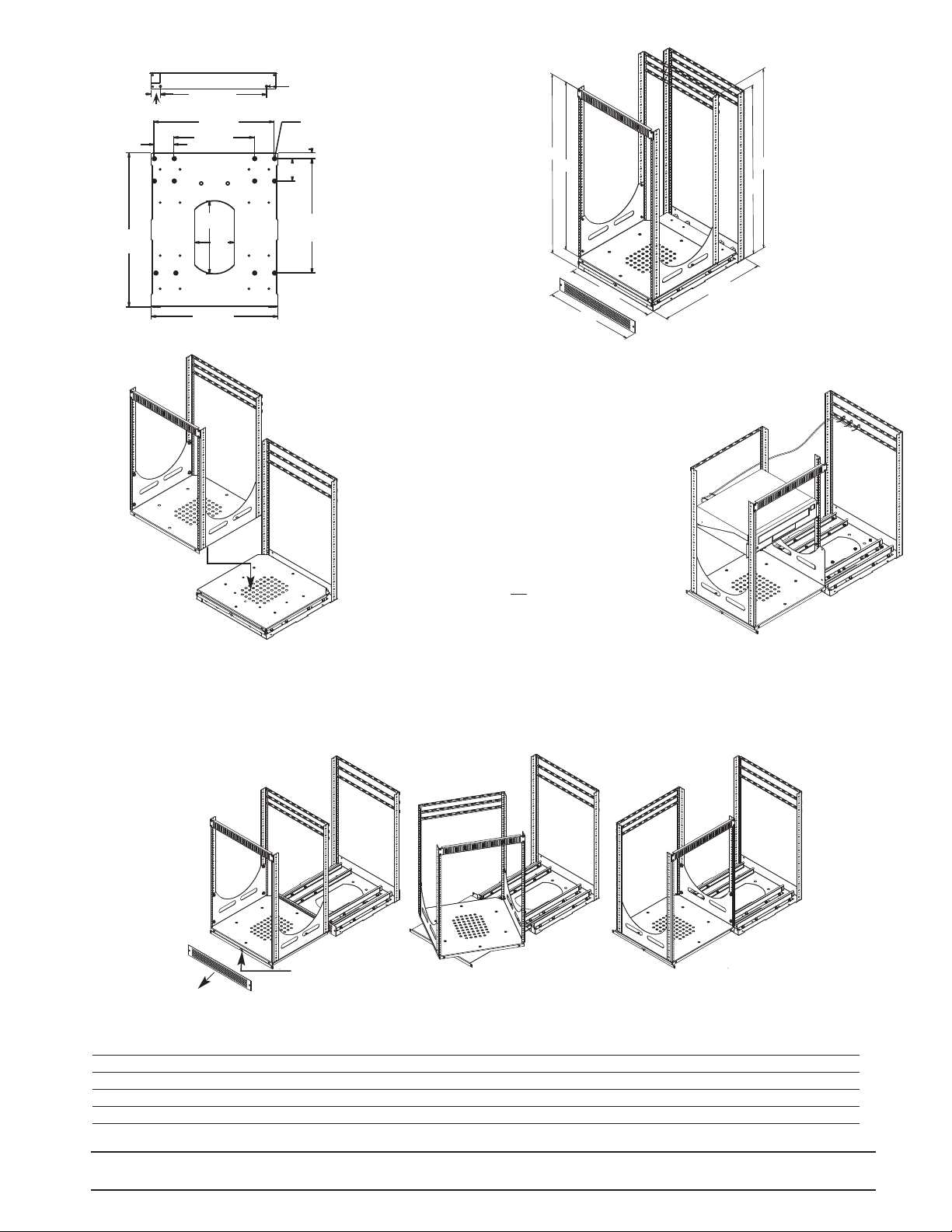

18.13

0.89

3.0

3.37

17.24

19.13

6.0

11. 0

23.23

16.00

1.41

0.261 hole if

mounting to stud

12.13

0.281 holes for

mounting

Bottom base installation

39.33

36.75

23.23

39.33

19.00

36.83

19.13

(Both bases are shown assembled with coner posts

and lacing panels)

Rack base

docks to the

bottom base.

After docking, the two bases

are secured with two screws in

front, two screws in rear.

with slides and turntable.

Bottom base

Removable rack base allows shop wiring of equipment.

0oRotation

(19”D model shown)

Docking and securing the rack base with

or without mounted equipment to the

bottom base with slides and turntable is

easily accomplished using two screws

on the front and rear frame (no wing

nuts under the rack). When all equipment is in place and wired, the assembly

is secured in fixed position with two

screws through the front of the bottom

base assembly.

Six lacing panels are provided to

guide cabling. TIP: Perform wire tie off

when the rack is in the 90

tated position to ensure adequate slack.

60oRotation

(19”D model shown)

o

maximum ro-

19”D Model Shown in 90oposition with

o

Rotation

90

(19”D model shown)

cabling tied off.

Security

panel

Panel Rack Overall Overall Overall Useable Load Cable Tie-off

Model No. Formerly Space Units Height Width Depth Depth Capacity Panels

LPTR4-1023 LPT4-2317 17.50” 10RU 20.08” 19.13” 23.23” 23.00” 300lbs. 6

LPTR4-1223 LPT4-2321 21.00” 12RU 23.58” 19.13” 23.23” 23.00” 300lbs. 6

Pushbutton turntable release

LPTR4-1623 LPT4-2328 28.00” 16RU 30.58” 19.13” 23.23” 23.00” 300lbs. 6

LPTR4-2123 LPT4-2336 36.75” 21RU 39.33” 19.13” 23.23” 23.00” 300lbs. 6

©2010 Lowell Manufacturing Company, 100 Integram Dr., Pacific MO 63069 USA. Ph–800.325.9660 or 636.257.3400. Fax—888.456.9355 or 636.257.6606. Lowellmfg.com

Lowell makes every effort to provide accurate information while reserving the right to change specifications and/or improve manufacturing methods without notification.

Spec #1037 Page 2 of 2

Loading...

Loading...