Lowell IMC8A-TS32-1W Data Sheet

8" 50W coaxial loudspeaker #IMC8A-TS32-1W

ships ready for installation

features 8" 50W coaxial driver & 70V 32W transformer

features. . . . . . . . . . . . .

Includes:

• 8 inch coaxial driver

• 70V 32W transformer

• Steel enclosure (1.25 cu.ft.)

w/forged eyebolts

• White grille

with global

grille | enclosure

components

• Description: Ready-to-install high performance

loudspeaker for suspended installations

provides quality sound distribution of

foreground or background music in all kinds of

commercial venues—it's ideal for high ceiling/

high energy applications like clubs and bars,

sporting facilities, concourses, hotel ballrooms,

transportation terminals, convention centers,

and exhibit halls.

• Driver (#8A50):

– 8" 50W driver features a 20 oz. LF magnet

with 1.4" copper voice coil to drive a

polyproylene cone with half-roll rubber

surround for long cone travel and good edge

damping. A post-mounted tweeter is a 1"

balanced-drive dome protected by Ferrouid

and a rst-order high-pass lter.

– See the spec sheet for driver #8A50 for more

information.

• Transformer (#TLS-3270):

– 70V 32W transformer for superior music

fidelity in 70V distributed applications has a

screwdriver-adjustable tap selector switch

accessible through an opening in the grille.

– Part of Lowell's 20/20 AudioVision™ line,

the transformer offers true 20Hz-20kHz

performance with full frequency response

and high power handling to allow the speaker

to operate at full potential while providing a

stable load to the amplier. The transformer

allows a distributed speaker system to sound

imperceptibly the same as a transformerless

direct-to-voice-coil system but with easier

wiring, reduced labor, and less expense.

• Enclosure:

–

The 1.25 cu.ft. precision-formed U.S.

steel cylindrical enclosure (19" x 12" dia.)

features a white powder epoxy nish and

1-1/2" thick premium acoustic lining.

– 1/4"–20 forged eyebolts are screwed

into mounting nuts for secure suspended

installation (yware by others).

– Externally accessible connections are

terminated through a 4" x 4" ush cover

plate.

• Grille:

– Perforated steel grille with white powder

epoxy nish (≈ 11.8" dia.)

IMC Series Summary

Model No. Driver Transformer Enclosure Grille*

IMC12Q-TS100-2W 12" 250W coaxial 70V 100W 2 cu.ft. 14.6" dia. 1 52

IMC12P-TS100-2W 12" 150W coaxial 70V 100W 2 cu.ft. 14.6" dia. 1 41

IMC8P-TS32-2W 8" 100W coaxial 70V 32W 2 cu.ft. 14.6" dia. 1 41

IMC8A-TS32-1W 8" 50W coaxial 70V 32W 1.25 cu.ft. 11.8" dia. 1 23

*Approximate overall diameter

Note: Black and custom color grilles and enclosures are available upon request. Additional charges and/or delivery times may apply.

Lowell strives to provide accurate information while reserving the right to change specications and/or improve manufacturing methods without prior notication.

©2019 Lowell Manufacturing Co., 100 Integram Dr., Pacic MO 63069 / tel. 800.325.9660 / www.lowellmfg.com

Std.Ctn.

Pack

Spec #1820 | Rev. 11-15-19

Ctn.Wt.

(lbs.)

pg. 1/4

8" 50W coaxial loudspeaker #IMC8A-TS32-1W

a&e specifications . . . . . . . . . . . . . . .

The speaker for suspended installation shall be Lowell iMount® Model #IMC8A-TS32-1W which shall feature an 8 in. 50W driver

mounted in a white cylindrical steel acoustic enclosure (19 in. high x 12 in.dia.; 1.25 cu.ft. volume) with 1-1/2 inch thick acoustic lining,

forged 1/4 inch-20 eyebolts screwed into mounting nuts for suspended installation using yware by others. It shall include a perforated

steel architectural grille (≈11.8 in.dia.) with white nish. System frequency response shall be 65Hz–12.3kHz (+6dB) and 50Hz–20kHz

(+8.2dB) with average sensitivity of 89.1dB @1W/1M. Dispersion shall be 95 degrees conical @2kHz octave measured 6dB down. The

system shall have a driver with 20oz. magnet, 1.4 in. copper voice coil driving a polypropylene cone with half-roll rubber surround, and

post-mounted tweeter (1 inch balanced drive dome).The speaker shall include a wired 70V 32W transformer with screwdriver-adjustable

tap selections accessible through the grille.

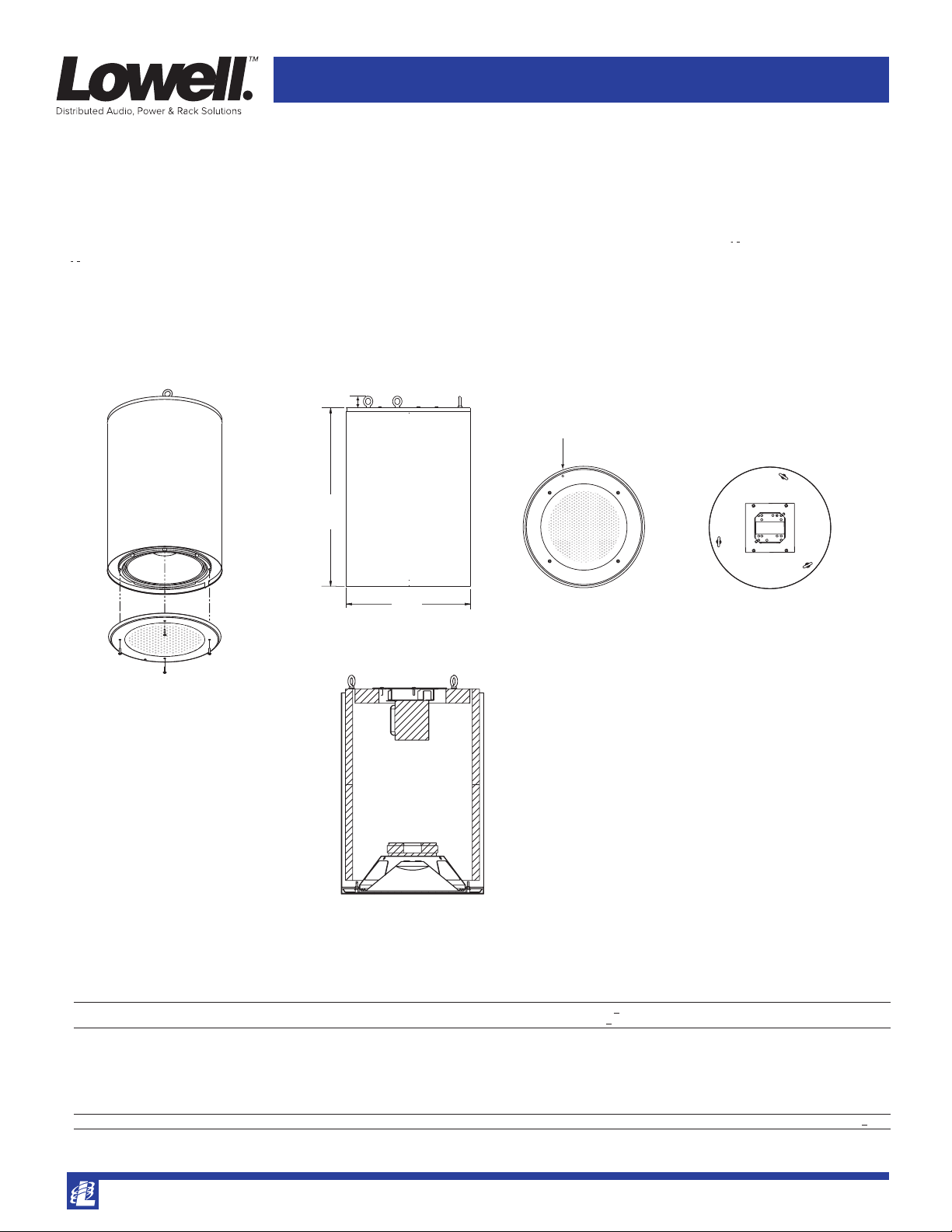

technical drawings . . . . . . . . . . . . . .

Factory installed 1/4 in.–20 forged eyebolts

are ready to attach to yware (by others)

1.375"

Access hole to transformer

tap selector (screwdriver-adjustable)

19.0"

(1.25 cu.ft.)

12.0"

Note: A standard 4 in. x 4 in. electrical extender ring can

be mounted for pass-through piping (in/out conduit)

Speaker termination pocket

behind 4 in. x 4 in. cover plate.

Transformer is mounted to a

bracket beneath the cover plate.

Acoustic lining (1-1/2 in. thick)

Factory-mounted driver

technical specifications . . . . . . . . . . . . .

System Specifications: #IMC8A-TS32-1W

Driver Driver Driver Driver Enclosure Enclosure System System System

No. Rating Size Type Volume Dimensions Response Dispersion* Sensitivity (SPL)**

8A50 50W 8 in. Coaxial 1.25 cu.ft. 19 in. high 65Hz–12.3kHz (+6dB) 95 degrees conical 89.1dB Avg @1W/1M

(8 ohm) x 12 in. diameter 50Hz–20kHz (+8.2dB) @2kHz octave (–6dB) 106.1dB Max @50W/1M

* For help in determinging speaker spacing, go online (www.lowellmfg.com) and see the paper, "Distributed Speaker Spacing for the Integrator." An online calculation tool—the Speaker Spacer—is also available.

** Maximum sensitivity is calculated based on power rating and measured sensitivity.

Transformer Specifications: #TLS-3270

Transformer Primary Power Primary Secondary Core Insertion Frequency

No. Voltage Rating Taps Impedance Size Loss Response

TLS-3270 70V 32W 32, 16, 8W 8, 4 ohms 1.25 x 1.25 in. .6dB 20Hz–20kHZ (+1dB)

* Lowell's 20/20 AudioVision™ series of transformers offer true 20Hz–20kHz performance for full delity audio in distributed applications.

Lowell strives to provide accurate information while reserving the right to change specications and/or improve manufacturing methods without prior notication.

©2019 Lowell Manufacturing Co., 100 Integram Dr., Pacic MO 63069 / tel. 800.325.9660 / www.lowellmfg.com

Spec #1820 | Rev. 11-15-19

pg. 2/4