Spring

Instructions for assembly

The parallel countermarch system .................................................................................................... 1

Spring assembly tips and information ............................................................................................... 3

Assembly of the Spring ..................................................................................................................... 5

Maintenance ................................................................................................................................... 17

Version: Spring-V5

1

The parallel countermarch system

In a countermarch loom, every shaft is actively

involved in each shed: Each shaft is either lifted

or pulled down by each treadle.

Uneven sheds, for example a satin weave

shed, where four shafts are lifted and one is

pulled down, open cleanly every time. The warp

ends on the fifth shaft do not tend to ride up as

they often do with jack looms.

When the shed is made, the same tension is

applied to the raised ends as to the lowered

ones, resulting in the best shed in relation to the

increase of the warp tension.

Traditional countermarch system

Look at the diagram to help you understand

how a countermarch loom works. The points

marked S are the pivoting points for the lams C

and D and the jacks E.

You will see that beneath each shaft, there are

two lams associated with it. One of those lams

is directly connected to the shaft and moves in

the same direction as it does: when this lam is

pulled down, the shaft moves down. When the

other lam is pulled down, the shaft rises.

Parallel countermarch

Each shaft is attached to a cord, which goes

over all six rollers. The ends of the cord are

joined, so the cord forms a continuous loop.

When treadle A is pressed down, the lower lam

C, attached to the outside part of the cord,

moves downward, pulling the shaft F up. When

treadle B is pressed down, the upper lam D

attached to the inside part of the cord, goes

down, pulling the shaft with it.

Compared to the traditional countermarch, the

parallel countermarch has five nice features:

1. In contrast to the traditional countermarch,

the lams of the parallel countermarch stay

horizontal, while moving the same distance

as the shafts. This means that the action of

all treadles is the same, not depending on

their location in the width of the loom.

2. The parallel countermarch system is more

compactly constructed, because the action

space the lams need is less than pivoting

lams and the rollers at the top take less

space than jacks.

3. Shaft bars and lams cannot slant. Their

ends are fixed to the cord and when the

cord moves, all parts of the cord have to

move the same distance.

4. There is no tie-up to the middle of the lower

shaft bars, so the heddles can be moved

freely over the shafts.

5. There are no cords, connecting the lams to

jacks, running through the middle of the

warp

Because each treadle is tied to one of the lams

of each shaft, twice as many tie-ups per treadle

must be made, on the average, compared to

looms with another system.

Before the advent of Texsolv cord, the time

required to tie up a countermarch loom was

2

daunting. Once the ties were made, there were

still problems as knots slipped or had to be

untied to adjust the cords. Fortunately this

drudgery is a thing of the past. The Texsolv

cords neither stretch nor require knots. The

Texsolv tie-up cords are attached to the lams

and can be simply hooked onto the treadles.

Changing the tie-up is easy and fast.

To improve the countermarch shed, to offer the

best shed a shaft action system can provide,

Louët invented an action system for another

part of the loom that holds the warp:

The moving breast beam, controlling the

warp tension

The moving breast beam allows the shafts to

move more easily in their opposite directions.

Looking at the diagram that shows the loom

from the side, you will see that a shed is giving

the warp a kind of parallelogram shape.

Imagine, the warp is made of inelastic material,

like metal wire, you will understand that making

a shed is only possible if the distance between

breast beam and back beam becomes smaller.

When this distance is fixed, as it is on other

looms, the shed depends completely on the

elasticity of the warp. When the shed becomes

wider, the tension on the yarns increases

(enormously, in case of a less elastic warp).

That causes heavy treadling and may damage

the warp.

The moving breast beam is held by springs,

adjustable to give your warp the tension needed

for your project. Besides improvement of the

shed and protection of the warp, the springs

guarantee exactly the same warp tension each

time you have to advance the fabric.

The Texsolv system

Texsolv cord and heddles are Swedish

products, crocheted out of polyester yarn.

Cotton heddles have the advantage of being

silent in use. Metal heddles, flat or wire, have

the advantage of having open eyes. Texsolv

heddles combine these features. A bundle of

Texsolv heddles is a continuous line of 100

heddles folded into a zigzag. Each bundle is

fastened in four places. These ties make it easy

to pass the shaft bars through the upper and

lower loop of the heddles. Do not remove the

ties from the bundles, until the heddles have

been slipped onto the shaft bars or the loops of

the bundles are inserted by sticks, to protect the

heddles from becoming entangled.

If you need to remove heddles from a shaft, first

tie them as they were originally. Use a pair of

sharp scissors to cut the heddles apart.

Texsolv cord consists of two cords, which are

connected every 12 mm, forming loops in

between. If needed, the cord should be cut

between two loops. To prevent unraveling, the

ends should be singed. Be careful not to overdo

the melting and be aware that melted polyester

is very hot and will burn the skin.

By mentioning the first or last loop in these

instructions, the loop is meant, next to the one

where the cord is cut, because when that loop

remains after cutting, it has no strength and

should not be used.

3

Spring assembly tips and information

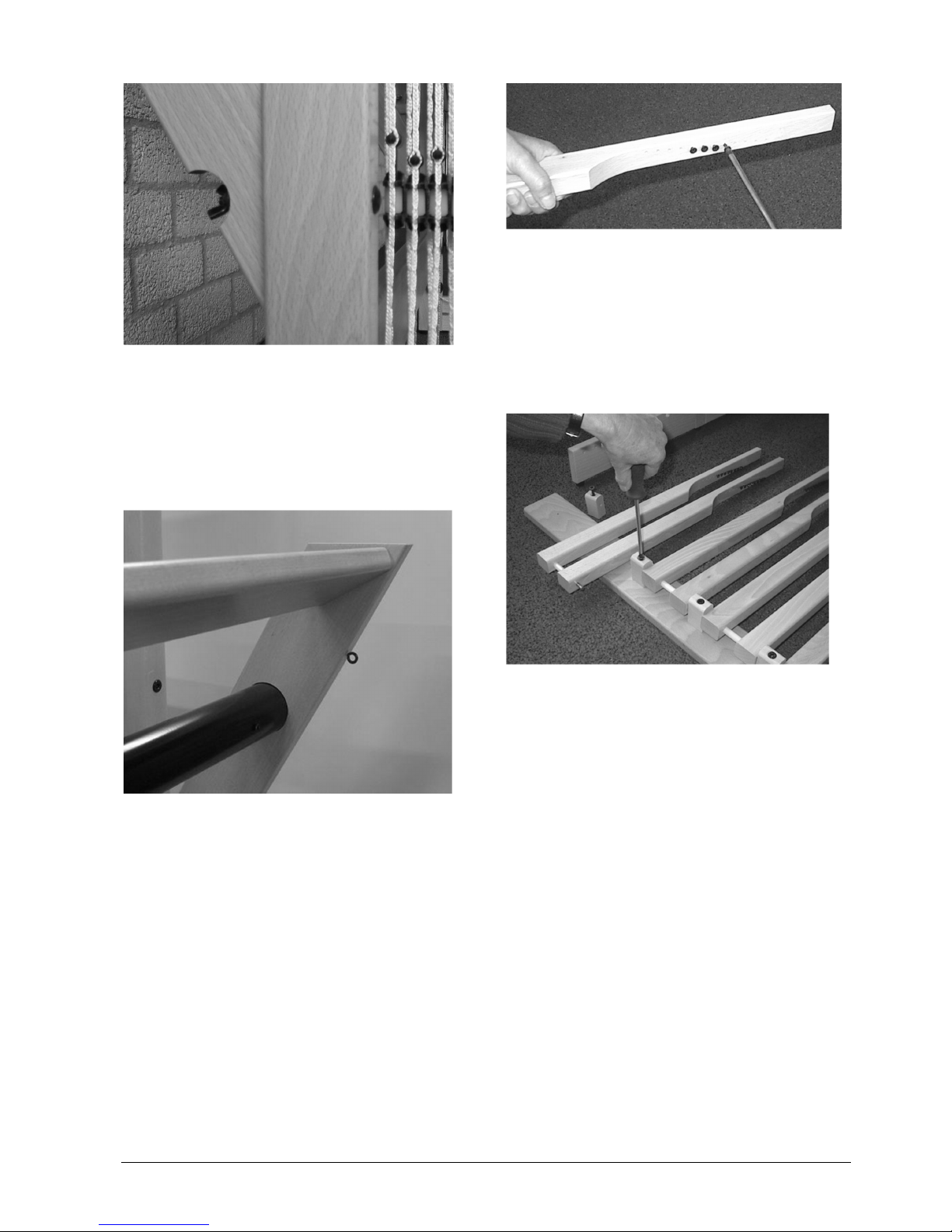

Barrel nuts

For the assembly of the looms, we use barrel

nuts and bolts or threaded ends to connect two

parts. These cylinder shaped nuts have a slot

on one of the flat sides. Always insert the barrel

nut into the wooden part, so that the slot in the

barrel nut is visible. The slot shows the direction

of the threaded hole in the nut. With a flat

screwdriver you can turn the barrel nut so that it

is positioned properly to catch the bolt. If you

have a problem inserting the bolt into the barrel

nut, try turning the barrel nut 180 degrees. This

usually helps.

Carriage bolts

In other locations, we use carriage bolt to

assemble wooden parts. These bolts have a

square enlargement (neck) under the bolt head.

When you tighten the nut on the bolt, this

square neck locks into the wood to prevent the

bolt from turning. In some instances, you will

notice, that the bolt is just a little too short for

assembly with the washer and nut. We advise

you to put the nut on the bolt without the

washer, and then tighten the nut sufficiently, so

that the square neck pulls into the wood. At this

stage, unscrew the nut, install the washer and

then replace and secure the nut again, tightly.

Alternatively, you can carefully tap against the

bolt head with a hammer, until the bolt head is

secured into the wood.

Washers and spacers

For the proper operation of the loom, it is very

important that you follow the correct assembly

sequence of the bolts, washers and spacers.

Please carefully follow the instructions.

To help you, we have assembled all the

washers and spacers in the hardware bags in

the right sequence.

Wood screws

Where wood screws are used, we have predrilled holes in the wood. The screws will cut

their own thread into these holes. Please note

however, that the screws are very sharp, and

will cut into the full wood outside the pre-drilled

holes, if you miss the pre-drilled hole during

assembly. However if this happens, you will

notice that after a couple of turns, it becomes

very hard to turn the screw. There is even a

chance that the screw will twist off. Moreover,

the parts will be assembled in the wrong

location.

If you have to assemble and disassemble the

loom several times, make sure that the wood

screw turns in the same thread again which

was cut the first time. If you do not follow this

instruction, the hole in the wood will become too

large for the screw. To find this screw thread,

turn the screw anti clock wise, until you "feel"

the screw "drop" into the threaded part in the

wood.

Tools

All parts used for the loom are metric. To

facilitate the assembly, we have included two

wrenches (10 mm for M6, 13 mm for M8), a

socket-head screw wrench and a pz2 cross

head screwdriver (not a Phillips head!).

4

List of parts

In box A:

Assembled middle part and a second box

containing, see picture:

1. 10 treadles

2. 2 beater supports (L=R)

3. 2 floating arms (L=R)

4. brake handle

5. 2 base sides (L+R)

6. 2 middle side pieces (L+R)

7. 2 top side pieces (L=R)

8. 2 warp beam supports (L+R)

9. locking pin

10. brake disc

11. cloth beam lever

12. beater handle

Not shown on the picture:

− hardware bags 1, 2, 3, 4, 5 and extra.

− 54 long and 54 short tie-up cords for the

treadles.

− 8 x 100 Texsolv heddles 39 cm.

In box B:

• lower reed holder

• upper reed holder

• cloth beam

• warp beam

• breast beam

• back beam and foot rail (attached to the

middle part in box A)

• shelf bottom

• reed (attached to the lams in Box A)

• 2 apron bars

• 2 cross sticks

• 16 warp sticks

5

Assembly of the Spring

Place the already assembled middle part of the

loom, with its black buffers on the floor. Don’t

worry about the look of the top side pieces; they

are attachments to keep parts in place and will

be replaced during assembly.

Open hardware bag 1:

− a pz2 cross head screwdriver

− wrenches 10 en 13 mm

− socket-head screw wrench

− 2 buffers

− 2 screws 4 x 25 mm

− 4 threaded ends M6 with a socket nut and a

barrel nut

− 6 screws 5 x 50 mm

− bracket

− 2 carriage bolts M6 x 100 mm with washer

and wingnut

− 2 screw eyes

Screw the buffers onto the bottom side of both

base side pieces.

Mount the base and the middle side pieces onto

the middle part:

These rails are marked A, B, C and D, which

indicates where they are to be mounted onto

the middle part.

Unscrew the barrel nuts from four of the

threaded ends, but leave the socket-head nuts

on. Insert these threaded ends from the back

side through the holes in the middle part, where

the side pieces have to be assembled.

Insert the barrel nuts into the holes of the side

pieces.

The barrel nuts have to face the inside of the

loom.

Fasten the side parts with the socket-head

screw wrench.

6

Replace the top side pieces one by one:

Remove the two screws that hold the front rail.

Unscrew the socket-head nut and remove the

side piece. If the threaded end remained in the

barrel nut, take it out and take the barrel nut out

too.

Insert the barrel nut into the new top side piece

and assemble it in the reversed sequence, the

barrel nut facing the inside.

Screwing the side piece to the front rail it is

important to find the thread that is cut in the

hole the first time: Lift the front rail and find its

hole with the tip of the screw. Now turn the

screw anti clock wise while giving some

pressure. You will feel and hear when the screw

falls in the original thread and you can screw it

in, which should easily.

Repeat the procedure at the other side of the

loom. Slip the shelf bottom into the slot of the

front rail (you may need to loosen the screws at

the side pieces one turn).

Slip the shelf bottom into the slot of the front

rail. You may need to loosen the screws at the

side parts one turn.

Fasten the shelf front to the top side pieces,

using two of the 50 mm screws.

7

Assembly of the back section of the loom

Take the warp beam, the back beam and the

two warp beam supports and place them

together as shown on the picture. Insert the

shaft of the warp beam through the right

support and slide the left support onto the other

end of the warp beam.

Attach the supports to the back beam with the

remaining 50 mm screws. At the right side you

have to use these screws to attach the metal

bracket.

Screw the two 4 x 25 mm screws a few turns

into the main uprights at the level of the holes in

where the back part will be attached. The

uprights are identical so you will find one pilot

hole at the inside and one at the outside of the

loom.

Place the back part in its location by inserting

the polyurethane dowels into the holes at the

rear of the loom.

Secure the polyurethane dowels by screwing

the screws completely into the uprights, while

holding the back part in a position that let the

dowel in completely.

8

Take the two carriage bolts with washer and

wing nut and secure the back part as shown on

the picture.

When the loom is not in use, you can fold the

back part of the loom after removing the wing

nuts and washers again.

Screw the two screw eyes into the pilot holes at

the backside of the warp beam supports. If you

are used to leaving the lease sticks in the warp,

attach them to these eyelets.

Assembly of the foot rail and treadles

Open hardware bag 2:

− 80 screws 4 x 17 mm

− 4 screws 5 x 50 mm

− 6 screws 6 x 70 mm

− 5 axles Ø6 x 122 mm

− 5 nylon spacer bushings

− 6 axle support blocks

Screw the small screws into eight holes of each

treadle, so far that the screw heads protrude

approximately 5 mm (3/16”) from the wood. The

thread of the screws should just disappear into

the wood.

Use the eight holes closest to the end of the

treadle; the other four holes are to be used for

an extension to twelve shafts.

Place the foot rail upside down (pilot holes up)

on the floor in front of the loom.

Assemble the treadles onto the foot rail. The

screw heads on the treadles should point to the

right.

Slide two treadles with a nylon bushing in

between on each axle. Use the axle suspension

blocks and the big screws to assemble these

pairs of treadles to the foot rail. On each side,

one pilot hole on the foot rail should not be

used, unless you are assembling four more

treadles of an extension to twelve shafts.

9

Turn the foot rail upside up again and connect it

with the four remaining screws to the base side

pieces.

Mounting the floating arms

Open hardware bag 3:

− 2 carriage bolts M8 x 60 mm with big

washer, bushing, small washer and cap nut

− 7 screws 4 x 17 mm

− 2 spring with a piece of Texsolv cord

− 2 short Texsolv cords

− 1 ratchet for the cloth beam

− 1 screw 4,5 x 20 mm round head

− 8 beam cords.

Take the wooden posts, recognizable for the

steel rod at the end. These floating arms will

hold the moving breast beam.

Tap the carriage bolts into the holes.

Slide the large washer and spacer bushing,

over the carriage bolt and attach the floating

arms at the inside of the middle side pieces of

the loom.

Use the small washers and cap nuts to finish

the assembly by strongly tightening the cap

nuts.

Screw four of the small screws into the pilot

holes at both sides at the bottom of the floating

arms and a small screw at the inside of the

base side pieces. The heads of these six

screws have to protrude about 5 mm (3/16”).

Hook on the springs to the screw eyes on the

back at the top of the middle part.

Bring the attached cords down through the

screw eyes at the bottom of the main upright

and lead them along the roller.

10

Attach the free ends of these cords onto the

screw heads at the inside of the floating arms.

Use the short Texsolv cords to connect the

screw heads at the outside of the floating arms

and the inside of the base side pieces.

Installing the cloth beam

Slide the cloth beam lever onto the cloth beam

and make sure that the ratchet is on the right

side of the ratchet wheel.

Install the cloth beam with the wooden end into

the hole of the right middle side piece and the

metal end into the circular groove of the left

side piece. You will need to push the side

pieces apart to install the cloth beam in

between.

Attach the cord of the lever with the remaining

4 x 17 mm screw onto the side piece.

Use the 4.5 x 20 mm screw to attach the ratchet

onto the side piece. The ratchet has to turn

freely, so don’t fasten it too much.

If the ratchet on the lever is falling to the wrong

side while advancing the cloth beam you need

to shorten the cord one or two cord loops

Attach the beam cords onto the screw heads of

the cloth beam and the warp beam.

Assembly of the beater

Open hard ware bag 4:

− 2 beater hinges

− 2 buffers

− 2 bolts M6 x 70 mm with washer and barrel

nut

− 2 lag bolts 8 x 90 mm

− 2 spacer bushings 33 mm

− 4 washers

− 2 carriage bolts M6 x 80 mm with washer

and wing nut.

− 1 locking pin

− 3 strips of thin cardboard

11

Remove the reed from its location between the

lams by taking away the tie straps. You can cut

them but you can also lift the small ratchet

inside with the tip of a knife so they can be used

again.

Insert the locking pin into the hole in the top rail

and through the marked cord loops. Now the

shaft bars and lams are fixed in their neutral

position.

Turn the beater hinges into the bottom of the

uprights.

Connect the lower reed holder (the one with the

slanted side) to the uprights: Place the barrel

nut into the hole on the end of the lower reed

tray. Slide the upright with the notch over the

lower reed tray. Place the bolt with washer in

the hole and screw it into the barrel nut. Tighten

the bolt and, in the same way, assemble the

other upright on the other side of the reed

holder.

Screw the buffers into the holes at the sides of

the loom, see picture. If your loom has twelve

shafts you need to use the other hole you see

on the picture.

12

Place the assembly of uprights and lower reed

tray into the loom. First guide one hinge along

the side rail and then the other one. Put the

hinges into the openings in the base side

pieces.

Assemble the handle to the upper reed

holder

Slide a washer over the lag bolts and then put

them through the holes in the upper reed

holder.

Next slide another washer and a spacer

bushing over the lag bolts.

Hold the handle with the holes over the points

of the lag bolts and then tighten the bolts so far

that the spacer bushings are tightened slightly

into the handle.

Assemble the upper reed holder with carriage

bolts, washers and wing nuts. Insure that the

washers rest under the wing nuts and not

between upright and reed holder.

Fasten the wing nuts, while you keep the top

reed holder parallel to the lower one. You can

also do this by placing a reed in between. After

each tap on the bolt head you turn the wing nut

tight again until the square part of the head is

completely pressed into the wood.

Move the beater backwards, so it rests against

the buffers at the sides of the loom.

Now we will check if the beater is even and

make a correction if necessary. First check if

the hinges protrude the same distance from the

bottom of the uprights. Take the beater by its

handle and pull it towards you, one or two

inches.

If the beater is even, both uprights will leave the

buffers at the same moment and also tough the

buffers at the same time when you let the

beater go back and rest against them.

If this is not the case, the beater is not even and

you will correct that with the small cardboard

strips from the hardware bag.

The upright that leaves the buffer latest when

you pull the beater, is the one that needs one or

more cardboard strips in its slit connection with

the lower reed holder.

Unscrew the M6 bolt several turns, so that

some play is created in this connection.

13

Slide a cardboard strip completely into the slit at

the bottom and fasten the M6 bolt again.

Check if the beater is even now, and if not, use

one or two more strips in the slit.

Assembly of the brake of the warp beam

Open hardware bag 5:

− 1 wooden dowel

− 2 screws 4 x 35 mm

− 1 carriage bolt M8 x 55 mm with 4 washers,

bushing, 1 washer and a cap nut

− 1 threaded hook with a knurled nut

− 1 lag bolt 6 x 30 mm.

− 1 ratchet

− 1 screw 4,5 x 20mm

− 1 spring

Slide the brake disc over the wooden end of the

warp beam and fasten it with the dowel and the

two screws 4 x 35 mm.

Screw the lag bolt 6 x 30 mm into the pilot hole

in the warp beam support, just so far that the

thread of the bolt disappears into the wood.

Hang the spring onto the head of this lag bolt.

Tap the carriage bolt into the hole of the lever

from the side that is curved and slip on four

washers and the bushing.

Hook the spring onto the hook of the lever.

Insert the lever with the carriage bolt and the

bushing through the hole in the warp beam

support.

Complete this assembly with the last washer

and by tightening the cap nut.

Attach the threaded hook and the knurled nut to

the bracket as shown on the picture.

Guide the cable two turns around the brake disc

and insure that the turns don’t cross each other.

Slip the eye of the cable onto the threaded

hook, while you lift the lever.

With the knurled nut you can adjust the position

of the brake lever, which should be about

horizontal. Lift the lever with your knee to

release the tension while you turn the knurled

nut.

14

Tying the treadles

In hardware bag 6 you will find shorter and

longer tie-up cords for the treadles.

The tie-up cords are pre-cut in the correct

lengths. The longer cords should be used to

connect the upper lams to the treadles, the

shorter cords should be used to tie the lower

lams.

If a shaft is tied to a treadle by means of its

upper lam, the treadle will pull the shaft down,

so the tie-ups to the upper lams correspond to

the X marks of a weaving draft. If a lower lam is

tied to a treadle, the treadle will lift its shaft up,

so these tie-ups correspond to the O marks.

Tying-up a countermarch loom, using a

weaving draft for a singular tie-up, that only

shows X marks, the blank squares are the

tie-ups to the lower lams and the other way

around, if the weaving draft is showing only O

marks, the blank squares are the tie-ups to the

upper lams.

First make the tie-ups to the upper lams. Loop

the cord around the lam and pass one end

through the last loop (see page 2) in the other

end. Tighten it after the cord is positioned in the

groove in the lam, right above the treadle to be

tied.

The tie-up cords of the upper lams have to pass

the lower lams. As a rule these cords pass

behind of the lower lam, associated with the

same shaft. That will help you to avoid the error

of tying-up both the lams of a shaft to the same

treadle: In front of each cord passing the lower

lams, the groove in the lower lam should not be

used for a tie-up.

The cords should be tied to the screw heads on

a treadle in a sequence, corresponding to the

shafts.

Tie the lower lams to the treadles: Each groove

in the lower lams that is not past behind by a

cord should be tied to the screw head on the

treadle right below.

When all the tie-ups are made, check if all the

cords are about the same tightness. If there are

big differences, you probably misjudged which

loop was the last loop of one or more cords.

Another cause may be that one or more lam is

not fixed to the right level (see next subject).

All shafts will be tied to all treadles used, some

to rise and some to fall. If you want to change

the tie-up, only unhook the cords from the

screw heads and slide the cord over the lam to

the groove where you need it. On some lams

you will need to add more cords, on some lams

they will be left over. You may leave that cords

looped over the lams at the sides.

Adjusting the shaft bars and lams

Shafts and lams are already adjusted of the

correct height. They may need a correction

after some time.

You can check the correct level after putting the

locking pin into the hole at the top of the castle

and through the marked loops of the parallel

cords. Now the whole system is locked in its

neutral position. If the marks on the cords fade,

mark them again with a felt pen.

The adjustment of shaft bars and lams can be

done in steps of 12 mm, by clicking them into

next loop of the cord. For finer adjustment you

have to turn the white nut that adjusts the hook,

attached to the cord.

15

The correct height of shafts and lams is easy to

understand and therefore easy to keep in mind:

In their neutral position the shafts have to be

fixed at the height that the warp on the loom

passes through the middle of the heddle eyes.

The distance between the shaft bars should be

far enough to keep the heddles stretched, but

remain moveable along the bars.

The lams should be at such a height, that their

tie-ups to the treadles keep the treadles in an

angle whereby the row of screw heads is

horizontal.

The difference in height of the upper and lower

lam has to correspond to the difference in

length of the tie-up cords to the treadles.

Adding or removing heddles

If you need to add heddles to a shaft, pull the

hook that connects the upper shaft bar to the

cord, out of its cord loop. Slip over a bundle of

heddles and push the hook back into the same

loop again. Repeat this with the lower shaft bar,

but untie the bundle before you attach the lower

bar into the cord again.

Naturally, reverse the steps to remove heddles

and don’t forget to tie them together at four

places, right after you release the tension by

unhooking the lower shaft bar.

If your warp doesn't need the whole weaving

width of the loom, you can leave the heddles

that you don't use on the shafts at the sides.

Clicking the hook out or into the cord is easier

after you release its tension by taking the cord

out of one or two rollers at the castle top. By

releasing the tension this way, the whole cord

changes place a bit and you have to pay

attention to use the same loop, pushing in the

hook again. The potential error shows up when

you replace the cord onto the rollers: The shaft

bar differs in level. To avoid errors you could

mark the loop with a felt pen.

The cross sticks

If you are used to leaving the cross sticks in

your warp while weaving, the cross sticks

should be tied to the screw eyes at the back of

the warp beam supports. By doing this, you will

avoid the lease sticks following the warp toward

the shafts, when you advance the fabric.

Cross sticks in between the back beam and

shafts reduce the usable depth of your loom.

The raddle

The plastic raddle strip on top of the castle has

2 dents to 1 cm (5 dents to the inch).

Because the raddle is built up from 10 cm strips

with half an opening at each end, you will lack

one opening for a loom wide warp. In that

situation you have to add some more warp

ends into the openings at the outside.

The middle of the raddle is marked as a guide

for starting to thread the warp.

Threading through

The warp always should be threaded through

the heddles of at least four shafts. Using only

two shafts for a tabby, you will overload the

shaft bars and lams. Lock the shafts, not in use,

in their neutral position.

Tying the warp to the beams

The apron rods are marked at the spots where

the cords have to be attached. The diagram

shows the usual loop to do this.

After the warp is threaded through the heddles

and the reed, the warp ends have to be tied to

the apron rod of the cloth beam. For this job the

breast beam should be blocked, otherwise it is

impossible to get an even tension on all warp

ends: Every time you tighten a bundle of

threads, the breast will move and release all the

other warp ends. When you take the spring

cords off the floating arms, the short cords you

installed to connect the arms to the loom will

block the breast beam.

16

Adjusting the warp tension

Release the warp tension after you have tied

the warp to the apron rod of the cloth beam, by

lifting the brake lever of the warp beam.

By attaching the spring cords to the screw

heads at the floating arms you can adjust the

tension on the warp: The tighter you tension the

cord, the more tension you will get on the warp.

Be sure to adjust about the same tension on

both sides.

The warp tension should always be judged with

the floating arms in the vertical position. The

arms move to the front when you advance the

cloth beam, and move backwards when you lift

the brake lever.

To advance the fabric while weaving, first lift the

brake lever. Due to the springs, the breast

beam moving toward to you, will pull some warp

from the warp beam. Advancing the fabric using

the cloth beam lever, you will bring the floating

arms back in their vertical position. Now the

moving breast beam demonstrates its other

feature: The warp tension is automatically the

same as it was before you advanced the fabric.

If you advance the fabric too far, first you have

to release the warp tension by lifting the brake

lever, than you can take both the ratchets out of

the ratchet wheel of the cloth beam. Turn the

cloth beam back and put in the ratchets again.

Now stand at the side of the loom and lift the

brake lever turning the warp beam backwards.

Adjusting the height of the beater

The beater hinges are screwed with their

threaded ends into the bottom of the beater

supports. This construction allows you to adjust

the beater level: Turn the beater hinges in- or

outwards. The beater height should be

adjusted, so that the lower shed just touches

the lower beater bar. So if you use a smaller

shuttle for fine yarn, you may adjust the beater

a bit higher, because a big shed is not needed.

Always be sure that the beater has the same

height at both sides. You can check this by

making a shed and watching the lower warp

ends touch the lower beater bar.

Folding the back section

To fold up the back section of your Spring, you

have to remove the wing nuts and washers at

the bottom of the warp beam supports.

If there is a warp on the loom, you can keep it

folded by the tension of the warp. In the other

case you have to tie the back section to the

main upright of the loom.

Folded, you can move the Spring through most

doors.

17

Maintenance

Your Spring loom is easy to maintain. One

month after you assembled it, retighten screws,

bolts and nuts of the construction, including the

part that was already assembled. Thereafter,

check all bolts, screws and nuts once a year.

Check points for proper functioning of your

Spring loom

− Check the level of the shafts, lams and

treadles, while the parallel cords are locked

by the pin in their marked loops.

− Check that the parallel cords run through

the grooves in the black plastic ends of the

lams and shaft bars.

− Check that both the spring cords run in the

grooves of their rollers.

− Check that the washers are underneath the

wing nuts, where the top beater bar is

attached to the supports. If the washer is

located in between the beater bar and the

support, it will make the beater unstable and

the wing nut will damage the wood.

When things do not work smoothly

The shed is poor or hard to make.

May be caused by:

− The treadles are tied too high or too low.

− The lams aren't adjusted at the right level.

− The beater is adjusted too high.

− The lease sticks are in the warp between

the shafts and the back beam.

− The fabric should be advanced.

− The tie-up cords to the treadles cross each

other.

A treadle cannot be pushed down.

May be caused by:

− The locking pin is still in the parallel cords.

− An error in tying-up the treadle: The treadle

is tied-up to both the upper and lower lam of

the same shaft.

During tying the warp to the apron bar of the

cloth beam, the tension on the warp stays

irregular.

May be caused by:

− The spring cords have not been unhooked

from the screw eyes of the floating arms.

− One of the extenders is not fixed onto its

support.

− The brake cable doesn't run properly over

the brake disc or the cable needs to be

tightened.

− One of the short cords doesn't block the

floating arm.

The warp wouldn’t come off from the warp

beam.

May be caused by:

− The brake lever has to be lifted further.

− The brake lever is adjusted too high:

release the cable a bit.

− While weaving with a very low warp tension,

the warp wouldn't pass the cross sticks:

Take them out. If that doesn't solve the

problem, you have to beam the warp beam

by hand, while lifting the brake lever.

The cloth is slanted.

May be caused by:

− One of the wing nuts that hold the warp

beam supports came lose.

− The beater is not adjusted on the same

level at both sides.

− The tension of the springs is not the same

on both sides.

− One of the spring cords has slipped of the

roller.

The cloth cannot be advanced.

May be caused by:

− One of the ratchets of the cloth beam is not

in the ratchet wheel.

− The apron bar of the cloth beam is caught

on one of the floating arms.

Loading...

Loading...