Page 1

Lotus Service Notes 340R

340R SUPPLEMENT

Sub-Section Page

Introduction 340R.# 2

Technical Data 340R.TD 2

Chassis 340R.A 3

Body 340R.B 4

Front Suspension 340R.C 8

Rear Suspension 340R.D 9

Engine 340R.E 9

Transmission 340R.F 16

Wheels & Tyres 340R.G 17

Steering 340R.H 18

Braking 340R.J 18

Cooling 340R.K 18

Fuel System 340R.L 18

Electrical 340R.M 19

Maintenance & Lubrication 340R.O 46

Heating 340R.P 50

Clutch 340R.Q 50

SPage Page 1

Page 2

Lotus Service Notes 340R

340R.# - INTRODUCTION

The Elise 340R made its debut at the 1998 Birmingham Motor Show as a radical lightweight sportscar

concept, focused on pure driving pleasure. Minimal changes were required to meet European homologation

regulations, and the car commenced production in January 2000.

The car is based on the standard Elise chassis, but uses completely different bodywork and interior, and

a road going version of the Rover VHPD powertrain. The car embodies the original philosophy of the Elise,

with performance achieved through light weight and efficiency, but is taken to a further extreme to focus on

driving pleasure, and is aimed at the enthusiast driver and for occasional circuit use. Features include a nonstructural, minimalist body without doors or roof structure, combined with separate close fitting carbon fibre

mudguards, translucent body side panels, a carbon fibre rear aerofoil mounted on alloy side plates, and a

special oval section steel roll over bar. Sport suspension is fitted, complete with the uprated and adjustable

front anti-roll bar.

The vehicle has proven to be an extremely rare phenomenon within the motor industry, as it is virtually

unknown for a concept vehicle to be productionised without drastic modification. The styling concepts first

shown at the 1998 International Motor Show at the Birmingham N.E.C. have remained true to their ideals in

production form. In fact, its uniqueness continues through to the rigouress acceptance criteria of the European

Whole Vehicle type approval authorities, no mean feat for a vehicle with these features.

340R.TD - TECHNICAL DATA

Dimensions

Overall length 3620 mm

Overall width 1702 mm

Overall height (at kerb weight) 1080 mm

Wheelbase 2300 mm

Track - front 1432 mm

- rear 1459 mm

Ground clearance (at kerb weight) 110 mm

Approach angle 12.4°

Departure angle 28°

Unladen weight - total 701 kg > inc. full

- front 278 kg > fuel tank

- rear 423 kg >

Maximum weight - total 928 kg } incl.

- front 387 kg } occupants

- rear 541 kg } & luggage

Trailer towing Not permissible

ohr2

Page 2

Page 3

Lotus Service Notes 340R

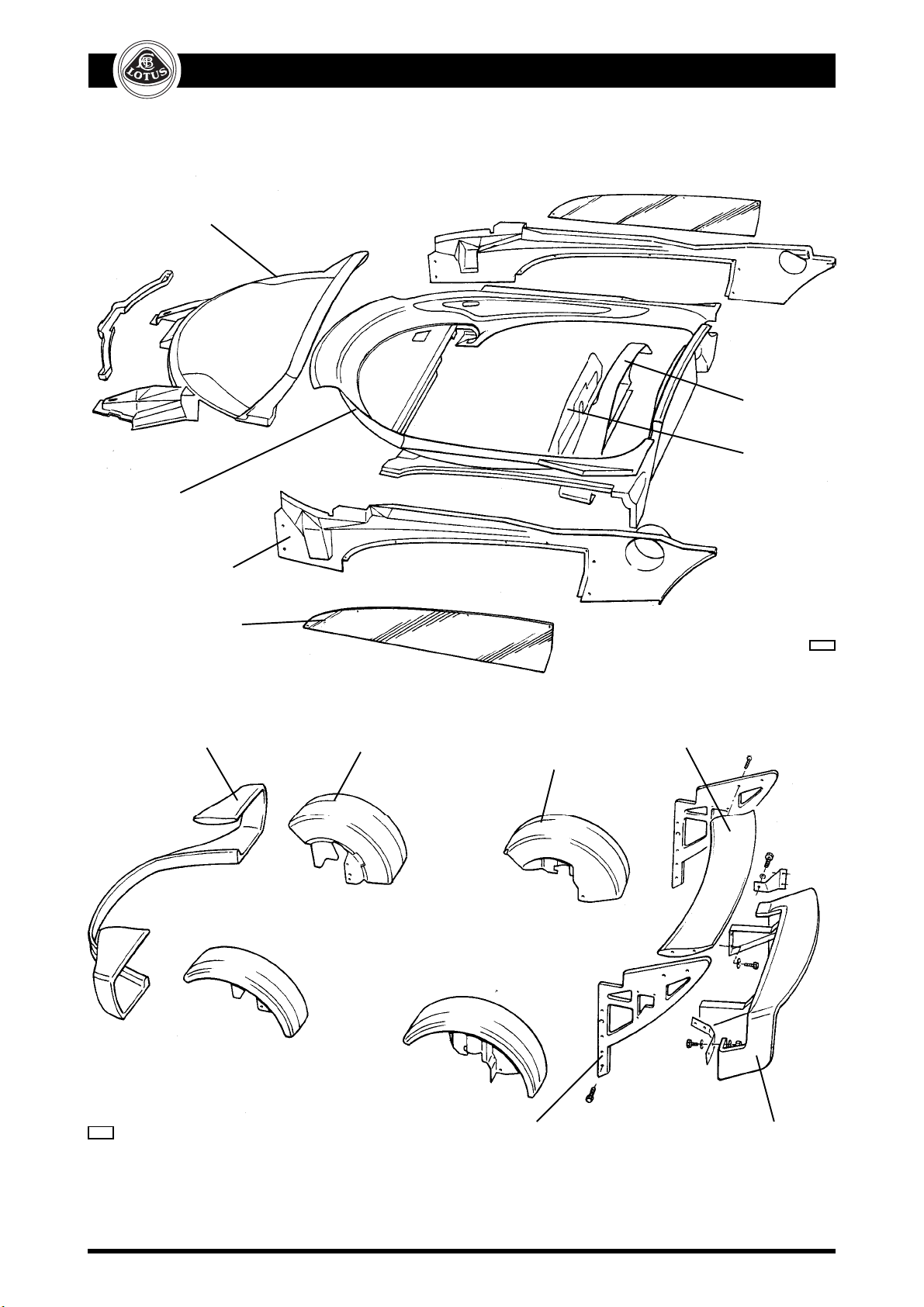

Windscreen frame

Electronics

housing

Access lid

Cockpit tub

Side closing panel

Cockpit side screen

Front splitter/spoiler Front mudguard Rear aerofoil

Rear mudguard

sb38

sb39 Aerofoil support plate Rear shroud

SPage Page 5

Page 4

Lotus Service Notes 340R

Removal of Topshell

The body topshell is secured by threaded fasteners. Removal of the topshell requires also that the seats

be removed and the roll over bar fixings released to allow the bar to be tilted forwards.

1. Remove the rear aerofoil from the mounting plates.

2. Remove both seats from the car by releasing the seat runners from the floor and unthreading the harness

straps.

3. Release the spherical vacuum reservoir from the roll over bar left hand backstay, and cut any tie wraps

around the backstays. Unplug the rear harness connector at the left hand lower corner of the engine bay.

4. Release the roll over bar from the top of both chassis side rails, and release both backstays from the

aerofoil mounting plates. Lean the roll over bar forwards to allow sufficient clearance for topshell removal.

5. Remove both outside mirrors, and disconnect the side repeater lamps.

6. Remove the front body access covers and disconnect the front harnesses (2) at the outboard rear corner

of the driver's side access hatch.

Topshell Height adjustable Mirror fixing Gutter Fixings to

fixing near wiper to screen frame fixing sill panel

spindle

Fixing to

toe panel

Rear

Fixings to wall to

sill panel Fixings to cockpit subframe

panel

b313 Rear wall to

topshell

Page 6

Page 5

Lotus Service Notes 340R

7. Remove the single fixing securing the front body spine to the plinth below the wiper spindle.

8. Remove the front undertray.

9. Remove the two screws at each side securing the topshell to the underside of the side sill behind the front

wheels, and the single adjacent screw securing the topshell leg to the toe panel.

10. Remove the two nuts each side securing the topshell to the cockpit coaming.

11. From the front edge of the engine lid gutter, remove the three socket head fasteners.

12. From inside the engine bay, remove the two nuts securing the topshell to each top rear end of the sill

panel.

13. Release the fixing securing each side of the engine bay rear wall to the subframe.

14. Protect (or remove) the front mudguards, and the sides of the windscreen pillars from scrape damage

before lifting the rear of the topshell, and manoeuvring over the windscreen and off the front crash

structure.

Fitment of Bonded Body Panels

The cockpit tub, windscreen frame, side closing panels and cockpit side screens are bonded, in that

assembly order, to the chassis and other panels using the polyurethane adhesives and techniques outlined in

section BM. Windscreen fitment is as described in section BN.13.

Instrument Mounting Rail

The curved mounting rail for the instruments is a hollow composite moulding, secured to the cockpit tub

with two screws at the passenger end, accessible from beneath the passenger side fascia, and a single screw

at the driver's end. For access to the latter, it is necessary to remove the topshell to expose an access hole in

the side closing panel.

SPage Page 7

Page 6

Lotus Service Notes 340R

340R.C - FRONT SUSPENSION

The 340R is fitted with the Elise Sport suspension package which includes adjustable spring platform

Koni dampers with the shorter and stiffer springs, and the uprated front anti-roll bar in Nylon chassis mounting

blocks. Standard Elise wishbones are used, but are powder coated silver, as are the steering arms and lower

ball joint plinths.

Two variations of suspension geometry are specified; one for road use (with Yokohama or Pirelli tyres);

and one optimised for track use with increased negative camber and toe settings. Ride height for both applications is common at 100mm front and 110mm rear, with sport kit steering rack positioning plates factory fitted.

The standard setting for the front anti-roll bar is the central of 5 available holes.

Geometry

Ride height (for geometry check) - front 100 mm below front end of chassis siderail

- rear 110 mm below rear end of chassis siderail

Steering axis inclination 12° nominal

Castor + 3.8°; ± 0.2°

max. side/side 0.2°

Road use (Yokohama A038-R or Pirelli P Zero tyres):

Camber - 0.5°; + 0.1°, - 0.2°

max. side/side 0.2°

Alignment 0.2 mm toe-out overall; + 0.2 mm, - 0

Dry track use (Yokohama A038-R tyres):

Camber - 1.8°; + 0.1°, - 0.2°

max. side/side 0.2°

Alignment 0.5 mm toe-out overall; + 0.2 mm, - 0

Page 8

Page 7

Lotus Service Notes 340R

340R.G - WHEELS & TYRES

The 340R uses, according to market, either special Lotus styled 10 spoke magnesium wheels, made by

Tecnomagnesio, or 10 spoke alloy wheels made by Rimstock. Both types are mounted on standard Elise hubs

using longer (42mm protrusion instead of 36mm) studs, but standard wheelnuts. The magnesium wheels are

common in size and inset to the race wheel set (6J x 15 front, 8J x 16 rear, inset 10mm front and rear), with the

alloy wheels differing only in the rear rim width (7.5J) and rear inset (4mm). All wheels should be carefully and

regularly cleaned, especially if used on salted roads.

Before fitting magnesium wheels, a coating of Duralac anti-corrosive compound (A111C6017S) should be

applied to the hub mating face to prevent electrolytic corrosion. Wheel nut torque for all wheels is unchanged

from standard Elise at 80 - 85 Nm, but it is most important that following the first fitment of a NEW MAGNESIUM wheel, the wheel nuts are retorqued after 25 miles driving to allow for material settlement.

The Yokohama A038-R tyres fitted to the Elise 340R have been jointly developed by Lotus and Yokohama

specifically for Elise models, and whilst the specification is optimised for track use, the tyre is road legal in the

U.K. and some European markets. The tyre offers a high level of grip in both dry and wet track conditions

combined with good braking performance. The water clearing ability of the tyre is limited in standing water,

such that appropriate allowances should be made in these conditions. For competition use, the eligibility of the

tyre should first be checked with the appropriate organising authority. Full tyre specification is detailed in subsection XA.15. Note that the tyre tread pattern is directional, with the correct rotation marked by an arrow on

the sidewall.

For cars used predominately on public roads, it may be preferred to fit Elise 111S specification Pirelli P

Zero tyres with appropriate suspension geometry (see front and rear suspension sections).

SPage Page 17

Page 8

Lotus Service Notes 340R

340R.H - STEERING

All the steering components used on the 340R are as standard Elise, except the steering wheel centre pad

which is trimmed in blue Alcantara, and the rack positioning plates which are 'sport' specification to suit the

lowered ride height. The Sport removeable wheel may be fitted for track use. For full details refer to section

HE and XA.

340R.J - BRAKES

The 340R uses the drilled cast iron discs and brake pads as fitted to the Elise 111S. For full details refer

to section JH.

340R.K - COOLING

The cooling system is unchanged from standard, with the exception of the radiator duct/crash structure

which is similar in concept but reshaped. A front mounted oil cooler is an optional fit.

340.L - FUEL SYSTEM

The fuel system is based on that of the standard Elise, but the fuel tank filler spigot is angled more acutely

to clear the cabin rear bulkhead. New hoses connect the tank to the filler neck, which uses a flush fitting

lockable cap. As the cap does not incorporate the safety pressure relief function provided by the standard cap,

an additional safety valve is fitted into the breather pipe connecting the filler neck to the roll over valve. This

valve functions only in cases of extreme pressure change to prevent potential fuel tank damage.

Filler breather hose

Roll over valve

To charcoal Pressure relief valve

canister

Page 18

l62

Loading...

Loading...