Page 1

Page 1

Lotus Service Notes 2-Eleven

SUPPLEMENT

2-Eleven

Sub-Section Page

Concept & Overview 2-Eleven.# 2

Technical Data

2-Eleven.TD 3

Chassis 2-Eleven.A 5

Body

2-Eleven.B 5

Front Suspension

2-Eleven.C 9

Rear Suspension

2-Eleven.D 9

Engine

2-Eleven.E 11

Wheels & Tyres

2-Eleven.G 17

Brakes

2-Eleven.J 17

Cooling

2-Eleven.K 18

Fuel System 2-Eleven.L 19

Electrical 2-Eleven.M 20

Maintenance & Lubrication

2-Eleven.O 26

Miscellaneous 2-Eleven.Z 26

Circuit Diagrams Index - 27

Page 2

Lotus Service Notes 2-Eleven

Page 2

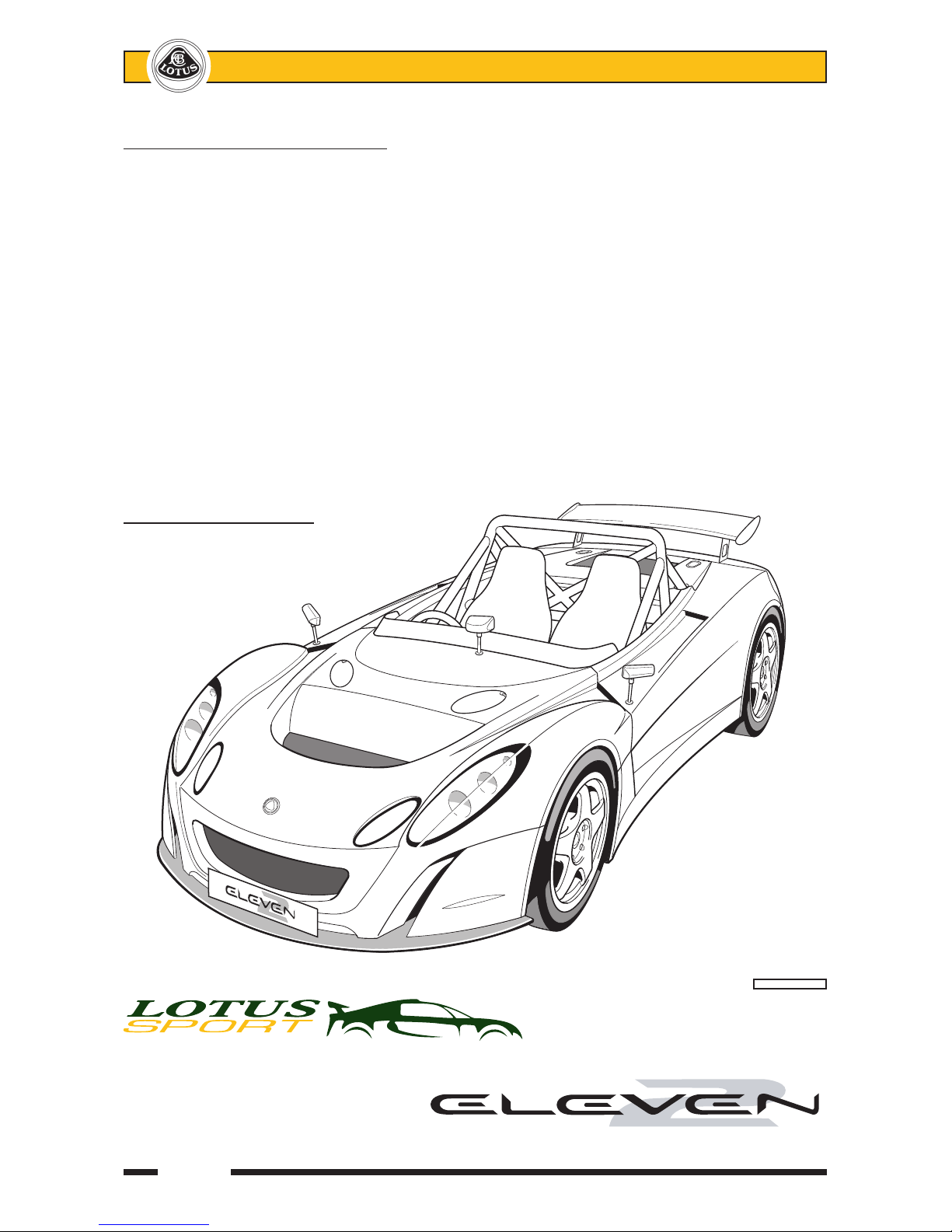

Lotus 2-Eleven (road spec.)

2-ELEVEN.# - CONCEPT & OVERVIEW

In March 2007, Lotus announced the Lotus 2-Eleven (255 PS) designed for the motorsport enthusiast, and

aiming to provide a high fun factor from a lightweight, high performance, distinctively styled vehicle, suitable

as a basis for various sporting disciplines, as well as offering U.K. customers the option of a unique road going

experience. The cars to be produced in small numbers for the U.K. and certain overeas territories tailored to

customer specification from an extensive options list.

The running gear is based on the Exige S, and shares that car's basic chassis and supercharged powertrain

componentry, but uses a new chargecooler arrangement and peripheral systems. Unique engine programming

is used in conjunction with 4 high flow fuel injectors as used on Exige Cup cars. The open top lightweight body

is designed to be amenable to economic accident repair and is supplemented by an FIA compliant roll over

bar, and strut mounted rear aerofoil acting directly onto the rear subframe. Options include a race specifica

tion carbon fibre adjustable rear aerofoil combined with an enlarged front splitter for enhanced aerodynamic

balanced downforce, and Ohlins fully adjustable spring/damper units with remote reservoirs.

This supplement describes the unique features of the 2-Eleven, and refers to other models where com-

ponentry is shared.

2-11 fq road black

Page 3

Page 3

Lotus Service Notes 2-Eleven

2-ELEVEN.TD - TECHNICAL DATA (Where different to standard naturally aspirated Exige)

Identification

The VIN coding of the 2-Eleven includes the following identifying characters:

Character 4 (engine type); 2-Eleven 2ZZ supercharged 255 bhp = N

Character 6/7/8 (vehicle type); 2-Eleven = 123

Character 12 (chassis specification); U.K. SVA RHD = F Note that the VIN label on the

U.K. SVA LHD = G 2-Eleven is located on the cabin

Track only LHD = H rear bulkhead, behind the

Track only RHD = J driver's seat.

Character 13 (model); 2-Eleven = 2

Dimensions

Overall length - SVA 3822 mm

Overall width - excluding mirrors 1709 mm

- including mirrors 1735 mm (approx.)

Overall height (at kerb weight) 1112 mm

Ground clearance 95 mm

Dry weight - base car 670 kg

Unladen weight - SVA 745 kg. incl. full fuel tank

Maximum weight 895 kg. incl. occupants

Capacities

Engine oil; refill incl. filter & Accusump 6.4 litre

(The oil cooler circuit contains an additional 3.5 litres, but this volume is not normally drained during routine

servicing)

Engine

Forced induction Magnuson MP62 supercharger with

integral by-pass valve.

Air/air chargecooler.

Maximum boost pressure 0.5 bar (7 psi)

Max. power 255 PS (252 bhp; 188 kW) @ 8000rpm

Max. torque 242 Nm (179 lbf.ft; 24.7 kgf.m) @

7000rpm

Power to weight ratio - base car 376 bhp/tonne

Specific power output 142 PS/l (140 bhp/l; 105 kW/l)

Lubrication system supplement Accusump oil storage reservoir

Oil cooling Twin front mounted oil coolers

Clutch

Spring cover assembly Uprated diaphragm spring

Friction plate Uprated cush drive springs

Wheels & Tyres

Wheels - type - std. Cast alloy, 8 x Y-spoke (as Exige)

- option Lightweight forged alloy 5-spoke

- size - std. - front 6.5J x 16

- rear 7.5J x 17

- option - front 7J x 16

- rear - rear 8J x 17

Page 4

Lotus Service Notes 2-Eleven

Page 4

Suspension

General Unique front top wishbones and steering

arms. Chassis rear brace

Ride height, mid-laden, front/rear 100/110 (2 x 75 kg pass., ½ tank fuel)

Option Siffened, 5-position adjustable front anti roll bar with Ohlins gas pressurised,

2-way adjustable, remote reservoir damp

ers, with adjustable spring top platforms.

Suspension Geometry (at mid-laden ride height)

Front

Castor + 3.5° to + 4.5° (+ 3°30’ to + 4°30’)

max. side/side 0.4° (0°24’)

Camber - 1.5° to - 1.3° (- 1°30’ to - 1°18’)

max. side/side 0.4° (0°24’)

Alignment - 0.4 mm to zero

Steering axis inclination 11°54’ to 12°06’

Rear

Camber - 2.75° to - 2.48° (- 2°45’ to - 2°29’)

Alignment 1.2 to 1.5 mm toe-in each side

Electrical

Battery - type Odyssey PC680

- rating PHCA 5 second 680 amps

- capacity (20 hr) 17 ah

- cold cranking 220 amps

- reserve capacity 24 minutes

- dimensions L185; W 79; H 187 mm

- weight 7 kg

Page 5

Page 5

Lotus Service Notes 2-Eleven

2-ELEVEN.A - CHASSIS

The 2-Eleven uses the basic chassis 'tub' of the Elise/Exige with minor revisions including;

- Deletion of door hinge upright extrusions on each end of scuttle beam.

- Full height side members (no cabin access cut down).

- Revised pick up points for the roll over bar.

- Addition of a body side attachment panel to the lower edge of each chassis rail sill extension.

The front crash structure is as Elise/Exige with minor fettling revisions, and the galvanised steel rear

subframe differs only in respect of incidental fixings.

Roll-Over Bar

The tubular steel roll-over bar is substantially cross-braced, including provision for shoulder harness

anchorage, and features integral bracing struts to both front and rear. The feet of the main hoop are bolted to

tapping plates riveted into the top surface of the chassis side rails, with the front bracing struts locating against

the joint between the side rail top and scuttle cross-beam and secured by similar riveted tapping plates. The

rear bracing struts use a single fixing bolt at each side to secure to the rear subframe.

The roll-over bar complies with FIA requirements for international motorsport, but note that any additions

or modifications to the 'bar may invalidate such compliance.

2-ELEVEN.B - BODY

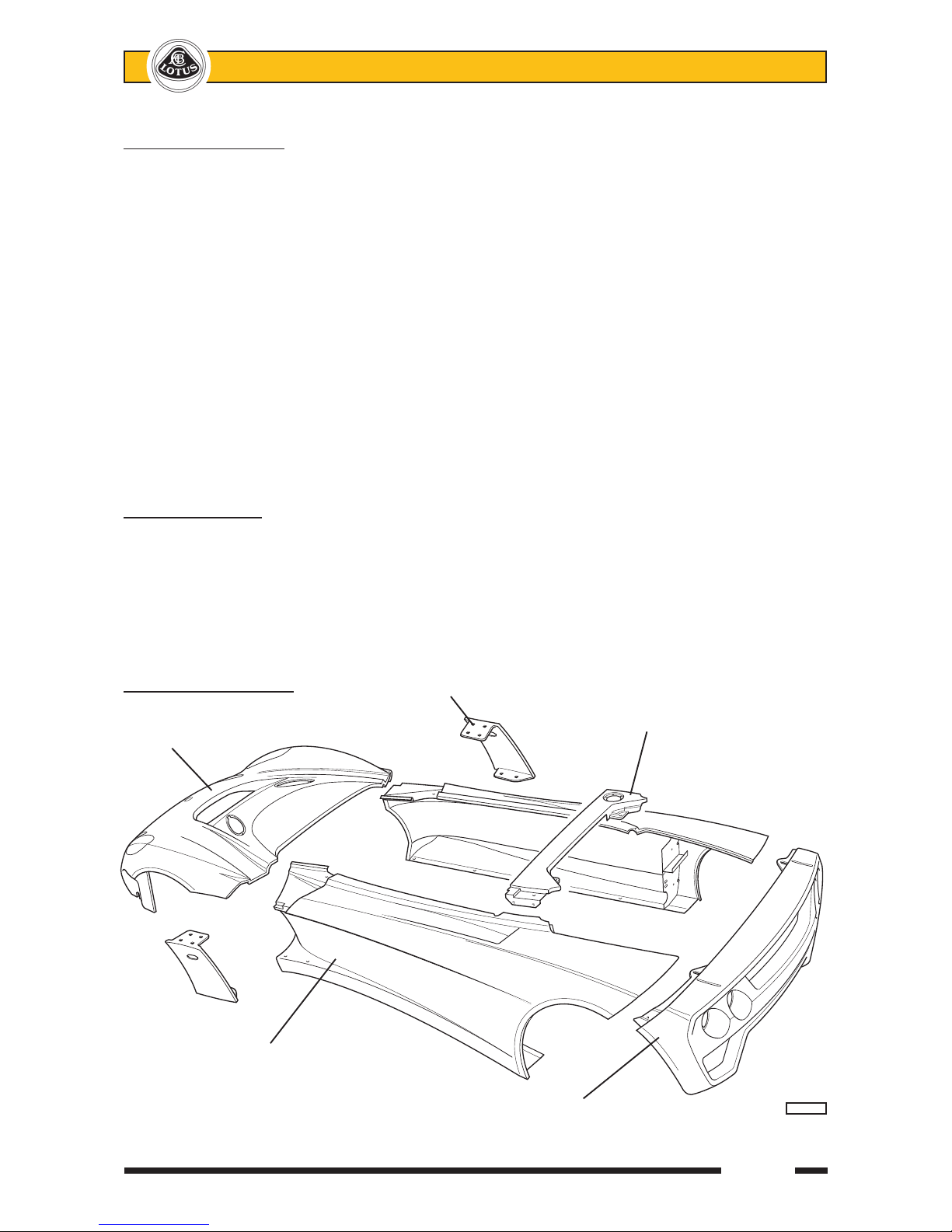

On the 2-Eleven, the rear transom/bumper, body exterior side panels, ‘A’ panels, front splitter and splitter

end support panels and the single panel comprising the whole of the nose section and front wings, are secured

by threaded fasteners to permit easy removal for access to chassis or powertrain components, and allow simple

and economic accident repair. The composite body inner sides, together with the alloy sheet front and rear

cabin bulkheads and rear scuttle panel, are secured with an elastomeric adhesive.

Screw fixed body panels 'A' panel

Rear scuttle panel (also bonded)

Front body section

Body side

Rear transom/bumper

pl1001cc

Page 6

Lotus Service Notes 2-Eleven

Page 6

All composite panels on the 2-Eleven are designed for light weight consistent with aerodynamic function,

with some panels featuring core mat technology to provide a sandwich construction for enhanced stiffness.

All panels are nevertheless vulnerable to damage caused by inappropriate subjection to bodyweight or other

misapplied forces.

Note: The 2-Eleven is not equipped with conventional shock absorbing bumpers, so extra care should be taken

when parking to guard against body damage. The Lotus 2-Eleven does not offer the same kind and degree of

impact resistance or energy absorption afforded by normal bumper systems. Some panels, including the front

quarter panels and ‘A’ panels, have sacrificial functions to help reduce repair costs and damage to the front

body section in minor accidents.

Care is also required, due to the low ground clearance, to guard against chassis underside damage caused

by ramps, kerbs and road humps. Note that the front splitter panel is constructed from timber composite,

sealed by a layer of resin, and that the occasional grounding of this panel, which is a normal occurrence under

track conditions, will cause erosion of the outer layer, requiring periodic repair (water absorption may promote

eventual de-lamination) or replacement.

Engine Lid

A removable panel in the rear body is secured by two recessed ‘Aerocatches’ and provides access to the

engine for maintenance operations.

To remove the cover, at each latch, press the smaller section of the flush fitting latch plate to allow the

latch plate lever to spring up. Fully raise the lever to release the latch. Lift the rear of the panel, and then draw

rearwards to disengage the front flange from beneath the rear scuttle, before lifting the panel forwards and over

the rear aerofoil. Park the panel where it is unlikely to be damaged or blown away by wind.

To refit, rest the panel on the two rubber buffers at the front of the body aperture and slide forwards to

engage the tang bracket at each side of the panel, beneath the body edge adjacent to the roll bar backstays,

and the panel front flange beneath the rear scuttle edge. Press down the two latch levers to engage the retaining pins, finally pressing the small buttons to allow the lever ends to be captured. Ensure that each lever is

correctly clipped shut, and flush with the body surface.

Rear Transom/Bumper Panel

The rear transom panel is screw fixed in the following manner:

- At each side, an angle bracket bonded to the underside of the transom top surface is secured by two

screws to the aerofoil mounting strut.

- A row of screws secures the lower edge of the panel to the muffler alloy heatshield, which is itself screwed

to the rear subframe.

Bonded Body Panels

Body inner side panel

Front bulkhead

pl1002cc

Body inner side panel Rear bulkhead

(also bonded to rear

scuttle panel)

Page 7

Page 7

Lotus Service Notes 2-Eleven

- At each side, two screws pass through the transom end flange into captive nuts in the body side panel.

Rear Scuttle Panel

The rear scuttle panel is fixed at each side by two horizontally disposed M6 screws into bond nuts on the

body side panel, and is bonded along the top edge of the rear bulkhead.

Body Side Panel

The body side panels are secured by screw fasteners for ease of access and replacement. Each panel

is retained as follows:

- The top edge of the body outer side panel lips over the body inner side panel, to which it is fixed with four

screws engaging with captive nuts in the inner panel.

- A single screw passes from beneath, through the end of the rear bulkhead capping rail into a captive nut

in the side panel.

- The lower edge of the body side is secured to four threaded inserts in a chassis extension flange.

- At the front of the rear wheelarch, two screws secure the side panel baffle/stiffener to a vertical angle

bracket bolted to the main chassis rail.

- At the rear end of the panel, two screws pass from beneath, through the rear transom flange into captive

nuts in the body side.

- At the front of the body side, two screws pass upwards into captive nuts in the rear end of the front body

panel.

'A' Panels

At the front of each body side, a separate 'A' panel is used to form a duct for air exhausting from the front

wheelarch. Each panel is secured by four screws at the top (2 into the body side, 2 into the front body panel),

and 2 screws into the body side sill at the bottom.

Front Quarter Panels

A front quarter panel is fitted ahead of each front wheel and forms a mounting and duct for the oil cooler,

as well as tying the front corner of the body to the splitter panel. The quarter panel is fixed by:

- 2 screws from beneath, through the splitter into captive nuts in the quarter panel lower flange.

- 2 screws down through the front body flange into captive nuts in the quarter panel upper flange.

Front Wheelarch Shields

A small moulded plastic panel is fitted within each front wheelarch, fixed between the body side and radiator mounting panel, and provides protection for the cooling and brake system components.

Front Undertray

An alloy sheet undertray is fitted beneath the nose, and stabilises the front body, splitter panel, and crash

structure to the front of the chassis. The undertray is secured by:

- 3 screws into the front edge of the chassis (also slots into the extrusion).

- 3 screws and nuts at each side into the lower flange of the crash structure.

- 5 fixings around the front edge, passing through the splitter into captive nuts in the front body flange.

- 2 screws and nuts to a central support bracket from the crash structure.

- 1 screw each side to the splitter panel.

Front Splitter Panel

A flat timber composite splitter panel is mounted beneath the nose to cleanly split the airflow above and

below the underside of the car to optimise aerodynamic downforce whilst minimising drag. A road and race

version of the panel are designed to balance the forces produced by the two types of rear aerofoil. Note that

the front splitter panel is constructed from timber composite, sealed by a layer of resin, and that the occasional

grounding of this panel, which is a normal occurrence under track conditions, will cause erosion of the outer

layer, requiring periodic repair or replacement.

The panel is secured by:

- Undertray fixings as listed above.

- 2 screws at each side to the front quarter panel.

Page 8

Lotus Service Notes 2-Eleven

Page 8

Front Body Panel

To remove the front body panel for access to the radiator, front suspension, brake control system and other

front chassis components, proceed as follows:

- Release each of the two oil coolers from the front body by removing the two securing screws.

- Remove the aero screen to prevent damage, or at least release the two rearmost fixings at each side

securing the screen to the body sides.

- Remove the single screw each side from within the front corner of the cockpit into a captive nut in the

body.

- Remove the two screws each side from within the 'A' panel duct into captive nuts in the body.

- Remove the two screws each side fixing to the top of the front quarter panels.

- Remove the single screw each side from beneath, fixing the splitter panel to the body inboard of the oil

coolers.

- From beneath the nose, remove the 5 screws securing the splitter panel to the body flange.

- Carefully lift the front body from the car, disconnecting the wiring harness if applicable.

Note that the front turn lamps (if fitted) are bonded into the front body using Betaseal products.

Rear Aerofoil

Two types of rear aerofoil are available. For road going cars, a fixed angle GFRP composite curved blade

with integral end plates is used, whereas the track optimised aerofoil is made using carbon fibre with alloy end

plates, and has provision for adjusting the angle of incidence. Each type should only be used with the corre

-

sponding front splitter panel in order to maintain the correct aerodynamic balance.

Both aerofoil types are mounted via machined alloy support plates to the top surface of the rear subframe.

Each plate uses an angle bracket at its base to secure to the subframe, and two of the same angle bracket to

brace the plate to the rear clamshell through which the plate penetrates. A further angle bracket secures the

blade to the top of the support plate.

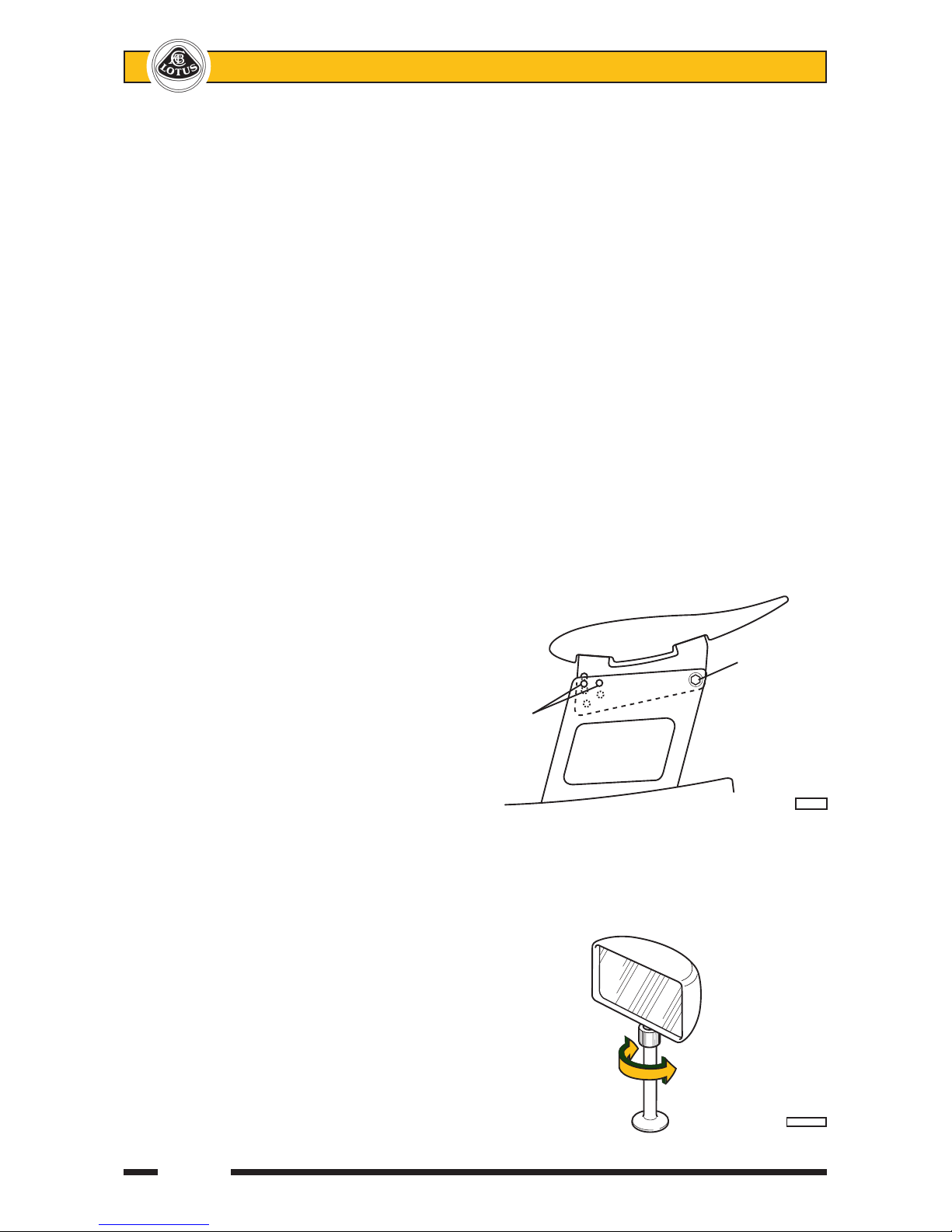

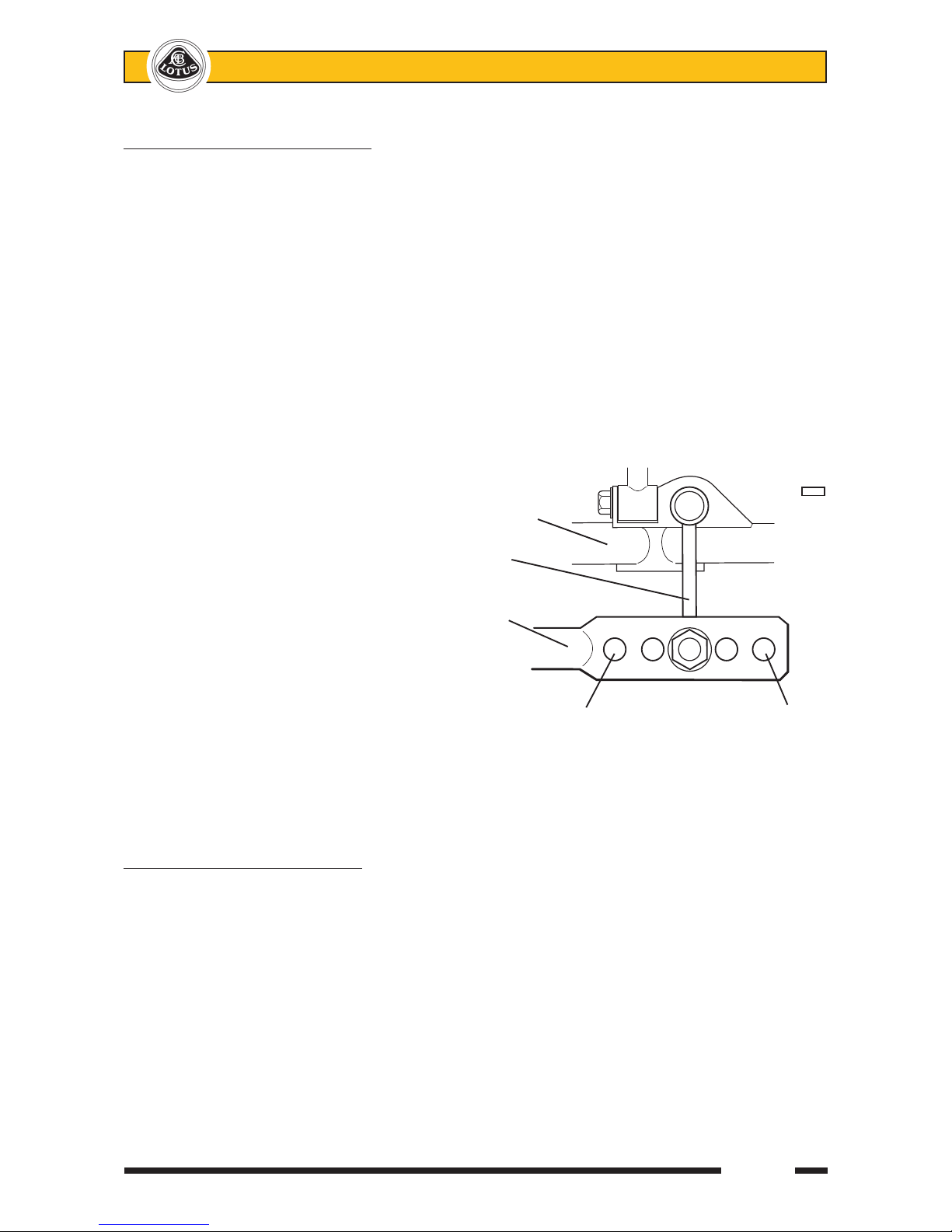

The track type aerofoil angle of attack

may be adjusted by loosening the rear pivot

screw on each support plinth, and removing

the front fixing screw. Tilt the blade to the

desired angle, and refit the screw in the most

appropriate fixing hole. Tighten all fixings

securely.

Slots are also provided on the endplates

to allow correct horizontal alignment to be

maintained after adjustment of blade angle.

Exterior

The Launch Edition of the 2-Eleven is finished in a two tone combination of B111 Lotus Sport Black and

B115 Arctic Silver, with yellow/black/silver styling decals. A '2 Eleven' decal is applied to the rear transom panel,

with optional larger decals on each body side. Stone chip film is fitted to vulnerable areas.

Mirrors

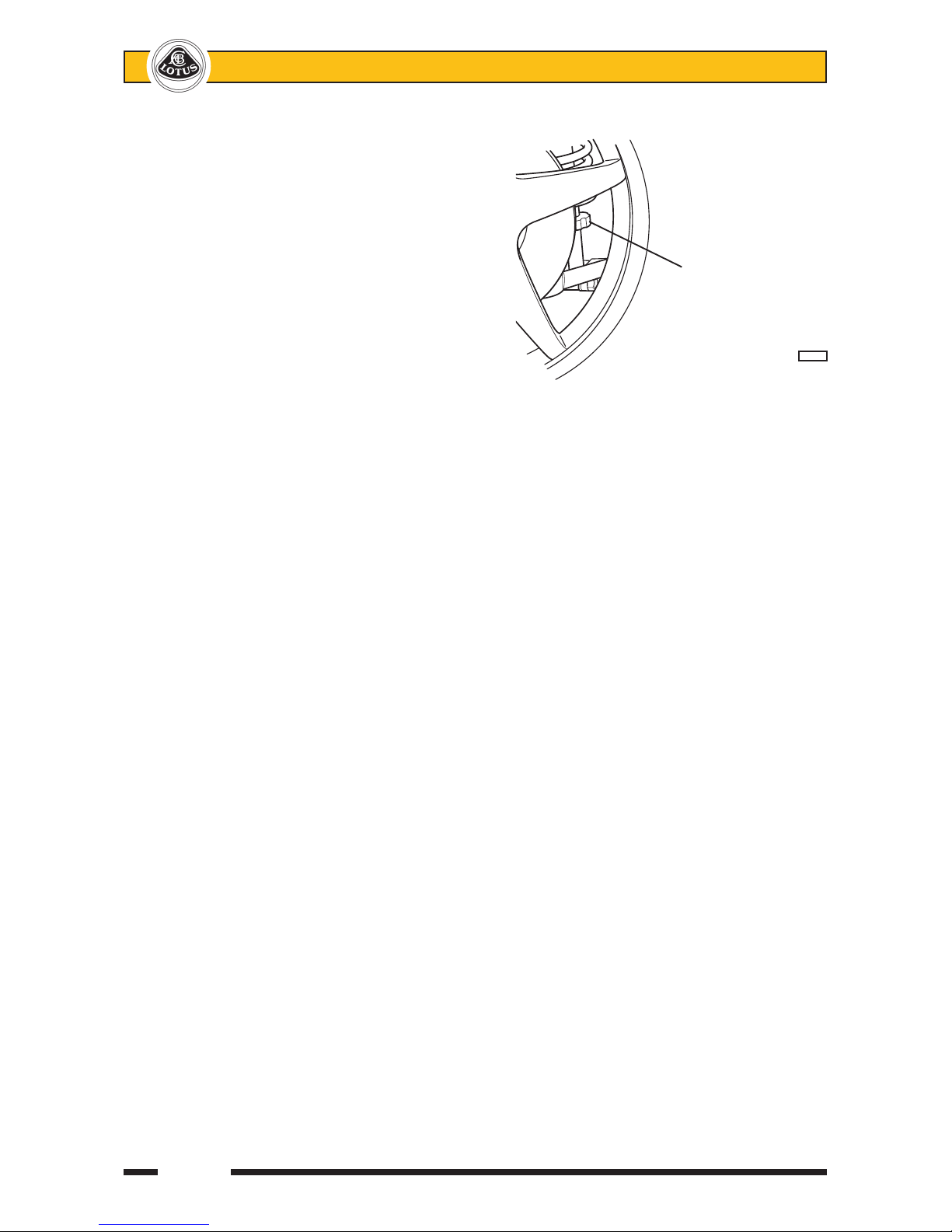

A central rear view mirror is mounted

on the top of the cabin front scuttle, with an

additional mirror on both the driver's and passenger's body sides. Each of the convex glass

mirrors may be adjusted after slackening (turn

anticlockwise from above) the knurled clamp

nut below the mirror.

Tighten

to fix

Slacken

to adjust

ohs164B

Pivot screw

Alternative

fixing hole

positions

ohs166

Page 9

Page 9

Lotus Service Notes 2-Eleven

2-ELEVEN.C - FRONT SUSPENSION

The front suspension is based on standard Elise/Exige componentry, but the angle of the top wishbone

ball joint housing differs to better suit the lowered ride height. For the same reason, re-configured steering

arms are fitted, being machined from solid EN16 steel billets, and heat treated.

On cars with the optional 'Sports Pack', revised road springs front and rear are fitted on Ohlins dampers

featuring remote gas reservoirs, adjustable spring platforms and separate adjustments for compression and

rebound damping. The 22 compression and 60 rebound damper settings allow the characteristics to be fine

tuned to individual requirements, whilst the threaded spring platforms allow adjustment of ride height and corner

weighting. Recommended front/rear mid-laden ride height for both road and track use is 100/110mm. Front

height should always lie within the range 95 - 110mm, with a corresponding rear setting 5 - 10mm higher.

Each gas reservoir is mounted on the side of the crash structure, and is connected to its damper body

by a steel braided hose. Compression (bump) damping is adjusted by turning the knob on the end of the gas

reservoir canister: Turn clockwise to increase damping, and counterclockwise to decrease. Recommended

settings are as follows:

Road use: 11 clicks from full hard

Track use: 11 clicks from full hard

Rebound damping is adjusted via a

ribbed collar below the bottom spring seat:

Turn clockwise (as viewed from below) to

increase damping, and counterclockwise to

decrease. Recommended settings are as

follows:

Road use: 8 clicks from full hard

Track use: 8 clicks from full hard

The motorsport stiffened and 5-position

adjustable front anti-roll bar (included as part

of the Sport Pack) provides further opportunity

for fine tuning. To stiffen the bar, use a more

forward hole, and to soften, use a more rear

-

ward hole. Recommended setting:

Road use: Central hole

Track use: Central hole

Note that the hard Nylon type chassis mountings used with this 'bar require periodic lubrication with MoS

2

grease at least every 3,000m (5,000km). For suspension geometry refer to Section 2-ELEVEN.TD - TECHNICAL DATA.

2-ELEVEN.D - REAR SUSPENSION

On cars with the optional 'Sports Pack', revised road springs front and rear are fitted on Ohlins dampers

featuring remote gas reservoirs, adjustable spring platforms and separate adjustments for compression and re

bound damping. Recommended front/rear mid-laden ride height for both road and track use is 100/110mm. Front

height should always lie within the range 95 - 110mm, with a corresponding rear setting 5 - 10mm higher.

The 22 compression and 60 rebound damper settings allow the characteristics to be fine tuned to individual

requirements. Each gas reservoir is mounted on the rear subframe and is connected to its damper body by a

steel braided hose.

c47B

Lower wishbone

Drop link

Anti-roll bar

Stiff Soft

Page 10

Lotus Service Notes 2-Eleven

Page 10

Compression (bump) damping is adjusted by turning the knob on the end of the gas

reservoir canister: Turn clockwise to increase

damping, and couterclockwise to decrease.

Recommended settings are as follows:

Road use: 15 clicks from full hard

Track use: 10 clicks from full hard

Rebound damping is adjusted via a

ribbed collar below the bottom spring seat:

Turn clockwise (as viewed from below) to

increase damping, and counterclockwise to

decrease. Recommended settings are as

follows:

Road use: 15 clicks from full hard

Track use: 12 clicks from full hard

All cars are equipped with through bolted spherical joints on the inboard ends of the rear toe-links, allied

to a tubular steel crossbrace connecting the rear sides of these joints to provide 'double shear' support. For

suspension geometry refer to Section 2-ELEVEN.TD - TECHNICAL DATA.

Rebound

adjustment

collar

d50aB

Page 11

Page 11

Lotus Service Notes 2-Eleven

2-ELEVEN.E - ENGINE

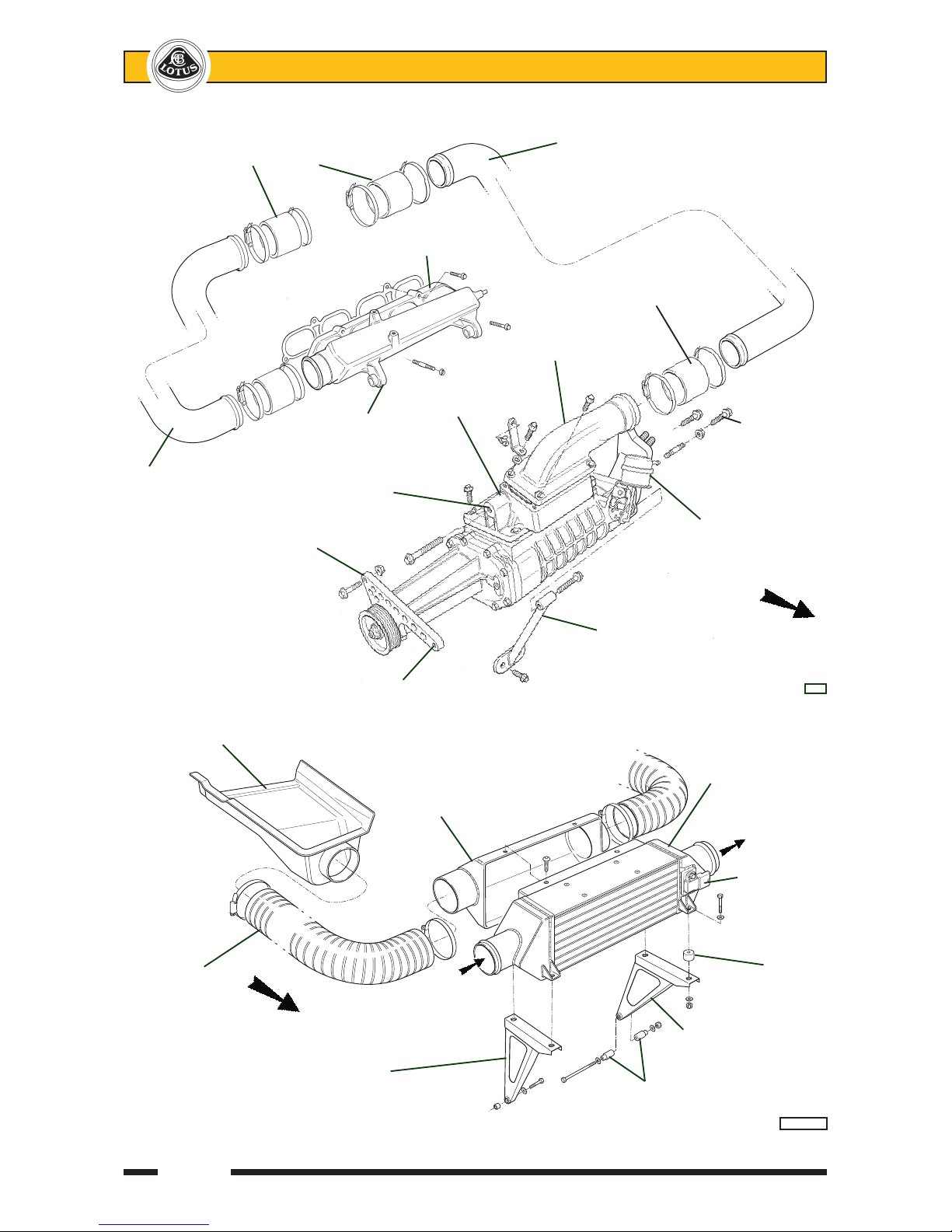

The 1.8 litre 2ZZ-GE engine with VVTL-i (Variable Valve Timing and Lift - intelligent) as used in other

Elise/Exige models, is fitted with a low pressure Roots type Magnuson MP62 supercharger to provide up to 0.5

bar (7 psi) of boost pressure. The supercharger is mounted on the left hand side of the block and driven by a

lengthened version of the multirib auxiliary belt. The unit is self contained and features helix twisted rotors to

minimise output pressure variations, and maintenance free gearing and bearings, requiring no externally sourced

lubrication. An integral by pass valve under ECU control, operates to recirculate air from the compressor outlet

back to the inlet under conditions of idle and part throttle to the benefit of economy and quiet operation.

The supercharger is hung off the new intake manifold by two bolts in conjunction with eccentric sleeves in

order to ensure stress free alignment. An alloy bracket supports the nose of the unit to the RH engine mounting

plinth, and a tubular strut braces the intake end of the unit to the clutch slave cylinder mounting point.

Air is drawn from an enlarged air cleaner through the throttle body and adaptor and into the supercharger

axial intake port. From the outlet port on the compressor top surface, the air is directed through a stainless

steel duct to the LH end of an air/air chargecooler mounted behind the engine, where airflow gathered from

an intake duct in each of the body sides aft of the cockpit, is directed by convoluted ducting to a chargecooler

shroud and through the radiator finning to cool the compressed intake charge. The cooled air exiting from

the RH end of the chargecooler flows via another stainless duct into a cast alloy intake plenum/manifold. The

whole intake tract uses large diameter ducting and generously radiused bends to optimise airflow and intake

efficiency and minimise any potential throttle lag. A charge air temperature sensor is mounted in the outlet

tank of the chargecooler.

Each end of the chargecooler is mounted by two alloy spacers to a fabricated steel mounting bracket secured to the engine crankcase by a single fixing bolt. A bonded rubber bush at this position supresses vibration

effects, and in conjunction with the rubber hose connections to the inlet and outlet ducts, provides an isolated

mounting of the chargecooler.

A re-shaped breather pipe is used to connect the crankcase breather spigot to the cam cover and circumnavigate the supercharger.

Road going cars use the standard catalytic converter, which is substituted by a plain pipe on track cars,

but all versions are fitted with a unique exhaust muffler, featuring a double pass design, with single RH tailpipe

exiting through the rear transom panel.

Four special high-flow port fuel injectors are used (common with Cup cars and USA Exige S) in conjuction

with unique engine programming, which incorporates control of the supercharger by-pass valve. The boost

characteristics have allowed the switching point from low to high lift cam profile to be varied between 4,500

and 6,200 rpm dependent on engine load (at normal running temperature). Twin front mounted oil/air coolers

are fitted one each side, ahead of the front wheels.

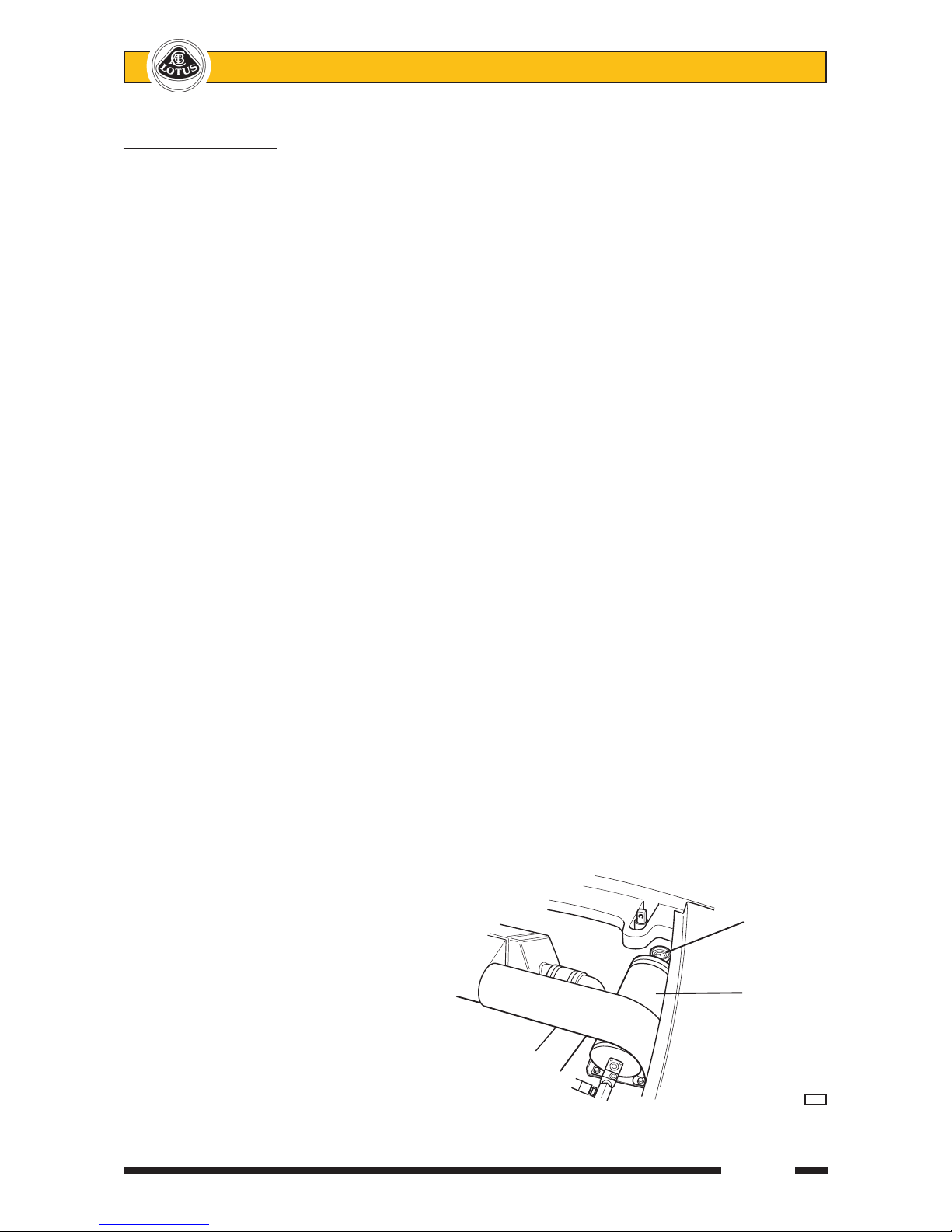

Accusump

To provide protection against the possibility of oil starvation caused by the extreme g-forces possible with

track use on slick tyres, the 2-Eleven is fitted with an Accusump oil storage system.

A 2-litre Accusump reservoir is mounted

behind the engine on the left hand side of the

rear subframe, and is plumbed into the LH oil

cooler return hose at the front of the engine

bay. The device comprises an alloy cylinder

divided by a sliding piston, one side of which

is connected to the engine oil supply, with

the other containing pressurised air. With

the engine running, the cylinder is charged

with oil provided by the engine oil pump, but

if the pressure should drop for a short period

due to oil pump pick up pipe exposure during

extreme braking or cornering events, the ac

cumulator air pressure forces the stored oil

into the engine lubrication system to maintain

continuity of oil supply until normal conditions

are resumed.

Pressure

gauge

Accusump

reservoir

e234

Page 12

Lotus Service Notes 2-Eleven

Page 12

pl4610cca

Connection to chargecooler Chargecooler inlet duct

outlet & inlet

New inlet

manifold

Supercharger

outlet connector

Supercharger

outlet elbow

Supercharger

outlet adaptor

Mounting lug Swan neck

for supercharger adaptor

fixings

Chargecooler Fixing point (s/c inlet)

outlet duct to manifold

By-pass valve

Fixed to engine capsule

mounting plinth

Front

Support strut to clutch

slave cylinder mounting

Alternator anchor

e235

Cooling air intake duct

Chargecooler

Collector

Outlet to engine

Charge air

temperature

sensor

Cooling air Alloy

trunking to Inlet spacer

chargecooler from s/c

Rear

Fixing bracket to

to crankcase

Fixing bracket to

clutch housing Spacers

Page 13

Page 13

Lotus Service Notes 2-Eleven

A one-way valve at the oil cooler connection of the 'T'- piece ensures that the oil discharged from the

Accusump is directed into the oil pump and not the cooler. An Electric Pressure Control (EPC) valve fitted at

the connection to the Accusump cylinder, allows cylinder charging when oil pressure is above 35 - 40 psi, and

cylinder discharging at engine oil pressures below 35 - 40 psi. The EPC is also linked to the ignition switch

such that with the ignition switched on the valve is open to allow oil flow, and with ignition off the valve is closed

to retain oil within the reservoir.

Normal Operation

When the ignition is turned on, the EPC valve on the Accusump is opened, allowing the pressurised oil

stored in the reservoir to flow out into the engine and prime the oil galleries and bearings ready for start up.

When the reservoir has been emptied, the pressure gauge on the end of the reservoir will indicate the precharge pressure which should be 7 - 15 psi.

When the engine is started, engine oil pressure will force the reservoir piston back, such that the reservoir

air pressure gauge will indicate engine oil pressure, with the quantity of stored oil dependent on this pressure

at any one time. With cold oil, 80 psi may be seen, but idling at normal running temperature should produce

around 30 - 40 psi. Note that the pressure reading on the reservoir gauge is damped and will lag behind the

actual instantaneous pressure. A pressure relief valve in the end of the reservoir protects the equipment from

over-pressure damage. If oil is seen to escape from this valve, a fault in the lubrication system is indicated, or

excessive rpm have been used with cold oil.

When the engine is stopped, the EPC valve closes and a quantity of oil pertaining to the oil pressure at

that time, will be retained in the Accusump ready for re-starting.

Routine Checks

Be aware that the indicated oil level on the dipstick will depend on the amount of oil stored in the Accusump, which itself is dependent on the both the Accusump pre-charge air pressure and the engine oil pressure

when the ignition was switched off.

Before checking the oil level, the Accusump pre-charge pressure should first be checked; turn on the

ignition to open the EPC valve and allow the stored oil to be discharged from the Accusump. The pressure

gauge reading will drop during this discharge, but should then register 7 - 15 psi representing the pre-charge.

If necessary, adjust the air pressure using tyre inflator equipment on the Schraeder valve adjacent to the gauge

and set to 15 psi. Allow adequate time for the gauge reading to stabilise.

The oil level should now be above the top

mark on the dipstick. To check for correct oil

level, the engine should be started to charge

the Accusump, and run to normal operating

temperature until the Accusump pressure

gauge registers 40 psi. If the engine is already

hot, idle oil pressure may not be sufficient to

open the Accusump valve, and the pressure

gauge will continue to show 15 psi pre-charge.

Increase engine rpm to open the valve. With

the gauge showing 40 psi, turn off the engine.

The EPC valve will then close and trap the

normal hot idle quantity of oil in the Accusump

cylinder.

After a suitable oil drainback pause, the sump oil level may then be inspected on the disptick, and the

level corrected to the top mark. It is important to maintain oil at this level to accommodate the oil transfer into

the Accusump at pressures greater than 40 psi. Be aware that checking the oil level under any conditions other

than 15 psi pre-charge and 40 psi oil pressure will produce inconsistent results.

Oil Changing

Before draining the sump, the ignition should first be switched on to open the EPC valve and allow the

Accusump to discharge the stored oil into the sump. Check that a pressure of 7 - 15 psi remains in the Accusump at the end of this process, and if necessary top up the pressure using tyre inflating equipment on the

Schraeder valve next to the gauge and set to 15 psi.

ohs149aB

OIL FILLER CAP

ohs131aB

DIPSTICK

Page 14

Lotus Service Notes 2-Eleven

Page 14

The oil can then be drained in the usual way, with the quantity contained in the oil cooler lines disregarded

for the purposes of routine maintenance. If an engine failure has occurred, with possible debris contamination

of oil hoses and coolers, it is recommended to replace both oil coolers, and to replace or thoroughly flush the

feed and return hoses. At each service interval the in-line filter gauze in the hose between the Accusump and

'T'- piece, and located in the RH rear wheelarch, should be renewed.

After renewing and pre-filling the engine oil filter, refill the sump to about 10mm above the top mark on the

dipstick. Start the engine and allow to idle. Do NOT rev the engine or drive the car. The Accusump will take

up to 2 litres of oil from the sump to store within the cylinder. Continue to idle the engine until the Accusump

pressure gauge drops to 40 psi (as the oil warms) and then switch off the engine. Top up the oil to the top

mark on the dipstick.

Supercharger Remove/Refit

To remove:

1. Remove the chargecooler inlet and outlet ducting.

2. Remove the throttle body and vacuum/breather hose plumbing.

3. Using a 6-point socket, relieve auxiliary belt tension and remove the auxiliary belt. Remove the alternator

top mounting bolt, slacken the lower, and swing down the alternator. Release the dipstick tube from the

supercharger.

4. Using a strap wrench, remove the supercharger pulley retaining nut, and slide off the pulley.

5. Remove the support strut between the throttle body adaptor and the clutch slave cylinder. Slacken the

pinch bolt securing the supercharger to the nose bracket. Remove the two bolts supporting the super

-

charger to the inlet manifold and withdraw the supercharger.

To refit:

1. With the supercharger nose bracket bolted to the engine mounting plinth, fit the upper fixing on the alter

nator to the nose bracket outer end (with 13.5mm spacer). This defines the position of the nose bracket.

Tighten bracket to engine mounting plinth to 50 Nm. Remove alternator top bolt and swing down to allow

supercharger to be fitted.

2. Prepare supercharger: Clean mating faces of supercharger and outlet adaptor using Betaclean 3900. Fit

'O' ring into groove in outlet adaptor and fit to supercharger using 6 off M8 x 25 setscrews with Permabond

A130. On the fixing located inside the adaptor, Permabond should be applied over the entire thread length.

Orientate the adaptor with the outlet towards the rear of the car when fitted. Torque tighten all fixings to

25 Nm.

Clean mating faces of outlet adaptor and outlet elbow using Betaclean 3900. Fit 'O' ring into groove in

outlet adaptor face. Fit outlet elbow to point to LH side of car using 4 off M8 x 25 setscrews with a pipe

clip bracket secured by both rearmost fixings. Tighten to 25 Nm.

ohs129ohs135

SUMP DRAIN PLUG

OIL FILTER

Page 15

Page 15

Lotus Service Notes 2-Eleven

3. Fit M8 stud B111E6081S into RH top (as viewed on face) fixing position in supercharger inlet flange. Clean

mating face on supercharger and inlet adaptor using Betaclean 3900. Fit 'O' ring into groove in adaptor

face and fit adaptor to supercharger using 2 off M8 x 30 flange head bolts in top positions and M8 flange

nut on stud - all 25 Nm. Disregard 4th position at this stage.

4. Mount supercharger: With the pulley removed from the supercharger, slide the nose into the nose bracket

until hard against the machined step. Support to the inlet manifold sliding bushes using M10 x 50 flange

head bolts and Permabond A130, but do not tighten. Tighten the nose bracket socket head pinch bolt to

25 Nm.

5. Loosley fit the supercharger support strut between the inlet adaptor (M8 x 55 bolt with A130) and the clutch

slave cylinder fixings (M8 x 25 with A130). Tighten the three support strut bolts to 25 Nm. Carefully tighten

the two M10 x 50 flange head bolts to pull in the two spacers evenly to clamp against the supercharger.

6. Refit the alternator upper bolt and spacer and tighten to 25 Nm. Tighten the lower bolt to 25 Nm.

7. Fit the pulley to the supercharger with the longer boss towards the 'charger. Fit the nut onto the shaft, and

use a strap wrench to hold the pulley whilst the nut is tightened to 61 Nm.

8. Use a 6-point socket on the tensioner arm to allow fitment of the multirib accessory drive belt around the

pulleys as shown, ensuring that the belt is correctly seated in all the ribbed pulleys.

9. Refit other components in reverse order to removal.

Note areas of change compared with standard models;

# Engine dipstick tube altered to avoid supercharger.

# Crankcase breather pipe altered to avoid supercharger.

# Relays on engine bulkhead move to avoid supercharger by-pass capsule

Belt tensioner

spring/damper

Water pump

Supercharger

Slave pulley

Belt tensioner

Alternator

Crankshaft pulley

pl4103cc

Page 16

Lotus Service Notes 2-Eleven

Page 16

Supercharger Nose Assembly

If the supercharger input shaft oil seal should be damaged or found to leak, the complete nose assembly in-

cluding the nose housing, shaft, bearings and seals should be replaced as a unit by the following procedure:

Parts Required

Supercharger Nose Assembly A128E6020S 1 off

Oil Fill Kit A128E6014S 1 off

1. Remove the complete supercharger assembly from the engine (see above).

2. Use a strap wrench to hold the pulley, and remove the pulley nut. Use a three leg puller to withdraw the

pulley from the shaft. Apply forces only to the pulley and shaft end. Other techniques may damage the

housing or internal components.

3. Provision for collecting the contained oil before removing the 8 bolts securing the nose housing to the

main supercharger body. To separate the nose from the body, expanding jaw pliers should be used in the

recesses provided around the flange. Do not pry between the mating faces, or damage will be caused

and oil leaks result. Drain all the old lubricant from the gearcase and discard appropriately.

4. Stand the supercharger body on end with the gearcase uppermost. Discard the old synthetic drive cou

pling, and fit the new part supplied in the oil fill kit onto the three pegs on the rotor drive gear. Check that

the two alignment dowels are fitted in the supercharger body flange.

5. Fill the gear case with 120 ml of Magnuson Products Supercharger oil as supplied in the oil fill kit.

6. Clean the mating face on the supercharger body and on the new nose housing, and apply a bead of Loc

tite Eliminator Sealant, supplied in the oil fill kit, around the whole of the joint face on the nose housing,

looping around each of the fixing holes.

7. Before attempting to fit the nose housing, first align the three pins on the input shaft with the vacant holes

in the drive coupling. Place the nose housing into postition, and ensure that the two alignment dowels

engage with their corresponding holes. It may be necessary for the casing bolts to be used to pull the two

housings together.

8. If re-using the casing joint bolts, the threads should be thoroughly cleaned before applying Loctite 242 or

equivalent medium strength threadlocking compound. New casing bolts are pre-treated. Fit the eight bolts

and tighten progressively to pull the joint evenly together. Finally torque tighten to 27 Nm in the pattern

shown.

9. Fit and secure the oil service plug, and position mark. Refit the supercharger.

1

4

7

8

5

6

2

3

Tightening sequence

e233

Page 17

Page 17

Lotus Service Notes 2-Eleven

2-ELEVEN.F - TRANSMISSION

Clutch

The 2-Eleven is fitted with an uprated clutch cover assembly rated for a maximum torque of 362 Nm, and

which enjoys a mass reduction of 0.6 Kg over the regular cover. Also fitted is an uprated friction plate which

uses 4 steel compression springs in the cush drive hub, in place of the regular item's 4 rubber blocks.

Differential

The 2-Eleven is fitted as standard with an 'open' bevel gear differential, supplemented by switchable Lotus

Traction Control (LTC), with an option package of variable LTC with Launch Control. For full details of these

electronic systems, refer to Section 2-Eleven.M

Two types of optional Limited Slip Differential (LSD) are also available.

Torsen Type: A Torsen (TORque SENsing) gear type LSD limits the speed differential between the two rear

wheels by mechanically distributing the applied torque in accordance with the available grip at each tyre. The

LSD uses worm wheels to interconnect the two output shafts and uses the poor torque reversal efficiency

of this type of gearing to ensure that both wheels are always supplied with driving torque. This feature can

enhance vehicle performance in some competition events, and help maintain mobility in some types of soft

ground condition.

Apart from the taper roller bearings supporting the differential in the transmission case, the LSD is not

serviceable. For details of bearing preload adjustment, refer to Service Notes sub-section FJ.6. There is no

special oil requirement for the Torsen LSD. All factory supplied transmission assemblies originally built with

Torsen LSD are identified on the bar code label applied to the top surface of the transmission case; The 3rd

character of the 7 digit code is 'O' for open differential, and 'L' for limited slip.

Plate Type: A competition type friction plate LSD made by TRD is available in both '2 way' and '1.5 way' variants.

This type of LSD uses a pack of friction clutch plates between each differential output gear and the differential

carrier. The load applied to the clutch pack is proportional to the input torque via a cam and ramp angle design

incorportated between the 4-pinion spider (driven by the crownwheel) and the two clutch pack assemblies. The

'stiffness' of the LSD operation is dependent on the ramp angle which may be specified on ordering. A '2 way'

LSD uses the same ramp angles for drive and overrun to provide similar slip control in both conditions. A '1.5

way' LSD uses different ramp angles for drive and overrun to reduce the clutch pack load on braking. There is

no special oil requirement for the plate type LSD, but to maintain design performance, inspection and cleaning

of the plates should be carried out every 15,000 miles (25,000 km) by a competent agent.

2-ELEVEN.G - WHEELS & TYRES

Optional on the 2-Eleven are 240R type lightweight forged alloy 5-spoke roadwheels, which at 7x16 and

8x17, are ½ inch wider, front and rear, than the standard Exige wheels, but retain the standard insets of + 31.3 mm

and + 38.0 mm. The wheels are finished in either Satin Black or High Power Silver, with 'Lotus Sport' moulded

into one of the spokes of each wheel. The Lotus specific, regular Exige Yokohama A048 tyres, identified by

'LTS', are fitted as standard. Each wheel is retained by four standard Elise/Exige spline head 60 degree taper

seat bolts, for which a splined adaptor tool is stowed in the vertical tube of one of the roll-over bar backstays.

No security coded wheel bolts are used.

Note that these forged alloy wheels incorporate a steel centralising sleeve to locate onto the hub spigot,

and is normally retained in the wheel. A smear of copper grease on the spigot will help prevent corrosion between the hub and sleeve causing the insert to become separated from the wheel.

2-ELEVEN.J - BRAKES

The anti-lock braking system is uprated in the following respects:

- Motorsport brake pads (Pagid RS14) are fitted front and rear together with cross-drilled brake discs;

- Steel braided brake hoses fitted all round;

- Optional Castrol 'SRF' synthetic racing brake fluid. Over 500°F boiling point. Dot 4.

- Brake callipers painted yellow.

Page 18

Lotus Service Notes 2-Eleven

Page 18

Access to the brake master cylinder reservoir is available via a small panel in the driver's side front body;

release the screw fastener using the tool provided in the roll over bar backstay, and withdraw the panel. To

refit, engage the tongue beneath the front end of the aperture, and secure the rear end with the fastener. Note

that to avoid erroneous low fluid tell tale activation under extreme track use, it may be necessary to fill the fluid

reservoir to the base of the neck.

Option

An optional brake upgrade comprises larger front discs (308mm vs. 288mm) mounted on alloy centres

and clasped by A.P. Racing 4- pot callipers.

Brake Pad Bedding

If new brake pads and/or discs are to be fitted, a bedding-in procedure should be followed:

WARNING; This procedure should be carried out only on a closed track, paying appropriate regard to

any other track users. Do not attempt on the public highway.

The purpose of brake pad bedding is to:

- Transfer a layer of friction material onto the disc faces to achieve maximum performance;

- Stabilise compressible materials to avoid a spongy pedal;

- Boil off volatile elements in the friction compound;

- Align the pad and brake disc surfaces for full contact.

If the pads are not bedded in correctly, or are used aggressively straight after fitting, pad glazing may oc-

cur. This condition results from resins in the pad material crystallising on both the pad friction surface and the

brake disc surface, producing brake judder and vibration. Also, rapidly escaping volatile elements and moisture

from the resin, in seeking an immediate escape route out of the friction compound, can create small fissures

that can lead to cracking and chunking of the material.

Bedding Procedure;

- To generate some heat in the discs and pads, perform 4 to 6 stops with medium brake pressure from

around 70 mph (110 km/h) to 40 mph (60 km/h), allowing around 30 seconds between stops. The pad

temperature should not exceed 400 degrees C.

- Immediately after this procedure, carry out one high speed stop with medium to heavy brake pressure,

without activating the ABS, from around 80 mph (130 km/h) to 40 mph (60 km/h).

- Perform 3 or 4 recovery stops to clean the discs and pads, using light pedal pressure from around 70 mph

(110 km/h) to 40 mph (60 km/h).

- Repeat the high speed stops, including the recovery stops, a further 2 or 3 times. The brakes may now

be considered fully bedded.

New Pads on Used Discs

If new brake pads are to be fitted on used discs, it is recommened to chamfer the edges of the pad to

allow optimum bedding.

Parking Brake

Immediately after track use or hard brake usage when the discs are still hot, if possible, avoid using the

parking brake (chock wheels) to prevent heat transfer into the pads and brake fluild.

2-ELEVEN.K - COOLING

The 2-Eleven uses the standard horizontally mounted radiator, with twin cooling fans on its underside.

The fans are switched individually by the engine ECM in conjunction with a fan control module mounted in

the chassis front well, behind the radiator. One fan is switched on at 98°C on rise, off at 93°C on fall, with the

second fan motor run in parallel, and switched on at 103°C on rise, off at 98°C on fall.

Twin front mounted oil/air coolers (std. Exige hot climate spec.) are fitted, one ahead of each front wheel.

An engine intake air chargecooler radiator is rubber mounted behind the engine, with cooling airflow gathered

by body apertures alongside the rear of the cabin, and fed via convoluted ducting to a collector on the forward

side of the chargecooler. Air exhausting from the chargecooler radiator escapes via a rear transom aperture.

Page 19

Page 19

Lotus Service Notes 2-Eleven

Engine Bay Ventilation

The body of the 2-Eleven incorporates

four air intake ducts;

- Grilled air intakes at each side of the front

scuttle, feed air via ducting formed within

the body sides to the engine bay; the left

hand duct feeds a cool air supply with a

small 'ram'effect to the engine air cleaner;

the right hand duct feeds cooling air to

the front of the engine bay.

- Two grilled air intakes at the rear of the

cockpit sides supply a plenum on the

front of the chargecooler radiator.

Hot air exhausts from the engine bay via

an aperture in the rear body.

2-ELEVEN.L - FUEL SYSTEM

In order to meet the fuelling requirements of the 255 PS engine specification, a high output fuel pump is

fitted in the otherwise unchanged tank. This pump is slightly longer than the standard item and requires a new

alloy cap (replaces original plastic cap) to retain the pump in the plastic housing inside the tank.

Engine bay cooling Chargecooler airflow

ohs161B

Engine intake airflow

Page 20

Lotus Service Notes 2-Eleven

Page 20

2-ELEVEN.M - ELECTRICAL

The 2-Eleven is available with three levels of lighting equipment:

- Track; with no lighting equipment.

- Race; with rear turn lamps, brake lamps and rear fog lamps.

- Road; with full lighting set, but no CHMSL.

Lighting Switches (if fitted)

Principal lighting functions are control

led by a row of three push button switches

mounted in a nacelle below the scuttle top

edge; for the rear fog switch (if fitted) see

later. Each switch is pressed once to switch

on, and pressed a second time to switch off.

A symbol accompanies each switch to indicate

its function.

Sidelamp Switch

Positioned in the right hand end of the panel, this switch functions with or without the ignition, and switches

on the sidelamps and instrument/switch illumination. A tell tale in the switch button lights up green to indicate

when the circuit is active.

Press the switch a second time to switch off the sidelamps, but note that the headlamps must first be off

(see below).

Headlamp Switch

Centremost of the three switches, that for the headlamps functions with or without ignition, and switches

on the headlamps together with the sidelamps and instrument/switch illumination. A tell tale in the switch button lights up green to indicate when the circuit is active. The steering column lever switch (see later) is used

to select main or dip beam.

Pressing the switch a second time will switch off the headlamps, but leave on the sidelamps (see

above).

Hazard Warning Lamps Switch

The hazard warning switch is located at the left hand end of the panel and has an icon in the switch but

ton which is back lit when the ignition is switched on. The switch is operative at all times, and when pressed,

causes all the turn indicator lamps to flash in unison. The turn lamps tell tale and the hazard switch icon will

also flash. Press a second time to switch off.

This facility should be used when the car is stopped on the highway in circumstances where a warning

to other traffic would be judicious. Use of the hazard warning lamps may be subject to local traffic laws, with

which drivers should familiarise themselves.

Instrument Illumination

A small button is provided on the steering column shroud ahead of the ignition switch, by which the brightness of the electroluminescent instrument illumination may be adjusted. To cycle through the range of brightness, first switch on the lights, and then press and hold the button before releasing at the desired setting.

Note that this dual function button also resets the trip distance recorder if pressed only briefly.

Headlamp switch

Hazard switch Sidelamp switch

RHD shown

ohs163B

Page 21

Page 21

Lotus Service Notes 2-Eleven

SIDE PANEL SWITCHES

Situated at the end of the fascia, outboard

of the steering column is a switch panel providing various functions dependent on vehicle

specification.

Engine Start Button

Fitted on all cars, at the bottom of this

panel is a red button to activate the engine

starter motor. This circuit is operative only

when the ignition is switched on. Care should

be taken not to press the button when the

engine is running, as damage to the starter

mechanism is likely to be caused.

For correct operation of this function see ‘Starting Procedure’.

Rear Fog/Rain Light Switch (if fitted)

On cars fitted with full road lighting, the switch above the starter button controls the two rear fog lamps,

which operate only in conjunction with the ignition and headlamps. Tell tales in the switch button and instrument

pack light up amber to indicate when the circuit is active. Press a second time to switch off the lamps.

Note that whenever the headlamps and/or ignition are switched off, the fog lamps will also switch off. On

re-instatement of ignition and headlamps, the fog lamps will remain off until requested again by pressing the

switch.

For track cars fitted with rear warning ‘rain’ lamps, these may be activated any time the ignition is on, by

pressing this button. Tell tales in the switch button and instrument pack light up amber to indicate when the

circuit is active. Press a second time to switch off the rain lamps.

Lotus Traction Control

All cars are equipped with Lotus Traction Control (LTC), whether or not the optional Limited Slip Differential

(LSD) is specified.

Lotus Traction Control (LTC) is a software programme within the engine electronic control unit (ECU) which

uses inputs from the wheel speed sensors to determine the degree of wheelspin occurring, and when necessary,

modulate fuel injector delivery to control engine power output until grip is restored. This feature, which operates

at all speeds above 6 mph, can improve vehicle stability in some extreme conditions of use, especially where

variable surface grip prevails, or when maximum vehicle performance is being exploited.

The optional Torsen type Limited Slip Differential (LSD) is a mechanical gear system incorporated into the

final drive unit, and limits the speed differential between the two rear wheels by distributing the applied torque

in accordance with the available grip at each tyre. This feature can enhance vehicle performance in certain

types of off-road or closed venue competition, and help maintain mobility in mud, snow or sand. LTC then acts

electronically to stabilise high speed vehicle behaviour under high cornering loads or extreme manoeuvres.

If the LTC tell tale in the instrument panel is seen to flicker, this is an indication that the tractive limit has

been reached, and traction control activated.

Lotus Traction Control ‘Off’ Button:

In certain circumstances, such as loose or soft surfaces, it may be desirable temporarily to switch off the

traction control, for which purpose an LTC ‘off’ button is provided on the switch panel outboard of the steering

column. To switch off the LTC; with the ignition switched on, hold the button pressed for 2 seconds. The button

tell tale together with the instrument panel tell tale will light up amber to confirm system de-activation.

WARNING:

• LTC should always be active when driving on the public highway.

• If the system is switched off when driving off-highway, be aware of the consequent change in

vehicle behaviour and modify driving style accordingly.

To re-activate LTC, press (momentarily) the button a second time and check that the button and instrument

panel tell tales go out. Note that the button tell tale will flicker in conjunction with the instrument panel tell tale

if traction control is triggered. Irrespective of the system status at the time of ignition switch off, LTC will default

to ‘on’ next time the ignition is switched on.

Variable traction control

Traction control 'off' switch

Rear fog/rain light switch

Engine start button

ohs162

Page 22

Lotus Service Notes 2-Eleven

Page 22

Variable Traction & Launch Control (if fitted)

Cars equipped with the optional variable traction and lauch control, have a rotary control knob mounted

above the LTC ‘off’ button on the switch panel.

Variable Traction Control

Each time the ignition is turned on, normal full LTC is activated. To enable variable traction control, turn

on the ignition and hold the LTC ‘off’ button pressed for 2 seconds. Do not touch the throttle pedal. Check that

the tell tale in the switch button is lit. Start the engine. Note that if the ignition is switched off (e.g. prior to a

second start attempt), the above procedure must be repeated in sequence.

With the switch button tell tale lit and the engine running, the rotary knob may then be used to select the

degree of traction control desired:

• For maximum traction control (0% slip) turn the knob fully counterclockwise.

• To reduce traction control (to allow up to 12% slip), turn the knob progressively clockwise.

• Fully clockwise, traction control is disabled, as indicated by the lighting of the instrument panel tell tale.

Variable Launch Control

This feature allows the engine rpm to be limited during a competition start in order to balance engine power

against available grip and provide a controlled degree of wheelspin for the first moment of acceleration, until

superseded by the traction control system at around 6 mph.

To enable this feature, turn on the ignition and hold the LTC ‘off’ button pressed for 2 seconds. Check that

the tell tale in the switch button is lit. Then;

• With ignition on, engine stopped, fully depress the throttle pedal for 5 seconds.

• Tacho will now show launch rpm. Turn the rotary knob as necessary to select any desired launch rpm

between 2000 and 8000.

• Release throttle and start engine.

• Turn the rotary knob to select the desired level of traction control (see above), noting that the launch control

setting will not be affected.

• Engage first gear, apply full throttle (ECU limits engine speed to selected launch rpm), and rapidly ‘drop’

clutch.

• Maintain full throttle throughout the transition from launch to traction control (at around 6 mph) until the

first gear change is required.

• To disable launch control when variable traction control is still required, reset launch rpm to 8,000.

NOTE

• Do not attempt to slip the clutch during this process, as overheating or damage to the clutch mechanism

may occur. An instant clutch engagement is required to ‘break’ rear tyre traction and initiate wheelspin.

• Do not attempt LC starts in any gear other than first.

• Do not hold the engine at or near maximum rpm for more than a few seconds.

• Under no circumstances should this track feature be employed on the public road.

• Use of Launch Control is an ultimate technique designed to produce the fastest possible race start.

Always allow the clutch to cool and recover before repeating a launch controlled start. The extreme

loads associated with such starts will result in reduced transmission component life cycles.

• At the next key-on, the system will default to full LTC and Launch Control off. Turning on the ignition and

holding the LTC 'off' button pressed for 2 seconds will restore the previous traction and launch settings.

Adjustment Tips

Note that the optimum settings for variable traction and launch control will differ for each set of track surface, tyre and ambient conditions. A suggested adjustment logic follows:

• Set the traction control to a mid position.

• Start with a low launch rpm e.g. 4,000 rpm.

• Trial launch and assess initial wheelspin control and transition into traction control.

• If launch control is set too low, the engine may ‘bog down’ and fall out of the power band. If set too high,

too much initial wheelspin may result, with poor step off from the line.

• Similar logic applies to traction control adjustment when this system takes over above about 6 mph.

Page 23

Page 23

Lotus Service Notes 2-Eleven

Battery Access

The lightweight 'Odyssey' battery uses absorbed glass mat, dry cell technology to provide high electrical

performance with minimum weight and size. The battery is located centrally in the cabin rear bulkhead, protected

by a composite cover. No routine inspection or topping up of the electrolyte is required, but at every service interval, the battery terminals should be checked for security and condition, and protected with petroleum jelly.

For access to the terminals, the bulkhead cover must first be removed. Use the 3mm hexagonal key to

remove the four fixings securing the battery cover to the chassis and bulkhead, and disconnect the auxiliary

power socket lead (if applicable).

Battery Isolator Switch

A battery master switch is mounted on the left hand side of the rear scuttle, and is provided as a safety

feature to allow a third party, from outside the vehicle, to turn off the engine and islolate all battery power.

This facility should be used only when necessary for safety reasons, or prior to removing the battery from

the car. If possible, do not operate the swtich until at least 10 seconds after switching off the ignition, in order

to allow the engine management system to adjust the setting of some components ready for re-starting, and

to avoid the loss of adaptive learn memory in the ECU.

To turn off battery power, turn the red key (knurled alloy knob on road cars) a quarter turn counterclockwise

until aligned fore/aft. Remove the key to prevent loss and fit the rubber cap to protect from rain ingress. To

turn on, insert the key, press down and turn a quarter clockwise. The key is now captive.

Battery Charging

The Odyssey PC680 battery fitted to the 2-Eleven uses aborbed glass mat (AGM) technology to provide

the virtues of both deep cycling ability and high cranking power. Thus low rate long duration drains and short

duration high amperage pulses are accommodated. The battery is fully sealed, recycling all gases internally

and using no external vent. There is also no electrolytic corrosion of the positive terminal, or corrosion to the

surrounding area. Never attempt to remove the top decal cover, or failure of the battery will ensue.

The state of charge in the battery can be determined from the following table:

Voltmeter reading State of charge

12.84 V 100%

12.50 V 75%

12.18 V 50%

11.88 V 25%

The battery does not lose its charged energy during cold storage temperatures, so there should be no

need to trickle or float charge during the winter months. To store off season, measure the battery voltage to

ensure it is fully charged; 12.8 volts or greater, and recharge if necessary. Turn off the battery isolator switch, or

disonnect the negative battery cable to prevent any applied electrical load during storage. The battery should

not freeze in temperatures down to - 40°C, so can be left in the vehicle except in the most extreme climates.

The battery can be stored for 2 years or more at temperatures below 25°C.

Under conditions of normal daily use, it should not be necessary to use external battery charging equipment. If the battery becomes discharged to the extent that the car cannot be started, the recommended course

of action is to fit a substitute battery whilst the original battery is trickle charged. If, in an emergency, the car has

BATTERY ACCESS

ccbatteryB

OFF

m264G BATTERY ISOLATOR

Page 24

Lotus Service Notes 2-Eleven

Page 24

to be ‘jump’ started, the subsequent conditions of vehicle use may not allow for sufficient alternator charging

of the battery to achieve a fully charged state. The battery should be trickle charged by external means until

12.8 volts is recorded.

The battery manufacturer recommends an Odyssey EPS 8A charger, which would require around 2½

hours to re-charge a fully discharged battery. Note that a trickle charger will not be capable of re-charging a

fully discharged Odyssey battery. Putting the battery into service at a less than fully charged state will reduce

the time period for which the car can be parked without subsequent starting difficulties. A battery left in a fully

discharged state for a prolonged period, may not be recoverable to its original condition. Allow several hours

after disconnecting a charger before measuring the battery voltage.

WARNING:

• Hydrogen gas generated by the battery could cause an explosion, resulting in severe personal

injuries.

• Charge battery in a well ventilated area.

• Never charge a frozen battery. It may explode because of gas trapped in the ice. Allow a frozen

battery to thaw out first.

• If you get electrolyte, which is an acid, in your eyes or on your skin, immediately rinse with cold

water for several minutes and call a doctor.

Auxiliary Power Socket

An auxiliary power socket is fitted in the right hand side of the battery cover. The socket is operative at

all times, and is provided with a protective hinged flap.

The format of the socket allows a standard cigarette lighter element to be used, or other electrical accessories requiring this type of fitting. Maximum current draw should not exceed 15 amps.

Page 25

Page 25

Lotus Service Notes 2-Eleven

Fuses

Two 4-slot fuseboxes are mounted on the rear bulkhead and control the principal engine circuits. Track cars

fitted with rear lamps, use a third 4-slot fusebox, located within the battery compartment for the lighting circuits.

Cars with full lighting sets replace this 4-slot box with a 22-slot fusebox within the battery compartment.

The ‘Littel’ type fuses are numbered and coloured according to their amperage rating, and may be removed

by withdrawing from their slots.

Engine Bay Fuses

Track Lights Fusebox

Full Lighting Set Fusebox

ABS Fuse: A 60A Maxi fuse protecting the ABS circuits is located within the battery box.

Fuse colours:

2A - Black;

3A - Violet;

4A - Pink;

5A - Orange;

7.5A - Brown;

10A - Red;

15A - Light Blue;

20A - Yellow;

25A - Clear.

Slot Rate Circuit

E1 7.5A Engine control

relay

E2 15A Cooling fan 1

E3 15A Cooling fan 2

E4 - Not used

Slot Rate Circuit

F1 15A Batt. services

F2 15A Ign. services

F3 20A Fuel pump

F4 10A Main relay

Slot Rate Circuit

R1 5A Turn lamps

R2 5A Rain lamp

Slot Rate Circuit

R3 5A Rvrs. lamps

R4 5A Stop lamps

Slot Rate Circuit

A1 - Not used

A2 - Not used

A3 7.5A Reverse lamps

A4 - Not used

A5 5A Brake lamps

A6 7.5A Turn lamps

A 7 - Not used

A8 - Not used

A9 10A Hazard

A10 7.5A Horn

A11 - Not used

A12 20A

Aux power socket

Slot Rate Circuit

A13 - Not used

A14 - Not used

A15 15A Switch pack &

dipswitch

A16 10A Sidelamps, rear

fog

A17 10A Dip beam LH

A18 10A Dip beam RH

A19 - Not used

A20 10A Main beam LH

A21 10A Main beam RH

A22 - Not used

ENGINE BAY FUSES m265

F4

F3

F2

F1

E4

E3

E2

E1

Fuse 1 Fuse 11

Fuse 12 Fuse 22

RHD front

LHD front

m255

Page 26

Lotus Service Notes 2-Eleven

Page 26

2-ELEVEN.O - MAINTENANCE & LUBRICATION

A Maintenance Schedule for the 2-Eleven is available under part number LSL519, and a Pre Track Ses

sion Check List, which should be completed before each and every track driving session, under part number

LSL520.

Recommended lubricants are unchanged apart from the option of Castrol SRF brake fluid. Spark plugs

are part number ALS3E6015F (NGK PFR7G) with 0.8mm (- 0.1, + 0) gap.

Vehicle Recovery

No towing eye is fitted on the 2-Eleven. If the car has to be recovered by towing either forwards or back

wards, a fabric towing strap should be secured to the passenger side of the roll over bar. In operation, care

should be taken to prevent damage to the aeroscreen or rear aerofoil.

2-ELEVEN.Z - MISCELLANEOUS

Warranty

‘Track Use’ Cars

The Lotus 2-Eleven is designed and supplied into markets other than the U.K. only as a track use vehicle,

as defined by character 12 of the V.I.N. being ‘H’ or ‘J’. This specification is also available as an option in the

U.K., identified in the same manner. All such cars are not eligible for European type approval, or Australian

Compliance Plate Approval, or equivalent regulations in other countries. The Lotus 2-Eleven is supplied with

no specific type approval paperwork or certification information and Lotus Cars will not provide any assistance

to any person or company seeking to register a 2-Eleven model for road use outside of the U.K.

Lotus offers no warranty other than that required by law, on any ‘track use’ car in any territory.

U.K. Road Use Cars

The following Warranty applies only to cars built by Lotus for road use in the U.K., as identified by V.I.N.

character 12 being ‘F’ or ‘G’, and only whilst being used in the U.K. It is permissible for the car to be driven on

closed circuits or private test tracks, but using the car in a competitive manner, including timed runs or laps,

will invalidate the Lotus Vehicle Warranty.

Warranty Periods

- Warranty period for vehicle; 12 months/12,000 miles.

- Warranty period for replacement parts; 12 months/12,000 miles.

- Corrosion perforation warranty; 2 years unlimited mileage.

Exclusions From Warranty Coverage

- The 2-Eleven features an open cockpit such that all issues relating to water ingress, including damage

to trim and upholstery, staining or discoloration of the chassis, and damage to electrical equipment within

the cabin, are not covered by this warranty; use a suitable outdoor car cover when necessary to protect

against weather damage.

- Adjustments to screw fixed body panels and components, glass and trim should be considered as routine

maintenance and may periodically be required, especially when subjected to high forces by repeated track

use.

- Internal and external mirrors are vulnerable to damage from driver/passenger ingress/egress as well as

from external strikes, and are excluded from warranty coverage.

- All composite panels on the 2-Eleven are designed for light weight consistent with aerodynamic function,

and may be damaged by inappropriate application of bodyweight or other injudicious treatment. The

durability and standard of the paint finish may not match that of more conventionally constructed cars.

There is no body or paint warranty on the Lotus 2-Eleven.

- If the car has ever been used on road or track with ‘slick’ or equivalent racing tyres, warranty is void.

- Clutch and brake discs are excluded.

For full details of the 2-Eleven warranty and its restrictions and limitations, refer to t

he Owner's

Handbook, or 2-Eleven specific Warranty Certificate LSL521

Page 27

Page 27

Lotus Service Notes 2-Eleven

Circuit Diagrams

Start, Alternator & Ignition Sheet 1 Page 28

Fuel Pump & Engine Management Sheet 2 Page 29

Engine Management Sheet 3 Page 30

Tail, Stop, Reverse & Fog Lamp Sheet 4 Page 31

Turn Indicators, Side & Hazard Warning Lamps Sheet 5 Page 32

Switch Pack & Headlamps Sheet 6 Page 33

Instruments Sheet 7 Page 34

Engine Cooling Fan Sheet 8 Page 35

Horn & Rain Lamp Relay (track option) Sheet 9 Page 36

ABS & Traction Control Sheet 10 Page 37

Harness Ground Splices Sheet 11 Page 38

Fuse Layout (base & SVA cars) Sheet 12 Page 39

Power & Ground Structure Sheet 13 Page 40

Fuse Layout (base & track cars) Sheet 14 Page 41

Page 28

Lotus Service Notes 2-Eleven

Page 28

Page 29

Page 29

Lotus Service Notes 2-Eleven

Page 30

Lotus Service Notes 2-Eleven

Page 30

Page 31

Page 31

Lotus Service Notes 2-Eleven

Page 32

Lotus Service Notes 2-Eleven

Page 32

Page 33

Page 33

Lotus Service Notes 2-Eleven

Page 34

Lotus Service Notes 2-Eleven

Page 34

Page 35

Page 35

Lotus Service Notes 2-Eleven

Page 36

Lotus Service Notes 2-Eleven

Page 36

Page 37

Page 37

Lotus Service Notes 2-Eleven

Page 38

Lotus Service Notes 2-Eleven

Page 38

Page 39

Page 39

Lotus Service Notes 2-Eleven

Page 40

Lotus Service Notes 2-Eleven

Page 40

Page 41

Page 41

Lotus Service Notes 2-Eleven

Loading...

Loading...