Page 1

Owner’s Manual

Congratulations on the purchase your new Losi

product. Before installing your engine, please

read these instructions to ensure reliable and

trouble-free performance.

Using the Proper Fuel and Glow Plug

Using the proper fuel and glow plug is critical in order

to achieve maximum performance and reliability.

You must use fuel, glow plugs and air filters that

are specifically designed for model car/truck/buggy

applications. Never use any type of model airplane

glow fuel! Use of model airplane fuel can damage

your engine and immediately void any warranty.

We recommend using Losi Nitrotane™ fuel, providing

the best combination of power and fuel economy. Losi

fuels are vigorously tested, researched and formulated

to deliver excellent power as well as engine protection.

A glow plug has been included and is ideal for

breaking in your new engine. In fact, during the

break-in procedure, it is not uncommon to go through

one or two glow plugs, as microscopic bits of metal

(from the cylinder/piston wearing in) bond themselves

to the plug element causing glow plug failure. We

recommend the Dynamite McCoy MC59 Glow Plug

(DYN2508) as the absolute best glow plug for this

engine. The MC59 Plug has been designed to deliver

an ideal balance of performance and longevity.

All car engines must use a properly oiled air filter

to keep dirt out of the engine. Any dirt that enters

the carburetor can immediately destroy your engine.

We recommend LOSB5020 as an excellent choice

for a quality air cleaner. Service the air filter after

every hour of running, by washing out the foam filter

with warm water. Dry the filter then re-apply air filter

oil to the foam filter.

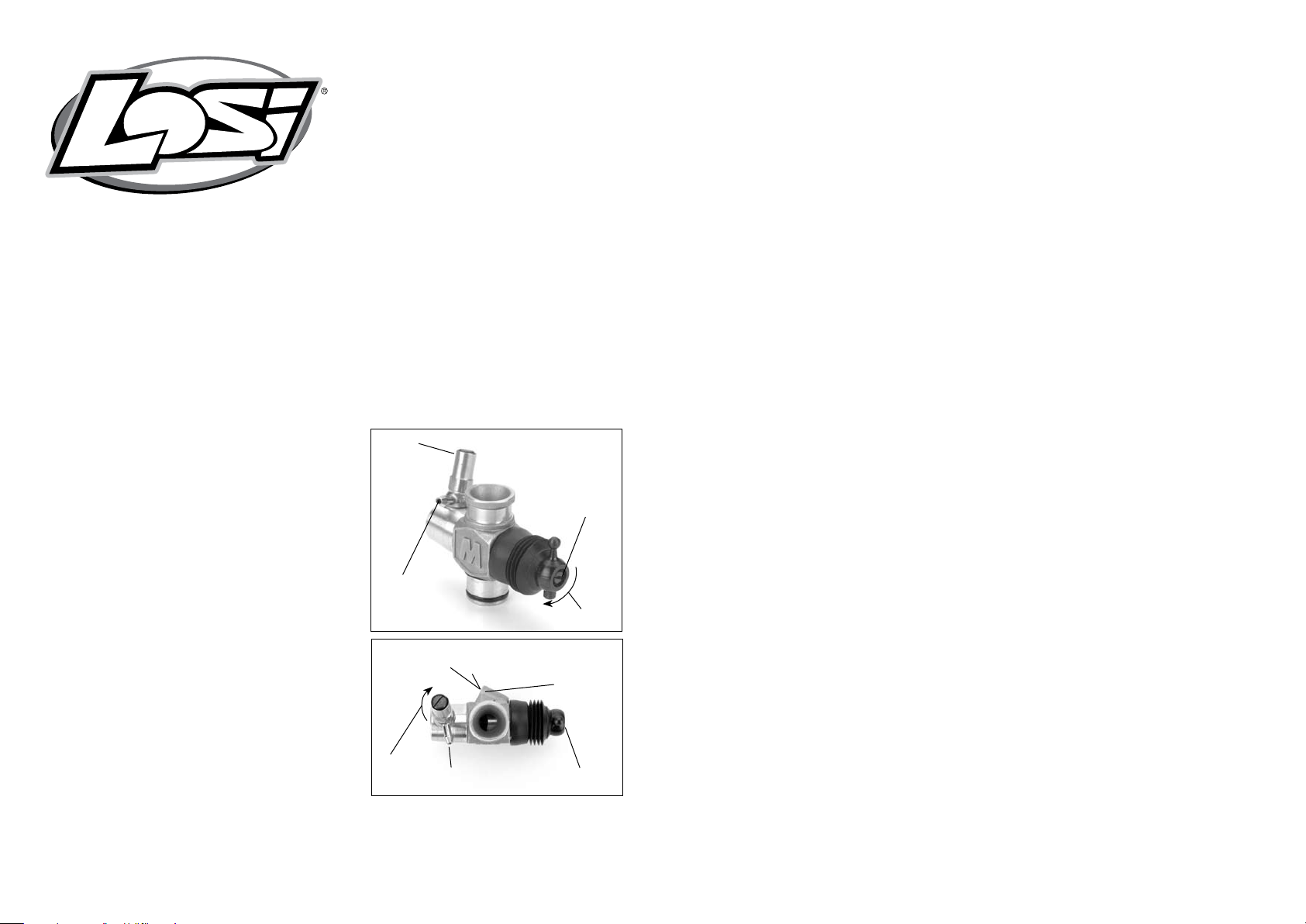

Carburetor Adjustments

Your Losi engine comes equipped with a precision

slide-valve carburetor. Take a moment to review the

pictures below to familiarize yourself with the various

functions of the carb. Loosening the nut located on the

side of the crankcase under the carburetor body will

allow you to rotate the carburetor to properly fit your

particular application. Make certain to mount the throttle

arm to the side required by your particular vehicle.

Although preset at the factory, some changes in the

needle setting can occur during shipping and handling.

High-Speed

Needle Valve

Low-Speed

Needle Valve

Fuel Inlet

(Adjustable)

Leaner

Fuel Inlet

(Adjustable)

Slower Idle

(counterclockwise)

Idle Stop

Adjustment

Low-Speed

Needle Valve

Faster Idle

(clockwise)

Leaner

We suggest the following settings for breaking in

your engine:

High-Speed Needle: 21/2 turns out (counterclockwise)

from closed.

1

Low-Speed Needle: 2

/2 turns out (counterclockwise)

from closed.

When checking the adjustment of the lowspeed needle, it is crucial that the throttle

slide is closed completely when turning the

needle and that you do not over-tighten the

needle. Use an engine tuning screwdriver to

make this job easier. When you feel resistance

in the needle, immediately stop turning and

begin turning the needles counterclockwise,

counting the number of turns from “closed.”

Starting Your Engine

for the First Time

The first start of your engine is the most critical time of

the engine’s life, dictating how well it will perform. After

installing the engine in your model and inserting the

glow plug, turn on your radio system and attach a glow

igniter to the glow plug. Place your finger over over the

exhaust and turn the engine over with the starter for

2–3 seconds to prime the fuel line.(This should only be

necessary when the engine is cold, do not touch the

exhaust pipe when the engine is warm.) Should

the engine become difficult for ospin start to turn over,

the engine may be flooded (hydro-locked). Excess fuel

between the cylinder head and piston will not allow the

piston to travel through its full range of compression,

effectively “locking up” the engine. Should this occur,

immediately remove the glow igniter from the plug.

Using a glow plug wrench (LOSB4603), remove the

glow plug and turn the model upside down and rotate

the flywheel to clear out the fuel, re-install the glow plug

and start again.

You may need to “blip” the throttle on the transmitter

(applying throttle on/off) while trying to start the engine,

as new engines are more difficult to start due to the

tight piston/cylinder fit.

We recommend using an spin starter or starter box for

the initial starts, even with a pull-start equipped engine.

You may need to “blip” the throttle on the transmitter

(applying throttle on/off) while trying to start the engine,

as new engines are more difficult to start due to the

tight piston/cylinder fit.

Never start an engine above 1⁄4 throttle.

Immediate damage to your engine can

and will occur.

When the engine starts, the exhaust should emit lots

of blue/white smoke, indicating that the engine is

excessively rich (a good thing during break in). During

the first tank of fuel, you may wish to set a higher than

normal idle speed and/or leave the glow plug igniter

attached in order to keep the engine from stalling.

Drive your vehicle around while “blipping” the throttle

and avoid operating the engine at full throttle for

more than 2–3 seconds at a time. Consume the entire

first two tanks of fuel in this manner. After the first two

tanks of fuel, begin leaning out the high-speed needle

valve 1/8 turn at a time. It generally takes about 5

or 6 tanks of fuel before you’d want to start tuning

for “maximum” power.

Page 2

Do not skip this process of breaking in a new

engine! Should you choose not to follow these

procedures, you risk damaging your engine

during the first tank of fuel.

Your patience during these procedures will be rewarded

by an engine that performs reliably and to its maximum

power potential. First run attempts can be more

frustrating than with other (less powerful) sport engines,

so take your time—it will be worth the wait. Glow

plug failure is a common occurrence when breaking

in a new engine. To test your plug, let the engine idle

at a properly adjusted low-speed needle setting with

the glow igniter attached. Then, remove the igniter. If

you hear no appreciable change in engine rpm, the

plug is still good. If the engine loads up and the rpm’s

decrease, it’s time to replace the glow plug.

Setting the Needle Valves

When tuning the needle valves for maximum

performance, adjust them in small increments,

1⁄16 turn at a time.

An engine should not be run too lean; doing so

severely shortens the life of the engine. When an

engine is set too lean, it will run very strong at

first but will soon begin to sag and hesitate or stall

when accelerating.

The best way to tune an engine is by using an

infrared temperature gauge, but you can also use

water to check the head temperature (refer to “Tuning

the High-Speed Needle”).

Tuning the High-Speed Needle

To obtain the correct high-speed needle setting, start

the engine and drive your vehicle around for a minute

or two, applying full throttle frequently. Place a drop

of water on the cylinder head. If the water sizzles away

(evaporates immediately), the needle setting is too

lean. A correct needle setting will result in the water

evaporating after 3–5 seconds. If the water does not

evaporate, chances are good that the needle setting is

too rich. Lean the needle 1/16 of a turn and run the

engine again, adjusting the needle setting to get the

desired evaporation time.

Check the temperature each time you change

the needle mixture. Do not let the engine

overheat, as this will damage the engine.

Tuning the Low-Speed Needle

The low-speed needle (also referred to as the idle

mixture or idle needle) should be set after you’re

satisfied with the high-speed needle setting. After

achieving the proper operating temperature, reduce the

engine throttle to idle and pinch the fuel line with your

fingers close to the carb fuel inlet nipple. If the engine

dies immediately, the low-speed needle is set too lean.

If the rpm’s increase dramatically, the setting is too rich.

The ideal setting results in the rpm’s increasing just a

slight amount after pinching the fuel line.

Idle Stop Adjustment

The last setting to be made is the idle stop screw.

Turning this screw clockwise increases the idle speed,

whereas turning the screw counterclockwise will

make the engine idle at a lower speed. Ideally, the

engine should idle just fast enough to be reliable in

acceleration and transition from idle to full speed.

Avoid an idle speed that is too fast, as it will cause

damage to your clutch.

After Operating Your Engine

Periodic maintenance must be performed in order

to keep your engine in proper operating condition.

After each day of running, it’s critical to use high

quality after-run oil to protect the internals of the

engine and help prevent corrosion. (This is not

necessary when using Losi fuels.) The methanol

used in the fuel attracts moisture that can cause

corrosion (particularly in the ball bearings). Follow

these steps after running your engine:

1) Empty all fuel from the tank and fuel lines.

2) Remove the glow plug and air filter and add

5 to 6 drops of a quality after-run oil into the

carburetor and cylinder head openings. Turn

the engine over a few times to distribute the oil

throughout the engine.

3) Clean and inspect the engine, air cleaner and

fuel system.

Problem

Engine won’t start

Engine starts, then dies

Engine starts and runs

for 1⁄2 tank, then quits

Troubleshooting Guide

Possible Cause/Solution

• Clogged fuel line

• Bad or improper glow

plug

• Glow igniter not

charged

• Bad or old fuel

• Glow plug is bad

• Engine flooded

• Pressure line blocked or

disconnected

• Bad glow plug

• High-speed needle too

lean

• Hole or tear in fuel line

• Bad glow plug or idle

speed set too low

• Overheated engine

(too lean)

• Improper needle

settings

Page 3

Warranty

Limited Warranty Period

Horizon Hobby, Inc. guarantees this product to be free

from defects in both material and workmanship at the

date of purchase.

Limited Warranty & Limits of Liability

Pursuant to this Limited Warranty, Horizon Hobby, Inc.

will, at its option, (i) repair or (ii) replace, any product

determined by Horizon Hobby, Inc. to be defective.

In the event of a defect, these are your

exclusive remedies.

This warranty does not cover cosmetic damage or

damage due to acts of God, accident, misuse, abuse,

negligence, commercial use, or modification of or

to any part of the product. This warranty does not

cover damage due to improper installation, operation,

maintenance, or attempted repair by anyone other than

an authorized Horizon Hobby, Inc. service center. This

warranty is limited to the original purchaser and is not

transferable. In no case shall Horizon Hobby’s liability

exceed the original cost of the purchased product and

will not cover consequential, incidental or collateral

damage. Horizon Hobby, Inc. reserves the right to

inspect any and all equipment involved in a warranty

claim. Repair or replacement decisions are at the sole

discretion of Horizon Hobby, Inc. Further, Horizon

Hobby reserves the right to change or modify this

warranty without notice.

REPAIR OR REPLACEMENT AS PROVIDED UNDER

THIS WARRANTY IS THE EXCLUSIVE REMEDY

OF THE CONSUMER. HORIZON HOBBY, INC.

SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

As Horizon Hobby, Inc. has no control over

use, setup, final assembly, modification or

misuse, no liability shall be assumed nor

accepted for any resulting damage or injury.

By the act of use, setup or assembly, the user

accepts all resulting liability.

If you as the purchaser or user are not prepared to

accept the liability associated with the use of this

product, you are advised to return this product

immediately in new and unused condition to the

place of purchase.

Safety Precautions

This is a sophisticated hobby product and not a toy.

It must be operated with caution and common sense

and requires some basic mechanical ability. Failure to

operate this product in a safe and responsible manner

could result in injury or damage to the product or other

property. This product is not intended for use by

children without direct adult supervision.

The product manual contains instructions

for safety, operation and maintenance.

It is essential to read and follow all the

instructions and warnings in the manual, prior

to assembly, setup or use, in order to operate

correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot

provide warranty support or repair. Once assembly,

setup or use of the product has been started, you must

contact Horizon Hobby, Inc. directly. This will enable

Horizon to better answer your questions and service

you in the event that you may need any assistance.

Questions or Assistance

For questions or assistance, please direct your

email to productsupport@horizonhobby.com, or call

877.504.0233 toll free to speak to a service technician.

Inspection or Repairs

If your product needs to be inspected or repaired,

please call for a Return Merchandise Authorization

(RMA). Pack the product securely using a shipping

carton. Please note that original boxes may be included,

but are not designed to withstand the rigors of shipping

without additional protection. Ship via a carrier that

provides tracking and insurance for lost or damaged

parcels, as Horizon Hobby, Inc. is not responsible

for merchandise until it arrives and is accepted at

our facility. Include your complete name, address,

phone number where you can be reached during

business days, RMA number, and a brief summary of

the problem. Be sure your name, address, and RMA

number are clearly written on the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your

original sales receipt verifying the proof-of-purchase

date. Providing warranty conditions have been met,

your product will be repaired or replaced free of

charge. Repair or replacement decisions are at the sole

discretion of Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty and

the expense exceeds 50% of the retail purchase cost,

you will be provided with an estimate advising you of

your options. You will be billed for any return freight

for non-warranty repairs. Please advise us of your

preferred method of payment. Horizon Hobby accepts

money orders and cashiers checks, as well as Visa,

MasterCard, American Express, and Discover cards. If

you choose to pay by credit card, please include your

credit card number and expiration date. Any repair left

unpaid or unclaimed after 90 days will be considered

abandoned and will be disposed of accordingly.

Electronics and engines requiring inspection

or repair should be shipped to the following

address (freight prepaid):

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other products requiring inspection or

repair should be shipped to the following

address (freight prepaid):

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

© 2007 Horizon Hobby, Inc.

Losi engines are manufactured in

Taiwan and distributed worldwide by:

Horizon Hobby, Inc.

4105 Fieldstone Rd.

Champaign, IL 61822

Customer support

1-877-504-0233

www.horizonhobby.com

www.losi.com

10543

Page 4

LOSB5111

LOSR1030

LOSR5051

DYN0915

LOSR1033

LOSR1040

LOSR1031

LOSR1032

LOSR1038

LOSR1062

DYN911

DYN913

LOSA9376

LOSR1038

LOSR1064

LOSR1026

LOSR1027

LOSR1063

LOSR1063

LOSR1023

LOSR1021

LOSR1060

LOSR1039

LOSR1024

LOSR1028

Engine Components

LOSA9376 Flywheel Collet w/Shims ..........................................

LOSB5051 Exhaust Header Seals & Springs .............................

LOSB5111 Spin Start Backplate .................................................

LOSR1002 TL427 Engine w/ “Spin-Start” Backplate ............

LOSR1021 Head Button: M26SS ...............................................

LOSR1023 Head Shims, .1mm (2): M26SS ..............................

LOSR1024 Head Shims, .2mm (2): M26SS ..............................

LOSR1026 Wrist Pin: M26SS

LOSR1027 Wrist Pin Clips (2): M26SS .....................................

LOSR1028 Connecting Rod: M26SS .......................................

LOSR1030 Crankshaft (w/PS)SC: M26SS ...............................

LOSR1031 Backplate: PS: M26SS .............................................

LOSR1032 PS One-Way Bearing: M26SS ...............................

LOSR1033 PS Shaft: M26SS

LOSR1038 O-Ring Set: M26SS

LOSR1039 Head Screw (4): M26SS ..........................................

LOSR1040 PS Screw Set: M26SS .............................................

LOSR1060 Cylinder Head, Grey: TL427 ..................................

LOSR1062 Crankcase: TL427 ...................................................

LOSR1063 Piston/Sleeve: TL427 .............................................

LOSR1064 Slide Valve Carb, 8.5mm: TL427

DYN0911 Carb Ret Post Set .....................................................

DYN0913 Front Bearing ............................................................

DYN0915 Rear Bearing ...........................................................

.....................................................$4.00

......................................................$2.50

..................................................$7.00

...........................$46.99

$3.00

$6.00

$6.00

$209.98

$9.00

$2.00

$2.00

$2.00

$35.99

$59.99

$6.00

$14.00

$2.00

$3.00

$49.99

$71.99

$49.99

$5.99

$9.49

$19.99

Spin Start

LOSB5100 Spin-Start Hand Held Starter .................................

LOSB5102 Spin-Start Motor & Battery Leads .........................

LOSB5103 Spin-Start Mechanics .............................................

LOSB5105 Spin-Start Hand Strap & Pin ...................................

LOSB5106 Spin-Start Case & Switch Set ..................................

LOSB5109 Spin-Start Hex Drive Rod (long) ..............................

LOSB5111 Spin-Start .21-.26 Backplate ....................................

$49.99

$16.99

$22.99

$5.00

$8.00

$5.00

$6.00

Loading...

Loading...