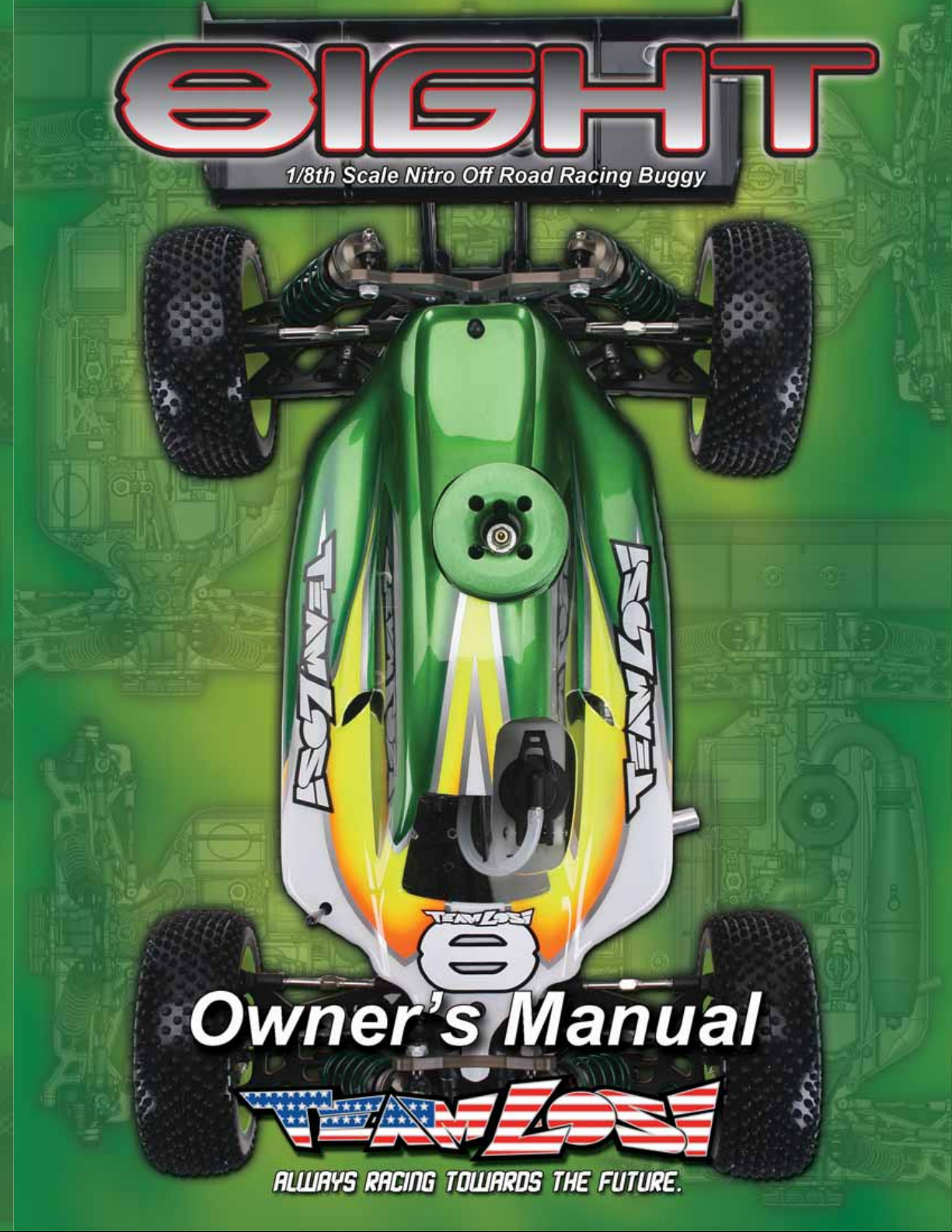

Losi LOSK0800 User Manual

INTRO

INTRO

STEP I-01

Intro to the 8IGHT Manual

Welcome Team Losi 8IGHT Owner!

Thank you for selecting the 8IGHT as your new racing buggy. The 8IGHT has already distinguished itself as a top caliber racing chassis and as you will see, we have made every effort to produce a kit that is not only the most competitive but also easy to build and maintain.

The simple bag-by-bag assembly sequence and easily followed instructions and drawings combined with Team Losi’s world famous quality

fi tting parts will make building the 8IGHT a most enjoyable project.

Before you open the fi rst bag, or start assembly, please take a moment to read through the following instructions. This will familiarize

you with the various parts, assembly tips, and descriptions as well as the tools needed. Taking an extra moment before starting can save a

good deal of time and assure proper assembly.

Good luck and good racing,

Team Losi

8IGHT COMPLETED KIT SPECIFICATIONS

Overall Chassis Length: 16-1/4in (413mm) Wheelbase: 12.64-12.80in (321-325mm) *Front Track W idth: 12.13in (308mm)

Overall Length w/Tires: 19-1/4in (489mm) *Overall Height: 6-5/8in (168mm) *Rear Track W idth: 12.13in (308mm)

Note: Final kit weight will vary depending on accessories used.

*All measurements taken at ride height (32mm).

Table 1: 8IGHT Completed Kit Specifi cations.

Kit/Manual Organization:

The kit is composed of different bags marked A through H. Each

bag contains all of the parts necessary to complete a particular section of the kit. Some of these bags have sub-assembly bags within

them. It is essential that you open only one bag at a time and follow

the correct assembly sequence, otherwise you may face diffi culties in

fi nding the correct part. It is helpful to read through the instructions

for an entire bag prior to beginning assembly. Next to each of the step

numbers is a check box. At the completion of each step, place a check

in this box so that if you must stop and come back to the assembly,

you will be able to pick up where you left off.

For your convenience, an actual-size Hardware Identifi cation

Guide is included as a fold-out page at the back of this manual. Hardware that is not easily differentiable in each step is called out with

an icon which contains a small

picture of the part genre (referenced on the Hardware Identifi cation Guide), the quantity of

that part required for what is

shown in the step, and the size

or name of that part. T o check a part, hold it against the silhouette until the correct part is identifi ed. Associated with each of these parts, in

the Hardware Identifi cation Guide, is a LOSA-Number which is used

when ordering replacement parts for your 8IGHT. In some cases, extra hardware has been supplied for parts that may be easy to lose.

Components used in each step are identifi ed by their relative

LOSA-Number and the component’s name. With the exception of

a few parts, these are not referenced in the Hardware Identifi cation

Guide.

The molded parts in Team Losi kits are manufactured to de-

manding tolerances. When screws are tightened to the point of being

snug, the parts are held fi rmly in place. For this reason, it is very

important that screws not be overtightened in any of the plastic

parts.

In some steps there will be a fi lled black circle with a white

number. These indicate the specifi c order by which assembly must

occur. In cases where steps are repeated (front/rear or left/right) these

numbers may be omitted. Please note that these numbers will not call

out every sub-step required for the step’s assembly procedures, they

will only highlight the critical order required for assembly.

In each step, there are specifi c “Detail Icons” (shaped like a stop

sign) that call out critical precautions or assembly tips for the process. There is a reference key that describes the meaning of each of

the icons located on the fold-out Hardware Identifi cation Guide at

the back of this manual.

To ensure that parts are not lost during construction, it is recommended that you work over a towel or mat to prevent parts from

rolling away.

IMPORTANT SAFETY NOTES:

1. Select an area for assembly that is away from the reach of small

children. Some parts in this kit are small and can be swallowed

by children, causing choking and possible internal injury;

PLEASE USE CAUTION!

2. The shock fl uid and greases supplied should be kept out of chil-

dren’s reach. They are not intended for human consumption!

3. Exercise care when using any hand tools, sharp instruments, or

power tools during construction.

4. Carefully read all manufacturer’s warnings and cautions for any

chemicals, glues, or paints that may be used for assembly and

operating purposes.

i

INTRO

INTRO

TOOLS REQUIRED FOR ASSEMBLY

Team Losi has supplied all necessary Allen wrenches and a special wrenchs that are needed for assembly and adjustments. The following

common tools will also be required: Needle-nose pliers, regular pliers, hobby knife, scissors or other body cutting/trimming tools, and a

soldering iron may be necessary for radio installation. 3/16”, 1/4”, 5/16”, and 11/32” nut drivers are optional.

RADIO/ELECTRONICS

A suggested radio layout is provided in this manual. Your high performance R/C center should be consulted regarding specifi c questions

pertaining to radio/electrical equipment.

HARDWARE IDENTIFICATION

When in question, use the Hardware Identifi cation Guide at the back of this manual.

For screws, the prefi x number designates the thread size and number of threads per inch (i.e., 4-40 is a #4 size thread with 40 threads per

•

inch). The second number, or fraction, designates the length of the screw. For cap head and button head screws, this number refers to the

length of the threaded portion of the screw. For fl at head and set screws, this number refers to the overall length of the screw.

Bearings and bushings are referenced by the inside diameter (I.D.) x outside diameter (O.D.).

•

Shafts and pins are designated by type (Roll, Solid) and referenced by diameter x length.

•

Washers, Spacers and Shims are described by inside diameter or the screw size that will pass through the inside diameter x the thickness

•

or by their designated application (i.e., Ball Stud washer is primarily used under a Ball Stud).

Retaining Clips are sized by the shaft diameter that they attach to or by type (Body). The Hardware Icon associated with E/C-Clips only

•

designates the part genre of clips, not the actual part.

Nuts come in four types, Non-Flanged, Flanged (F), Plain, and Locking (L) (designated on the Hardware Icons). The prefi x number desig-

•

nates the thread size and number of threads per inch. The second number, or fraction, designates the size of the hex. For example, L 4-40

x 1/4” designates a Lock nut that will thread onto a 4-40 screw using a 1/4” nut driver.

Setscrews come in three types, Cup (C), Flat (F) and Oval (O) (designated on the hardware Icons). The prefi x number designates the thread

•

size and number of thread per inch. The second number, or fraction, designates the length of the threade portion of the screw.

TABLE OF CONTENTS

SECTIONS

1. INTRODUCTION...................................................i

Kit/Manual Organization ................................... i

Important Safety Notes ...................................... i

Tools Required for Assembly ............................ii

Radio/Electronics .............................................. ii

Hardware Identifi cation ....................................ii

2. Bag A: Steering Assembly ...................................1-2

3. Bag B: Front Clip ................................................3-8

4. Bag C: Center Transmission ..............................9-12

5. Bag D: Rear Clip .............................................13-18

6. Bag E: Shocks .................................................19-21

7. Bag F: Radio Tray ...........................................22-26

8. Bag G: Engine Installation .............................. 27-30

9. Bag H: Wheels, Tires, Body ............................31-34

8. Checklist Before Your First Run ........................35

9. Setup Guide ....................................................35-39

10. Blank 8IGHT Setup Sheet ...................................24

11. Hardware Identifi cation Guide ...........................25

12. Filled-out 8IGHT Kit Setup Sheet ......................26

TABLES

Table 1: 8IGHT Completed Kit Specifi cations ............ i

Table 2: Servo Installation .........................................23

T eam Losi is continually changing and improving designs; therefore, the actual part may appear slightly different than the illustrated part. Illustrations of parts and assemblies

may be slightly distorted to enhance pertinent details.

ii

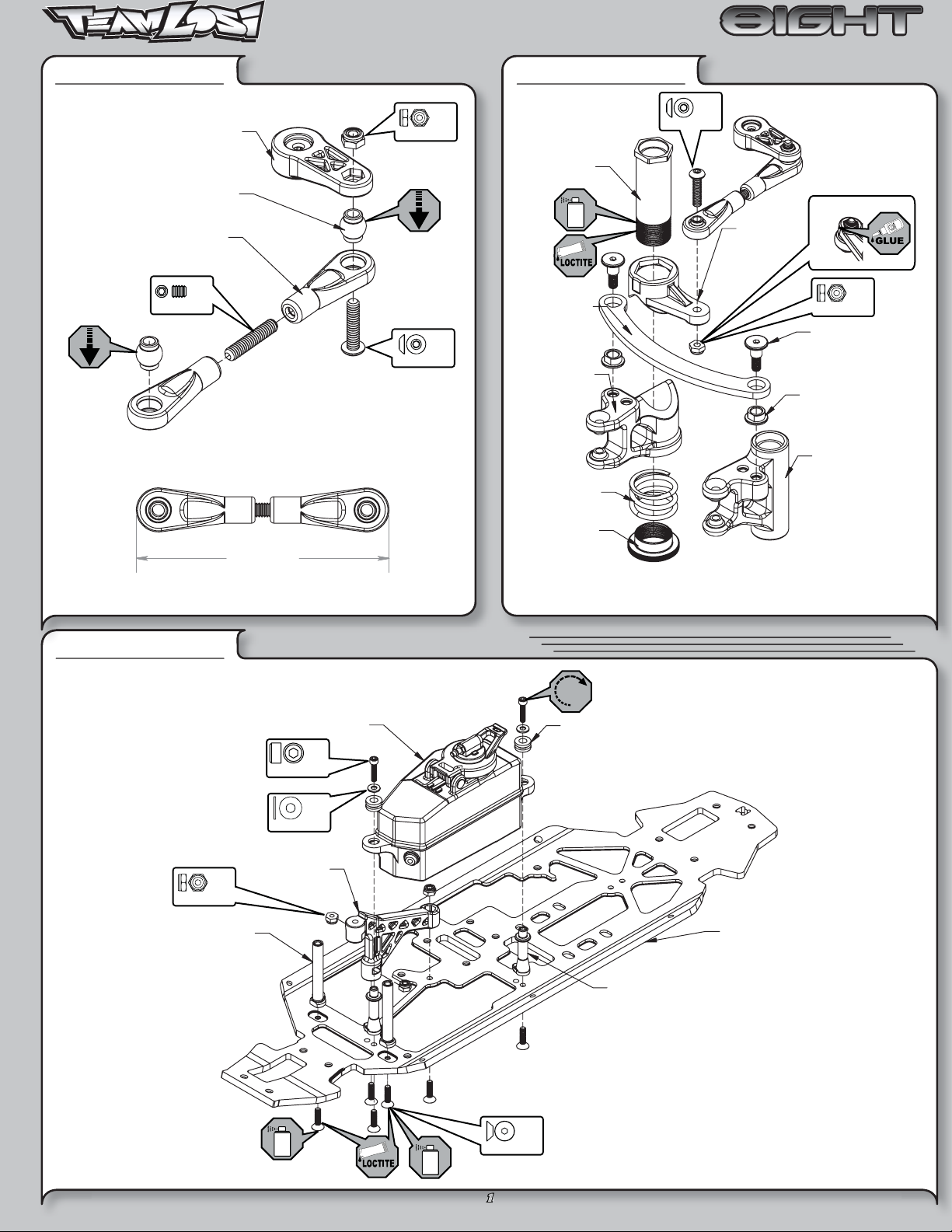

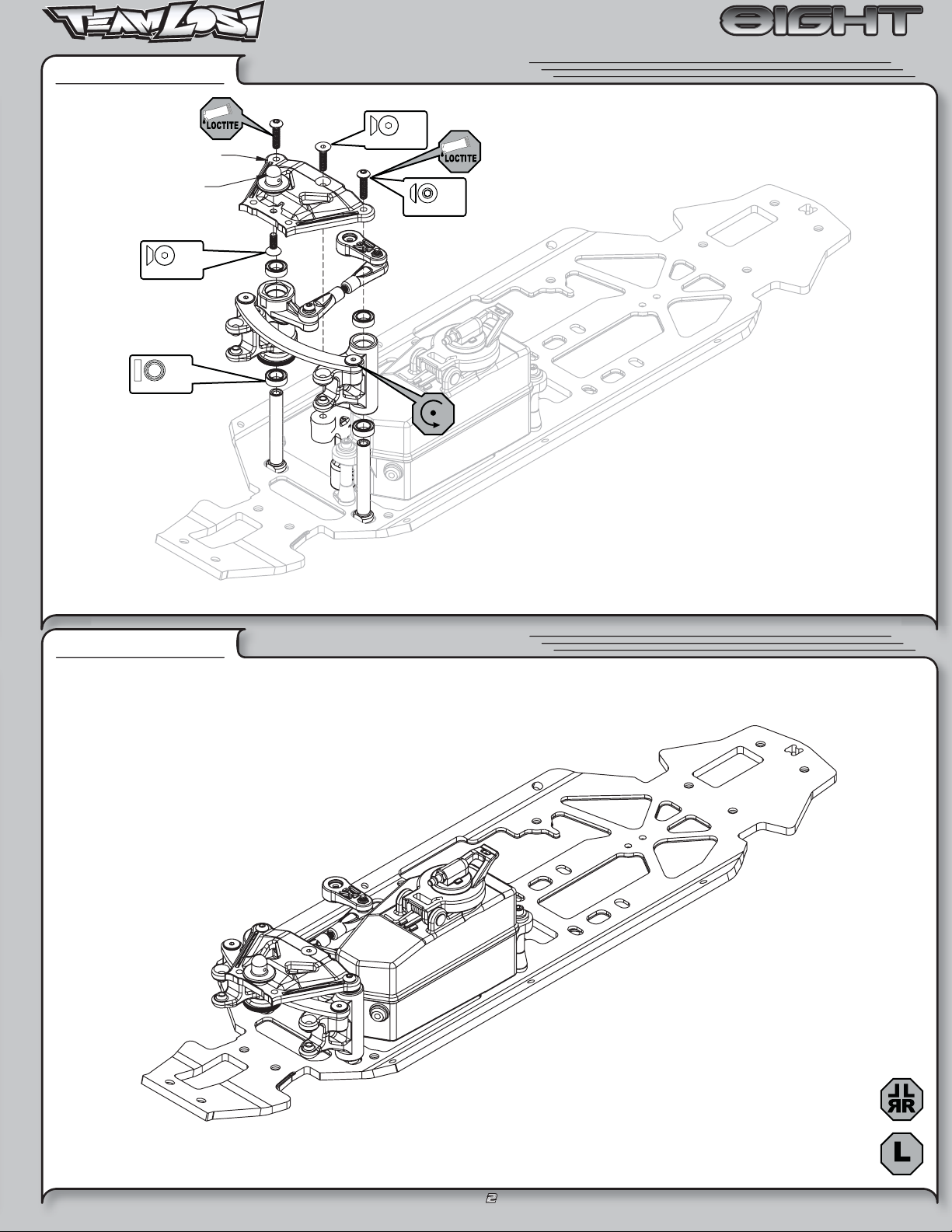

BAG A

BAG A

STEP A-01

A9166

Steering Servo Arm

A6043

Rod End Ball

A6043

Rod End

x 1

5-40 x 5/8”

Steering Link Assembly

L 4-40 x 3/16”

4-40 x 1/2”

x 1

x 1

STEP A-02

A4410

Servo Saver Tube

A4411

Steering Drag Link

A4409

teering Bellcrank R

A4410

Servo Saver Spring

Servo Saver Assembly

x 1

4-40 x 1/2”

A4409

Steering Arm

Maintenance Tip

x 1

L 4-40 x 3/16”

A4411

Drag Link Screw

A4411

Drag Link Bushing

A4409

Steering Bellcrank L

STEP A-03

x 3

L 5-40 x 1/4”

A4408

Steering Post

2.26"

57.40mm

Fuel Tank/Chassis Brace Assembly

A9160

Fuel Tank

x 2

4-40 x 1/2”

x 2

#4 x .030

A4413

Front Chassis Support

A4410

Servo Saver Nut

A4424

Fuel Tank Grommet

Tighten the Servo Saver

nut all the way down and

then back it off 2 1/2 turns.

A4401

Chassis

5-40 x 1/2”

1

x 6

A4424

Tank Mount

BAG A

BAG A

STEP A-04

Front Body Mount

6x10x3mm

A4413

Front Chassis Brace

A4424

x 1

5-40 x 3/8”

x 4

Steering/Top Plate Assembly

x 1

5-40 x 1/2”

x 2

5-40 x 1/2”

STEP A-05

Completed Steering Assembly

2

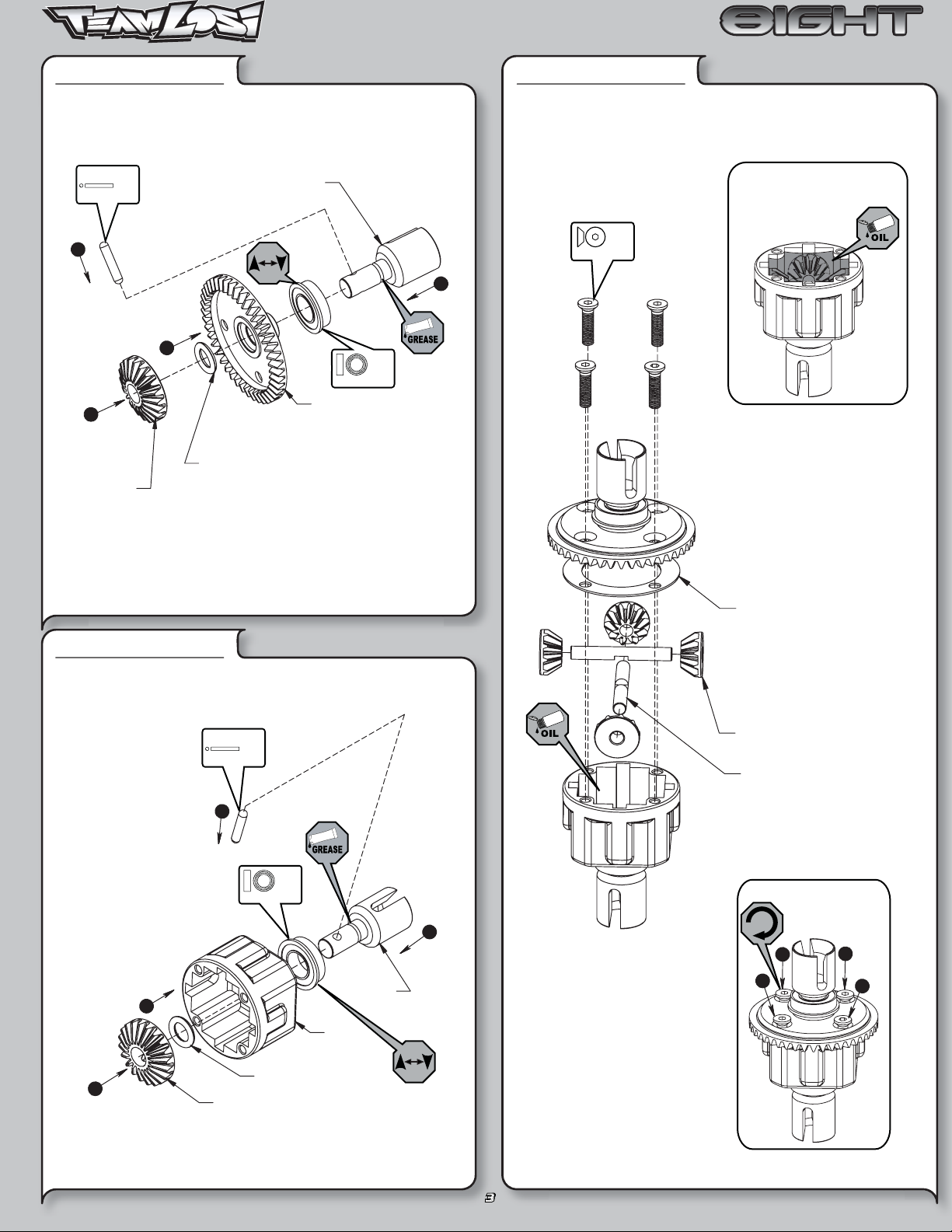

BAG B

BAG B

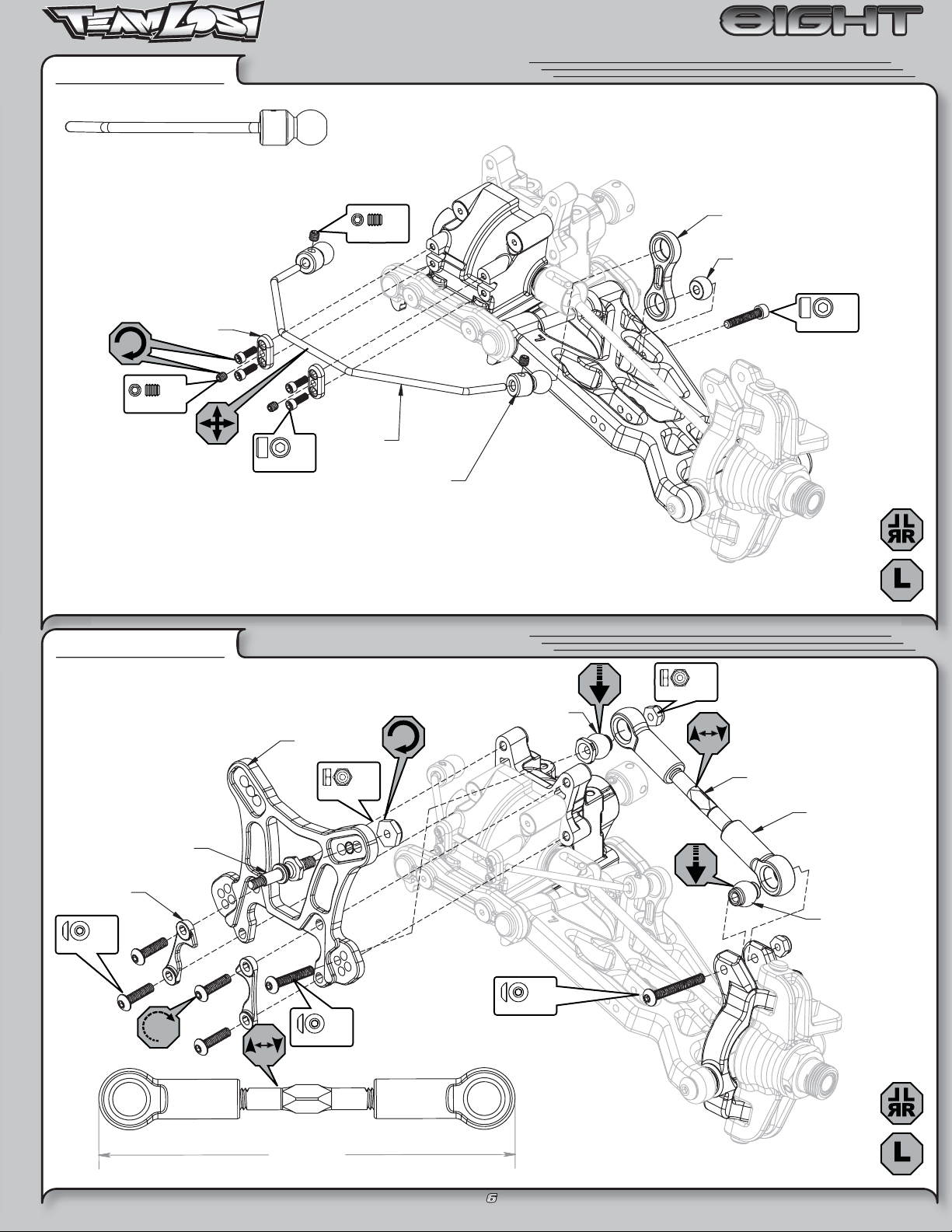

STEP B-01

Solid

x 1

2.5 x 12.80mm

3

4

A3502

Sun Gear

Ring Gear Assembly

A3504

Outdrive Cup

1

2

x 1

F 8x14x4mm

A3509

Ring Gear

A3505

O-Ring

STEP B-03

3x12mm

x 4

Complete Diff Assembly

Fill with 5000wt. oil just above

the planetary gear

STEP B-02

A3505

Diff Seal

Diff Case Assembly

Solid

x 1

2.5 x 12.80mm

3

x 1

F 8x14x4mm

1

A3504

2

Outdrive Cup

A3500

Diff Housing

A3502

Planetary Gear

A3502

Planetary Gear

Axle

Tighten the diff screws

in this order

1

4

3

2

A3505

4

A3502

Sun Gear

O-ring

3

BAG B

BAG B

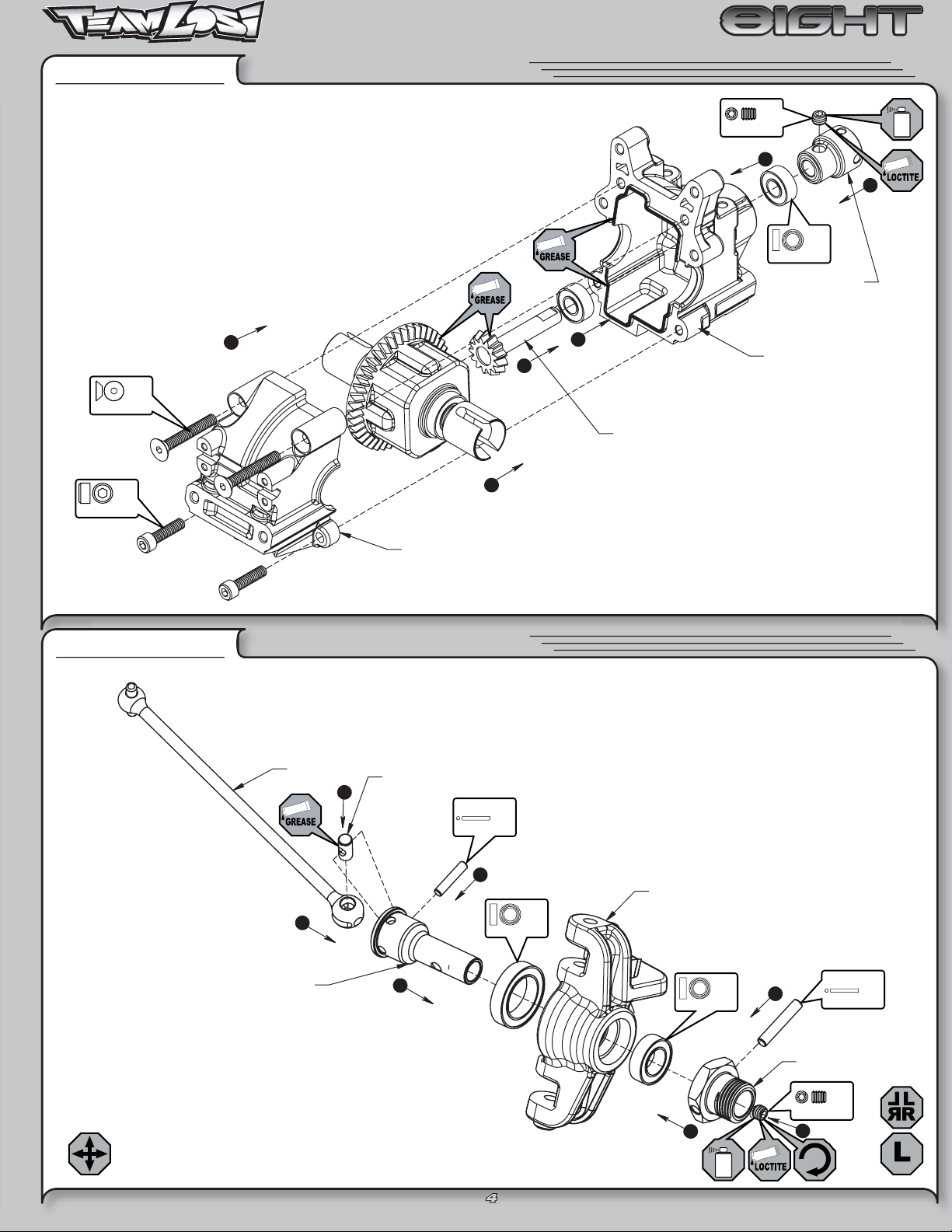

STEP B-04

x 2

5-40 x 7/8”

x 2

5-40 x 1/2”

Front Diff Install

6

To prevent fi ne dust from enter-

•

ing the gear box, apply a thin

bead of grease along the edge

of the case as pictured.

2

5

1

Pinion Gear, Bevel

A3508

x 1

F 8-32 x 1/8”

3

Front Bulkhead

5x11x4mm

A4427

x 2

A3514

Drive Adapter

4

STEP B-05

A4427

Front Diff Cover

Front Spindle & CV Assembly

A3521

Dogbone

2

A3522

Axle

1

A3523

CV Coupling

4

Solid

2.5 x 12.4mm

3

x 1

1/2” x 3/4”

x 1

A170 7

Left Spindle

8x14x4mm

x 1

Solid

6

x 1

3 x 17mm

A353 0

Wheel Hex

x 1

C 8-32 x 1/8”

5

4

7

BAG B

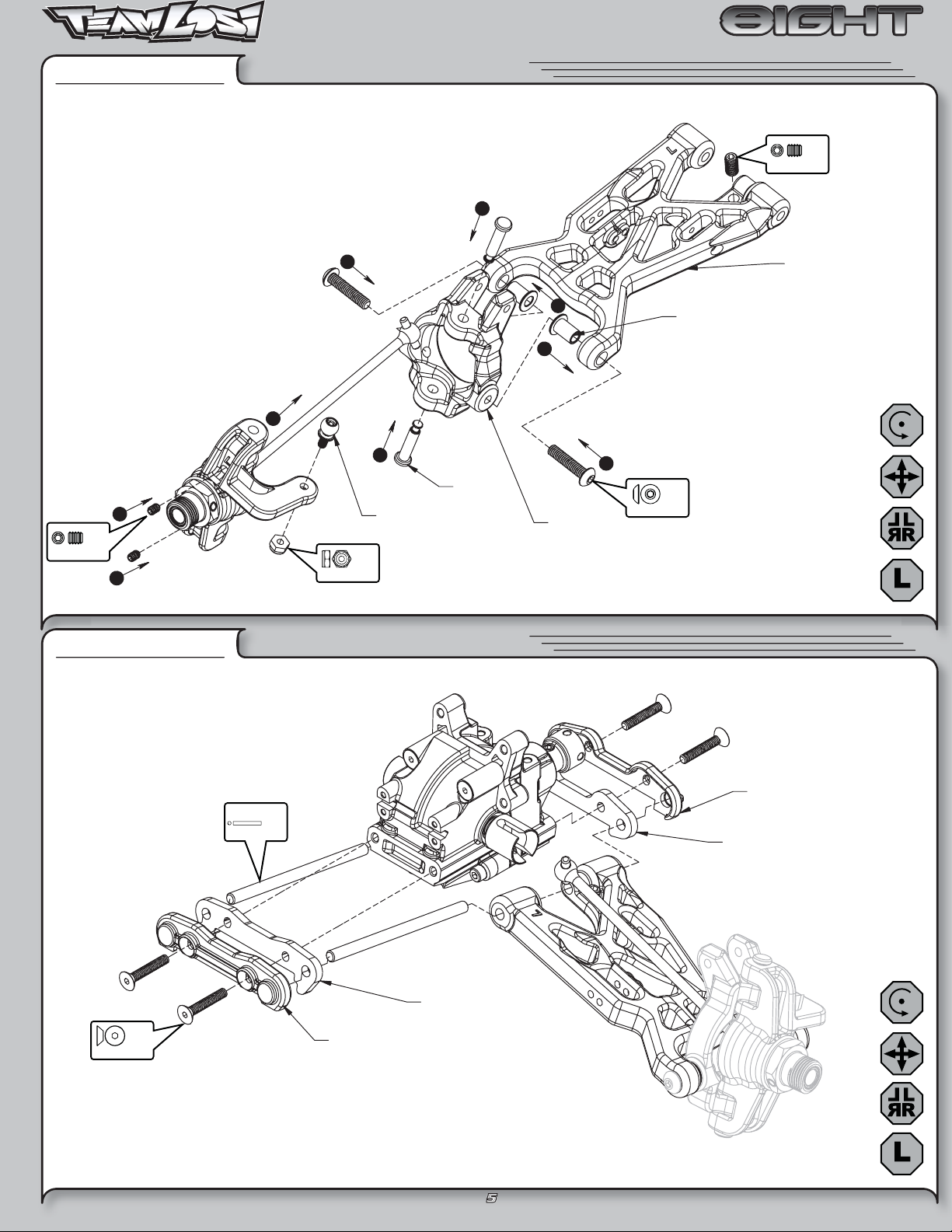

BAG B

STEP B-06

x 2

C 5-40 x 3/16”

Spindle/Carrier Assembly

x 1

O 10-32 x 3/8”

2

5

4

4

1

2

A6501

Hinge Pin

3

3

5-40 x 1/4”

A6050

Steering Ball Stud

x 1

A1710

Left Spindle Carrier

5

8/32 x 3/4”

A1701

Front Arm Bushing

x 2

A1700

Left Front Arm

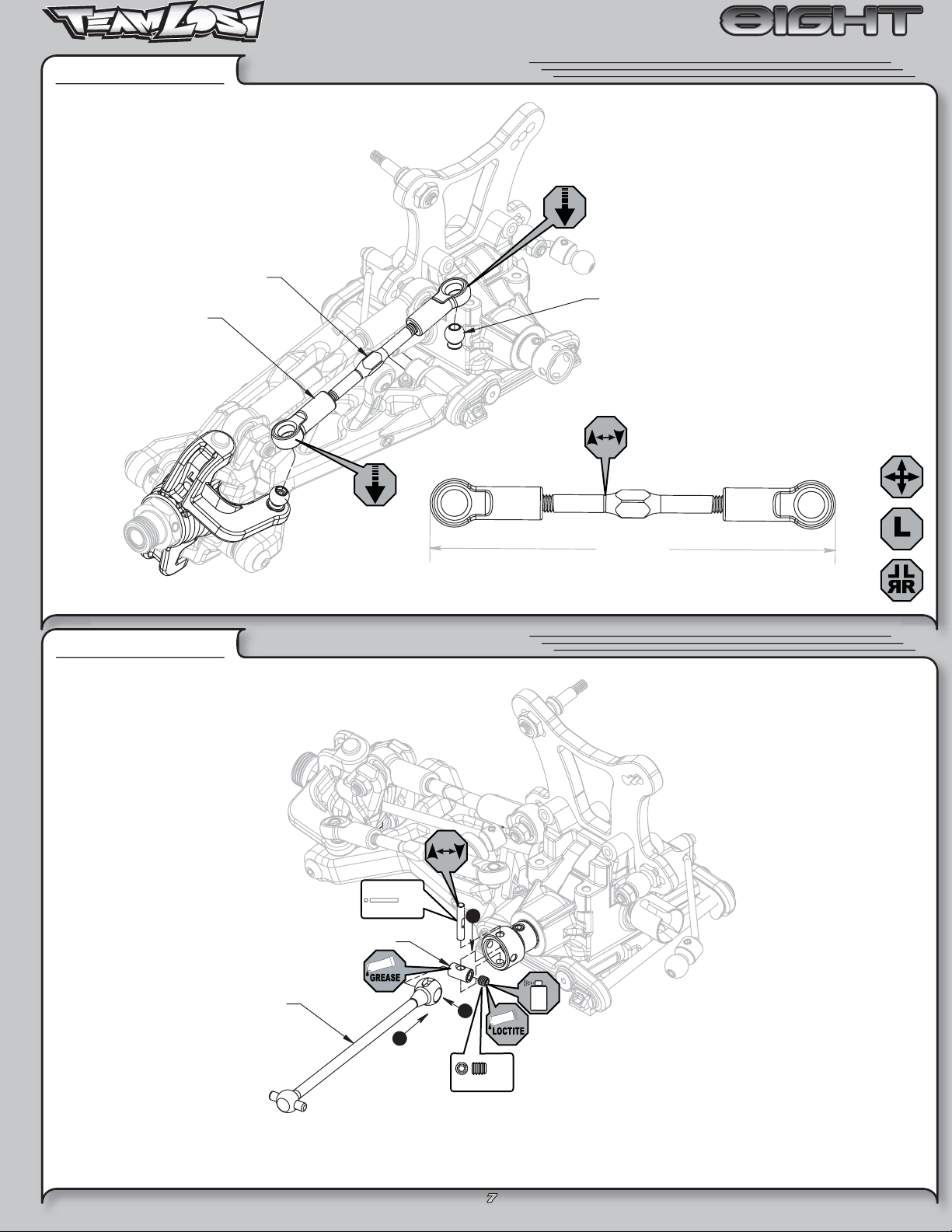

STEP B-07

x 4

5-40 x 3/4”

Front Suspension Arms Assembly

Solid

x 2

4mm x 65mm

A1744

Front Outer Hinge Pin Brace

A4431

Front Outer Hinge Pin Cap

Front Inner Hinge Pin Cap

A1744

Front Inner Hinge Pin Brace

A4431

5

BAG B

BAG B

STEP B-08

Install the Swaybar Ball onto the Swaybar Wire

until the end of the wire is fl ush with the ball as

pictured above

A4426

Swaybar Mount

Cap

x 2

C 4-40 x 1/8”

Swaybar Assembly

x 4

2-56 x 1/4”

C 5-40 x 1/8”

A1750

Front Swaybar

x 2

A1750

Swaybar Ball

A1750

Swaybar Link

A1750

Swaybar Ball, Arm

x 2

4-40 x 5/8”

STEP B-09

Shock Stand-Off

A4426

Shock Tower

Mount Cap

x 4

5-40 x 1/2”

A5438

Tie Rod/Shock Tower Assembly

Suspension Ball, Flanged

A1715

Front Shock Tower

x 2

L 8-32 x 11/32”

x 2

5-40 x 3/4”

A6048

5-40 x 1”

x 1

x 2

L 5-40 x 1/4”

Be sure to install the assembled

Tierod onto the car with the groove

(next to the center square section)

on the driver’s left side for easier

adjustment later.

A6540

Turnbuckle, Front

A6047

Rod End

A6049

Suspension Ball

3.72"

94.50 mm

6

BAG B

BAG B

STEP B-10

Steering Turnbuckle

A6046

Steering Rod End

Front Camber Link Assembly

A6542

A6050

Steering Ball

Be sure to install the assembled

Tierod onto the car with the groove

(next to the center square section)

on the driver’s left side for easier

adjustment later.

STEP B-11

Center CV Assembly

Solid

2.5mm x 14mm

A3526

CV Coupling, Center

3.62"

92.00mm

x 1

3

A3526

Driveshaft, Center

1

2

x 1

F 5-40 x 1/8”

7

e

BAG B

BAG B

STEP B-12

Front Clip Assembly

A4422

Front Bumper

x 2

5-40 x 3/4”

4

1

5-40 x 3/4”

2

8-32 x 1/2”

x 2

x 4

A4426

Front Bulkhead Spac

3

STEP B-13

Completed Front Assembly

8

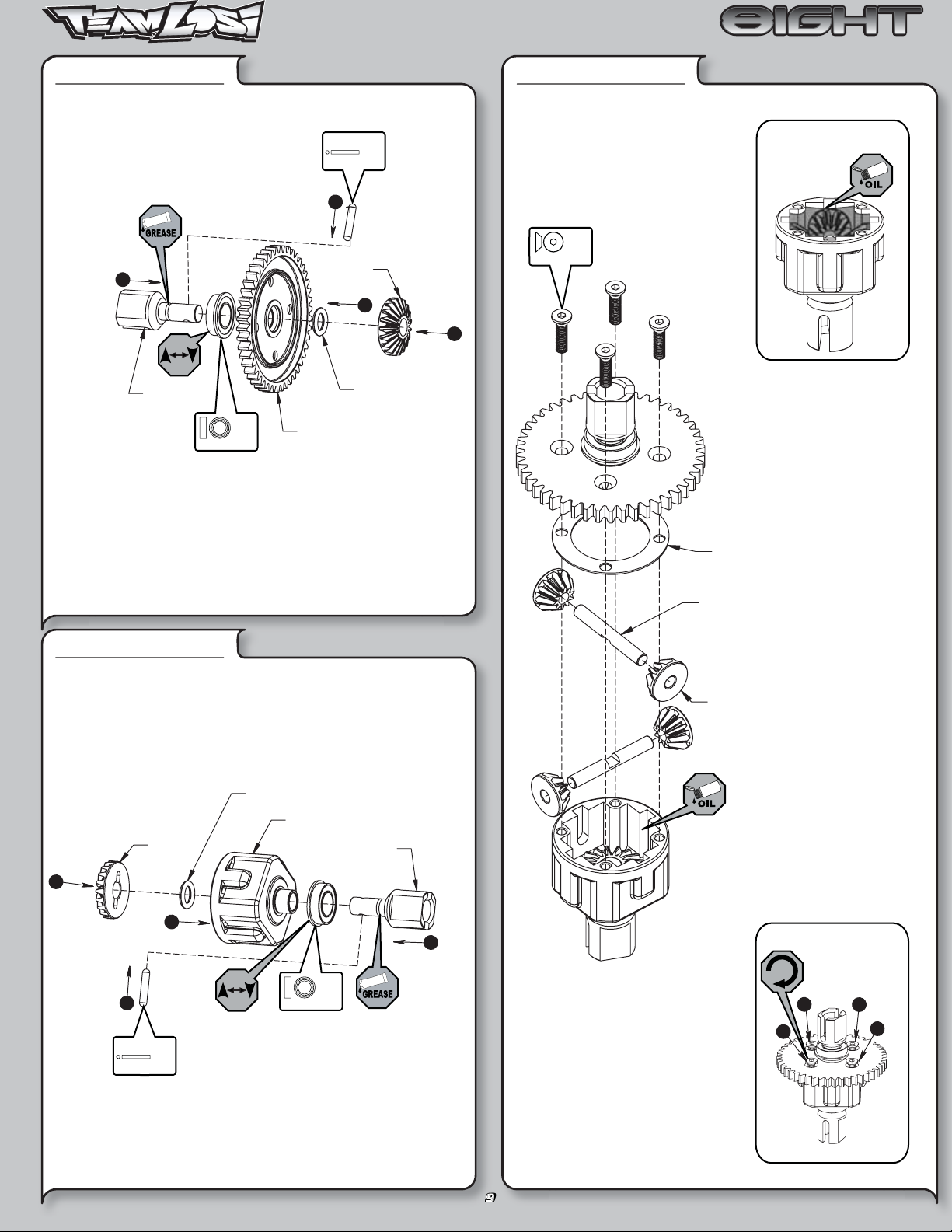

BAG C

BAG C

STEP C-01

1

A3506

Center Outdrive

x 1

F 8x14x4mm

Ring Gear Assembly

Solid

x 1

2.5 x 12.80mm

3

A3502

Sun Gear

2

A3505

O-ring

A3516

Spur Gear

STEP C-03

x 4

3x12mm

4

Complete Diff Assembly

Fill with 7000wt.

oil just above the

planetary gear

STEP C-02

4

A3502

Sun Gear

3

Solid

x 1

2.5 x 12.80mm

A3505

Diff Seal

A3502

Planetary Gear Axle

Diff Case Assembly

A3502

Planetary Gear

A3505

O-ring

A3500

Diff Housing

A3506

Center Outdrive

2

1

x 1

F 8x14x4mm

Tighten the diff screws

in this order

1

3

4

2

9

BAG C

BAG C

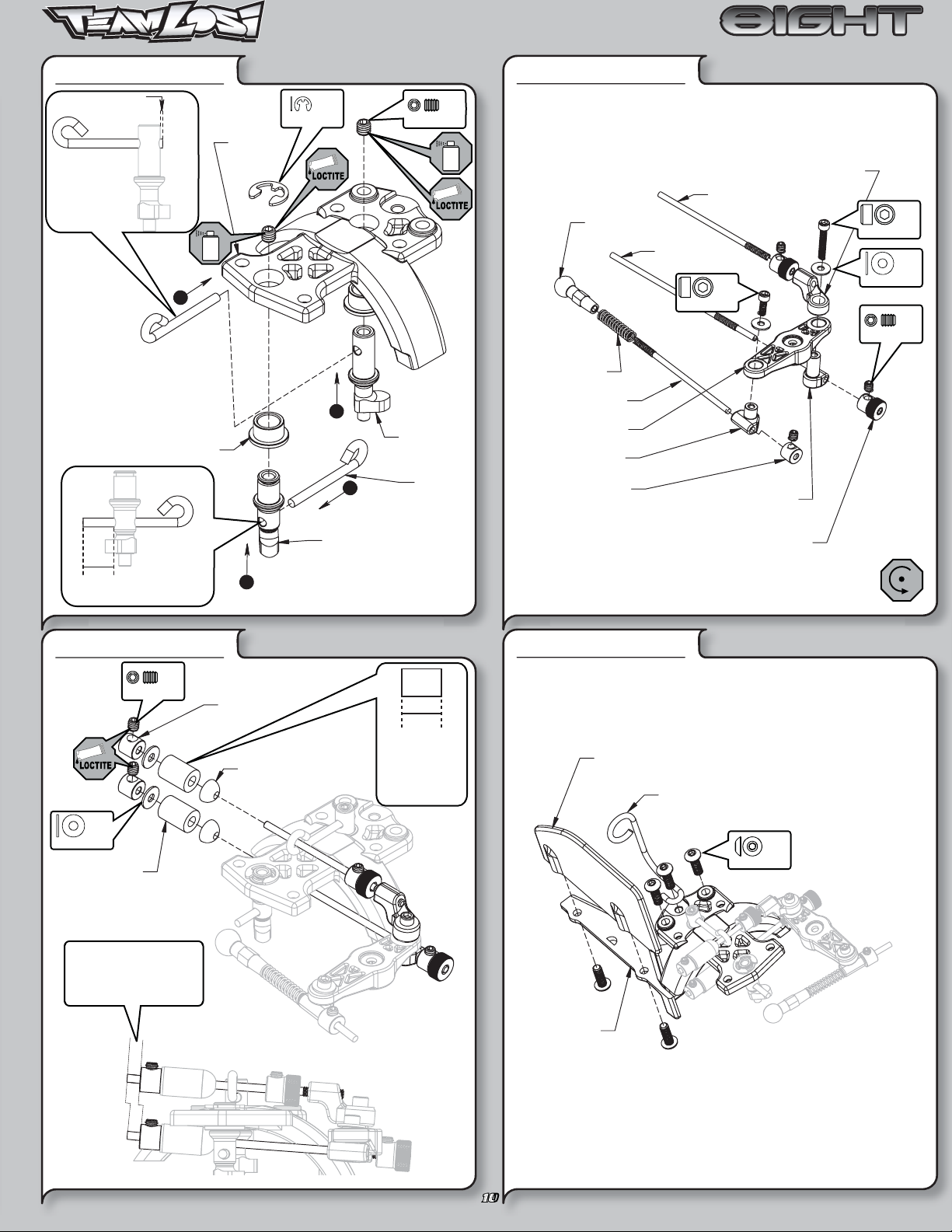

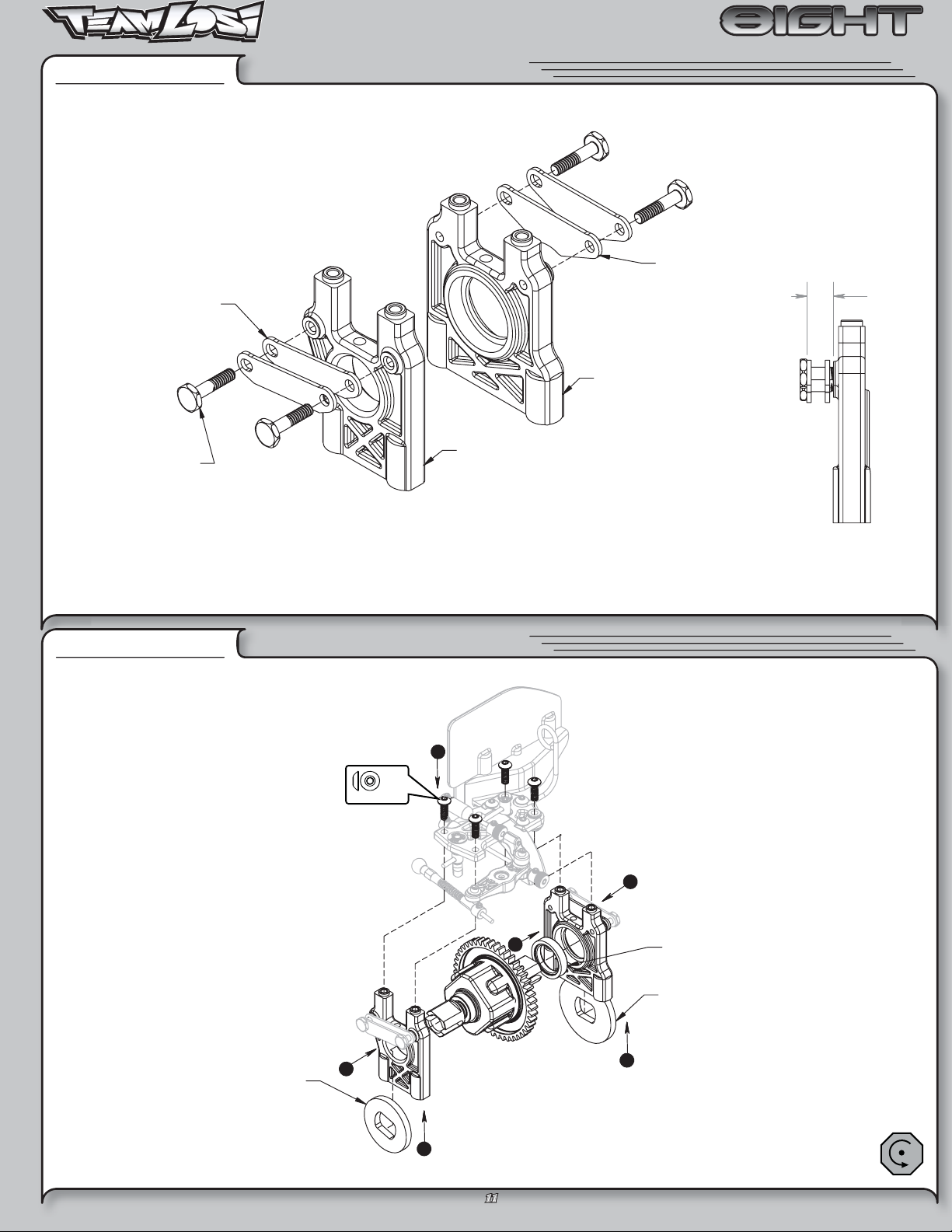

STEP C-04

(.5mm)(.020)

2

A3544

Brake Cam Bushing

Center Top Brace Assembly

x 1

A4415

Top Brace,

Center Diff

5mm E-Clip

1

1

A3544

Rear Brake Cam

5-40 x 1/8”

A3544

Front Brake Cam

Brake Wire

A9166

x 2

STEP C-05

Throttle Rod End

A9166

Throttle Return Spring

A9166

Threaded Servo Rod

A9166

Throttle Servo Arm

A9166

Throttle Actuator

A9166

Brake Lever Collar

A9166

A9166

Rear Brake Rod

2-56 x 1/4”

Linkage Assembly

A9166

Front Brake Actuator

A9166

Threaded Servo Rod

x 1

A9166

Rear Brake Actuator

A9166

Adjuster Collar

x 1

2-56 x 1/2”

x 2

.250x.094x020

x 3

C 4-40 x 1/8”

(7mm)

(.2760in)

STEP C-06

C 4-40 x 1/8”

x 2

.250x.094x.020

A9315

Fuel Line

Assemble both Front and

Rear Brake Lever Collars

2.80mm (.11”) from the

end of the Brake Rod.

x 2

2

Linkage Assembly

A9166

Brake Lever

Collar

A9166

Brake Bushing

(9mm)

(.3545in)

Cut two pieces

of fuel tubing

to size pictured

STEP C-07

Air Filter Guard

A4422

Tank Guard

A4422

Air Filter Mount & Guard

A9150

Air Filter Mount

x 5

5-40 x 3/8”

10

BAG C

BAG C

STEP C-08

Brake Shoulder Screw

Rear Brake Pad

A3541

A3541

Brake Caliper Assembly

A4415

Rear Center Diff Mount

A3541

Front Brake Pad

A4415

Front Center Diff Mount

0.230"

5.80mm

STEP C-09

Center Diff/Brake Rotor Assembly

4

x 4

5-40 x 3/8”

A3540

Rear Brake Disk

3

3

2

1

A4415

Bearing Insert

A3540

Front Brake Disk

1

11

Loading...

Loading...