Page 1

Operation Manual

Bedienungsanleitung

Guide de mise en oeuvre

Manuale di istruzioni

Not responsible for errors.

Losi, a Division of Horizon Hobby, Inc.

Stronghold Motorsports, Maxxis Tires, Lamb Energy, Simpson, Pro Am

Racing, Lucas Oil Products Inc., Fiberwerx Inc., K & N, Multi Mechanical

Inc., VP Racing Fuels and ReadyLift are property of their respective owners

and are used by permission or license by Horizon Hobby.

Page 2

Notice

All instructions, warranties and other collateral

documents are subject to change at the sole discretion

of Horizon Hobby, Inc. For up-to-date product literature, visit

http://www.horizonhobby.com and click on the support tab for

this product.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm when

operating this product:

NOTICE: Procedures, which if not properly followed,

create a possibility of physical property

damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed,

create the probability of physical property

damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed,

create the probability of property damage,

collateral damage, and serious injury OR

create a high probability of supercial injury.

Register your Losi Product Online

Register your 1/18 vehicle now and be the rst to nd out

about the latest option parts, product updates and more. Log

on to www.LOSI.com and follow the product registration link

to stay connected.

Connect - Register - Win

Visit WWW.LOSI.COM/REGISTER and follow the product

registration link to stay connected.

For registering your Losi Product you will be automatically

entered for a chance to win the Losi Pick-Your-Prize

Sweepstakes of $1,000 (retail value) based on winner

preference.

Losi/Horizon Support

If you have any questions concerning setup or operation of

your 1/16 vehicle please contact the appropriate Horizon

Product Support ofce (see page 12).

Kit Contents

WARNING: Read the ENTIRE instruction manual to

become familiar with the features of the product before

operating. Failure to operate the product correctly can result

in damage to the product, personal property and cause

serious injury.

This is a sophisticated hobby product and NOT a toy. It must

be operated with caution and common sense and requires

some basic mechanical ability. Failure to operate this Product

in a safe and responsible manner could result in injury or

damage to the product or other property. This product is not

intended for use by children without direct adult supervision.

Do not attempt disassembly, use with incompatible

components or augment product in any way without the

approval of Horizon Hobby, Inc. This manual contains

instructions for safety, operation and maintenance. It is

essential to read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in order to

operate correctly and avoid damage or serious injury.

Introduction

Thank you for choosing the Mini SCT from Losi. This guide

contains the basic instructions for operating your new Mini

SCT. It is critical that you read all of the instructions in order

to operate your model correctly and avoid unnecessary

damage.

• 1/16th Scale Mini SCT

• Losi® Radio System with Spektrum™ 2.4GHz DSM

• 4 AA batteries (for transmitter)

• Losi 7.2V 1100mAh NiMH Pack with EC2™ connector

• Losi AC wall charger (110V)

®

2 - EN

The Spektrum trademark is used with

permission of Bachmann Industries, Inc.

Losi, DSM, EC2 are trademarks or registered

trademarks of Horizon Hobby, Inc.

Page 3

Charging Warnings and Precautions

Failure to exercise caution while using this product and

comply with the following warnings could result in product

malfunction, electrical issues, excessive heat, FIRE, and

ultimately injury and property damage.

• Read all safety precautions and literature prior to use of

this product.

• Never leave the battery and charger unattended during

use.

• Never attempt to dismantle the charger.

• Never attach your charger to both an AC and DC power

source at the same time.

• Never reverse the positive and negative terminals.

Wrong connection will damage the battery and may

cause damage to the charger.

• Never allow minors to charge battery packs

• Never drop charger or batteries.

• Never attempt to charge dead or damaged batteries

• Never attempt to charge a battery pack containing

different types of batteries.

• Never charge a battery if the cable has been pinched or

shorted.

• Never allow batteries or battery packs to come into

contact with moisture at any time.

• Never charge batteries in extremely hot or cold places

(recommended between 50-80 degrees F) or place in

direct sunlight.

• Always use only rechargeable batteries. This charger

cannot charge batteries such as “heavy duty,” “Alkaline

battery,” or “Mercury battery.”

• Always connect the positive red lead (+) and negative

black lead (-) terminals of the battery to the charger

terminals correctly.

• Always disconnect the battery after charging, and let the

charger cool between charges.

• Always inspect the battery before charging.

• Always terminate all processes and contact Horizon

Hobby if the product malfunctions.

• Always keep batteries and charger away from any

material that could be affected by heat (such as ceramic

and tile), as they can get hot.

• Always monitor the area, use a re alarm and have a re

extinguisher available at all times.

• Always make sure you know the specications of the

battery to be charged or discharged to ensure it meets

the requirements of this charger. If the program is set

up incorrectly, the battery and charger may be damaged.

Improper settings can cause the battery to become

overcharged potentially leading to re or explosion.

• Always connect the charge cable to the charger rst,

then connect the battery to avoid short circuit between

the charge leads. Reverse the sequence when

disconnecting.

• Never connect more than one battery pack to this

charger at a time.

• Always constantly monitor the temperature of the battery

pack while charging.

• Always end the charging process if the charger or

battery becomes hot to the touch or starts to change

form (swell) during the charge process.

Getting Started

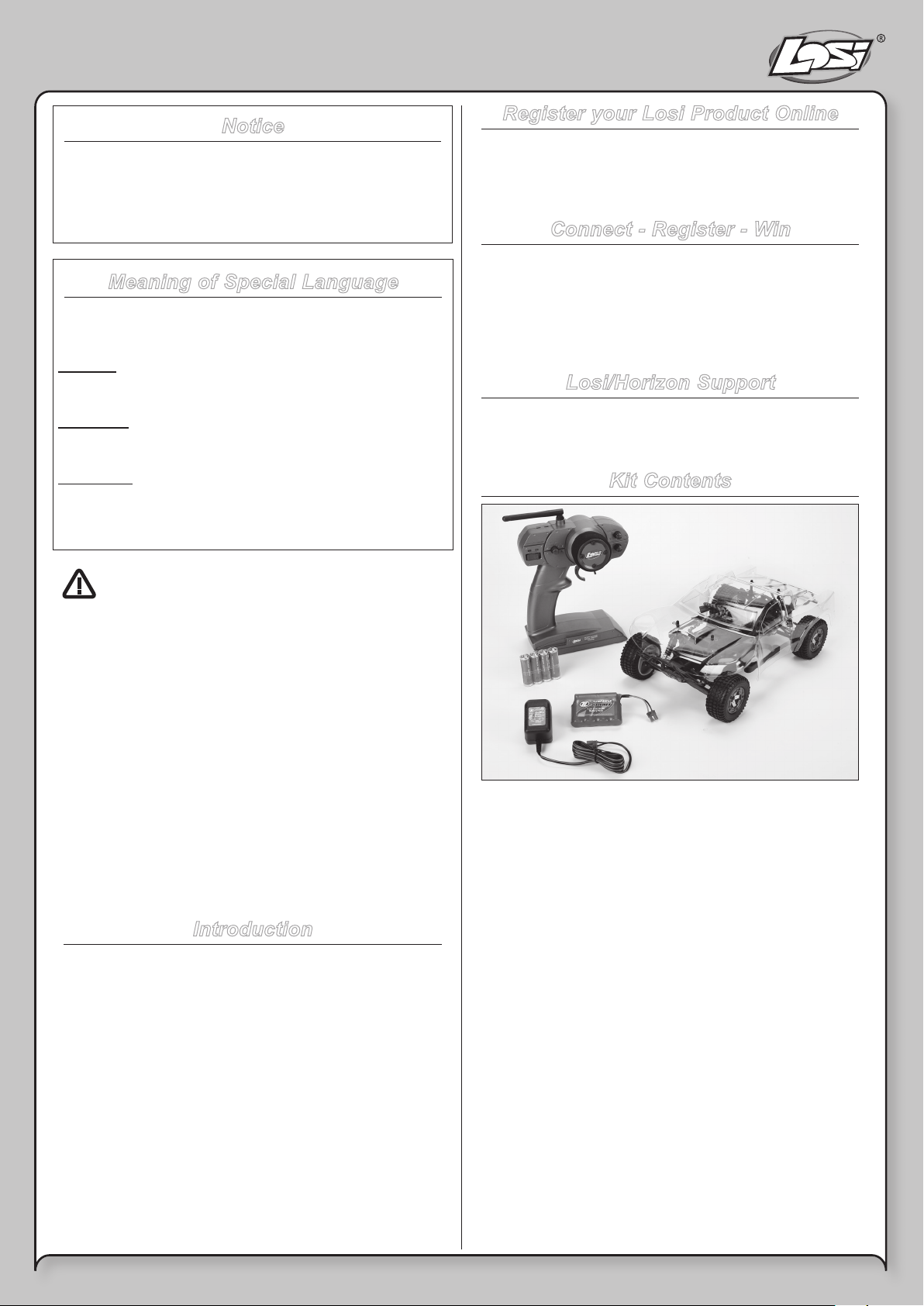

STEP 1

Plug the charger into the proper wall receptacle then the

battery into the charger and let it charge for 3 hours for the

rst time. For subsequent charges allow 5 to 6 hours for a full

charge.

STEP 2

Remove the transmitter battery cover, install four (4) AA

batteries and replace cover. Pay close attention to the

polarity of the positive (+) and negative (-) ends and replace

cover.

STEP 3

Once the battery is charged, remove the body clip from the

front battery hold-down and lift the battery strap.

3 - EN

Page 4

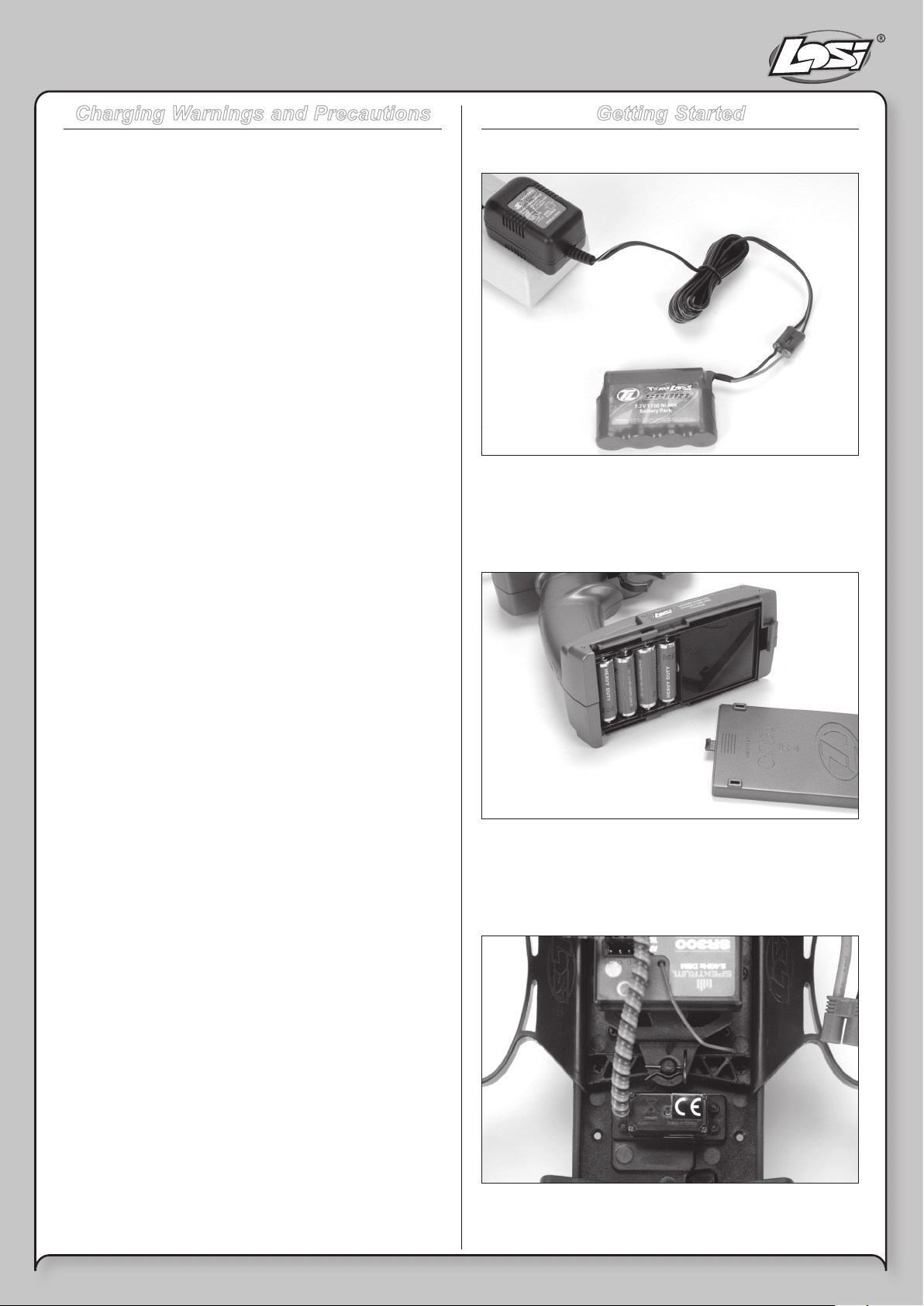

STEP 4

Install the charged battery pack into the chassis as shown.

Ensure the battery is laying at on the chassis.

STEP 5

STEP 7

Once the transmitter has been powered on, turn on your

vehicle by sliding the switch on the ESC to the “ON” position.

STEP 8

Reinstall the battery strap and body clip. Plug the battery

pack into the ESC.

STEP 6

Off

Off On

On

Left

Left Right

Brake/Reverse

Brake/Reverse

Forward

Forward

If the rear wheels turn during power-on, adjust the “TH. Trim”

knob located to the lower right of the steering wheel until they

stop.

To make the vehicle move forward, pull the trigger back. To

reverse the vehicle, wait for the model to stop and then push

the trigger forward.

When going forward the vehicle should move in a straight

line. If not, adjust the “ST. Trim” so that it tracks in a straight

line without having to turn the steering wheel.

Right

ST Trim

ST Trim

TH Trim

TH Trim

STEP 9

After you have nished, turn your vehicle off FIRST by sliding

the ESC switch to the “OFF” position. After the model has

been turned off, turn off the transmitter.

Always turn on the transmitter rst. The small red and green

lights above the switch should both light up. If not, you need

to check for low or incorrectly installed batteries.

STEP 10

If you wish to clean your vehicle, use compressed air and/or

a soft brush to remove dust and dirt. NEVER use chemicals

or anything wet as it can cause damage to both electronics

and plastic parts.

4 - EN

Page 5

ALWAYS:

• Turn on the transmitter before the vehicle

• Use caution when running your vehicle near people

• Turn both the vehicle and transmitter “OFF” when done

• Check the battery condition of the transmitter before

running

NEVER:

• Operate the vehicle with low battery power

• Run the vehicle through water or wet grass

• Use chemicals to clean the chassis

• Run the vehicle without a gear cover

Safety Precautions

Losi and Horizon Hobby shall not be liable for any loss or

damages, whether direct, indirect, special, incidental, or

consequential, arising from the use, misuse, or abuse of this

product or any product required to operate it.

Age Recommendation

Not for children under 14 years. This is not a toy.

• This model is controlled by a radio signal subject to

interference from many sources outside your control.

This interference may cause momentary loss of control

so it is advisable to always keep some distance in all

directions around your model as a safety margin to

avoid collisions.

• Always operate your model in an open area away from

cars, trafc and people.

• Avoid running your model in the street where damage

can occur.

• Never run your Mini SCT with low transmitter batteries.

• Carefully follow the directions and warnings for this and

any optional support equipment.

• Keep all chemicals, small parts and anything electrical

out of the reach of children.

Tools and Items You Will Find Handy

• Soft bristle brush for cleaning

• 5.5mm nut driver for the wheel nuts

• #0 or #1 Phillips screwdriver

• LOSA99100 .050-inch Hex Wrench

Note: Use only Losi tools or other high-quality tools. Use of

inexpensive tools can cause damage to the small screws and

parts used on this type of model.

The Radio System

The following is an overview of the various functions and

adjustments found on your Losi Mini SCT radio system.

Since the Mini SCT operates on a radio signal, it is important

for you to read and understand these functions before driving

the model.

THE RECEIVER

8

9

10

2

1

3

7

4

6

5

1. Receiver/ESC Power Lead: Connects to the battery lead

for power

2. Servo Port/Plug: Where the steering servo plugs in (note

polarity on case)

3. Bind port: Used to bind the receiver to the transmitter

4. Indicator Light: Indicates the operation status of the

receiver

5. On/Off Switch: Controls Power to the Receiver/ESC

6. Setup Button: Enters ESC into setup mode

7. Battery Leads: Connects the battery to the ESC

8. Motor Lead: Connects the ESC to the motor

9. Antenna Wire: Receives the radio signal from your

transmitter

10. Aux. Port

5 - EN

Page 6

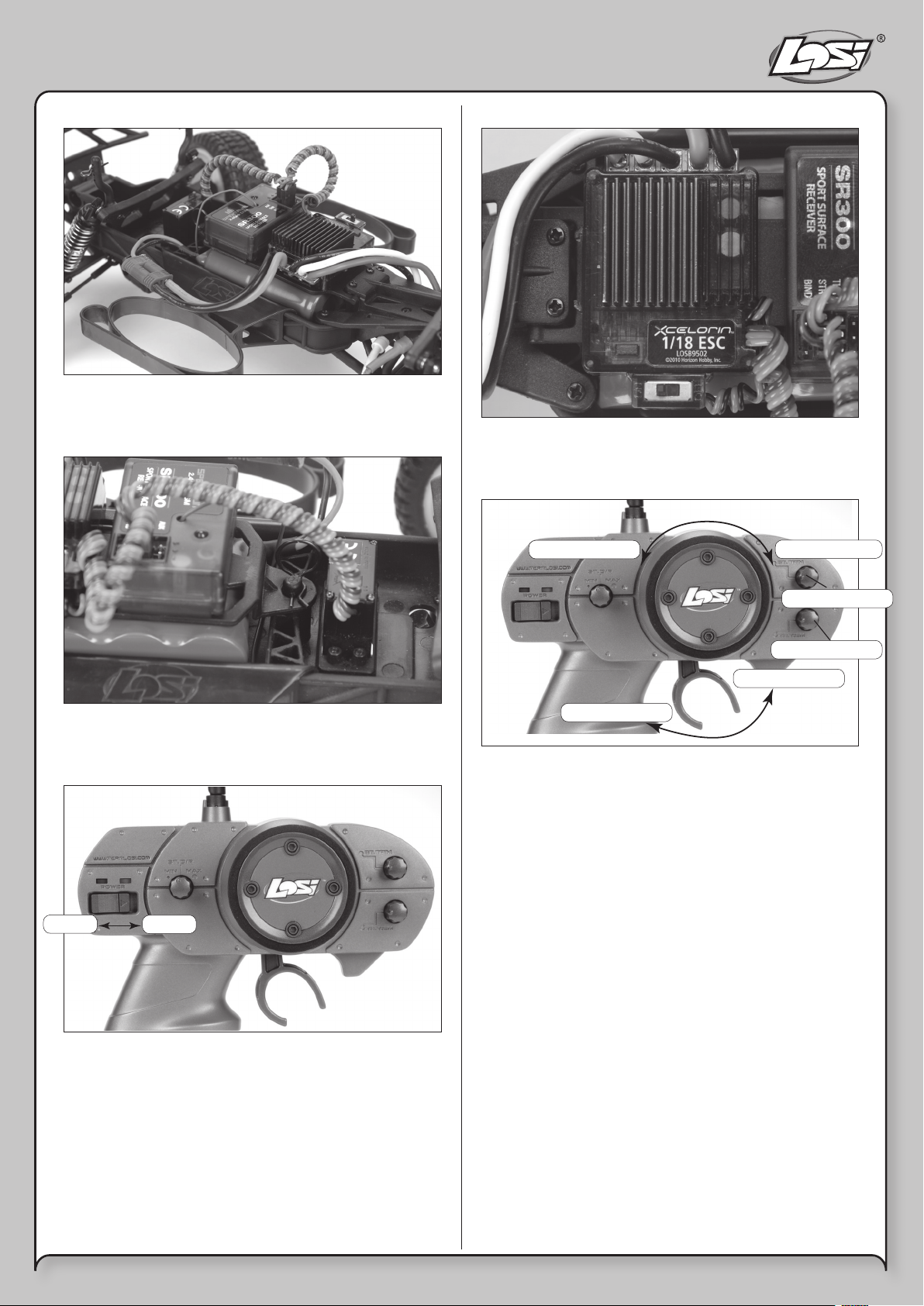

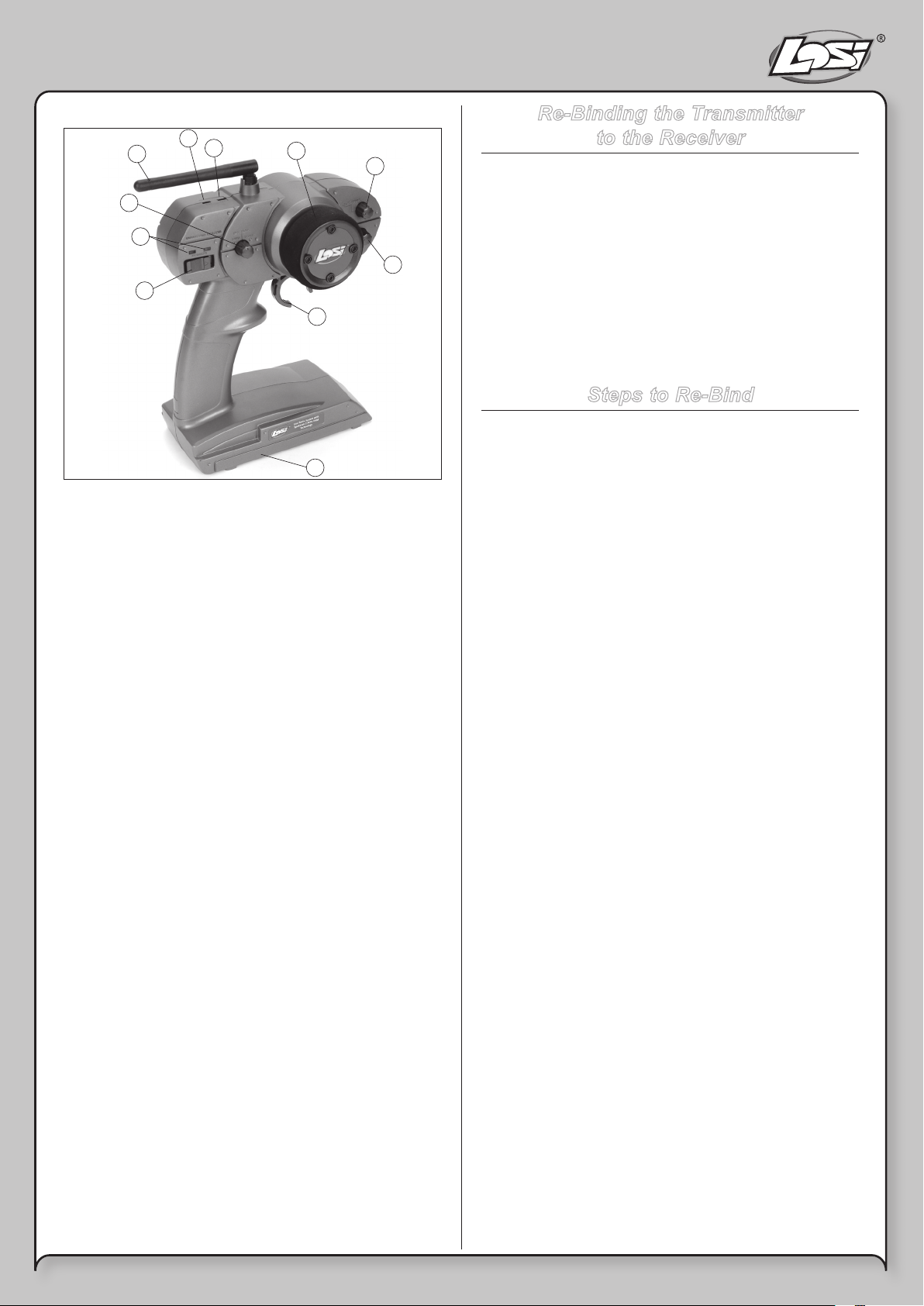

THE TRANSMITTER

9

3

8

5

4

10

1. Steering Wheel: Controls direction (left/right) of the

model.

2. Throttle Trigger: Controls speed and direction (forward/

reverse) of the model.

3. Antenna: Transmits signal to the model.

4. On/Off Switch: Turns the power on/off for the transmitter.

5. Indicator Lights: Green (right) light indicates adequate

battery power. Red (left) indicates signal strength.

6. ST. Trim: Adjusts the “hands off” direction of the model.

7. TH. Trim: Adjusts the motor speed to stop at neutral.

8. Steering Rate: Adjusts amount front wheels move when

the steering wheel is turned left and right.

9. ST. REV: Reverses the function of the steering when the

wheel is turned left or right.

10. TH. REV: Reverses the function of the speed control

when pulled back or pushed forward.

11. Bottom Cover: Covers and holds the batteries that

power the transmitter.

1

6

7

2

11

Re-Binding the Transmitter

to the Receiver

The Losi DSM radio system included in the Mini SCT

operates on 2.4GHz. The communication between the

transmitter and receiver starts in the few seconds after the

transmitter and vehicle are both turned on. This is called

the “binding process”. The Losi DSM radio system will not

interfere with previous technology radio systems that operate

on 27MHz or 75MHz frequencies and you will not receive any

interference from them. Although set at the factory, below are

the steps required to re-bind your transmitter to the receiver

should the need arise. During the bind process there is a

unique ID from the transmitter communicated to the receiver

to ensure trouble-free radio operation.

Steps to Re-Bind

1. Ensure the transmitter and vehicle are both turned off.

2. Using the supplied Bind plug (which looks like a

standard receiver plug with a wire loop installed) insert

or plug into the receiver slot labeled “BIND”. Looking

down on the receiver this slot would be below the LED

and is the furthest from the LED, or nearest to the corner

of the receiver.

Note: You do not need to remove any

of the other plugs to re-bind.

3. With the Bind plug installed, turn on the vehicle. Notice a

blinking Orange LED within the receiver.

4. Now you are ready to turn on the transmitter. You should

notice on the back of the transmitter a similar blinking

Orange LED under the translucent cover.

5. Both the receiver and transmitter blinking Orange LEDs

will stop blinking and become solid indicating they have

“bound” themselves together.

6. Please turn off both the vehicle and transmitter to

remove the Bind plug from the receiver. Failing to

remove the Bind plug will cause the transmitter to

attempt to rebind every time you turn on the vehicle and

transmitter.

7. Turn on both the vehicle and transmitter to ensure

operation. If the transmitter does not control the vehicle,

please repeat steps 1 to 6. Should this not correct the

problem please call Horizon Service/Repair for further

assistance.

8. The Bind process is complete. Your vehicle’s radio

system should be ready for use.

6 - EN

Page 7

Resetting and adjusting the

FEATURES

MSC-18BL ESC

Battery Type Programming

1. LED indicator

After power is turned on, the LED will display the selected

Battery Type for 2 seconds.

Red and Green LEDs are used to display selected Battery

Type:

Red LED Flashing = LiPo is selected

Green LED Flashing = NiMH is selected

To change from one battery type to another (colors described

above), press the setup button during the rst 2 seconds

after turning on ESC. Cutoff voltage will automatically adjust

based on battery type:

For LiPo battery: ESC will auto detect whether it is 1 cell

(3.3V), 2 cell (6V) or 3 cell (9V)

For NiMH: ESC will cutoff at 4.3V

2. LED display during “Normal Operation”

1. Auto Detects Brushed or Brushless motor (See Select

Motor Type)

2. One-Touch Endpoints calibration

3. Battery Selection:

a. LiPo (ESC auto detects number of cell:

1S to 3S)

b. NiMH

4. 2 ESC prole:

a. Forward / Reverse with Smart Brake II

b. Forward Only

5. Battery Over Voltage Protection (Max Input voltage =

13V)

6. Thermal Protection

7. Motor Stall Detection

Speed Control Programming

Select Motor Type

When ESC is turned on, it will check the connection

between Red and White wire. If the wires are shorted,

then it will go into brushed motor mode.

Brushed Motor

a. Motor (+) connected to Red and White Wire of ESC

b. Motor (-) connected to Black Wire of ESC

Brushless Motor

Connect the 3 motor wires to Red, White and Black wire of

ESC.

Condition

Stop

Partial Forward

Max Forward

Partial Reverse

Max Reverse

Brake

3. One-Touch Endpoints Calibration Programming:

a. Turn on Transmitter, Throttle in neutral position

b. Hold the ESC setup button and turn on ESC

c. Red and Green LED will turn on, release setup

button

d. Green LED will begin ashing, pull trigger to full

throttle position until Green light turns solid, then

return to neutral position

e. Red LED will ash at this time

f. Push trigger to at maximum reverse position until

Red LED turns solid

g. Release trigger to neutral position and programming

is complete

4. LED display for “Error”

a. Battery Voltage too high (over 13V)---Solid Red LED

and Green LED ashing slowly (Only during Power

ON)

b. Overheat---Alternatively Flashing Red and Green

c. Motor Failure, e.g., wire broken, bad motor, or

jam---Red LED ashing quickly 3 times (repeating

sequence)

d. Battery Low---Green LED solid on and Red LED

ashing slowly

LED

Green

Off

Red

Off

Red

Red & Green

5. Technical Specication:

1. Sensorless Brushless ESC

2. Resistance per phrase: 0.0036 ohm

3. Up to 25A continuous current, 250A surge current

4. Max RPM: 120,000

5. 4 to 7 cells NiMH, or 1, 2 or 3 cell Li Polymer

6. BEC: 6V, 1A

7 - EN

Page 8

Warning

This model may only be powered by the stock 6-cell 7.2volt NiMH battery pack (LOSB1212), a 2-cell 7.4-volt LiPo

battery pack (LOSB9826) or 3-cell 11.1 volt LiPo battery pack

(LOSB9827). Please consult the Motor/Battery Chart below

for suggested motor/battery combos. The use of higher

voltage battery packs will cause ESC damage and void

any warranty. Consult your local hobby dealer or check

www.losi.com.

4100

4500

5000

7.2V NiMH (LOSB1212)

7.4V LiPo (LOSB9826)

11.1V LiPo (LOSB9827)

(LOSB9458)

x

x

x

(LOSB9457)

x

x

x

(LOSB9459)

x

x

x

6000

(LOSB9460)

x

x

(LOSB9461)

7400

x

x

8200

(LOSB9462)

x

x

9400

(LOSB9463)

x

x

Chassis Tuning

The Mini SCT has several adjustments available to you for

tuning the performance for your needs. Although there are

multiple shock positions and camber link locations provided,

we have built the model with the best overall settings. The

following are simple adjustments and easily maintained

settings to assure proper operation and performance. It is

advised when making any adjustment that you do so in small

increments and always check for other parts of the chassis

that are affected.

Slipper Adjustments

The Mini SCT is equipped with a slipper device offering

both traction control and protection for the transmission.

The slipper is primarily used to help absorb sudden impacts

on the drivetrain due to landing big jumps or when using

more powerful aftermarket motors and/or battery packs.

Additionally, it can be used to smooth out the ow of power

to the rear wheels and limit wheel spin when running on

extremely slick surfaces.

When adjusted properly, you should be able to hold the rear

tires rmly and barely be able to push the spur gear forward

with your thumb.

To track test, turn the Mini SCT on and place it on the

ground. As you push it backwards allowing it to roll freely,

punch the throttle. The slipper should slip no more than an

inch or two as it accelerates. With the included motor and

battery pack it should slip just a little. Make sure you replace

the gear cover before running.

Steering Rate

Your transmitter is equipped with a steering rate control to

the left of the steering wheel. This advanced feature, usually

found only on competition-type radios, allows you to adjust

the amount the front tires move when you turn the steering

wheel. This is really helpful when you are on slick, as well as

high-traction surfaces.

Less Rate

Increase

Slip

Reduce

Slip

Adjustment is made by turning the 3mm adjustment nut

clockwise (to the right) to reduce the slip, or counterclockwise

(to the left) to increase the slip.

8 - EN

If your Mini SCT turns too sharply and/or spins out easily,

try turning the steering rate down by rotating the knob

counterclockwise (to the left).

Page 9

More Rate

For sharper or additional steering, try turning the knob

clockwise (to the right).

Toe-In

This is the relationship of the left and right side tire to one

another.

Camber

Camber is the angle of the tires to the racing surface when

viewed from the front or rear of the truck.

Less Camber More Camber

You want to keep both the front and rear tires straight up and

down or leaning in at the top very slightly.

If you are running on carpet or similar high traction surfaces,

you may nd leaning the tires in a bit more helps. This

adjustment is made with the threaded links extending from

the front or rear bulkhead to the spindle carrier or rear hub.

Making the camber rods shorter increases the camber and

lean-in of the tire, while making the camber rods longer

decreases the camber.

Less Toe-In More Toe-In

Ideally, you want the front of the tires to be pointed inward

toward each other just slightly when viewed from above. This

makes the model track straight and stable. This is controlled

with the threaded steering rods on either side. As you make

them longer you will increase the toe-in and vice versa.

Ride Height

This is the height the chassis sits and runs at. Spring spacers

included with the Mini SCT, when installed between the

shock top and spring, will increase the pre-load on the spring

and raise the chassis. You may want to try this when running

on extremely rough surfaces.

Service/Repair

Radio/Speed Control & Motor

If you have any problems other than those covered in

the troubleshooting section, please call the appropriate

electronics service department. They will be able to give your

specic problem additional attention and instruct you as to

what needs to be done.

Maintenance

If you have any questions other than those covered in the

troubleshooting or maintenance sections, please call the

appropriate Horizon product support department.

Cleaning

Performance can be hindered if dirt gets in any of the moving

suspension parts. Use compressed air, a soft paintbrush, or

toothbrush to remove dust or dirt. Avoid using solvents or

chemicals as they can actually wash dirt into the bearings or

moving parts as well as cause damage to the electronics.

9 - EN

Page 10

Rebuilding the Differential

Reassembly

The gears in the differential will wear over time. The same

is true for the outdrives, driveshafts, and rear axles. We

suggest using a small rag or paper towel to lay out the parts

you remove to make it easier to reassemble.

Disassembly

1. Unplug the 3 motor wires from ESC.

2. Remove the gear cover (three screws pictured)

3. Remove the 2 screws on the front of the rear shock

tower that attach to the rear upper cage. Once the

screws are removed, rotate the rear cage toward the

rear enabling access to the rear camber block.

4. Remove the 2 screws attaching the rear camber block to

the transmission case.

5. Remove 4 screws from rear skid plate and remove

transmission from vehicle.

6. Remove bracket on top of transmission by removing the

2 front screws and removing the long screw (secured

with a bolt), which passes through the transmission from

the motor plate side.

7. Remove the left side of the gearbox by removing the

three screws.

8. Remove any shims on the bevel gears (not used on all

models) and set them aside so they can be reinstalled in

the same location.

9. Carefully remove the large plastic sun gear and the

bevel gears on either side of it. You can use the

removed differential assembly as a guide for putting

together the replacement unit. For the best performance

Losi Grease (LOSA3066) can be applied to these gears.

10. Remove the center mounted idler gear from the

gearbox. Remove the shaft and push the ball bearings

out of both sides. Install these bearings in the new gear.

Replace the idler gear and shaft into the center of the same

right side of the gearbox. Replace any shims removed from

the right bevel gear and slide it through the lower bearing.

Replace any shims that came off of the left side bevel gear

and allow it to slide through the lower bearing as you put the

left gearbox half back into position. Replace the screws and

reinstall the rebuilt gearbox using the above steps in reverse

order. Consult the exploded view in the back of this manual

for more details.

Changing the Spur Gear

Remove the gear cover by removing the three small screws.

If you are replacing the spur gear with one of a different size

(number of teeth), you must rst loosen (do not remove) the

two screws that secure the motor and slide it back slightly.

Remove the 3mm nut at the end of the slipper shaft and all

of the slipper parts on the outside of the spur gear as well

as the old gear. Place the new spur gear into position and

replace the slipper parts. If you have changed the size of

the spur, see Setting the Gear Mesh below. After you have

changed the spur gear, you will have to adjust the slipper as

described elsewhere.

Changing the Pinion Gear/Gear Ratio

Before you change the pinion gear ask yourself why you are

doing it. In general, if you change to a larger pinion the top

speed will improve but you will see less acceleration and

run time. This would only be advisable for really long track

layouts with few tight turns. Changing to a smaller pinion

will give you quicker acceleration and possibly a bit longer

run time but a little less top speed. This would be good for

short layouts or when running hotter motors. The pinion on

the Mini SCT offers the best balance of both. To change the

pinion, remove the gear cover, loosen the motor screws, and

slide the motor back. Use a pair of small needle-nose pliers

between the motor plate and back of the pinion to push the

pinion off. Place the new pinion on the end of the motor shaft

and, using the at of the pliers or a similar at tool, push it

on to the same position as the one removed. See Setting the

Gear Mesh below.

CAUTION: When running aftermarket motors, check

with the motor manufacturer for correct gearing. Never

over-gear the motor as it can cause overheating, damaging it

and the speed control.

Setting the Gear Mesh

The motor screws should be slightly loose. Slide the motor

forward allowing the pinion gear to mesh with the spur gear.

Snug (not tight) the bottom motor screw and try rocking the

spur back and forth. There is a slight bit of movement before

the motor is forced to turn over. If not, pull the top of the

motor back slightly and recheck. If there is too much slop

between the gears, push the top of the motor forward. When

set properly, the wheels can be spun forward freely with

very little noise. Make sure to tighten both motor screws and

replace the gear cover before running.

10 - EN

Page 11

Steering Servo Installation/Removal

Unplug the servo lead from the receiver. Remove the four

small screws located on the bottom of the chassis that

secure the servo to the chassis. Use a screwdriver or small

pliers to pop the steering link off of the servo, so it can be

removed. Replace in the reverse sequence used to remove

the servo.

Receiver/Speed Control (ESC)

Installation/Removal

Unplug the power lead, motor leads and steering servo. Do

not attempt to open the receiver or electronic speed control

(ESC) as only a factory technician has the proper tools

and parts to make any repairs necessary. The receiver and

ESC are mounted with double-sided foam tape. Use your

thumb and index nger at the bottom of the front corners

to pull them from the mount. If this is difcult, ask for help.

If necessary, carefully use a large at blade screwdriver

between the unit and the mount to pry it loose. Make

sure you remove any left over foam or adhesive before

remounting with common servo tape or hobby type foam

tape.

Warranty and Repair Policy

WARRANTY PERIOD

Exclusive Warranty- Horizon Hobby, Inc., (Horizon)

warranties that the Products purchased (the “Product”) will

be free from defects in materials and workmanship at the

date of purchase by the Purchaser.

LIMITED WARRANTY

Horizon reserves the right to change or modify this

warranty without notice and disclaims all other

warranties, express or implied.

(a) This warranty is limited to the original Purchaser

(“Purchaser”) and is not transferable. REPAIR OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY

IS THE EXCLUSIVE REMEDY OF THE PURCHASER. This

warranty covers only those Products purchased from an

authorized Horizon dealer. Third party transactions are not

covered by this warranty. Proof of purchase is required for all

warranty claims.

(b) Limitations- HORIZON MAKES NO WARRANTY OR

REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE OF THE PRODUCT.

THE PURCHASER ACKNOWLEDGES THAT THEY

ALONE HAVE DETERMINED THAT THE PRODUCT

WILL SUITABLY MEET THE REQUIREMENTS OF THE

PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder

shall be that Horizon will, at its option, (i) repair or (ii) replace,

any Product determined by Horizon to be defective. In

the event of a defect, these are the Purchaser’s exclusive

remedies. Horizon reserves the right to inspect any and

all equipment involved in a warranty claim. Repair or

replacement decisions are at the sole discretion of Horizon.

This warranty does not cover cosmetic damage or damage

due to acts of God, accident, misuse, abuse, negligence,

commercial use, or modication of or to any part of the

Product. This warranty does not cover damage due to

improper installation, operation, maintenance, or attempted

repair by anyone other than Horizon. Return of any Product

by Purchaser must be approved in writing by Horizon before

shipment.

DAMAGE LIMITS

HORIZON SHALL NOT BE LIABLE FOR SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCT, WHETHER

SUCH CLAIM IS BASED IN CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY. Further, in no event

shall the liability of Horizon exceed the individual price of

the Product on which liability is asserted. As Horizon has

no control over use, setup, nal assembly, modication

or misuse, no liability shall be assumed nor accepted for

any resulting damage or injury. By the act of use, setup or

assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept

the liability associated with the use of this Product, you

are advised to return this Product immediately in new and

unused condition to the place of purchase.

Law: These Terms are governed by Illinois law (without

regard to conict of law principals).

Warranty Services

QUESTIONS, ASSISTANCE, AND REPAIRS

Your local hobby store and/or place of purchase cannot

provide warranty support or repair. Once assembly, setup

or use of the Product has been started, you must contact

Horizon directly. This will enable Horizon to better answer

your questions and service you in the event that you may

need any assistance. For questions or assistance, please

direct your email to productsupport@horizonhobby.com, or

call 877.504.0233 toll free to speak to a Product Support

representative. You may also nd information on our website

at www.horizonhobby.com.

11 - EN

Page 12

INSPECTION OR REPAIRS

If this Product needs to be inspected or repaired, please

use the Horizon Online Repair Request submission process

found on our website or call Horizon to obtain a Return

Merchandise Authorization (RMA) number. Pack the Product

securely using a shipping carton. Please note that original

boxes may be included, but are not designed to withstand

the rigors of shipping without additional protection. Ship

via a carrier that provides tracking and insurance for lost

or damaged parcels, as Horizon is not responsible for

merchandise until it arrives and is accepted at our facility. An

Online Repair Request is available at www.horizonhobby.com

http://www.horizonhobby.com under the Repairs tab. If you

do not have internet access, please contact Horizon Product

Support to obtain a RMA number along with instructions for

submitting your product for repair. When calling Horizon, you

will be asked to provide your complete name, street address,

email address and phone number where you can be reached

during business hours. When sending product into Horizon,

please include your RMA number, a list of the included items,

and a brief summary of the problem. A copy of your original

sales receipt must be included for warranty consideration.

Be sure your name, address, and RMA number are clearly

written on the outside of the shipping carton.

NOTICE: Do not ship batteries to Horizon. If you

have any issue with a battery, please contact the

appropriate Horizon Product Support ofce.

WARRANTY INSPECTION AND REPAIRS

To receive warranty service, you must include your

original sales receipt verifying the proof-of-purchase

date. Provided warranty conditions have been met, your

Product will be repaired or replaced free of charge. Repair or

replacement decisions are at the sole discretion of Horizon.

NON-WARRANTY REPAIRS

Should your repair not be covered by warranty the

repair will be completed and payment will be required

without notication or estimate of the expense unless

the expense exceeds 50% of the retail purchase

cost. By submitting the item for repair you are agreeing to

payment of the repair without notication. Repair estimates

are available upon request. You must include this request

with your repair. Non-warranty repair estimates will be billed

a minimum of ½ hour of labor. In addition you will be billed for

return freight. Horizon accepts money orders and cashiers

checks, as well as Visa, MasterCard, American Express,

and Discover cards. By submitting any item to Horizon for

inspection or repair, you are agreeing to Horizon’s Terms and

Conditions found on our website under the Repairs tab.

UNITED STATES

(Electronics and engines)

Horizon Service Center

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

Online Repair Request visit:

www. horizonhobby.com/repairs

877-504-0233

(All other products)

Horizon Product Support

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

productsupport@horizonhobby.com

877-504-0233

UNITED KINGDOM

Horizon Hobby Limited

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

sales@horizonhobby.co.uk

+44 (0) 1279 641 097

GERMANY

Horizon Technischer Service

Hamburger Str. 10

25335 Elmshorn

Germany

service@horizonhobby.de

+49 4121 46199 66

FRANCE

Horizon Hobby SAS

14 Rue Gustave Eiffel

Zone d’Activité du Réveil Matin

91230 Montgeron

infofrance@horizonhobby.com

+33 (0) 1 60 47 44 70

12 - EN

Page 13

Compliance Information for the

European Union

DECLARATION OF CONFORMITY

(in accordance with ISO/IEC 17050-1)

No. HH2010081901

DISPOSAL OF WEEE BY USERS

IN THE EUROPEAN UNION

Product(s): 1/16 Mini Stronghold SCT RTR

Item Number(s): LOSB0211i

Equipment class: 1

The object of declaration described above is in conformity

with the requirements of the specications listed below,

following the provisions of the European R&TTE directive

1999/5/EC:

EN 300-328 Technical requirements for

Radio equipment.

EN 301 489 General EMC requirements

EN 60950 Safety

Signed for and on behalf of:

Horizon Hobby, Inc.

Champaign, IL USA

Aug 19, 2010

Steven A. Hall

This product must not be disposed of with other waste. Instead,

it is the user’s responsibility to dispose of their waste equipment

by handing it over to a designated collection point for the

recycling of waste electrical and electronic equipment. The

separate collection and recycling of your waste equipment at

the time of disposal will help to conserve natural resources and

ensure that it is recycled in a manner that protects human health

and the environment. For more information about where you can

drop off your waste equipment for recycling, please contact your

local city ofce, your household waste disposal service or where

you purchased the product.

FCC Information

This device complies with part 15 of the FCC rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

unde-sired operation.

Caution: Changes or modications not expressly approved

by the party responsible for compliance could void the user’s

authority to operate the equipment.

This product contains a radio transmitter with wireless

technology which has been tested and found to be compliant

with the ap-plicable regulations governing a radio transmitter in

the 2.400 GHz to 2.4835 GHz frequency range.

Vice President

International Operations and Risk Management

Horizon Hobby, Inc.

13 - EN

Page 14

Rebuilding/Refilling the Shocks

Step 1

After removing the shock,

push up on the lower spring

cup and remove it from the

shaft. Remove the spring and

preload spacers.

Step 2

Turn the shock upside down

and remove the black shock

cartridge/shaft assembly

from the shock body by

turning it counterclockwise.

Note: If you only wish to

change or fill the shock fluid,

skip to step 5.

Step 5

If you plan on completely

changing the shock fluid

(suggested), dump out the

old fluid from the shock body.

Carefully fill the shock body

with fluid to the bottom of the

threads inside the shock body.

Step 6

Pull the shaft out so the

piston is next to the

cartridge and reinstall the

assembly into the shock

body. Turn in a clockwise

direction until snug—DO NOT

TIGHTEN yet!

Step 3

Remove the top E-clip from the

shock shaft. Remove the shock

piston. Remove second E-clip.

Remove the old cartridge.

Put a drop of oil on the shock

shaft before installing a new shock

cartridge.

Step 4

Reinstall the lower E-clip.

Slide the shock piston onto

the shock shaft against the

E-clip. Reinstall the top E-clip.

Step 7

Turn the shock over and use a #0 Phillips

screwdriver to remove the small bleed

screw at the top of the shock. Slowly push

the shock shaft up until it stops. Excess fluid

should flow out of the bleed hole. Slowly pull

the shock shaft halfway back and replace

the bleed screw. Use pliers to tighten the

cartridge, being careful not to strip the

plastic lobes on the cartridge.

Step 8

Replace the spring and

spring cup and test the shock

action for smoothness and

leaks. Retighten the bleed

screw or cartridge if either

leaks. Remount the shock on

your truck.

Note: Production shocks may differ slightly from those shown

in the drawings.

14 - EN

Page 15

VEHICLE TROUBLESHOOTING GUIDE

Symptom Possible Cause(s) Possible Solution(s)

Doesn’t operate

Motor runs but rear

wheels don’t move

Steering doesn’t work

Won’t turn in one direction

Motor doesn’t run

ESC gets hot

Poor run time

and/or sluggish acceleration

Poor range and/or glitching

Battery not charged or plugged in

Receiver switch not “On”

Transmitter not “On” or low battery

Pinion not meshing with spur gear

Pinion spinning on motor shaft

Slipper too loose

Transmission gears stripped

Charge battery/plug in

Turn on receiver switch

Turn on/replace batteries

Adjust pinion/spur mesh

Replace pinion gear on motor

Check & adjust slipper

Replace transmission gears

Check and replace drive pin

Servo plug not in receiver

Servo gears or motor damaged

Check if plug in/in all the way

Replace or repair servo

Servo gears damaged Replace servo

Motor plugs loose

Motor wire broken

ESC damaged

Motor over-geared

Driveline bound up

Plug in completely

Repair or replace as needed

Contact Horizon Hobby Product Support

Use smaller pinion on motor

Check wheels, suspension,

and transmission for binding

NiMH pack not fully charged

Charger not allowing full charge

Slipper slipping too much

Motor worn out

Driveline bound up

Recharge battery

Try another charger

Check/adjust slipper

Replace motor

Check wheels and transmission

for binding

Transmitter batteries low

Transmitter antenna loose

Vehicle battery low

Loose plugs or wires

Check and replace

Check and tighten

Recharge or replace

Check motor and power plugs

Slipper won’t adjust

Drive pin missing in shaft

Spur gear face worn out

Replace drive pin

Replace spur gear and adjust slipper

Recommended Motor and Battery Chart

7.2V NiMH (LOSB1212)

7.4V LiPo (LOSB9826)

11.1V LiPo (LOSB9827)

4100

(LOSB9458)

x

x

x

4500

(LOSB9457)

x

x

x

5000

(LOSB9459)

x

x

x

6000

(LOSB9460)

x

x

7400

(LOSB9461)

x

x

8200

(LOSB9462)

x

x

9400

(LOSB9463)

x

x

Warning

This model may only be powered by the stock 6-cell 7.2-volt NiMH battery pack (LOSB1212), a 2-cell 7.4-volt LiPo battery

pack (LOSB9826) or 3-cell 11.1 volt LiPo battery pack (LOSB9827). Please consult the Motor/Battery Chart above for

suggested motor/battery combos. The use of higher voltage battery packs will cause ESC damage and void any warranty.

Consult your local hobby dealer or check www.losi.com.

15 - EN

Page 16

Replacement Parts

LOSB0805 Losi DSM Transmitter

LOSB0813 MS20DSL Servo with Long Lead

LOSB1009 Main Chassis

LOSB1018 Front Bulkhead, Kickplate & Brace

LOSB1020 F/R Pivot Block Set

LOSB1024 F/R Suspension Arm Set

LOSB1027 Spindle, Carrier & Rear Hub Set

LOSB1029 Steering Bellcrank Set

LOSB1037 Front Axle & Pin Brace Set

LOSB1040 Camber & Steering Link Set

LOSB1041 Suspension Pin Set

LOSB1043 E-Clips (10)

LOSB1045 Wheel Nuts & Drive Pins

LOSB1049 Rod End Set (14)

LOSB1051 Ball Stud Set (10)

LOSB1059 Transmission Case & Motor Plate Set

LOSB1060 Transmission Ball Bearing Set (7)

LOSB1061 Battery Hold Down Set

LOSB1063 Transmission Shaft Set

LOSB1064 Slipper Hardware Set

LOSB1065 Transmission Gear Set, Metal

LOSB1068 Spur Gear Set (50T & 60T)

LOSB1073 Outdrive/Dogbone/Rear Axle Set

LOSB1074 F/R Bumper and Mount/Support Set

LOSB1100 F/R Ball Bearing Set (8)

LOSB1212 7.2V 1100mAh NiMH Battery

with EC2 Connector

LOSB1260 Pinion Gear Set (9T–12T)

LOSB1291 Front Shock Springs (pr)

LOSB1292 Rear Shock Springs (pr)

LOSB1293 Front Shocks with Springs, Assm. (pr)

LOSB1294 Rear Shocks with Springs, Assm. (pr)

LOSB1295 Front Shock Body Set (pr)

LOSB1296 Rear Shock Body Set (pr)

LOSB1297 Front Shock Shaft Set (pr)

LOSB1298 Rear Shock Shaft (pr)

LOSB1299 F/R Shock Rebuild Kit (pr)

LOSB1850 Side Guard

LOSB1852 Front/Rear Shock Tower

LOSB1853 Front/Rear Ladder & Mount Set

LOSB1854 Front/Rear Bumper & Support Set

LOSB1855 Motor Plate

LOSB1856 Body Post, Gear Cover Set

LOSB1859 Fastener Set

LOSB1950 Front Mounted Tire

LOSB1951 Rear Mounted Tire

LOSB9457 4500Kv Sensorless Motor

LOSB9502 MSC-18BL Brushless ESC

SPMSR300 Spektrum 3-Channel Surface Receiver

Option Parts

LOSB1013 Track Dots, Neon Orange (12)

LOSB1100 F/R Ball Bearing Set (8)

LOSB1110 Aluminum Shock Set

LOSB1117 Front Spring Set for Oil Shocks

LOSB1119 Rear Spring Set for Oil Shocks

LOSB1125 Ball Differential, Assembled with Bearings

LOSB1206 AC Peak Charger (1 hour)

LOSB1226 Servo Saver Set

LOSB1230 Titanium Turnbuckle Set

LOSB1240 CV Driveshaft Set

LOSB1260 Pinion Gear Set, 9T-12T

LOSB1261 Pinion Gear Set, 13T-16T

LOSB1262 Pinion Gear Set, 17T-20T

LOSB1263 Pinion Gear Set, 14T, 16T, 18T, 20T

LOSB1264 Pinion Setscrew with Wrench

LOSB1322 Painted Body Set with Stickers,

ReadyLift/Geiser Painted Body Set

LOSB1323 Painted Body Set with Stickers, Rockstar

Painted Body Set

LOSB1326 Body Set with Stickers, Clear

LOSB1339 Sticker Set

LOSB9458 1/18th Xcelorin 4100Kv Brushless Motor

LOSB9459 1/18th Xcelorin 5000Kv Brushless Motor

LOSB9460 1/18th Xcelorin 6000Kv Brushless Motor

LOSB9461 1/18th Xcelorin 7400Kv Brushless Motor

LOSB9462 1/18th Xcelorin 8200Kv Brushless Motor

LOSB9463 1/18th Xcelorin 9400Kv Brushless Motor

LOSB9535 1/18th Xcelorin Brushless Electronics

Speed Control

LOSB9560 Xcelorin 6000Kv Brushless Combo

(requires setscrew, pinion)

LOSB9561 Xcelorin 7400Kv Brushless Combo

(requires setscrew, pinion)

LOSB9562 Xcelorin 8200Kv Brushless Combo

(requires setscrew, pinion)

LOSB9563 Xcelorin 9400Kv Brushless Combo

(requires setscrew, pinion)

LOSB9606 MultiPro Intelligent Balance Charger

LOSB9626 Mini Plug to EC2 Charger Adaptor

LOSB9826 7.4V 1300mAh 2S 15C LiPo Battery

LOSB9627 Tamiya to EC2 Charger Adaptor

LOSB9827 11.1V 1300mAh 2S 20C LiPo Battery

16 - EN

Page 17

Rear shock

part numbers

Front shock

part numbers

Complete

rear shock

LOSB1294

Complete

front shock

LOSB1293

1296

1295

1299

1298

1297

1292

1291

1299

1856

1299

1064

1068

LOSB1859

ALL FASTENERS

1856

1854

1852

1854

1853

1853

1051

1049

1041

1051

1040

1073

1043

1045

1041

1951

1100

1020

1037

1043

1024

1100

1051

1027

1073

1045

1853

1060

1060

1063

1855

9457

1950

1260

1073

1059

1065

1059

1073

1045

1323

1856

9502

SPMSR300

1852

1061

0813

1009

17 - EN

1853

1850

1853

1074

1029

1051

1029

1051

1049

1049

1040

1037

1049

1018

1049

1040

1027

1040

1037

1051

1043

1049

1024

1041

1051

1041

1020

1854

1100

1041

* All part numbers

prefixed by LOSB

Page 18

29727.i

800-0440

© 2010 Horizon Hobby, Inc.

Not responsible for typographical errors.

Loading...

Loading...