Page 1

1/18TH SCALE ARR PRO VERSION OF

THE CHAMPIONSHIP WINNING XXX-T

Operations Manual

Introduction

Thank you for choosing the Mini-T Pro from Team Losi Sport. This model requires you to install

the Radio gear and fill the shocks with fluid. This guide contains these and the basic instructions

for operating your new Mini-T Pro. It is critical that you read all of the instructions and all accompanying printed material in order to operate your model correctly and avoid unnecessary damage.

Please take a moment to look them over before building the model.

Copyright 2004 Team Losi

A Division of Horizon Hobby Inc.

800-0249

RT 11-04

Page 2

Saftey Precautions

This is a sophisticated radio controlled model that must be operated with caution and common

sense.

Failure to operate your Mini-T Pro in a safe and responsible manner could result in damage to the

model and property. The Mini-T Pro is not intended for use by children without direct supervision.

Team Losi and Horizon Hobby shall not be liable for any loss or damages, whether direct, indirect,

special, incidental, or consequential, arising from the use, misuse, or abuse of this product or any

product required to operate it.

This model is controlled by a radio signal that is subject to interference from many sources

outside your control. This interference can cause momentary loss of control so it is advisable to

always keep a safety margin in all directions to aviod collisions.

Always operate your model in an open area away from cars, traffic and people

Never run out into the street for any reason.

Never run your Mini-T Pro with low transmitter batteries

Carefully follow the directions and warnings for this and any optional support equipment (chargers,

rechargable battery packs, etc.) that you use.

Keep all chemicals, small parts and anything electrical out of the reach of children.

Required Equipment

2 Channel Radio System with Receiver Electronic Speed Controller

Micro size Servo Battery and Charger

Radio Installation

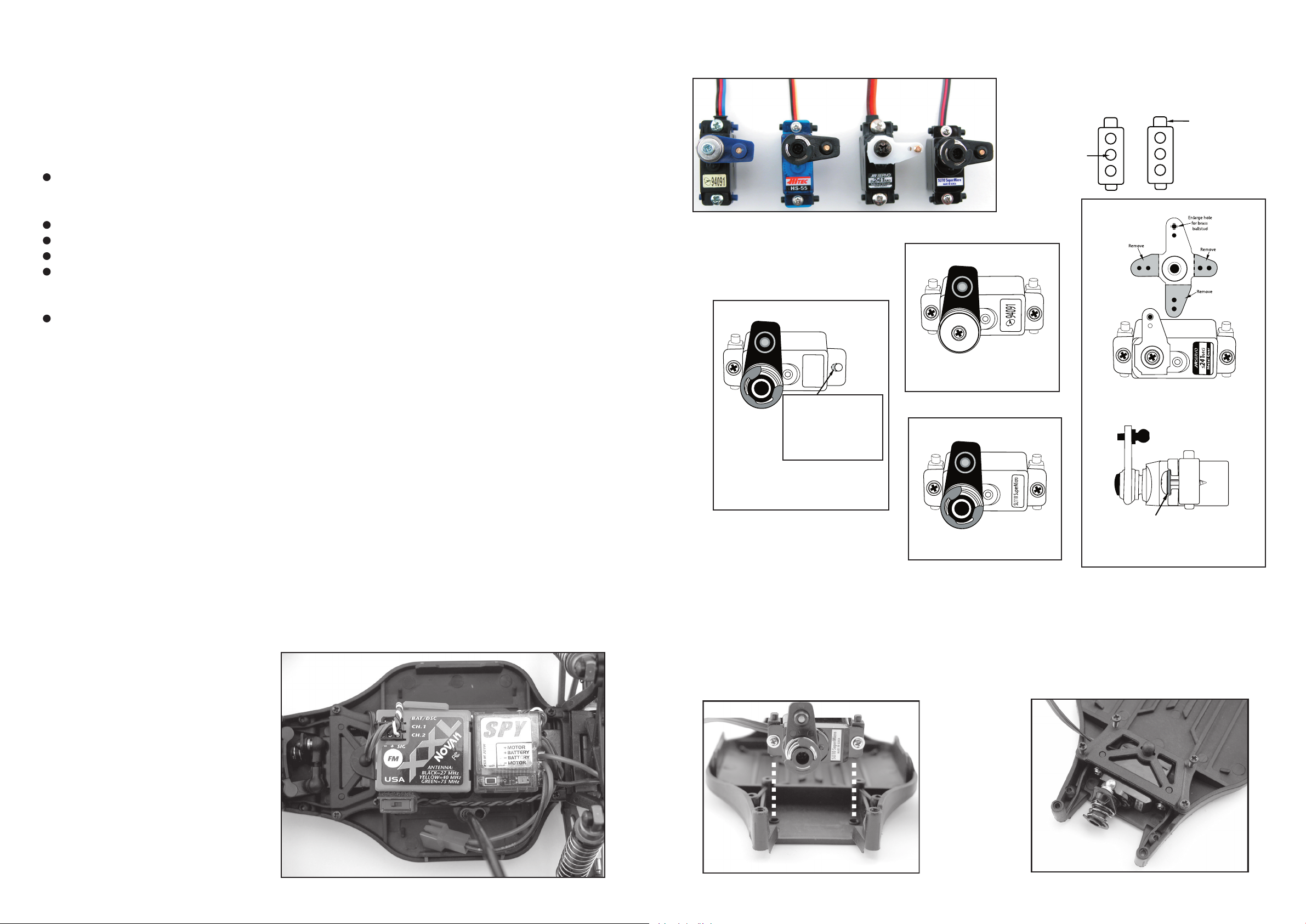

You will need a receiver, electronic speed control (ESC), and micro steering servo to complete

your Mini-T Pro. If you do not already have these we suggest you use one of the newer smaller

receivers and ESC’s as it will be easier to fit these in the space available. All of the popular radio

manufactures as well as Novak, GM Racing and LRP offer these items. We show mounting four of

the most popular steering servos. Please note that in most cases we suggest the use of a servo

saver as noted.

1) Cut a piece of double sided mounting tape to fit the bottom of both the receiver and ESC. Remove the paper backing from one side and apply to the bottom – Do Not remove the remaining

backing yet!

2) Test position the receiver and ESC on the top surface of the battery plate checking for adequate

clearance and convenient access for all wiring. Mark or note these positions before proceeding.

3) Remove the protective backing from the mounting tape on the receiver and ESC. Carefully

mount them on the battery plate.

Sample picture of electronics installed in the Mini-T Pro

Final Connections

Follow the radio manufactures instructions when making the final electronic

connections. Specifically, the orientation of the color-coded wires in the

various plugs where they plug into the

receiver. If you plan on removing the

wires attached to the motor mark the

endbell with a “+” at the red wire and “-“

at the black wire for future reference.

Follow the radio instructions to set the

proper steering and throttle movement.

Follow the instructions included with the

ESC for correct operation.

Recommended Servos

Installing the Servo

Be sure that

the taller pin

Use this hole

to mount

servos listed

Airtronics

94091Z

HiTec HS-55

To install this servo, use the included

Mini-T Servo Saver Kit and make

modifications to servo as pictured

above.

HiTEC

HS-55

c

te

i

H

Carefully using a hobby

knife, remove shaded

material to open servo

mounting hole as shown.

Do this modification on

both mounting “ears”.

JR Propo

S241MG

5

5

S

H

Expert Electronics

SL110

Airtronics 94091Z

To install this servo you will need to

purchase the Airtronics 98302 Micro

Servo Saver kit.

Expert Electronics SL110

To install this servo, use the included

Mini-T Servo Saver Kit.

JR Propo S241MG (Metal Gear)

At the time of this printing, a servo

saver was not available. Using only the

Metal geared version, follow the steps to

modify the servo horn.

LOSA6215 #4 Narrow Washer

To install this servo, you will need to purchase LOSA6215 #4 Narrow Washer to

space the mounting screw as pictured above.

Install the Servo into the Chassis as shown in Figure 1. Insert the pins on the Servo Mounting

Post into the holes in the Chassis. Move the Servo Posts slightly until both the left and right Posts

are inserted in the holes in the Chassis. Next place the Chassis Brace on top of the Servo. The

pins from both Servo Mounting Posts should line up with the holes on the Servo Brace. If they do

not, move the Posts slightly until the pins fit into the holes. Secure the Brace to the Chassis with

the four Phillips head screws as shown in Figure 2.

Figure 1

Figure 2

is at the top

Page 3

Making Adjustments

The following are simple adjustments and easily maintained settings that will assure proper operation and performance. Since the Mini-T Pro comes from the factory with optimum settings, we suggest first-time R/C drivers leave these as they are and simply maintain them as necessary. Only

after gaining experience should new drivers try experimenting with different settings.

Chassis Tuning

The Mini-T Pro has several adjustments available to you for tuning the performance for your

needs. Although there are multiple shock positions and camber link locations provided, as noted

above we have built the model with the best overall settings. The following are simple adjustments

and easily maintained settings that will assure proper operation and performance. It is advised that

when making any adjustment you do so in small increments and always check for other parts of

the chassis that are affected.

Steering Rate

Your transmitter may be equipped with a steering rate control. This

“Less Rate”

feature allows you to adjust the amount the front tires move when you

turn the steering wheel. This is really helpful when you are on slick as

well as high traction surfaces. If your Mini-T Pro turns too sharply

and/or spins out easily, try decreasing the steering rate. For sharper

or additional steering, try increasing the steering rate.

“Full Rate”

Camber

Camber is the angle of the tires to the racing surface when viewed

from the front or rear of the truck. You want to keep both the front

and rear tires straight up and down or leaning in at the top very

slightly. If you are running on carpet or similar high traction surfaces you may find leaning them in a bit more helps. This adjustment is made with the turnbuckle links that extend from the front

or rear bulkhead to the spindle carrier or rear hub. The Mini-T Pro

is equipped with adjustable Titanium Turnbuckles that if turned

one way (using the provided wrench) get shorter and if turned in

No Camber More Camber

the opposite direction get longer. Making these shorter increases the camber and lean-in of the tire

while making them longer decreases the camber.

Toe-In

This is the relationship of the left and right side tires to one

another. Ideally, you want the front of the tires to be pointed

No Toe-In More Toe-In

inward toward each other just slightly when viewed from

above. This makes the model track straight and stable. This

is controlled with the adjustable steering rods on either side.

As you make them longer you will increase the toe-in and

vice versa.

Ride Height

This is the height the chassis sits and runs at. There are spring spacers included with the Mini-T

Pro that, when installed between the shock top and spring, will increase the pre-load on the spring

and raise the chassis. You may want to try this when running on extremely rough surfaces.

Setting The Gear Mesh

The motor screws should be slightly loose. Slide the motor forward allowing the

pinion gear to mesh with the spur gear. Snug (not tight) the bottom motor screw

and try rocking the spur back and forth. There is a slight bit of movement before

the motor is forced to turn over. If not, pull the top of the motor back slightly and

recheck, there should be a slight bit of movement. If there is too much slop

between the gears push the top of the motor forward. When set properly the

wheels can be spun forward freely with very little noise. Make sure to tighten

both motor screws and replace the gear cover before running.

NEVER Let your differential slip!

Follow the instructions below for proper operation and adjustment

Ball Diff/Slipper Adjustment Instructions

Always make sure your slipper will slip before the diff, as this will diminish the load on the dif

ferential and transmission. The diff should never slip. Hold the right tire and the spur gear in one

hand and rotate the left tire. As you rotate the left tire, the slipper plate, and shaft should turn. This

means the slipper is slipping before the differential. If the slipper shaft is not turning, your differential is slipping. You must either tighten the diff and/or loosen the slipper and recheck. To tighten the

diff, remove the left side driveshaft and use a .050” Allen wrench and turn the diff screw clockwise

in one-hour increments and recheck as noted above until it no longer slips. Any time you tighten

the slipper you should check the diff as noted and tighten if necessary.

Slipper Adjustments

The Mini-T Pro is equipped with a Double Disk slipper device that

offers both traction control and protection for the transmission. The

slipper is primarily used to help absorb sudden impacts on the drive

train due to landing big jumps or when using more powerful aftermarket motors and/or battery packs. Additionally, it can be used to smooth

out the flow of power to the rear wheels and limit wheel spin when

Increase

Slip

Reduce

running on extremely slick surfaces. Adjustment is made by removing

the access plug in the gear cover and turning the 3mm adjustment

Figure 3

nut clockwise (to the right) to reduce the slip or counterclockwise (to

the left) to increase the slip (Figure 3). When adjusted properly, you

should be able to hold the rear tires firmly and barely be able to push

the spur gear forward with your thumb (Figure 4). To track test, turn

the Mini-T on and place it on the ground. As you push it backwards

allowing it to roll freely, punch the throttle. The slipper should slip no

more than an inch or two as it accelerates. With a 5 or 6 cell battery

pack it should slip just a little. Make sure you replace the gear cover

before running.

LOSB1133

LOSB113

LOSB113

4

LOSB113

5

LOSB113

7

LOSB113

5

4

LOSB113

Figure 4

2

-

Slip

More Pre-load Less Pre-load

*Gear Cover LOSB1136

LOSB1131 (Bearings not included)

Page 4

Rebuilding The Ball Differential

1) Remove your ball differential from your tranny. 2) Remove left outdrive cup and loosen diff ad-

justing screw with a small flathead screw driver or a .050 allen wrench. Remove right side outdrive

assembly. 3) Clean diff gear, diff rings and balls. If needed, replace worn parts and lube with Losi

Silicone Diff Grease LOSA3065 4) Remove “C” clip from male oudrive half and carefully remove

diff thrust assembly. 5) Clean all thrust components and replace if needed. Reassemble thrust

components (Figure5). 6) Install thrust assembly into male oudrive as shown in (Figure 6). Install

a new “C” Clip. 7) While holding male outdrive half install large diff washers, diff gear with balls. 8)

Apply thread lock to diff screw and reassemble diff. Carefully bottom the diff screw out and back

the screw out 1/16th of a turn. Your diff is now set. 9) Reassemble tranny. 10) Refer to Ball Diff/

Slipper Adjustment Instructions on the previous page.

S

Y

N

T

LU

H

E

B

T

R

I

C

I

LO

CA

N

SA

T

306

Fig 5.

Washers should

6

be stacked in

this order

LOSB112

5

Battery Placement

The Mini T Pro features a choice of battery positions. In the “Back” position, the Mini-T Pro will

have a bit more traction and will jump nose high with less steering. In the “Forward” position, the

Mini-T Pro will have more steering and jump with the nose down. Try playing with the different

positions to find the best handling for your track.

Fig 6.

Screwhead

LOSB1129

LOSB112

LOSB112

8

6

LOSB112

6

LOSB112

7

Filling and Maintaining the Racing Shock Absorbers

Filling and Bleeding Your Shocks

Helpful Tools

1. Remove the spring by pushing the lower

spring cup away from the shock end and sliding

Small Screwdirver

7mm Wrench

it out, off of the shaft.

2. Unscrew the shock cartridge (7mm) and remove the shaft/cartridge/

piston assembly.

3. Use the included Team Losi 20 weight silicone fluid to fill the shock

body to the bottom of the internal threads.

4. With the shaft half way through the cartridge, insert the piston into the

fluid and start to thread the cartridge into the body approximately two turns.

5. With the cartridge loose, and holding the shock with the shaft up, push

the shaft all the way in, allowing the excess fluid to escape.

6. Tighten the cartridge down (about 1/2 to 1 turn) being careful not to

stripe the threads.

7. Move the shaft back and forth through its normal range of movement.

There should be a costant resitance. If there is a greater resistance as the

shaft is fully compressed, there is too much oil and it needs to be re-bled

by following step #5. If there is less resistance at any point, there is not

enough oil and you need to repeat steps #2 through #5. Otherwise, replace the spring and spring cup.

NOTE: If leakage occurs where the cartridge seals to the shock body, you

should replace the thin circular seal between the shock cartridge and shock

body.

LOSB112

Pliers

LOSB1129

8

Battery Position “Back” Battery Position “Forward”

Body Painting

Before you start, please note the following tips. Use only paint that is designed for polycarbonate

bodies or it may chip, flake, or cause the body to crack. Use quality masking tape (3M, Scotch,

etc) or commercially available precut masks (XXX Main, Parma, etc) – do not use clear “sealing”

tape, as it is very difficult to remove. Always try to apply darker colors first. Backing a lighter color

with white will produce a brighter appearance. Back white with a coat of silver (unless it is the last

color applied) to prevent other colors from bleeding through. Always allow plenty of time for the

paint to dry before pulling the tape or applying another color.

1) Wash the inside of the body with a little liquid detergent and warm water. 2) After drying thor-

oughly, position the precut window masks (supplied) to the inside of the body and firmly press

them down for good adhesion. 3) Use masking tape or precut masks (not supplied) to the inside of

the body to produce the pattern you desire. Try to tape the body so you will apply the darker colors

first following the tips noted above. 4) Follow the paint manufactures instructions when applying

the paint being careful not to allow it build up in any one spot. Remember to allow plenty of drying time between colors. 5) Remove the window masks and protective film from the outside of the

body. Use R/C Body cleaner or Isopropyl Alcohol (do not use any hot solvents) to clean up any

overspray etc. on the outside of the body if any, before applying the stickers.

Changing the Shock Cartridge

1. Remove the cartridge/assembly from the shock.

2. Remove the shock piston and the small e-clips above and below it.

3. Remove the old cartridge an dslide the new cartridge onto the shaft. Replace the e-clips and

shock piston. Put a new seal onto the cartridge and follow steps #3 through #6 above.

Changing the Pistons

1. Remove the cartridge/assembly from the shock.

2. Remove the e-clip from above the piston at the end of the shock shaft.

3. Replace the piston wit the one of you choice (small, medium or large hole.

4. Replace the e-clip and follow steps #3 through #6 above.

NOTE: Always replace front or rear pistons in pairs-never just one piston.

Page 5

Mini-T Pro Trouble Shooting Guide

Doesn’t operate Battery not charged or plugged in Charge battery / plug-in

No crystal in receiver Check and replace if neces sary

No crystal in transmitter Check and replace if neces sary

Receiver switch not “on” Turn on receiver switch

Transmitter not “on” or low battery Turn on / replace batteries

Motor runs but rear Pinion not meshing with spur gear Adjust pinion/spur mesh

wheels don’t move Pinion spinning on motor shaft replace pinion gear on motor

Slipper too loose Check & adjust slipper

Differential slipping Adjust / check differential

Drive pin in axle missing Check & replace

Steering doesn’t work Servo plug not in receiver Check if plug in / all the way

Servo damaged Replace or repair servo

Won’t turn one direction Servo gears damaged Replace servo gears

Motor doesn’t run Motor plugs loose Plug-in completely

Motor wire broken Repair or replace as needed

ESC damaged Check with manufacture

ESC gets hot Motor over geared Put smaller pinion on motor

Driveline bound up Check wheels & trans for

binds

Poor run time and/or Batteries weak or low Check / replace battery pack

sluggish acceleration Ni-Cad pack not fully charged Recharge

Charger not allowing full charge Try another charger/power

source

Slipper slipping too much Check/adjust slipper & diff

Differential slipping Tighten immediately

Motor worn out Replace motor

Driveline bound up Check wheels & trans for

binds

Poor range/glitches Transmitter battery low Check & replace as neces sary

Transmitter antenna loose Check & tighten

Battery low in truck Replace or recharge

Loose plugs or wires Check motor and power

plugs

Slipper won’t adjust Drive pin missing in shaft Replace drive pin

Slipper pads worn out Replace & adjust slipper

Loading...

Loading...