Page 1

Operation Manual

Thank you for choosing the Mini-DT from Losi®. This

guide contains the basic instructions for operating

your new Mini-DT. While the Mini-DT is great for rst-

time RC drivers, it does require some mechanical

experience and/or parental supervision for drivers

under 12. It is critical that you read all of the

instructions in order to operate your model correctly

and avoid unnecessary damage. Please take a

moment to look over all the printed materials before

operating your new Mini-DT.

Page 2

Mini-DT Manual―Page 2

Safety Precautions

This is a sophisticated radio controlled model that must be operated with caution and common sense. Failure to

operate your Mini-DT in a safe and responsible manner could result in damage to the model and property. The

Mini-DT is not intended for use by children without direct adult supervision. Losi and Horizon Hobby shall not be liable

for any loss or damages, whether direct, indirect, special, incidental, or consequential, arising from the use, misuse, or

abuse of this product or any product required to operate it.

• This model is controlled by a radio signal subject to interference from many sources outside your control. This

interference may cause momentary loss of control so it is advisable to always keep some distance in all directions

around your model as a safety margin to avoid collisions.

• Always operate your model in an open area away from cars, trafc and people.

• Avoid running your model in the street where damage can occur.

• Never run your Mini-DT with low transmitter batteries.

• Carefully follow the directions and warnings for this and any optional

support equipment.

• Keep all chemicals, small parts and anything electrical out of the

reach of children.

Warning

This model may only be powered by the stock 6-cell 7.2-volt NiMH battery pack

(LOSB1202) or a 2-cell 7.4-volt LiPo battery pack (LOSB0871). The use of higher

voltage battery packs will cause ESC damage and void any warranty. To use

brushless or 3-cell LiPo batteries you must change the electronics. Consult your

local hobby dealer or check www.losi.com.

Tools and Items You Will Find Handy

• Soft bristle brush for cleaning

• 5.5mm nut driver for the wheel nuts

• #0 or #1 Phillips screwdriver

• LOSA99100 .050” Allen Wrench

Note: Use only Losi tools or other high-quality tools. Use of inexpensive tools

can cause damage to the small screws and parts used on this type of model.

The Radio System

The following is an overview of the various functions and adjustments found on your Losi/Mini-DT radio system. Since

the Mini-DT operates on a radio signal, it is important for you to read and understand about all of these functions

before driving the model.

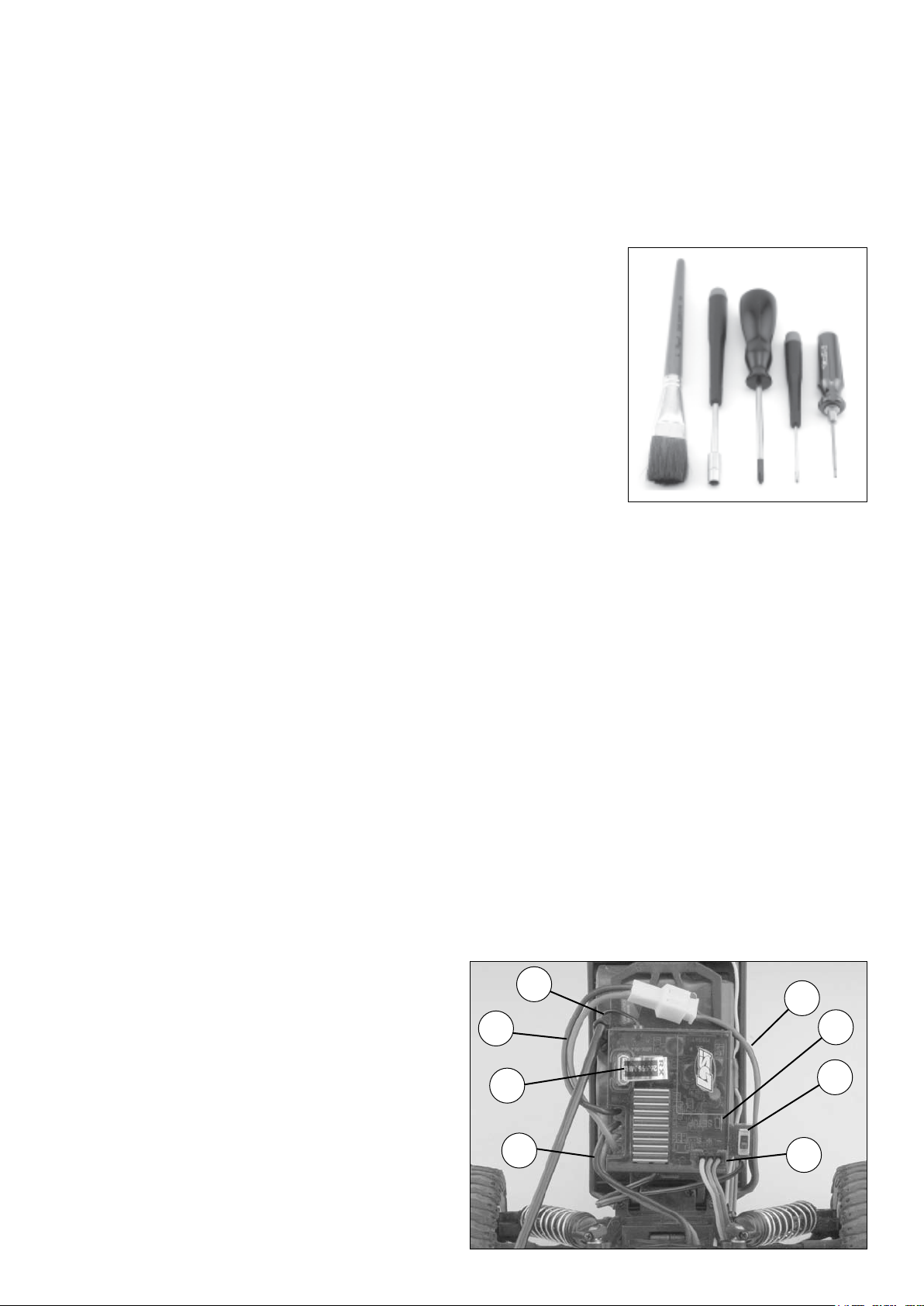

The Receiver

1. On/Off Switch: Controls Power to the Receiver/ESC.

2. Servo Port/Plug: Where the steering servo plugs in (note polarity on case).

3. Antenna Wire: Receives the radio signal from your transmitter.

4. Receiver/ESC Power Lead: Connects to the battery lead for power.

5. Frequency Crystal: Determines the frequency/channel you are operating on.

6. Motor Lead: Connects the ESC to the motor.

7. Battery Leads: Connects the motor battery to the ESC.

8. Setup Button: Enters ESC into setup mode.

3

4

4

8

5

7

1

2

Page 3

Mini-DT Manual―Page 3

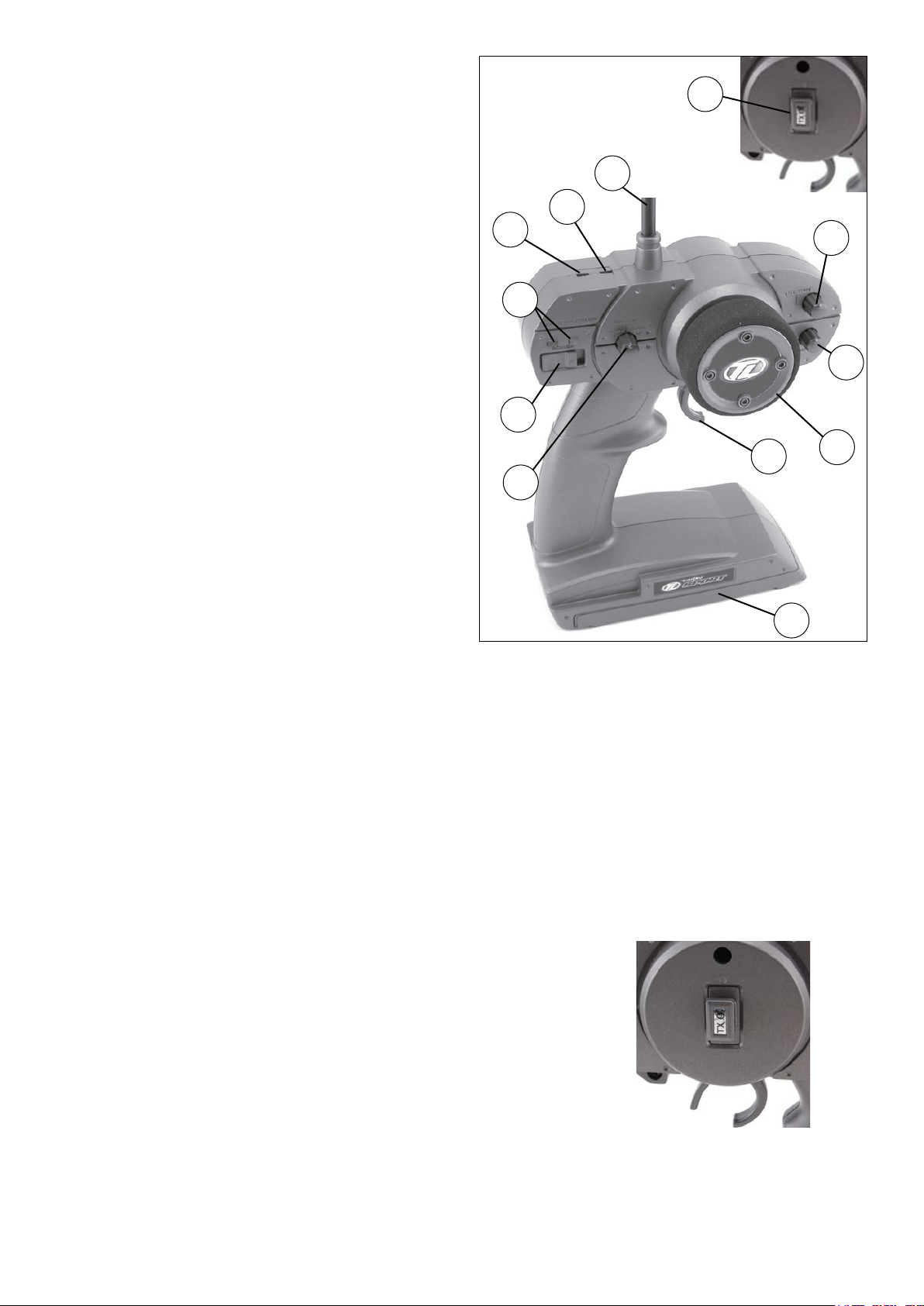

The Transmitter

1. Steering Wheel: Controls direction (left/right) of the

model.

2. Throttle Trigger: Controls speed and direction (forward/

reverse) of the model.

3. Antenna: Transmits signal to the model.

4. On/Off Switch: Turns the power on/off for the

transmitter.

5. Indicator Lights: Green (right) light indicates adequate

battery power. Red (left) indicates signal strength.

6. ST. Trim: Adjusts the “hands off” direction of the model.

7. TH. Trim: Adjusts the motor speed to stop at neutral.

8. Steering Rate: Adjusts amount front wheels move when

the steering wheel is turned left and right.

9. ST. REV: Reverses the function of the steering when the

wheel is turned left or right.

10. TH. REV: Reverses the function of the speed control

when pulled back or pushed forward.

11. Bottom Cover: Covers and holds the batteries that

power the transmitter.

12. Transmitter Crystal: Determines frequency/channel

you transmit on. The receiver must have a matching

frequency/channel to operate.

12

3

10

9

6

5

7

4

2

1

8

11

Changing Frequencies/Channels

The Mini-DT radio operates on 27MHz AM and has 6 different frequencies/channels available. Simply put, a frequency

is like a TV channel. The transmitter you hold in your hand is like the TV station and the model with the matching

crystal is like your TV tuned exclusively to the channel of that station. The Mini-DT radio is equipped with changeable

crystals that allow you to change the frequency/channel you operate on. This is especially useful when you want to run

a group of Losi Mini-DT’s at the same time. When changing crystals/channels, you must always replace the crystals

as a matched set with one each going in both the transmitter and the receiver in the truck. Each of the 6 different

channels are numbered and color-coded. Each set includes a unique crystal for the receiver marked (Rx) and one

from the transmitter marked (Tx). The crystals are changed by gently pulling them out, then lining up the two pins of

each new crystal with its socket and carefully pushing them into place. DO NOT force them as damage can occur. If

they do not slide into the socket easily check for bent or misaligned pins.

Channel 1 Brown 26.995MHz (LOSB1094)

Channel 2 Red 27.045MHz (LOSB1095)

Channel 3 Orange 27.095MHz (LOSB1096)

Channel 4 Yellow 27.145MHz (LOSB1097)

Channel 5 Green 27.195MHz (LOSB1098)

Channel 6 Blue 27.255MHz (LOSB1099)

Page 4

Mini-DT Manual―Page 4

Resetting the ESC

The ESC comes preset and ready for use. If for some reason you should need to reset the ESC, use the following

instructions:

1. Turn on the transmitter and ESC. Press the setup button – the RED

and GREEN LEDs will come on.

2. Pull the throttle trigger all the way back (full speed) and press the setup

button once – only the GREEN LED will come on.

3. Push the trigger full forward (brake/reverse) and push the setup button

once – only the RED LED will come on.

4. Let the throttle trigger return to the neutral (center) position and press

the setup button once more to save the program and exit setup mode –

only the GREEN LED will be on.

Notes:

A: If the receiver does not receive a signal from the Transmitter, the ESC will not enter program mode.

B: While in program mode, the motor will not run.

C: If the setup button is not pressed for 20 seconds while in program mode, the ESC will exit the program mode, and

the data will be restored to default settings.

Slipper Adjustments

The Mini-DT is equipped with a slipper device offering both

traction control and protection for the transmission. The

slipper is primarily used to help absorb sudden impacts

on the drive train due to landing big jumps or when using

more powerful aftermarket motors and/or battery packs.

Additionally, it can be used to smooth out the ow of power

to the rear wheels and limit wheel spin when running on

extremely slick surfaces. Adjustment is made by turning

the 3mm adjustment nut clockwise (to the right) to reduce

the slip, or counterclockwise (to the left) to increase the

slip. When adjusted properly, you should be able to hold

the rear tires rmly and barely be able to push the spur

gear forward with your thumb. To track test, turn the Mini-

DT on and place it on the ground. As you push it

backwards allowing it to roll freely, punch the throttle.

The slipper should slip no more than an inch or two

as it accelerates. With the included motor and battery

pack it should slip just a little. Make sure you replace

the gear cover before running.

Steering Rate

Your transmitter is equipped with a steering rate

Page 5

Mini-DT Manual―Page 5

control to the left of the steering wheel. This advanced feature, usually found only on competition-type radios, allows

you to adjust the amount the front tires move when you turn the steering wheel. This is really helpful when you are

on slick, as well as high-traction, surfaces. If your Mini-DT turns too sharply and/or spins out easily, try turning the

steering rate down by rotating the knob counterclockwise (to the left). For sharper or additional steering, try turning the

knob clockwise (to the right).

Camber

Less Rate Full Rate

Chassis Tuning

The Mini-DT has several adjustments available to you for tuning the performance for your needs. Although there are

multiple shock positions and camber link locations provided, as noted above we have built the model with the best

overall settings. The following are simple adjustments and easily maintained settings to assure proper operation and

performance. It is advised when making any adjustment you do so in small increments and always check for other

parts of the chassis that are affected.

Camber is the angle of the tires to the racing surface when viewed from the front

or rear of the truck. You want to keep both the front and rear tires straight up

and down or leaning in at the top very slightly. If you are running on carpet or

similar high-traction surfaces, you may nd leaning the tires in a bit more helps.

This adjustment is made with the threaded links extending from the front or rear

bulkhead to the spindle carrier or rear hub. Making the camber rods shorter

increases the camber and lean-in of the tire, while making the camber rods

longer decreases the camber.

Toe-In

This is the relationship of the left and right side tire to one another.

Ideally you want the front of the tires to be pointed inward toward

each other just slightly when viewed from above. This makes the

model track straight and stable. This is controlled with the threaded

steering rods on either side. As you make them longer you will

increase the toe-in and vice versa.

Normal More Toe-In

Normal More Camber

Ride Height

This is the height the chassis sits and runs at. Spring spacers included with the Mini-DT, when installed between the

shock top and spring, will increase the pre-load on the spring and raise the chassis. You may want to try this when

running on extremely rough surfaces.

Page 6

Mini-DT Manual―Page 6

Service/Repair

Radio/Speed Control & Motor

If you have any problems other than those covered in the troubleshooting section, please call the electronics service

department at (877) 504-0233. They will be able to give your specic problem additional attention and instruct you as

to what needs to be done.

Chassis

If you have any questions other than those covered in the troubleshooting or maintenance sections, please call

(877) 504-0233.

Cleaning

Performance can be hindered if dirt gets in any of the moving suspension parts. Use compressed air, a soft

paintbrush, or toothbrush to remove dust or dirt. Avoid using solvents or chemicals as they can actually wash dirt into

the bearings or moving parts as well as cause damage to the electronics.

Rebuilding the Differential

The gears in the differential will wear over time. The same is true for the outdrives, driveshafts and rear axles. We

suggest using a small rag or paper towel to lay out the parts you remove to make it easier to reassemble.

Disassembly

1. Unplug the motor.

2. Remove the gear cover (three screws).

3. Remove the motor guard screws at the top of the transmission and the two at the

extreme rear bottom of the chassis.

4. Remove the screw attaching the rear shock tower to the transmission and the four

screws at the bottom of the chassis holding the gearbox in place and slide it out of the

chassis

5. Remove the left side of the gearbox by removing the three screws.

6. Remove any shims on the bevel gears and set them aside so they can be reinstalled in

the same location.

7. Carefully remove the large plastic sun gear and the bevel gears on either side of it.

You can use the removed differential assembly as a guide for putting together the

replacement unit (a little Losi Teon grease #LOSA3066 can be

applied for even better performance).

8. Remove the center mounted idler gear from the gearbox. Remove

the shaft and push out the ball bearings from either side. Install

these bearings in the new gear.

Reassembly

Replace the idler gear and shaft into the center of the same right side

of the gearbox. Replace any shims removed from the right bevel gear

and slide it through the lower bearing. Replace any shims that came

off of the left side bevel gear and allow it to slide through the lower

bearing as you put the left gearbox half back into position. Replace

the screws and reinstall the rebuilt gearbox using the steps in reverse

order that were used to remove it.

Changing the Spur Gear

Remove the gear cover by removing the three small screws. If you are replacing the spur gear with one of a different

size (number of teeth), you must rst loosen (do not remove) the two screws that secure the motor and slide it back

slightly. Remove the 3mm nut at the end of the slipper shaft and all of the slipper parts on the outside of the spur gear

as well as the old gear. Place the new spur gear into position and replace the slipper parts. If you have changed the

size of the spur, see Setting the Gear Mesh on the following page. After you have changed the spur gear, you will

have to adjust the slipper as described elsewhere.

Page 7

Mini-DT Manual―Page 7

Changing the Pinion Gear/Gear Ratio

Before you change the pinion gear ask yourself why you are doing it. In general, if you change to a larger pinion the

top speed will improve but you will see less acceleration and run time. This would only be advisable for really long

track layouts with few tight turns. Changing to a smaller pinion will give you quicker acceleration and possibly a bit

longer run time but a little less top speed. This would be good for short layouts or when running hotter motors. The

pinion on the Mini-DT offers the best balance of both. To change the pinion, remove the gear cover, loosen the motor

screws, and slide the motor back. Use a pair of small needle-nose pliers between the motor plate and back of the

pinion to push the pinion off. Place the new pinion on the end of the motor shaft and, using the at of the pliers or a

similar at tool, push it on to the same position as the one removed. If you have changed the size of the spur, see

Setting the Gear Mesh below.

Warning: When running after-market motors, check with the motor manufacturer for correct gearing. Never over-gear

the motor as it can cause overheating, damaging it and the speed control.

Suggested Mini-DT Gearing

LOSB1089 Mini-DT Motor 14 pinion / 60 spur

LOSB1216 RX-280 BB Motor 14/60

LOSB0837 Insane BB Motor 14/60 or 15/60

™

Note: If you wish to use a brushless motor like the Losi Xcelorin

electronics. Check with your hobby dealer or www.losi.com for complete information.

models you must change the

Setting the Gear Mesh

The motor screws should be slightly loose. Slide the motor forward allowing the pinion gear to mesh with the spur

gear. Snug (not tight) the bottom motor screw and try rocking the spur back and forth. There should be a slight bit of

movement before the motor is forced to turn over. If not, pull the top of the motor back slightly and recheck. If there

is too much slop between the gears, push the top of the motor forward. When set properly the wheels can be spun

forward freely with very little noise. Make sure to tighten both motor screws and replace the gear cover before running.

Radio Replacement/Service

If you have a radio problem please call (877) 504-0233 for customer service. Most likely, unless you have gotten the

components wet, the service technician can help you x the problem over the phone. If the problem is more severe,

you may be asked to send in the truck and transmitter or the entire radio system, which would include the receiver/

speed control unit and steering servo. In some cases, like a broken servo or a speed control that has failed due to

getting wet, your local dealer can sell the replacement component. The following is a complete guide to removing the

system.

Steering Servo

Unplug the servo lead from the receiver. Remove the four small screws that

secure the servo mount/chassis brace to the chassis. Use a screwdriver or small

pliers to pop the steering link off of the servo, so it can be removed. There is no

need to remove the servo mounts on either side as all service can be done with

them on. Replace in the reverse sequence used to remove it.

Receiver/Speed Control (ESC)

Unplug the power lead, motor leads and steering servo. Carefully remove the

antenna wire from the antenna tube. Do not attempt to open the Receiver/ESC

as only factory technicians have the proper tools and parts to make any repairs

necessary. The Receiver/ESC are mounted with double-sided foam tape. Use

your thumb and index nger at the bottom of the front corners to pull them from

the mount. If this is difcult, ask for help. If necessary, carefully use a large at

blade screwdriver between the unit and the mount to pry it loose. Make sure you

remove any left over foam or adhesive before remounting with common servo tape or hobby-type foam tape.

Service/Tech Help

(877) 504-0233

Page 8

Rebuilding/Relling the Shocks

Rebuilding/Relling the Shocks

Step 1

After removing the shock,

push up on the lower spring

cup and remove it from the

shaft. Remove the spring and

preload spacers.

Note: If you only wish to

change or ll the shock uid,

skip to step 6.

Step 3

Remove the top E-clip from the

shock shaft. Remove the shock

piston. Remove second E-clip.

Remove the old cartridge.

Put a drop of oil on the shock

shaft before installing a new shock

cartridge.

Step 2

Turn the shock upside down

and remove the black shock

cartridge/shaft assembly

from the shock body by

turning it counterclockwise.

Step 4

Reinstall the lower E-clip.

Slide the shock piston onto

the shock shaft against the

E-clip. Reinstall the top E-clip.

Step 5

If you plan on completely

changing the shock uid

(suggested), dump out the

old uid from the shock body.

Carefully ll the shock body

with uid to the bottom of the

threads inside the shock body.

Note: Your Mini-DT comes with

30wt shock uid from

the factory.

Step 7

Turn the shock over and use

a #0 Phillips screwdriver to

remove the small bleed screw

at the top of the shock. Slowly

push the shock shaft up until it

stops. Excess uid should ow

out of the bleed hole. Slowly

pull the shock shaft halfway

back and replace the bleed

screw. Use pliers to tighten

the cartridge, being careful not

to strip the plastic lobes on

the cartridge.

Step 6

Pull the shaft out so the

piston is next to the

cartridge and reinstall the

assembly into the shock

body, turn in a clockwise

direction until snug—DO NOT

TIGHTEN yet!

Step 8

Replace the spring and

spring cup and test the shock

action for smoothness and

leaks. Retighten the bleed

screw or cartridge if either

leaks. Remount the shock on

your truck.

** Production shock parts may differ from those shown in above drawings.

Mini-DT Manual―Page 8

Loading...

Loading...