Page 1

EN DE FR IT

Not responsible for errors. All prices

subject to change without notice.

Page 2

2 - E2 -

E

Notice

Notice

Introduction

Register your Losi

®

Product Online

Getting Ready

Safety Precautions and Guidelines

All instructions, warranties and other collateral documents are

subject to change at the sole discretion of Horizon Hobby, Inc.

For up-to-date product literature, visit www.horizonhobby.com

and click on the support tab for this product.

Introduction

Thank you for choosing the TEN-SCTE. We are con dent you will

be satis ed with the performance of this durable and resilient

vehicle. Please read through the entire manual before setting

up and using your vehicle.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm when

operating this product:

NOTICE: Procedures, which if not properly followed, create

a possibility of physical property damage AND a little or no

possibility of injury.

CAUTION: Procedures, which if not properly followed, create

the probability of physical property damage AND a possibility

of serious injury.

WARNING: Procedures, which if not properly followed, create

the probability of property damage, collateral damage, and

serious injury OR create a high probability of super cial injury.

WARNING: Read the ENTIRE instruction manual to

become familiar with the features of the product before

operating. Failure to operate the product correctly can

result in damage to the product, personal property and

cause serious injury.

This is a sophisticated hobby product and NOT a toy. It must be

operated with caution and common sense and requires some

basic mechanical ability. Failure to operate this Product in a safe

and responsible manner could result in injury or damage to the

product or other property. This product is not intended for use

by children without direct adult supervision. Do not attempt

disassembly, use with incompatible components or augment

product in any way without the approval of Horizon Hobby,

Inc. This manual contains instructions for safety, operation

and maintenance. It is essential to read and follow all the

instructions and warnings in the manual, prior to assembly,

setup or use, in order to operate correctly and avoid damage or

serious injury.

®

Register your Losi

Register your TEN-SCTE now and be the rst to nd out about

the latest options parts, product updates and more. Log on to

www.LOSI.com and follow the product registration link to stay

connected.

Getting Ready

Thoroughly read all the enclosed material, precautions and

follow instructions to avoid damaging your new RC vehicle. If

you choose to not follow these steps or instructions, it will be

considered negligence. If after review of this manual and prior

to running your TEN-SCTE, you determine this RC vehicle is not

what you want—Do Not proceed and Do Not run the TEN-SCTE.

If the TEN-SCTE has been run, your local hobby store will not be

able to process a return or accept it for exchange.

Safety Precautions and Guidelines

Age Recommendation: Not for children under 14 years. This

is not a toy.

Always operate this RC model in a safe, reasonable and cautious

fashion. When driving the TEN-SCTE avoid someone being hit

by the vehicle. You may cause serious injury to another person,

or to personal property should you make contact while running

the TEN-SCTE.

Product Online

General

• This RC Vehicle is not intended for use on public highways

or roads.

• Avoid areas that have many pedestrians or crowds of

people.

• Keep in mind that this vehicle is radio controlled and can

experience moments of radio loss or interference, provide

for a margin of error at all times.

• Be aware that the motor and batteries of this RC vehicle

will get HOT during each use. Be careful not to burn

yourself.

2 - EN

Page 3

3 - E3 -

E

Peak Detection Charger

Supplied and Required Equipment

Batteries and Charging

Quick Start

The TEN-SCTE uses rechargeable batteries such as NiMH. These

batteries all have special requirements to preserve performance

and last.

• Read all instructions provided by the manufacturer of the

batteries.

• Never allow minors to charge battery packs.

• Always check to ensure the polarity of battery connection

is correct.

• Never leave batteries unattended while charging.

• Never charge a battery while it is installed in the TEN-SCTE.

• Do not charge any battery that appears to have any

damage.

• I f there are exposed wires, do not charge or use the

battery until you install shrink-wrap or replace the

complete wire.

When charging NiMH batteries, select a charger to meet your

requirements. You need a charger that is a 100-240V wall

charger or one which requires a 12V power supply. Follow the

charger manufacturer’s instructions and precautions during

each use.

Quick Start

Note: Please read the entire manual to gain a full understanding

of the TEN-SCTE vehicle, ne-tuning the setup and performing

maintenance.

1. Read the safety precautions found on this page.

2. Charge the battery pack you have chosen (NOT

INCLUDED). Refer to the Manufacturer’s Supplied

instructions for battery charging information.

3. Install the AA batteries into the Transmitter. Use alkaline or

rechargeable batteries only.

4. Install a fully charged battery pack.

5. Turn on the transmitter and then the vehicle. Always turn

the transmitter on before the vehicle and turn it o after

the vehicle has been turned o .

6. Check steering. Verify that the servo is functioning

properly.

7. Driving the TEN-SCTE.

8. Performing maintenance of the TEN-SCTE.

Peak Detection Charger

Peak detection chargers monitor the battery during charging

and automatically shut o upon full charge. You can either

purchase a peak detection charger that plugs into a household

AC wall socket or one that requires you to also purchase a 12V

power supply.

If using a charger other than a peak detection charger, make

sure your battery is fully discharged prior to charging. Many of

these have a 15–20 minute timer that allows you to set a charge

time. If the battery is not fully discharged, you can potentially

over-charge your battery pack. Do not charge any battery

unattended, and monitor for heat build up. If the battery pack

is more than warm to the touch, immediately discontinue

charging. Read all safety precautions supplied by the charger

and battery manufacturer.

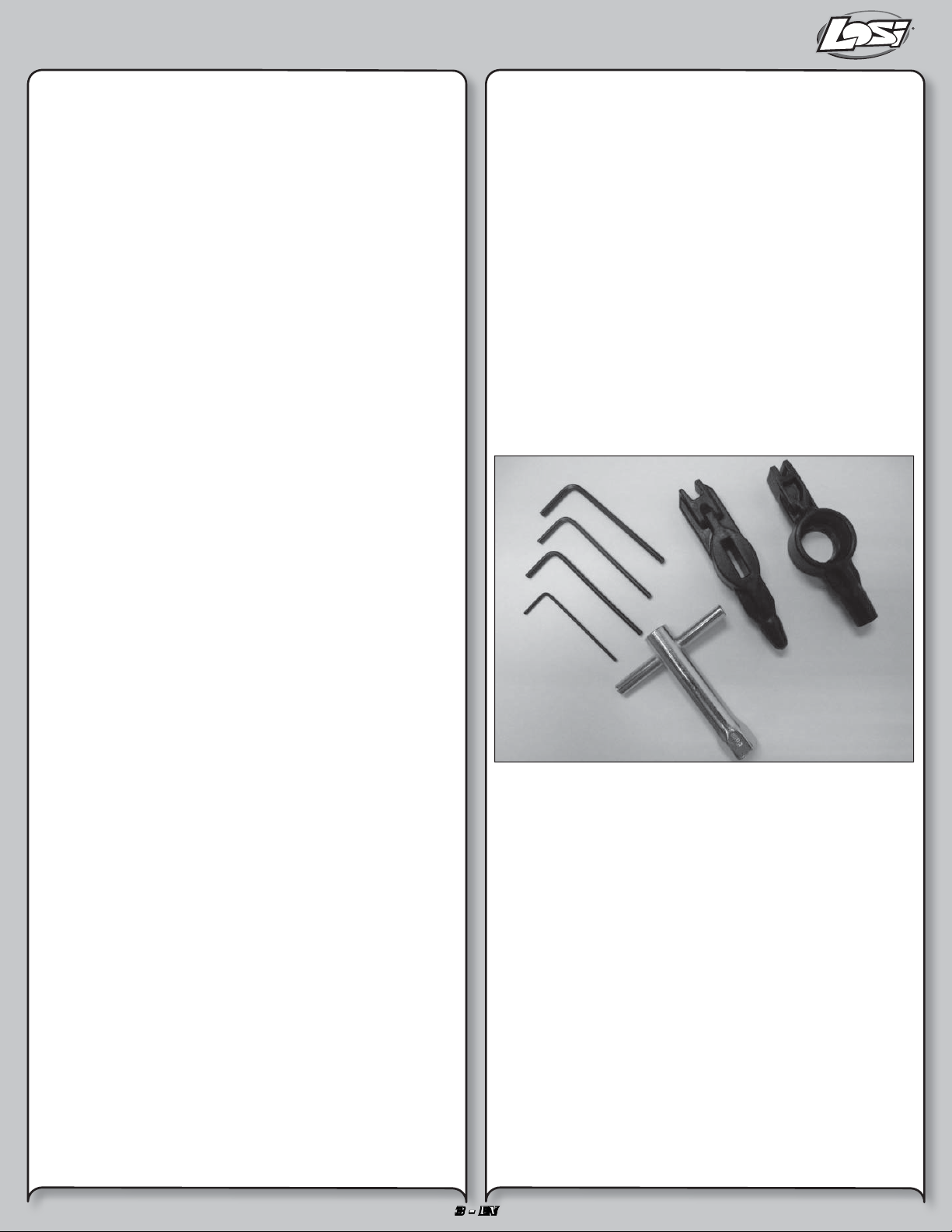

Supplied and Required Equipment

Supplied tools:

Wheel Wrench

Four (4) Hex “L” Wrench Set

.050-inch, 1/16-inch, 5/64-inch, and 3/32-inch

Shock Bottom wrench

Turnbuckle/Shock Top wrench

3 - EN

Page 4

4 EN4

EN

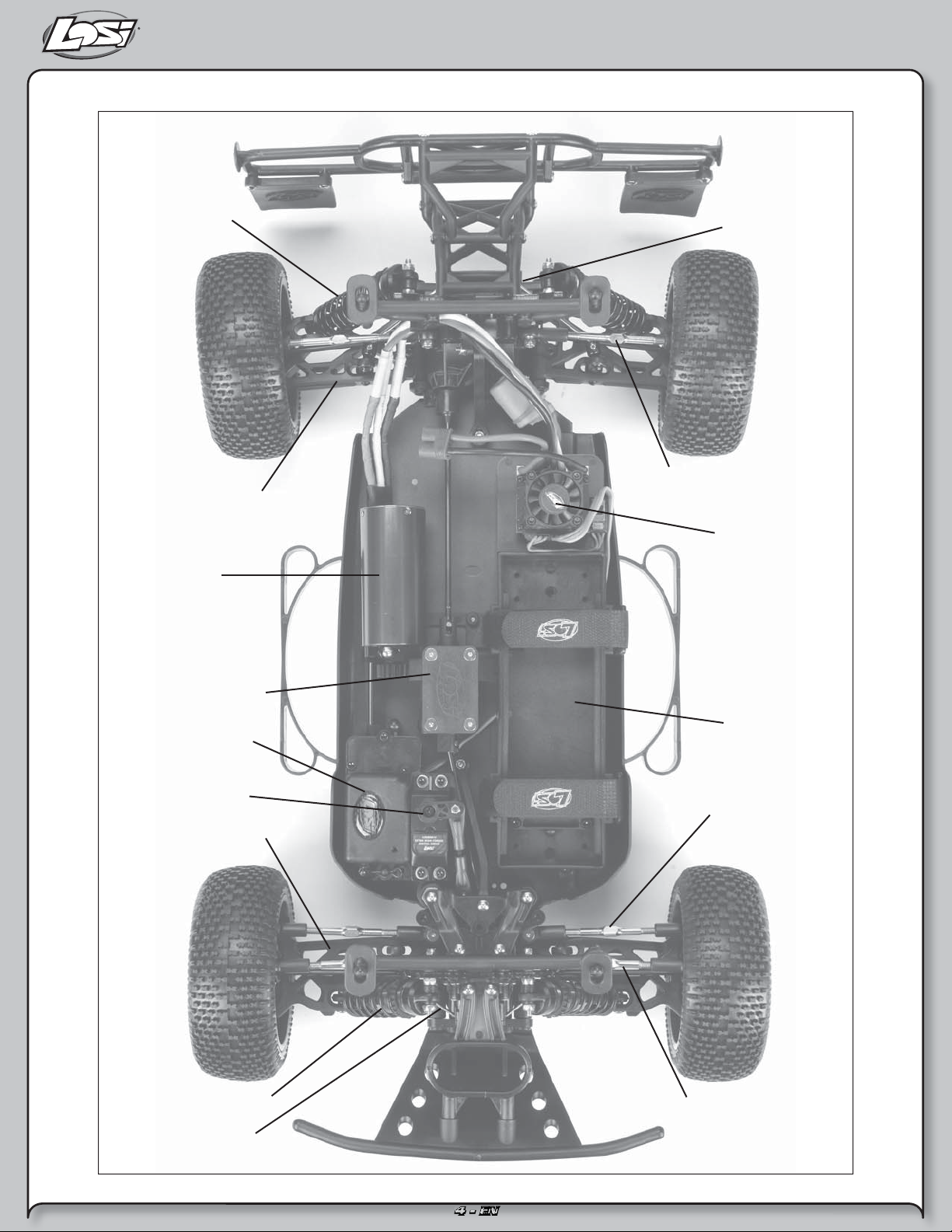

The Losi TEN-SCTE Overview

The Losi TEN-SCTE Overview

Rear Shock

Rear Suspension Arm

Motor

(not included)

Sway Bar

Rear Camber Link

ESC with Fan

(not included)

Center Di erential

Receiver Location

Steering Servo

(not included)

Front Suspension Arm

Front Shock

Battery Tray

Tie Rod

Front Camber Link

Sway Bar

4 - EN

Page 5

5 - E5 -

E

Tools You Will Find Handy

Basic Electronics Installation Instructions

Receiver and Electronic Speed Control Installation:

In addition to the tools included with the TEN-SCTE, you will

nd the following both useful and in some cases necessary.

• Small at blade and Phillips screwdrivers

• Needle-nose pliers

• Quality .050-inch, 1/16-inch, 5/64-inch, 3/32-inch, 1.5mm

and 2.5mm hex (Allen) drivers

Required Equipment:

Electronic Speed Control - We recommend the Xcelorin®

Sensored Brushless Speed Control

Motor - Any 550-sized motor

Basic Electronics Installation Instructions

Caution: Please be sure to follow the electronics

manufacturers guidelines when installing and setting up

your radio, motor, servo, electronic speed control, and

battery.

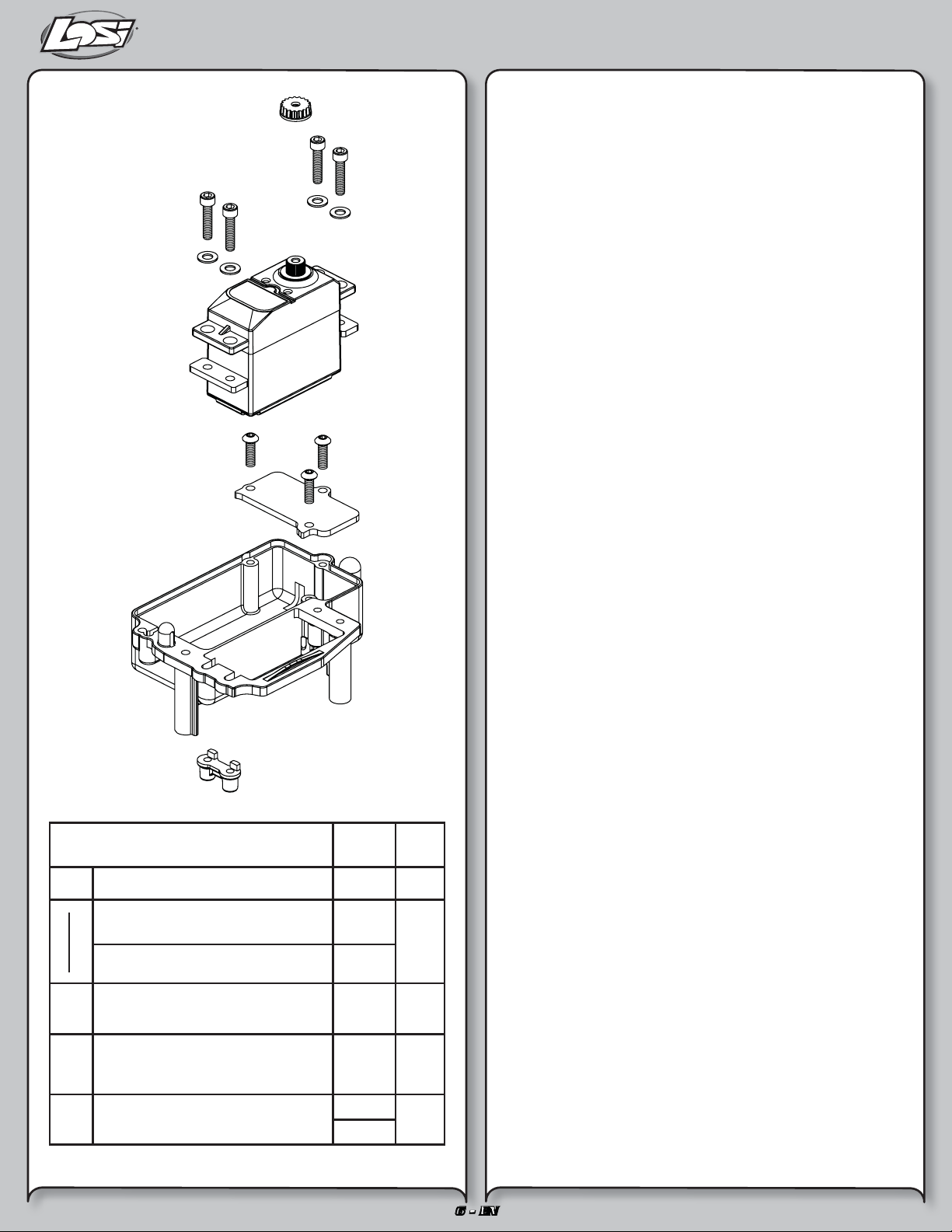

Motor Installation: Follow diagram below

1. Install motor adapter onto motor with two supplied

M3x10mm screws.

2. Install pinion gear (recommendations supplied earlier).

3. Slide motor with adapter into motor mount, set mesh, and

tighten using 5-40 x 3/8 button head screw. Be sure to use

threadlock.

Battery - We recommend the Xcelorin 7.4V 60C 2S 6000mAh

LiPo (LOSB9877)

Charger - We recommend the Xcelorin MultiPro™ Intelligent

LiPo Balancing Charger (LOSB9606)

Servo - Preferably Spektrum™ S6040

Pinion Gear - Any Mod 1 Pinion Gear

Note: We recommend a Losi LOSA3576 16T pinion gear for 4.5T

550 can motor, or a Losi LOSA3577 17T pinion gear for 5.5T 550

can motor.

Two Channel Radio - We recommend a Spektrum DX3R or DX3S

transmitter and matching receiver.

Paint (always test the paint on material removed from the body

to make sure the paint and body material are compatible.)

Receiver and Electronic Speed Control Installation:

Install with double-sided tape. Be sure to route wires so they

will not get caught in the spur gear.

Servo Installation: (use following diagrams)

1. Install servo as shown in diagram using the four supplied

4-40 x 1/2 in screws and washers. Please look at supplied

chart to determine if spacers are needed.

2. Choose correct servo horn adapter using servo horn chart

and press onto servo.

3. After servo is centered, install servo horn on servo using

the screw provided with your servo so that in the centered

position the servo horn is parallel to the servo saver arm.

5 - EN

Page 6

6 - E6 -

E

Before Running Your TEN-SCTE

Before Running Your TEN-SCTE

Driving the TEN-SCTE

1. Break in the di erentials. While holding the chassis with

only the left side tires rmly on the ground, give the car

about one eighth throttle, for 30 seconds. The right side

tires should spin freely during this time. Repeat this with

only the right side tires rmly on the ground, allowing the

left side tires to spin freely. Repeat this 2–3 times.

2. Check for free suspension movement. All suspension arms

and steering components should move freely. Any binds

will cause the car to handle poorly.

3. Set the ride height. Set the ride height of your truck with

all components installed so that the bottom of the chassis

is 29.5mm from the ground in the front and 24.5mm in the

rear by adjusting the shock collars.

4. Set the camber. Adjusting the camber tie rod length

changes the camber. Set the front tires to have 0 degrees

of camber at ride height. Set the rear tires to have 2.5

degrees of negative camber at ride height.

5. Set the front toe-in. Adjust the steering tie rods so that

when the servo is centered on the transmitter, the front

tires are both pointing straight.

6. Charge a battery pack. Charge a battery pack as per the

battery manufacturers and/or charger manufacturers’

instructions.

7. Adjust the electronic speed control. Follow the

manufacturers instructions to setup and adjust the speed

control for your TEN-SCTE.

8. Set the transmitter steering trim. Follow the manufacturers

instructions to set the steering trim/subtrim so that the

vehicle goes straight with no input to the steering.

9. Set the transmitter steering endpoints. Follow the

manufacturers’ instructions to set the endpoints so that

the servo hits full steering upon reaching full input from

the transmitter.

Servo Manufacturer, Make/Model

JR

Sanwa

All (DZ9100T/S Needs Spacer) No 23T

Airtronics

94357Z, 94358Z, 94649Z, 94360Z,

94452Z, 94758Z, 94737Z, 94738Z

94102Z, 94112Z Yes

Hitec

Futaba

All (S9102 DOES NOT FIT)No25T

PROPO

KO

PDS-2123, 2344, 2363, 2365, 2366

Servo

Spacer

Servo

Horn

Yes

23T

All No 24T

No

23T

No

Driving the TEN-SCTE

Always follow these precautions when running your TENSCTE.

Do not run the TEN-SCTE at dusk or in the dark when

visibility is limited.

Do not attempt to run this model if it will be out of sight for

any amount of time.

Do not run this model near a crowd of people.

Always check for proper radio function and battery condition

before operating.

Check to make sure the tires are securely glued to the rims.

Check the model thoroughly for loose nuts, bolts and screws

before and after running.

Make sure you use proper dirt tires if running o -road.

Never run the model with old or discharged batteries.

Leave plenty of room to stop the model. It will take as much

room to stop as it did to accelerate.

6 - EN

Page 7

E

E

Tuning, Adjusting and Maintaining the TEN-SCTE

Tuning, Adjusting and Maintaining the TEN-SCTE

Periodically examine your TEN-SCTE for the following:

• Keep your vehicle clean using a brush to remove dirt

and dust.

• Look for cracks in the suspension arms and other

molded parts.

• Check that the tires are still glued to the wheels.

• Check that all the wheel bearings are clean and lubricated.

• Using your tools, attempt to tighten all the screws and

nuts.

• Verify that the Camber Links and Steering linkage are

not bent.

• Check that the Toe and Camber settings are as desired

and equal.

• Check the Drivetrain:

o Check the Spur gear for wear.

o Check the Pinion gear.

• Take the shocks o the vehicle and check, especially if they

appear to be leaking as it is time to rebuild them.

• Look over all the wiring and connections for bare wire or

any place which could lead to a short circuit.

After you become familiar with driving your TEN-SCTE,

you may need to reset or make adjustments for better

driving performance.

MIDDLE

Just as in a real car, alignment is an important factor in your

vehicle’s handling. When you are ready to make adjustments

it is a good idea to have a at work space to place your vehicle

on. This will enable you to easily and more quickly make both

Toe-in and Camber adjustments. These adjustments should be

set with the vehicle sitting at its normal ride height.

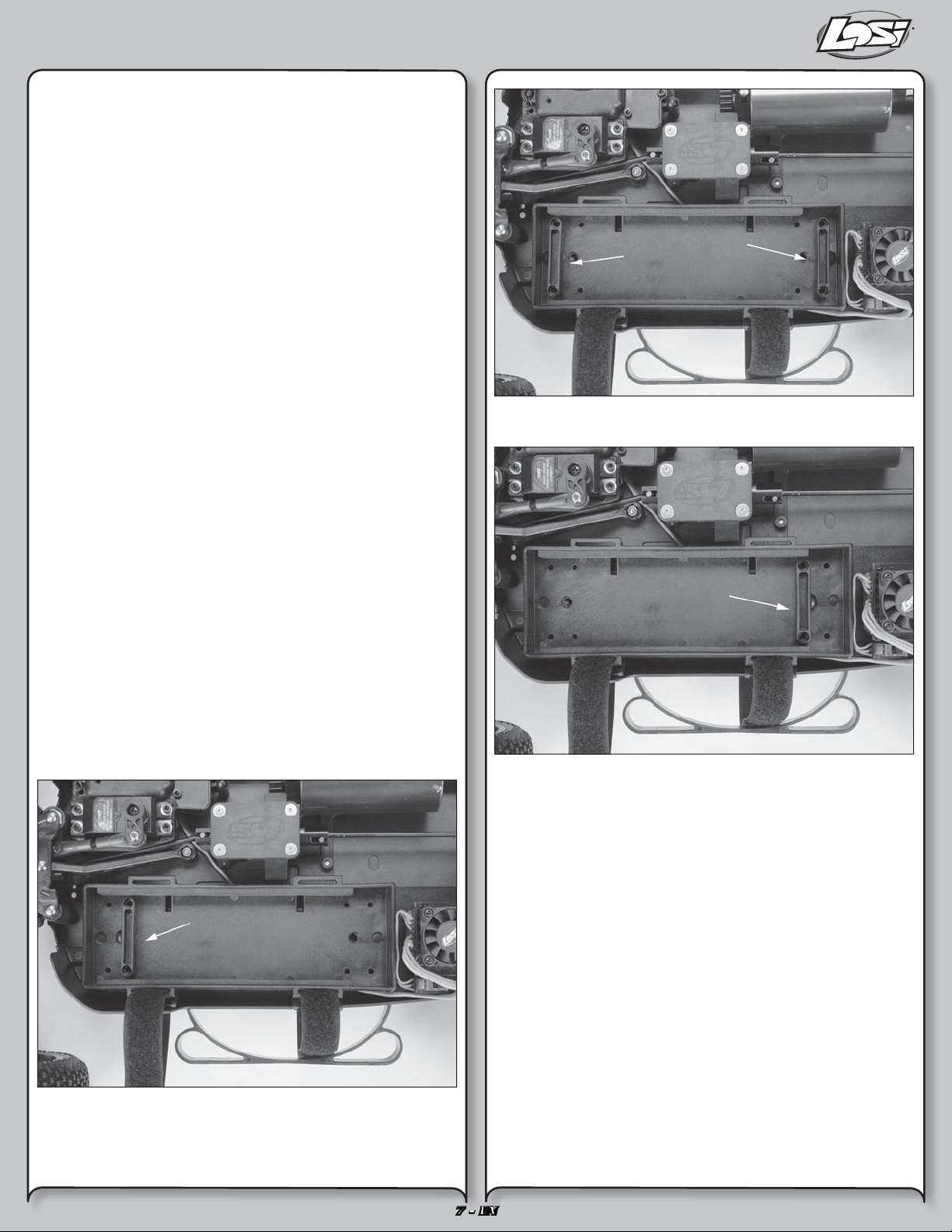

Three-Position Battery Tray: Your TEN-SCTE comes with

a three-position battery tray to alleviate the need for foam

blocks. You can move the included battery stops in order to run

the battery in a back, middle, or forward position. Please see

pictures as follows.

FORWARD

BACK

7 - EN

Page 8

E

E

Maintenance

Maintenance

Maintaining Di erentials:

In addition to the service needs pointed out in this guide,

you should try to maintain your new TEN-SCTE for proper

performance and to prevent wear. If dirt gets in the moving

parts it can seriously hinder the performance of the model.

Use compressed air, a soft paintbrush and/or a toothbrush

to remove dirt and dust. Avoid using solvents, if possible, as

this can actually wash the dirt into bearings and areas not

accessible without disassembly, causing additional wear. We

suggest you follow these basic guidelines.

• Remove as much freestanding dirt and dust as noted

above.

• Never leave the battery plugged in while vehicle is not

running.

• Inspect the chassis for worn, broken or binding parts and

repair as necessary.

Maintaining Di erentials:

1. Remove di erential from vehicle using exploded view.

2. Clean loose dirt o using brush.

3. Open di erential as shown in diagram.

4. Clean out internals using motor spray.

5. Fill with oil to your liking and reverse steps to reinstall.

Tuning the Front End of the TEN-SCTE

Shock Location: The TEN-SCTE has three mounting locations

on the front shock tower. The position can be easily adjusted

by simply moving the top of the shock to another hole. The

standard location works best on most surfaces. Moving the

top of the shock inward a hole will slow steering response

and make the TEN-SCTE smoother in bumps. The standard

position on the arm is middle, which o ers the best balance.

Running the inside shock location will give the TEN-SCTE more

steering into the turn and less steering on corner exit. Running

the shock location outside on the front arm will give you less

overall steering into the turn and keep the front end atter

through the turn, making the TEN-SCTE smoother and easier to

drive. This can be used on high-traction surfaces. Keep in mind

as you move the shocks in on the arm this will require internal

limiters to obtain the correct suspension travel. For the inside

location a total of .200-inch limiter works great. Losi sells a

shock spacer set (LOSA5050) that includes .030-inch, .060-inch,

.090-inch and .120-inch spacers.

All of the Camber and Steering linkages feature left and

right-hand threads at either end like a turnbuckle to make

adjustments easy. The side with right-hand threads has a small

groove machined into it. Use the plastic turnbuckle wrench

supplied with the TEN-SCTE to adjust these. Using the righthand threaded side as your reference: if you turn the link to the

right (clockwise) you will make it shorter. If you turn it to the left

(counterclockwise) you will make it longer. If you will be making

a lot of adjustments-you should consider using the LOSA99165

Aluminum Turnbuckle Wrench.

Static Camber: This refers to the angle of the wheels/tires

relative to the surface (viewed from either the front or back).

Negative camber means that the top of the tire leans in toward

the chassis. Positive camber means the top of the tire leans out,

away from the chassis. Camber can be precisely measured with

after-market camber gauges, sold at a local hobby shop. It can

be measured (roughly) using any square (to the ground) object

by checking the gap between the square edge and the top of

the tire. Testing has shown that 1 degree of negative camber

is best for most track conditions. Increasing negative camber

(in the range of 1-2 degrees) will generally increase steering.

Decreasing negative camber (in the range of 0-1 degree) will

generally decrease steering and the TEN-SCTE will feel easier to

drive as a result. This is, most often, a very critical adjustment in

tuning your TEN-SCTE that can be made quickly and easily.

8 - EN

Page 9

E

E

Inboard Camber Location: The TEN-SCTE has two di erent

inner locations with vertical adjustment for the front camber

tie rod. In general, the lower or further out the inside position

is, relative to the outside, the more camber gain (total camber

change through the total throw of the suspension) is present.

This is an adjustment that is di cult to make a generic

statement as it can have slightly di erent results in various

conditions. The following is a summary of how this adjustment

will usually impact the handling of the TEN-SCTE. A longer front

camber link will usually make the TEN-SCTE feel sti er. This will

help keep the TEN-SCTE atter with less roll, but can make the

TEN-SCTE handle worse in bumpy conditions. It also will make

the TEN-SCTE easier to drive. A shorter front camber link will

result in more front end roll, which will provide more steering

on tighter turns with the loss of some stability. You will also lose

some high-speed steering but might gain some more steering

response. Too short of a front link may make the TEN-SCTE feel

“twitchy” or “wandery” meaning that it may be di cult to drive

straight at high speed.

To e -I n /Out: This is the parallel relationship of the front tires to

one another. Toe-in/out adjustments are made by changing the

overall length of the steering tie rods. Toe-in (the front of the

tires point inward, to a point in front of the front axle) will make

the TEN-SCTE react a little slower, but have more steering from

the middle of the turn, out. The opposite is true with toe-out

(the front of the tires point outward, coming to a point behind

the front axle), the TEN-SCTE will turn into the corner better but

with a decrease in steering from the middle of the turn, out.

Toe-in will help the TEN-SCTE to “track” better on long straight

high-speed runs, where toe-out has a tendency to make the

TEN-SCTE wander. We recommend to run between 0-degree of

toe-in/out to 1 degree of toe-in.

Di erentials: The TEN-SCTE comes equipped with grease

in all three di erentials. You can switch to oil. Thinner front

oil increases o -power steering, but if the oil is too thin the

steering will become grabby and inconsistent. Thicker front

di erential oil increases o -power stability and increases onpower steering. Thinner center di erential has less forward

drive, can unload more under acceleration and is easier to drive

on rough and slick tracks. Thicker center di erential has more

acceleration, increases on-power steering, and less o -power

steering. Thinner rear di erential has more cornering traction

and increases steering in the middle of the turn. Thicker rear

di erential has less steering in the middle of the turn and more

forward traction.

Tuning the Rear End of the TEN-SCTE

Shock Location: Moving the shocks out on the arm will result

in less forward traction and let the TEN-SCTE make more of

an arc through the exit of the turn. In general, when changing

shock locations on the arm, it will be necessary to go down one

spring rate when moving out on the arm.

Static Camber: Having the same de nition as for the front end

and measured in the same fashion, rear camber can also be a

critical tuning feature. Testing has shown that running a small

amount of negative camber (.5-1 degree) is best. Increasing

negative rear camber (in the range of 1.5-3 degrees) will

increase stability and traction in corners, but decrease highspeed stability. Decreasing rear camber (in the range of 0-1.5

degrees) will decrease stability and traction in corners, but will

increase high-speed stability.

Inboard Camber Location: The TEN-SCTE has two inner

camber link locations. These locations work in the same

fashion and have the same e ect as noted for the front. You

will nd that you will get more noticeable changes with the

outer locations in the hub. In general the upper hole will make

the TEN-SCTE more stable and keep the front end atter. This

works well on higher traction surfaces. The lower location will

make the steering more aggressive which works well on lower

traction surfaces. This can be good in some conditions but can

also make the TEN-SCTE di cult to drive in others.

Outboard Camber Location: Running the camber link in the

inside position on the hub will generate more rotation entering

a turn, but decrease steering on exit. Running the camber link

in the furthest outer position on the hub will generate more

stability entering a turn and increase steering on exit.

To e -I n : Having the same de nition as for the front end, the

toe-in can be adjusted on the TEN-SCTE with the rear hubs. The

stock toe-in is 3 degrees of inboard per side and 0 degrees in

the hub. Increasing rear toe-in will increase forward traction

and initial steering, but reduce straightaway speed. Decreasing

rear toe-in will decrease forward traction and “free-up” the TENSCTE. Less toe-in can be used to gain top speed.

Ride Height: This is the height of the chassis in relation to the

surface. It is an adjustment that a ects the way your TENSCTE jumps, turns and goes through bumps. To check the

ride height, drop one end (front or rear) of the TEN-SCTE from

about a 5 to 6-inch height onto a at surface. Once the TENSCTE settles into a position, check the height of that end of the

TEN-SCTE in relationship to the surface. To raise the ride height,

lower the shock adjuster nuts on the shock evenly on the end

(front or rear) of the TEN-SCTE that you are working on. To lower

the ride height, raise the shock adjuster nuts. Both left and right

nuts should be adjusted evenly. Check the setup sheet included

and for additional setup information visit www.losi.com.

9 - EN

Page 10

N

N

Use the same technique to adjust the rear ride height. Again,

Troubleshooting your TEN-SCTE

Servicing Your Shocks

refer to the included setup sheet. Every driver likes a little

di erent feel so you should try small ride height adjustment

to obtain the feel you like. This should be the last adjustments

you make after everything else is dialed in. Note: Do not use

ride height adjustments as a substitute for a spring rate change.

If your TEN-SCTE needs a softer or rmer spring, change the

spring. Do not think that simply moving the shock nuts will

change the spring sti ness as it will NOT!

Wheels and Tires

The tires come pre-mounted with the vehicle and should be

checked to make certain they stay glued to the wheels. The

wheel spinning speeds this vehicle is capable of tend to pull the

rubber tire away from the rim. When a tire or tires come loose

from the rim you will notice the vehicle is hard to control.

Tip the vehicle on its side and using both hands to hold one

wheel at a time, use your thumb to press the tire away from the

rim. If you see a tire pull away from the rim, use Losi Tire Glue

(LOSA7880 thick or LOSA7881 thin) to reglue. It only takes a

small drop of glue generally. Be careful—this is CA-type glue

and you do not want to glue your ngers to the wheel and tire.

Use safety goggles when gluing tires.

Check the mounting of the tire periodically to ensure proper

performance and handling.

Troubleshooting your TEN-SCTE

Many questions are the result of simple user errors or minor

adjustments which are easily addressed. If after reading below

you cannot resolve your problem, then please contact the

appropriate Horizon product support department.

Servicing Your Shocks

From time to time you should check your shocks for adequate

uid. If the uid is low, or it is getting dirty, you should change

the uid in the shocks. You may also want to change the shock

uid and or the pistons to better address the conditions you

are running on. Regardless of what the reason you will want to

follow these simple steps to service, re ll, and bleed your TENSCTE shocks. If you are cleaning or changing the uid, you will

nd the LOSA99217 Nitrotec™ Spray Cleaner to be the quickest

and easiest way to remove oil uid and dirt safely.

1. If you are changing the pistons, clean the threads on the

end of the shock shaft and apply threadlock (LOSA99202)

to the threads.

2. Install the small shock piston washer and shock piston

using the 4-40 mini lock nut on the shock shaft to secure

them.

3. Put a drop of shock uid on the shaft before replacing it in

the shock body.

4. If you are changing the shock end, use the shock tool

provided with the TEN-SCTE to hold the shaft. You will

see that this plastic tool has serrations on both sides that

allow you to hold it with a pair of pliers and not scratch up

the micro nished surface. This method works very well to

protect the shock shafts from damage.

5. After installing, make sure the shaft is fully extended when

lling the shock.

6. Fill the shock body with 30–35-weight shock uid until it is

to the top of the Body.

7. Work the shock shaft up and down a few times. This will

release the air bubbles trapped beneath the piston.

8. Place the lled shock, in the upright position, o to the

side for a few minutes until the air bubbles escape from

the uid.

9. Once all the air bubbles are out of the uid, gently place

the shock bladder onto the top of the shock. Some uid

will “bleed” from around the bladder.

10. Screw the shock cap onto the body until a little resistance

is felt.

11. Slowly push the shock shaft up. This will allow excess uid

to bleed out.

12. Tighten the cap all the way down using the shock tools

included in your kit.

13. Move the shock shaft up and down. The shaft should be

easy to push up into the body of the shock.

14. If increased pressure is felt towards the top, there is too

much oil in the shock. Loosen the shock cap and bleed the

shock as done in steps 11 and 12.

15. Make sure each pair (front/rear) of shocks has the same

rebound and compression. This is checked by holding

one shock in each hand horizontally and pushing them

together by the shock end. Watch carefully to ensure that

both compress evenly. Now release both shocks and again

watch carefully as they should rebound the same.

10 - EN

Page 11

N

N

Warranty and Repair Policy

Warranty and Repair Policy

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties

that the Products purchased (the “Product”) will be free from

defects in materials and workmanship at the date of purchase

by the Purchaser.

Limited Warranty

Horizon reserves the right to change or modify this warranty

without notice and disclaims all other warranties, express or

implied.

(a) This warranty is limited to the original Purchaser

(“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT

AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE

REMEDY OF THE PURCHASER. This warranty covers only those

Products purchased from an authorized Horizon dealer. Third

party transactions are not covered by this warranty. Proof of

purchase is required for all warranty claims.

(b) Limitations- HORIZON MAKES NO WARRANTY OR

REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT

THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF

THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall

be that Horizon will, at its option, (i) repair or (ii) replace, any

Product determined by Horizon to be defective. In the event of

a defect, these are the Purchaser’s exclusive remedies. Horizon

reserves the right to inspect any and all equipment involved

in a warranty claim. Repair or replacement decisions are at

the sole discretion of Horizon. This warranty does not cover

cosmetic damage or damage due to acts of God, accident,

misuse, abuse, negligence, commercial use, or modi cation

of or to any part of the Product. This warranty does not cover

damage due to improper installation, operation, maintenance,

or attempted repair by anyone other than Horizon. Return

of any Product by Purchaser must be approved in writing by

Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT

OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED

WITH THE PRODUCT, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

Further, in no event shall the liability of Horizon exceed the

individual price of the Product on which liability is asserted.

As Horizon has no control over use, setup, nal assembly,

modi cation or misuse, no liability shall be assumed nor

accepted for any resulting damage or injury. By the act of use,

setup or assembly, the user accepts all resulting liability.

If you as the Purchaser or user are not prepared to accept

the liability associated with the use of this Product, you are

advised to return this Product immediately in new and unused

condition to the place of purchase.

Law: These Terms are governed by Illinois law (without regard

to con ict of law principals).

11 - EN

Page 12

N

N

Warranty Services

Warranty Services

Compliance Information for the European Union

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide

warranty support or repair. Once assembly, setup or use of the

Product has been started, you must contact Horizon directly. This

will enable Horizon to better answer your questions and service

you in the event that you may need any assistance. For questions

or assistance, please direct your email to productsupport@

horizonhobby.com, or call 877.504.0233 toll free to speak to a

Product Support representative. You may also nd information on

our website at www.horizonhobby.com.

Inspection or Repairs

If this Product needs to be inspected or repaired, please use

the Horizon Online Repair Request submission process found

on our website or call Horizon to obtain a Return Merchandise

Authorization (RMA) number. Pack the Product securely using a

shipping carton. Please note that original boxes may be included,

but are not designed to withstand the rigors of shipping without

additional protection. Ship via a carrier that provides tracking and

insurance for lost or damaged parcels, as Horizon is not responsible

for merchandise until it arrives and is accepted at our facility. An

Online Repair Request is available at www.horizonhobby.com

http://www.horizonhobby.com under the Repairs tab. If you do

not have internet access, please contact Horizon Product Support

to obtain a RMA number along with instructions for submitting

your product for repair. When calling Horizon, you will be asked

to provide your complete name, street address, email address and

phone number where you can be reached during business hours.

When sending product into Horizon, please include your RMA

number, a list of the included items, and a brief summary of the

problem. A copy of your original sales receipt must be included

for warranty consideration. Be sure your name, address, and RMA

number are clearly written on the outside of the shipping carton.

Notice: Do not ship batteries to Horizon. If you have

any issue with a battery, please contact the appropriate

Horizon Product Support office.

Warranty Inspection and Repairs

To receive warranty service, you must include your original

sales receipt verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product will be repaired

or replaced free of charge. Repair or replacement decisions are at

the sole discretion of Horizon.

Non-Warranty Repairs

Should your repair not be covered by warranty the repair will

be completed and payment will be required without notification

or estimate of the expense unless the expense exceeds 50% of

the retail purchase cost. By submitting the item for repair you

are agreeing to payment of the repair without noti cation. Repair

estimates are available upon request. You must include this request

with your repair. Non-warranty repair estimates will be billed a

minimum of ½ hour of labor. In addition you will be billed for

return freight. Horizon accepts money orders and cashiers checks,

as well as Visa, MasterCard, American Express, and Discover cards.

By submitting any item to Horizon for inspection or repair, you are

agreeing to Horizon’s Terms and Conditions found on our website

under the Repairs tab.

United States

(Electronics and engines)

Horizon Service Center

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

877-504-0233

Online Repair Request visit:

www.horizonhobby.com/repairs

(All other products)

Horizon Product Support

4105 Fieldstone Rd

Champaign, Illinois

61822 USA

productsupport@horizonhobby.com

877-504-0233

United Kingdom

Horizon Hobby Limited

Units 1-4 Ployters Rd

Staple Tye

Harlow, Essex

CM18 7NS

United Kingdom

sales@horizonhobby.co.uk

+44 (0) 1279 641 097

Germany

Horizon Technischer Service

Hamburger Str. 10

25335 Elmshorn

Germany

service@horizonhobby.de

+49 4121 46199 66

France

Horizon Hobby SAS

14 Rue Gustave Eiffel

Zone d’Activité du Réveil Matin

91230 Montgeron

infofrance@horizonhobby.com

+33 (0) 1 60 47 44 70

Compliance Information for the European Union

INSTRUCTIONS FOR DISPOSAL OF WEEE BY USERS IN

THE EUROPEAN UNION

This product must not be disposed of with other waste. Instead, it

is the user’s responsibility to dispose of their waste equipment by

handing it over to a designated collection point for the recycling

of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time of

disposal will help to conserve natural resources and ensure that

it is recycled in a manner that protects human health and the

environment. For more information about where you can drop

o your waste equipment for recycling, please contact your local

city o ce, your household waste disposal service or where you

purchased the product.

12 - EN

Page 13

EN E

N

REPLACEMENT PARTS LIST

Part Number Description

LOSB2021 Front Suspension Arm Set: 10-T

LOSB2022 Rear Suspension Mount Cover: TEN-SCTE

LOSB2023 Rear Suspension Arm Set: 10-T

LOSB2100 Front Spindles and Carriers: 10-T

LOSB2103 Rear Hubs and Spacers: 10-T

LOSB2123 Steering Bellcrank Set: 10-T

LOSB2124 Steering Posts/Tube and Hardware: 10-T

LOSB2163 Front Shock Towers and Caps: 10-T

LOSB2170 Rear Shock Tower: 10-T

LOSB2211 Front and Rear Pin Mount Cover Set: 10-T

LOSB2213 Pivot Pin Mount Set (4): 10-T

LOSB2222 Front and Rear Sway Bar Set: 10-T

LOSB2278 Chassis Brace and Spacer Set (3): 10-T

LOSB2279 Steering Drag Link and Hardware: 10-T

LOSB2359 Radio Tray with Switch Cover Blank and

Receiver Cover: TEN-SCTE

LOSB2411 Chassis: TEN-SCTE

LOSB2412 Top Brace: TEN-SCTE

LOSB2413 Motor Mount with Adapter: TEN-SCTE

LOSB2414 Body Posts: TEN-SCTE

LOSB2415 Battery Tray with Stop Tab, Foam Pad

and Screws: TEN-SCTE

LOSB2416 Battery Straps (2): TEN-SCTE

LOSB2417 Rear Bumper Pack: TEN-SCTE

LOSB2418 Rear Mud Flap (2): XXX-SCT/TEN-SCTE

LOSB2419 Sideguards: TEN-SCTE

LOSB2421 Front Bumper Pack: TEN-SCTE

LOSB2825 Front Shock Body Set: 10-T

LOSB2826 Rear Shock Body Set: 10-T

LOSB2845 Front and Rear Shock Shaft Set: 10-T

LOSB2904 Front and Rear Shock Plastics and Ball Set (4): 10-T

LOSB2905 Front and Rear Shock Boots (8): 10-T

LOSB2906 Shock Rebuild Set (2): 10-T

LOSB2961 Front and Rear Spring Set (4)–Med (Black): 10-T

LOSB3104 Front and Rear Gearbox Set: 10-T

LOSB3436 40T Spur Gear, Mod 1: TEN-SCTE

LOSB3495 Wheel Hex (4) with Pins: TEN-SCTE

LOSB3536 Center Differential Mount and Shock Tool Set: 10-T

LOSB3542 Differential Housing and Seal Set: 10-T

LOSB3553 Center Differential Outdrive Set: 10-T

LOSB3555 Center Front CV Driveshaft Assembly: 10-T

LOSB3556 Center CV Driveshaft Couplers: 10-T

LOSB3563 F/R Differential Outdrive and Hard Set (2)

LOSB3564 F/R CV Driveshafts and Couplers (2): 10-T

LOSB3565 F/R CV Couplers (4): 10-T

LOSB3568 Differential Seals/Pin and Gasket: 10-T

LOSB3569 Differential Gear Set with Hardware: 10-T

LOSB3571 Front Ring and Pinion Gear Set: 10-T

LOSB3572 Rear Ring and Pinion Gear Set: 10-T

LOSB3574 Axle (2): TEN-SCTE

LOSB3578 Center Rear Drive Shaft: TEN-SCTE

LOSB3592 Differential Standoff: TEN-SCTE

LOSB4003 F/R Camber/Steering Turnbuckle Set: 10-T

LOSB4023 Rod End Set (15): 10-T

LOSB4022 Camber and Steering Ball Set (12): 10-T

LOSB4109 Suspension Hinge and King Pin Set (10): 10-T

LOSB4210 Steering/Throttle/Brake Link Set: 10-T

LOSB7018 Wheel Set (2): TEN-SCTE

LOSB7019 Beadlock Ring with Screws, Chrome:XXX-SCT/

TEN-SCTE (2)

LOSB8028 TEN-SCTE Body, Clear

LOSA4006 Antenna Kit

LOSA6204 4-40 x 1/2 Cap Screws

LOSA6206 4-40 x 3/8 Cap Screws

LOSA6227 4-40 x 1/8 Setscrews

LOSA6229 4-40 x 3/8 Button Head Screws

LOSA6240 5-40 x 1/2 Cap Screws

LOSA6250 4mm and 5mm Setscrews

LOSA6254 2-56 x 1/4 Cap Screws

LOSA6256 4-40 x 1/2 Button Head Screws

LOSA6264 8-32 x 3/8 Flat Head Screws

LOSA6270 5-40 x 3/8 Flat Head Screws

LOSA6271 5-40 x 1/2 Flat Head Screws

LOSA6272 5-40 x 3/4 Flat Head Screws

LOSA6275 5-40 x 5/8 Flat Head Screws

LOSA6277 5-40 x 3/8 Button Head Screws

LOSA6278 5-40 x 1/2 Button Head Screws

LOSA6279 5-40 x 3/4 Button Head Screws

LOSA6282 5-40 x 7/8 Button Head Screws

LOSA6286 5-40 x 5/8 Button Head Screws

LOSA6290 8-32 x 1/2 Button Head Screws

LOSA6293 8-32 x 1/4 Setscrews

LOSA6295 10-32 x 3/8 Setscrews

LOSA6298 8-32 x 1/8 Setscrews

LOSA6299 5-40 x 1/8 Setscrews

LOSA6302 5-40 Steel Lock Nuts

LOSA6350 #4 and 1/8-Inch Hardened Washer (24)

LOSA6907 5 x 8 x 2.5 Ball Bearing (2)

LOSA6947 5 x 11 Sealed Ball Bearings (2)

LOSA6954 5 x 10 x 4 Sealed Ball Bearings (2)

LOSA6956 12 x 18 x 4 Sealed Ball Bearings (2)

LOSA6957 10 x 15 x 4 Sealed Ball Bearings with

Plastic Retainer (2)

LOSA6958 6 x 12 x 4 Sealed Ball Bearings with

Plastic Retainer (2)

LOSA7215 Eclipse SCT Tires with Foams

13 - EN

Page 14

EN E

N

OPTIONAL PARTS LIST

Part Number Description

LOSA5224 Certifi ed Shock Fluid 30 wt.

LOSA5225 Certifi ed Shock Fluid 35 wt.

LOSA5226 Certifi ed Shock Fluid 40 wt.

LOSA99004 Losi Cargo Bag

LOSA99006 Losi Pit Roller Carrier/Pit Boxes

LOSA99013 Losi Large Pit Mat

LOSA99015 Losi Pit Apron

LOSA99104 Losi Wrench Set US (4 pc)

LOSA99165 Aluminum Turnbuckle Wrench

LOSA99772 Camber Gauge

LOSA99173 Ride Height Gauge

LOSA99174 Car Stand

LOSA99202 Losi-Lok Threadlock, Blue

LOSA99203 High-Pressure Black Grease

LOSA99217 Nitrotec Cleaner Spray

LOSB2167 Front Shock Tower, Machined Aluminum: TEN

LOSB2171 Rear Shock Tower, Machined Aluminum: TEN

LOSB2172 Rear Shock Tower, Carbon, 4mm: TEN

LOSB2173 Front Shock Tower, Carbon, 4mm: TEN

LOSB2130 Rear Hubs, Aluminum: TEN

LOSB2223 Front Chassis Brace, Aluminum: TEN

LOSB2224 Rear Chassis Brace, Aluminum: TEN

LOSB2846 Shock Tops, Aluminum (2): TEN

LOSB2907 One-Piece Shock Standoffs: TEN

LOSB2908 Shock Collars, Aluminum (2): TEN

LOSB2909 Piston Pack (2), Ten-T, TEN-SCTE

LOSB2960 Front and Rear Spring Set (4)–Soft (Silver): 10-T

LOSB2962 Front and Rear Spring Set (4)–Firm (Gold): 10-T

LOSB4112 Adjustable Front Hinge Pin Holder Set: TEN

LOSB4113 Adjustable Rear Hinge Pin Holder Set: TEN

14 - EN

Page 15

- I

- I

Ten-SCTE

10/06/10

x

x

1 degrees OUT

29.5mm

0 degree

Stock/20 degrees

2.0mm

4 holes @ 1.07mm/40 wt

Gold/Hard

Long

Up

Position 1

Position 1 / Outside

Grease

Grease

xx

85mm Center to Center

x

Inside

Center

Outside

For increased stability, use 10000

weight oil in the front and center

differentials.

3

2

1

1

2

3 degrees

Black/Medium

Electronics

Motor:

Losi 3.4

ESC:

Battery:

Stock

Notes

2 degrees

24.5mm

-2.5 degrees

All the way back

1.8mm

4 holes @ 1.09mm/30 wt

100.8mm Center to Center

Position 2 - A

Position 2 - Inside

Grease

1

2

3

B

A

Inside

Center

Outside

1

2

For increased traction, use 2000 weight

oil in the rear differential.

57 - IT

Page 16

A6302

B2278

B3578

B3578

B2213

A6947

VISTA ESPLOSA DELLA PARTE POSTERIORE

REAR EXPLODED VIEW

HECK EXPLOSIONSZEICHNUNG

VUE ÉCLATÉE ARRIÈRE

A6302

B4109

B4109

B2023

A6302

A6957

B3495

A6286

A6271

B2211

A6958

A6279

A6295

B2103

B3564

B4022

A6279

B3572

B3564

B4003

B4023

A6302

A6947

A6302

B2222

B3104

B4023

B4022

A6272

A6278

B3104

A6282

B2170

A6279

A6302

B2213

A6229

A6256

A6278

B2022

B2414

A6236

A8200

B2417

B3553

B2414

A6278

B2417

A6956

A6278

B3553

A6956

B3542

B3570

B3546

B3542

B3569

B3542

Page 17

B3563

B3563

B3568

B3568

B3542

B3563

B3569

B3542

B3563

B3568

B3563

B3542

Rear

Front

B3572

B3571

B3542

B3563

B3568

A6956

A6286

A6290

B2021

B4109

B4109

B2100

A6957

A6240

A6227

B2222

A6302

B2421

A6272

B3104

B3564

A6278

B3564

A6286

A6947

B4022

B3571

A6277

B2421

A6302

B3104

B2906

A6302

A6229

A6282

B2163

A6256

A6947

B2278

B2414

A8200

VISTA ESPLOSA DELLA PARTE ANTERIORE

FRONT EXPLOSIONSZEICHNUNG

A6236

FRONT EXPLODED VIEW

VUE ÉCLATÉE AVANT

A6275

B2211

B2213

A6240

B2222

B2021

A6295

A6278

A6282

A6302

B2100

B3495

A6958

B2100

B2100

A6272

B4022

B4023

B3574

B4022

B4023

B4003

A6302

B2213

B2211

59

A6275

B3556

B3555

A6275

B3556

Page 18

B2279

B2279

B4023

VISTA ESPLOSA DEL TELAIO

B2419

CHASSIS EXPLODED VIEW

CHASSIS EXPLOSIONSZEICHNUNG

VUE ÉCLATÉE DU CHÂSSIS

A6270

A6271

A6271

B4022

B2411

B2279

B2124

A6907

B4022

A6270

B2123

B2124

A6907

B4003

B2124

A6907

B2123

A6275

B2123

A6306

A6275

B2124

A6302

B4023

A2278

A6907

A4210

A6302

B2278

A6256

B4210

A6256

B4210

A6278

B4210

A6277

A6306

B3542

B3568

B3553

A6956

A6270

B3570

B3542

B3553

B3568

B3542

B3436

B3542

B2419

B3553

B3542

B3568

B3569

B3553

B3542

A6956

B3553

B3542

B3568

60

Page 19

B2359

B2904

B2904

A4006

B2360

B2359

A6271

A6229

B4210

B2359

A6204

A6350

B2359

B2960

Soft

B2961

Medium

B2962

Firm

B2904

B2906

B2845

B2825

B2906

B2904

B2905

B2904

B2960

Soft

B2961

Medium

B2962

Firm

B2904

B2906

B2845

B2826

B2906

B2904

B2905

B2904

A6267

B3592

B2413

B2416

B2412

A6277

A6240

B2415

61

Page 20

A6315

A7215

A6258

B7018

B7109

A6240

B2421

A6264

62

Page 21

©2010 Horizon Hobby, Inc.

Not responsible for typographical errors.

The Spektrum trademark is used with permission of Bachmann Industries, Inc.

Losi, Xcelorin and MultiPro are trademarks or registered trademarks of Horizon Hobby, Inc.

Airtronics® is a registered mark of Sanwa Electronic Instrument Co., Ltd., Osaka, Japan.

Futaba is a registered trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan

KO PROPO® is a registered trademark of Kondo Kagaku Co., Ltd., Tokyo, Japan.

Printed 11/2010

30160.I

Loading...

Loading...