Page 1

TM

TM

LOSB0102 1/10th Desert Truck RTR

Not responsible for errors. All prices subject to

change without notice.

Losi, a Division of Horizon Hobby, Inc.

1

Page 2

TM

Table of Contents

Introduction

Introduction .................................................................................................2

Safety Precautions: .....................................................................................3

Supplied and Required Equipment .....................................................4

Battery/Charging ........................................................................................5

Technical Overview ...............................................................................6–8

ESC Overview/Requirements .................................................................9

Transmitter Battery Installation ...........................................................10

Vehicle Battery Installation ...................................................................11

Quick Start ..................................................................................................12

Losi DSM Radio System ..........................................................................13

Driving the Desert Truck ........................................................................15

Tuning, Adjusting and Maintaining the Desert Truck .................16

Troubleshooting your Desert Truck ...................................................20

Warranty Information .............................................................................21

RC Terminology .........................................................................................22

Parts Listing ................................................................................................24

Optional parts Listing .............................................................................26

Exploded Views .........................................................................................27

Thank you for purchasing the Losi™ Desert Truck. We are

confident you will be satisfied with the performance in this

durable and resilient vehicle.

Understanding that you are anxiously wanting to get your

Desert Truck ready for the open road, it will be to your long

term benefit to make the effort and read through the entire

manual. In the following pages you will find all the information

you will need to set up as well as operate your new Desert Truck

to its full potential.

If you are an experienced RC hobbyist, or new to RC vehicles,

it will benefit you to read all enclosed information.

From everyone at Losi we would like to thank you again for

choosing the Desert Truck. Our goal is helping people have fun

and enjoy using our products.

Register your Losi Product Online

Register your Desert Truck now and be the first to find out

about the latest options parts, product updates and more.

Log on to www.LOSI.com and follow the product registration

link to stay connected.

Losi/Horizon Support

If you have any questions concerning setup or operation of

your Desert Truck RC please call Horizon Customer Support at

1-877-504-0233.

Hours:

Monday thru Friday from 8:00am CST to 5:00pm CST

You are welcome to call us with any support issue, or question

you may have about the Desert Truck.

Getting Ready

Thoroughly read all the enclosed material, precautions and

follow instructions to avoid damaging your new RC vehicle. If

you choose to not follow these steps or instructions, it will be

considered negligence.

If after review of this manual and prior to running your Desert

Truck, you determine this RC vehicle is not what you want—DO

NOT proceed and DO NOT run the Desert Truck. If the Desert

Truck has been run, your local hobby shop will not be able to

process a return or accept it for exchange.

Caution:

THIS PRODUCT IS NOT A TOY. This product is not intended for

use by children without direct adult supervision.

When driving the Desert Truck it is important that you take

measures to avoid someone being hit by the vehicle. You may

cause serious injury to another person, or to personal property

should you make contact while running the Desert Truck.

2

Page 3

TM

Safety Precautions

We hope you operate this RC model in a safe, reasonable

and cautious fashion so it leads to your enjoyment and

fun with this vehicle. Should you operate this vehicle

without a cautious and reasonable approach it may result

in serious injury and/or property damage. Only you can control

and make certain that safety precautions and instructions are

followed.

General:

• The Desert Truck is not a toy. This product is not intended

for use by children without direct adult supervision.

• This RC Vehicle is not intended for use on public highways

or roads.

• Avoid an area that has many pedestrians or crowds

of people.

• Keep in mind that this vehicle is radio controlled and

can experience moments of radio loss or interference, so

provide for a margin of error at all times.

• Please be aware that the motor and batteries of this

RC vehicle will get HOT during each use. Be careful not

to burn yourself.

Electronic Speed Control (ESC):

• Read all safety precautions prior to each use.

• Never leave the vehicle/ESC unsupervised while it is

switched on, in use or connected to a power source. If

there is a short-circuit or product defect, it could result in

fire.

• If there are exposed wires, do not use the ESC until you

have installed shrink-wrap or replaced the wire.

• Disconnect the battery from the ESC after use.

• The ESC is not water proof and should not be exposed

to moisture.

• Do not attempt to use 3-cell LiPo or 7-cells NiMH; doing so

will damage the ESC and could result in fire.

• Always turn on the transmitter first then the ESC to

prevent an out-of-control vehicle.

• When setting your Electronic Speed Controller:

º Please disconnect motor or remove the pinion gear

during ESC setup or calibration functions.

º Keep loose clothing, hair, gloves and fingers away

from moving parts at all times.

º Rubber tires can cause severe injury if there is a

failure while running the vehicle while on a stand or

when being held. Ensure rubber tires are securely

mounted to the rims and if not, re-glue them and

check them often for security.

Batteries and Charging:

The Desert Truck uses rechargeable batteries such as NiMH.

These batteries all have special requirements to preserve

performance and last a long time. Read all instructions and

precautions that are provided with the batteries intended to

be used in the Desert Truck.

• Read all instructions provided by the manufacturer

of the batteries.

• Responsible adult supervision is necessary while

charging batteries.

• Always check to ensure the polarity of battery

connection is correct.

• Never leave batteries unattended while charging.

• Never charge a battery while it is installed in the Desert

Truck.

• Do not charge any battery that appears to have

any damage.

• If there are exposed wires do not charge or use the

battery until you have installed shrink-wrap or replaced

the complete wire.

When charging NiMH batteries, select a charger to meet

your requirements. Chargers can be of two primary types

for their source of power; a 100-240V wall charger, or one

which requires a 12V power supply. Follow the charger

manufacturer’s instructions and precautions during each use.

3

Page 4

TM

Supplied and Required Equipment

Supplied tools:

2-Way wrench

Transmitter / Receiver BIND Plug

Four (4) Hex Wrench “L” shaped

.050, 1/16, 5/64, and 3/32

Flat Turnbuckle Wrench

Recommended Accessories:

- Hobby grade knife

- CA glue (LOSA7880 or LOSA7881)

- Needle nose pliers

- Side cutting pliers

- Double sided tape (LOSA4004)

- Safety Goggles

- Soldering iron

NiMH battery charger with automatic “peak detection”

recommended.

DYN4044 Vision Peak 2 AC/DC Charger

Using your charger:

If you do not yet have a charger a peak-detecting charger

will provide the performance required and take care of your

expensive batteries.

A popular choice for a charger would be a peak detection

charger that can be plugged into a household A/C wall socket.

The peak detection portion of the charger monitors the battery

charging and will automatically shut off upon full charge.

The other choice of peak detection charger requires a 12V

power source to charge your batteries. You would need to use

or purchase a hobby grade 12V power supply before charging.

Required Equipment:

Four (4) AA alkaline batteries for the transmitter.

Transmitter Batteries

A Six (6) cell NiMH battery pack. Or with proper

knowledge, LiPo battery packs.

Vehicle Battery

(6-Cell 7.2V “Stick Pack”)

LOSB9900

4

Page 5

TM

If you are going to be using a charger other than a peak

detection charger it is important to have your battery fully

discharged prior to recharging. Many of these have a 15-20

minute timer that allows you to set to the amount of charge

time. If the battery was not fully discharged from prior use, you

can potentially over charge your battery pack.

Do not charge any battery unattended, and monitor for

heat build up. If the battery pack is more than warm to the

touch immediately discontinue charging.

Read all safety precautions supplied by the charger

manufacture, and also any from the battery manufacture.

5

Page 6

TM

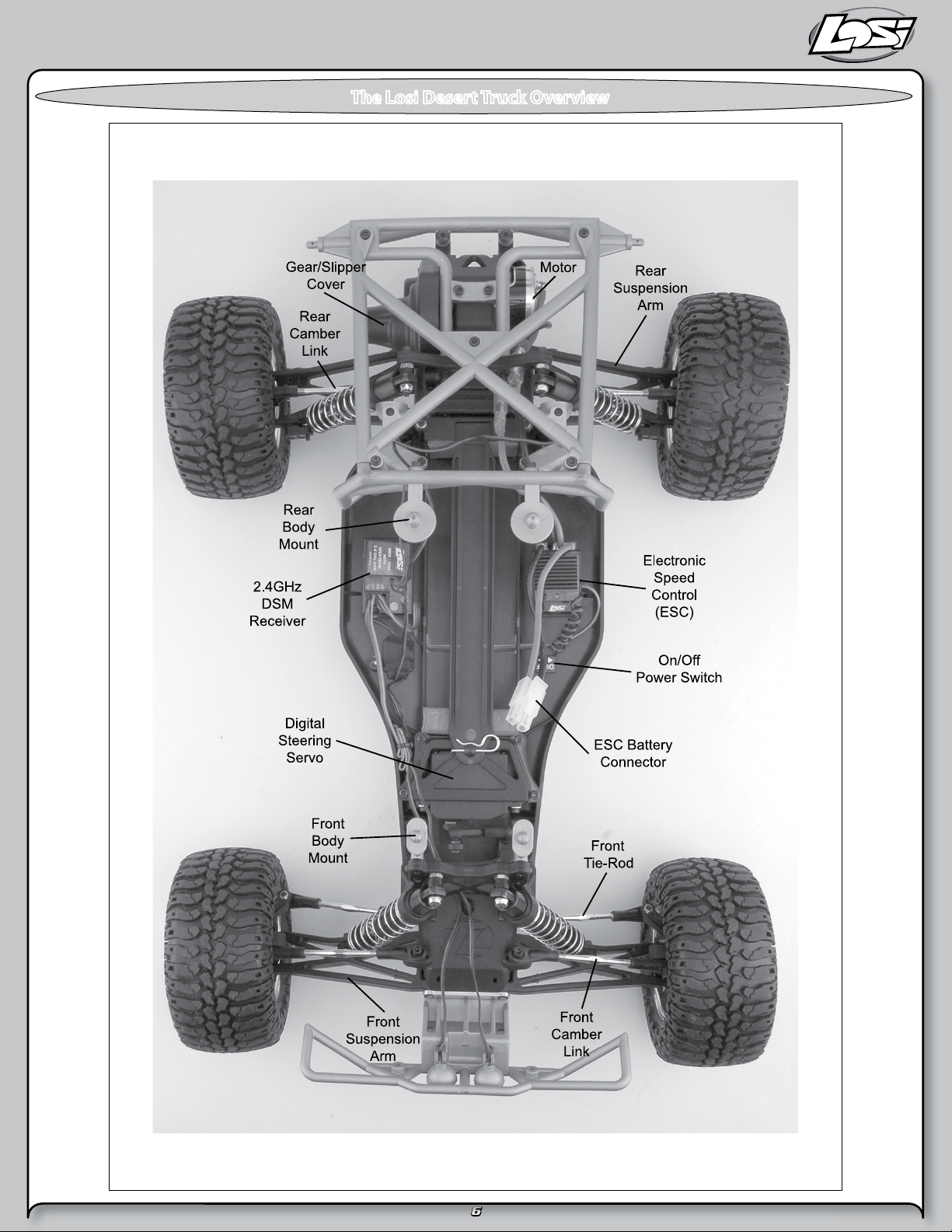

The Losi Desert Truck Overview

6

Page 7

TM

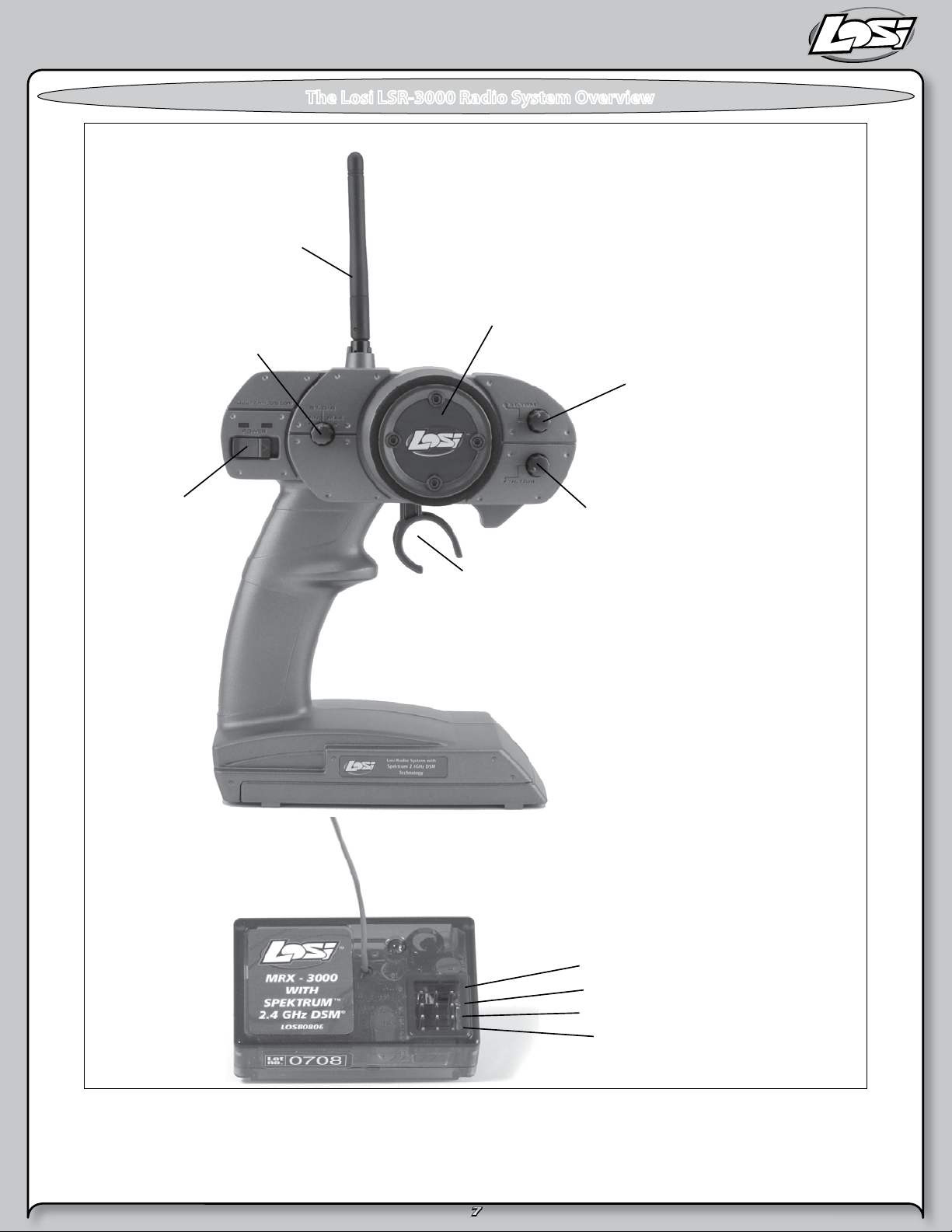

Steering Trim

(ST. Trim)

Throttle Trim

(TH. Trim)

Throttle/Brake

Trigger

Auxiliary Channel

Throttle Channel

Steering Channel

Binding Port

Power On/Off

Switch

Dual Rate

Adjustment (ST. D/R)

Antenna

Steering Wheel

The Losi LSR-3000 Radio System Overview

7

Page 8

TM

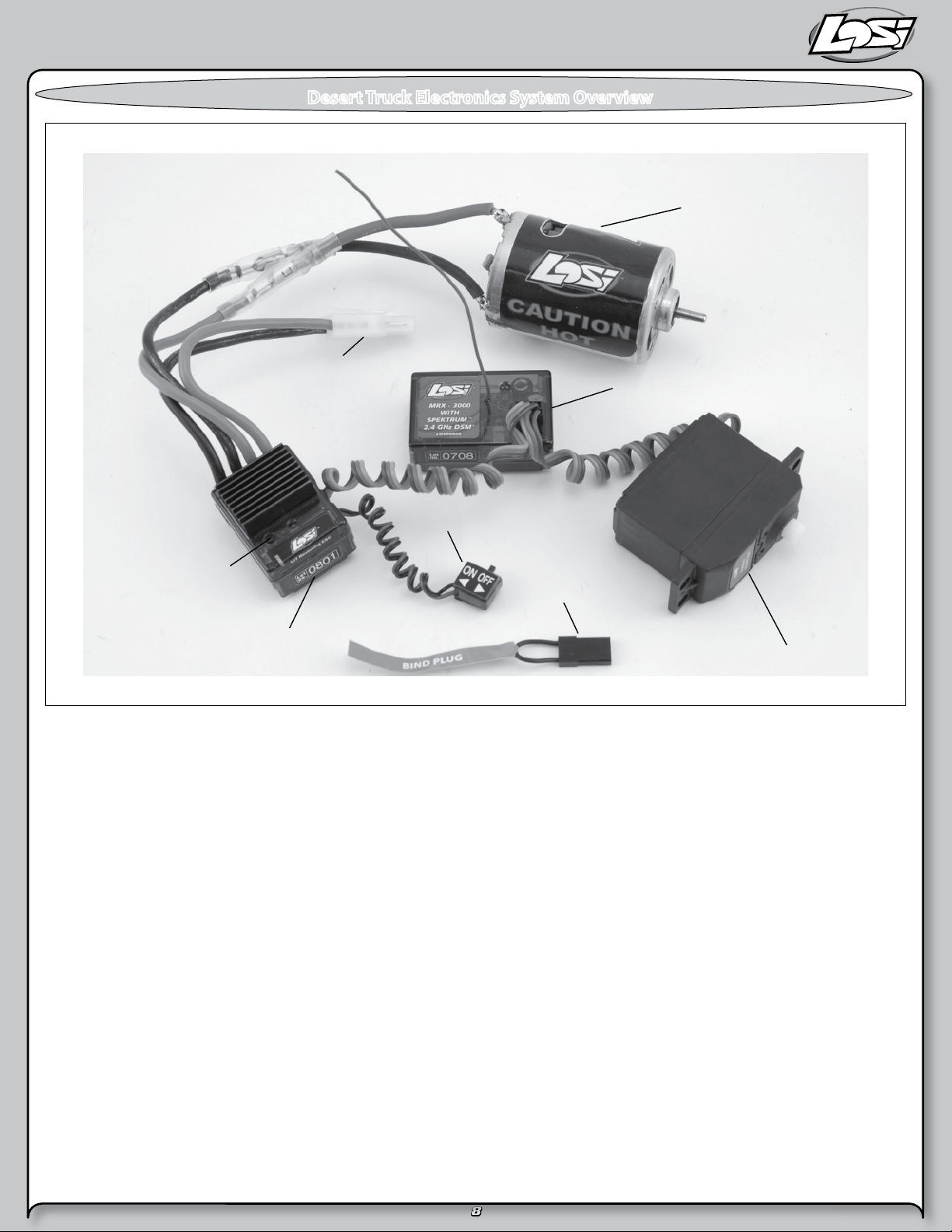

Motor

Bind Plug

On/ Off Switch

MSC 12RB 12T ESC

MRX3000 Receiver

Digital Servo

Male Battery

Plug

Setup Button

Desert Truck Electronics System Overview

8

Page 9

TM

MSC 12RB 12T Fwd/Rev ESC

Features

• High power FET control with proportional forward and reverse.

• High frequency design delivers smooth speed transition.

• Thermal Overload Protection prevents damage due to over current conditions.

• Pre-wired with Tamiya battery plug and bullet-style motor connectors.

• Designed to operate with stock motors (12 turns or higher).

• Push-button programming makes setup a breeze.

Connecting the Battery

The MSC 12RB comes pre-wired with a Tamiya-style connector,

compatible with most battery packs. Use battery packs from 4-cell

(4.8-volt) to 6-cell (7.2-volt) sub-C size battery packs.

1. Be sure the on/off switch is in the “off” position.

2. Connect a fully charged battery pack to the speed control’s battery

connector.

Selecting Forward Only or

Forward/Reverse Mode

The MSC 12RB has 2 modes: Forward Only mode and Foward

and Reverse mode. The Forward Only mode can be selected for

racing purposes. When the ESC is powered on, the LED will flash

for 2 seconds: the color of the LED indicates which mode the

ESC is operating in:

Forward and Reverse Mode–The Green LED will Flash

Forward Only Mode–The Red LED will flash.

To change modes, push the set button and turn on the ESC. The

LED will flash, indicating the new mode has been selected. Note

the color of the LED to determine the mode of your ESC.

Adjusting theTransmitter

1. Set the “throttle reversing” switch to the NORMAL position.

2. Set the “throttle trim” to the CENTER position.

Speed Control Programming

NOTE: While in the programming mode, no power is

applied to the motor.

1. Turn on the transmitter’s power switch. (Be sure the transmitter

batteries are fully charged).

2. Turn the ESC switch on.

3. Press and release the setup button. The red and green LEDs

will light.

4. Move the throttle to the full throttle position and press the

programming button. The green LED will remain lit and the red

LED will go out. (If the ESC does not sense throttle movement

in 3 seconds by the transmitter, it will exit the programming

mode and you will have to begin again.)

5. Now move the throttle to full reverse and press the

programming button. The red LED will glow and the green

LED will go out.

6. Return the throttle to neutral and press the programming

button. The green LED will glow and the red LED will go out,

indicating programming is complete.

During normal operation, the green LED indicates neutral and the

red LED indicates full forward and full reverse.

Troubleshooting Guide

Symptom Solution

Steering servo operates but the motor does not run Programming is not complete. Re-program the ESC by following the programming instructions.

Speed control connected to receiver incorrectly.

Motor defective. Test motor independently, repair or replace as needed.

Low batteries. Charge as needed.

Overload Protection enabled. Check motor and connections

Steering and motor do not function

Receiver wired incorrectly. Check polarity and orientation of control plugs.

Batteries discharged. Recharge or replace.

Full speed not attainable

Transmitter adjusted improperly.

ESC programmed incorrectly. Re-program.

Motor slows but will not stop

Throttle trim may be set improperly

ESC program does not match transmitter.

Operation....................................... Proportional forward,

proportional reverse with

braking delay

Input Voltage ..................................4-cell (4.8 volts) to

6-cell (7.2 volts) DC

Peak Current .................................. 900 amperes

Continuous Current ........................ 46 amperes

Full-On Resistance ......................... 0.0014 ohms

Frequency ...................................... 2 kHz

BEC output ..................................... 4.8 VDC, 1 amp max.

Overload Protection........................ Thermal

Dimensions .................................... 1.25" x 1.02" x .888"

(38.6mm x 26.2mm x

22.5mm)

Weight ............................................ 1.2 oz (34 g)

9

Page 10

TM

Installing Batteries:

Transmitter

Remove the battery cover from the bottom of the transmitter by sliding it away from the base of the handle. Install the four (4) AA size

batteries (not included) into the base, noting polarity when inserting each battery.

Transmitter with batteries

Reinstall the battery cover by sliding it back on the handle base.

10

Page 11

TM

Battery Pack(s)

To install the battery pack remove the battery hold-down strap by removing the clip from the front mounting boss, and then, while

lifting the strap, pulling forward in one motion.

After you have inserted the fully-charged battery pack reinstall the battery hold-down strap.

Notice that the battery hold-down has a flat side while the other side has strengthening ribs; the rib side should be facing

down to the battery.

Insert on an angle into the rear support, and then down on the front pin and secure it with the previously removed clip.

11

Page 12

TM

Quick Start

Note: Please read the entire manual to gain a full understanding of the Desert Truck

vehicle, fine-tuning the setup and performing maintenance.

1. Read the safety precautions found on page 3. This is important for your safety and

prevention of personal injury.

2. Charge the battery pack you have chosen (NOT INCLUDED). Refer to the

Manufacturer’s Supplied instructions for battery charging information.

3. Install the AA batteries into the LSR-3000 Transmitter (see page 10). Use alkaline or

rechargeable batteries only (NOT INCLUDED).

4. Install the battery pack (see previous page). This battery pack should be fully charged

before installation.

5. Turn on the transmitter and then the vehicle. It is a good practice to

turn on the transmitter before the vehicle and turn it off after the vehicle has

been turned off.

6. Check Steering (see page 13). Verify that the servo is functioning properly.

7. Driving the Desert Truck (see page 15)

8. Performing maintenance of the Desert Truck. Refer to Tuning, Adjusting, and

Maintenance of the Desert Truck on page 16.

12

Page 13

TM

Steering Trim

(ST. Trim)

Throttle Trim

(TH. Trim)

Throttle/Brake

Trigger

Power On/Off

Switch

Dual Rate

Adjustment (ST. D/R)

Antenna

Steering Wheel

Losi LSR-3000 Radio System

The Losi LSR-3000 Radio System with Spektrum™ 2.4GHz DSM® Technology radio system included with the Desert Truck operates

on 2.4GHz and provides 79 unique channels, which are automatically selected when the transmitter and vehicle are turned on. The

communication between the transmitter and receiver begins in the few seconds after both are turned on.

They are bound together from the factory to uniquely operate together.

The Losi LSR-3000 DSM radio system will not interfere with radio systems operating on legacy frequencies such as

27MHz or 75MHz, neither will you experience any overlapping interference from other 2.4GHz systems.

Operation and Adjustment

Transmitter

The Losi LSR-3000 transmitter has several adjustments available to increase your enjoyment of the Desert Truck vehicle.

1. Power switch – Turns the transmitter On and Off.

2. Dual rate – (ST.D/R) Adjusts how much the wheels can turn left/right in equal proportion.

3. Steering Trim – (ST.TRIM) Adjusts the “Hands Off” direction of the Desert Truck.

4. Throttle Trim – (TH.TRIM) Fine adjustment for the throttle and brake center.

13

Page 14

TM

Receiver

Steering Trim

(ST. Trim)

Throttle Trim

(TH. Trim)

Throttle/Brake

Trigger

Steering and Throttle

End-Point Adjustment Pots (4)

Auxiliary Channel

Throttle Channel

Steering Channel

Binding Port

Power On/Off

Switch

Dual Rate

Adjustment (ST. D/R)

Antenna

Steering Wheel

There is no adjustment required of the receiver. Please note the different slots for connection.

There is Bind, channel one, channel two and auxiliary slots.

The bind slot is used to bind the transmitter to the receiver. The Losi LSR-3000 DSM® radio system uses a unique GUID ID to “bind” the

transmitter to each receiver. This bind process has been performed during assembly and is described should you replace the receiver

or during a trouble shooting exercise you be requested to rebind your transmitter and receiver.

Although the transmitter and receiver are set “bound” at the factory, below are the steps required to rebind your transmitter and

receiver should the need arise.

Rebind Process

1. Ensure that the transmitter and vehicle are both turned off.

2. Using the supplied Bind plug (which looks like a standard receiver plug with a short wire loop installed), insert the Bind plug

into the receiver slot labeled BIND. When you look down on the receiver slots it is the slot furthest from the LED, and nearest

to the corner of the receiver.

Note: You do not need to remove any other plugs to rebind.

3. With the bind plug installed, turn on the vehicle. Notice the LED is now blinking.

4. You are now ready to turn on the transmitter. You should notice on the back of the transmitter a similar blinking LED

under a translucent cover.

5. Both the receiver and transmitter LEDs will stop blinking and be on solid, indicating that they have bound

themselves together.

6. Turn off the vehicle and then the transmitter.

7. Remove the bind plug from the receiver.

8. Turn on the transmitter and then the vehicle to ensure operation. If the transmitter does not control the vehicle,

please repeat steps 1-7 above. If after several attempts you are unsuccessful please call Horizon product support.

9. The bind process is complete. Your vehicle’s radio system is now ready for use.

Receiver Antenna

Using your fingers gently straighten the antenna wire to be close to vertical from the chassis for the best radio reception.

Factory Settings of Radio/ESC

The Electronic Speed Control was calibrated together with the radio system at the factory. When you turn on and run the Desert Truck

for the first time you may be required to slightly adjust the Throttle Trim. If the vehicle creeps in reverse or in forward just make a fine

adjust to the Throttle Trim knob on the transmitter. Sometimes during the bumps and bounces of transportation the settings can be

slightly altered.

14

Page 15

TM

Driving the Desert Truck

Please note the following precautions before running

your Desert Truck.

• The Electronics in this vehicle are not waterproof and you

must avoid running the vehicle in or through standing

water, wet grass, mud or snow.

• This vehicle is quick:

o Do not run the vehicle if it will be out of sight for any

amount of time.

o Do not drive your vehicle near a crowd of people.

• Perform a check of the vehicle before going out to run it.

o Ensure the tires are not coming off the rims.

o Generally check the vehicle for items such as a

loose wheel nut, or anything loose on the steering

assembly. The vibrations of running off-road tend to

loosen screws and nuts.

• The Desert Truck’s gearing choice from the factory IS NOT

meant for running the vehicle in tall grass.

• Be careful driving when the battery is nearly discharged or

the car is running slowly. You could lose enough power for

the receiver to shutdown and you may lose control.

• When driving the Desert Truck be cautious and use

common sense.

• If your vehicle gets caught or stuck do not pull the throttle

in either forward or reverse. This will overload the ESC

and/or motor resulting in damage to one or possibly both

and is not covered by your warranty.

• After running a battery pack, allow the electronics several

minutes to cool, before running the next battery pack.

How you drive your Desert Truck will also affect your run

times. If you are performing runs, going from a standstill to full

speed repeatedly, you are asking a lot from your batteries and

electronics. Hard acceleration draws a lot of current from any

battery and will lead to shortened run time.

If the bearings are dirty they will cause significant drag causing

reduced run times and speed.

To improve run times consider the following:

• Keep your vehicle clean and maintained.

• Allow more airflow to the heat sink of the MSC 12RB ESC.

• Change the gearing to a lower ratio, this will make the

electronics run cooler. This can be accomplished by using

a smaller pinion gear, or a larger spur gear than those

originally supplied. (The Desert Truck comes with a 16tooth pinion and an 88-tooth spur gear.)

• Change to battery packs of higher mAh rating.

• Is the charger you’re using the best at charging your

batteries? Check with your local hobby dealer.

Run time consideration for the Desert Truck vehicle.

The single largest factor in run time is the capacity mAh of

your battery pack. The larger the mAh rating the more run time

you will experience. On the same note, the longer you run, the

hotter the battery plugs can get. Please check the standard

plugs periodically.

For example: if you have a 4600mAh battery pack you can

expect close to twice the run time of a 2000mAh battery pack.

The condition of a battery pack is also an important factor in

both run time and speed. As batteries see more use they will

degrade in performance and capacity.

15

Page 16

TM

Tuning, Adjusting & Maintaining the Desert Truck

Periodically examine your Desert Truck for the following:

• Keep your vehicle clean using a brush to remove dirt

and dust.

• Look for cracks in the suspension arms and other

molded parts.

• Check that the tires are still glued to the wheels.

• Check that all the wheel bearings are clean and lubricated.

• Using your tools, attempt to tighten all the screws and

nuts.

• Verify that the Camber Links and Steering Linkage are

not bent.

• Check that the Toe and Camber settings are as desired

and equal.

• Remove the gear cover.

o Check the Spur gear for wear.

o Check the Pinion gear.

o Check the Slipper Pads for wear.

• Take the shocks off the vehicle and check, especially if they

appear to be leaking as it is time to rebuild them.

• Look over all the wiring and connections for bare wire or

any place which could lead to a short circuit.

• Verify that the ESC is securely mounted to the chassis.

• Verify the receiver is still securely mounted to the chassis.

• Turn on the radio and if the Green LED is off or dim replace

the 4 AA batteries in the transmitter.

After you become familiar with driving your Desert Truck,

you may need to reset or make adjustments for better

driving performance.

Just as in a real car, alignment is an important factor in your

vehicle’s handling. When you are ready to make adjustments

it is a good idea to have a flat work space to place your vehicle

on. This will enable you to easily and more quickly make both

Toe-in and Chamber adjustments. These adjustments should be

set with the vehicle sitting at its normal ride height.

Tuning the Front End of the Desert Truck

Shock Location: The Desert Truck has two mounting locations

on the front shock tower. The position can be easily adjusted

by simply moving the top of the shock to another hole. The

standard location (outside hole on the tower) works best on

most surfaces. Moving the top of the shock inward a hole will

slow steering response and make the Desert Truck smoother

in bumps. The standard position on the arm is in the middle,

which offers the best balance. Running the inside shock

location will give the Desert Truck more steering into the turn

and less steering on corner exit. Running the shock location

outside on the front arm will give you less overall steering

into the turn and keep the front end flatter through the turn,

making the Desert Truck smoother and easier to drive. This can

be used on high traction surfaces.

All of the Camber and Steering Linkages have been assembled

in the following way.

Using the supplied flat metal turn buckle wrench if you need

to SHORTEN any link on the Desert Truck rotate the wrench

towards the front of the vehicle (counter-clockwise). If you need

to LENGTHEN any link then rotate the wrench towards the rear

of the vehicle (clockwise).

Static Camber: This refers to the angle of the wheels/tires

relative to the surface (viewed from either the front or back).

Negative camber means that the top of the tire leans in toward

the chassis. Positive camber means the top of the tire leans out,

away from the chassis. Camber can be precisely measured with

after-market camber gauges, sold at a local hobby shop. It can

be measured (roughly) using any square (to the ground) object

by checking the gap between the square edge and the top of

the tire. Testing has shown that 1 degree of negative camber

is best for most track conditions. Increasing negative camber

(in the range of 1-2 degrees) will generally increase steering.

Decreasing negative camber (in the range of 0-1 degree) will

generally decrease steering and the Desert Truck will feel easier

to drive as a result. This is, most often, a very critical adjustment

in tuning your Desert Truck that can be made quickly and easily.

16

Page 17

TM

Inboard Camber Location: The Desert Truck has three

different inner locations with vertical adjustment for the front

camber tie rod. In general, the lower or further out the inside

position is, relative to the outside, the more camber gain (total

camber change through the total throw of the suspension) is

present. This is an adjustment that is difficult to make a generic

statement for as it can have slightly different results on various

conditions. The following is a summary of how this adjustment

will usually impact the handling of the Desert Truck. A longer

front camber link will usually make the Desert Truck feel stiffer.

This will help keep the Desert Truck flatter with less roll, but can

make the Desert Truck handle worse in bumpy conditions, it

also will make the Desert Truck easier to drive. A shorter front

camber link will result in more front end roll, which will provide

more steering on tighter turns with the loss of some stability.

You will also lose some high speed steering but might gain

some more steering response. Too short of a front link may

make the Desert Truck feel “twitchy” or “wandery” meaning that

it may be difficult to drive straight at high speed.

Inboard Camber Vertical Adjustment: Washers are often

used under the inner ball stud mounting location; this is one

of the most important adjustments on the Desert Truck. You

should get a feel for how the number of washers affects the

handling. Adding washers will make the Desert Truck more

stable and keep the front end flatter. This works well on higher

traction surfaces. Removing washers will make the steering

more aggressive, which works well on lower traction surfaces.

This can be good in some conditions, but can also make the

Desert Truck difficult to drive in others. The best all-around

adjustment is with three washers as the vehicle comes built.

The washers that are used are included in an assortment

package of washers (LOSA6350).

Outboard Camber Location: In addition to the inboard

camber location, the Desert Truck also provides three outboard

mounting options. The middle location is the most used as it

provides the best and most consistent handling on different

surfaces. The outer location also helps the Desert Truck stay

tighter in turns with a more precise steering feel. Moving the

link to the inner hole will make the steering react slightly slower

and steer smoother. The advantage to the inner hole is that it

can increase on-power steering and help the Desert Truck get

through bumps better.

Toe-In/Out: This is the parallel relationship of the front tires to

one another. Toe-in/out adjustments are made by changing

the overall length of the steering tie rods. Toe-in (the front

of the tires point inward, to a point in front of the front axle)

will make the Desert Truck react a little slower, but have more

steering from the middle of the turn, out. The opposite is true

with toe-out (the front of the tires point outward, coming to a

point behind the front axle), the Desert Truck will turn into the

corner better but with a decrease in steering from the middle of

the turn, out. Toe-in will help the Desert Truck to track better on

long, straight, high-speed runs, where toe-out has a tendency

to make the Desert Truck wander. We recommend to run

between 0-degree of toe-in/out to 1 degree of toe-in.

Bump-In/Out: Bump-out (front of the front tires toe-outward

under suspension compression) will result in more off-power

steering and less consistent handling if you have too much

bump-out. This effect is obtained by adding washers under

the steering spindle ball stud. Bump-in (front of the front tires

toe-inward under suspension compression) will result in less

off-power steering and running. Too much bump-in can make

the steering feel very inconsistent. This effect is obtained by

installing a ball stud washer on the bottom of the spindle.

Testing has shown that running a little bit of bump-in (kit

setup) in the Desert Truck offers the best overall setup.

Caster: This is the angle of the kingpin from vertical when

viewed from the side of the Desert Truck. The Desert Truck

comes equipped with 30-degree spindle carriers and a 30degree kick-up angle. Total caster is determined by adding

the amount of kick-up (Desert Truck has 30 degrees) and the

kingpin angle of the front spindle carriers. Increasing total

caster will provide more steering entering a turn but less on

exit. Decreasing total caster will cause the steering to react

faster and increase on-power steering.

17

Page 18

TM

Tuning the Rear End of the Desert Truck

Shock Location: Moving the shocks out on the arm will result

in less forward traction and let the Desert Truck make more of

an arc through the exit of the turn. In general, when changing

shock locations on the arm, it will be necessary to go down one

spring rate when moving out on the arm.

Static Camber: Having the same definition as for the front end

and measured in the same fashion, rear camber can also be a

critical tuning feature. Testing has shown that running a small

amount of negative camber (.5-1 degree) is best. Increasing

negative rear camber (in the range of 1.5-3 degrees) will

increase stability and traction in corners, but decrease high

speed stability. Decreasing rear camber (in the range of 0-1.5

degrees) will decrease stability and traction in corners, but will

increase high speed stability.

Inboard Camber Location: The Desert Truck has multiple rear

camber locations. Using a longer camber link will improve

stability and traction (grip). Using a shorter camber link will

increase steering while decreasing rear grip. Running the

camber link in the inside position on the shock tower will give

your Desert Truck more steering entering the turn as it will

let the Desert Truck set over the rear tire and give you more

forward traction exiting the turn. As you move the camber link

towards the outside of the Desert Truck, you will gain less initial

steering, however, you will gain more steering as the Desert

Truck exits the turn. The Desert Truck now has the capabilities

of a lower row of holes in the rear shock tower for the inner

camber link location. The lower hole gives the Desert Truck

more camber gain (more angle relative to arm = more camber

gain). This can be helpful when tracks get bumpy and rutted

to help the rear end of the Desert Truck go through the bumps

easier due to the increased camber gain of the tires.

Outboard Camber Location: Running the camber link in the

inside position on the hub will generate more rotation entering

a turn, but decrease steering on exit. Running the camber link

in the furthest outer position on the hub will generate more

stability entering a turn and increase steering on exit.

Toe-In: Having the same definition as for the front end, the

toe-in can be adjusted on the Desert Truck with the rear hubs.

The stock toe-in is 3 degrees of inboard per side and 0 degrees

in the hub. Increasing rear toe-in will increase forward traction

and initial steering, but reduce straightaway speed. Decreasing

rear toe-in will decrease forward traction and “free-up” the

Desert Truck. Less toe-in can be used to gain top speed.

Anti/Pro-Squat: Increasing anti-squat is generated by raising

the front of the pivot block, relative to the rear of the pivot.

This will increase initial steering and forward traction. You can

increase anti-squat in 1 degree increments by using two .030

washers between the front of the pivot plate and pivot block.

Pro-squat is generated by raising the rear of the pivot relative to

the front. This will decrease forward traction and initial steering,

but provide more on-power steering on high traction surfaces.

Pro-squat will also help the Desert Truck from pulling wheelies

on high bite surfaces. Also available is an aftermarket part that

is a 0 degree rear pivot block (LOSA2112), if pro-squat is desired

it is best to start with this option.

Tuning the Chassis of the Desert Truck

Slipper Adjustment: After fully tightening the adjustment

nut (so the coils of the spring just touch) loosen the slipper

adjustment nut 2 1/4 turns. This will be a good starting point for

your slipper settings.

Ride Height: This is the height of the chassis in relation to the

surface. It is an adjustment that affects the way your Desert

Truck jumps, turns and goes through bumps. To check the ride

height, drop one end (front or rear) of the Desert Truck from

about a 5-6 inch height onto a flat surface. Once the Desert

Truck settles into a position, check the height of that end of

the Desert Truck in relationship to the surface. To raise the ride

height, lower the shock collar on the shock evenly on the end

(front or rear) of the Desert Truck that you are working on. To

lower the ride height, raise the shock collar. Both left and right

nuts should be adjusted evenly.

Every driver likes a little different feel so you should try small

ride height adjustments to obtain the feel you like. This should

be one of the last adjustments after everything else has been

dialed in (tuned). Do not use ride height adjustment as a

substitute for a change in spring rate. If your Desert Truck needs

a softer or firmer spring, change the spring. Do not think that

simply moving the shock collars will change the stiffness of the

spring; it will not.

18

Page 19

TM

Battery Position: This is a critical adjustment that is often

Spur Gear Size

Pinion Gear Size

X 2.43 = Final Drive Ratio

overlooked but can be very useful. Start by running the battery

spaced in the middle (standard setup with 6-cell battery pack).

Moving the battery back can improve rear traction on slippery

surfaces and steering response. Moving the battery back too

far can cause the rear end to swing through turns on some

tracks and “dump” the rear end causing instability issues. This

is a result of having the weight too far back. The Desert Truck

comes equipped with two foam battery spacers to split the

difference when adjusting the battery position, hence offering

a middle position when either extreme is inadequate.

Camber Rise Relationship: The Desert Truck setup out of the

box comes with less front camber gain than the rear camber

gain. The reason for this is that less front camber lets the front

end drive flatter and makes the Desert Truck more stable. By

having more camber gain in the rear, the Desert Truck has more

rear traction, this helps the rear tires accelerate through the

bumps and ruts.

Wheels and Tires

The tires come pre-mounted with the vehicle and should be

checked to make certain they stay glued to the wheels. The

wheel spinning speeds can pull the rubber tire away from the

rim. When a tire or tires come loose from the rim you will notice

the vehicle is hard to control.

Tip the vehicle on its side and using both hands to hold one

wheel at a time, use your thumb to press the tire away from

the rim. If you see a tire pull away for the rim use Losi Tire Glue

(LOSA7880 thick or LOSA7881 thin) to re-glue. It only takes a

small drop of glue generally. Be careful this is CA-type glue and

you do not want to glue your fingers to the wheel and tire.

Use safety goggles when gluing tires.

Check the mounting of the tire periodically to ensure proper

performance and handling.

Steering Assembly: Occasionally, check the steering assembly

and you may notice increased looseness. There are several

components which will wear out from use: tie rod ends

(part LOSA6074), the servo saver (part LOSA1610), the bell

crank bushings (part LOSA1620), and the Drag link ball ends

(LOSA6074). You can easily replace these components to restore

factory specifications.

Note: The bell crank bushings may be replaced with

ball bearings (part LOSA6912).

Adjusting Gear Mesh

Incorrect gear mesh is the most common cause of stripped spur

gears. To set the gear mesh, one method is to cut a narrow strip

of notebook paper and thread it in between the gears. Loosen

the motor screws and slide the motor and pinion gear into the

spur gear. Retighten the motor screws and then remove the

strip of paper. Or you can loosen the motor and carefully slide

the motor leaving a small amount of backlash (play) between

the spur and pinion gears. It should not be tight and if you look

up-close there should be slight movement of the spur before

contacting the teeth on the pinion gear.

Gear Ratio

Changing the gearing provides you a quick and easy way

to tune the Desert Truck. Use the temperatures of both the

motor and your battery pack as a guide to gearing to your

environment. When the Motor is above 160-170 degrees

Fahrenheit or the batteries are above 125-135 degrees

Fahrenheit, these are both strong indications that you should

drop the pinion size smaller. This would be a lower gear ratio

or larger number, for example from 11.25 to 12.40. Going up

a pinion size is called gearing higher or a small number, for

example 11.25 to 10.6, and will increase power consumption

and allow more speed.

Use the following formula to calculate the overall ratio for

combinations not listed on the gear chart:

When using higher gear ratios, it is extremely important to

monitor the temperatures of the battery and motor. If the

battery is extremely hot, and/or the motor is so hot that you

cannot touch it, most likely you are over-geared and drawing a

lot of current.

The gear combination that comes on the Desert Truck (16-tooth

pinion / 88-tooth Spur) provides high-speed running intended

for hard surfaces, and this gearing is not recommended for

off-road, running in grass or constant starting and stopping.

Storage

When you are through running the model for the day

• Blow it off with compressed air or use a soft bristled paint

brush to dust-off the vehicle.

• Always disconnect and remove the battery from the

model whenever the model is stored. If the model will

be stored for a long time, then also remove the batteries

from the transmitter.

19

Page 20

TM

Troubleshooting your Desert Truck

Many questions are the result of simple user errors or minor

adjustments which are easily addressed. If after reading below

you cannot resolve your problem, then please call Horizon

Customer Service at 1-877-504-0233.

Vehicle runs slowly/slow acceleration:

Check the battery connectors.

Confirm that battery is charged.

Vehicle will not reverse:

Make sure the throttle trim is at neutral.

Radio system does not work properly:

If the power light on the transmitter is not turning on, first

ensure the batteries are installed correctly. You should also

check that the batteries are good and/or if rechargeable are

fully charged. Replace them if needed. If the power light is

blinking, then the transmitter batteries are weak and should

be replaced. If the transmitter light is on but the radio is still

not responding, you may need to rebind the transmitter to the

receiver. Please see page 14

Short radio range:

If the radio range appears short, make sure the batteries are all

fully charged and/or are in good condition.

Steering works but the motor will not run:

The speed control may have gotten too hot and thermally

shut down. Allow time for the speed control to cool. If this is

the problem and has happened a few times, consider using a

smaller pinion or a larger spur gear.

Check the transmission, do the rear wheels spin easily?

Check that a motor wire has not come loose.

Verify that the electronic speed control is plugged into the

throttle channel of the receiver.

Recalibrate/Setup the ESC (see page 9).

Check to see if the ESC is in Forward only mode that does not

have reverse active.

Keep stripping spur gears:

Improper gear mesh, refer to page 19.

Improperly adjusted slipper, refer to page 18.

Check using another battery. Contact Horizon support for

service instructions.

Steering servo does not work:

Check all wires, radio system, battery connectors, and the

battery pack.

Contact Horizon support for service instructions.

Motor runs backwards:

The Black wire lead from the motor should be connected to the

Black wire lead from the ESC and the same for the Red wires.

If not, please correct by swapping the wires. If you are still

experiencing problems please contact Horizon support.

Motor starts running immediately after the battery has

been connected.

There may be internal ESC damage. Contact Horizon

Customer Support.

20

Page 21

TM

Warranty Information

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc., (Horizon) warranties

that the Products purchased (the “Product”) will be free from

defects in materials and workmanship at the date of purchase

by the Purchaser.

If you as the Purchaser or user are not prepared to accept

the liability associated with the use of this Product, you are

advised to return this Product immediately in new and unused

condition to the place of purchase.

Law: These Terms are governed by Illinois law (without regard

to conflict of law principals).

Limited Warranty

(a) This warranty is limited to the original Purchaser

(“Purchaser”) and is not transferable. REPAIR OR REPLACEMENT

AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE

REMEDY OF THE PURCHASER. This warranty covers only those

Products purchased from an authorized Horizon dealer. Third

party transactions are not covered by this warranty. Proof

of purchase is required for warranty claims. Further, Horizon

reserves the right to change or modify this warranty without

notice and disclaims all other warranties, express or implied.

(b) Limitations- HORIZON MAKES NO WARRANTY OR

REPRESENTATION, EXPRESS OR IMPLIED, ABOUT NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT

THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF

THE PURCHASER’S INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation hereunder shall

be that Horizon will, at its option, (i) repair or (ii) replace, any

Product determined by Horizon to be defective. In the event of

a defect, these are the Purchaser’s exclusive remedies. Horizon

reserves the right to inspect any and all equipment involved

in a warranty claim. Repair or replacement decisions are at

the sole discretion of Horizon. This warranty does not cover

cosmetic damage or damage due to acts of God, accident,

misuse, abuse, negligence, commercial use, or modification

of or to any part of the Product. This warranty does not cover

damage due to improper installation, operation, maintenance,

or attempted repair by anyone other than Horizon. Return

of any goods by Purchaser must be approved in writing by

Horizon before shipment.

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT

OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR

PRODUCTION OR COMMERCIAL LOSS IN ANY WAY CONNECTED

WITH THE PRODUCT, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

Further, in no event shall the liability of Horizon exceed the

individual price of the Product on which liability is asserted.

As Horizon has no control over use, setup, final assembly,

modification or misuse, no liability shall be assumed nor

accepted for any resulting damage or injury. By the act of use,

setup or assembly, the user accepts all resulting liability.

Safety Precautions

This is a sophisticated hobby Product and not a toy. It

must be operated with caution and common sense and

requires some basic mechanical ability. Failure to operate

this Product in a safe and responsible manner could result

in injury or damage to the Product or other property. This

Product is not intended for use by children without direct adult

supervision. The Product manual contains instructions for

safety, operation and maintenance. It is essential to read and

follow all the instructions and warnings in the manual, prior to

assembly, setup or use, in order to operate correctly and avoid

damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of purchase cannot provide

warranty support or repair. Once assembly, setup or use of the

Product has been started, you must contact Horizon directly.

This will enable Horizon to better answer your questions and

service you in the event that you may need any assistance.

For questions or assistance, please direct your email to

productsupport@horizonhobby.com, or call 877.504.0233 toll

free to speak to a service technician.

Inspection or Repairs

If this Product needs to be inspected or repaired, please call

for a Return Merchandise Authorization (RMA). Pack the

Product securely using a shipping carton. Please note that

original boxes may be included, but are not designed to

withstand the rigors of shipping without additional protection.

Ship via a carrier that provides tracking and insurance for

lost or damaged parcels, as Horizon is not responsible for

merchandise until it arrives and is accepted at our facility. A

Service Repair Request is available at www.horizonhobby.com

on the “Support” tab. If you do not have internet access, please

include a letter with your complete name, street address, email

address and phone number where you can be reached during

business days, your RMA number, a list of the included items,

method of payment for any non-warranty expenses and a brief

summary of the problem. Your original sales receipt must also

be included for warranty consideration. Be sure your name,

address, and RMA number are clearly written on the outside of

the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must include your original

sales receipt verifying the proof-of-purchase date. Provided

warranty conditions have been met, your Product will be

repaired or replaced free of charge. Repair or replacement

decisions are at the sole discretion of Horizon Hobby.

21

Page 22

TM

Non-Warranty Repairs

Should your repair not be covered by warranty the repair

will be completed and payment will be required without

notification or estimate of the expense unless the expense

exceeds 50% of the retail purchase cost. By submitting

the item for repair you are agreeing to payment of the repair

without notification. Repair estimates are available upon

request. You must include this request with your repair. Nonwarranty repair estimates will be billed a minimum of ½

hour of labor. In addition you will be billed for return freight.

Please advise us of your preferred method of payment.

Horizon accepts money orders and cashiers checks, as well

as Visa, MasterCard, American Express, and Discover cards. If

you choose to pay by credit card, please include your credit

card number and expiration date. Any repair left unpaid or

unclaimed after 90 days will be considered abandoned and will

be disposed of accordingly. Please note: non-warranty repair

is only available on electronics and model engines.

Electronics requiring inspection or repair should be shipped to

the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other Products requiring warranty inspection or repair

should be shipped to the following address:

Horizon Product Support

4105 Fieldstone Road

Champaign, Illinois 61822

RC Terminology

BEC (Battery Elimination Circuit) – The BEC is used to eliminate

the need for a receiver pack to power the radio system. On

most electric vehicles this is located in the electronic speed

control (ESC), but can also be a stand-alone device.

BIND Process – Programming a receiver to recognize the GUID

code of only one specific transmitter or transmitter module.

Calibration – Also called ESC setup. It is the process used to

match the transmitter throttle, brake and neutral to the ESC.

Current – Refers to the power flow from the battery to the ESC

and Motor when used in the RC vehicle environment. Typically

this is measured in Ampere or Amp.

Deadband – This refers to the amount of travel (movement) on

the transmitter trigger before the vehicle is requesting the ESC

to move the vehicle forward or backwards. It is an advanced

adjustment used by experienced drivers.

DSM – (Digital Spectrum Modulation) – The 2.4GHz technology

of Spektrum radios.

ESC (Electronic Speed Control) – The ESC is what translates

the signals past from the transmitter trigger through the

receiver into commands that reach the motor to signal

forward or reverse, acceleration or braking. The Xcelorin

system is an advanced electronic speed controller that is

very efficient in passing precise requests to the brushless

motor. The BEC is also controlled by the ESC along with the

Low Voltage Protection circuit.

GUID – Globally Unique Identification Code. Each

individual module or radio is factory programmed with

its own unique serial code. In the binding process, the

receiver is programmed to only recognize the GUID code

of one specific radio or module.

Please call 877-504-0233 with any questions or concerns

regarding this product or warranty.

Instructions for Disposal

of WEEE by Users in the European Union

This product must not be disposed of with other waste.

Instead, it is the user’s responsibility to dispose of their waste

equipment by handing it over to a designated collection point

for the recycling of waste electrical and electronic equipment.

The separate collection and recycling of your waste equipment

at the time of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that protects human

health and the environment. For more information about where

you can drop off your waste equipment for recycling, please

contact your local city office, your household waste disposal

service or where you purchased the product.

LiPo – A Lithium Polymer battery’s abbreviation indicating

the chemistry used in these rechargeable batteries. These

batteries require special attention by the user and are only

recommended for the most experienced of users.

mAh – The Milliampere Hour abbreviation, which represents

the capacity of a battery pack. The higher this rating the longer

the run time of each charge.

Neutral Position – Referring to the Transmitter when at rest,

meaning the throttle trigger and steering have no input. When

you turn the transmitter on, set it to the side while turning the

car on, the transmitter will be in a Neutral state.

NiMH – The abbreviation for nickel-metal hydride rechargeable

batteries. These have replaced the use of NiCd batteries as the

battery of choice in RC vehicles.

22

Page 23

TM

Profiles – The MSC 12RB has two (2) preset profiles. Forward

Only and Forward and Reverse profile. The Forward only profile

can be selected for racing purposes. The Forward/Reverse

profile is great for running in your neighborhood.

Receiver – A device mounted into the vehicle that receives and

decodes a signal sent by a transmitter. Servos, ESC and other

devices are plugged into the receiver.

Resistance – As used here refers to the power loss from the

battery to the ESC and Motor. Typically this is measured in

Ampere or Amp. Too much resistance between the battery, ESC

and motor can result in low performance and run time.

Servo – An electronic device connected to the receiver used to

actuate steering control of the vehicle.

Spektrum – The technology brand of 2.4GHz radio system

supplied with the Desert-T. The use of this technology

eliminates the concern of conflicting frequencies found with

older legacy radio systems. It further reduces to a minimum

potential radio interference common with the legacy radio

systems of the past.

Transmitter – Is the device held in your hand that relays

steering and throttle/brake requests made to the receiver.

Trim – This is a setting used on the transmitter to make

fine adjustments to the steering or throttle/brake trigger.

For steering you would use the trim to make the adjustment

for the vehicle to drive straight without adding steering input

to the transmitter.

Thermal Shutdown – Refers to the ESC operating

temperature. The MSC 12RB ESC monitors its internal

temperature and will automatically prevent the ESC from

delivering power to the motor, preventing damage due to

overheating the ESC’s electronics.

23

Page 24

TM

Replacement Parts List

Part Number Description Price

LOSA1022 Front Axles for XX-T Wheels (GTX, NXT, XXX-T) ..................................................................................

$6.00

LOSA1113 Front Shock Tower (Desert Truck) ........................................................................................................... $5.99

LOSA1118 Front Suspension Arms (Desert Truck) .................................................................................................

$7.99

LOSA1146 Front Outer & Kingpins 3/32” (XX, ‘CR’, XXX, XXX-T) .........................................................................$3.00

LOSA1150 Front Outer Hinge Pin (XXX-T) .................................................................................................................$3.50

LOSA1610 Steering Hardware Set ...............................................................................................................................$3.50

LOSA1615 Short Ball Cups and Threaded Rod ........................................................................................................$2.75

LOSA1620 Steering/Servo Mount Assembly (XXX, XXX-T) .................................................................................$6.00

LOSA2006 Swivel Suspension Balls .250” (8) ............................................................................................................$4.00

LOSA2007 Hinge Pin 1.42” (XXT, XXX, XXX-T) ...........................................................................................................$3.00

LOSA2105 Rear Shock Tower (Desert Truck) ............................................................................................................$5.99

LOSA2108 Rear Pivot Plate (XXX, XXX-T) ...................................................................................................................

$4.00

LOSA2143 Rear Suspension Arms (Desert Truck) ...................................................................................................$8.50

LOSA2164 1/8” Upper Bulkhead / Outer Rear Hinge Pin (2) ............................................................................... $3.00

LOSA2166 Inner Rear Hinge Pins (XXX, XXX-T) .......................................................................................................$3.00

LOSA2919 Desert Truck Transmission Case (Gear Diff only) ................................................................................ $5.99

LOSA2930 Desert Truck Complete Diff Set ............................................................................................................. $15.99

LOSA2931 Desert Truck Diff Gear Housing ................................................................................................................ $4.99

LOSA2934 Deset Truck Steel Outdrives w/Pins (2) ..................................................................................................$6.99

LOSA2942 Motor Plate and Front Pin Brace (Desert Truck) ................................................................................$8.99

LOSA2960 RCVD Set Axle, Dog Bone Hdw ............................................................................................................ $19.99

LOSA3042 Gear Cover with Access Plug (Desert Truck, XXX-T CR) ...................................................................$5.00

LOSA3060 Slipper Shaft, Spacer & Hardware ........................................................................................................... $5.50

LOSA3066 Teflon™ Assembly Lube .............................................................................................................................. $2.50

LOSA3075 Transmission Upper Gear, Idler, Shaft ...................................................................................................$6.00

LOSA3079 Idler Gear (2.19:1 and 2.43:1) ...................................................................................................................$3.50

LOSA3123 Slipper Pad ......................................................................................................................................................$3.00

LOSA3124 Slipper Spring, Cup, Spacer, Bushing, and Washer ...........................................................................$3.00

LOSA3132 Slipper Backing Plate ..................................................................................................................................$6.00

LOSA3928 88T 48-Pitch Spur Gear ............................................................................................................................... $3.50

LOSA4004 Servo Tape (6) ................................................................................................................................................$1.75

LOSA4015 Foam Battery Block .......................................................................................................................................$7.99

LOSA4060 Desert Truck Front Bumper & Skid Plate ...............................................................................................$7.99

LOSA4061 Desert Truck Roll Cage Set ...................................................................................................................... $13.99

LOS4116 48 Pitch Pinion Gear, 16T ............................................................................................................................ $5.99

LOSA4109 Main Chassis and Brace (XXX-T CR,Speed-T, Desert-T) ................................................................. $24.99

LOSA4112 Desert Truck Front & Rear Body Mount Set..........................................................................................$2.99

LOSA4122 Front Kickplate, Bulkhead, and Steering Brace(XXX,T) ...................................................................$9.00

LOSA4125 Front Spindles/Carriers, and Rear Hubs (XXX-T) ................................................................................$7.50

LOSA4126 Front and Rear Pivot Block Set (XXX, XXX-T) .......................................................................................$6.00

LOSA4132 Front Bumper, Motor Guard (Speed T, Desert -T) ..............................................................................$6.99

LOSA4136 Front and Rear Inner Pin Brace Set (XXX, XXX-T) ...............................................................................$3.00

LOSA4170 Battery Strap, Pad, and Foam Block (XXX-TCR-Desert Truck) ........................................................$4.49

LOSA4136 Front and Rear Inner Pin Brace Set (XXX, XXX-T) ...............................................................................$3.00

LOSA4170 Battery Strap, Pad, and Foam Block (XXX-TCR-Desert Truck) ........................................................$4.49

LOSA4224 Threaded Chassis Inserts - Short and Long ........................................................................................$6.50

LOSA5015 Double O-Ring Shock Cartridge .............................................................................................................$2.00

LOSA5023 Spring Clamps & Cups (2) ..........................................................................................................................$2.50

LOSA5026 Desert Truck Blue Aluminum Shock Body (2).................................................................................. $11.99

LOSA5045 Shock Pistons #56 (Red) (4) .......................................................................................................................$3.00

24

Page 25

TM

Part Number Description Price

LOSA5047 Shock Pistons #55 (Orange) (4) ...............................................................................................................

$3.00

LOSA5156 2.5” Spring 3.4 Rate Rear (Silver) .............................................................................................................$2.50

LOSA5224 Team Losi Certified Shock Fluid 30 wt Front .......................................................................................$3.50

LOSA6001 Ball Studs w/Rod Ends 4-40 x 3/16” (4) .................................................................................................$3.50

LOSA6020 H.D. 30-degree Plastic Rod Ends (Sport)(12) ......................................................................................$4.50

LOSA6030 Assembly Wrench (version 2) ...................................................................................................................$1.50

LOSA6044 H.D. Rod Ends & Balls: Desert-T, Speed-T 8B, 8T .................................................................................$6.99

LOSA6074 Adjustable L/R Turnbuckle Set (6) (Speed-T, Desert-T) ....................................................................$9.99

LOSA6100 1/8” E-Clips ......................................................................................................................................................$1.25

LOSA6102 C-clips, .1875” - Large (12) .........................................................................................................................$1.75

LOSA6201 3mm x 8mm Cap-Head w/Washers (10) ..............................................................................................$3.00

LOSA6204 4-40 x 1/2” Cap-Head Screws (10) ..........................................................................................................$1.50

LOSA6206 4-40 x 3/8” Cap-Head screws (10) ........................................................................................................... $1.50

LOSA6210 4-40 x 3/8” Flat-Head Screws (10) ........................................................................................................... $1.50

LOSA6215 #4 Narrow Washers (10) .............................................................................................................................$1.25

LOSA6216 4-40 x 7/8” Cap-Head Screws (10) ..........................................................................................................$1.50

LOSA6229 4-40 x 3/8” Button-Head Screws (10) ..................................................................................................... $2.00

LOSA6230 Shim Assortment - 3/16”, 1/4”, 1/2” (20) ................................................................................................$2.50

LOSA6233 4-40 x 5/8” Flat-Head Screws (10) ........................................................................................................... $2.50

LOSA6300 4-40 Hex Nuts (10) ........................................................................................................................................$1.00

LOSA6303 10-32 Locknuts (4ea Nylon & Steel) (8) .................................................................................................$1.50

LOSA6305 4-40 Aluminum Locknuts, Low Profile (10) .........................................................................................$3.50

LOSA6306 4-40 Aluminum Mini Nuts (10) ................................................................................................................$3.50

LOSA6350 #4 and 1/8” Hardened Washers ...............................................................................................................$2.50

LOSA6401 1/16” Pins for Wheels and Gears .............................................................................................................$1.25

LOSA6903 3/16” x 3/8” Teflon™-Sealed Bearings (2) .............................................................................................. $5.50

LOSA6908 1/2” x 3/4” Ball Bearings w/Teflon Seal (2) ........................................................................................ $14.25

LOSA6909 1/8” x 3/8” Ball Bearings (‘XX’ Trans) (2) ................................................................................................. $6.00

LOSA7007 Desert Truck Chrome Front Wheels w/spacer(pr) ..............................................................................$8.99

LOSA7107 Desert Truck Chrome Rear Wheels (pr) ..................................................................................................$8.99

LOSA7679B Desert Truck A/T Tires (Blue) w/Foam ................................................................................................. $19.99

LOSA9941 Bearing Spacer/Wheel Washer ................................................................................................................$9.95

LOSA17679B Desert Truck A/T Tires (Blue) mounted on Front Wheels ............................................................. $28.99

LOSA27679B Desert Truck A/T Tires (Blue) mounted on Rear Wheels ............................................................... $28.99

LOSB8057 Desert Truck Painted Body w/Stickers (Black) .................................................................................. $38.99

LOSB8058 Desert Truck Painted Body w/Stickers (Burgundy) ........................................................................ $38.99

LOSB8059 Desert Truck Painted Body w/Stickers (White) ................................................................................ $38.99

LOSB8060 Desert Truck Painted Body w/Stickers (Blue) ................................................................................... $38.99

LOSB8061 Desert Truck Clear Body w/Stickers ..................................................................................................... $28.99

LOSB9998 Desert Truck LED Light set ...................................................................................................................... $18.99

LOSB9999 1/10th LM-32K Motor ............................................................................................................................... $19.99

25

Page 26

TM

Optional Parts for the Desert Truck

Part Number Description Price

LOSA2961 CVD Rebuild Kit: Desert Truck ...................................................................................................................

$5.99

LOSA3065 Silicone Differential Compound (Optional) ......................................................................................... $2.50

LOSA3927 90-Tooth, 48-Pitch Spur Gear for Double-Disk Slipper ...................................................................$3.50

LOSA3929 86-Tooth, 48-Pitch Spur Gear for Double-Disk Slipper ...................................................................$3.50

LOSA3930 84-Tooth, 48-Pitch Spur Gear for Double-Disk Slipper ...................................................................$3.50

LOSA3932 78-Tooth, 48-Pitch Spur Gear for Double-Disk Slipper ...................................................................$3.50

LOSA3933 76-Tooth, 48-Pitch Spur Gear for Double-Disk Slipper ...................................................................$3.50

LOSA4060C Desert Truck Chrome Front Bumper & Skid Plate ........................................................................... $11.99

LOSA4061C Desert Truck Chrome Roll Cage Set ..................................................................................................... $17.99

LOS4112 48 Pitch Pinion Gear,12T .............................................................................................................................$4.00

LOS4113 48 Pitch Pinion Gear,13T .............................................................................................................................$4.00

LOS4114 48 Pitch Pinion Gear,14T .............................................................................................................................$4.00

LOS4115 48 Pitch Pinion Gear,15T .............................................................................................................................$4.00

LOS4117 48 Pitch Pinion Gear,17T .............................................................................................................................$4.00

LOS4118 48 Pitch Pinion Gear,18T .............................................................................................................................$4.00

LOS4119 48 Pitch Pinion Gear,19T .............................................................................................................................$4.00

LOS4120 48 Pitch Pinion Gear,20T .............................................................................................................................$4.00

LOS4121 48 Pitch Pinion Gear,21T .............................................................................................................................$4.00

LOSA5062 1.2” Titanium Nitride Shock Shaft ...........................................................................................................$7.00

LOSA6912 3/32” x 3/16” Bearings for Steering (XX, XXT, XXX,T) ..................................................................... $19.95

LOSA7058 320 Series Spokez Chrome Wheel, Front (2) .................................................................................... $10.99

LOSA7158 320 Series Spokez Chrome Wheel, Rear (2) ...................................................................................... $10.99

LOSA7684B 320 Series Road Weapon Tires, Fr/R Blue (2) .................................................................................... $17.99

LOSA7684V 320 Series Road Weapon Tires, Fr/R Violet (2) ................................................................................. $17.99

LOSA9713 Graphite Kickplate, Bulkhead, & Steering Brace ............................................................................ $16.00

LOSA9831 Graphite/Composite Rear Pivot Plate (XXX, XXX-T) .........................................................................$6.50