Page 1

Removing The Front Differential - continued

Remove the 5-40 shock screws from the suspension arms. (fig. 3) Loosen the 5-40 set screws on the sway bar ball

ends. Remove the two 5-40 flathead screws from the front of the diff cover (fig. 4), and remove the two 5-40

caphead screws from the bottom of the diff cover. Slide the diff cover off of the bulkhead and remove the diff. (fig. 5)

3

Removing The Rear Differential

To remove the rear differential, the “rear clip” of your 8IGHT RTR has to be removed. Remove four 8-32 flathead screws from

the chassis and the 5-40 flathead screw from the brace (fig. 6). Lift the rear clip up and off of the chassis (fig. 7).

6

Loosen the 5-40 setscrews on the sway bar ball ends and remove the ball ends from the sway bar. Remove four 5-40

flathead screws from the rear clip (fig. 8). Slide the pivot support and rear diff cover off of the bulkhead and remove

the diff (fig. 9).

4

7

5

8

Removing The Center Differential

To remove the center differential, the radio tray on your 8IGHT RTR has to be removed.

• Turn on the transmitter and receiver.

• Note the position of the throttle and steering servo horns. This is important so you know where

to position the servo horns during re-assembly.

• Remove the 3mm Phillips head machine screw, (fine threads), from the steering servo and the 3mm self

tapping screw, (coarse threads), from the throttle servo, (fig.10). Remove the servo horns leaving the

inserts on the servos. Turn the transmitter and receiver off.

• Remove the four 8-32 x 3/8” flathead screws from the radio tray, (fig. 11).

Front

10

11

Page 6

9

Page 2

Removing The Center Differential - continued

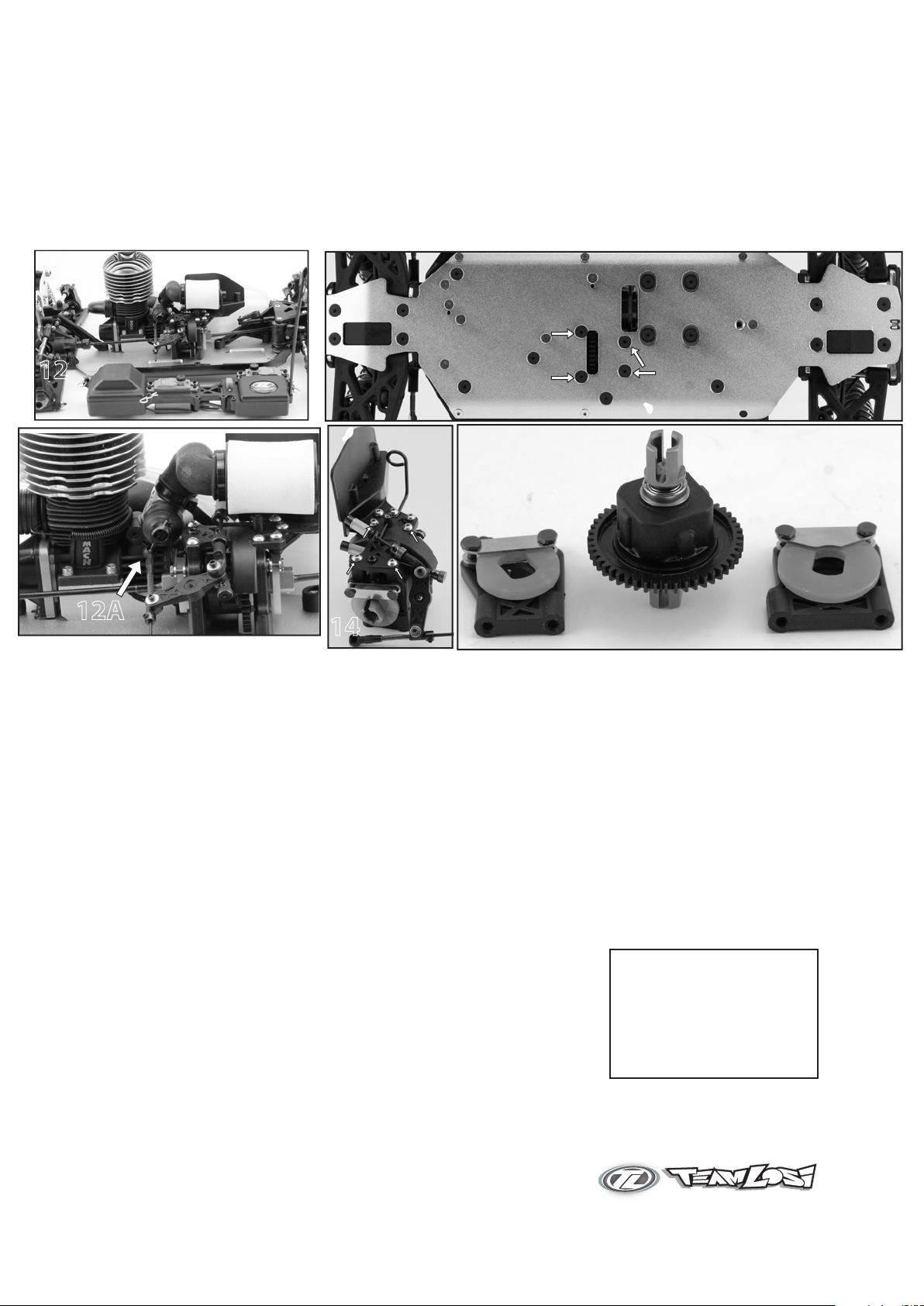

• Remove the radio tray from the chassis, (fig. 12).

• Pop the ball end off of the carburetor slide, fig. (12A)

• Remove four 8-32 x 1/2” flathead screws from the center differential housing, (fig. 13), and remove the

center diff from the chassis.

• Remove four 5-50 x 3/8” button head screws from the center top brace, (fig. 14).

• Slide the front and rear brake rotor assemblies off of the center diff, (fig. 15). NOTE: There are two

different size brake discs. The large disc is in the front brake assembly and the small disc is in the rear

brake assembly.

13

12

13

12A

14

Diff Service - Refer to exploded views on page 8.

• Remove the four 3mm flat head screws from the ring gear allowing it to be removed (use the 5/64 allen wrench).

• Inspect the ring and pinion gears for wear - replace if necessary.

• Remove the cross shafts and bevel gears from the carrier.

• Clean and inspect all parts - replace as needed.

• Check all ball bearings. Clean or replace as necessary.

• Lube all shafts and gears with LOSA3066 assembly grease and reassemble.

• Load cross shafts with gears into the carrier with extra grease. Apply the diff

seal gasket to the carrier and reinstall ring gear.

• Lube ring and pinion and with grease (LOSA #3066), and reassemble diff into diff housing.

• Grease the edges of the gear cases. This will ensure a dust free seal.

• Reinstall into chassis

For Viscous Differential

Instead of grease you can use Silicone fluid in the differential for a limited

slip feel as desired for racing. Simply fill the diff up to the top of the gears

before replacing the ring gear. (Be sure to reinstall the rubber gasket).

You may have to replace the o-rings on the outdrives at the same time

you change to this type of differential if the old ones are worn. Team Losi

recommends 5000cs. fluid for the front diff, 7000cs. fluid for the center diff,

and 2000cs. fluid for the read diff.

15

TEAM LOSI

SILICONE DIFF FLUID

A5278 - 2000 cs.

A5280 - 5000 cs.

A5281 - 7000 cs.

Page 7

Page 3

Front, Rear and Center Differential Exploded Views

1

2

3

4

1

2

3

4

Center DifferentialFront & Rear Differentials

Fill with 5000cs. oil (front) or

2000cs. oil (rear) just above the

planetary gear.

Fill with 7000cs. oil just

above the planetary

gear.

Tighten the diff screws

in this order

Tighten the diff screws

in this order

Page 8

Page 4

Clean the 2-56 x 1/4” button head screw and apply loctite to the threads.

Install the #55 shock piston using the 2-56 x 1/4” button screw into the shock shaft with a .050” allen wrench.

Place a drop of Shock Oil into the bottom of the Shock Body to lubricate the Shock Seals.

Thread the shock shaft into the shock end using pliers. Use caution when threading the shock shaft ends onto the shafts. Avoid gouging or scratching the shock

shaft while gripping the shock shaft with pliers by placing the edge of a towel over the shaft, then gripping the portion of the shaft covered by the towel. This method

will work very well to protect the shock shafts from damage.

Ensure the shaft is fully extended when filling the shock.

Fill the shock body with 35wt. shock oil until the oil is to the top of the body.

“Work” the shock shaft up and down a few times. This will release the air bubbles trapped beneath the piston. Place the filled shock, in the upright position, off to the side

for a few minutes until the air bubbles escape from the oil.

Once all the air bubbles are out of the oil, gently place the shock bladder onto the shock as shown. Some oil should “bleed” from the shock.

Screw the shock cap onto the body until some resistance is felt.

Slowly push the shock shaft up. This will bleed excess oil from the shock.

Tighten the cap all the way down using the shock tools included in your kit.

Move the shock shaft up and down. The shaft should be easy to push up into the body of the shock. If increased pressure is felt towards the top, there is to much oil in

the shock. Loosen the shock cap and “bleed” the shock as done previously.

Make sure each pair (front/rear) shocks have the same rebound and compression. This is checked by holding one shock in each hand horizontally and pushing them

together by the shock end. Watch carefully to ensure that both compress evenly. Now release both shocks and again watch carefully as they should rebound the same.

•

•

•

•

•

•

•

•

•

•

•

•

•

Rebuilding/Refilling the Shocks

Rebuilding/Refilling the Shocks

x2 x2

x 1

2-56 x 1/4”

Front

Rear

Page 9

Page 5

Quick Reference Guide

Quick Reference Guide

Initial Factory Settings

Initial Factory Settings

Engine

x 4

x2.5

Hi-Speed Needle - 4 turns out Low-Speed Needle 2.5 turns out

Shocks

Camber Links

4.07"

103.4mm

Rear Camber Link

Front Camber Link

3.72"

94.50mm

Steering Tie Rods

92.00mm

x5

3.62"

Team Losi 35wt

Shock Oil

(LOSA5225)

Page 10

Page 6

Losi 427 Customer Support

Horizon Hobby Inc

4105 Fieldstone Rd.

Champaign, IL 61821

1-877-504-0233

Trouble shooting Chart

Trouble shooting Chart

Problem Things To Check Remedy

Engine won't start.................................. Out of fuel

Spoiled or improper fuel

Glow plug not lighting

Glow igniter not charged

Engine overheating

Engine flooded

Air cleaner blocked

Exhaust blocked

Losi 427 Customer Support

Horizon Hobby Inc

4105 Fieldstone Rd.

Champaign, IL 61821

1-877-504-0233

Check/Replace Glow plug

Charge/change battery

Let cool - see "Testing the Teperature

Clean & reoil aircleaner

Engine won't turn over......................... Engine is flooded

Engine seized

Engine starts then stalls....................... Idle speed set too low

Glow plug is fouled/weak

Air bubbles in fuel line

Engine is overheated

Insufficient fuel tank pressure/blockage

Engine performing poorly.................. Hi-Speed fuel mixture is too rich

Engine overheating

Leaking glow plug

Carburetor dirty or blocked

Fuel bad or contaminated

Clutch slipping

Bound up drive-train

Engine worn out

Engine overheats................................... Hi-Speed fuel mixture is too lean

Low-Speed fuel mixture too lean

Spoiled or improper fuel

Cooling air is being blocked

Excessive load on the engine

Engine hesitates or stumbles............. Engine overheated

Hi-Speed mixture too lean

Low-Speed mixture to rich

Air bubbles in fuel line

Glow plug fouled

See "About Glow Plugs"

See "Engine Tuning"

See "About Glow Plugs"

Check for split/hole in fuel line

See "Testing the Temperature"

Clear pressure line

See "Engine Tuning"

Replace glow plug

Try fresh fuel

Clean/Adjust/Repair

Check for binds in drive-train

Rebuild

See "Understanding Rich and Lean

Clean head fins

Check for binds

See "Engine Tuning"

Check fuel line for holes

Change glow plug

Engine stalls instantly when throttle

is fully opened from idle...................... Glow plug fouled

Hi-Speed mixture too rich

Low-Speed mixture too lean

Engine stalls while driving around

turns............................................................ Fuel level is low

Idle speed set too low

Engine stalls while idling..................... Low-Speed mixture too rich

Low-Speed mixture too lean

Idle speed to low

Clutch shoes dragging

Clutch spring broken

Clutch bearings failed

Engine worn out

Page 11

Change glow plug

See "Engine Tuning"

Add Fuel

Increase Idle speed

See "Engine Tuning"

Increase idle speed

Check for broken clultch springs

Check/Clean/Replace

Rebuild

Loading...

Loading...