Page 1

8IGHT/8IGHT-T

8IGHT/8IGHT-T

Starter Box

Starter Box

LOSA99061

LOSA99061

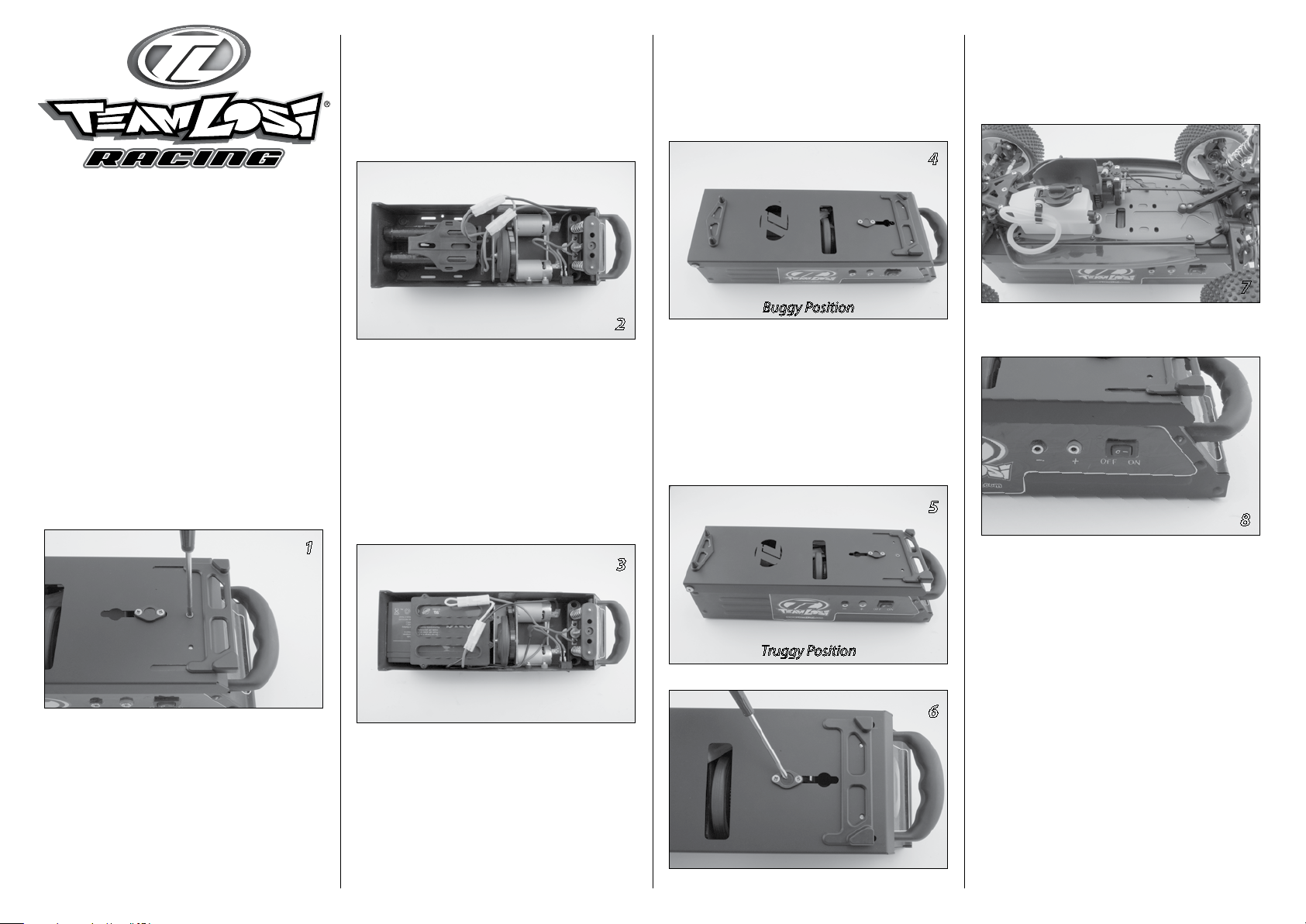

Installing the battery

You have several battery options to power your

8IGHT starter box. You can use 7.2V Ni-Cd or

Ni-MH battery packs or a single 12V gel cell.

Pre-assembled wiring harnesses and mounting

fixtures for both of these options are included.

Please note the proper mounting and wiring

layout in Images 2 and 3. Start by moving the

chassis fixtures to the truggy (Long) position

as seen in Images 4 through 6 and explained in

the “Adjusting the Chassis Fixtures” section and

remove the small Phillips head screw on the top

of the box as shown in Image 1.

Two 7.2V battery packs

Install the holder and packs as seen in

Image 2. Plug one pack into each of the plugs.

Note: The plugs are keyed so they can

only be installed one way.

2

Gel Cell

Install the holder and gel cell as seen in Image 3

or the wiring diagram on Page 2. Note the Red (+)

and Black (-) terminals on the battery. Install the

jumper plug and battery power plug as shown.

Unless you plan on using the power terminals

next to the switch, you must tape and/or cut the

ends of the loose battery leads. Do not leave these

exposed as they can easily short out the battery

and cause damage and a safety hazard.

Adjusting the chassis fixtures:

For the 8IGHT buggy—rotate the front fixture

with the “v” pointing toward the end of the box

as shown in Image 4. Depress the lock button as

shown in Image 6.

4

Buggy Position

Move the rear fixture to the innermost

(short) position.

For the 8IGHT-T truggy—rotate the front fixture

with the “v” pointing inward as shown in image 5.

Depress the lock button as in image 6 and move

the rear fixture to the outermost (long) position as

seen in Image 5.

5

Starting

Place the chassis into the fixtures as shown in

Image 7. Note how buggy chassis sits in fixtures

and location of starter wheel.

7

Turn the power switch “ON” (Image 8).

8

1

3

Truggy Position

Press down on the rear of the chassis at which

point the motors should power up and the starter

wheel will engage the flywheel on the engine.

Note: If the engine is new, tight, or

flooded, it may be necessary to loosen

the glow plug 2–3 turns to get it

turning over. Re-tighten after engine

6

starts turning over. Do not continue

to stall the motors or allow the rubber

wheel to grind on the flywheel or

chassis.

After the engine starts, release the chassis—it

should be able to sit in the fixtures and idle

without interference. Turn switch off.

1

Page 2

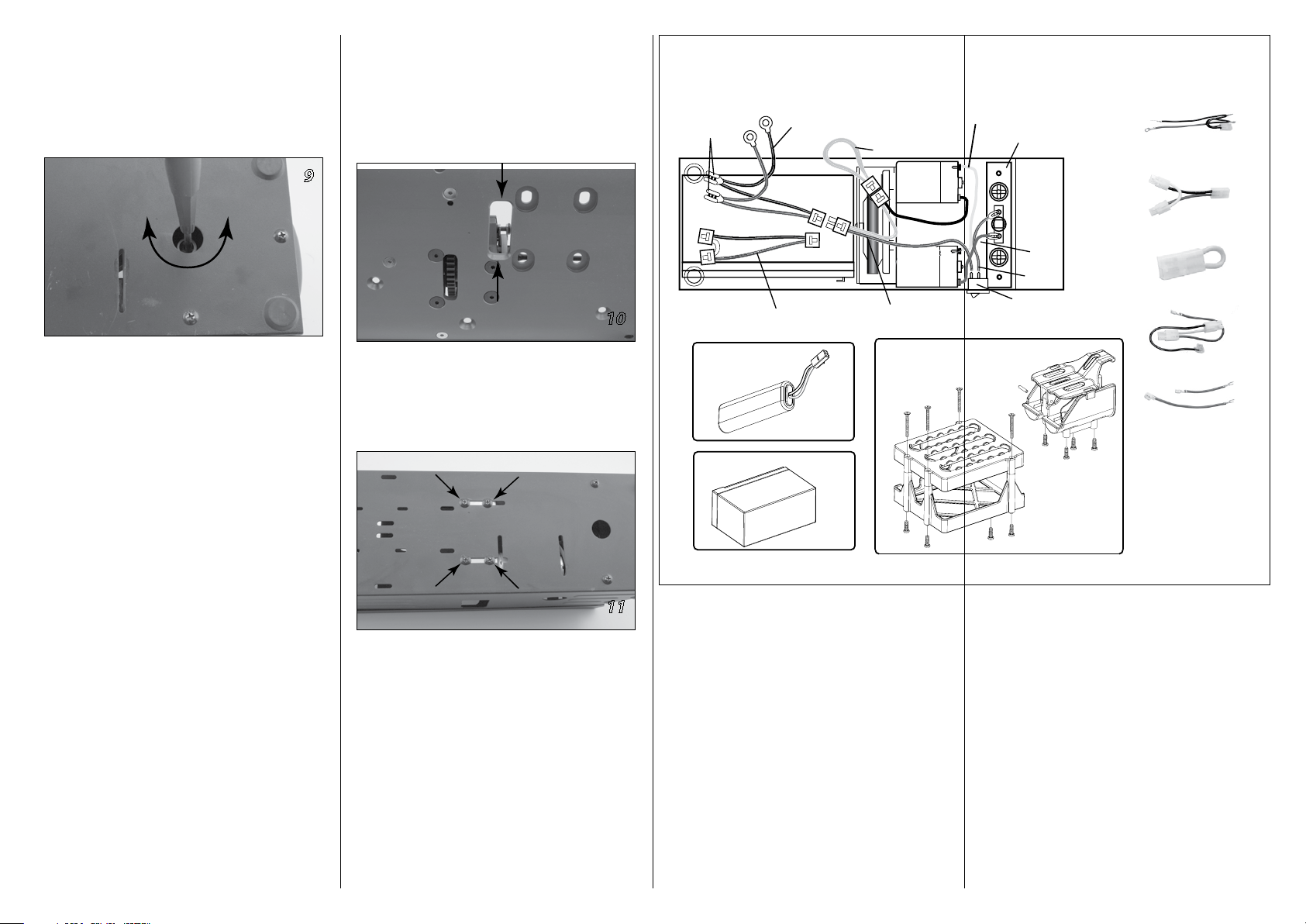

Adjusting the starter switch:

Sooner

Later

Connect to Power Ports

12V Gel Cell Harness

Jumper

*Pre-Wired at Factory

Starter Switch

12V Gel Cell Harness

Stick Pack Harness

Jumper

Wiring Harness

Red 87mm/131mm

12V 2Ah

Gel Cell

Battery Holder

7.2V

Battery Holder

7.2V Battery

(not included)

12V 2Ah Battery

(not included)

Stick Pack Harness

Wiring Harness

Power Switch

Red

131mm

Red

87mm

Wiring Diagram

Connect to

12V Battery

Terminals

You can adjust the starter switch and the point

at which the motors start running by turning

the Phillips head adjustment screw (accessible

through the hole in the bottom of box as seen

in Image 9).

Tech/Service Tips

• On some models it may be necessary to relieve

the ends of the flywheel opening on the

bottom of your chassis (Image 10) to prevent

the chassis from interfering with the starter

wheel and allow the wheel easy access to

engage the flywheel on the engine.

9

10

Turning the adjustment screw counterclockwise

will allow the motors to start sooner and have

better starting power. Turning the adjustment

screw clockwise will start the motors later and give

you more travel before the motors start to power

up. You may want to adjust this to compensate for

starter wheel wear.

Ideally, the motors should start when the top plate

is depressed about 1/8-inch. If you find that the

motors are easily stalled while trying to start your

8IGHT, adjust the starter switch as noted above so

that the motors start sooner.

Troubleshooting Guide

Motors run slow

Battery(s) needs to be charged

Starter wheel won’t turn over engine

Loosen glow plug

Adjust switch to motors start sooner

Put a few drops of fuel in carburetor

Check for wheel interference with chassis

(See Image 10)

Check for starter wheel wear

• It’s a good idea to use compressed air to clean

• To replace the starter wheel, remove the four

Disconnect the wires from the motor and

the dust and dirt out of the starter box.

screws in the center of the box bottom as

indicated in Image 11.

11

mark the location of the mounting screws

before removing. Remove the screws on

either side of the wheel shaft. After replacing

the wheel, be sure to re-install the assembly

in its original position.

2

Page 3

Exploded View

LOSA99411

LOSA99411

LOSA99412

LOSA99412

LOSA99410

LOSA99401

LOSA99407

LOSA99408

LOSA99412

LOSA99405

LOSA99402

LOSA99412

LOSA99404

LOSA99403

LOSA99410

Replacement Parts

Part # Description Price

LOSA99401 Starter Box Wheel (8) 3.99

LOSA99402 Starter Box Pulley (8) 4.99

LOSA99403 Motor Pulley Set (8) 2.99

LOSA99404 Starter Drive Belt (8) 7.99

LOSA99405 Starter Switch Set—Adjustable (8) 6.99

LOSA99407 Starter 550 Motor w/Screws (8) 14.99

LOSA99408 Starter Rubber Feet (4ea) (8) 2.99

LOSA99410 Starter Front Chassis Fixture (8) 7.99

LOSA99411 Starter Rear Chassis Fixture (8) 9.99

LOSA99412 Starter Misc Hardware Set (8) 3.50

3

Page 4

Warranty Period

Exclusive Warranty- Horizon Hobby, Inc.,

(Horizon) warranties that the Products

purchased (the “Product”) will be free from

defects in materials and workmanship at the

date of purchase by the Purchaser.

Limited Warranty

(a) This warranty is limited to the original

Purchaser (“Purchaser”) and is not transferable.

REPAIR OR REPLACEMENT AS PROVIDED UNDER

THIS WARRANTY IS THE EXCLUSIVE REMEDY OF

THE PURCHASER. This warranty covers only those

Products purchased from an authorized Horizon

dealer. Third party transactions are not covered

by this warranty. Proof of purchase is required

for warranty claims. Further, Horizon reserves the

right to change or modify this warranty without

notice and disclaims all other warranties, express

or implied.

(b) Limitations- HORIZON MAKES NO

WARRANTY OR REPRESENTATION, EXPRESS

OR IMPLIED, ABOUT NON-INFRINGEMENT,

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OF THE PRODUCT. THE PURCHASER

ACKNOWLEDGES THAT THEY ALONE HAVE

DETERMINED THAT THE PRODUCT WILL SUITABLY

MEET THE REQUIREMENTS OF THE PURCHASER’S

INTENDED USE.

(c) Purchaser Remedy- Horizon’s sole obligation

hereunder shall be that Horizon will, at its option,

(i) repair or (ii) replace, any Product determined by

Horizon to be defective. In the event of a defect,

these are the Purchaser’s exclusive remedies.

Horizon reserves the right to inspect any and all

equipment involved in a warranty claim. Repair or

replacement decisions are at the sole discretion

of Horizon. This warranty does not cover cosmetic

damage or damage due to acts of God, accident,

misuse, abuse, negligence, commercial use, or

modification of or to any part of the Product. This

warranty does not cover damage due to improper

installation, operation, maintenance, or attempted

repair by anyone other than Horizon. Return of any

goods by Purchaser must be approved in writing

by Horizon before shipment.

4

Damage Limits

HORIZON SHALL NOT BE LIABLE FOR SPECIAL,

INDIRECT OR CONSEQUENTIAL DAMAGES, LOSS

OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY CONNECTED WITH THE

PRODUCT, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY. Further, in no event shall the liability

of Horizon exceed the individual price of the

Product on which liability is asserted. As Horizon

has no control over use, setup, final assembly,

modification or misuse, no liability shall be

assumed nor accepted for any resulting damage

or injury. By the act of use, setup or assembly, the

user accepts all resulting liability.

If you as the Purchaser or user are not prepared to

accept the liability associated with the use of this

Product, you are advised to return this Product

immediately in new and unused condition to the

place of purchase.

Law: These Terms are governed by Illinois law

(without regard to conflict of law principals).

Safety Precautions

This is a sophisticated hobby Product and not a

toy. It must be operated with caution and common

sense and requires some basic mechanical

ability. Failure to operate this Product in a safe

and responsible manner could result in injury

or damage to the Product or other property.

This Product is not intended for use by children

without direct adult supervision. The Product

manual contains instructions for safety, operation

and maintenance. It is essential to read and follow

all the instructions and warnings in the manual,

prior to assembly, setup or use, in order to operate

correctly and avoid damage or injury.

Questions, Assistance, and Repairs

Your local hobby store and/or place of

purchase cannot provide warranty support or

repair. Once assembly, setup or use of the

Product has been started, you must contact

Horizon directly. This will enable Horizon to

better answer your questions and service

you in the event that you may need any assistance.

For questions or assistance, please direct your

email to productsupport@horizonhobby.com, or

call 877.504.0233 toll free to speak to a service

technician.

Inspection or Repairs

If this Product needs to be inspected or repaired,

please call for a Return Merchandise Authorization

(RMA). Pack the Product securely using a shipping

carton. Please note that original boxes may be

included, but are not designed to withstand the

rigors of shipping without additional protection.

Ship via a carrier that provides tracking and

insurance for lost or damaged parcels, as Horizon

is not responsible for merchandise until it

arrives and is accepted at our facility. A Service

Repair Request is available at www.horizonhobby.

com on the “Support” tab. If you do not have

internet access, please include a letter with your

complete name, street address, email address

and phone number where you can be reached

during business days, your RMA number, a list of

the included items, method of payment for any

non-warranty expenses and a brief summary of

the problem. Your original sales receipt must also

be included for warranty consideration. Be sure

your name, address, and RMA number are clearly

written on the outside of the shipping carton.

Warranty Inspection and Repairs

To receive warranty service, you must

include your original sales receipt verifying

the proof-of-purchase date. Provided warranty

conditions have been met, your Product will be

repaired or replaced free of charge. Repair or

replacement decisions are at the sole discretion of

Horizon Hobby.

Non-Warranty Repairs

Should your repair not be covered by warranty

the repair will be completed and payment will

be required without notification or estimate of

the expense unless the expense exceeds 50%

of the retail purchase cost. By submitting the

item for repair you are agreeing to payment of

the repair without notification. Repair estimates

are available upon request. You must include this

request with your repair. Non-warranty repair

estimates will be billed a minimum of ½ hour

of labor. In addition you will be billed for return

freight. Please advise us of your preferred method

of payment. Horizon accepts money orders

and cashiers checks, as well as Visa, MasterCard,

American Express, and Discover cards. If you

choose to pay by credit card, please include your

credit card number and expiration date. Any repair

left unpaid or unclaimed after 90 days will be

considered abandoned and will be disposed of

accordingly. Please note: non-warranty repair

is only available on electronics and model

engines.

Electronics requiring inspection or repair should

be shipped to the following address:

Horizon Service Center

4105 Fieldstone Road

Champaign, Illinois 61822

All other Products requiring warranty

inspection or repair should be shipped to the

following address:

Contact Losi:

4710 East Guasti Road

Ontario, CA 91761

(909)390-9595

feedback@teamlosi.com

Please call 877-504-0233 with any

questions or concerns regarding this

product or warranty.

©2007 Team Losi Racing is an exclusive brand of

Horizon Hobby, Inc.

4105 Fieldstone Rd.

Champaign, IL 61822

Customer Support

1-877-504-0233

www.horizonhobby.com

www.losi.com

part# 800-032 4

10624

Loading...

Loading...