Page 1

INSTRUCTION MANUAL

BEDIENUNGSANLEITUNG

MANUEL D’UTILISATION

MANUALE DI ISTRUZIONI

Before operating this vehicle, please read all printed materials thoroughly.

Horizon Hobby is not responsible for inadvertent errors in this manual.

Page 2

NOTICE

All instructions, warranties and other collateral documents are subject to change at the sole discretion of Horizon Hobby, LLC. For up-to-date product literature, visit

horizonhobby.com and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

NOTICE: Procedures, which if not properly followed, create a possibility of physical property damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property damage, collateral damage, and serious injury OR create a high probability of

superfi cial injury.

WARNING: Read the ENTIRE instruction manual to become familiar with the features of the product before operating. Failure to operate the product correctly can

result in damage to the product, personal property and cause serious injury.

This is a sophisticated hobby product. It must be operated with caution and common sense and requires some basic mechanical ability. Failure to operate this Product in a safe

and responsible manner could result in injury or damage to the product or other property. This product is not intended for use by children without direct adult supervision. Do

not attempt disassembly, use with incompatible components or augment product in any way without the approval of Horizon Hobby, LLC. This manual contains instructions for

safety, operation and maintenance. It is essential to read and follow all the instructions and warnings in the manual, prior to assembly, setup or use, in order to operate correctly

and avoid damage or serious injury.

AGE RECOMMENDATION: NOT FOR CHILDREN UNDER 14 YEARS. THIS IS NOT A TOY.

Register your Losi Product Online

Register your vehicle now and be the fi rst to fi nd out about the latest option parts, product updates and more. Click on the Support tab at WWW.LOSI.COM and follow the

product registration link to stay connected.

General Safety Precautions and Guidelines

WARNING: This vehicle is only intended for advanced RC drivers capable

of operating large-scale model vehicles.

WARNING: Failure to follow all instructions can lead to damage to your

vehicle, property damage and bodily injury or death.

CAUTION: If you make changes or adjustments not shown in the instruction

manual, your vehicle may be damaged. To prevent any serious

personal injury and/or damage to property, please be responsible when

operating all remote controlled models.

This model is controlled by a radio signal subject to interference from many sources

outside your control. This interference may cause momentary loss of control, so it

is advisable to always keep some distance in all directions around your model as a

safety margin to avoid collisions.

• Always ensure all screws and nuts are tightened.

• Always carefully follow the directions and warnings for this and any optional support

• Always keep all chemicals, small parts and anything electrical out of the reach of

• Always ensure the failsafe is properly set during binding.

• Always operate your model in an open area away from cars, traffi c and people.

• When operating this vehicle, always keep it at least 20 feet from spectators,

• Never run your vehicle through deep water that will submerge the vehicle.

• Never run your model in a public street where damage can occur.

• Never run your model with low transmitter batteries.

• When fi nished operating, always power off the engine fi rst, then the receiver, then the

• Always perform maintenance on the vehicle after each and every use. Due to engine

Li-Po Charger Safety Precautions and Warnings

• Never leave the charger and battery unattended during use.

• Never attempt to charge dead, damaged or wet battery packs.

• Never attempt to charge a battery pack containing different types of batteries.

• Never allow minors to charge battery packs.

• Never charge batteries in extremely hot or cold places or place in direct sunlight.

• Never charge a battery if the cable has been pinched or shorted.

• Never connect more than one battery pack to this charger at a time.

• Never connect the charger if the power cable has been pinched or shorted.

• Never attempt to dismantle the charger or use a damaged charger.

• Never reverse the positive and negative terminals.

• Always use only rechargeable batteries designed for use with this type of

charger.

• Always inspect the battery before charging.

• Always keep the battery away from any material that could be affected by heat.

• Always monitor the charging area and have a fi re extinguisher available at all

times.

• Always end the charging process if the battery becomes hot to the touch or

• Always disconnect the battery after charging, and let the charger cool between

• Always terminate all processes and contact Horizon Hobby if the product

which can lead to user injury or property damage. Please contact Horizon Hobby or

an authorized retailer with compatibility questions.

equipment.

children.

especially small children.

transmitter.

vibration, all screws and nuts will need to be checked to ensure they are tight.

starts to change form (swell) during the charge process.

charges.

malfunctions.

WARNING: Never leave the charger unattended, exceed maximum charge

rate, charge with non-approved batteries or charge batteries in the wrong

mode. Failure to comply may result in excessive heat, fi re and serious injury.

CAUTION: Always ensure the battery you are charging meets the

specifi cations of this charger and that the charger settings are correct. Not

doing so can result in excessive heat and other related product malfunctions,

2

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 3

Water-resistant Vehicle with Waterproof Electronics

Your new Horizon Hobby vehicle has been designed and built with a combination of

waterproof and water-resistant components to allow you to operate the product in

many “wet conditions”, including puddles, creeks, wet grass, snow and even rain.

While the entire vehicle is highly water-resistant, it is not completely waterproof

and your vehicle should NOT be treated like a submarine. The various electronic

components used in the vehicle, such as the servo(s) and receiver are waterproof,

however, most of the mechanical components are water-resistant and should not be

submerged.

Metal parts, including the bearings, hinge pins, screws and nuts, as well as the

contacts in the electrical cables, will be susceptible to corrosion if additional

maintenance is not performed after running in wet conditions. To maximize the longterm performance of your vehicle and to keep the warranty intact, the procedures

described in the “Wet Conditions Maintenance” section below must be performed

regularly if you choose to run in wet conditions. If you are not willing to perform the

additional care and maintenance required, then you should not operate the vehicle in

those conditions.

CAUTION: Failure to exercise caution while using this product and

complying with the following precautions could result in product

malfunction and/or void the warranty.

Wet Conditions Maintenance

• Remove the battery pack(s) and dry the contacts. If you have an air compressor

or a can of compressed air, blow out any water that may be inside the recessed

connector housing.

• Remove the tires/wheels from the vehicle and gently rinse the mud and dirt off with

a garden hose. Avoid rinsing the bearings and transmission.

NOTICE: Never use a pressure washer to clean your vehicle.

• Use an air compressor or a can of compressed air to dry the vehicle and help

remove any water that may have gotten into small crevices or corners.

• Spray the bearings, drive train, fasteners and other metal parts with a waterdisplacing light oil or lubricant.

GENERAL PRECAUTIONS

• Read through the wet conditions maintenance procedures and make sure that you

have all the tools you will need to properly maintain your vehicle.

• Not all batteries can be used in wet conditions. Consult the battery manufacturer

before use. Caution should be taken when using Li-Po batteries in wet conditions.

• Most transmitters are not water-resistant. Consult your transmitter’s manual or the

manufacturer before operation.

• Never operate your transmitter or vehicle where lightning may be present.

• Do not operate your vehicle where it could come in contact with salt water (ocean

water or water on salt-covered roads), contaminated or polluted water. Salt water is

very conductive and highly corrosive, so use caution.

• While the air fi lter assembly can be designed to limit or restrict water ingestion into

the engine, no air fi lter is completely waterproof. If too much water is ingested into

the engine, severe damage to the engine may result.

• Do not expose your engine to rapid changes in temperature. These engines

tend to operate at temperatures between 200–250°F (93–121°C) in normal

operating conditions. If the engine is exposed to cold water while operating at this

temperature, there is a risk of “thermal shock”, which could cause undue stress on

the engine and a shortened engine lifespan.

• Driving in wet conditions can reduce the life of the engine. The additional

resistance of operating in water causes excess strain. Alter the gear ratio by using

a smaller pinion or larger spur gear. This will reduce the load on the engine (and

engine temperatures) when running in mud, deeper puddles, or any wet conditions

that will increase stress on the engine for an extended period of time.

• Let the vehicle air dry before you store it. Water (and oil) may continue to drip for a

few hours.

• Increase the frequency of disassembly, inspection and lubrication of the following:

• Front and rear axle hub assembly bearings.

• All transmission cases, gears and differentials.

• Engine air fi lter element.

• Engine clutch assembly, including shoes and bearings.

Components

• 1/8-Scale LST XXL™ 2 Monster Truck

• Spektrum

• Dynamite

• Spektrum High-Torque Servo

• 4 AA batteries (for transmitter)

• Dynamite 7.4V 2000mAh Li-Po receiver pack.

• Dynamite Spin-Start handheld Starter

LOSI LST XXL 2 • INSTRUCTION MANUAL

™

DX2E 2.4GHz DSM® Radio System

®

.31 Gasoline Engine

Tools Included

• Wheel wrench

• Four (4) Hex “L” Wrench Set: .050-inch, 1/16-inch, 5/64-inch and 3/32-inch

• Shock Bottom wrench

• Turnbuckle/Shock Top wrench

Needed to Complete

• Gasoline

• 500cc Fuel Bottle (DNY2003)

• 7.2V battery and charger for the Spin-Start (included)

• Small fl at blade and Phillips screwdrivers (DYN3093 and DYN3048)

• Needle-nose pliers

• Quality .050-inch, 1/16-inch, 5/64-inch, 3/32-inch, 1.5mm and 2.5mm hex

(Allen) drivers (DYN2950)

Use only Dynamite

can cause damage to the small screws and parts used on this type of model.

tools or other high-quality tools. Use of inexpensive tools

EN

3

Page 4

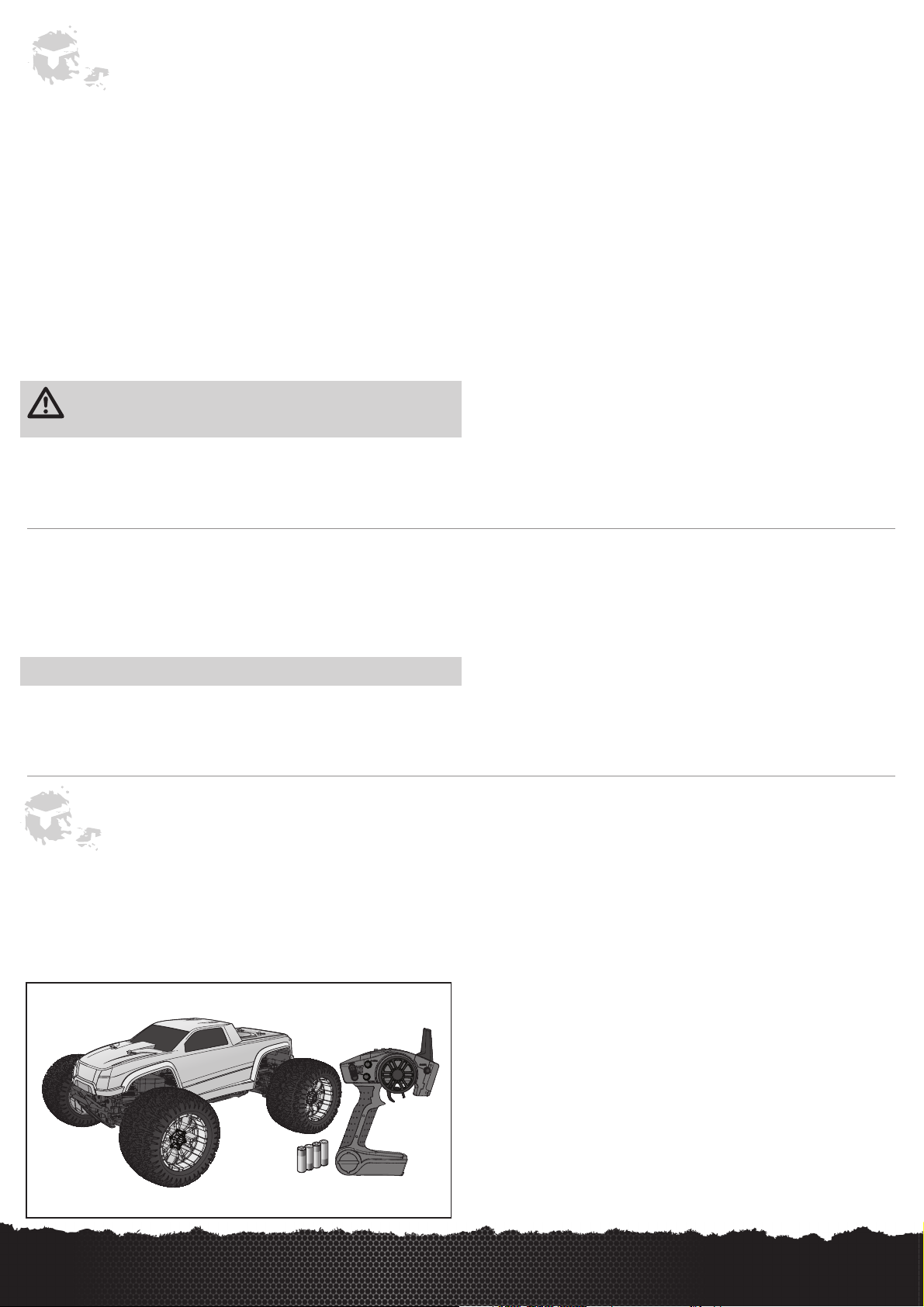

Charging the Receiver Battery Pack

Dynamite 7.4V 2000mAh Li-Po receiver pack.

The Dynamite 2S Li-Po battery pack features a balancing lead that allows you

to safely charge your battery pack when used with a Li-Po balancing charger.

1. Remove the LiPo receiver battery pack from the battery box and disconnect the

red JST connector.

2. Connect the LiPo battery charger to an AC power outlet.

3. Refer to manufacturers battery charging directions.

Installing the Receiver Battery in the Battery Box

1. Connect the fully charged LiPo battery pack to the red JST connector

in the battery box.

2. Place the battery box cover on the battery box.

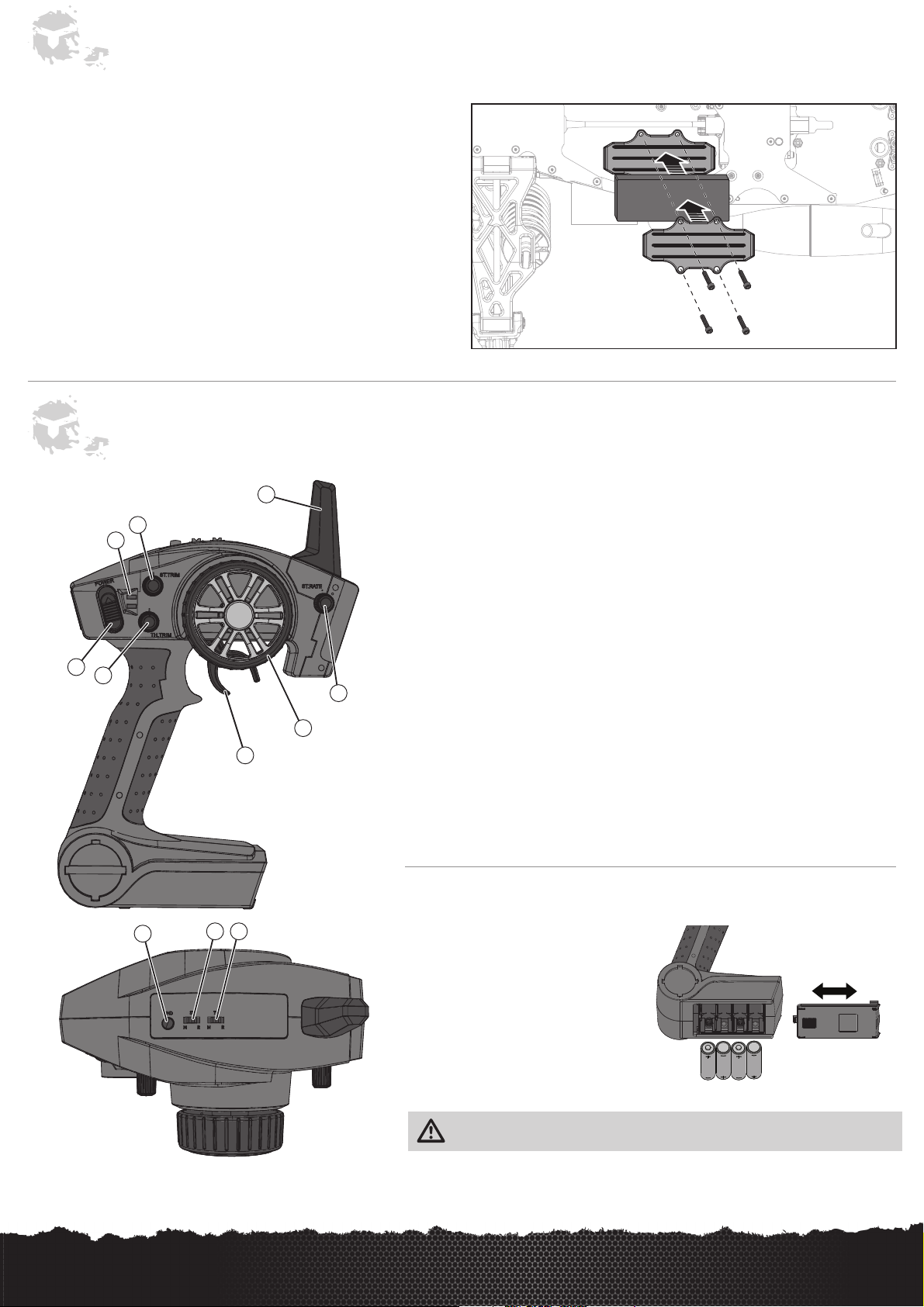

Spektrum DX2E Radio System

For more information on the transmitter, go to www.spektrumrc.com and click on the support tab

3

to find the full manual for the DX2E transmitter.

6

5

4

7

8

1

2

1. Steering Wheel controls direction (left/right) of the model.

2. Throttle Trigger controls speed.

3. Antenna transmits the signal to the model.

4. ON/OFF Switch turns the power ON/OFF for the transmitter.

5. Indicator Lights

• Solid green light indicates adequate battery power.

• Flashing green light indicates the battery voltage is critically low. Replace batteries.

6. ST. Trim adjusts the “hands off” direction of the model.

7. TH. Trim adjusts the engine speed to idle at neutral.

8. ST. Rate Adjusts the AVC sensitivity.

9. BIND/R.O.S.S. button puts the transmitter into Bind Mode and starts or stops the engine

using R.O.S.S. (the LST XXL 2 does NOT use ROSS)

10. ST. REV reverses the function of the steering when the wheel is turned left or right.

11. TH. REV reverses the throttle control when pulled back or pushed forward.

Installing the Transmitter Batteries

10

9

11

1. Push in the battery cover a small amount

to release the retaining tab, then remove

the cover.

2. Install 4 AA batteries, taking care to align

battery polarity to the diagram in the

transmitter’s battery case.

3. Carefully reinstall the battery cover by

aligning the tabs with the slots on the

transmitter.

CAUTION: NEVER remove the transmitter batteries while the vehicle is powered on, as

loss of control, property damage or injury may result.

4

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 5

AVC – Active Vehicle Control

The Spektrum™ AVC™ stabilization system adds a whole new level of control to

your RC driving experience. AVC technology utilizes sensors to adjust steering and

throttle output, providing you with a more stable and controlled driving experience.

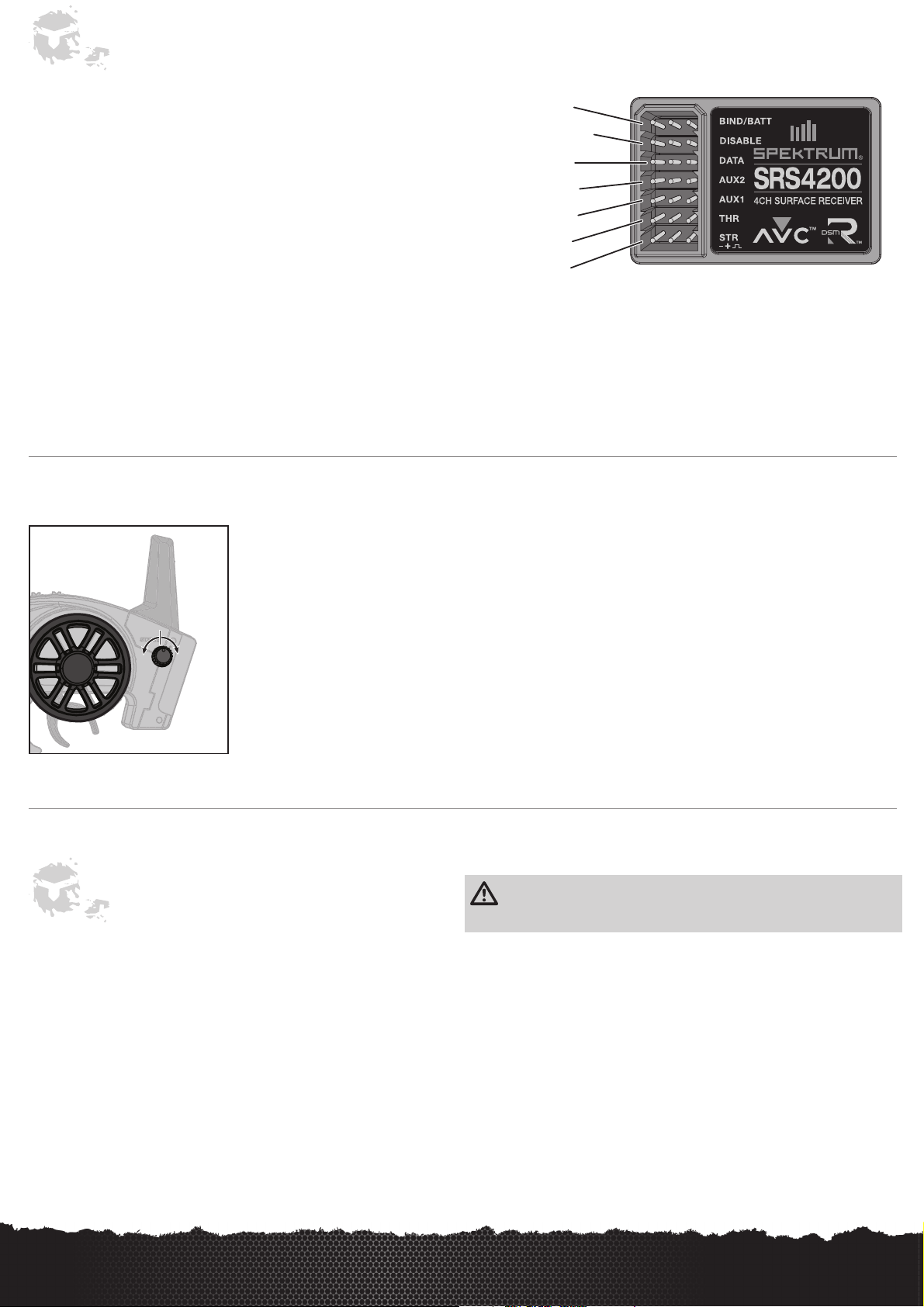

Spektrum SRS4200

The Spektrum SRS4200 receiver features AVC technology that responds similar to

traction control in full-scale vehicles. In addition to traction control, AVC technology

also increases steering stability during high speed driving or while driving over rough

terrain. As you increase the AVC sensitivity, the system increases steering stability

and traction control, similar to reducing the amount of steering rate in a computer

transmitter. Reducing the sensitivity value increases the amount of steering control

from the transmitter. The SRS4200 receiver also enables you to quickly turn AVC on

or off if you participate in organized racing.

IMPORTANT: You must use digital servos with the SRS4200 receiver. Using analog

servos will reduce the performance of the system and may cause analog servos to

overheat.

1. BIND

2. DISABLE

3. DATA

4. AUX 2

5. AUX 1

6. THR

7. STR

Adjusting AVC Sensitivity

The ST. RATE dial adjusts the sensitivity, or stability, value in the receiver. If you increase the sensitivity, the AVC system becomes

more sensitive to the vehicle drifting left or right. You would use maximum sensitivity during high speed driving or drag racing, when

you want the vehicle to stay in a straight line. As the sensitivity value increases, the amount of steering travel decreases.

Turn the ST. RATE knob counter-clockwise to reduce the sensitivity.

Turn the ST. RATE knob clockwise to increase the sensitivity.

IMPORTANT: The ST. RATE knob will only adjust the sensitivity when the transmitter is bound to a DSMR receiver. When the

transmitter is bound to a DSM, DSM2 or DSM Marine receiver, the ST. RATE knob controls the steering dual rate.

Driving Precautions

• Maintain sight of the vehicle at all times.

• Inspect the vehicle for loose wheel hardware.

• Inspect the steering assembly for any loose hardware. Driving the vehicle offroad can cause fasteners to loosen over time.

• Stop driving the vehicle when you notice a lack of power. Driving the vehicle

when the battery is discharged can cause the receiver to power off. You may

lose control of the vehicle.

CAUTION: Do not discharge a LiPo battery below 3V per cell. Batteries discharged

to a voltage lower than the lowest approved voltage may become damaged,

resulting in loss of performance and potential fi re when batteries are charged.

• Do not apply the throttle in forward or reverse if the vehicle is stuck. Applying

throttle in this instance can damage the engine.

• Let the engine cool to ambiant temperature between runs.

LOSI LST XXL 2 • INSTRUCTION MANUAL

EN

5

Page 6

Fuel Safety and Use Instructions

• Always observe all warnings, precautionary statements and instructions supplied

by the fuel manufacturer/provider.

• Fuel is a fire accelerant. Never operate your vehicle near open flames. Never

smoke while operating your vehicle or while handling fuel.

• Always only use a mixture of gasoline and two-cycle oil for fuel. Do not use glow

(nitro) fuel.

• Always use caution when handling gasoline.

• Always run your model engine in a well-ventilated area. Model engines produce

harmful carbon monoxide fumes.

• Always drain your engine after you have finished running your vehicle. Do not store

the vehicle with fuel in the gas tank.

• Never handle model engines and mufflers until they have had time to cool. They

become extremely hot when in use.

• Always store your fuel in a safe place well away from sparks, heat or anything that

can ignite.

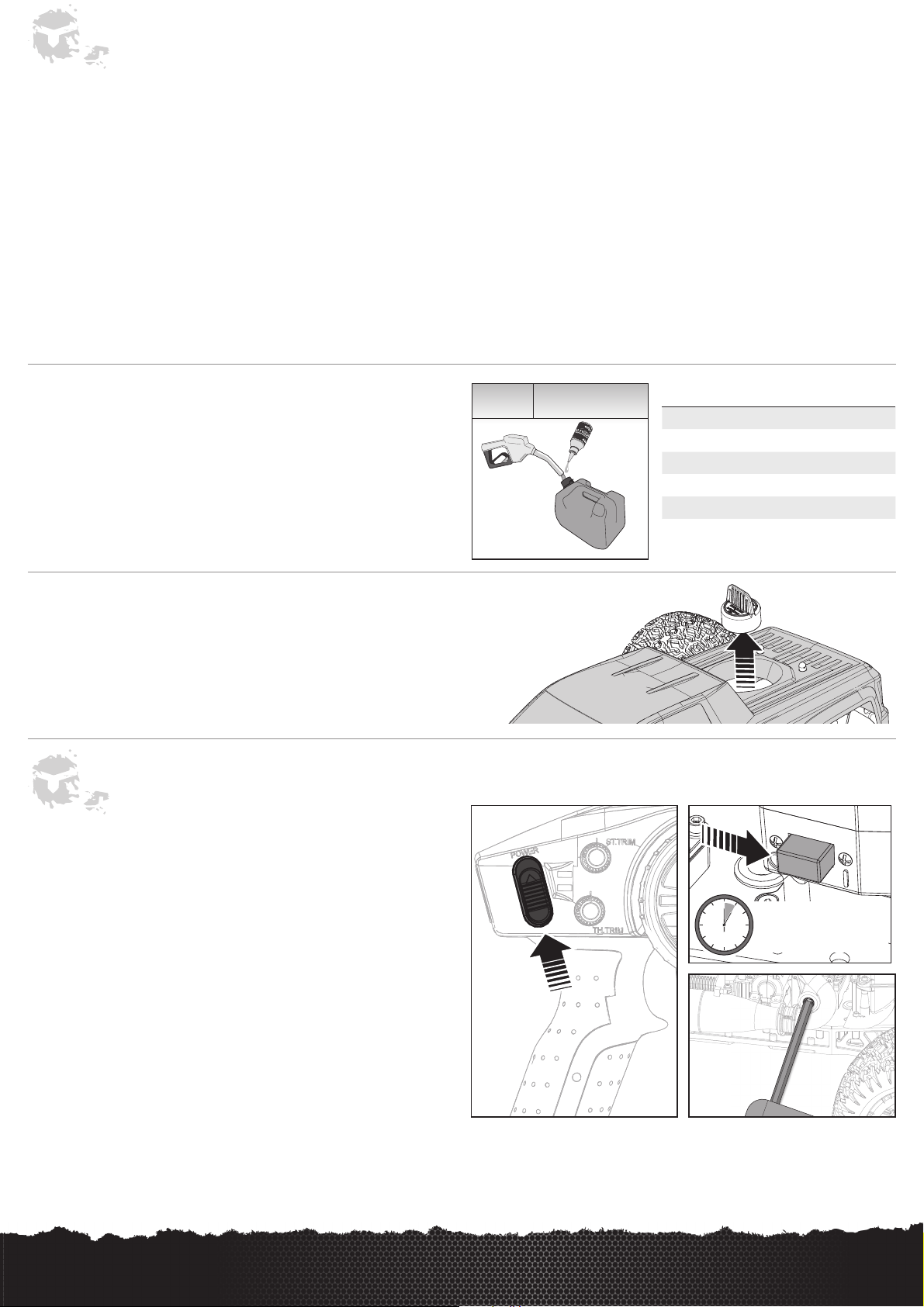

Fuel Mixing Precautions and Guidelines

• Only use gasoline mixed with two-cycle engine oil.

• Only use Dynamite Pre-Mix Two-Cycle Engine Oil (DYNE4105).

Do not use any other kind of oil.

• Always use 92–98 Octane RON (Europe) and 91–93 Octane AKI (US) gasoline.

• Always blend gasoline with two-cycle engine oil at a 14:1 ratio.

• Never use a 40:1, 32:1 or 25:1 gas-oil ratio.

• Never use glow (nitro) fuel.

• Always ensure that gasoline and fuel are stored in a clearly marked container well

away from the reach of children.

• Always mix and store your fuel safely in a sealed, water-resistant container

specifically made for gasoline.

• Always store fuel in a cool, dry location. Do not allow fuel containers to come in

direct contact with concrete, as the fuel may absorb moisture.

• Always responsibly discard fuel if there is condensation and/or water inside the

fuel container.

• Never allow fuel to come into contact with eyes or mouth.Gasoline and other fuels

used in model engines are poisonous.

• Never return unused fuel from the fuel tank back into the fuel container.

• Contact your local waste disposal authorities for more information about discarding

fuel waste responsibly.

Gasoline

14 : 1

2-Cycle

Engine Oil

Gasoline : 2-Cycle Engine Oil

1 gallon : 9.5 fl oz

1/2 gallon : 4.8 fl oz

1/4 gallon : 2.4 fl oz

4 liters : 282 ml

2 liters : 141 ml

1 liter : 71 ml

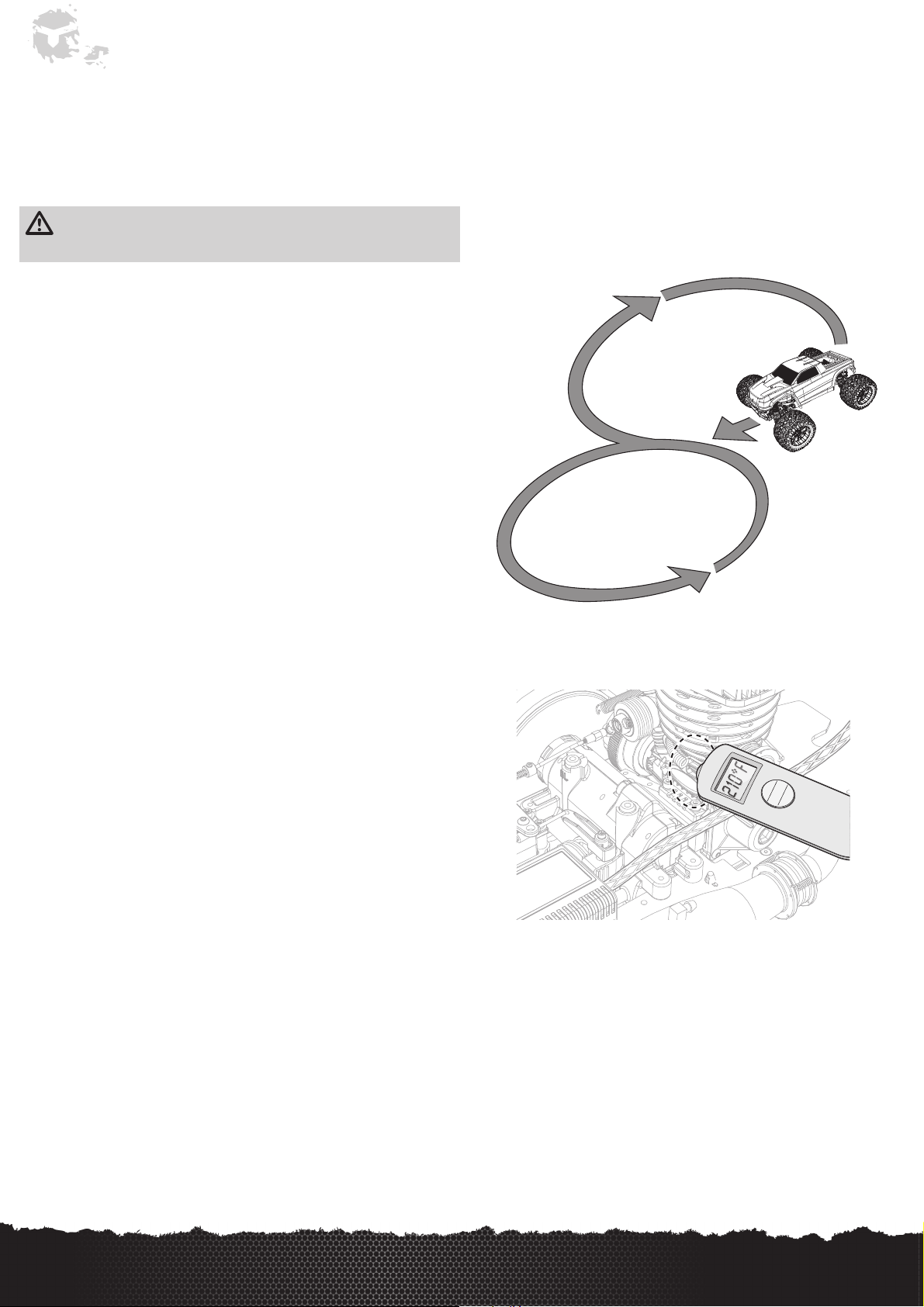

Fueling the Truck

Remove the fuel tank cap and fill the fuel tank. Tighten the fuel tank cap securely

back in place.

NOTICE: Running a loose fuel tank cap will cause inconsistency and high idle speed.

Vehicle Starting and Running with AVC

1. Center the ST. TRIM and TH. TRIM dials on the transmitter.

2. Fill the fuel tank with 2-stroke gasoline (14:1 gasoline:oil ratio).

3. Power on the transmitter.

4. Power on the vehicle. The vehicle and receiver MUST remain motionless for at

least 5 seconds.

5. Place the machined end of the starter shaft into the matching hex socket in the

back-plate of the engine.

6. Holding the starter securely, press on the switch button and the engine should

turn over and start up.

Follow the engine break-in procedure before attempting any racing or highperformance operation. Use caution when adding fuel while the engine is running. Do

not over fi ll or spill fuel outside the tank.

IMPORTANT: Always make sure the vehicle is motionless and on a level surface

before powering on the vehicle. Each time you power on the vehicle, the Spektrum

SRS4200 receiver automatically detects the receiver position (or orientation). The

vehicle must remain motionless and level until the receiver calibration is complete

(normally 5-10 seconds after powering on the vehicle). Moving the vehicle or not

placing it on a surface will reduce the performance of the receiver.

Keep immobile for

5-10 seconds

6

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 7

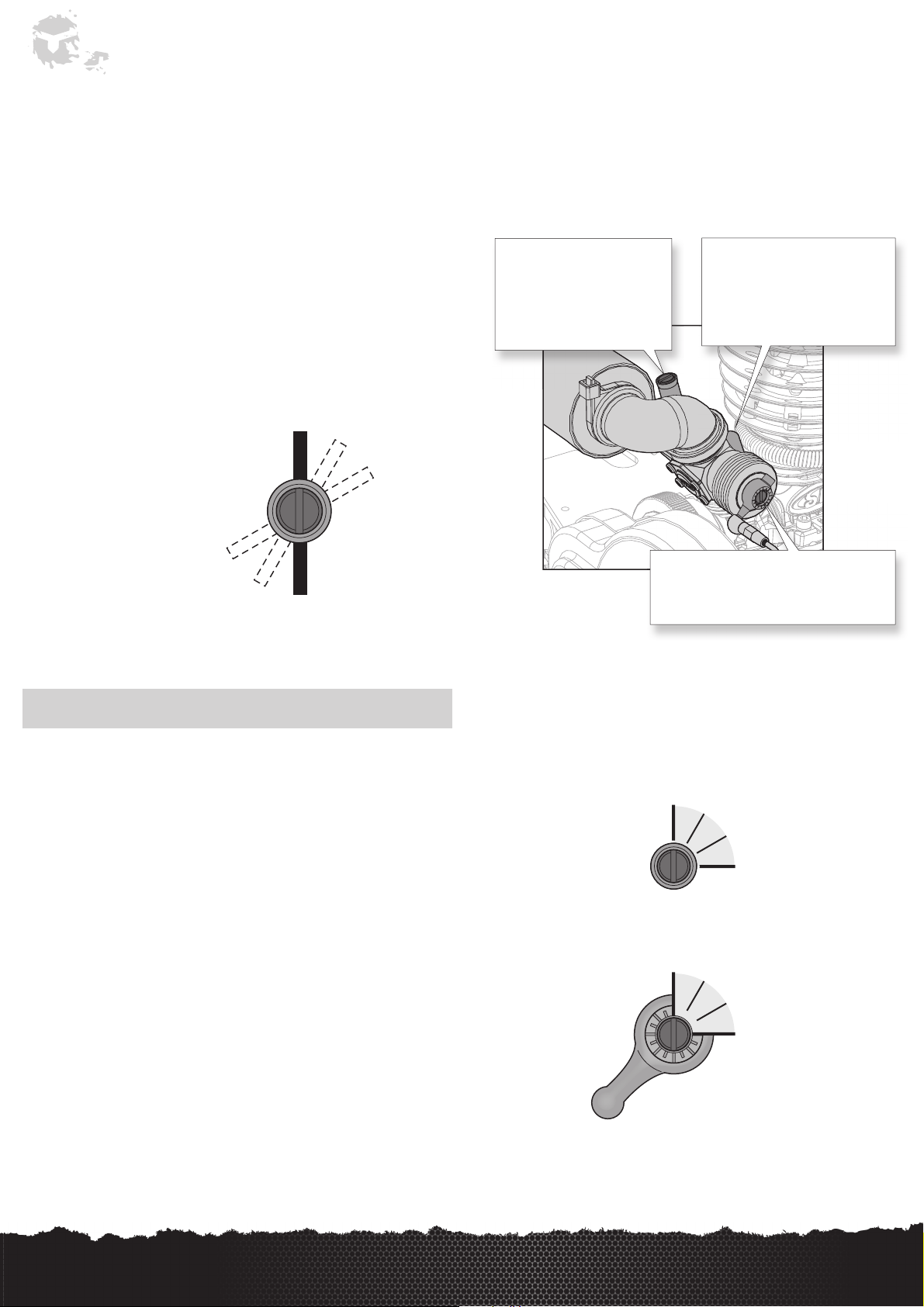

Engine Break-In

Breaking in your new engine is critical for proper performance. Failure to follow the break-in procedures can cause engine damage and shortened engine life. Always use a

14:1 gasoline:oil mixture during the break-in process and when running the engine.

If you change fuel or run in dramatically different environments (hot/cold, high/low elevation, etc.) you will need to adjust the carburetor needles to prevent overheating and

maintain proper performance. Never allow the engine to rev freely with the wheels off the ground.

Use the optional Dynamite Pro Temp Gun with Laser Sight (DYNP2000) to check engine temperatures.

Break-In Procedure:

CAUTION: You must complete the break-in process on a smooth surface, such

as pavement or concrete. Do not drive the vehicle on dirt or grass during the

break-in process; doing so will damage the engine.

Priming the Carburetor

Before turning on the vehicle, install the spin-start into the side of the engine. Hold

fi nger over exhaust tip and press spin-start button for one second to prime the

carburetor. Stop spin-start. With spin-start still installed into the side of the engine,

remove fi nger from exhaust tip and press spin-start button for two seconds.

NOTICE: Unlike nitro engines, do not allow the gasoline engine to idle for several

tanks. Allowing the engine to idle prevents the engine from reaching operating

temperature.

Fuel Tank #1:

1. Drive the vehicle in a fi gure 8 for the fi rst half tank of fuel. Keep the throttle

position between 1/4 – 3/4 throttle. Do not exceed ¾ throttle.

2. During the second half of the tank, move the throttle position between ¼ and full

throttle. Do not hold full throttle for more than one second.

Engine temperature: Do not exceed

Fuel Tank #2: Move the throttle position between ¼ and full throttle. Do not hold full

throttle for more than one second.

Engine temperature: Do not exceed

Fuel Tank #3:

1. For the fi rst half tank of fuel, move the throttle position between ¼ and full

throttle. Do not hold full throttle for more than one second.

2. Lean the high speed needle 2-3 hours when the fuel level reaches ½ tank.

3. For the second half of the tank, move the throttle position between ¼ and full

throttle. Do not hold full throttle for more than two seconds.

Engine temperature: Do not exceed

Fuel Tank #4:

1. For the fi rst half tank of fuel, move the throttle position between ¼ and full

throttle. Do not hold full throttle for more than two seconds.

2. Lean the high speed needle 1-2 hours when the fuel level reaches ½ tank.

3. For the second half of the tank, move the throttle position between ¼ and full

throttle. Do not hold full throttle for more than three seconds.

Engine temperature: Do not exceed 230ºF (

195ºF (

210ºF (

225ºF (

)

90ºC

)

99ºC

107ºC

110ºC

)

)

Notice: Engine temperatures are measure on the side of the

engine block and not at the top of the head like a traditional

nitro engine.

Fuel Tanks #5-8:

At the end of Tank #4, the vehicle is ready to run on dirt surfaces. Maintain the

same carburetor settings that were used during Tank #4 through Tank #8. After

8 tanks of fuel, you can tune the engine for peak performance.

Engine temperature: Never exceed

250ºF (

121ºC

)

LOSI LST XXL 2 • INSTRUCTION MANUAL

EN

7

Page 8

Vehicle Tuning

After the engine is broken in, you can tune it for optimum performance. When tuning, it is critical that you be cautious of overheating as severe damage and pre-mature wear

can occur. You want to make all carburetor adjustments in “one hour” increments.

Before making adjustments:

• Ensure there are no leaks or obstructions in the fuel tank, fuel tubing or the

carburetor. Any faults can affect engine operation and tuning.

• The carburetor needle is very sensitive. Adjusting the needle even 1/12 of a turn is

a significant change. Be careful when making adjustments.

Idle Needle (left, rear of

carburetor). The engine includes an

idle needle for carburetor function,

however it is not used for engine

tuning. DO NOT ADJUST THE IDLE

NEEDLE.

Factory Needle Settings:

Low Speed Needle: 30 hours from the bottom

High Speed Needle: 18 hours from the bottom

Carb Adjustments:

Make all carburetor adjustments in

one-hour increments.

Imagine the slot in the needle is the

hour hand on a clock. Adjust it as

though you were moving the hour

hand from one hour to the next or

previous one.

High-Speed Needle (top, left

side). Close the high-speed

needle by turning it clockwise

until it stops, then turn it

counterclockwise 18 hours out

(open).

1 hour

2 hour

Low-Speed Needle (on the right side). Close

the low-speed needle by turning it clockwise

until it stops, then turn it counterclockwise

30 hours out (open).

NOTICE: When making adjustments, only turn the needle 1/12 turn at a time.

Adjusting the High Speed Needle

Turn the high-speed needle until you achieve the ideal engine temperature and

amount of exhaust smoke. The engine should have a noticeable smoke trail during

initial acceleration and fade to a minor smoke trail when the engine reaches full

throttle.

If the engine exceeds proper running temperature, 240F (116 C), richen the highspeed needle immediately. If the engine temperature is very low considering normal

running temperature, then lean the high-speed needle.

If the high-speed needle is too lean, it will cause a high idle speed.

Adjusting the Low Speed Needle-Idle Adjustment

Turn the low-speed needle to adjust the engine idle speed. Once you have achieved

a proper idle speed, you can turn the low-speed needle by one hour in either

direction to reach the optimal engine performance. Leaning (turn in) produces a

higher idle speed. Richening (turn out) produces a lower idle speed.

8

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 9

A

s

Vehicle Tuning

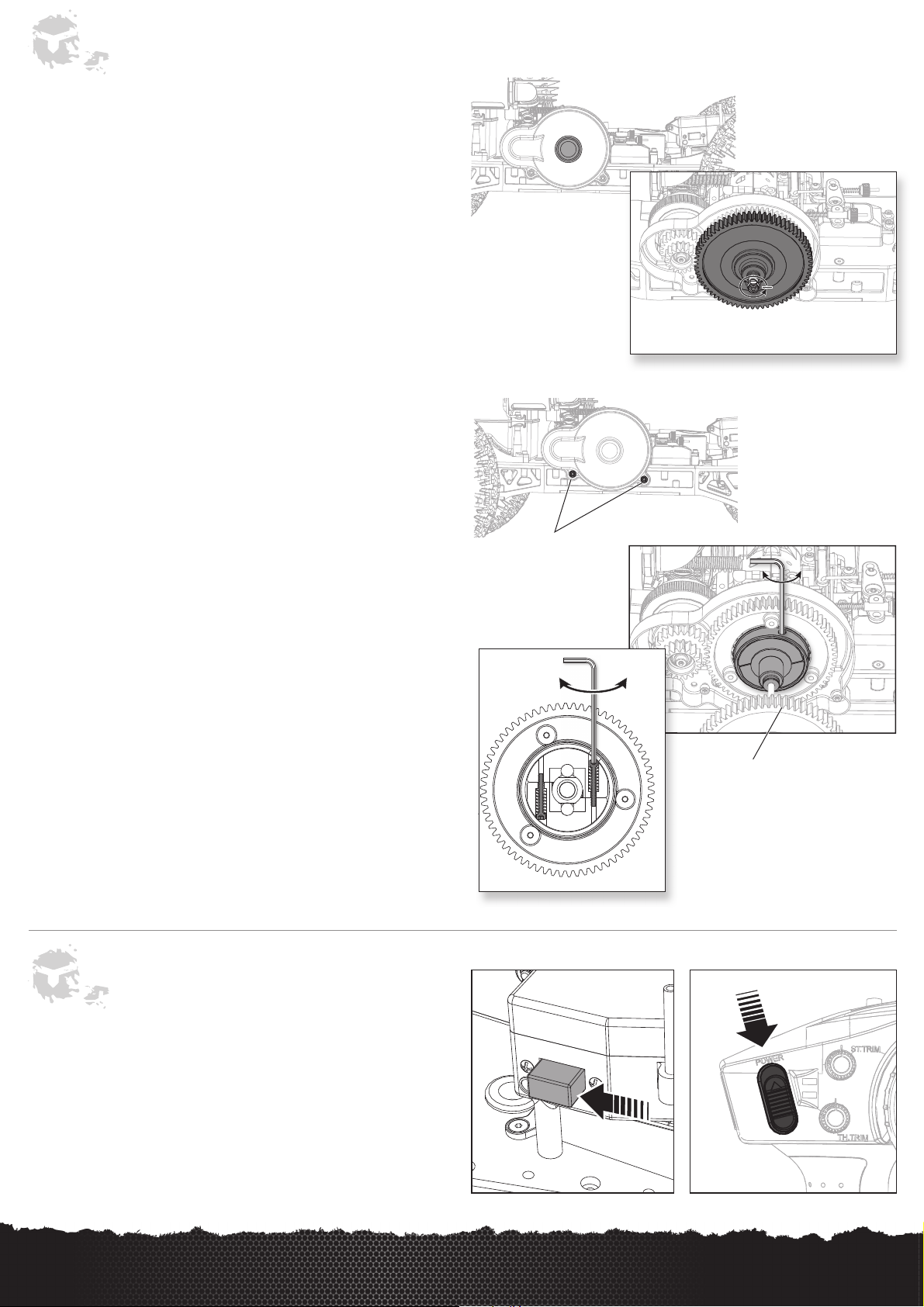

Adjusting the Slipper

The slipper is a key component of the drivetrain that is designed to help absorb

sudden or large impacts that would otherwise stress various drivetrain parts. You

should never run the LST XXL 2 vehicle with the slipper locked (completely tight).

The slipper can also be used as a tuning aid for extremely slick conditions. To

easily adjust the slipper, remove the plug from the gear cover. Start by turning

the 1/4-inch adjustment nut clockwise (tighten) until it gets tight and the spring is

compressed. Do not overtighten as you will strip the nut. Now turn the adjustment

nut counterclockwise (loosen) one full turn. This should be a good overall setting.

2-Speed Adjustment

Although pre-adjusted at the factory, the two-speed can be adjusted to shift at the

point that suits you best. Under normal circumstances, it should shift slightly before

the engine reaches maximum power. The actual distance traveled will vary with

the gear ratio and tune of the engine. There are two adjustment screws (see fig 1)

that must be changed evenly for the two-speed to function correctly. Turning these

clockwise will make it shift later and require the engine to rev higher. Turning them

counterclockwise will make it shift earlier and require less engine speed. If you

should get lost adjusting the two-speed, start over at the factory setting by lightly

bottoming out the adjustment screws and then backing them out five full turns. The

procedure for adjusting the two-speed is as follows.

• Remove the gear cover.

• Turn the spur gears until the adjustment hole is visible in the bell housing between

the large and small spur gears.

• Hold the small spur gear and, using your thumb, rotate the slipper forward until

you can see the head of one of the adjustment screws.

• Use a 5/64 Allen wrench to make your adjustment in 1/2-turn increments. Use the

bent leg of the wrench as your guide.

• Turn the slipper forward 1/2 rotation to adjust the other adjustment screw like the

first.

(Remember to always adjust BOTH screws the same amount)

• Test drive the model to check the new shift point and replace the gear cover if

satisfied.

• Never run your model without the gear cover, as it is dangerous and gear damage

will occur!

Remove 2 screws to

remove gear cover.

Fig 1

Later

Always adjust BOTH adjustment

screws evenly

Sooner

Gear cover removed for

illustration purposes.

Turn one full turn out

Outer spur gear removed for illustration

purposes.

Turning Off the Truck

1. To turn off the truck, simply move the truck's receiver power switch to the off

position. This will eliminate power to the CDI and will turn off the engine.

2. Power off the transmitter.

LOSI LST XXL 2 • INSTRUCTION MANUAL

1. 2.

EN

9

Page 10

Troubleshooting Guide

Possible Cause Solution

ENGINE DOES NOT START

Out of fuel Refi ll the tank and follow starting instructions.

Engine fl ooded Remove the spark plug. Roto-start for 3 to 5 seconds. Replace and test

Air fi lter is clogged Check and replace if necessary

Fuel mixture is old or bad Mix fresh fuel per instructions

Spark plug is not working Check the spark plug and ignition coil and replace if necessary

Throttle servo failed/Setup is wrong Check servo operation. Set it to neutral and reset the linkage according

Carburetor is incorrectly adjusted Return the carburetor to the factory settings and retune if necessary

Piston and cylinder is worn Check the piston and cylinder for wear or damage and replace if necessary

Vehicle's power switch is not in the on

position

ENGINE STARTS THEN STALLS

Out of fuel Refi ll the tank and follow starting instructions

Air fi lter is clogged Check and replace if necessary

Engine may be overheated Let the engine cool. Reset the carburetor to factory settings and restart

Engine idle is too low Follow the instructions to increase idle speed

Carburetor is incorrectly adjusted Return the carburetor to the factory settings and retune if necessary

Clutch is slipping or locked-up Check the clutch for worn/broken lining or spring. Also check clutch

Fuel mixture is old or bad Mix fresh fuel per instructions

Throttle servo is improperly set up Set the servo to neutral and reset the linkage according to radio and model

Drivetrain is not functioning properly Check the drivetrain for smooth operation/damage

to your radio and model manufacturer's specifi cations

Locate the power switch on the side of the receiver box and switch to ON

position

bearings and ensure free rotation

manufacturer's specifi cations

ENGINE IS RUNNING, BUT VEHICLE DOES NOT MOVE

Brakes are stuck Look for damage or foreign matter locking the brakes

Drivetrain is damaged Check for damaged driveshaft or diff. Replace as needed

Receiver battery capacity is low Charge the receiver battery

Radio is not responding despite charged

battery

ERRATIC CONTROL

Transmitter and/or receiver batteries are weak Install new batteries in the transmitter. Recharge the receiver battery

Connectors are inserted improperly Check the connectors and reinstall if necessary

Brake is not working Check the servo, brakes, and linkage for damage. Repair/replace/reset

The steering gain is set too high Turn down the steering gain

The throttle channel was reversed after

calibration

The steering channel was reversed after

calibration

Make sure binding is properly set up

the servo linkage to factory settings

Rebind and calibrate

Rebind and calibrate

10

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 11

Maintenance and Trouble Shooting

Binding and Calibrating the Receiver

In order to operate, the receiver must be bound to the transmitter. Binding is

the process of programming the receiver to recognize the GUID (Globally Unique

Identifier) code of a single specific transmitter. When areceiver is bound to

atransmitter/model memory, the receiver will only respond to that specific

transmitter/model memory.

You must calibrate the receiver each time it is placed in bind mode.

IMPORTANT: The following sequence of steps must be followed in order for AVC to

function properly.

1. Insert the Bind Plug in the BIND port on the receiver.

2. Power on the receiver. The orange LED fl ashes, indicating the receiver is in bind

mode.

3. Center the ST TRIM and TH TRIM on the transmitter.

4. Put your transmitter in bind mode.

5. The bind process is complete when the orange LED on the receiver is solid.

6. Pull the transmitter trigger to Full Throttle.

7. Push the transmitter trigger to Full Brake, then return the trigger to center.

8. Turn the transmitter steering wheel to Full Right.

9. Turn the transmitter steering wheel to Full Left, then return the steering wheel to

center. The orange LED fl ashes once.

10. Remove the bind plug once the calibration and binding process is complete.

11. Power off the transmitter.

IMPORTANT: You must rebind the transmitter and receiver if you:

•

Change the servo reverse after binding

•

Change the travel after binding

•

Want to use the receiver with a different model memory

If you change the servo reversing or travel adjust after binding, AVC will not work

properly.

Disabling the Stability Assist Function

If you participate in organized racing, you may be required to turn AVC technology

off. To turn off AVC technology, insert a second Bind Plug in the Disable port before

binding.

IMPORTANT: You must calibrate the receiver each time it is placed in bind mode. To

activate AVC, see the steps in BINDING AND CALIBRATING THE RECEIVER.

Failsafe

In the unlikely event that the radio connection is lost during use, the receiver will

drive the servos to their pre programmed failsafe positions (normally no throttle and

straight steering).

If the receiver is powered on before powering on the transmitter, the receiver will

enter this failsafe mode. When the transmitter is powered on, normal control is

resumed.

Changing the Travel Adjust Settings

The travel function supports precise endpoint adjustments in each direction for the

steering and throttle channels.

1. Hold the trigger in the full brake position while powering on the transmitter. The

LED fl ashes rapidly, indicating the programming mode is active.

2. Throttle End Point: Hold the trigger in the full throttle position. Turn the TH TRIM

knob to adjust the full throttle end point.

3. Brake End Point: Hold the trigger in the full brake position. Turn the TH TRIM

knob to adjust the full brake end point. Return the trigger to the center position.

4. Left Steering End Point: Hold the steering wheel in the full left position. Turn the

ST TRIM knob to adjust the left end point.

5. Right Steering End Point: Hold the steering wheel in the full right position. Turn

the ST TRIM knob to adjust the right end point. Return the steering wheel to the

center position.

6. Power off the transmitter to save the travel adjust settings. The minimum travel

is 75% and the maximum travel is 150%. The default travel settings are 125%

steering and 100% throttle.

IMPORTANT: Failsafe activates only in the event that signal is lost from the

transmitter. Failsafe will NOT activate in the event that receiver battery power

decreases below the recommended minimums or power to the receiver is lost.

LOSI LST XXL 2 • INSTRUCTION MANUAL

EN

11

Page 12

Maintenance and Trouble Shooting

Adjusting Steering and Throttle Trims

Throttle Trim

Adjust the TH. Trim so the carburetor is completely closed when the throttle trigger

is at neutral. If throttle can not be closed using TH. Trim, please take the following

steps:

1. Make sure TH. Trim knob is set to "0" or neutral.

2. Use needle-nose pliers or ball link pliers (RVO1005) to remove or install a link on

a control horn.

3. Turn the linkage clockwise or counterclockwise until the throttle is closed.

4. Attach the linkage to the control horn after adjustment.

NOTICE: Throttle trim change may affect engine operation. Carburetor settings must

be set correctly or damage may result.

See Engine Tuning for carburetor adjusments.

Steering Trim

The model should go straight without turning the steering wheel. If not, turn the

ST. Trim knob in the direction needed for the model to go straight.

Brake

Forward

12

2.7 in (68mm)

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 13

Maintenance and Trouble Shooting

Spark Plug Test

The spark plug used with your engine (DYNE0550) is designed specifically for

the engine and is only available from Dynamite. Only use the spark plug with the

designed cylinder head button (DYNE0513), as the head button creates the spark

and controls the spark plug gap.

CAUTION: Before testing the spark plug, clean up spilled fuel and close fuel

containers. Failure to do can result in injury, fi re or damage.

Remove the spark plug from the engine and attach the plug wire and boot to the

spark plug. Place the threaded end of the spark plug against the muffler. If there is

no spark:

• Install a new spark plug (DYNE0550)

CAUTION: Do not test the spark plug near the spark plug hole or residual fuel

may ignite.

Flooded Engine

The engine will not start if too much fuel is in the cylinder. Excess fuel can be

expelled by following the steps below.

1. Disconnect and remove the spark plug.

2. Install spin-start and rotat engine over for two seconds.

3. Replace the spark plug and make sure the boot is tightly secured.

NOTICE: Always clean up spilled fuel. Failure to do so may result in injury or

damage.

LOSI LST XXL 2 • INSTRUCTION MANUAL

EN

13

Page 14

Limited Warranty

What this Warranty Covers

Horizon Hobby, LLC, (Horizon) warrants to the original purchaser that the product

purchased (the "Product") will be free from defects in materials and workmanship at

the date of purchase.

What is Not Covered

This warranty is not transferable and does not cover (i) cosmetic damage, (ii) damage

due to acts of God, accident, misuse, abuse, negligence, commercial use, or due to

improper use, installation, operation or maintenance, (iii) modifi cation of or to any

part of the Product, (iv) attempted service by anyone other than a Horizon Hobby

authorized service center, (v) Product not purchased from an authorized Horizon

dealer, or (vi) Product not compliant with applicable technical regulations.

OTHER THAN THE EXPRESS WARRANTY ABOVE, HORIZON MAKES NO OTHER

WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS ANY AND ALL IMPLIED

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES

OF NON-INFRINGEMENT, MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. THE PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED

THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE

PURCHASER’S INTENDED USE.

Purchaser’s Remedy

Horizon’s sole obligation and purchaser’s sole and exclusive remedy shall be that

Horizon will, at its option, either (i) service, or (ii) replace, any Product determined by

Horizon to be defective. Horizon reserves the right to inspect any and all Product(s)

involved in a warranty claim. Service or replacement decisions are at the sole

discretion of Horizon. Proof of purchase is required for all warranty claims. SERVICE

OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY.

Limitation of Liability

HORIZON SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL

LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, TORT, NEGLIGENCE, STRICT LIABILITY OR ANY OTHER THEORY OF

LIABILITY, EVEN IF HORIZON HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. Further, in no event shall the liability of Horizon exceed the individual price

of the Product on which liability is asserted. As Horizon has no control over use, setup,

fi nal assembly, modifi cation or misuse, no liability shall be assumed nor accepted for

any resulting damage or injury. By the act of use, setup or assembly, the user accepts

all resulting liability. If you as the purchaser or user are not prepared to accept the

liability associated with the use of the Product, purchaser is advised to return the

Product immediately in new and unused condition to the place of purchase.

Law

These terms are governed by Illinois law (without regard to confl ict of law principals).

This warranty gives you specifi c legal rights, and you may also have other rights

which vary from state to state. Horizon reserves the right to change or modify this

warranty at any time without notice.

Inspection or Services

If this Product needs to be inspected or serviced and is compliant in the country

you live and use the Product in, please use the Horizon Online Service Request

submission process found on our website or call Horizon to obtain a Return

Merchandise Authorization (RMA) number. Pack the Product securely using a shipping

carton. Please note that original boxes may be included, but are not designed to

withstand the rigors of shipping without additional protection. Ship via a carrier

that provides tracking and insurance for lost or damaged parcels, as Horizon is not

responsible for merchandise until it arrives and is accepted at our facility. An Online

Service Request is available at http://www.horizonhobby.com/content/_servicecenter_render-service-center. If you do not have internet access, please contact

Horizon Product Support to obtain a RMA number along with instructions for

submitting your product for service. When calling Horizon, you will be asked to provide

your complete name, street address, email address and phone number where you can

be reached during business hours. When sending product into Horizon, please include

your RMA number, a list of the included items, and a brief summary of the problem.

A copy of your original sales receipt must be included for warranty consideration. Be

sure your name, address, and RMA number are clearly written on the outside of the

shipping carton.

NOTICE: Do not ship LiPo batteries to Horizon. If you have any issue with

a LiPo battery, please contact the appropriate Horizon Product Support

offi ce.

Warranty Requirements

For Warranty consideration, you must include your original sales receipt verifying the

proof-of-purchase date. Provided warranty conditions have been met, your Product

will be serviced or replaced free of charge. Service or replacement decisions are at

the sole discretion of Horizon.

Non-Warranty Service

Should your service not be covered by warranty, service will be completed and

payment will be required without notifi cation or estimate of the expense unless the

expense exceeds 50% of the retail purchase cost. By submitting the item for service

you are agreeing to payment of the service without notifi cation. Service estimates are

available upon request. You must include this request with your item submitted for

service. Non-warranty service estimates will be billed a minimum of ½ hour of labor.

In addition you will be billed for return freight. Horizon accepts money orders and

cashier’s checks, as well as Visa, MasterCard, American Express, and Discover cards.

By submitting any item to Horizon for service, you are agreeing to Horizon’s Terms

and Conditions found on our website http://www.horizonhobby.com/content/_servicecenter_render-service-center.

ATTENTION: Horizon service is limited to Product compliant in the

country of use and ownership. If received, a non-compliant Product will

not be serviced. Further, the sender will be responsible for arranging

return shipment of the un-serviced Product, through a carrier of the

sender’s choice and at the sender’s expense. Horizon will hold noncompliant Product for a period of 60 days from notifi cation, after which

it will be discarded.

WARRANTY SERVICES

Questions, Assistance, and Services

Your local hobby store and/or place of purchase cannot provide warranty support

or service. Once assembly, setup or use of the Product has been started, you

must contact your local distributor or Horizon directly. This will enable Horizon

to better answer your questions and service you in the event that you may need

any assistance. For questions or assistance, please visit our website at www.

horizonhobby.com, submit a Product Support Inquiry, or call the toll free telephone

number referenced in the Warranty and Service Contact Information section to speak

with a Product Support representative.

14

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 15

Warranty and Service Contact Information

Country of

Purchase

United States of America

United Kingdom

Germany

France

China

Horizon Hobby Contact Information Address

Horizon Service Center

(Repairs and Repair Requests)

Horizon Product Support

(Product Technical Assistance)

Sales

Service/Parts/Sales:

Horizon Hobby Limited

Horizon Technischer Service service@horizonhobby.de

Sales: Horizon Hobby GmbH +49 (0) 4121 2655 100

Service/Parts/Sales:

Horizon Hobby SAS

Service/Parts/Sales:

Horizon Hobby – China

servicecenter.horizonhobby.com/RequestForm/

infofrance@horizonhobby.com

info@horizonhobby.com.cn

FCC Information

This device complies with part 15 of the FCC rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may

cause unde-sired operation.

CAUTION: Changes or modifi cations not expressly approved by the

party responsible for compliance could void the user’s authority to operate the

equipment.

www.quickbase.com/db/

bghj7ey8c?a=

GenNewRecord

888-959-2306

sales@horizonhobby.com

888-959-2306

sales@horizonhobby.co.uk

+44 (0) 1279 641 097

+33 (0) 1 60 18 34 90

+86 (021) 5180 9868

Harlow, Essex, CM18 7NS, United Kingdom

4105 Fieldstone Rd

Champaign, Illinois, 61822 USA

Units 1–4 , Ployters Rd, Staple Tye

Christian-Junge-Straße 1

25337 Elmshorn, Germany

11 Rue Georges Charpak

77127 Lieusaint, France

Room 506, No. 97 Changshou Rd.

Shanghai, China 200060

Antenna Separation Distance

When operating your Spektrum transmitter, please be sure to maintain a separation

distance of at least 5 cm between your body (excluding fi ngers, hands, wrists, ankles

and feet) and the antenna to meet RF exposure safety requirements as determined by

FCC regulations.

The following illustrations show the approximate 5 cm RF exposure area

and typical hand placement when operating your Spektrum transmitter.

This product contains a radio transmitter with wireless technology which has been

tested and found to be compliant with the applicable regulations governing a radio

transmitter in the 2.400 GHz to 2.4835 GHz frequency range.

LOSI LST XXL 2 • INSTRUCTION MANUAL

EN

15

Page 16

Compliance Information for the European Union

AT BE BG CZ CY DE DK

EE ES FI FR GR HR HU

IE IT LT LU LV MT NL

PL PT RO SE SI SK UK

IS LI NO CH

Declaration of Conformity

(in accordance with ISO/IEC 17050-1)

No. HH2014041706

Product(s): LOS LST XXL 2.0 (Spektrum DX2E transmitter and

SPMSRS4200 receiver included)

Item Number(s): LOS04002

Equipment class: 2

The object of declaration described above is in conformity with the requirements

of the specifications listed below, following the provisions of the European R&TTE

directive 1999/5/EC, EMC Directive 2004/108/EC and LVD Directive 2006/95/EC:

EN 300-328 V1.7.1: 2006

EN301 489-1 V1.9.2: 2012

EN301 489-17 V2.1.1: 2009

EN60950-1:2006+A11:2009+A1:2010+A12: 2011

EN55022:2010 + AC:2011

EN55024:2010

Instructions for Disposal of WEEE by Users in

the European Union

This product must not be disposed of with other waste. Instead, it is the user’s

responsibility to dispose of their waste equipment by handing it over to a designated

collection point for the recycling of waste electrical and electronic equipment. The

separate collection and recycling of your waste equipment at the time of disposal will

help to conserve natural resources and ensure that it is recycled in a manner that

protects human health and the environment. For more information about where you

can drop off your waste equipment for recycling, please contact your local city office,

your household waste disposal service or where you purchased the product.

Signed for and on behalf of:

Horizon Hobby, LLC

Champaign, IL USA

Apr 17, 2014

Robert Peak

Chief Financial Officer

Horizon Hobby, LLC

16

EN

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 17

Replacement Parts List • Teileliste • Liste des pièces de rechange • Elenco dei ricambi

Part # English Deutsch Français Italiano

SUSPENSION PARTS • AUFHÄNGUNG • SUSPENSION • PARTI DELLE SOSPENSIONI

LOSB2035

LOSB2102

LOSB2104 Front Spindles & Carriers (LST2/XXL)

LOSB2106 Rear Hub Carriers (LST/2/XXL) Radträger hinten Fusées arrières (LST/XXL) Portamozzi posteriori (LST/2/XXL)

CHASSIS PARTS • CHASSIS • CHÂSSIS • CHASSIS

LOSB2250 Chassis Side Rails - Long (XXL) Chassis Seitenteile - Lang (XXL) Longerons long (XXL) Traverse laterali telaio - lunghe (XXL)

LOSB2254 Motor Plate/Chassis Brace (LST/2/XXL) Motorplatter / Chassishalter

LOSB2257

LOS241000 Chassis Kit: XXL 2 Gas Chassis Kit: XXL 2 Benziner Plaques de châssis (XXL 2 GAS) Kit telaio: XXL 2 Gas

LOSB2401 F/R Bumpers & Braces (LST/2/XXL)

LOSB2450

SHOCKS • STOSSDÄMPFER • AMORTISSEURS • AMMORTIZZATORI

LOSB2815 Shock Nut & Cap Molded (4) (LST)

LOS243000 Shock Body Set (4), Red: XXL 2 Gas Dämpfergehäuse Set, Rot XXL 2 Benzin

LOSB2840 Shock Shaft (LST/2) Stoßdämpferkolben (LST/2) Tige d'amortisseur (LST/2) Albero ammortizz. (LST/2)

LOSB2875 Shock Cartridges & Seals (2) (LST/2)

LOSB2876

LOSB2900 Shock Hardware - All Plastic (LST/2) Stoßdämpferzbh. Kunststoff. (LST/2)

LOSB2950 Shock Springs - Silver (pr) (LST/2/XXL) Dämpferfeder Silber Pr. (LST/2/XXL) Ressorts argent (paire) (LST/2/XXL)

TRANSMISSION • ANTRIEB • TRANSMISSION • TRASMISSIONE

LOSB3102 Transmission Case Set (LST/2) Antriebsgehäuse Set (LST/2) Boîtier de transmission (LST/2) Set scatola trasmissione (LST/2)

LOSB3118 Front/Rear Bevel Set Kegelrad Set v/h Pignons coniques AV/ARR Set coppia conica ant/post

LOSB3125 Trans Drive & Selector Pin Set (LST/2) Antriebsstifte-Set (LST/2)

LOSB3127 Trans Output Shaft & Spacer (LST/2)

LOSB3128 Trans Outdrive Cup Set (LST/2) Mitnehmer für Kardanwelle (LST/2) Noix de sorties (LST/2) Set bicchierino trasmissione (LST/2)

LOSB3132 Forward Only INput Shaft Set: LST/2 Welle Freilauf (LST/2)

LOSB3133 Forward Only Input Gear, 22T: LST/2 Zahnrad Freilauf (LST/2)

LOSB3135

LOSB3136

LOSB3138 Fwd. Only Trans Plug Set (LST/2/AFT) Getriebeabdeckung (2Gang) (LST)

LOSB3190 Gear Cover (2-Speed) (LST)

LOSB3193 Inside Gear Cover (LST)

LOSB4203 FWD/REV & Brake Arms (LST/2)

CLUTCH PARTS • KUPPLUNG • EMBRAYAGE • PARTI FRIZIONE

LOSB3322 Clutch Spring Set (3) Silver (LST/2) Kupplungsfedern silber (3) (LST/2) Set de ressorts d'embrayage argent (3) Set molle frizione (3) argento (LST/2)

LOSB3323

2-SPEED & SLIPPER PARTS • 2-GANG GETRIEBE U. RUTSCHKUPPLUNG • BOITE À 2 VITESSES ET SLIPPER • PARTI 2 VELOCITA' E SLIPPER

LOSB3341 Clutch Bell Two Speed, 18/25T: LST/2

LOSB3401 2-Speed Cam & Bushings (LST/2) 2-Gang Träger und Gleitlager (LST/2) Came avec paliers Cam 2 velocità e boccole (LST/2)

F/R HD Suspension Arms (pr) (XXL/

LST2)

Steering Bell Cranks, Shafts, & Chassis

Braces (LST/2)

R&L Bulkheads & Hardware (LST/2/

XXL)

F/R Body Mount Posts & Hardware

(LST/2/XXL)

Shock Cartridge & Cap O-Rings (8)

(LST/2)

Fwd. Only Counter Shaft Set (LST/2/

AFT)

Fwd. Only Counter Gear 23T Ti-ni

(LST/2/AFT)

Aluminum Clutch Shoe & Spring Set

(All)

Querlenkerset Vorne/Hinten: XXL, LST2

Servosaver und Chassishalter (LST/2)

Achsschenkel und Achsschenkelträger

(LST2/XXL)

Bulkhead l+r m. Zbh.(LST/2/XXL)

Stoßfänger vorne u. Distanzstücke

(LST/2XXL)

Karosseriehalter v/h (LST/2/XXL)

Dämpfermutter und. Endkappe (4)

(LST)

Stoßdämpferkappe m. Dichtung (2)

(LST/2)

Stoßdämpferkappe mit Oringen (8)

LST/2)

Getriebeausgangswelle und Hülse

(LST/2)

Gegenwelle Freilauf (LST/2)

Gegenzahnrad Freilauf 23 Zähne

(LST/2)

Getriebeabdeckung innen (2Gang)

(LST)

Getriebeabdeckung innen (2Gang)

(LST)

Vorwärts/rückwärts Anlenkhebel

(LST/2)

Team Losi Aluminium

Kupplungsbacken

Losi Kupplungsglocke, 2-Gang 18/25Z:

LST2

Triangles de suspension AV/ARR

renforcés (Paire) (XXL/LST2)

Renvois de direction, axes et renforts

de châssis (LST/2)

Fusées avant avec étriers (LST2/XXL) Perni e guide anteriori (LST2/XXL)

Platine moteur/renfort châssis (LST/2/

XXL)

Cellules gauche/droite avec support de

diff (LST/2/XXL)

Pare-choc av/arr avec renfort (LST/2/

XXL)

Support de carrosserie AV/ARR avec

visserie (LST/2/XXL)

Bouchon supérieur/bague de réglage

(4) (LST)

Corps d'amortisseur rouges (4) (XXL

2 GAS)

Cartouches avec joints (2) (LST/2)

Joints toriques de cartouche (8)

(LST/2)

Accessoires d'amortisseur en plastique

(LST/2)

Set de goupilles de transmission

(LST/2)

Arbre de sortie avec entretoise (LST/2)

Arbre d'entrée marche avant

uniquement

Pignon d'entrée marche avant

uniquement

Arbre intermédiaire marche avant

uniquement

Pignon intermédiaire marche avant

uniquement

Capuchons pour marche avant

uniquement.

Couvercle de protection (transmission

à 2 vitesse)

Couvercle interne de transmission Coperchio interno ingranaggi (LST)

Leviers de freins et de M AV/ARR FWD/REV & bracci freno (LST/2)

Set de mâchoires en aluminium et

ressorts

Cloche d'embrayage 18/25T

F/R HD bracci sospensioni (pr) (XXL/

LST2)

Rinvii sterzo, alberi e supporti telaio

(LST/2)

Piastra motore/Supporto telaio (LST/2/

XXL)

R&L paratie e viteria (LST/2/XXL)

Paraurti A/P e supporti (LST/2/XXL)

Supporti carrozzeria A/P e viteria

(LST/2/XXL)

Dadi ammort. e tappi stampati (4) (LST)

Set corpo ammortizz. (4), rosso: XXL

2 Gas

Cartucce ammort. e guarniz. (2)

(LST/2)

Cartucce ammort. e o-ring tappo. (8)

(LST/2)

Viteria ammort. - tutta plastica (LST/2)

Molle ammort. - argento (pr) (LST/2/

XXL)

Set trasmissione e perni selettore

(LST/2)

Albero uscita trasmissione e distanziale

(LST/2)

Set solo albero entrata anter: LST/2

Solo ingranaggio entrata anter 22T:

LST/2

Solo set albero secondario anter.

(LST/2/AFT)

Solo ingranaggio secondario anter. 23T

Ti-ni (LST/2/AFT)

Set solo spina trasm. anter. (LST/2/

AFT)

Coperchio ingranaggi (2-velocità) (LST)

Pattini frizione alluminio e set molla

(All)

Campana frizione 2 velocità, 18/25T:

LST/2

LOSI LST XXL 2 • INSTRUCTION MANUAL

59

Page 18

Part # English Deutsch Français Italiano

LOSB3404

LOSB3410

LOSB3411

LOSB3420 70T Spur (1st) Gear (LST/2/XXL)

LOSB3424 63T Spur (2nd) Gear (LST/2/XXL)

LOSB3450 Slipper Cage (LST/2) Kupplungskäfi g (LST/2) Cage de slipper Gabbia slipper (LST/2)

LOSB3451 Slipper Pads & Plates (LST/2) Kupplungsbeläge u. Platten (LST/2) Plateaux et garnitures de slipper Palette e piastre slipper (LST/2)

LOSB3455

DRIVETRAIN PARTS • GETRIEBE • TRANSMISSION • PARTI TRASMISSIONE

LOS242000 20mm Wheel Hex Set, Red: XXL 2 Gas Radmuttern 20mm Rot: XXL 2 Benzin Hexagônes de roues 20mm rouges

LOSA3505 Diff Seal Set: 8B, 8T, LST, XXL/2 Losi 8B/T,LST: Diff-Dichtungs Set set de joints de différentiel Set guarnizioni diff, XXL/2

LOSB3520

LOSB3521

LOSB3522 F/R Super-Duty CV Axle (LST2/XXL) Achse v/h (LST2/XXL) Axe de roue AV/ARR

LOSB3523

LOSB3534 F/R Diff Ring & Pinion Gears (All) Triebling und Tellerrad Diff v/h (Alle) Pignons et couronne de diff AV/ARR F/R Anello diff. e pignoni (tutti)

LOSB3537 F/R Diff Housing (All) Diffgehäuse v/h Corps de diff AV/ARR F/R Scatola diff. (tutti)

LOSB3538 F/R Diff Bevel Gear Set (All) Diff. Kegelrad v/h. (alle) Pignons coniques de diff AV/ARR Set coppie coniche diff. (tutte)

LOSB3540 F/R Diff Outdrive Set (All) Diff-Abtriebs Set (Alle) Noix de sortie de diff AV/ARR F/R Set bicchierini diff. (tutti))

LOSB3541 F/R Diff Drive Yoke (All) Diff Mitnehmer v/h (alle) Noix de cardans central AV/ARR F/R Staffa azionamento diff. (tutti)

LOSB3547

LOSB3601 Brake Disks - Steel(2) (LST/2) Bremsscheibe Stahl (2) (LST/2) Disques de frein acier (2) Disco freno - acciaio (2) (LST/2)

LOSB3603 Brake Cam (LST/2) Bremsnock (LST/2) Came de frein Cam freno (LST/2)

LOSB3605 Brake Pads & Bracket (LST/AFT/XXL) Brensbleag u. Halter (LST/AFT/XXL) Plaquettes de frein avec guide Pattini freno e supporto (LST/AFT/XXL)

HARDWARE • SCHRAUBEN U. ZBH. • VISSERIE • VITERIA

LOSA4002 Antenna Tube & Cap Losi Antennen Kit Tube d'antenne avec capuchon Antenna Tube & Cap

LOSA4003 Antenna Caps Antennen Kappen Capuchons d'antenne CAppucci antenna

LOSA6100 1/8” E-Clips 1/8 E-Clips Circlips 1/8 1/8” E-Clips

LOSA6103 3/32” E-Clips 3/32 E-Clips Circlips 3/32 3/32” E-Clips

LOSA6106 4mm E-Clips (12) 4mm E-Clips (12) Circlips 4mm (12) 4mm E-Clips (12)

LOSA6107 6mm W-Clips (12) 6mm W-Clips (12) Circlips 6mm (12) 6mm W-Clips (12)

LOSA6204 4-40 x 1/2” Cap Head Screw (10) 4-40 x 1/2 Zylinderkopfschrauben (10) Vis CHC 4-40 x 1/2 (10) 4-40 x 1/2” Vite testa a brugola (10)

LOSA6205 4-40 x 3/4” Cap Head Screw (10)

LOSA6206 4-40 x 3/8 Cap Head Screw (10) 4-40 x 3/8 SH Schrauben (10) Vis CHC 4-40 x 3/8 (10) 4-40 x 3/8 Vite testa a brugola (10)

LOSA6210 4-40 x 3/8 Flat Head Screw (10) 4-40 x 3/8 Flachkopfschrauben (10) Vis FHC 4-40 x 3/8 (10) 4-40 x 3/8 Vite testa piatta (10)

LOSA6216 4-40 x 7/8” Cap Head Screw (10)

LOSA6220 4-40 x 1/2” Flat Head screw (10) 4-40 x 1/2 Flachkopfschrauben (6) Vis FHC 4-40 x 1/2 (10) 4-40 x 1/2” Vite testa piatta (

LOSA6221 4-40 x 5/8” Cap Head Screw (6) 4-40 x 5/8 Zylinderkopfschrauben (10) Vis CHC 4-40 x 5/8 (6) 4-40 x 5/8” Vite testa a brugola (6)

LOSA6227 4-40 Hardened Setscrew (10) Madenschrauben gehärtet 4-40 (10) Vis HC 4-40 trempée (10) 4-40 Grano indurito (10)

LOSA6229 4-40 x 3/8” Button Head Screw (10) 4-40 x 3/8 Rundkopfschrauben (10) Vis BHC 4-40 x 3/8 (10) 4-40 x 3/8” Vite a testa tonda (10)

LOSA6232 2-56 x 1/4” Cap Head Screw (10) 2-56 x 1/4 Inbusschrauben Vis CHC 2-56 x 1/4(10) 2-56 x 1/4” Vite testa a brugola (10)

LOSA6233 4-40 x 5/8” Flat Head Screw (10) 4-40 x 5/8 Flachkopfschrauben (10) Vis FHC 4-40 x 5/8 (10) 4-40 x 5/8” Vite testa piatta(10)

LOSA6234 4-40 x 1/4” Button Head Screw (10) 4-40 x 1/4 Halbrundschrauben (10) Vis BHC 4-40 x 1/4 (10) 4-40 x 1/4” Vite a testa tonda (10)

LOSA6240 5-40 x 1/2” Cap Head Screw (8) 5-40 x 1/2 Inbusschrauben (8) Vis CHC 5-40 x 1/2 (8) 5-40 x 1/2” Vite testa a brugola (8)

LOSA6241 5-40 x 5/8” Cap Head Screw (8) 5-40 x 5/8 Inbusschrauben (8) Vis CHC 5-40 x 5/8 (8) 5-40 x 5/8” Vite testa a brugola (8)

LOSA6242 5-40 x 1-1/4” Cap Head Screw (4) 5-40 x1 1/4 Inbusschrauben (8) Vis CHC 5-40 x 1-1/4 (4) 5-40 x 1-1/4” Vite testa a brugola (4)

LOSA6244 Kingpin Screw (LST) (8) Kingpin Schraube (LST) (8) Vis/pivot de fusée (8) Vite a perno (LST) (8)

LOSA6245 4-40 x 5/16” Cap Head Screw (10) 4-40 x 5/16 Inbusschrauben (10) Vis CHC 4-40 x 5/16 (10) 4-40 x 5/16” Vite testa a brugola (10)

LOSA6246 2-56 x 5/8” Cap Head Screw (8) 2-56 x 5/8 Inbusschrauben (8) Vis CHC 2-56 x 5/8 (8) 2-56 x 5/8” Vite testa a brugola (8)

2-Speed Clutch Shoes & Hardware

(LST/2)

2-Speed Low Gear Hub w/One-Way

(LST/2/XXL)

2-Speed High Gear Hub w/Bearing

(LST/2/XXL)

2-Speed/Slipper Thrust Bearing &

Hardware (LST/2)

F/R Super-Duty CV Drive Shaft (pr)

(LST2/XXL)

F/R Super-Duty CV Drive Shaft Only

(LST2/XXL)

F/R Super-Duty CV Rebuild Set (pr)

(LST2/XXL)

Center CV Driveshaft Assm. - Long

(XXL)

Losi 2-Gang Kupplungsbacken und

Zubehör: LST/2

2-Gang Träger 1.Gang mit Freilauf

(LST/2/XXL)

2-Gang Träger 2.Gang mit Freilauf

(LST/2/XXL)

70T Hauptzahnrad/ 2 Gang (LST/2/

XXL)

63T Hauptzahnrad/Schaltstufe 2:

LST/2/XXL)

2-Gang Rutschkupplung Drucklager m.

Zbh (LST/2)

Antriebswellenset Vorne/Hinten: LST2, cardan CVD renforcé AV/ARR (paire)

Antriebswelle: LST2,

Achse v/h Reperaturset (Pr) (LST2/XXL)

Antriebswelle Mitte lang (XXL) Cardans CVD centraux longs

4-40 x 3/4 Zylinderkopf Schrauben

(10)

4-40 x 7/8 Zylinderkopf Schrauben

(10)

Mâchoires avec visserie

Moyeu de roue libre de 1ère vitesse

Moyeu de 2 ème vitesse

Couronne 70T (1ère vitesse) Prima corona 70T (LST/2/XXL)

Couronne 63T (2ème vitesse) Seconda corona 63T (LST/2/XXL)

Butée à billes et accessoires de slipper

Tige de cardan CVD renforcé AV/ARR

Kit de réparation pour cardan CVD

renforcé (paire)

Vis CHC 4-40 x 3/4 (10) 4-40 x 3/4” Vite testa a brugola (10)

Vis CHC 4-40 x 7/8 (10) 4-40 x 7/8” Vite testa a brugola(10)

Pattini frizione 2 velocità e viteria

(LST/2)

Mozzo ingran. veloc. bassa c/

ruotalibera (LST/2/XXL)

Mozzo ingran. veloc. alta c/cuscinetto

(LST/2/XXL)

Cuscinetto reggispinta 2 veloc./slipper

e viteria (LST/2)

Set esagoni ruote 20mm, rossi: XXL

2 Gas

F/R Super-Duty CV Drive Shaft (pr)

(LST2/XXL)

Albero trasmissione rinforzato CV

(LST2/XXL)

Solo albero trasmissione rinforzato CV

(LST2/XXL)

F/R Asse rinforzato CV (pr) (LST2/XXL)

Albero trasm. centrale CV assembl. lungo (XXL)

10)

60

LOSI LST XXL 2 • INSTRUCTION MANUAL

Page 19

Part # English Deutsch Français Italiano

LOSA6247 2-56 x 3/4” Cap Head Screw 2-56 x 3/4 Inbusschraube Vis CHC 2-56 x 3/4 2-56 x 3/4” Vite testa a brugola

LOSA6250 4 & 5mm Setscrews (4 ea) 4 u. 5mm Madenschrauben (je 4) Vis HC M4 et M5 (4 de chaque) 4 & 5mm Grani (4 ea)

LOSA6307 5-40 Nuts - Lock & Hex (4 ea) 5-40 Stopmutter Ecrous freins 5-40 (4)

LOSA6305 4-40 Steel Locknuts 4-40 1/2 Muttern Stahl (10) Ecrous frein inox 4-40 4-40 Autobloccanti in acciaio

LOSA6321 5mm Locknuts - R & L Thread (4 ea)

LOSA6350 #4 x 1/8” Hardened Washers Unterlegscheiben #4 and 1/8 gehärtet Rondelles trempées #4x 1/8 #4 x 1/8” Rondelle indurite

LOSA6355 2.2 & 3.6mm Washers (6 ea) 3.6 x 10mm U-Scheiben (6) Rondelles 2.2 et 3.6mm (6) 2.2 & 3.6mm rondelle (6 ea)

LOSA6356 5 & 6mm Shim Set Unterlegescheiben 5mm / 6mm Set de cales de 5 et 6mm 5 & 6mm Shim Set

LOSA6937 5 x 10mm Shielded Ball Bearings (2) 5x10mm Kugellager gekapselt(2) Roulement fl asqué 5x10mm (2)

LOSA6939 6 x 10mm Shielded Ball Bearings (4) 6x10mm Kugellager gekapselt (4) Roulement fl asqué 6x10mm (4)

LOSA6940 6 x 12mm Shielded Ball Bearings (4) 6x12mm Kugellager gekapselt (4) Roulement fl asqué 6x12mm (4)

LOSA6941 6 x 12mm Flanged Ball Bearings (4) 6x12 Kugellager m. Flansch (4) Roulement épaulé 6x12mm (4)

LOSA6942 8 x 16mm Sealed Ball Bearings (4) 8x16mm Kugellager (4) Roulement étanche 8x16mm (4) 8 x 16mm Sealed Ball Bearings (4)

LOSA6944 15x21x4mm Shielded Ball Bearings 15x 21x4mm Kugellager gekapselt(2) Roulement fl asqué 15x21x4mm

LOSB3951 Differential Shims (13mm) (LST/2/AFT)

LOSB4001 93mm Turnbuckle Set w/Ends (2) (LST)

LOSB4020 Rod Eds & Pivot Balls (8) (LST) Kugelpfanne und Pivot Kugel (8) (LST) Chapes avec rotules (8) Attacchi a sfera (8) (LST)

LOSB4104 Pivot Pin Set (4 ea) (LST) Querlenkerstifte aussen (je 4) (LST2) Set d'axe des pivots (4) Set perni rotanti (4 ea) (LST)

LOSB4111 Spindle Bearing Spacer Set (LST/AFT)

LOSB4201 Steering Hardware Set (LST/2) Schraubenset für Lenkung (LST/2) Accessoires de direction Set viteria sterzo (LST/2)

LOSB4203 Fwd/Rev & Brake Arms (LST/2/AFT)

LOSB4204

LOSB4250 Servo Saver & Mount Set (LST/2)

LOSB4603 4-Way Wrench (Steel). 4-fach Schraubenschlüssel (Stahl) Clé en croix en inox Chiave in acciaio a 4 vie (Steel)

TLR8202 Body Clips Body Clips Clips de carrosserie Clips carrozzeria

TLR237000 5 x 8mm Shielded Ball Bearings 5x8x2.5mm Kugellager (2) Roulement fl asqué 5x8mm 5 x 8mm Cuscinetti a sfere schermati

ENGINE PARTS • ENGINE PARTS • PIÈCES MOTEUR • PARTI MOTORE

DYNE0500 .31 Gas Engine .31 Benzin Motor Moteur essence .31 .31 Motore a benzina

DYNE0505 .31 Gas Engine with CDI

DYNE0510 Cylinder Head Screws (16): .31 .31:Zylinderkopfschrauben Moteur .31 - Vis de culasse (16) Viti testa cilindro (16): .31

DYNE0511 Cylinder Head Upper: .31 .31: Zylinderkopf oberes Teil

DYNE0512 Cylinder Head Lower: .31 .31: Zylinderkopf unteres Teil

DYNE0513 Head Button: .31 .31: Zylinderkopfzentralstück Moteur .31 - Insert de culasse Viti testa .31

DYNE0514 Head Shims .1mm (2), ,2mm (2): .31 .31: Unterlegscheibe .1mm

DYNE0516 Piston/Sleeve/Connecting Rod: .31 .31: Laufbuchse / Kolben/ Pleuel Moteur .31 - Piston/chemise/ bielle Pistone/Cilindro/Biella .31

DYNE0517 Connecting Rod: .31 .31: Pleuel Moteur .31 - Bielle Biella: .31

DYNE0518 Wrist Pin w/clips: .31 .31: Kolbenbolzen Moteur .31 - Axe de piston avec clips Spinotto c/clips .31

DYNE0519 Clutch Nut: .31 .31: Kupplungsmutter Moteur .31 - Ecrou d'embrayage Dado frizione: .31

DYNE0520 Flywheel 42mm: .31 .31: Schwungrad 42mm Moteur .31 - Volant diam. 42mm Volano 42mm: .31

DYNE0521 Collet: .31 .31: Stellring Moteur .31 - Cône Collare conico: .31

DYNE0522 Carb. Retain Post Set: .31 .31: Vergaserhaltestift

DYNE0523 Exhaust Manifold Gasket: .31 .31: Krümmerdichtung Moteur .31 - Joint d'échappement Guarnizioni scarico: .31

DYNE0524 Front Bearing (7x19x6): .31 .31: Kugellager vorne (7x19x6) Moteur .31 - Roulement avant 7x19x6 Cuscinetto anteriore (7x19x6): .31

DYNE0525 Rear Bearing (14x25.5x6): .31 .31:Kugellager hinten (7x19x6)

DYNE0526 Crankcase: .31 .31: Kurbelgehäuse Moteur .31 - Carter Carter: .31

DYNE0527 Crankshaft: .31 .31: Kurbelwelle Moteur .31 - Vilebrequin Carter: .31

Throttle, Brake Reverse Linkage Set

(LST)

5mm Stopmutter/Rechts Links drehend

(je 4)

Diff Unterlegscheiben (13mm) LST/2/

AFT)

Gewindestiftsatz R/L/m.End, 93mm

(2): LST

Kugellagerdistanzhülse im Radträger

8LST/AFT)

Vorwärts/rückwärts Anlenkhebel

(LST/2/AFT)

Anlenkset Gas Bremse Rückwärtsgang

(LST2)

Servo-Saver u. Befestigungssatz

(LST/2)

.31 Benzinmotor (5,5cc) m.

Einspritzung

Ecrous freins M5 -Pas à gauche et à

droite (4 de chaque)

Cales de différentiel (13mm) Rasamenti diff. (13mm) (LST/2/AFT)

Biellettes 93mm avec chapes (2)

Set d'entretoises pour roulements de

fusées

Leviers de frein et de marche AV/ARR

Set de tringleries de gaz, de freins et

de marche arrière

Set de sauve-servo et de fi xations Set salva servo e supporto (LST/2)

Moteur essence .31 avec CDI .31 Motore a benzina con CDI

Moteur .31 - Partie supérieure de la

culasse

Moteur .31 - Partie inférieure de la

culasse

Moteur .31 - Joint de culasse ep

0.1mm (2) et 0.2mm (2)

Moteur .31 - Set de fi xation de

carburateur

Moteur .31 - Roulement arrière

14x25.5x6

5-40 Dadi auto bloccanti ed esagoni

(4 ea)

5mm Dadi autobloccanti con fi letto

destro e sinistro (4 ea)

5 x 10mm Cuscinetti a sfere schermati

(2)

6 x 10mm Cuscinetti a sfere schermati

(4)

6 x 12mm Cuscinetti a sfere schermati

(4)

6 x 12mm Cuscinetti a sfere schermati

(4)

15x21x4mm Cuscinetti a sfere

schermati

93mm Set tenditori c/terminali (2)

(LST)

Set distanziali cuscinetti perni (LST/

AFT)

Bracci avanti/indietro e freno (LST/2/

AFT)

Set comandi motore, freno reverse

(LST)

Testa cilindro superiore .31

Testa cilindro inferiore .31

Rasamenti testa.1mm (2), ,2mm (2):

.31

Set fermo carburatore: .31

Cuscinetto posteriore (14x25.5x6): .31

LOSI LST XXL 2 • INSTRUCTION MANUAL

61

Page 20

Part # English Deutsch Français Italiano

DYNE0528 Carburetor (3 Needle): .31 .31: Vergaser (3 Nadeln) Moteur .31 - Carburateur Carburatore (3 spilli) .31

DYNE0529 Carb O-Ring/Seal Set: .31 .31: Vergaser O-ring / Dichtungsset

DYNE0530 Throttle Barrel: .31 .31: Gasküken Moteur .31 - Boisseau de carburateur Protezione barilotto: .31

DYNE0531 Low Speed Needle: .31 .31: Halbgasnadel Moteur .31 - Pointeau de reprise Spillo minimo: .31

DYNE0532 Throttle Barrel Boot: .31 .31: Manschette Gasküken

DYNE0533 Carb Ball Link/Ball End: .31 .31: Kugelkopfanschluss Vergaser

DYNE0536 High Speed Needle Valve: .31 .31: Vollgasnadelventil Moteur .31 - Pointeau de richesse Porta spillo del massimo: .31

DYNE0537 High Speed Needle Holder: .31 .31: Halter Vollgasnadel

DYNE0538 Fuel Inlet Nipple: .31 .31: Kraftstoffnippel Moteur .31 - Prise d'arrivée carburant Presa ingresso carburante: .31

DYNE0539 Idle Speed Screw: .31 .31: Leerlaufschraube Moteur .31 - Vis de ralenti Vite velocità minimo: .31

DYNE0541 Carb Body: .31 .31: Vergasergehäuse Moteur .31 - Corps de carburateur Corpo carburatore: .31

DYNE0542 Backplate w/O-Ring, Screws: .31

DYNE0543 Backplate O-ring (2): .31 .31: O-Ring Rückplatte

DYNE0544 One Way Bearing: .31 .31: Freilauf Moteur .31 - Roue libre Cuscinetto ruota libera: .31

DYNE0545 Spin Start Shaft: .31 .31: Drehstarterwelle Moteur .31 - Axe de démarrage Albero Spin-start: .31

DYNE0546 Backplate/Shaft/One-Way: .31 .31: Rückplatte /Welle/Freilauf

DYNE0547 Spin Start Assembly: .31 Dynamite .31: Drehstarterset Moteur .31 - Backplate complète Gruppo Spin-start: .31

DYNE0548 Ignition Unit: .31 .31: Zündung Moteur .31 - Module d'allumage Unità accensione: .31

DYNE0549 Igntion Sensor Set: .31 .31: Zündsensor

DYNE0550 Spark Plug: .31 .31: Zündkerze Moteur .31 - Bougie Candela: .31

DYNE0551 Tuned Pipe Set: .31 .31: Tuningschalldämpfer Moteur .31 - Résonateur Set risonanza: .31

DYNE4105 Small Block 2-Cycle Oil 282cc Small Block 2-Takt Öl, 282cc

ENGINE ACCESSORIES • ENGINE ACCESSORIES • ACCESSOIRES MOTEUR • ACCESSORI MOTORE

DYN5645 Spin-Start Handheld Starter Spin-Start Handstarter Démarreur électrique portatif Avviatore da palmo Spin-start

LOS241001 Gas Tank Assembly: XXL 2 Gas Tank m. Zbh.: XXL 2 Réservoir à essence Gruppo serbatoio: XXL 2 Gas

LOS54000 Air Filter Boot: XXL 2 Gas Luftfi lterfl ansch (2): LST XXL 2 Gas Chaussette de fi ltre à air Attacco fi ltro aria: XXL 2 Gas

LOSA9150 Air Filter Set: 8B, 8T Luftfi lter Set: 8B /8T Filtre à air complet Set fi ltro aria: 8B, 8T

LOSA9151 Air Filter Foams, Pre-Oiled: 8B, 8T Luftfi ltereinsatz vorgeölt: 8B/8T Mousses de fi ltre à air pré-huilées Spugna fi ltro aria già oliato: 8B, 8T

LOS24002

LOSB5056

WHEELS & TIRES • RAD & REIFEN • JANTES ET PNEUS • RUOTE & GOMME

LOS44000

LOSB7202 420 Series ATX Tires w/Foam Losi 420 ATX Reifen mit Schaum

ELECTRONICS • ELEKTRONIK • ELECTRONIQUE • ELECTRONICS

SPMS601 Extra Hi Tork WP Servo

SPM2322

SPMSRS4200 AVC Receiver AVC Empfänger Récepteur AVC Ricevitore AVC

DYNB0502 7.4V 2000mAh 2S 5C LiPo Receiver Pack

BODIES & ACCESSORIES • KAROSSERIE UND ZBH. • CARROSSERIE ET ACCESSOIRES • CARROZZERIA & ACCESSORI

LOS240000 XXL Body Painted Red w/Stickers Losi LST XXL 2 Gas: Karosserie lackiert

Engine Mount & Throttle Linkage Set:

XXL 2 Gas

Tuned Pipe Mount & Hardware (LST/2/

XXL)

420S Force Wheel w/Cap, Blk Chrome

(2): LST

DX2E 2.4GHz DSM Radio System Spektrum DX2E 2 Kanal DSMR

.31: Rückplatte m. O-Ringen und

Schrauben

Motorhalter u. Gasgestänge Set: XXL

2 Gas

Schalldämpfer u. Zbh (LST/2/XXL) Support de résonateur avec visserie

420 Force Rad Chrom (2): LST

Spektrum Extra High Torque Servo

Spritzwasserdicht

Fernsteuerungs System

7.4V 2000mAh 2S 5C LiPo

Empfängerakku

Moteur .31 - Set de joints toriques de

carburateur

Moteur .31 - Souffl et de boisseau de

carburateur

Moteur .31 - Rotule de levier de

carburateur

Moteur .31 - Buse de pointeau de

richesse

Moteur .31 - Bouchon de carter avec

joint torique et vis

Moteur .31 - Joint torique de bouchon

de carter (2)

Moteur .31 - Plaque arrière avec axe

et roue libre

Moteur .31 - Set de capteurs

d'allumage

Huile pour moteur essence 2T de petite

cylindrée, 282cc

Supports moteur et tringlerie de gaz

LST - Jantes 420S Force avec

enjoliveur, chrome fumé (2)

Pneus ATX série 420 avec inserts en

mousse (2)

Servo étanche couple élevé Servo WP extra alta coppia

Emetteur DX2E 2.4GHz DSM

Batterie RX Li-Po 2S 7,4V 2000mA 5C

Carrosserie peinte avec autocollants

rouges

Set guarnizione o-ring carburatore: .31

Protezione barilotto: .31

Attacchi a sfera carburatore: .31

Porta spillo del massimo: .31

Viti tappo senza o-ring: .31

O-ring tappo (2): .31

Tappo/Albero/Ruota libera: .31

Set sensore accensione: .31

Olio 2 tempi

Set supporto motore e comandi

acceleratore: XXL 2 Gas

Supporto risonanza e viteria (LST/2/

XXL)

420S Ruote Force w/Cap, Blk Chrome

(2): LST

420 Serie gomme ATX c/spugna

Radiocomando DX2E 2.4GHz DSM

Batteria LiPo ricevitore 7.4V 2000mAh

2S 5C

Carrozzeria dipinta in rosso con adesivi

62