Lorentz PS2-150 Boost, PS2-150, PS2-200, PS2-600, PS2-1800 Manual For Installation And Operation

...

PS2-150 to PS2-4000

Solar Pumping System

Manual for Installation and Operation

Manuel d’installation et de fonctionnement

Manual de Instalación y Operación

EN

FR

The Solar Water Pumping Company

ES

ENGLISH

2

Introduction

Thank you for purchasing a LORENTZ pump system. LORENTZ has set a new standard for quality, efficiency and

durability in solar pumping.

Before you begin: All pump systems are equipped with nameplates, which contain all important data. Check the model

numbers of all the components of your system, verify that they are the items that you ordered and ensure that the packaging

is undamaged and complete. To allow best system performance and to avoid damage read and follow the installation

instructions carefully.

How to use this guide: This manual is for system installation only, follow it closely for a safe and durable installation.

The system layout must be planned beforehand. We advise using the LORENTZ COMPASS software for correct pump system

sizing.

SITES: We highly recommend registering the installation at SITES in LORENTZ partnerNET. SITES provides an easy overview

of all installed pump systems, including serial numbers and installation details. This will be essential information should

problems occur and will simplify trouble shooting and warranty topics to great extent.

Installation Overview

This installation overview is provided to familiarize you with the typical steps that are taken when installing a solar water

pumping system. Your particular installation may require the steps to be done in a different order. You should read the whole

manual before making your first installation.

WARNING – This installation overview does not substitute the detailed instructions given in this

manual. Read and follow the manual carefully to ensure reliable operation and long life of the

product and to avoid danger to health and life.

1. PV and Controller Installation

Please follow manufacturer instructions for PV installation.

Every PV installation must be equipped with a PV disconnect switch. Suitable switches are available from LORENTZ.

Install the controller close to the PV array in a shaded

location to minimize cable length on the input side.

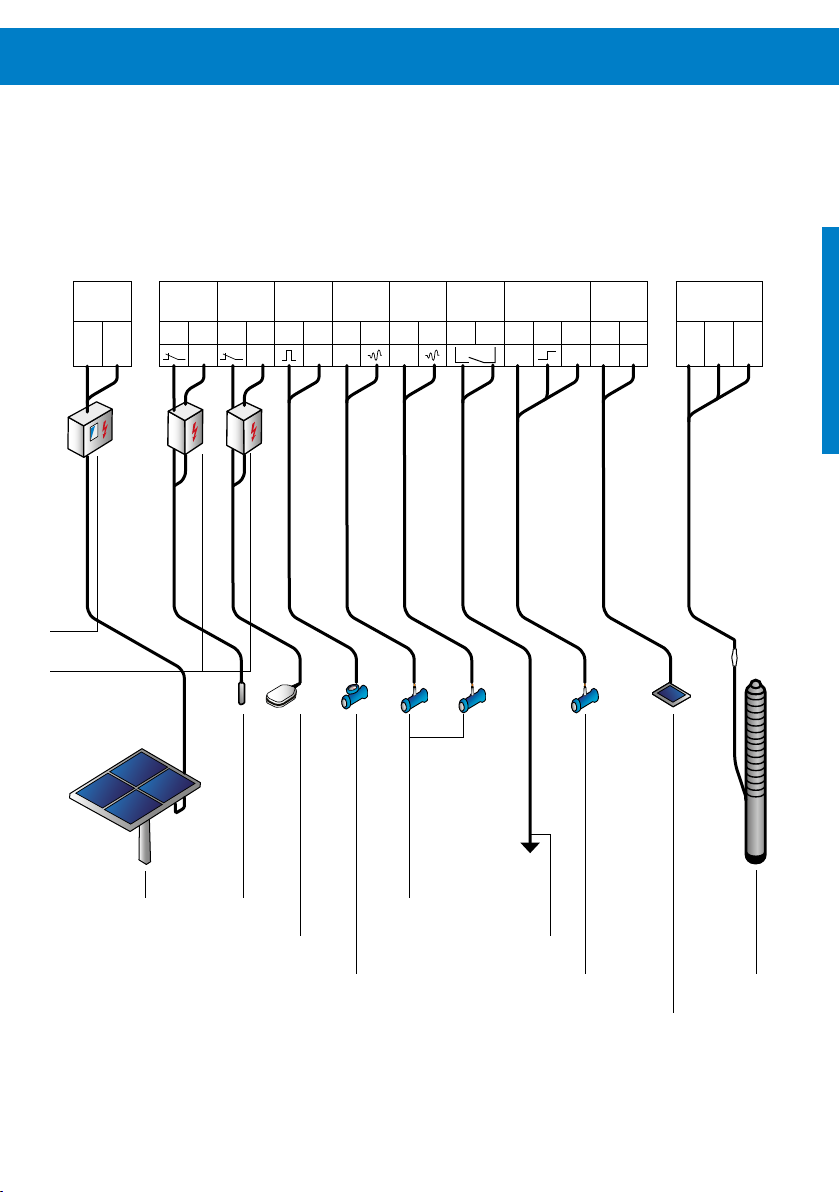

2. Electrical Installation

1. Pump wiring: The ECDrive must be connected to the

terminals L1, L2, L3 and to the earth connector

the pcb. Observe rotation direction.

2. Accessories wiring: Connect a source low protector to

terminals 1 and 2 (required). Remote control switches must

be connected to terminals 3 and 4, water meters to terminals 5 and 6, 4– 20mA sensors to terminals 7 and 8 or 9

and 10, water sensors to 13, 14 and 15 and the SunSensor

module to terminals 16 and 17. Terminals 11 and 12 are

an output relay switch.

3. DC input wiring: Connect the positive terminal of the

PV array to +, the negative terminal to −. Observe max.

input voltage. If the controller is connected to a battery

then battery mode must be activated in PumpScanner.

4. Grounding: A protective earth connection must be

wired to the earth connector below the pcb.

below

Please refer to “DC Disconnect Switch” on page 17 for

more information on the requirements the PV disconnect

must meet.

For detailed information refer to “7.5 Mounting, Space and

Ventilation Requirements” on page 19.

For detailed information refer to “7.6.2 Pump Wiring” on

page 26.

For detailed information refer to “7.6.3 Pump Accessories

Wiring” on page 27.

For detailed information refer to “7.6.4 Input Wiring for

Solar-direct Systems” on page 28.

For detailed information refer to “7.6.6 Grounding” on

page 30.

3. Pump Installation

Submersible pumps: Lower the pump into the water

source with caution, use a safety rope.

Surface pumps: Install the surface pump on an adequate

foundation with sufficient pipe sizing to ensure efficient operation. Fill the pump with clean water prior to starting it.

For detailed information refer to “8.3 Submersible Pumps”

on page 34.

Depending on your pump system, refer to “8.4 CS-F Surface Pumps” on page 39 or “8.3 Submersible Pumps”

on page 34 for detailed information.

4 Contents Contents 5

1 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Receipt, Storage and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.3 Approvals / Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.4 Naming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6 Pump System Sizing & Layout Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.1 Pump System Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 System Layout: Submersible Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3 System Layout: Surface Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4 System Layout: Surface Boost Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Controller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.2 Controller Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Technical Data of the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.4 Controller Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.5 Mounting, Space and Ventilation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.6 Wiring the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.6.1 Terminal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.6.2 Pump Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6.3 Pump Accessories Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.6.4 Input Wiring for Solar-direct Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.6.5 Input Wiring for Battery-based Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.6.6 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.7 PS2 pool pump systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.8 PS2 boost pump systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8 Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.1 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1.1 Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.1.2 Cable Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Pump System Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.3 Submersible Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3.1 Wiring the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3.2 Installation and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3.3 Installation Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3.4 Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.3.5 Additional Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.5.1 Safety Rope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.3.5.2 Plastic Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.4 CS-F Surface Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3.5.3 Stilling Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.4.1 Placement and Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.4.2 Pump Motor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4.3 Installation and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Contents 5

8.4.4 Suction Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.4.5 Initial Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4.5.1 Filling Pump with Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4.5.2 Rotary Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.5 Pool Surface Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.6 Boost Surface Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9 Pump Accessories Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

9.1 Well Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.2 Float Switch (Full Tank Shut-off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.3 Water Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.4 Sacrificial Anode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

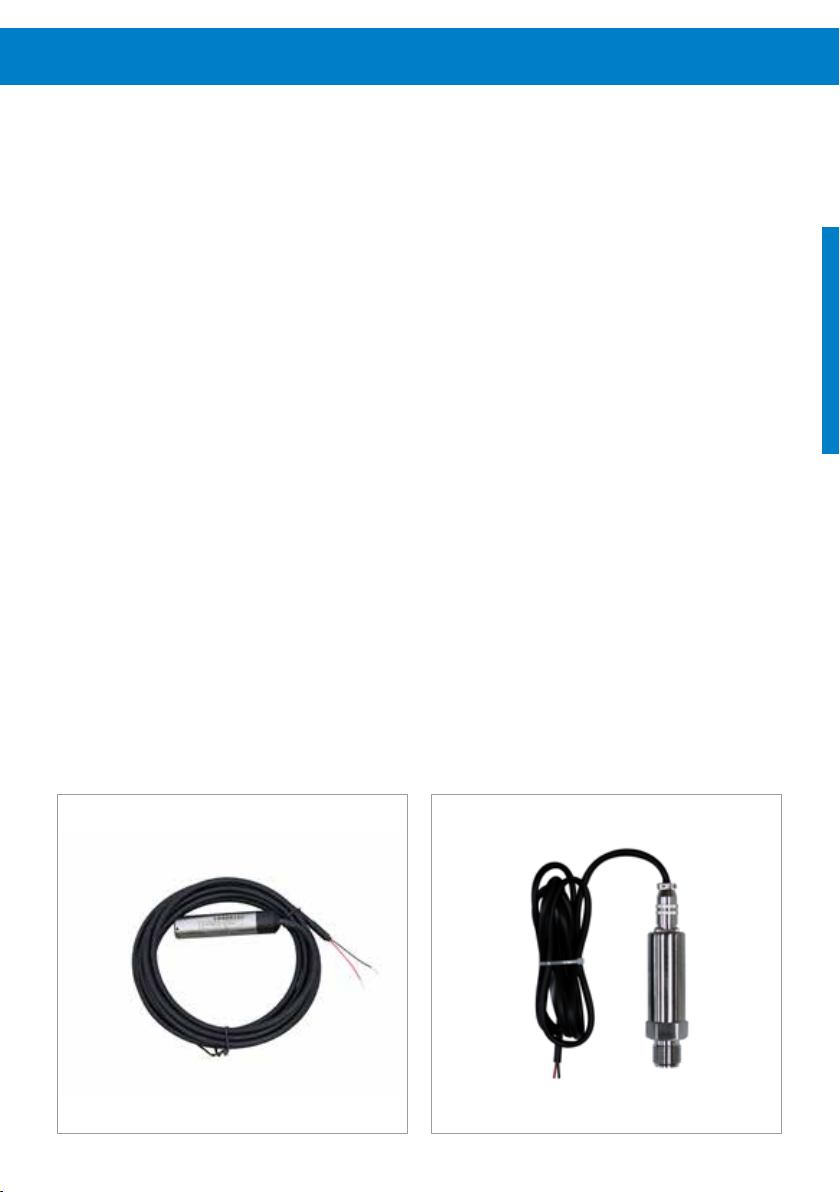

9.5 Liquid Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.6 Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.7 Sun Sensor module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.8 Surge Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.9 PV Disconnect with Lightning Surge Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.4.5.3 Final Check-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.5.1 Placement and Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.5.2 Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5.3 Installation and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.5.4 Initial start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.5.4.1 Filling Pump with Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.5.4.2 Rotary Directon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.5.4.3 Final Check-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.5.5 Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.5.5.1 General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.5.5.2 Cleaning the Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.5.5.3 Use with salt water or sea water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.5.5.4 Replacement of the Mechanical Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.6.1 Placement and Foundation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.6.2 Pump Motor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8.6.3 Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.6.4 Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.6.5 Plumbing Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.6.6 Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

10 Operating the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

10.1 LED Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.2 Starting the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.3 Time Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.4 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11 LORENTZ CONNECTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

11.1 DataModule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.2 PumpScanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

11.3 PS Communicator & pumpMANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

12 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

12.1 Pump does not run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12.2 Pump attempts a Restart every 120 Seconds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12.3 Flow Rate is to low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12.4 General checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6 Declaration of Conformity

1 Declaration of Conformity

We, BERNT LORENTZ GmbH & Co. KG Germany, declare

under our sole responsibility that the products

PS2-150 Boost, PS2-150 C, PS2-150 HR, PS2-200 HR,

PS2-600 HR, PS2-600 C, PS2-600 CS-F, PS2-600 Pool

CS-17-1, PS2-1800 HR, PS2-1800 C, PS2-1800 CS-F,

PS2-1800 Pool CS-37-1, PS2-4000 HR, PS2-4000 C,

PS2-4000 CS-F

to which the declaration relates, are in conformity with the

Council Directives on the approximation of the laws of the

EC Member States relating to:

Machinery (2006/42/EC)

Electromagnetic compatibility (2014/30/EU)

Electrical equipment designed for use with certain

voltage limits (2014/35/EU)

BERNT LORENTZ GmbH & Co. KG

Siebenstücken 24

24558 Henstedt-Ulzburg

Germany

1 January 2016

2 Receipt, Storage and Handling

Check upon receipt that the packaging is undamaged and

complete. If any abnormity is found, contact your supplier.

LORENTZ pumps are supplied from the factory in proper

packing in which they should remain until they are to be

installed at the site. Handle the pump with care and avoid

unnecessary impacts and shocks.

Prolonged intermediate storage in an environment of high

humidity and fluctuating temperatures must be avoided.

Moisture condensation may damage metal parts. Non-compliance can void the warranty. It is recommended storing

the parts in a closed and dry room.

The motor, the pump end and controller can be stored (not

used) in the range of –20 °C to +65 °C (–4 °F to +149 °F).

The components should not be exposed to direct sunlight.

Bernt Lorentz, CEO

3 Product Specification

3.1 General

LORENTZ solar submersible and surface pump systems

are designed to efficiently deliver high volumes of water

running exclusively on solar power. They are typically used

in irrigation projects and for wide area drinking water

applications where they reliably meet the most demanding

requirements, economically, without pollution and without a

grid connection or diesel generator.

A typical solar pumping system is composed of a PV generator array, a pump and a solar pump controller. Based on

the design philosophy that it is more efficient to store water

rather than electricity, there is no energy storing device such

as a storage battery in a typical solar pumping system.

The PV generator, an aggregation of PV modules connected

in series and in parallel, absorbs solar irradiation and converts it into electrical energy, providing power for the whole

system. The pump controller controls and adjusts the system

operation and adjusts the output frequency in real-time

according to the variation of sunlight intensity to realize the

maximum power point tracking (MPPT).

Each LORENTZ pump system consists of a pump end,

pump motor and a controller. This modular concept keeps

all electronics above ground even for submersible pumps,

simplifying servicing and lowering cost of ownership.

3.2 Features

LORENTZ pumps have the following features:

Engineered in Germany using high quality non

corrodible materials

IP65/ NEMA 3A corrosion resistant controller housing

Pump control based on power available

ECDRIVE DC Brushless motors, specifically designed for

solar operation with up to 92% efficiency

Monitoring and management including on-board record-

ing of up to 5 years of performance data, smart device

access via PumpScanner Android™ App and integration

to LORENTZ pumpMANAGER remote management

service optionally available.

3.3 Approvals / Certification

LORENTZ PS2 systems are sold in more than 130 countries.

Versions and approvals requirements will vary from country

to country. Please see the actual controller labelling to

confirm exact version and approvals marking. Full approvals

certificates can be found on partnerNET.

8 Product Specification

3.4 Naming

Pump model definition for submersible pumps:

For centrifugal pumps

C

- SJ 60 - 2 - 2

number of small impellers

stages

rated flow (m³/h)

submersible

centrifugal

For helical rotor pumps

HR

- 23 H/HH/L - 1

temperature class

high lift / very high lift /

long rotor

rated flow (cm³/revolution)

Pump model definition for surface pumps:

For CS-F1 to CS-F20 pumps

CS

- F 4 - 3

stages

rated flow (m³/h)

vertical multistage pump

centrifugal surface

For CS-F32 to CS-F85 pumps

CS

- F 32 - 60 - 2

number of small impellers

stages x 10

rated flow (m³/h)

For pool pumps

CS

- 37 - 1

helical rotor pump

number of impellers

rated flow (m³)

centrifugal surface

For boost pumps

Boost

- 330

vertical multistage pump

centrifugal surface

rated flow (GPH)

positive displacement vane

type surface pump

4 Operating Conditions

Ambient requirements: PS2 pump systems can be oper-

ated up to 3000 meters above sea level and at an ambient

temperature of up to 50 °C. When the temperature reaches

the limit the power will be reduced automatically. The PS2

controller is designed for use in environments classified as

pollution degree 3 in accordance with IEC-664-1: Conductive pollution occurs, or dry non-conductive pollution, which

becomes conductive due to condensation, is to be expected.

Fluid: LORENTZ PS2 Helical Rotor (HR) and Centrifugal

pumps can be used for drinking water supply, livestock

watering and irrigation applications not containing solid or

long fibred particles larger than sand grains, with a max.

grain size of 2 mm. The max. permitted sand content is 50

ppm, a higher sand content will reduce the pump life considerably due to wear. The max. salt content is 300-500 ppm

at max. 30°C / 85°F. Defects due to pumping other liquids

are not covered by the warranty.

LORENTZ PS2 Pool pumps can be used in chloride water,

salt water and sea water swimming pools. When used in

salt and sea water pools, the pump must be inspected and

cleaned regularly.

LORENTZ PS2 BOOST pumps can be used for clean

water applications only. The water must not contain any

abrasive particles. It is highly recommended to install an

intake strainer to protect the pump from any dirt ingress.

Please refer to “8.6.4 Filtering” on page 54 for further

information.

Fluid temperature: Depending on the type of your

LORENTZ pump system, different requirements for fluid

temperatures apply:

PS2 centrifugal submersible - The maximum fluid

temperature for centrifugal submersible pumps is +50°C

(122 °F).

PS2 centrifugal surface - The maximum fluid temperature

for centrifugal surface pumps is +70°C (158 °F).

PS2 pool pumps - The maximum fluid temperature for

pool pumps is +60°C (140 °F).

PS2 helical rotor (HR) submersible - Designing and

building helical rotor pumps for a narrow range of fluid

temperature is important to ensure the best possible

efficiency. LORENTZ PS2 helical rotor pumps are available in

five different temperature classes:

Temp. class 0: 0 – +10 °C (32 – 50 °F)

Temp. class 1: +10 – +20 °C (50 – 68 °F)

Temp. class 2: +20 – +30 °C (68 – 86 °F)

Temp. class 3: +30 – +40 °C (86 – 104 °F)

Temp. class 4: +40 – +50 °C (104 – 122 °F)

The pumps have a tolerance range of ±2 °C (±3.6 °F)

regarding the respective temperature ranges, except for the

lowest allowed temperature of 0 °C.

The temperature class is part of the pump units’ name tag,

please refer to chapter”3.4 Naming” on page 8. The

pump system shall only be operated within the temperature

range specified upon ordering.

CAUTION – PS2-200 HR pump ends and

pump units must always be ordered with

the next higher temperature class, to avoid

starting problems in weak irradiation

conditions.

CAUTION – Operating the pump outside of

the specified temperature range can lead

to reduced efficiency and/or damage the

pump and can void the warranty.

INFORMATION – Due to the precise

tolerances within LORENTZ HR pumps

there may be situations where a higher

temperature class pump than the actual

water temperature is recommended.

These recommendations are based on

prior experience of local water impurities

and particulates within the water.

PS2 boost surface - The maximum fluid temperature for

boost pumps is +80°C (176 °F).

10 Safety Instructions

5 Safety Instructions

Safe operation of this product depends on its correct transportation, installation, operation and maintenance. Failure to

follow these instructions can be dangerous to life or health

and/or void the warranty.

READ AND FOLLOW

ALL INSTRUCTIONS!

Explanation of warning symbols

WARNING – Disregard can lead to injury,

death or damage the system.

CAUTION – Recommended to avoid

damage, premature ageing of the pump or

similar negative consequences.

CAUTION – Hot surface. Indicates that the

marked item may be hot and should not

be touched .

Refer to the operating instructions

When installing and using this electrical equipment, basic

safety precautions should always be followed, including the

following:

WARNING – To reduce the risk of injury, do

not permit children to use this product

unless they are closely supervised at all

times.

WARNING – The appliance is not to be

used by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they are instructed and

closely supervised.

WARNING – To reduce the risk of electric

shock, replace damaged cords

immediately.

WARNING – It must be assured that all

grounding connections are properly made

and that the resistances meet local codes

or requirements.

The manual contains basic instructions which must be

observed during installation, operation and maintenance.

Before installation and start-up, the manual should be

carefully read by the person in charge of the installation. The

manual should also be read by all other technical personnel/

operators and should be available at the installation site at

all times.

Personnel qualifications and training – All per-

sonnel for the operation, maintenance, inspection and

installation must be fully qualified to perform that type

of job. Responsibility, competence and the supervision of

such personnel must be strictly regulated by the operator.

Should the available personnel be lacking the necessary

qualification, they must be trained and instructed accord-

ingly. If necessary, the operator may request the manu-

facturer/supplier to provide such training. Furthermore

the operator/user must make sure that the personnel fully

understand the contents of the manual.

Dangers of ignoring the safety symbols – Ignoring

the safety directions and symbols may pose a danger

to humans as well as to the environment and the

equipment itself. Non-observance may void the warranty.

Non-observance of safety directions and symbols may

for example entail the following: Failure of important

functions of the equipment/plant; failure of prescribed

methods for maintenance and repair; danger to persons

through electrical, mechanical and chemical effects; dan-

ger to the environment because of leakage of hazardous

material; danger of damage to equipment and buildings.

Safety-oriented operation – The safety directions

contained in the manual, existing national regulations for

the prevention of accidents as well as internal guidelines

and safety-regulations for the operator and user must be

observed at all times.

General safety directions for the operator/user –

If hot or cold equipment parts pose a danger then they

must be protected by the operator/user against contact

with people. Protective covers for moving parts (e.g.

couplings) must not be removed when the equipment

is running. Leaks (e.g. at the shaft seal) of hazardous

pumping media (e.g. explosive, toxic, hot liquids) must be

disposed of in such a way that any danger to personnel

and the environment is removed. All government and local regulations must be observed at all times. Any danger

to persons from electrical energy must be eliminated by

using good installation practices and working to local

regulations (e.g. VDE in Germany).

Safety directions for maintenance, inspection

and assembly work – It is the user’s responsibility to

make sure that all maintenance, inspection and assembly

work is performed exclusively by authorized and qualified

experts sufficiently informed through careful study of the

operating instructions. The accident prevention regulations must be observed. All work on the equipment must

be done when it is not operational and ideally electrically

isolated. Ensure all power sources and accessories (e.g.

float switch) are disconnected when working on the

system. Follow all appropriate electrical codes. There are

no user-serviceable parts inside the motor or the controller. The sequence for shutting the equipment down is

described in the manual and must be strictly observed.

Pumps or pump units handling hazardous liquids must

be decontaminated. Immediately upon completion of

the work, all safety and protective equipment must be

restored and activated. Before restarting the equipment,

all points contained in chapter “Initial start-up” must be

observed.

Unauthorized operation – The operational safety of

the equipment delivered is only guaranteed if the equip-

ment is used in accordance with the directions contained

in this manual. Limits stated in the data sheets may not

be exceeded under any circumstances.

RETAIN THESE

INSTRUCTIONS

FOR FUTURE USE!

Authorized changes and manufacturing of spare

parts – Any conversion of or changes to the equipment

may only be undertaken after consulting the manufacturer. Original spare parts and accessories authorized by

the manufacturer guarantee operational safety. Using

non-authorized parts may void any liability on part of the

manufacturer. There are no user-serviceable parts inside

the motor or the controller.

12 Pump System Sizing & Layout Diagrams

6 Pump System Sizing & Layout Diagrams

6.1 Pump System Sizing

To professionally size and install a water pumping system,

depending on the pump type and application various

variables need to be taken into consideration:

Static head - Vertical height from the dynamic water level

to the highest point of water delivery.

Suction head - Vertical height from the water level to the

pump inlet where the water level is below the pump inlet.

Pressure losses - Loss of water pressure due to pipe

length and friction caused by pipe material and additional

pipe line elements like elbows, valves.

For solar water pumping additionally local irradiation

levels are necessary to calculate the available power during

each day and the effect on water output.

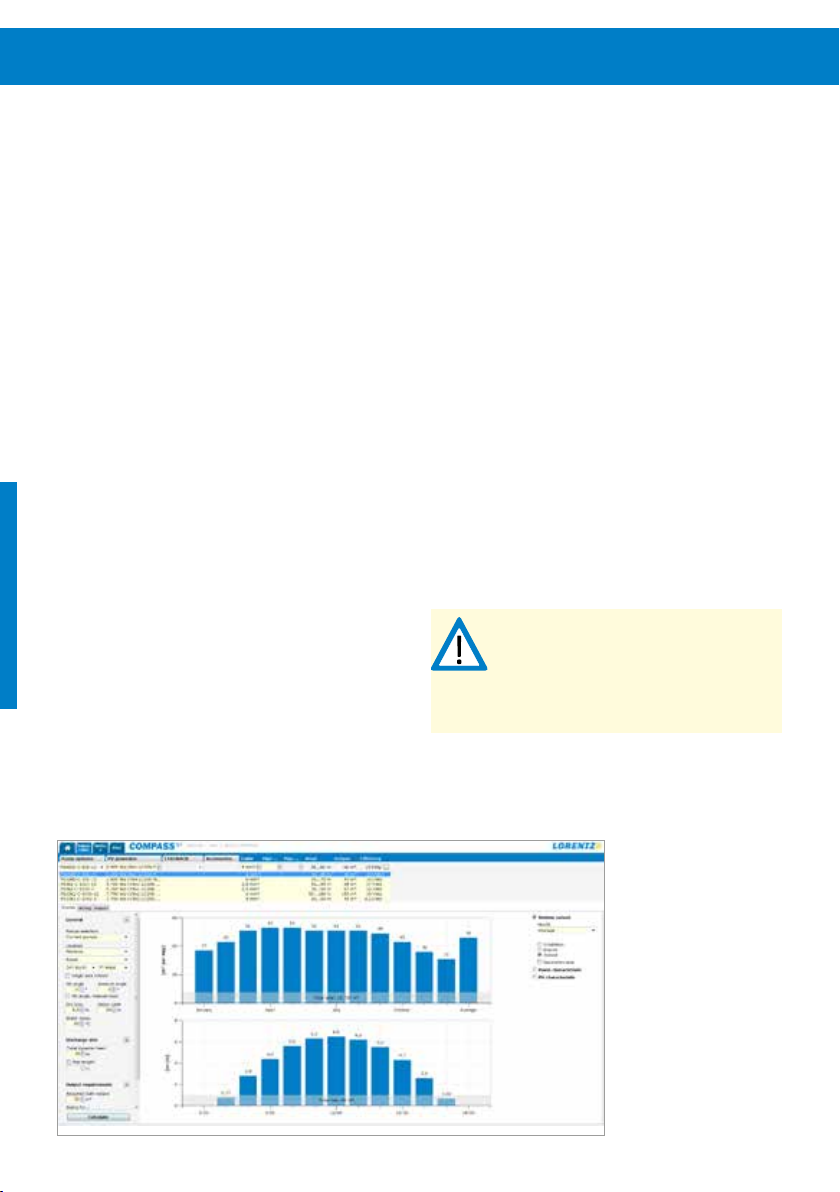

To easily manage and consider the different variables,

LORENTZ strongly advises to size pump systems with

LORENTZ COMPASS, the solar pump planning software.

COMPASS is the LORENTZ tool for designing,

planning and specifying solar pump systems. It

is available for download to all LORENTZ partners on

partnerNET.

COMPASS is a PC-based tool to simply specify solar

pumping systems in real time. It is based on NASA weather

data and uses precise algorithms for even the most complex

calculations.

By selecting the location from a list of more than 250,000

cities, entering the total dynamic head (TDH) and the

necessary amount of water per day the software will

automatically show suitable pump systems and the

necessary size of the PV generator.

For more complex situations COMPASS offers features from

suction head calculation to pipe type specific pressure loss

calculation.

NOTE - Always ensure the values used for

sizing with COMPASS match the conditions

on site. Incorrect parameters can lead to a

wrong sizing report.

Figure 1: COMPASS sizing

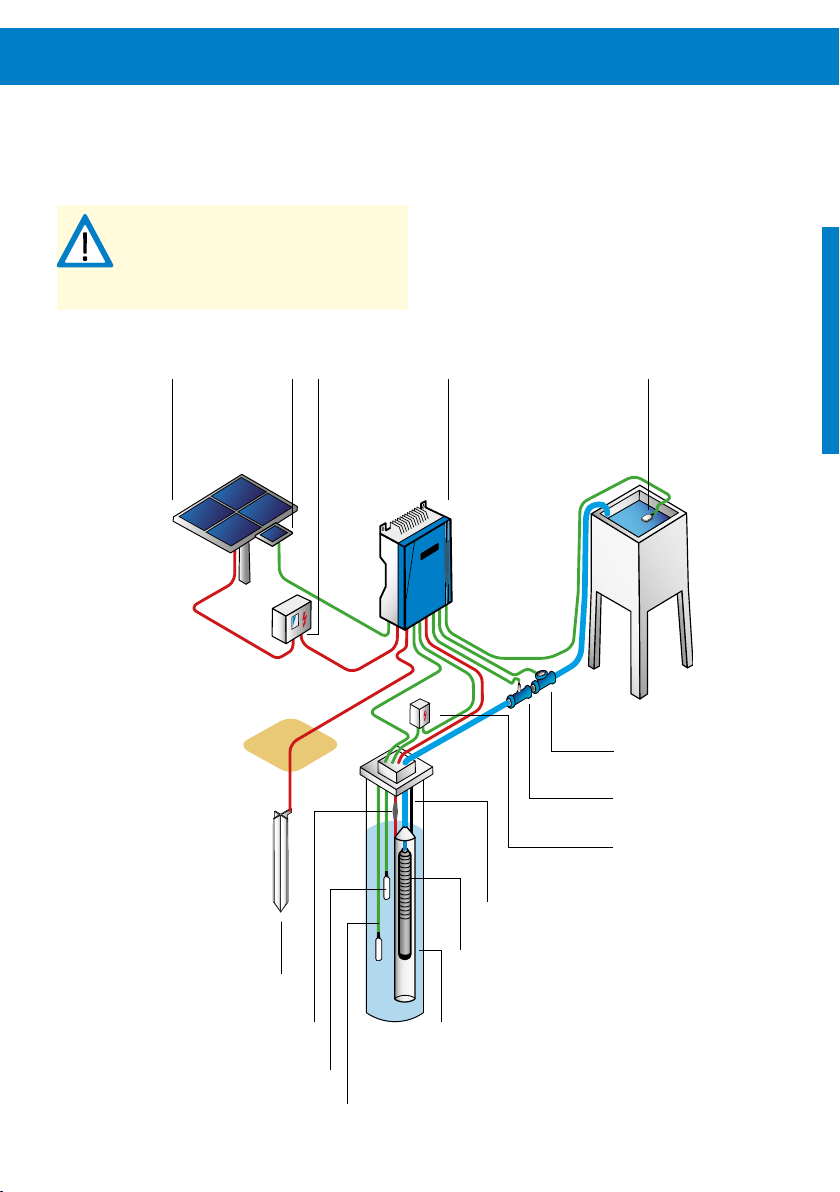

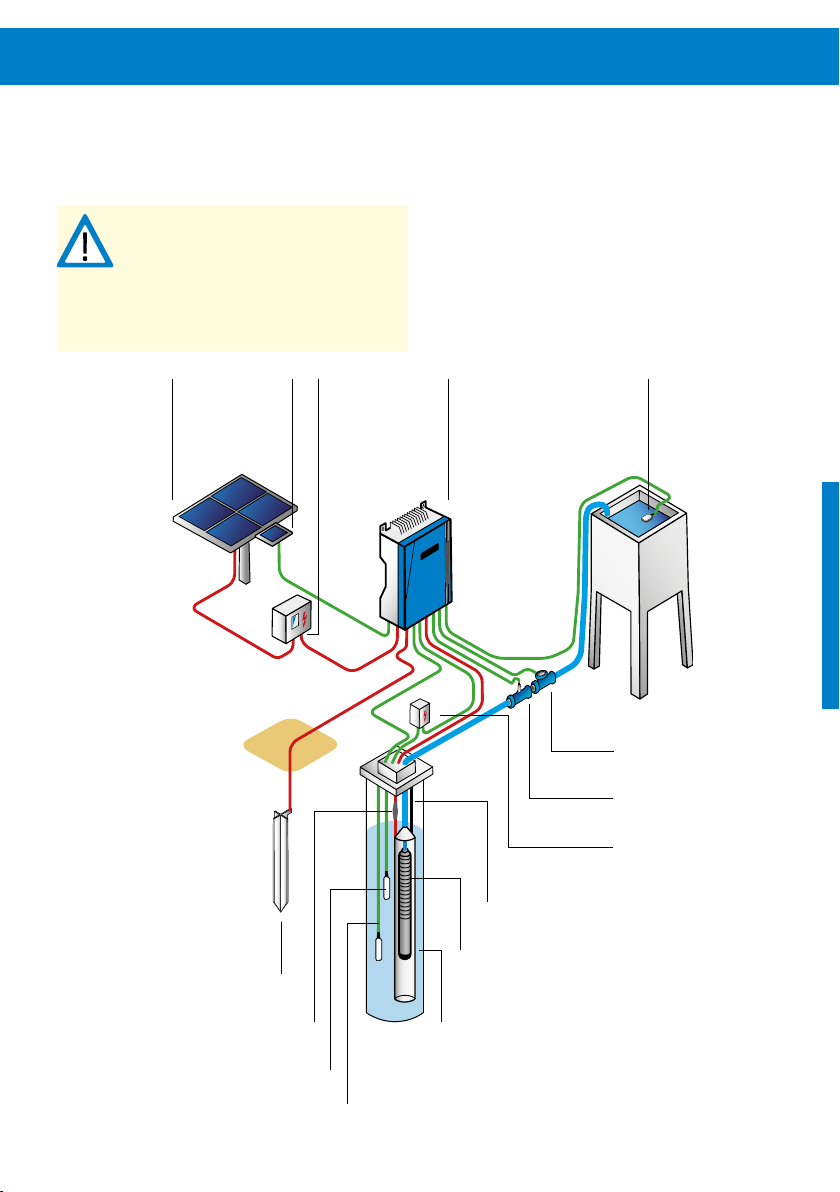

6.2 System Layout: Submersible Pumps

CAUTION - This graphic is an example

pump system layout diagram for ease of

understanding only. For system installation

and wiring read and follow the detailed

instructions given in this manual.

PV generator Sun Sensor

module

grounding rod

PV disconnect PS2 controller float switch

water meter

pressure sensor

surge protector

safety rope

submersible pump

splicing kit

well probe

level sensor

stilling tube

14 Pump System Sizing & Layout Diagrams

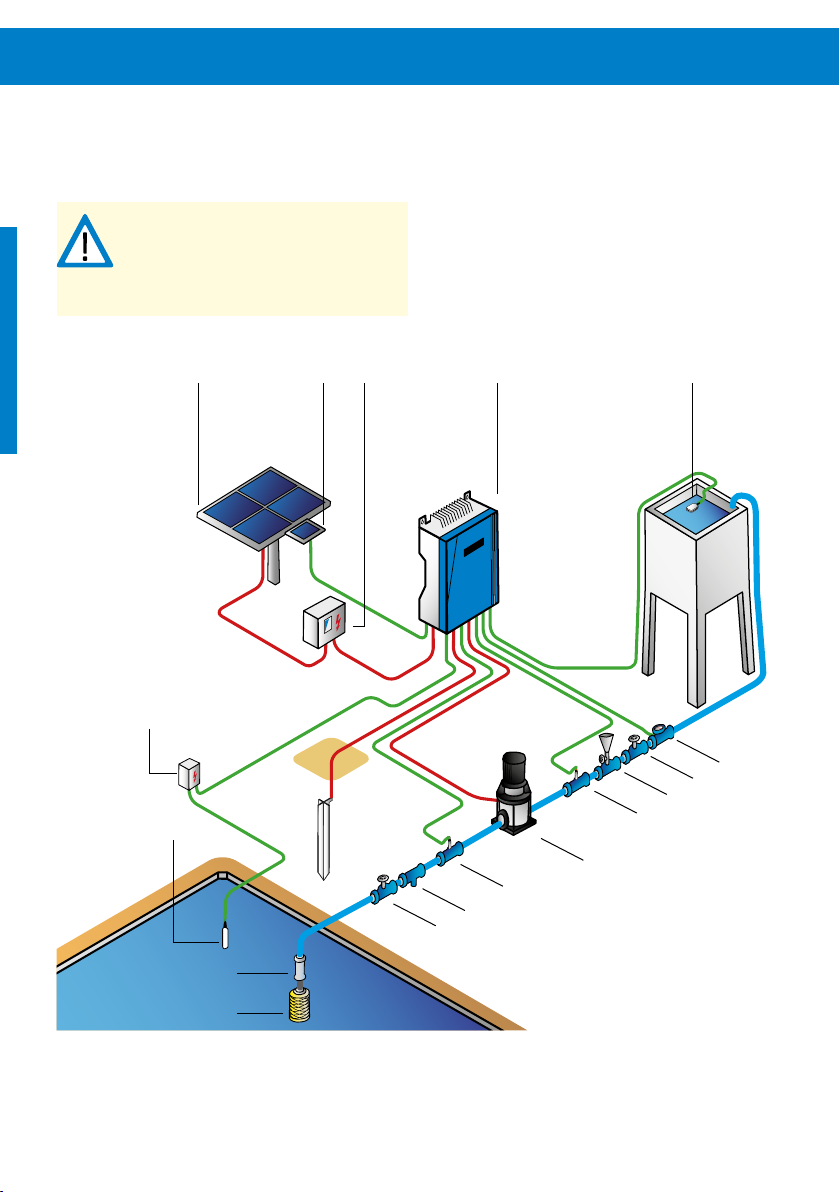

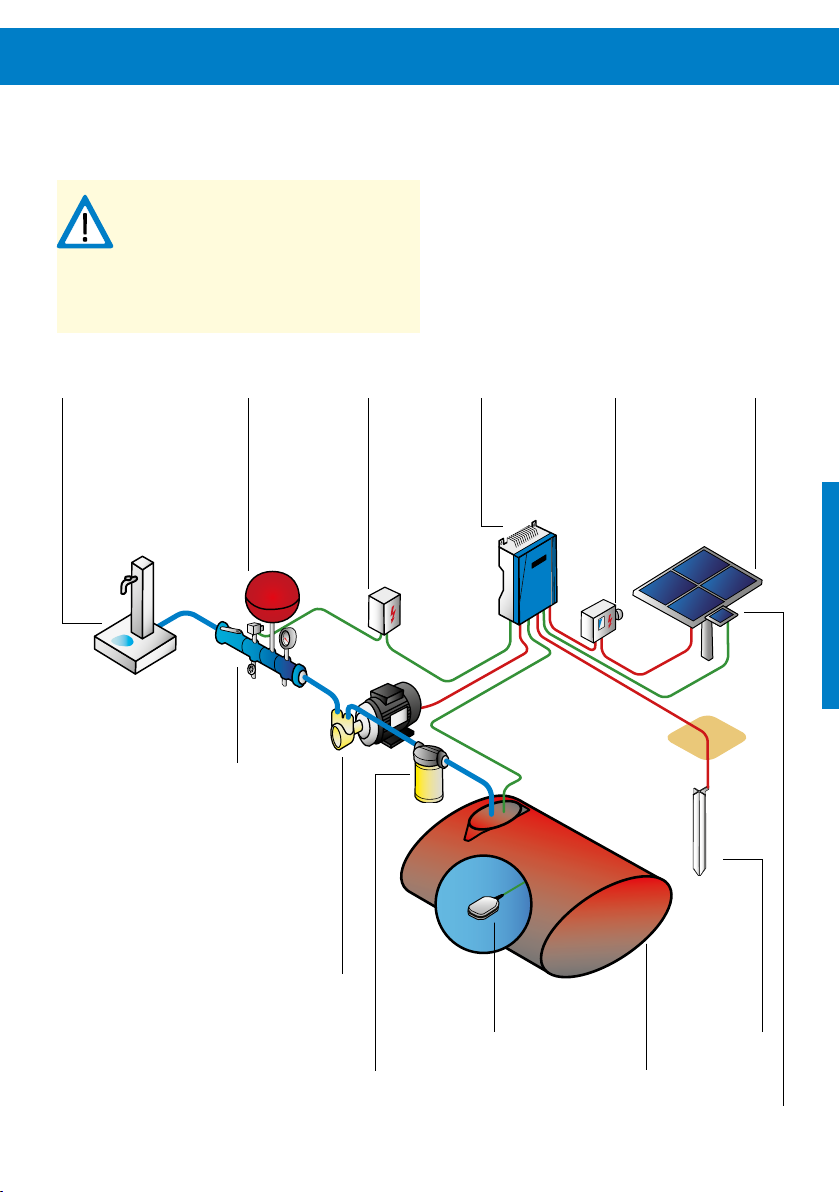

6.3 System Layout: Surface Pumps

CAUTION - This graphic is an example

pump system layout diagram for ease of

understanding only. For system installation

and wiring read and follow the detailed

instructions given in this manual.

PV generator Sun Sensor module PV disconnect PS2 controller float switch

surge protector

well probe

or float switch

nonreturn valve

filter cage

grounding rod

water meter

valve

filler

pressure sensor

surface pump

water sensor

strainer

gate valve

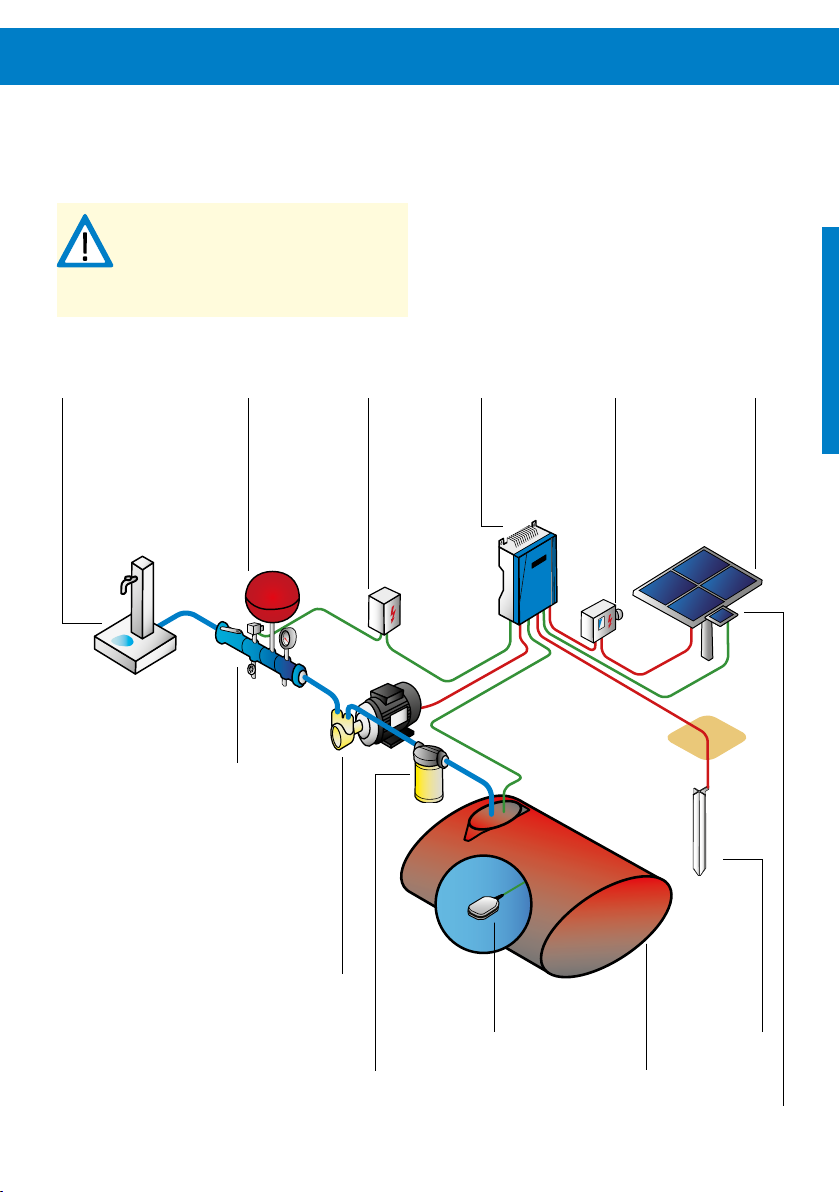

6.4 System Layout: Surface Boost Pumps

CAUTION - This graphic is an example

pump system layout diagram for ease of

understanding only. For system installation

and wiring read and follow the detailed

instructions given in this manual.

pressure tank

PS Boost installation kit

PV generatorPV disconnectPS2 controllersurge protectorwater tap

PS Boost pump

PS Boost inline filter

float switch

grounding rod

underground tank

Sun Sensor module

16 Controller Installation

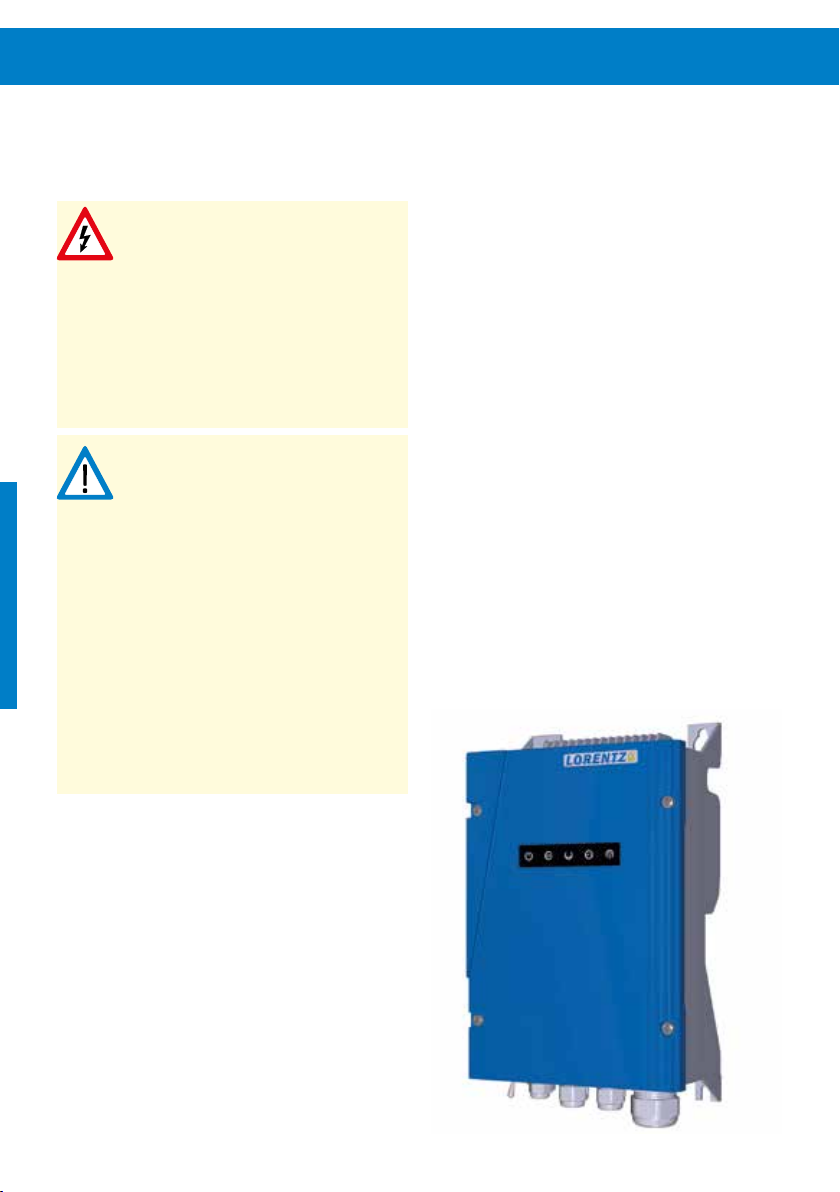

7 Controller Installation

7.1 General

WARNING – All electrical connections must

be performed by qualified experts only.

WARNING – Do not dismantle the

controller while still connected to the

power supply! Before any installation,

maintenance or inspection activities wait

at least two minutes after the power

supply has been disconnected from the

controller!

CAUTION – To avoid multiple starts of the

pump in twilight conditions, the Sun

Sensor module must be connected and

configured for all PS2-1800 CS-F and all

PS2-4000 pump systems. Operating

without a Sun Sensor module can lead to

increased wear or damage to the pump.

Such damage is excluded from the

warranty.

CAUTION – Never let the pump run dry.

Dry running will damage the pump and

void the warranty. LORENTZ requires a dry

run protection for every pump system.

For more information on mandatory accessories and their

installation, please refer to “7.6.3 Pump Accessories Wiring”

on page 27 and “9 Pump Accessories Installation” on

page 57.

Treat the controller as industrial waste when processing the

discarded controller. It is possible that some components

could produce toxic and harmful gas.

A plug kit is available separately from the controller if plug

connectors shall be used.

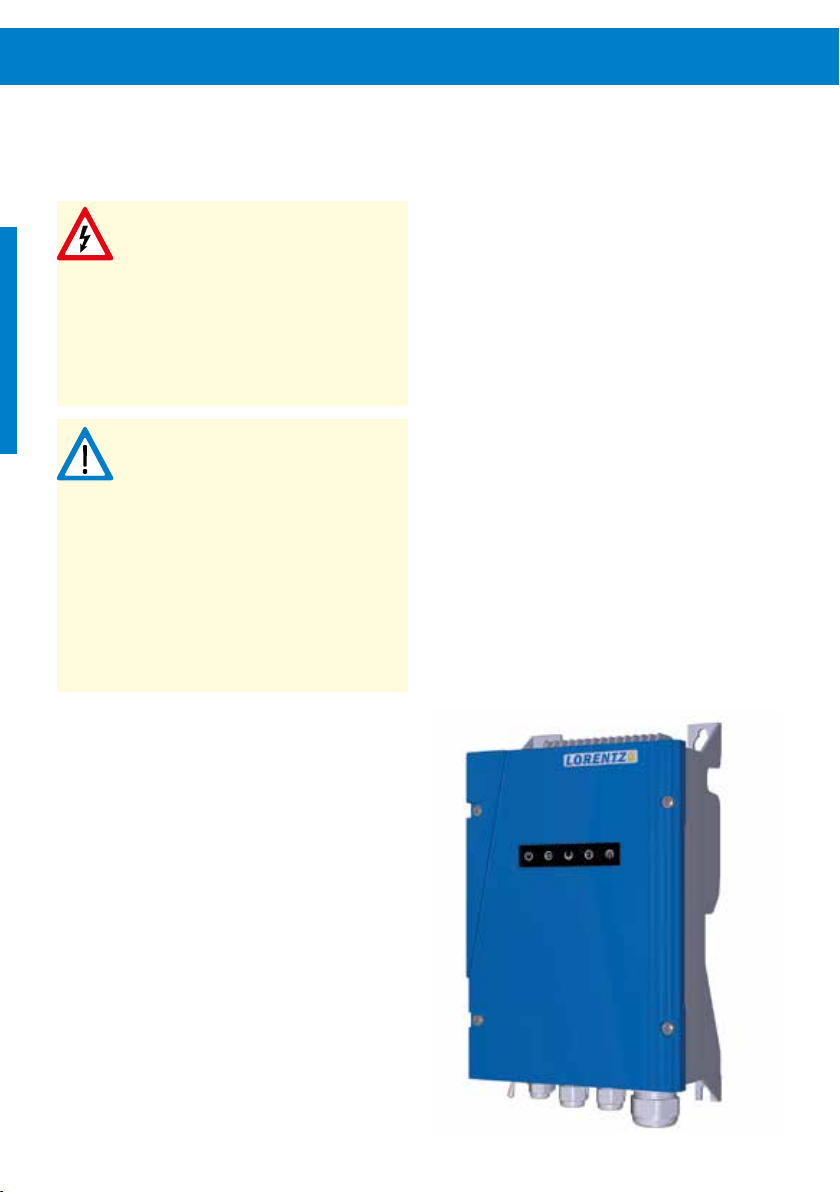

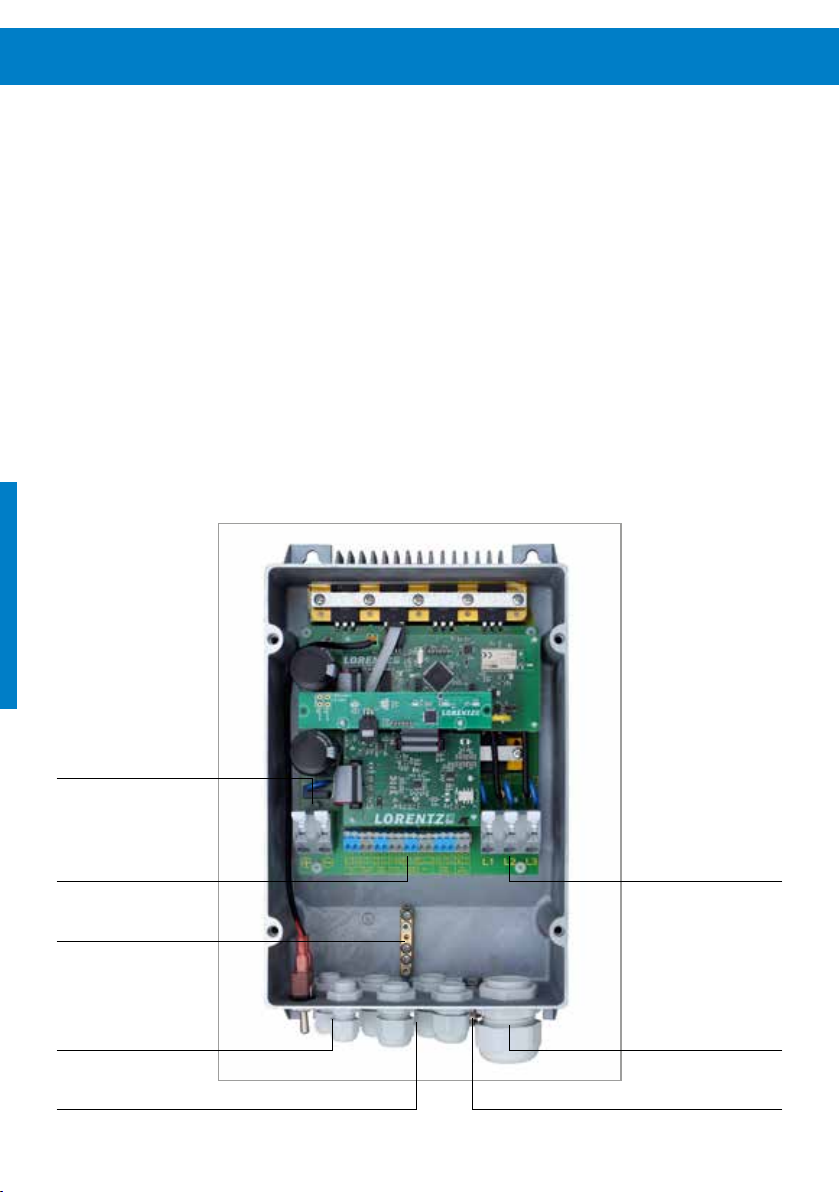

Figure 2: PS2 controller

DC Disconnect Switch

Electrical Conduit

Every solar pump system must be equipped with a properly

sized DC disconnect switch. The switch must be installed

between the PV generator and controller. It must meet the

following requirements:

minimum rating according to “Table 1: Minimum DC

disconnect rating” on page 17

continuous current rating according to maximum

current of the connected PV generator or higher

the switch must be rated for DC current, not AC

A PV disconnect switch matching all requirements above

can be purchased from LORENTZ.

CAUTION – The use of a properly sized

disconnect switch is an important safety

measure and obligatory for a professional

installation of a solar pump system.

Table 1: Minimum DC disconnect rating

Controller Min. DC disconnect switch rating

PS2-150 50V DC

PS2-200 100V DC

PS2-600 150V DC

Electrical conduit is recommended. We recommend the use

of an electrical conduit (pipe) to protect outdoor wiring

from the weather, from human activities and from damage

caused by animals. If you do not use a conduit, use a strong,

high-quality outdoor cable. Where cables enter the junction

box, install sealed strain-relief cable glands.

Wire sizes

For signal cables, the min. wire size should be 1.5 mm²

(16AWG). For power cables, the min. wire size should be 2.5

mm² (14AWG). Compare your wire sizes to the LORENTZ

COMPASS sizing reports. Cables should be shielded to meet

EMC the requirement.

For outdoor use, cables meeting the requirements of 60245

IEC 66 are recommended. For indoor use, the recommended

cable type is defined in 60245 IEC 57. The installer must

always consider the local situation, codes of practice and

regulations and use a cable that meets these requirements.

PS2-1800 200V DC

PS2-4000 375V DC

18 Controller Installation

7.2 Controller Elements

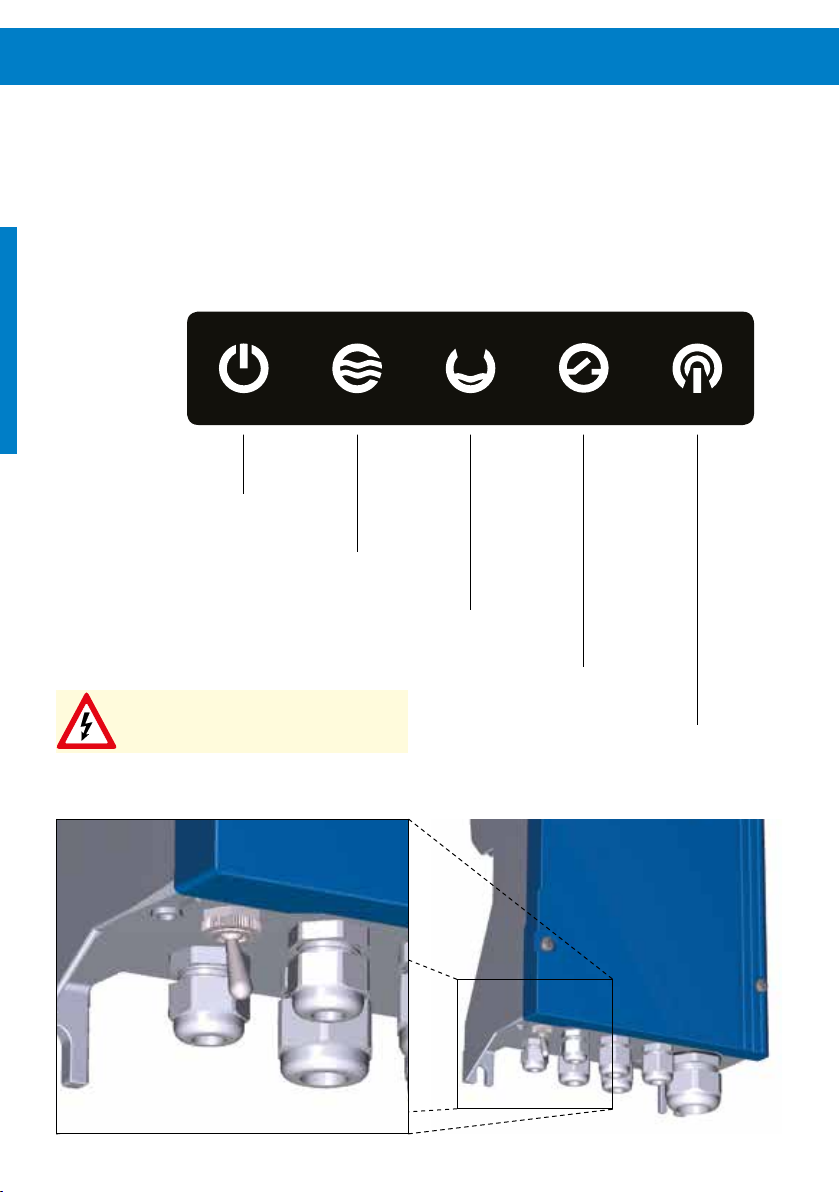

Power on/off switch – The power switch is used to

start or stop the system and as a reset switch. It does not

work as power disconnect switch.

Indicator Lights – The five LED lights on the front

indicate different operational situations. For a detailed

explanation refer to chapter “10 Operating the Pump”

on page 64.

Table 2: Technical data of the PS2 controller

Model Pump motor:

PS2-150

Boost

PS2-150 0.3 ECDRIVE 150-C 50 17 22

rated power

[kW] [V] [V] [A]

0.3 ECDRIVE 150-Boost 50 17 22

Affiliated pump

motor

7.3 Technical Data of the Controller

Refer to “Table 2: Technical data of the PS2 controller” on

page 18 for an overview of the most important technical

specifications of the PS controller.

Max. DC input

voltage

Min. recommended

Vmp

Max.output

current

PS2-200 0.3 ECDRIVE 200-HR 100 34 11

ECDRIVE 600-HR

PS2-600 0.7

PS2-1800 1.7

PS2-4000 4.0

ECDRIVE 600-C

ECDRIVE 600-CS-F

ECDRIVE 1800-HR

ECDRIVE 1800-C

ECDRIVE 1800-CS-F

ECDRIVE 4000-HR

ECDRIVE 4000-C

ECDRIVE 4000-CS-F

150 68 13

200 102 14

375 238 14

7.4 Controller Placement

7.5 Mounting, Space and Ventilation Requirements

The controller must be protected from water, moisture and

animals, so keep the controller box sealed. Place the controller in a dry and sufficiently ventilated environment.

Place the controller close to the solar array, not the pump,

to reduce the risk of lightning damage. The controllers’ input

circuitry is more sensitive to surges than its output. Therefore it is safest to minimize the length of the input wiring.

Electronic devices are most reliable when they are protected

from heat. Mount the controller where it is shaded from

the midday sun. An ideal location is directly under the PV

generator. If no shade is available, cut a piece of sheet metal

and bolt it behind the top of the controller. Bend it over the

controller to provide shade. This is especially important in

extremely hot locations. Extreme heat may trigger a thermal

function in the controller causing it to reduce the power

consumption or turn it off. The controller housing can reach

high temperatures when operating at high ambient temperatures. This is normal and will not reduce the expected

lifetime of the controller or its components.

PS2 controllers can be mounted side by side.

For grounding of the front cover the cover screws must be

tightend to a minimum torque of 2Nm.

All PS2 controllers have a fan-less design; they are cooled

by air convection. It is strictly advised not to install the controller in an additional enclosure. If an additional enclosure

is necessary a sufficient vertical airflow (from bottom to top)

has to be ensured to allow sufficient cooling.

PS2 controllers have a keyhole mounting system to

simplify mounting on appropriate surfaces. For mounting

on poles and similar structures the PS2 is compatible with

the LORENTZ PM accessory brackets for a maximum of

convenience.

When mounting the PS2 controller with the LORENTZ PM

accessory brackets tighten the screws diagonally and evenly.

CAUTION – do not over tighten the

mounting screws on the PS2 housing when

using the PM accessory brackets to avoid

damage to the PS2 controller housing.

CAUTION – When using PM accessory

brackets, for high performance systems

and/or with high ambient temperatures a

backplate must be installed between the

controller and the PM accessory brackets

to preserve the funnel effect of the

cooling fins. Operating without a

backplate can lead to insufficient cooling

which will result in reduced performance.

For controller dimensions, cf. “Table 3: PS2 Controller dimensions for installation” on page 20.

20 Controller Installation

Figure 3: PS2 Controller dimensions for installation

W3

H1

H2

H3

D1W2

W1

Table 3: PS2 Controller dimensions for installation

Dimension in mm [in]

Weight in kg [lbs]W1 W2 W3 H1 H2 H3 D1

207 170 164 352 333 300 124 4.5

[8.15] [6.69] [6.46] [13.86] [13.11] [11.81] [4.88] [9.9]

7.6 Wiring the Controller

WARNING – All electrical connections must

be performed by qualified experts only!

Unqualified handling might lead to shock,

burns, or death.

WARNING – Beware of high voltage.

Never work on a system connected to

power or within two minutes after

disconnection to avoid electric shock

hazard.

Before starting to work on the electrical system make sure

that all components are disconnected from the power

source. Do not work on any components when power is

connected or within two minutes after disconnection. The

controller needs time to discharge.

Switch the system on only when all work is completed.

CAUTION – The controller should only be

connected to power after correct wiring or

the controller might get damaged.

CAUTION – Do not install disconnect

switches in the power wires between the

motor and pump controller. Connecting the

motor wires to a switched-on controller

may cause irreparable damage. Such

damage is excluded from the warranty.

CAUTION – Solar-direct systems only – Do

not connect any electrical load to the PV

generator other than the LORENTZ pump

controller. Connection of a battery charger,

active solar tracker controller, electric

fence charger, or other load simultaneously with LORENTZ PS2 systems may

interfere with the controller and prevent

proper operation.

CAUTION – Measure the voltage before

connecting power to the controller.

Voltage (open circuit) must not exceed the

max. DC input (refer to “Table 2: Technical

data of the PS2 controller” on page 18).

22 Controller Installation

7.6.1 Terminal Descriptions

Open the housing by loosening the four screws on the front

cover. After removing the cover the terminal can be accessed

easily.

For “Power in” and “Motor” open the clamp, insert the

wires and lock the clamps in place. Use caution and keep

hold of the clamp handles as the terminals contain strong

springs. Refer to “Figure 6: “Power in” and “Motor” terminal” on page 23. The length of wire stripping for these

terminals is 12 - 13 mm (0.5 in).

Figure 4: View of open PS2 controller

Solar in +–

For terminals 1 to 17 open the terminal by pushing back

the clamp handle with a screw driver, insert the wire, then

release the handle to lock the wire in place. Refer to “Figure

7: Terminals 1 – 17” on page 23. The length of wire

stripping for these terminals is 5 - 6 mm (0.2 in).

Terminals 1 - 17

Ground

Sensor cable glands

Pump L1 L2 L3

Motor cable glandSolar in cable glands

Outside grounding bolt

Terminal Description PS2

Figure 6: “Power in” and “Motor” terminal Figure 7: Terminals 1 – 17

Figure 5: Terminal PS2

Open

Close

Insert wire

use a flat screwdriver

to push back

Close

Open

Insert wire

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

com com com +24V +24V +24V com + –

Well

probe

Remote

switch

Water

meter

Analog 1

4-20mA

Analog 2

4-20mA

Out

Water

sensor

Sun

Sensor

24 Controller Installation

Table 4: Terminal explanation

Socket Terminal Connection Function

Power in

Well probe

(Source low switch)

Remote switch

Water meter

Analog input 1

Analog input 2

Out

Water sensor

+ connect to positive terminal of PV module

– connect to negative terminal of PV module

1 connect to NC

2 connect to COM

3 connect to NC

4 connect to COM

5 connect to Imp

6 connect to COM

7 connect to positive (+)

8 connect to signal

9 connect to positive (+)

10 connect to signal

11

12

13 connect to positive (+)

14 connect to signal

15 connect to COM

Connect the PV array to the controller.

Connect well probe or float switch to

protect the pump system from running

dry.

Connect a float switch, pressure switch

or any other suitable remote switch.

(Factory setting: jumper installed)

Connect a water meter with pulse

output. l/imp must be configured with

PumpScanner.

Connect a 4−20mA signal sensor;

supply voltage +24V load; must be

configured with PumpScanner.

Connect a 4−20mA signal sensor;

supply voltage +24V load; must be

configured with PumpScanner.

Potential-free signal output to control

third party devices; must be configured

with PumpScanner.

Connect a water detection sensor for

surface pumps. (Factory setting: jumper

installed between 14 and 15)

Sun Sensor

Output to motor

16 connect to positive (+)

17 connect to negative (–)

L1 connect to the L1 phase of the motor

L2 connect to the L2 phase of the motor

L3 connect to the L3 phase of the motor

Connect the LORENTZ SunSensor for

irradiation based pump control; must be

configured with PumpScanner.

Connect the power wires of the

LORENTZ pump motor.

Terminal Wiring Example

Figure 8: Terminal wiring example

SOLAR

IN

+ –

PV disconnect

Surge protector

Well

Remote

probe

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

com com com +24V +24V +24V com + –

switch

Water

meter

Analog 1

4-20mA

Analog 2

4-20mA

Out

Water

sensor

Sun

Sensor

Pump

L1 L2 L3

PV generator

Well probe

Remote switch

Analog sensors

Out

Water sensorWater meter

Pump

Sun Sensor

26 Controller Installation

7.6.2 Pump Wiring

The motor cables of the pump have a marking to allow

correct wiring. Connect the wires using this sequence:

1: Motor cable L1

2: Motor cable L2

3: Motor cable L3

: Ground connection

If necessary, interchange any two phases to reverse direction. Refer to chapter “8 Pump Installation” on page 32

for detailed pump installation instructions.

7.6.3 Pump Accessories Wiring

Terminals 1 and 2

To protect the pump from being damaged by dry running

connect a suitable source low protection switch to terminal

1 and 2. Every pump system must be equipped with dry run

protection. If dry run protection is not needed, add a jumper

wire between these two terminals.

CAUTION - Never let the pump run dry.

Dry running will damage the pump and

void the warranty. LORENTZ requires a dry

run protection for every pump system.

Terminals 3 and 4

Connect any kind of external switch for remote control of

the controller. To run the pump the switch must be closed

(NC). If no switch is used the terminals No. 3 and 4 have to

be connected with a jumper cable (factory setting).

Terminals 5 and 6

Install a water meter in the pipeline and connect it to

terminal 5 and 6. The output of the water meter must be

an impulse signal. The time between two impulses must not

exceed 5 minutes. The DataModule can handle up to 10

impulse per second. Select a water meter appropriate for the

expected flow. The flow can be viewed with the LORENTZ

PumpScanner software.

Terminals 7 and 8 / 9 and 10

Any suitable sensor for 24VDC supply voltage, current

(signal) range of 4–20mA and load impedance of 100Ω

can be connected, e.g. LORENTZ pressure sensor, LORENTZ

liquid level sensor. The sensor must then be configured in

PumpScanner.

Terminals 11 and 12

This is a potential-free signal output contact that can be

configured in PumpScanner to control third party devices. It

is rated for: 24VAC, 24VDC, 1A.

Terminals 13, 14 and 15

Connect a water sensor to detect the presence of water, this

is usually installed on the suction side of surface pumps for

dry run protection. If no water sensor is connected a jumper

wire must be installed between terminals 14 and 15 (factory

setting). The maximum allowed current for sensor supply is

20mA.

Terminals 16 and 17

Connect a LORENTZ 1.5Wp Sun Sensor module module.

This PV module is used to measure the solar irradiation and

allows you to set irradiation dependent START / STOP values

for the pump. These settings can only be done via LORENTZ

PumpScanner.

CAUTION – Only connect a suitable sensor

to terminals 7 and 8 / 9 and 10 / 13, 14 and

15. Never create a short circuit. Observe

the polarity of the pressure sensor.

28 Controller Installation

7.6.4 Input Wiring for Solar-direct Systems

WARNING – Beware of high voltage!

Electric shock hazard! Hazardous

electricity may be present and can shock,

burn, or cause death! Authorised, qualified

personnel only!

The PV generator can produce hazardous voltage even under low light exposure. To prevent shock hazard while wiring

the array, leave one or more wires disconnected or cover the

solar array with opaque material.

Table 5: Max. voltage input

Controller

PS2-150 50VDC

PS2-200 100VDC

PS2-600 150VDC

PS2-1800 200VDC

PS2-4000 375VDC

Max. DC input voltage

CAUTION – An input voltage higher than

specified in “Table 5: Max. voltage input”

on page 28 will damage the controller

and void the warranty. Damage may occur

if the solar generator array is wired

incorrectly. Measure the voltage and

confirm the polarity before connecting the

power to the controller.

Connect the positive terminal of the PV modules to + and

the negative terminal of the PV modules to –. Connect the

protective ground wire to an appropriate ground system.

Refer to “7.6.1 Terminal Descriptions” on page 22 for

terminal descriptions and to “7.6.6 Grounding” on page

30 for grounding instructions.

7.6.5 Input Wiring for Battery-based Systems

CAUTION – The PS2-4000 pump system can

not be operated from batteries.

The battery mode for PS2-150 to PS2-1800 controllers

must be activated in PumpScanner. This will deactivate

the MPP-Tracking function and activate the Low Voltage

Disconnect (LVD).

Connect the PS2 controller directly to the battery and NOT

to the load terminals of the charger as the terminals may

not be rated for the starting load current of the pump. The

PS2 controller has a low voltage disconnect function to

protect the battery from being deeply discharged.

Some charge controllers monitor the capacity of the battery

and regulate the charging accordingly. This method does not

work when the PS2 controller is connected to the battery. In

order to provide correct charging the charger should be set

to voltage orientated regulation. This may require a jumper

to be set in the charger. Check the manuals of the charger

manufacturer.

Short circuit protection: Install a fuse or circuit breaker

near the power source. Use a 30 A circuit breaker or a time

delay (slow blow) fuse.

Low-voltage disconnect function: Lead-acid batteries

can be permanently damaged by over-discharge when the

voltage falls below a critical point. To prevent this, the PS2

battery system controller will turn off at low voltage for at

least 20 minutes, and turn back on only after the battery has

recovered significantly.

Battery high run mode: If high run mode is activated in

PumpScanner, the low voltage disconnect points for 12V

batteries are changed to OFF at 12.3VDC, ON at 13VDC.

Set points for low voltage disconnect

Controller Voltage OFF ON

PS2-150

PS2-200

PS2-600 48VDC 44VDC 48VDC

PS2-1800 96VDC 88VDC 96VDC

12VDC 11VDC 12VDC

24VDC 22VDC 24VDC

24VDC 22VDC 24VDC

48VDC 44VDC 48VDC

30 Controller Installation

7.6.6 Grounding

Before starting to work on the electrical system make sure

that all components are disconnected from the power

source. Only switch on the system when you have finished

all work.

Grounding is mandatory to protect the users from potentially fatal electric shocks. It also protects against electric charging or a short circuit inside the device. This is accomplished

through clamping, bolting or other mechanical means to

provide an effective grounding path to the earth to ensure

safe operation at all time.

The grounding is also important to the system for lightning

protection. In general it is meant for indirect lightning strikes

and induced electrical potentials during operation of the

pump system.

Before installation, contact the local code authorities to

determine the necessary grounding requirements.

Insufficient ground source: Where there is an

inadequate ground source you can use a grounding rod.

A grounding profile rod should be located not more than

4 – 5m (13 – 16 ft) from the controller. The cable must not

carry any mechanical loads. The rod must be completely buried in the ground (2.5 m/8 ft below ground level). You must

refer to local standards and requirements. The grounding

cable should be a copper cable with a cross section of not

less than 16 mm2 (AWG 6).

A protective earth connection must be linked to the

controllers earth connector which is located below the pcb

and marked with the protective earthing symbol . The

protective earth wire of the motor must also be connected

to the controllers earth connector.

The protective earth connection can also be linked to the

grounding bolt on the outside of the controller near the

cable glands.

All metallic support structures and electrical enclosures must

be grounded.

For grounding of the front cover the cover screws must be

tightend to a minimum torque of 2Nm.

For grounding of the PV generator, follow manufacturer

instructions.

7.7 PS2 pool pump systems

7.8 PS2 boost pump systems

NOTE – The following chapter is relevant

for PS2 controllers operating pool pumps

only.

WARNING – The use of pumps for

swimming pools and the restricted area

around them is only permitted if pumps

are installed in accordance with DIN/VDE

0100 part 702 or other local standards.

Please consult your licensed electrician!

WARNING – A cord and plug connected

unit shall be provided with a permanently

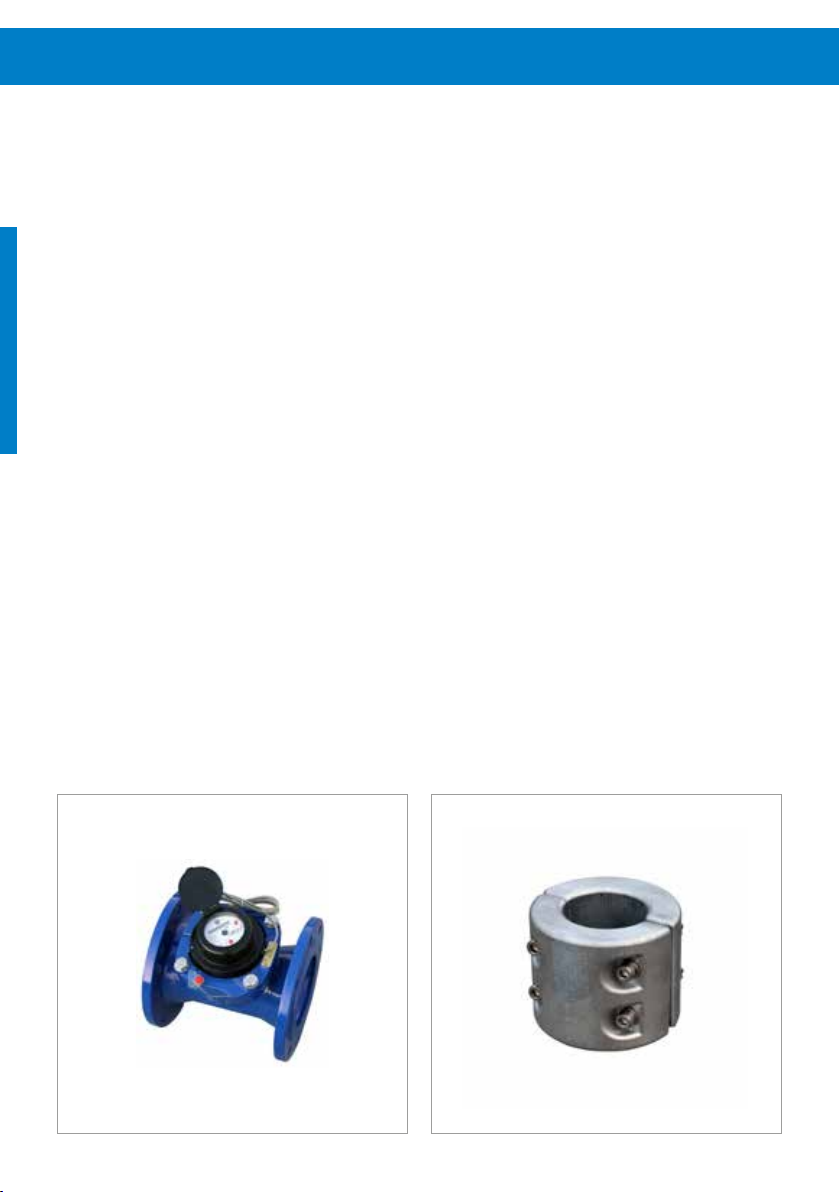

attached flexible cord of a water-resistant

type, e.g. SEW, SEOW, SJW, SJOW, SJEW,

SJEOW, SJTW, SJTOW, SOW, STW, or STOW.

When the pump is connected by cable, use

extra-hard type (toughened) cable for

connections.

WARNING – When the motor is installed

within 1.5 m/5 ft of the inside walls of a

swimming pool, spa, or hot tub, a

solid-copper bonding-conductor not

smaller than 8.4 mm²/ AWG 8 must be

connected from the accessible wire

connector on the motor to all metal parts

of the swimming pool, spa, or hot tub

structure and to all electrical equipment,

metal conduit, and metal piping within 1.5

m/5 ft of the inside walls of the swimming

pool, spa, or hot tub.

NOTE – The following chapter is relevant

for PS2-150 controllers operating boost

pumps only.

Before start-up of the boost pump system manually set the

system to the correct boost pump end with PumpScanner.

Please refer to the PumpScanner manual on partnerNET.

CAUTION – starting the boost pump

without selecting the correct boost pump

end will damage the pump. Such damage

is excluded from the warranty.

Before start-up of the pool pump system manually configure

the controller to the correct pool pump end with PumpScanner. Please refer to the PumpScanner manual on partnerNET.

32 Pump Installation

8 Pump Installation

8.1 General Instructions

WARNING – All electrical connections

must be performed by qualified experts

only.

WARNING – Before starting any work on

the pump/motor, make sure that the

electricity supply has been switched off

and that it cannot be accidentally

switched on!

CAUTION – Before you start the assembly,

make sure that all parts were delivered

and have not been damaged during

transport.

8.1.1 Pipe Sizing

LORENTZ pump systems are extremely efficient. It is important to keep this efficiency throughout the entire system.

A main reason for loss of efficiency is pipe pressure losses.

Make sure that you have included the pipe pressure losses

during the sizing process of your system.

Consider a smart pipeline design from the beginning.

CAUTION – Consult COMPASS or a pipe

pressure sizing chart to determine the

correct size. Oversize the pipe line to

reduce the pressure drop.

CAUTION – The length of the inlet and of

the outlet pipeline must be considered for

the calculation of the pressure losses

CAUTION – Only run the pump when it is

completely prefilled with water (surface

pumps), submersible pumps must be

completely submerged. This means there

must be no air in the pipes.

CAUTION – For surface pumps, air locks

must be avoided at the inlet pipe line.

Avoid sharp 90° elbows and sharp pipe

size adaptors.

8.2 Pump System Type

8.1.2 Cable Splicing

To connect the motor cable with a cable extension you

should connect the cable ends with a splicing kit.

It is very important that the cable joints are fully sealed otherwise moisture could cause a short circuit. This will damage

the pump system.

For more information about connecting cable ends with a

splicing kit see the “submersible cable splicing” manual in

the package of the splicing kit.

CAUTION – Cable splice failures are a

common source of errors. Check the splice

for proper connections.

CAUTION – Bad cable splicing can damage

the controller and/or the pump. Such

damage is excluded from the warranty.

Depending on your pump system, please refer to the correct

chapter for installation instructions:

Pump type Chapter

Submersible 8.3

Surface CS-F 8.4

Surface Boost 8.3

To determine the type of system you have, please refer to

chapter “3.4 Naming” on page 8.

34 Pump Installation

8.3 Submersible Pumps

For submersible pumps only: The ECDrives are water

lubricated and therefore prefilled with water. If the motor is

stored for more than three months, the water will have been

pressed out; the rotor must be turned by hand before use to

ensure that the rotor is not stuck.

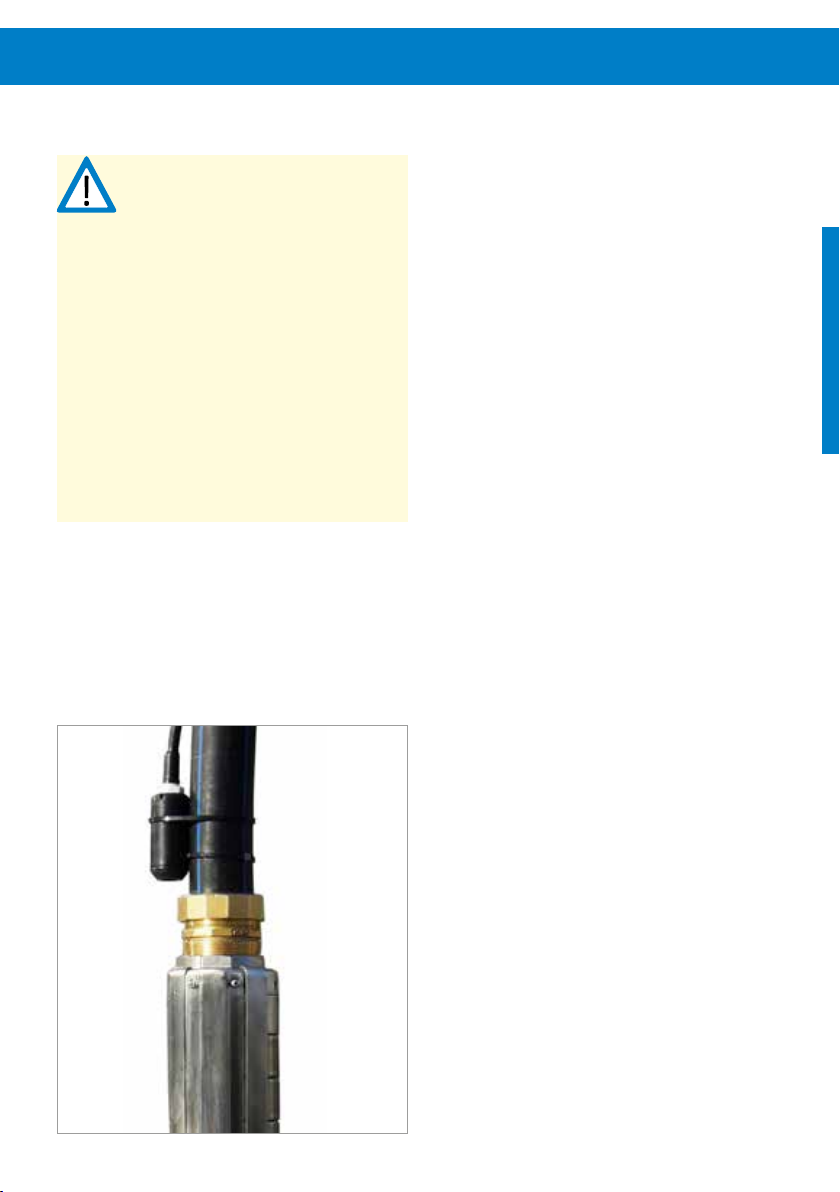

8.3.1 Wiring the Pump

CAUTION - No disconnect switches must

be installed between the motor and the

pump controller. Connecting the motor

wire to the switched-on controller might

irreparably damage it. Such damage is

excluded from the warranty.

CAUTION – If the pump wires are in the

wrong order, the motor will run in reverse

and the pump will not function correctly.

Damage may result. Check the direction

before installing the pump. The proper

direction is counter-clockwise when

viewed from above.

CAUTION – Never let the pump run dry.

Dry running will damage the pump and

void the warranty. LORENTZ requires dry

run protection for every submersible

pump system.

Figure 9: Exemplary LORENTZ submersible pumps

The motor cables of the pump have a marking to allow

correct wiring. Connect the wires using this sequence:

1: Motor cable L1

2: Motor cable L2

3: Motor cable L3

: Ground connector

The submersible pump must be submerged in water before

checking the correct rotational direction. The correct rotation

direction for submersible pumps is counter-clockwise,

viewed from the top. It is also labelled with an arrow on the

pump end.

The testing process for rotational direction depends on

the pump type. Please refer to the next page for detailed

instructions on testing helical rotor (HR) and centrifugal

submersible pumps. To determine which type of pump you

have, please refer to “3.4 Naming” on page 8.

HR Pumps:

Centrifugal Pumps:

The HR pumps are positive displacement pumps and

hence will only deliver flow rate when running with correct

rotation direction. They will be damaged when running in

reverse.

A new pump “out-of-the-box” is shipped from the factory

with a temporary lubrication film on the rotor which allows

a test run of max. 5 seconds in total without submerging

the pump. Once the pump came in contact with water the

temporary lubrication is gone and the pump must not be

operated without being completely submerged! Submerging

only the inlet is not sufficient and will result in damage to

the pump end.

Check the rotational direction as follows:

(1) Connect the pump to the controller and power supply.

(2) Observe the information regarding HR pump testing

above and follow them strictly!

(3) Start the pump and check the rotation direction by

observing the motor shaft at the pump inlet.

(4) Compare to the indicated rotation direction on the

pump end.

(5) In case the direction is wrong, switch off immediately

and change two of the three phase leads.

(6) Start the pump again and check the rotation direction.

Do not exceed 5 seconds of combined testing time.

Check the rotational direction as follows:

(1) Connect the pump to the controller and power supply.

(2) Start the pump and check the delivered flow rate.

(3) Stop the pump, disconnect the power supply and

change two of the three phase leads.

(4) Start the pump again and check the delivered flow.

(5) Stop the pump, disconnect the power supply and com-

pare the flow rates from point 2 and 4. The wiring with

the better flow rate has the right rotational direction.

(7) The pump will only deliver water flow when running

with correct rotation direction.

36 Pump Installation

8.3.2 Installation and Handling

To lower the pumps into the borehole, a crane or hoist is

recommended, depending on the size and weight of your

pump system.

All parts have to be strong enough to withstand the weight

of the pump, the motor, the motor cable and the pipe

system.

It is also helpful to lower a pump dummy into the borehole

before you lower the pump to make sure that the hole

is completely free and the pump can slide into the hole

without obstructions.

WARNING – Never stand under suspended

loads.

WARNING – Always take suitable security

precautions (e.g. a strong safety rope) to

safeguard the pump against slipping into

the well during installation!

CAUTION – Be careful not to bend the

pump, take particular care with centrifugal (C) pumps with a high number of

stages. Make sure that the pump never

stands on the motor cable, that the cable

does not get jammed or damaged by

sharp ledges or that the cable is not

pulled or jerked where it enters the motor.

Round off the edges of a flange to prevent damage to the

cable. Do not fix the cable tightly. Leave space for the pipes

to expand. The cable needs to get fixed every 3 m.

NOTE – Measuring and noting down the

distances between the fixing will help to

lower the pump to the right depth.

Figure 10: Fixing of the motor cable at a joint and a strait

pipe

50

tape

During the process of lowering the pump into the well the

motor cable has to be fixed properly to the pipe, see “Figure

10: Fixing of the motor cable at a joint and a strait pipe” on

page 36. Where a plastic pipe is used, the longitudinal

stretch of the pipe under load has to be considered by

leaving a sufficient gap between the pipe and the cable! The

cable should be fixed with water-resistant tape. It is a good

installation practice to form a loop with the motor cable

near the pump and repeat it about every 40 m / 130 ft along

the riser pipe. This will keep any tensile forces away from the

motor cable.

To extend the motor cable pay attention to chapter “8.1.2

Cable Splicing” on page 33.

77

5050

3 m

77

8.3.3 Installation Depth

8.3.4 Removal

Make sure that the pump unit is suspended properly and is

not in contact with sand and mud from the well bottom. It

is recommended to install the pump above the filter zone

(= water entry zone) of the well to keep the sand content in

the water low and ensure proper cooling of the motor.

CAUTION – The pump must be submerged

completely. Never let the pump run dry.

Dry running will damage the pump and

void the warranty. LORENTZ requires a dry

run protection for every pump system.

CAUTION – If the pump does not hang

above the filter zone a flow sleeve is

necessary.

If you have to remove the pump system it is the same principle as the installation in reverse order. When removing the

pump the pipes will be full of water and will be heavier.

CAUTION – When the pump system is

lifted out of the well the pipes are full of

water. This causes additional weight.

In the table below you can see the additional weight of the

water per meter pipe length.

Table 6: Additional weight per meter pipe length

Pipe diameter Additional weight

[in] [kg/m] [lb/ft]

2 2.0 14.5

2.5 3.2 23.1

3 4.6 33.3

4 8.2 59.3

5 12.7 91.9

6 18.4 133.1

38 Pump Installation

8.3.5 Additional Features

8.3.5.1 Safety Rope

We recommend the use of a safety rope as a loss insurance.

If the pipe breaks because of start-up torques of the motor,

too much weight, pipe corrosion or wrong installation a

safety rope can prevent the total loss of the pump system

and damage to the well.

Choose a safety rope that can handle the weight of the

whole installation and the water inside the pipes. The rope

material must be water-resistant. Near the well head the

rope needs to be UV-resistant or protected from sunlight.

CAUTION - Do not use a nylon rope. Nylon

is known to absorb water over time which

will weaken the rope.

8.3.5.2 Plastic Pipes

When the pipes are strong enough the use of plastic pipes is

possible. If you are not sure about the strength of your pipes

contact the pipe manufacturer.

CAUTION - The pipes must be strong

enough to hold the whole weight of the

pump, the motor, the pipe system and the

water in the pipes. It must also withstand

the water pressure generated by the total

dynamic head.

8.3.5.3 Stilling Tube

For the maximum recommended sand content, before any

significant detrimental effects occur, check chapter “4

Operating Conditions” on page 9.

A higher content will cause excessive wear within the pump

and reduce the pump’s life span considerably. Any pump

that is blocked by sand will not be covered by warranty.

To reduce the amount of particles entering the pump, a

stilling tube can be installed, see “Figure 11: Stilling tube”.

Figure 11: Stilling tube

CAUTION - When using plastic pipes you

should always use a safety rope.

8.4 CS-F Surface Pumps

8.4.1 Placement and Foundation

Rain and weather protection – The pump is equipped

with IPX4-type motor protection. If it is installed outside, the

pump must be protected from rain and direct sunlight. This

will increase the durability of your pump.

CAUTION – CS-F pumps must not be

submerged in water or subjected to rain

or dripping water.

CAUTION – If the pump is installed in a

humid area, effective ventilation and

aeration must be provided in order to

prevent condensation.

CAUTION – When installing in very small

installation spaces the natural cooling

may be insufficient. Carefully consider the

ventilation in order not to exceed the

maximum ambient temperature.

CAUTION – The pump might heat up in

operation. The pump must not be installed

on combustible surfaces. Strong

incombustible surfaces should be used,

e.g. concrete or stone surfaces.

Foundation – An arrow on the pump base shows the

direction of the flow of the fluid through the pump. It is

recommended to install the pump on a concrete foundation.

The foundation must be level and should have min. approx.

1.5 times the weight of the pump to absorb vibration, shock

and strain.

Connecting the pump to the foundation – Fastening

the pump to the foundation should be done exclusively by

means of properly sized bolts or threads (dowels) in order to

avoid any movement of the pump unit.

CAUTION – The pump must be mounted

vertically.

Space – During installation, make sure that there is enough

space available to permit subsequent disassembly of the

motor unit. It is recommended to have at least 1m of free

space above the pump.

Figure 12: Exemplary LORENTZ surface pumps

40 Pump Installation

8.4.2 Pump Motor Wiring

WARNING – The wiring has to be done by

qualified service personnel only.

WARNING – Beware of high voltage!

Electric shock hazard!

The ECDRIVE must be connected to the terminals L1, L2, L3

and the ground connector. The ECDRIVE requires four-conductor (four-wire) cable between the controller and the

motor. The three wires L1, L2 and L3 carry power. The fourth

wire carries ground. Connect the ground wire to the ground

connection below the pcb in the controller. Grounding helps

to prevent shock hazard if there is a fault in the motor.

The correct order of the three motor phases is marked on

the motor cables itself. Prior to splicing the order of the

motor phases should be transferred to the cable. This will

simplify the wiring.

CAUTION – No disconnect switches must

be installed in power wires between

motor and pump controller. Connecting

the motor wires to a switched-on

controller may cause irreparable damage

which is excluded from the warranty.

CAUTION – If the pump wires are in the

wrong order, the motor will run in reverse

and may damage the pump. Never let the

pump run dry, not even for the purpose of

checking the direction of rotation.

Check the correct rotation direction after the pump is filled

with water, see chapter “8.4.5.2 Rotary Direction” on page

44.

8.4.3 Installation and Handling

Handling – When lifting the pump use the eyebolts at the

motor housing. If that is not possible lift the pump at the

motor flange by using a holder or straps.

Strainer – If pipelines are welded together metal pieces

might be present in the pipeline. Before pump installation,

the inlet pipeline must be carefully cleaned. It is recommended to install a strainer about 1 m / 3 ft in front of the

pump inlet to avoid pump damage due to any kind of impurities (cp. “Figure 13: Strainer”). The pressure drop of the

strainer must be considered in the suction lift calculation.

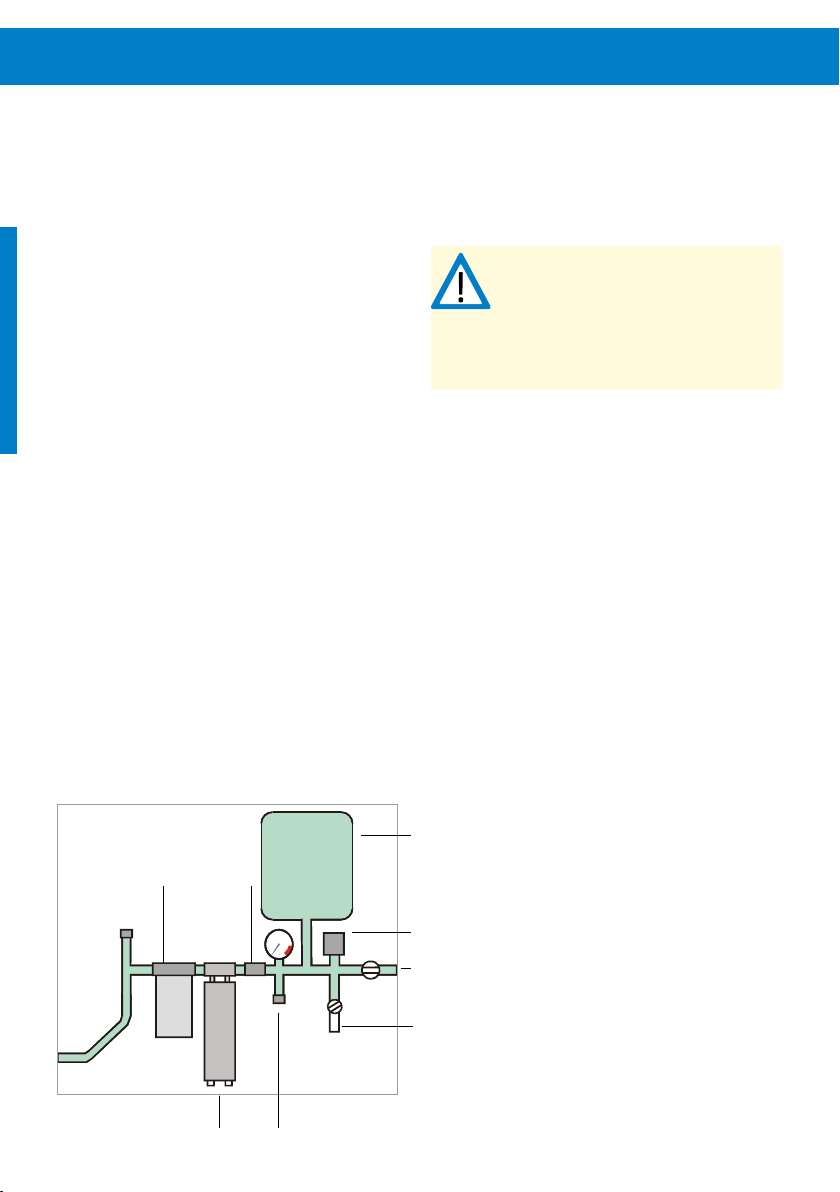

Pipe system – We advise that pipe expansion joints are

used close to the pump on both inlet and outlet to reduce

noise and vibration (cp. “Figure 14: Pipe expansion joints”).

It is recommended that you install a gate valve in the

suction and discharge pipeline close to the pump to avoid

draining of the pipe while cleaning (e.g. filters), repairing,

servicing or replacing the pump system.

WARNING – Inlet and outlet pipes must be

mounted to the pump housing free of

tension.

CAUTION – Make sure that the suction

pipe is sealed with no leaks, otherwise the

pump will not prime or will prime

insufficiently.

CAUTION – The pumps are shipped with

plastic covers on the pump inlet and

outlet. Remove them before connecting

the pipes to the pump.

Check valve – A check valve at the inlet pipe is needed

to assure that the pump and its suction pipeline remains

completely water filled during the time the pump is switched

OFF. Always install a check valve with one inch (1”) larger

diameter than the suction pipe in order to avoid too much

suction pressure drop. For example if the suction pipe size is

3”, then a 4” check valve should be installed.

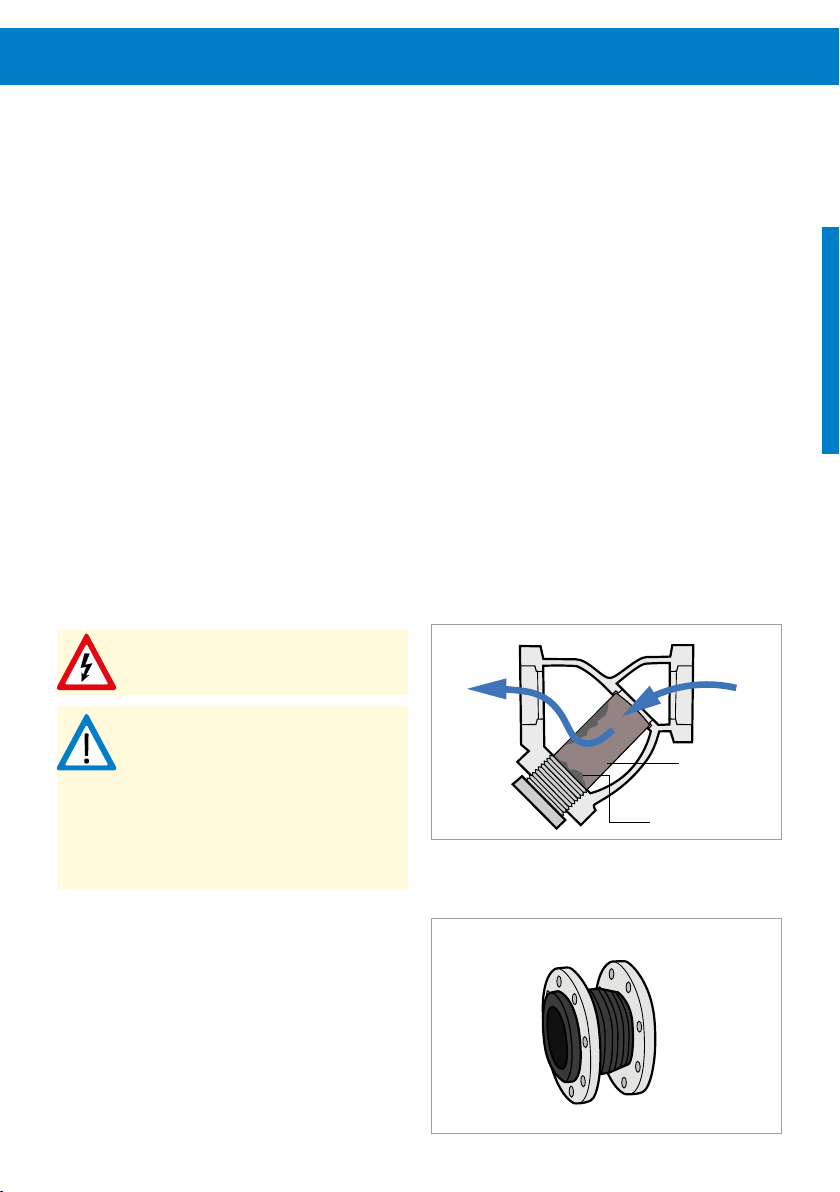

Figure 13: Strainer

filtered

flow

particle accumulation

Figure 14: Pipe expansion joints

unfiltered

flow

filter element

42 Pump Installation

8.4.4 Suction Head

The maximum suction head is limited by the local air pressure, the water temperature of the medium, the pipe losses

and the NPSH value of the pump.

CAUTION – If the suction pressure in the

pump is lower than the vapor pressure of

the fluid, cavitation will occur. Cavitation

creates noise and will damage the pump.

Damage due to cavitation is not subject to

warranty. To avoid cavitation, the pressure

of the fluid must be maintained above its

vapor pressure at all points as it passes

through the pump.

The maximum suction head (H) must be calculated in

advance. The LORENTZ pump sizing software COMPASS can

be used for NPSH calculation.

8.4.5 Initial Start-up

CAUTION – Never start the pump if it is

not filled with water and has not been

vented. The pump and suction pipe must

be fully filled with clean water otherwise

the pump will be damaged

8.4.5.1 Filling Pump with Water

The pump and the whole suction pipe must be fully filled

with clean water.

If the water source level is higher than the pump

inlet:

1. Close the gate valve in the outlet pipe and loosen the

air vent screw.

2. Open the gate valve in the suction pipe slowly.

3. Tighten the air vent screw when water streams out

continuously.

If the water source level is below the pump inlet:

Suction pipeline and pump must be filled with water

manually.

1. Close the gate valve in the outlet pipe and open the

gate valve in the suction pipeline.

2. Loosen the air vent screw and fill clean water into the

pump through the filler pipe.

3. Fasten the air vent screw after the pump and the

suction pipeline are completely filled with water.

WARNING – Do not start the pump until it

has been filled completely with water.

WARNING – Make sure that the installed