H100LonWorksManual

1

Thank you for purchasing LONWORKS Option Board.

SAFETY PRECAUTIONS

Always follow safety instructions to prevent accidents and potential hazards from occurring.

Safety precautions are classified into “WARNING” and “CAUTION” and their meanings are as follows:

WARNING

CAUTION

The indicated illustrations on the product and in the manual have the following meanings.

Danger may be present. Read the message and follow the instructions carefully.

Particular attention should be paid because danger of an electric shock may be present.

Keep operating instructions handy for quick reference.

Read the operating instructions carefully to fully understand the functions of the H100 series and to use it properly.

CAUTION

Be cautious, when handling the CMOS components of the Option Board.

Static may lead to malfunctioning of the product.

Turn off the inverter power, when changing the communication cable.

Otherwise, you may damage the board or a communication error may occur.

Make sure to insert the Option Board connector to the inverter precisely.

Otherwise, you may damage the board or a communication error may occur.

Check the parameter unit before setting up the parameter.

Otherwise, a communication error may occur.

Improper operation may result in serious personal injury or death.

Improper operation may result in slight to medium personal

injury or property damage.

H100LonWorksManual

2

1. Introduction

1.1 About the LonWorks (Local Operating Network) Platform

The LonWorks is a networking platform created by Echelon Corporation, which is widely utilized in the field of

building automation. On a LonWorks network, all the devices connected to the network nodes can freely

communicate with each other using the LoneTalk protocol. There is no distinction between ‘the master’ and ‘the slave’

devices. Devices connected to the LonWorks network are manufacturer-independent. This independence is achieved

by the use of the standard network variable types (SNVT). The H100 communication module supports these standard

network variable types. Using the standard network variable types, automated data communication becomes

available at the initial installation of the devices. This is done by configuring the input and output variables with an

installation tool. When configuring the input and output variables of the devices, the network variable types used

must always match.

1.2 The H100 LonWorks Communication Module Features

The H100 LonWorks communication module provides control and monitoring for inverters. The LonWorks platform

allows the connection of multiple inverters to a single line, thus saving on the expenses of network implementation.

Also, the LonWorks network features simple wiring, which allows for decreased installation time and easier

maintenance.

1.3 The H100 LonWorks Communication Module - Model Name

Model Name: CLON-H100

1.4 Included Items

The H100 communication module comes with the following items.

- H100 LonWorks communication module x 1EA

- H100 LonWorks user manual x 1EA

- Screws (M3xL08) x 2EA

- 3-Pin connector (PTR AK 950/03-5.0-GREEN) x 1EA

- Module supporter x 1EA

H100LonWorksManual

3

2. About The H100 Lon Works Communication Module

2.1 Technical Data

Items

Description

Power

Power supply to the H100 LonWorks

communication module

Power is supplied by the inverter(s)

Network Topology

Free Topology

(Bus, Star, Loop, or any combination of these 3 types)

Baud Rate

78 Kbit/s

LonWorks Communication Chipset

FT3150-P20 chip (Echelon)

LonWorks Transceiver

FT-X1

Data Networking Type

Peer-to-peer

Channel Type

TP/FT-10

Transfer Cable

Free Topology Twisted Pair

Maximum Number of Nodes

Maximum 2

48

nodes (48bit addressing)

64 channels per segment (including the Master)

Maximum Transfer Distance per Segment

Free Topology : 500m

Bus Topology : 2700m

Available PDO (Physical Device Object)

Node Object

Variable Speed Motor Object(6010)1

User Object(20001, User Function Profile Type)2

LonWorks Connector

Plug-in Connector

Terminal Resistance

Free Topology : 50Ω

Bus Topology : 100Ω

Built-in terminal resistance (switch on the module for topology

selection)

1

Variable Speed Motor Object (6010) is a universally compatible object throughout all manufacturers.

2

User Object is a manufacturer-defined object whose flexibility is dependent upon the manufacturer design.

H100LonWorksManual

4

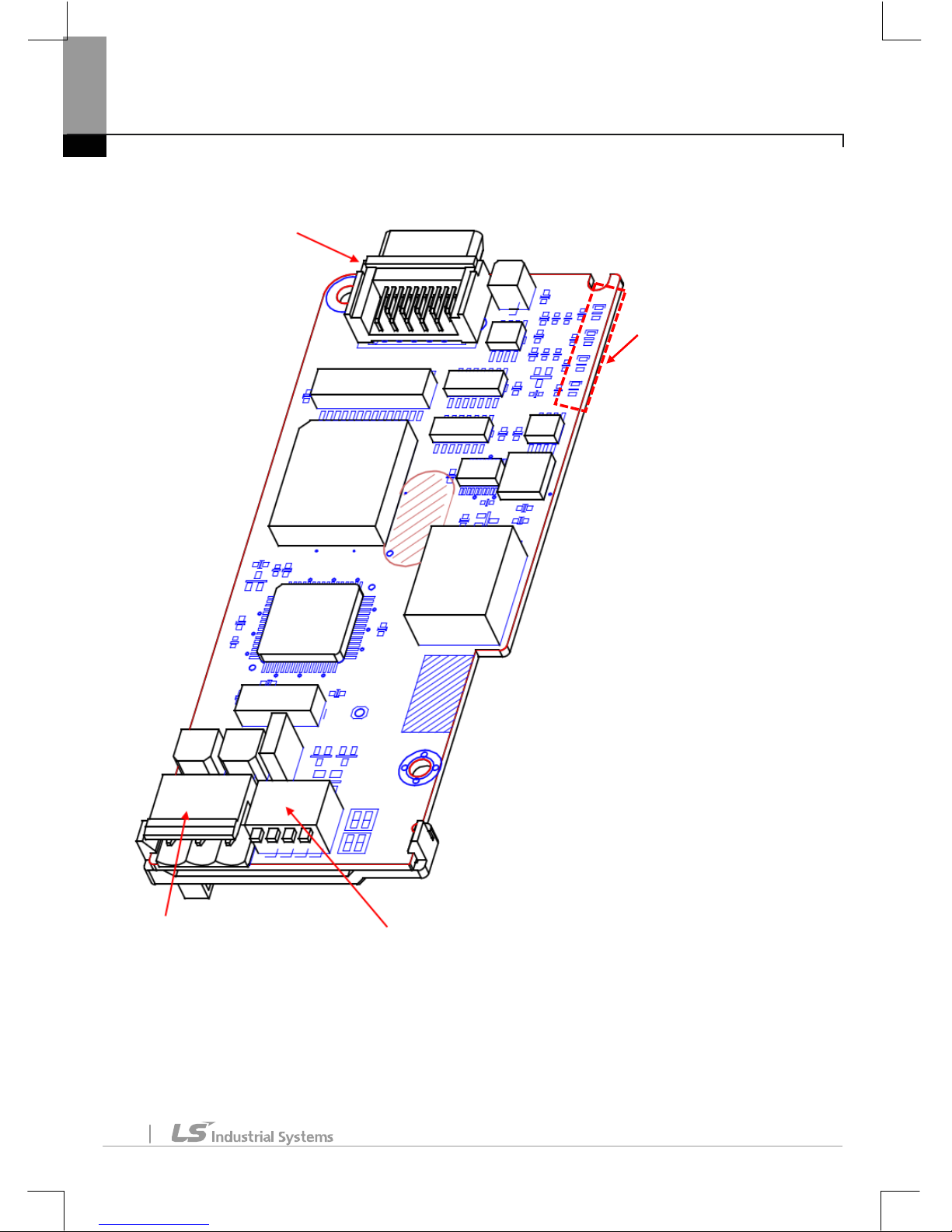

2.2 Device Layout

Connector to

the Inverter

Connector

(to Inverter)

DIP Switch

-Terminal resistance

-Service Pin Configuration

Communication

Connector (A, B, S)

LED

-CPU Operation

-Error

-Service

-COM

H100LonWorksManual

5

2.3 Installing the H100 LonWorks Communication Module

Warning

Turn off the power to the inverter before installation and network connection. Installing or removing the

communication module while the power is on may damage the inverter or the LonWorks communication module.

Make sure that the inverter is fully discharged before installing or removing the H100 LonWorks communication

Module.

■

Turn off the inverter and remove

the power terminal block cover.

■

Remove the keypad(2),

and then remove the top cover(3).

(1)

(2)

(3)

H100LonWorksManual

6

■

Install the H100 LonWorks communication

module (4) into the connector on the I/O board.

■

Secure the communication module with the 2 screws supplied with the device.

(4

H100LonWorksManual

7

■

Replace the top cover (5), then the keypad (6).

■

Replace the power terminal block cover (7). The inverter is now ready for use.

(7)

(5)

(6)

H100LonWorksManual

8

2.4 Wiring the H100 LonWorks Communication Module

The H100 Lon Works communication module has a connector socket for network connection.

The following table describes the details of the connector. Connector #1 and #2 are for the LonWorks

communication connection. The LonWorks communication connection does not require a certain order of polarity in

network wiring. Therefore, arranging of the polarity is not necessary.

No

Signal

Description

1

A

Network signal cable (no polarity)

2 B 3

S

Shield

Note

Use the 3-pin cable connector (PTR AK 950/03-5.0-GREEN) supplied with the device to connect the H100 LonWorks

communication module to a network.

2.5 Configuring a Network

Warning

Turn off the power to the inverter before installation and network connection. Installing or removing the

communication module while the power is on may damage the inverter and the LonWorks communication module.

Make sure that the inverter is fully discharged before installing or removing the H100 LonWorks communication

Module.

The LonWorks network allows for various types of network topology.

Appropriate network termination is required to guarantee data reliability and to reduce noise. The H100 LonWorks

communication module has built-in terminal resistance. Therefore, network termination can be made by simply

turning on the termination switch.

For a bus network, turn on the termination switch of the H100 LonWorks communication modules at both ends.

H100LonWorksManual

9

When the termination switch is set to BUS, 100Ω 1/8W termination resistance is connected between communication

terminals A and B.

For a free topology network connection, terminate one module on the network. When the termination switch is set to

FT, 50Ω 1/8W termination resistance is connected between communication terminals A and B.

The following table describes the type and feature of the termination resistance for each switch position.

<Termination Switch Configuration for the H100 LonWorks communication module>

Switch Position

Termination Type

FT

For use with a free topology network

50Ω terminal resistance

Terminate one module on the network.

NO

Termination is not used.

BUS

For use with a bus topology

100Ω terminal resistance

Terminate two modules at the ends of the network.

① NO

③ BUS

Bus Topology

(100 Ω)

② FT

Free Topology

(50 Ω)

ON

1 2 3 4

ON

1 2 3 4

ON

1

2 3 4

H100LonWorksManual

10

2.6 Installation Guidelines

Refer to the following guidelines when installing the H100 LonWorks communication module.

1. When you unpack the H100 LonWorks communication module, inspect the device to make sure that it is not

physically damaged.

2. Connect power to the H100 inverter and test the module to ensure that all functions work properly. Use the

keypad to operate the inverter and ensure that it operates normally.

3. Turn off the inverter and wait for at least five minutes for the internal charge to fully discharge. Before

working on the H100 inverter, test the DC link voltage to ensure that the charge is at a safe level.

4. Install the H100 LonWorks communication module in the H100 inverter. Remove the covers from the H100

inverter before installing the communication module.

5. Connect communication cables A and B to the H100 communication module. Polarity arrangement is not

necessary because the LonWorks communication module does not require specific network wiring polarity.

Make sure that the cables are connected securely.

6. If the node (the H100 inverter) is the last device on the network, terminate the network by setting the

termination switch.

7. To configure the LonWorks communication module, download the external interface file

(H100_LONWORKS.XIF) from the LSIS web site

(

http://www.lsis.com/support/download/

)

.

8. Turn on the power to the inverter and use the keypad to ensure that CNF-30 Option-1 Type displays

‘LonWorks.’

9. Configure the Lon Works communication parameters.

10. Inspect the H100 Lon Works communication module’s LED status. The ‘Service’ LED flashes in 2-sec intervals

if the device has not been configured.

11. Turn off the power to the H100 inverter and wait for 5 minutes until the DC link voltage discharges. Replace

the inverter covers. The installation process is finished. Turn the power on to the H100 inverter, and then

configure the device using the network tool.

Note

After first installing the H100 communication module, it must be configured at least once before it can communicate

with the inverter. Communication will be available once the communication module is configured after installation.

While configuring the communication module, an ‘Option Trip’ occurs because internal-interface communication

is not available immediately after installation. Bypass the ‘Option Trip’ at this stage and operate the inverter.

The communication module will communicate with the inverter properly once it is configured.

To configure the H100 communication module, turn the service switch ON, and then turn it off. The service LED will

turn off if the module was successfully configured.

H100LonWorksManual

11

2.7 Maximum Ranges for Different Network Cables

As shown in the following table, the maximum ranges of a network are limited based on the topology and the type of

cables used. Reliable network communication cannot be guaranteed beyond the maximum ranges listed in the table.

BUS Topology

Free Topology

Cable Type

Maximum Bus Length

Belden 85102

2,700 m

Belden 8471

2,700 m

Level IV, 22AWG

1,400 m

JY(St) Y 2x2x0.8

900 m

TIA Category 5

900 m

Cable Type

Maximum Distance between

Devices

Maximum

Total Range

Belden 85102

500 m

500 m

Belden 8471

400 m

500 m

Level IV, 22AWG

400 m

500 m

JY(St) Y 2x2x0.8

320 m

520 m

TIA Category 5

250 m

450 m

H100LonWorksManual

12

3. Inverter Parameters

3.1 Table of Parameters

Code

Parameter Name

Default Value

Settings

CNF-30

Option-1 Type

-

-

DRV-06

Cmd Source

1.Fx/Rx-1

0. Keypad

1. Fx/Rx-1

2. Fx/Rx-2

3. Int 485

4. FieldBus

5.Time Event

DRV-07

Freq Ref Src

0.Keypad-1

0. Keypad-1

1. Keypad-2

2. V1

4. V2

5. I2

6. Int 485

7. Fieldbus

9. Pulse

BAS-04

Cmd 2nd Src

1. Fx/Rx-1

0. Keypad

1. Fx/Rx-1

2. Fx/Rx-2

3. Int 485

4. FieldBus

5.Time Event

BAS-05

Freq 2nd Src

0. Keypad-1

0. Keypad-1

1. Keypad-2

2. V1

4. V2

5. I2

6. Int 485

7. Fieldbus

9. Pulse

H100LonWorksManual

13

Code

Parameter Name

Default Value

Settings

IN-65–71

P1–P7 Define

17. 2ndSource

COM-06

FBus S/W Ver

-

COM-09

FBus LED

-

COM-10

Opt Parameter1

-

-

COM-11

Opt Parameter2

COM-12

Opt Parameter3

COM-13

Opt Parameter4 - -

COM-14

Opt Parameter5

0

0 1 COM-31

Para Status-1

0x000A

0–0xFFFF

COM-32

Para Status-2

0x000E

0–0xFFFF

COM-33

Para Status-3

0x000F

0–0xFFFF

COM-34

Para Status-4

0x0000

0–0xFFFF

COM-35

Para Status-5

0x0000

0–0xFFFF

COM-36

Para Status-6

0x0000

0–0xFFFF

COM-37

Para Status-7

0x0000

0–0xFFFF

COM-38

Para Status-8

0x0000

0–0xFFFF

COM-51

Para Control-1

0x0005

0–0xFFFF

COM-52

Para Control-2

0x0006

0–0xFFFF

COM-53

Para Control-3

0x0000

0–0xFFFF

COM-54

Para Control-4

0x0000

0–0xFFFF

COM-55

Para Control-5

0x0000

0–0xFFFF

COM-56

Para Control-6

0x0000

0–0xFFFF

COM-57

Para Control-7

0x0000

0–0xFFFF

COM-58

Para Control-8

0x0000

0–0xFFFF

COM-94

CommUpdata

0.No

0. No

1. Yes

PRT-12

Lost Cmd Mode

0.None

0. None

1. Free-Run

2. Dec

3. Hold Input

4. Hold Output

5. Lost Preset

PRT-13

Lost Cmd Time

1.0 sec

0.1 – 120.0 sec

PRT-14

Lost Preset F

0 Hz

Start Frequency – Max frequency

H100LonWorksManual

14

3.2 Basic Field Bus Parameters

3.2.1 Communication Module Information– Option Type (CNF-30)

CNF-30

Option Type

This parameter automatically displays the name of the currently installed communication module.

If the LonWorks communication module is installed, CNF-30 Option Type displays ‘LonWorks.’

If the CNF-30 Option Type does not display any communication module names, this may mean that there is a faulty

connection between the inverter and the LonWorks communication module.

3.2.2 Command Source Options–Cmd Source (DRV-06)

DRV-06

Cmd Source

This parameter is used to select a command source.

To operate the inverter using the Lon Works communication, setDRV-06Cmd Source to ‘4.Fieldbus.’

3.2.3 Source of Frequency Reference Options– Freq Ref Src (DRV-07)

DRV-07

Freq Ref Src

This parameter is used to select a frequency reference.

To provide a frequency reference using the LonWorks communication, set DRV-07 Freq Ref Src to ‘7.Fieldbus.’

3.2.4 Secondary Command Source Options (for switching between two different command sources)

BAS-04

Cmd 2nd Src

BAS-05

Freq 2nd Src

IN-65–71

P1–P7 Define

This parameter is used to provide a second command source (frequency reference and run command) using the multipurpose input terminals. If the inverter is operated by remote network commands from network modules such as the

Lon Works communication module, this parameter may be used to stop remote operation and switch to local

operation using the inverter keypad.

This feature requires that the multi-purpose terminals P1–P7 (parameters IN65–71) are set to ‘2nd Source.’

3.2.5 Version information for the installed Communication Module– Fbus S/W Ver (COM-06)

H100LonWorksManual

15

This parameter is used to display the version information about the Lon Works communication module that is

installed in the inverter.

3.2.6 Communication Module LED Status Display– FbusLED (COM-9)

This parameter is used to display the status of the four LEDs (CPU, Error, Service, and COM) of the

communication module on the inverter keypad.

Each bit indication(On or Off) on the keypad display, from right to left, represent the status of the COM, Service,

Error and CPU LED.

An example of COM-09 LED State – 1101

LED

COM

(GREEN)

SERVICE

(GREEN)

ERR

(RED)

CPU

(GREEN)

Status

ON

ON

OFF

ON

Keypad Display

3.2.7 Display the Neuron ID– Opt Parameter1–3(COM-10–12)

COM-10

Opt Parameter1

COM-11

Opt Parameter2

COM-12

Opt Parameter3

These read-only parameters are used to display on the keypad the neuron IDs (a 6Byte data value) stored in the

neuron chip of the communication module. Parameters COM10–12 display the neuron ID information in HEX values,

in the order of upper to lower level information.

The information in the neuron IDs 1–3 may be used when you are installing the network manually without using the

service pin on the Lon Works communication module.

H100LonWorksManual

16

3.2.8 Display Node Status– Opt Parameter4(COM-13)

COM-13

Opt Parameter4

This read-only parameter is used to display the network interface status. When the interface is operating normally,

‘Configured on-line’ is displayed. This means that the relevant node has been commissioned by the network and is on-

line. ‘Soft’, ‘Bypass’, or ‘Hard off-line’ states indicate that the node failed to participate in the network.

Values

Description

0

Unknown state

1

Not configured

2

Application unassigned

3

Configured on-line

4

Configured off-line

5

Soft off-line

6

Configured bypass off-line

7

Hard off-line, Bypass off-line

3.2.9 Enable Service Pin– Opt Parameter5 (COM-14)

COM-14

Opt Parameter5

This parameter is used to enable the service pin feature without using the service pin switch on the LonWorks

communication module. Set COM-14 Service Pin Enable to ‘1’ to enable the service pin feature. This allows the Lon

Works communication module to send its Neuron ID and Program ID to the network.

Note

The Service Pin may be enabled on the keypad ONCE OLNY, after the inverter has been turned on the first time.

Once decommissioned from the configuration tool, the inverter cannot be commissioned again on a network using

the ‘Enable Service Pin’ parameter. You must turn on the service pin switch on the LonWorks communication module

to connect to the network.

H100LonWorksManual

17

3.2.10 User Object Output Variables (COM-31–38)

COM-31–38

Para Status-1–8

This parameter is used to configure the addresses for User Object output variables. For more details, refer to the ‘User

Object’ section of this manual.

3.2.11 User Object Input Variables (COM-51–58)

COM-51–58

Para Control-1–8

This parameter is used to configure the addresses for User Object input variables. For more details, refer to the ‘User

Object’ section of this manual.

3.2.12 Communication Update (COM-94)

After making changes to the parameters related to configuring Drive Objects using the keypad, a communication

update is required to apply the changes. Set COM 94 Comm Update to ‘Yes’ to perform a communication update.

After the update, the Comm Update parameter automatically changes back to ‘No.’

Keypad parameters that require the communication update are listed in the table below.

Codes

Parameters

DRV-03

Acc Time

DRV-04

Dec Time

DRV-18

Base Frequency

DRV-19

Start Frequency

DRV-20

Max Frequency

BAS-11

Pole Number

Note

After commissioning the H100 Lon Works communication module, COM-94 Comm Update must be set to ‘Yes’ to

apply the inverter’s configuration properties configured using the keypad.

H100LonWorksManual

18

3.2.13 Operation Options for a Lost Command– Lost Cmd Mode (PRT-12)

DRV-06

Cmd Source

DRV-07

Freq Ref Src

PRT-12

Lost Cmd Mode

PRT-13

Lost Cmd Time

PRT-14

Lost Preset F

This parameter is used to select an operation mode to be used when the command is lost. When remote command

via network is lost for the ‘lost command decision time’, the inverter decides that the command is lost.

This feature is available only when DRV-06 is set to ‘4.Fieldbus,’ or when DRV-07 is set to ‘7.Fieldbus.’

With this feature enabled, the selected operation mode is used when the network command is lost.

Settings

Description

0

None

Keeps the inverter operation at lost command.

1

Free-Run

The inverter blocks output. The motor performs a free-run stop.

2

Dec

The motor decelerates and then stops at the time set at PRT-07 Trip Dec

Time.

3

Hold Input

The inverter calculates the average input value for 10 sec before the loss of

the speed command and uses it as the speed reference.

4

Hold Output

The inverter calculates the average output value for 10 sec before the loss

of the speed command and uses it as the speed reference.

5

Lost Preset

The inverter operates at the frequency set at PRT-14 Lost Preset F.

H100LonWorksManual

19

3.2.14 Lost Command Decision Time– Lost Cmd Time (PRT-13)

DRV-06

Cmd Source

DRV-07

Freq Ref Src

PRT-12

Lost Cmd Mode

PRT-13

Lost Cmd Time

This parameter is used to set the time the inverter takes to decide that the command is lost. When the remote

command via network is lost for the lost command decision time (PRT-13 Lost Cmd Time + the time set at

nciRdvHrtBt), the inverter decides that the command is lost.

This feature is available only when DRV-06 is set to ‘4.Fieldbus,’ or when DRV-07 is set to ‘7.Fieldbus.’ If the network

command is recovered before the lost command decision time (PRT-13 Lost Cmd Time + the time set at nciRdvHrtBt)

is passed, the inverter does not output a fault trip and continues normal operation.

Caution

Lost command time protection operates only when the ‘nciRcvHrtBt’ variable is set to any value other than ‘0.’

Lost Command Period

Lost Command Period

Comm Line Status

Command was

recovered before

the Lost Cmd Time.

Lost command was

not detected.

Lost Command was detected.

The inverter runs according to

the Lost Cmd Mode Settings.

Time

H100LonWorksManual

20

4. Functional Profile

4.1 Node Object

Network Input Variables

Function

Variable Name

SNVT Type

Min

Max

Node Object Request

nviRequest

SNVT_obj_request

-

-

4.1.1 ‘nviRequest’ Variable

The ‘nviRequest’input variable enables or updates the command inputs from a network. This input variable supports

RQ_ENABLE, RQ_DISABLE, RQ_CLEAR_ALARM, RQ_NORMAL, RQ_CLEAR_STATUS, RQ_UPDATE_STATUS,

RQ_REPORT_MASK.

Network Output Variables

Function

Variable Name

SNVT Type

Min

Max

Node Object Status

nvoStatus

SNVT_obj_status

-

-

4.1.2 ‘nvoStatus’ Variable

The following table shows the Node Object states indicated by the ‘nvoStatus’ output variable.

Bit Setting Description

Invalid ID

Invalid node ID has been requested.

Report mask

Reporting supported fields.

Disabled

RQ_DISABLE is active.

Electrical_fault

Drive fault has occurred.

Manual_control

Drive is in local control mode.

In_alarm

Drive alarm has been turned on.

Node Object

Mandatory

Network

Variables

nviRequest

SNVT_obj_request

nv1

nvoStatus

SNVT_obj_state

nv2

Input Network

Variable

Output Network

Variable

H100LonWorksManual

21

4.2 Drive Object

Mandatory

Network

Variables

nviDrvSpeedStpt

SNVT_switch

nv1

nvoDrvSpeed

SNVT_lev_percent

nv4

Variable Speed Motor

Drive (6010)

Optional

Network

Variables

nviDrvSpeedScale

SNVT_lev_percent

nv2

nvoDrvCurrent

SNVT_amp

nv3

nvoDrvVolt

SNVT_volt

nv5

nvoDrvPwr

SNVT_power_kilo

nv6

nvoDrvRunHours

SNVT_time_hour

nv7

nc17 nciLocation (Optional)

nc50 nciMaxSpeed (Mandatory)

nc53 nciMinSpeed (Mandatory)

nc48 nciRcvHrtBt (Optional)

nc49 nciSndHrtBt (Mandatory)

nc52 nciMinOutTm (Optional)

nc158 nciNmlSpeed (Mandatory)

nc159 nciNmlFreq (Mandatory)

nc160 nciRampUpTm (Mandatory)

nc161 nciRampDownTm (Mandatory)

nc162 nciDrvSpeedScale (Optional)

Configuration Properties

Input Network

Variable

Output Network

Variable

H100LonWorksManual

22

Network Input Variables

Function

Variable Name

SNVT Type

Min

Max

Drive Speed Setpoint

nviDrvSpeedStpt

SNVT_switch

N/A

N/A

Drive Speed SetpointScaling

nviDrvSpeedScale

SNVT_lev_percent

-163.840%

163.830%

4.2.1 ‘nviDrvSpeedStpt’ and ‘nviDrvSpeedScale’ Variables

Definition

Network input SNVT_switch nviDrivSpeedStpt

Network input SNVT_lev_percent nviDrvSpeedScale

Description

Variables ‘nviDrvSpeedStpt’ and ‘nviDrvSpeedScale’ are used for run commands and speed references. The state

variable value for ‘nviDrvSpeedStpt’ decides whether to run or stop an inverter. The inverter stops when the

‘nviDrvSpeedStpt’ state is set to ‘0’, and runs when it is set to ‘1.’

The ‘nviDrvSpeedScale’ variable provides rotation direction information for the inverter. The inverter operates in the

forward direction (Fx) when the ‘nviDrvSpeedScale’ value is set to a positive number, and in the reverse direction (Rx)

when it is set to a negative number.

Frequency reference information is given by a combination of the ‘nviDrvSpeedScale’ and ‘nviDrvSpeedStpt’ variable

values. The ‘nviDrvSpeedScale’ and ‘nviDrvSpeedStpt’ values are in percentages (%).

To calculate the frequency reference, multiply the ‘nviDrvSpeedStpt’ value with the ‘nviDrvSpeedScale’ value, and

then multiply the resulting value (%) with the base frequency. This means that the ‘nviDrvSpeedScale’ variable

provides the scale value for the ‘nviDrvSpeedStpt’ variable.

For Example, if the ’nviDrvSpeedStpt’ value is set to ‘100 (%)’ and the ‘nviDrvSpeedScale’ value is set to ‘-80 (%),’ the

resulting value will be -80% (1 X -0.8 = -0.8). As a result, the inverter operates in the reverse direction, at a frequency

that is 80% of the base frequency (if the base frequency is set to 60.00 Hz) and the resulting frequency reference will

be 48Hz (60.00Hz X 0.8).

The ‘nviDrvSpeedScale’ value range is between -163.840% – 163.830%. Therefore, a value of 0x7fff (+163.835%)

becomes an invalid data.

H100LonWorksManual

23

NviDrvSpeedStpt States and Value Range

State

Value

Inverter Operating Frequency / Operation State

0

-

Stop

1

0

Frequency reference at 0% of the base frequency

1

0.5–100.0

Frequency reference at 0.5–100.0% of the base frequency

1

100.0

Frequency reference at 100% of the base frequency

0xFF

-

Auto

In the communication (COMM) group, set DRV-06 Cmd Source to ‘FieldBus’ and DRV-07 Freq Ref Src to ‘FieldBus’

using the keypad. These settings configure the inverter to receive run commands and frequency references from the

LonWorks communication.

Code Number/

Common Area Address

Code Description

Default

Settings

DRV-06

Cmd Source

Fx/Rx-1

Keypad

Fx/Rx-1

Fx/Rx-2

Int 485

FieldBus

Time Event

DRV-07

Freq Ref Src

Keypad-1

Keypad-1

Keypad-2

V1

Reserved

V2

I2

Int 485

FieldBus

Reserved

Pulse

nviDrvSpeedScale Range

-163.840% – 163.830%

nviDrvSpeedScale Default

0.000%

H100LonWorksManual

24

Inverter Parameters Related to the ‘nviDrvSpeedStpt’ and ‘nviDrvSpeedScale’ Variables

Code Number/

Common Area Address

Code Description

Default

Range

0x0005

Frequency Command

0.00 Hz

0.00 – 400.00

0x0006

Run Command

Refer to the ‘Common Area’ section.

DRV-18

Base Frequency

60.00 Hz

30.00–400.00

Note

Network variables ‘nviDrivSpeedStpt’ and ‘nviDrvSpeedScale’ may be used in combination with the ‘nciRcvHrtBt’

variable to configure the lost command options.

Network Output Variables

Function

Variable Name

SNVT Type

Min

Max

Drive Speed Feedback

nvoDrvSpeed

SNVT_lev_percent

-163.840%

163.830%

Actual Motor Current

nvoDrvCurnt

SNVT_amp

0.0 A

3276.7 A

Drive Output Voltage

nvoDrvVolt

SNVT_volt

0.0 V

3276.7 V

Actual Drive Power

nvoDrvPwr

SNVT_power_kilo

0.0 kW

6553.5 kW

Drive total running hours

nvoDrvRunHours

SNVT_time_hour

0 h

65535 hr

‘nvoDrvSpeed’ Variable

Definition

Network output SNVT_lev_percent nvoDrvSpeed

Description

The ‘nvoDrvSpeed’ variable is used to output the inverter’s operating frequency as a percentage of the base

frequency. The ‘nvoDrvSpeed’ value is positive if the inverter is running in the forward direction (Fx) and negative if it

is running in the reverse direction (Rx).

For example, if the base frequency is set at 60.00 Hz, and the inverter is running at 30.00 Hz in the reverse direction

(Rx), ‘nvoDrvSpeed’ outputs a value of-50.000%.

Typical Range

-163.840 – 163.830 % (0.001 %)

H100LonWorksManual

25

Inverter Parameters Related to the ‘nvoDrvSpeed’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

0x000A

Output Frequency

0x000E

Status of Inverter(FWD, REV)

DRV-18

Base Frequency

60.00 Hz

30.00–400.00

4.2.4 ‘nvoDrvCurnt’ Variable

Definition

Network output SNVT_amp nvoDrvCurnt

Description

The ‘nvoDrvCurnt’ variable is used to output the inverter’s output current in amperes (A).

Typical Range

0.0 – 3276.6 A (0.1 A)

Inverter Parameters Related to the ‘nvoDrvCurnt’ Variable

Code Number/

Common Area Address

Code Description

x0009

Current

4.2.5 ‘nvoDrvVolt’ Variable

Definition

Network output SNVT_volt nvoDrvVolt

Description

The ‘nvoDrvVolt’ variable is used to output the inverter’s output voltage (V).

Typical Range

0.0 – 700.0 V (0.1 V)

H100LonWorksManual

26

Inverter Parameters Related to the ‘nvoDrvVoltCurnt’ Variable

Code Number/

Common Area Address

Code Description

0x000B

Output Voltage

4.2.6’nvoDrvPwr’ Variable

Definition

Network output SNVT_power_kilo nvoDrvPwr

Description

The ‘nvoDrvPwrNetWork’ variable is used to output the inverter’s power output in kilowatts (kW).

Typical Range

0.0 – 6553.4 kW (0.1 kW)

Inverter Parameters Related to the ‘nvoDrvPwr’Variable

Code Number/

Common Area Address

Code Description

MAK-01

0x0301

Inverter Capacity

4.2.7’nvoDrvRunHours’ Variable

Definition

Network output SNVT_time_hour nvoDrvRunHours

Description

The ‘nvoDrvRunHours’ variable is used to output the inverter’s total operation time.

Inverter Parameters Related to the ‘nvoDrvPwr’ Variable

Code Number/

Common Area Address

Code Description

0x0342

0x0343

Total Operation Time

0x0342 – in days

0x0343 – in minutes

Network Configuration Variables

H100LonWorksManual

27

Function

Variable Name

Optional/

Mandatory

SNVT Type

Location Label

nciLocation

Optional

SCPTlocation

Maximum Motor Speed

nciMaxSpeed

Mandatory

SCPTmaxSetpoint

Minimum Motor Speed

nciMinSpeed

Mandatory

SCPTminSetpoint

Receive Heartbeat Time

nciRcvHrtBt

Optional

SCPTmaxRcvTime

Send Heartbeat Time

nciSndHrtBt

Mandatory

SCPTmaxSndTime

Minimum Send Time

nciMinOutTm

Optional

SCPTMinOutTime

Nominal Motor Speed in RPM

nciNmlSpeed

Mandatory

SCPTnomRPM

Nominal Motor Frequency

nciNmlFreq

Mandatory

SCPTnomFreq

Minimum Ramp Up Time

nciRampUpTm

Mandatory

SCPTrampUPTm

Minimum Ramp Down Time

nciRampDownTm

Mandatory

SCPTrampDownTm

Default Value for nviDrvSpeedScale

nciDrvSpeedScale

Optional

SCPTdefScale

Note

After modifying the parameters related to configuration variables from the keypad, set COM-94Comm Update to

‘Yes’ to apply the changes to the configuration variables.

Code Number/

Common Area Address

Code Description

Default

Options

COM-94

Comm Update

No

No

Yes

H100LonWorksManual

28

4.2.8 Location Label (Optional)

Definition

Network config input SNVT_str_asc nciLocation

Description

The ‘nciLocation’ variable is used to obtain the physical location information (6 byte location string) from the neuron

chip.

Default

Empty spaces

4.2.9 Maximum Motor Speed (Mandatory)

Definition

Network config input SNVT_lev_percent nciMaxSpeed

Description

The ‘nciMaxSpeed’ variable is used to configure the maximum speed of a motor. The ‘nciMaxSpeed’ value is

expressed as a percentage of the nominal frequency (nciNmlFreq) configuration value.

For example, if the ‘nciNmlFreq’ is 60.0 Hz and the ‘nciMaxSpeed’ is set to 120%, the resulting frequency is 72 Hz (60.0

x 1.2). The maximum frequency configured by these variables can be viewed on the keypad at DRV-20 Max Freq.

Changes cannot be made to the ‘nciMaxSpeed’ variable while the inverter is running. Stop the inverter operation

before making changes to the ‘nciMaxSpeed’ variable.

The default value for the ‘nciMaxSpeed’ variable is 100.00%, which is 100% of the base frequency (DRV-18Base Freq),

and the resulting value becomes the maximum frequency (DRV-20 Max Freq).

The ‘nciMaxSpeed’ variable values must comply with the following formula.

Typical Range

100.000 – 150.000 % (0.001% increments)

Default

100.000%

Note

As shown in the descriptions above, the ‘nciMinFreq(nciMinSpeed)’ and the ’nciMaxSpeed(%)’ values adjust the

maximum frequency set at DRV-20 Max Freq. Because the maximum frequency (Max Freq) must fall within the 40–

120.00 Hz range, the inverter will maintain the current maximum frequency if the ‘nciNmlFreq’ is changed to a value

less than 40 Hz. (For example, if the ‘nciNmlFreq’is set to 30 Hz and the ‘nciMaxSpeed‘ is set to 100.00%, the

maximum frequency will not be changed to 30 Hz).

840.163840.163 SpeedMaximumSpeedMinimum

H100LonWorksManual

29

Inverter Parameters Related to the ‘nciMaxSpeed’ VariableI

Code Number/

Common Area Address

Code Description

Default

Range

DRV-18

Base Frequency

60.00 Hz

30.00 – 400.00

DRV-20

Max Frequency

60.00 Hz

40.00 – 400.00

4.2.10 Minimum Motor Speed (Mandatory)

Definition

Network config input SNVT_lev_percent nciMinSpeed

Description

The ‘nciMinSpeed’ variable is used to configure the minimum speed of a motor. The ‘nciMinSpeed’ value is expressed

as a percentage of the nominal frequency (nciNmlFreq) configuration value. For example, if the ‘nciNmlFreq’ is 60.0

Hz and the ‘nciMinSpeed’ is set to 10%, the resulting frequency is 6 HZ (60.0 x 0.1). The minimum frequency

configured by these variables can be viewed on the keypad (DRV-19 Start Freq).

Changes cannot be made to the ‘nciMinSpeed’ variable while the inverter is running. Stop the inverter before making

any changes to the ‘nciMinSpeed’ variable.

The default value for the ‘nciMinSpeed’ variable (expressed as percentage) is calculated based on the base frequency

and the start frequency (‘DRV-19 Start Freq’ divided by ‘DRV-18 Base Freq’). Because the default for the start

frequency (DRV-19 Start Freq) is 0.5 Hz, the ‘nciMinSpeed’ variable value becomes 0.8% (0.5/60=0.0083, rounded off

and expressed as a percentage).

The ‘nciMinSpeed’ variable values must comply with the following formula.

Typical Range

0.000– 40.000 % (0.001 % increments)

Default

0.000%

※

As shown in the descriptions above, the ‘nciMinFreq(nciMinSpeed)’ and the’nciMaxSpeed (%)’ values adjust the

maximum frequency set at DRV-20 Max Freq. Because the maximum frequency (Max Freq) must fall within the 40–

400 Hz range, the inverter will maintain the current maximum frequency if the ‘nciNmlFreq’ is changed to a value less

than 40 Hz. (For example, if the ‘nciNmlFreq’ is set to 30 Hz and the ‘nciMaxSpeed‘ is set to 100.00%, the maximum

frequency will not be changed to 30 Hz).

830.163840.163 SpeedMaximumSpeedMinimum

H100LonWorksManual

30

Inverter Parameters Related to the ‘nciMaxSpeed’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

DRV-18

Base Frequency

60.00 Hz

30.00 – 400.00

DRV-20

Start Frequency

0.50 Hz

0.01–10.00

4.2.11 Receive Heart Beat Time (Optional)

Definition

Network config input SNVT_time_sec nciRcvHrtBt

Description

The ‘nciRcvHrtBt’ variable is used to configure the maximum update interval for the network input variables

‘nviDrvSpeedStpt’ and ‘nviDrvSpdScale’. If the ‘nviDrvSpeedStpt’ and ‘nviDrvSpdScale’ variables are not updated for

the set time (‘nciRcvHrBt’ time value + PRT-13 Lost Cmd Time), the inverter decides that the command is lost. It then

runs in the operation mode set by thePRT-12 Lost Cmd Mode.

Lost command time protection operates only when the ‘nciRcvHrtBt’ variable is set to a value other than 0.0 sec,

DRV-06 Cmd Source or DRV-07 Freq Ref Src is set to ‘Fieldbus’, and PRT-12 Lost Cmd Mode is set to any other value

than ‘None’.

The lost command protection feature is disabled if the ‘nciRcvHrBt’ variable is set to 0.0 sec.

Typical Range

0.0 – 120.0 sec (0.1 sec increments)

A value of 0xFFFF(6553.5 sec) is invalid data.

Default

0.0 sec (Receive Heart Beat feature is disabled)

H100LonWorksManual

31

Inverter Parameters Related to the ‘nciRcvHrtBt’ Variable

Code Number/

Common Area Address

Code Description

Default

Settings

DRV-06

Cmd Source

Fx/Rx-1

Keypad

Fx/Rx-1

Fx/Rx-2

Int 485

FieldBus

Time Event

DRV-07

Freq Ref Src

Keypad-1

Keypad-1

Keypad-2

V1

Reserved

V2

I2

Int 485

FieldBus

Reserved

Pulse

PRT-12

Lost Cmd Mode

None

None

FreeRun

Dec

Hold Input

Hold Output

Lost Preset

PRT-13

Lost Cmd Time

1.0sec

0.1–120.0sec

Caution

When the LonWorks network is used as a command source, the inverter’s lost command time becomes the time set

at ‘nciRcvHrtBt’ and PRT-13Lost Cmd Time added together. However, if the ‘nciRcvHrBt’ variable is set to 0.0 sec, the

lost command protection feature is disabled.

H100LonWorksManual

32

4.2.12 Send Heart Beat Time (Mandatory)

Definition

Network config input SNVT_time_sec nciSndHrtBt

Description

The ‘nciSndHrtBt’ variable is used to configure the time it takes to perform a data update on the network, regardless

of the presence of changes in the data.

The ‘nciSndHrtBt’ variable configures the maximum output time for the network output variables ‘nvoDrvSpeed’,

‘nvoDrvCurnt’, ‘nvoDrvVolt’, ‘nvoDrvPwr’, and ‘nvoDrvRunHours.’

Typical Range

0.0 – 6553.4 sec

A value of 0xFFFF (6553.5 sec) is invalid data.

Default

0.0 sec (Send Heart Beat feature is disabled)

4.2.13 Minimum Out Time (Optional)

Definition

Network config input SNVT_time_sec nciMinOUtTm

Description

The ‘nciMinOUtTm’ variable is used to configure the minimum wait time before the output variables ‘nvoDrvSpeed’,

‘nvoDrvCurnt’, ‘nvoDrvVolt’, ‘nvoDrvPwr’, and ‘nvoDrvRunHours’ are sent to the network.

Rather than reflecting the changes in the variables each time they are made, a network update is performed when the

set period of ‘nciMinOutTm’ has elapsed to reflect the changes. This feature is used to decrease network traffic.

Typical Range

0.0 – 6553.4 sec (0.1 sec increments)

A value of 0xFFFF (6553.5 sec) is invalid data.

Default

0.0 sec (Minimum Out Time feature is disabled)

4.2.14 Nominal Motor Speed in RPM (Mandatory)

Definition

Network config input SNVT_freq_hz nciNmlSpeed

Description

The ‘nciNmlSpeed’ variable is used to configure the inverter’s base frequency.

The default value for the ‘nciNmlSpeed’ variable is 1800.00 RPM which is the default base frequency of 60Hz set at

DRV-18 Base Freq, expressed in PRM (for a 4-pole motor). When the ‘nciNmlSpeed’ value is changed, the value (RPM)

H100LonWorksManual

33

converted back to Hertz (Hz) is reflected in DRV-18 Base Freq.

The following formula converts an RPM value into Hertz (Hz). In this formula, the number of motor poles is set at M210 Pole Num. The motor pole number must be configured correctly to ensure proper operation.

Valid Range

0 – 65534 RPM (1 RPM)

Default

1800 RPM

Inverter Parameters Related to the ‘nciNmlSpeed’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

BAS-11

0X0E0A

Pole Number

4

2–48

DRV-18

Base Frequency

60.00 Hz

30.00 – 400.00

Note

When a change is made to the ‘nciNmlSpeed’ variable, it is automatically reflected in the ‘nciNmlFreq’ value. For

example, if the current ‘nciNmlSpeed’ value is set to 1800 RPM, the ‘nciNmlFreq’ is set to 60.0 Hz, DRV-18 Base

Frequency is set to 60 Hz, and BAS-11 Pole Number is set to 4 (poles), decreasing the ‘nciNmlFreq’ value to 1700 RPM

changes the ’nciNmlFreq’ value to 56.7 Hz (a rounded-up value of the DRV-18 Base Frequency value), and DRV-18

Base Frequency to 56.66 Hz.

When the values set at ‘nciNmlSpeed’ or ‘nciNmlFreq’ are changed, the changes are reflected in DRV-19 Start

Frequency and Drv-20 Max Frequency as well. In the example above, if the ‘nciMaxSpeed’ is set to 100.000% and

‘nciMinSpeed’ is set to 10.000%, DRV-19 Start Frequency is changed to 5.66 Hz and Drv-20 Max Frequency is changed

to 56.66 Hz.

4.2.15 Nominal Motor Frequency (Mandatory)

Definition

Network config input SNVT_freq_hz nciNmlFreq

Description

The ‘nciNmlFreq’ is used to configure the motor’s base frequency. The ‘nciNmlFreq’ value is essential in configuring

the motor’s minimum and maximum frequency (‘nciMinSpeed’ and ’nciMaxSpeed’) because these values are

expressed as a percentage of the value set at ’nciNmlFreq.’ The default ‘nciNmlFreq’ value is 60 Hz which is the

default frequency set at DRV-18 Base Freq.

ploesmotor ofnumber the

120 Hz)Frequency( Base

minuteper rotation ofnumber The

poles

H100LonWorksManual

34

Valid Range

30.0–400.0 (0.1 Hz)

Default

60.0 Hz

Inverter Parameters Related to the ‘nciNmlFreq’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

DRV-18

Base Frequency

60.00 Hz

30.00 – 400.00

4.2.16 Minimum Ramp Up Time (Mandatory)

Definition

Network config input SNVT_time_sec nciRampUpTm

Description

The ‘nciRampUpTm’ variable is used to configure the inverter’s acceleration time. When the ‘nciRampUpTm’ value is

changed, it is reflected in DRV-03 Acc Time. The default ‘nciRampUpTm’ value is 20.0 sec, which is the default

acceleration time that is set as DRV-03 Acc Time.

Valid Range

0.0–600.0 sec (0.1 sec increments)

Default

20.0 sec

Inverter Parameters Related to the ‘nciRampUpTm’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

0x0007

DRV-03

Acc Time (Acceleration time)

20.0 sec

0.0 – 600.0

4.2.17 Minimum Ramp Down Time (Mandatory)

Definition

Network config input SNVT_time_secnciRampDownTm

Description

The ‘nciRampDownTm’ variable is used to configure the inverter’s deceleration time. When the ‘nciRampDownTm’

value is changed, it is reflected in DRV-04 Dec Time. The default ‘nciRampDownTm’ value is 30.0 sec, which is the

default acceleration time set at DRV-04 Dec Time.

Valid Range

0.0–600.0 sec (0.1 sec increments)

Default

30.0 sec

H100LonWorksManual

35

Inverter Parameters Related to the ‘nciRampDownTm’ Variable

Code Number/

Common Area Address

Code Description

Default

Range

0x0008

DRV-04

Dec Time (Deceleration time)

30.0 sec

0.0 – 600.0

4.2.18 Default for nviDrvSpeedScale (Optional)

Definition

Network config input SNVT_lev_percentnciDrvSpeedScale

Description

The ‘nciDrvSpeedScale’ value is used as the default value of the network output variable ‘nviDrvSpeedScale.’

Valid Range

-163.840– 163.830 (0.005 %)

Default

0.000 %

Note

The inverter parameters DRV-18 Base Freq, DRV-19 Start Freq, DRV-20 Max Freq, BAS-11 Pole Num, DRV-03 Acc

Time, and DRV-04 Dec Time are closely related to the configuration property variables ‘nciNmlFreq’, ‘nciNmlSpeed’,

‘nciMaxSpeed’, ‘nciMinSpeed’, ‘nciRampUPTm’, and ‘nciRampDownTm’ in Drive Objects.

After making changes to the parameter values for DRV-18 Base Freq, DRV-19 Start Freq, DRV-20 Max Freq, BAS-11

Pole Num, DRV-03 Acc Time, and DRV-04 Dec Time using the inverter keypad, either turn off the inverter and then

turn it back on, or set COM-94CommUpDate to ‘Yes’ to reflect the changes in the configuration property variables

‘nciNmlFreq’, ‘nciNmlSpeed’, ‘nciMaxSpeed’, ‘nciMinSpeed’, ‘nciRampUPTm’, and ‘nciRampDownTm’.

For example, if the inverter parameters are set as shown in the following table, the ‘nciMaxSpeed’ value becomes

120.000%, the ‘nciMinSpeed’ value becomes 20.000%, the ‘nciNmlSpeed’ value becomes 1,500 RPM, the ‘nciNmlFreq’

value becomes 50.0Hz, the ‘nciRampUpTm’ value becomes 19.0 sec, and the ‘nciRampDownTm’ becomes 29.0 sec.

Code

Parameter Name

Value

Code

Parameter Name

Value

DRV-03

AccTIme

19.0 sec

DRV-04

Dec TIme

29.0 sec

BAS-11

Pole Num

4

DRV-18

Base Freq

49.99 Hz

BAS-19

Start Freq

10.00 Hz

BAS-20

Max Freq

60.00 Hz

① The ‘nciNmlFreq’ variable value uses one decimal place and the DRV-18 Base Freq variable uses two decimal places.

Because of the difference, the DRV-18 Base Freq value needs to be rounded up to one decimal place before it is

adopted as the ‘nciNmlFreq’ variable. The value set at DRV-18 becomes 50 Hz after it is rounded up to one decimal

H100LonWorksManual

36

place, and the ‘nciNmlFreq’ value is 50 Hz.

The ‘nciNmlFreq’ values must be used in the formula for the base frequency values.

The maximum frequency (MaxFreq) value cannot be set higher than 163.830% of the base frequency (Base Freq).

Therefore, the maximum value of the ‘nciMaxSpeed’ variable is 163.830%.

49.99

1,500RPM

60.0

50.0

10.0

50.0

120.000%

20.00%

H100LonWorksManual

37

4.2 User Object (User Function Profile Type)

Mandatory

Network

Variables

User Object(20001)

nvoUsrParaState1

SNVT_count

nv9

nvoUsrParaState2

SNVT_count

nv10

nvoUsrParaState3

SNVT_count

nv11

nvoUsrParaState4

SNVT_count

nv12

nvoUsrParaState5

SNVT_count

nv13

nvoUsrParaState6

SNVT_count

nv14

nvoUsrParaState7

SNVT_count

nv15

nvoUsrParaState8

SNVT_count

nv16

nviUsrParaCtrl1

SNVT_count

nv1

nviUsrParaCtrl2

SNVT_count

nv2

nviUsrParaCtrl3

SNVT_count

nv3

nviUsrParaCtrl4

SNVT_count

nv4

nviUsrParaCtrl5

SNVT_count

nv5

nviUsrParaCtrl6

SNVT_count

nv6

nviUsrParaCtrl7

SNVT_count

nv7

nviUsrParaCtrl8

SNVT_count

nv8

Input Network

Variable

Output Network

Variable

nc1 nciUsrRcvHrtBt (Optional)

nc2 nciUsrSndHrtBt (Optional)

nc3 nciUsrMinOutTm (Optional)

Configuration Properties

H100LonWorksManual

38

Network Input Variables

Function

Variable Name

SNVT Type

Min.

Max.

User Parameter Control1

nviUsrParaCtrl1

SNVT_count

0

65535

User Parameter Control2

nviUsrParaCtrl2

SNVT_count

0

65535

User Parameter Control3

nviUsrParaCtrl3

SNVT_count

0

65535

User Parameter Control4

nviUsrParaCtrl4

SNVT_count

0

65535

User Parameter Control5

nviUsrParaCtrl5

SNVT_count

0

65535

User Parameter Control6

nviUsrParaCtrl6

SNVT_count

0

65535

User Parameter Control7

nviUsrParaCtrl7

SNVT_count

0

65535

User Parameter Control8

nviUsrParaCtrl8

SNVT_count

0

65535

4.3.1 nviUsrParaCtrl1–nviUsrParaCtrl8

Definition

Network input SNVT_count nviUsrParaCtrl1 –nviUsrParaCtrl8

Description

Network input variables ‘nviUsrParaCtrl1–nviUsrParaCtrl8’ are used to provide added flexibility while using LS

inverters. Because these variables are user-definable to match with the inverter parameters that the users intend to

adjust rather than permanently assigned to certain parameters, more convenient and enhanced configuration of the

inverter over a network becomes available.

For example, if the user decides to modify COM51–COM58 parameters over the network, these parameters may be

assigned to the network variables ‘nviUsrParaCtrl1–nviUsrParaCtrl8.’ Then, by registering addresses 0x0005

(Frequency Reference), 0x0006 (Command Source) and 0x0007 (Acceleration Time) to the inverter’s communication

parameters (COM51, COM52, and COM53), users can control the frequency reference with ‘nviUsrParaCtrl1’, provide

run commands with ‘nviUsrParaCtrl2,’ and adjust acceleration time with ‘nviUsrParaCtrl3.’

If the user intends to operate the inverter in the reverse (Rx) direction at 6000 Hz, with a 10.0 sec acceleration time,

‘nviUsrParaCtrl1’ may be set to 6000, ‘nviUsrParaCtrl2’ to 0x0004, and ‘nviUsrParaCtrl3’ to 100.

H100LonWorksManual

39

Inverter Parameters Related to the ‘nviUsrParaCtrl1– nviUsrParaCtrl8’ Variables

Code Number/

Common Area Address

Code Description

Default

Range

COM-50

User Parameter Control Number

3

0–8

COM-51

User Parameter Control 1

0x0005

0–0xFFFF

COM-52

User Parameter Control 2

0x0006

0–0xFFFF

COM-53

User Parameter Control 3

0x0000

0–0xFFFF

COM-54

User Parameter Control 4

0x0000

0–0xFFFF

COM-55

User Parameter Control 5

0x0000

0–0xFFFF

COM-56

User Parameter Control 6

0x0000

0–0xFFFF

COM-57

User Parameter Control 7

0x0000

0–0xFFFF

COM-58

User Parameter Control 8

0x0000

0–0xFFFF

Note

When the inverter is used on a Lon Works network, COM-50 User Parameter Control Number is automatically set to

‘8’. If the user sets COM-50 to any other value from the keypad, it automatically reverts back to ‘8.’

Network Output Variables

Function

Variable Name

SNVT Type

Min

Max

User Parameter State1

nvoUsrParaState1

SNVT_count

0

65535

User Parameter State2

nvoUsrParaState2

SNVT_count

0

65535

User Parameter State3

nvoUsrParaState3

SNVT_count

0

65535

User Parameter State4

nvoUsrParaState4

SNVT_count

0

65535

User Parameter State5

nvoUsrParaState5

SNVT_count

0

65535

User Parameter State6

nvoUsrParaState6

SNVT_count

0

65535

User Parameter State7

nvoUsrParaState7

SNVT_count

0

65535

User Parameter State8

nvoUsrParaState8

SNVT_count

0

65535

H100LonWorksManual

40

4.3.2 nviUsrParaState1–nviUsrParaState8

Definition

Network output SNVT_count NvoUsrParaState1–nvoUsrParaState8

Description

Network input variables ‘nvoUsrParaState1 – nvoUsrParaState8’ are used to provide flexibility in the monitoring

features of the LS inverters. Because these variables are user-definable to match with the inverter parameters that

the users intend to monitor, rather than permanently assigned to certain monitoring parameters, easy monitoring of

the inverter parameters over a network becomes available.

For example, if the user decides to monitor COM31–COM38 parameters over the network, these parameters may be

assigned to the network variables ‘nvoUsrParaState1 – nvoUsrParaState8.’ Then, by registering addresses

0x000A(Output Frequency), 0x000B(Output Voltage), and 0x941E (Jog Frequency) to the inverter’s communication

parameters (COM31, COM32, and COM33), users can monitor the output frequency with ‘nvoUsrParaState1’, the

output voltage with ‘nvoUsrParaState2,’ and the jog frequency with ‘nvoUsrParaState3.’

If the inverter is operating at 30 Hz with the DC link voltage of 150.0V and the jog frequency is 20.00 Hz,

‘nvoUsrParaState1’ displays 3000, ‘nvoUsrParaState2’ displays 1500, and ‘nvoUsrParaState3’ displays 2000.

Inverter Parameters Related to the ‘nviUsrParaState0– nviUsrParaState7’ Variables

Code Number/

Common Area Address

Code Description

Default

Range

COM-30

User Parameter State Number

3

0–8

COM-31

User Parameter State 1

0x000A

0–0xFFFF

COM-32

User Parameter State 2

0x000E

0–0xFFFF

COM-33

User Parameter State 3

0x000F

0–0xFFFF

COM-34

User Parameter State 4

0x0000

0–0xFFFF

COM-35

User Parameter State 5

0x0000

0–0xFFFF

COM-36

User Parameter State 6

0x0000

0–0xFFFF

COM-37

User Parameter State 7

0x0000

0–0xFFFF

COM-38

User Parameter State 8

0x0000

0–0xFFFF

Note

When the inverter is used on a LonWorks network, COM-30 User Parameter Control Number is automatically set to

‘8’. If the user sets COM-30 to any other value from the Keypad, it automatically reverts back to ‘8.’

H100LonWorksManual

41

Network Configuration Variable

Feature

Variable Name

Optional/

Mandatory

SNVT Type

Receive Heartbeat Time for User Object

nciUsrRcvHrtBt

Optional

SCPTmaxRcvTime

Send Heartbeat Time for User Object

nciUsrSndHrtBt

Optional

SCPTmaxSndTime

Minimum Send Time for User Object

nciUsrMinOutTm

Optional

SCPTMinOutTime

4.3.3 Receive Heart Beat Time for User Object (Mandatory)

Definition

Network config input SNVT_time_sec nciUsrRcvHrtBt

Description

The ‘nciUsrRcvHrtBt’ variable is used to configure the maximum update interval for network input variables

‘nviUsrParaCtrl1–nviUsrParaCtrl8.’ If the ‘nviUsrParaCtrl1–nviUsrParaCtrl8’ variables are not updated for the set time

(‘nciRcvUsrHrBt’ time value + PRT-13 Lost Cmd Time), the inverter decides that the command is lost, and runs in the

operation mode set at PRT-12 Lost Cmd Mode.

Lost command time protection operates only when the ‘nciUsrRcvHrtBt’ variable is set to a value other than ‘0,’ DRV06 Cmd Source and DRV-07 Freq Ref Src is set to any other value than ‘Fieldbus,’ and PRT-12 Lost Cmd Mode is set to

any other value than ‘None.’

The lost command protection feature is disabled if the ‘nciUsrRcvHrBt’ variable is set to 0.0 sec.

Typical Range

0.0 – 120.0 sec (0.1 sec)

A value of 0xFFFF (6553.5 sec) is invalid data.

Default

0.0 sec (Receive Heart Beat is disabled)

Inverter Parameters Related to the ‘nciUsrRcvHrtBt’ Variable

Code Number/

Common Area Address

Code Description

Default

Settings

DRV-06

Cmd Source

Fx/Rx-1

Keypad

Fx/Rx-1

Fx/Rx-2

Int 485

FieldBus

Time Event

DRV-07

Freq Ref Src

Keypad-1

Keypad-1

H100LonWorksManual

42

Keypad-2

V1

Reserved

V2

I2

Int 485

FieldBus

Reserved

Pulse

PRT-12

Lost Cmd Mode

None

None

FreeRun

Dec

Hold Input

Hold Output

Lost Preset

PRT-13

Lost Cmd Time

1.0sec

0.1–120.0sec

Note

When the LonWorks network is used as a command source, the inverter’s lost command time becomes the time set

for the ‘nciUsrRcvHrtBt’ and PRT-13 Lost Cmd Time added together. However, if the ‘nciRcvHrBt’ variable is set to 0.0

sec, the lost command protection feature is disabled.

4.3.4 Send Heart Beat Time for User Object (Mandatory)

Definition

Network config input SNVT_time_sec nciUsrSndHrtBt

Description

The User Object network output variable ‘nciUsrSndHrtBt’ is used to configure the maximum output times

for‘nvoUsrParaState1 – nvoUsrParaState8’variables.

Typical Range

0.0 – 6553.4 sec

A value of 0xFFFF (6553.5 sec) is invalid data.

Default

0.0 sec (Send Heart Beat is disabled)

H100LonWorksManual

43

4.3.5 Minimum Out Time for User Object (Mandatory)

Definition

Network config input SNVT_time_sec nciUsrMinOUtTm

Description

The ‘nciUsrMinOUtTm’ variable is used to configure the minimum wait time before the network output variables

‘nvoUsrParaState1–nvoUsrParaState8’ are sent to the network.

Rather than reflecting the changes in the variables each time they are made, a network update is performed when a

set period of ‘nciUsrMinOutTm’ has elapsed to reflect the changes. This feature is used to decrease the network

traffic.

Typical Range

0.0 – 6553.4 sec (0.1 sec increments)

A value of 0xFFFF (6553.5 sec) is invalid data.

Default

0.0 sec (Minimum Out Time is disabled)

H100LonWorksManual

44

5. LED Information

The H100LonWorkscommunication module has four LEDs that indicate the current operation status of the

communication module. The following list shows the LED indicators on the H100 LonWorks communication module.

Note

Error LED or service LED may flash if one of the two communication cables (A or B) is not wired properly. Inspect the

communication cables to ensure that the connections are secure.

Indicator

Color

Description

SERVICE

Green

OFF

– indicates that the H100 LonWorks communication module has been configured.

Flashing (0.5 Hz)

– indicates that the H100 LonWorks communication module has not

been configured.

ON

– lights when the service switch is turned on. If the LED stays on after turning off

the service switch, it means that the H100 LonWorks communication module does not

have the LonWorks application installed in it.

Flashing in 2-sec intervals

– indicates that the H100 LonWorks communication

module has not been configured.

Flashing intermittently

– indicates that electronic interference is affecting the

LonWorks network. Inspect network cables to ensure that the connections are secure.

CPU

Green

Flashing in 1-sec intervals

– indicates that power is supplied to the communication

module and the CPU is operating normally.

COMM

Green

OFF

– indicates that the module is not communicating.

Flashing

– indicates that the module is currently communicating.

When the COMM LED flashes, the ‘ON’ state indicates transmission and the ‘OFF’ state

indicates reception.

ERROR

Red

CPU, ERROR LED flashing simultaneously

– indicates a CAN (controller area

network) communication error. CAN refers to the type of interface used for

communication between the LonWorks communication module and the H100 Inverter.

Check the ‘Option Trip’ messages on the Keypad display.

Flashing intermittently

– indicates that electronic interference is affecting the

LonWorks network. Inspect the network cables to ensure that the connections are

secure.

Service (Green)

COMM (Green)

ERROR (Red)

CPU (Green)

Loading...

Loading...