USER

MANUAL

FOR

HIGH

PRESSURE

OXYGEN

GENERATOR

r F-qg

I

Contents

Foreword.

Caution....

Safety

lnstruction

Attention..

Product lntroduction..............

Operating condition..

Scope

Technical

Name and function............

Operation steps........

Maintenance

Troubles

Condition for

of application...........

parameter

instruction..........

and so1ution..............

transportation and stora9e.............

..........3

........4

............4

....4-5

................6-7

........7

..................7

.......8

........9-16

....16-17

17-20

.....21

.. .....22

Accompany

Quality

Appendix l:

Appendix ll: Connection

spare

guarantee

Schematic Diagram...

parts........

Schematic

Diagram

............22

.........22

.....23

.......

of Control board.. ...................24

Foreword

Thank

This

operation

solution

read

of this

you

and so

purchasing

for

manual

on. To

operation

products,

our

contains function,

ensure

manual

your

efficient

before

operating

hoping

operation

use

you

will

be satisfied

steps,

of the machine,

it.

attention,

with

basic

please

our

trouble

have

products.

a close

.

CautionA

1.

Please

check

the

power

(voltage

and

frequency),adjust

needed

oulet

pressure

before

2'

safety,

3.

naturally,

and

Ltd written

4' ln

prohibited

life

5. Keep

cm.

6. Don't

use

When

all

grease

Oil,

other

order

of

the machine.

Oxygen

touch

the

machine.

use

oxygen

combustibles

or some

and

these

oxygen

recommendation,

to achieve

to switch

generator,

material

substances

parts.

optimal

on

or off

generator

oxygen

generator

should

Please

the

away

far

pay

away

the

stay

use

the

wet

should

be

under

must

don't

performance

machine

from

with

special

from

oxygen

pressure

away

any

frequently

wall,

lubricant.

of the

furniture

from

oxygen

hand.

attention

generator

when

oxygen

unless

in

short

and

meeting

generator,

to reduce

oxygen

generator,

Longfian

time,

which

similar

fire

will

oxygen

Scitech

it

is

stricly

can

objects

hazards,

easily

tube

Co.,

reduce

at

least

in

fire

the

20

7.

cut

off

the

*

Safety

1.

Oxygen

2. When

electric

3.

When

quality

producer.But

*

Attention

1.

Oxygen

2.

When

othenrvise

generator

checking

shock.

using

problem

generator

using

it will

power

plug,

lnstruction

should

and

maintenance,

the machine,

or

unusual

forbidden

to

A

should

oxygen

cause

generator,

machine

when

A

be kept

it

was

alarm,

open

be

not

using

not

customer

and

maintain

kept in

the

overheating.

the oxygen

far

away

please

allowed

well-ventilated

bottom

generator.

from

open

pull

off

to open

should

by themselves.

should

power

the

the

contact

space

guaranteed

be

fire

panel

with

and

fire

plug

in

freely.

dealer

to avoid

origin

order

the

good

in

not

lf

there

and

pollution.

ventilation,

to be

is

3. Oxygen

4.

From

turn

generator

on

to setting

may

have

the

time less

exhaust

then

10

noise

mins.

intervals.

5. When

for

Maintenance.

oxygen

concentration

display(

OCSI)show

unnormal,

user

should

state dealer

6. What

change

7.

Clean

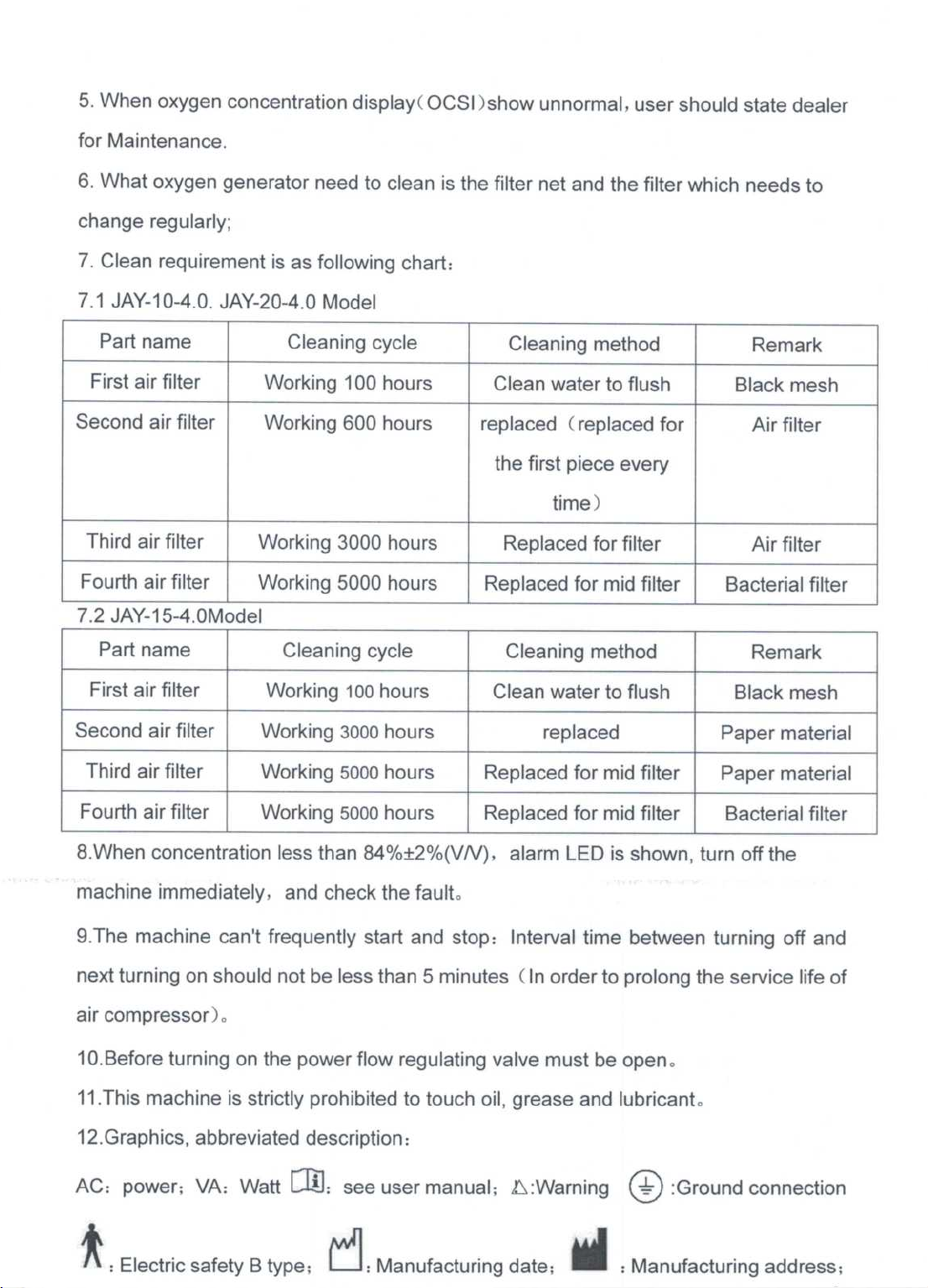

7.1

Part name

First

Second

Third

Fourth

7.2

Part name

oxygen

regularly;

requirement

JAY-10-4.0.

air

filter

air filter

air filter

air filter

JAY-15-4.0Model

generator

is

as following

JAY-20-4.0

Cleaning

Working

Working

Working

Working

Cleaning

need

to clean is

Model

cycle

100

600 hours

3000 hours

5000 hours

cycle

chart:

hours

the filter

net

Cleaning

Clean water

replaced

the first

Replaced

Replaced

Cleaning method

and

(

replaced

piece

time

for

for

the filter which

method

to flush

for

every

)

filter

mid filter

needs

Remark

Black

to

mesh

Air filter

Air filter

Bacterialfilter

Remark

First

air filter

Second

Third air filter

Fourth

8.When

machine immediately,

9.The

next

air

10.Before

11.This

1 2.Graphics,

air filter

air filter

concentration less

machine

turning on should

can't frequently

compressor).

turning on

machine is

abbreviated

Working

Working

Working

the

strictly

Working

than

and check

not be less

power

prohibited

description :

100

hours

3000 hours

5000 hours

5000 hours

Clean water

Replaced

Replaced for

84%+2%(VN), alarm

the fault.

start and stop: lnterval

than 5 minutes

flow regulating

to touch

(

valve must

grease

oil,

to flush

replaced

for mid

mid filter

LED is shown,

time

ln

order to

be open.

and lubricant.

Black

Paper

filter Paper

Bacterialfilter

turn off

between turning

prolong

the service life of

mesh

material

material

the

off and

AC:

*

power;

,

VA:

Watt

safety B type;

fH,

see usermanual;

d,

,rnufacturing date;

A:Warning

*

:Oround connection

@

,Manufacturing address;

*

Product

.,

1

General

lntroduction

principle

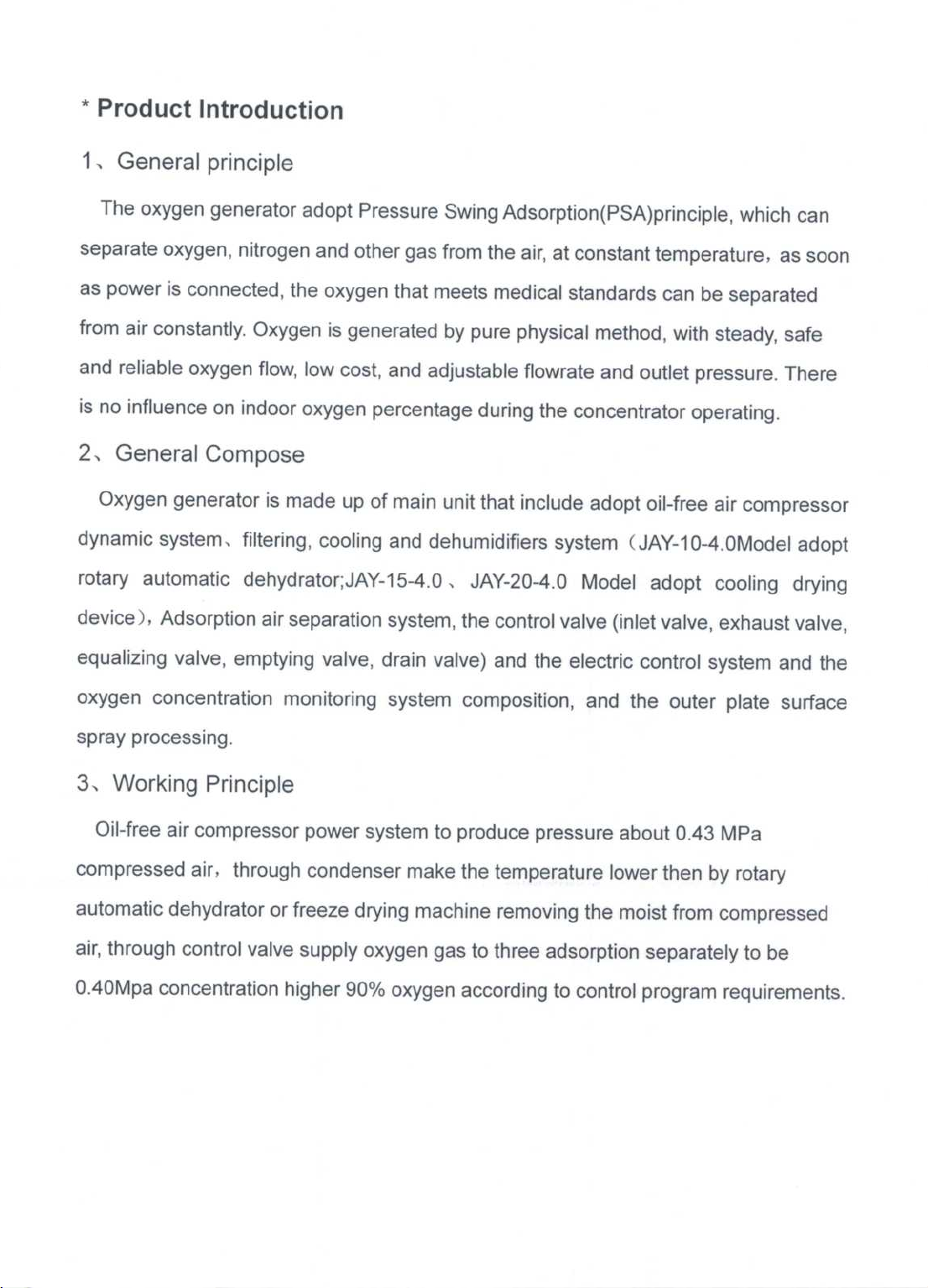

The

oxygen

separate

power

as

from

air constantly.

and

reliable

is

no

influence

2.

General

Oxygen

dynamic

rotary

device),

system.

automatic

Adsorption

equalizing

generator

oxygen,

is

connected,

oxygen

on

Compose

generator

valve,

nitrogen

the oxygen

Oxygen

flow,

indoor

is made

filtering,

adopt

low

oxygen

Pressure

and other

generated

is

cost,

and

percentage

up of

cooling

and

gas

that

adjustable

main

dehumidifiers

dehydrator;JAY-15-4.0.

air separation

emptying

valve,

system,

drain

Swing

from

meets

by

Adsorption(PSA)principle,

the air,

medical

pure

at

constant

standards

physical

flowrate

during

unit

that include

the

concentrator

adopt

system

JAY-20-4.0

the controlvalve (inlet

valve)

and

Model

the etectric

temperature,

can

be separated

method,

and

with

outlet

pressure.

operating.

oil-free

(JAY-10-4.0Model

adopt

valve,

control

system

which

steady,

can

as

safe

soon

There

air compressor

adopt

cooling

exhaust

drying

valve,

and

the

oxygen

spray

3.

oil-free

compressed

automatic

air,

0.40Mpa

concentration

processing.

Working

air

dehydrator

through

concentration

Principle

compressor

air,

through

or freeze

control valve

monitoring

power

condenser

supply

higher

system

drying

oxygen

g0%

system

to

make

machine

gas

oxygen

composition,

produce

the

to three

according

pressure

temperature

removing

adsorption

to control

and

the outer

about

lower

the moist

separately

program

0.43 Mpa

then

by rotary

from

compressed

plate

surface

to be

requirements.

flowmeter

*rr*.

valve

fi

ourPUTA

I

ourpur a

EMPTY VALVE

AIR

GAUGE

*

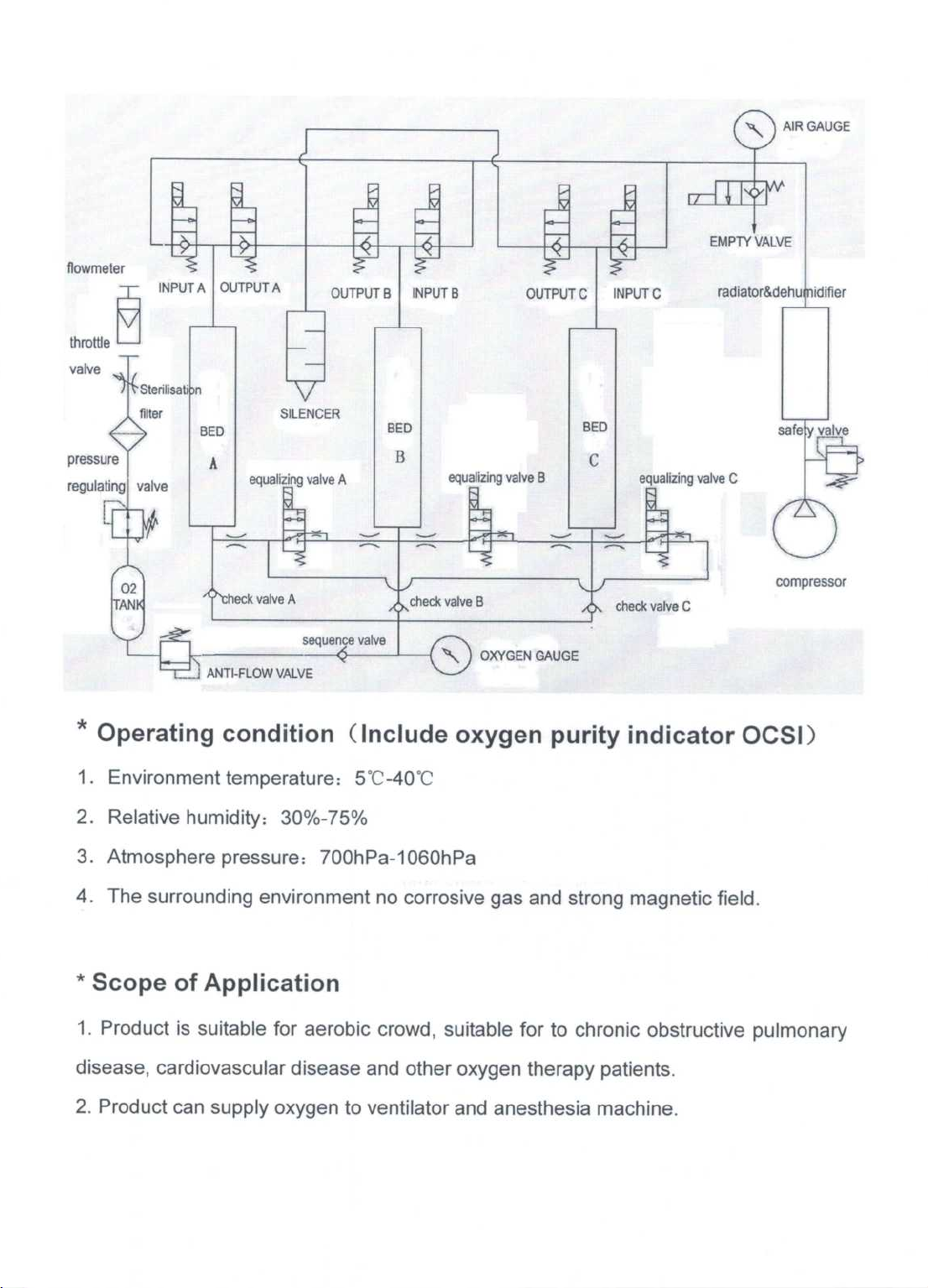

operating

1. Environment

2. Relative

humidity:

3. Atmospher€

4. The

surrounding

equalizing

ANTI.FLOW

VALVE

condition

temperature:

30o/o-75o/o

pressure

environment

valve

A

(lnclude

5C-40C

700hPa-1060hPa

:

no

corrosive

equalizing

valve B

OXYGEN

oxygen

gas

check valve

GAUGE

purity

and strong magnetic

indicator

C

compressor

ocsl)

field.

*

Scope

1. Product

disease, cardiovascular

2. Product

of Application

is suitable

can

supply oxygen

for

aerobic crowd,

disease

and other

to ventilator

suitable for

oxygen therapy

and anesthesia

to chronic

obstructive

patients.

machine.

pulmonary

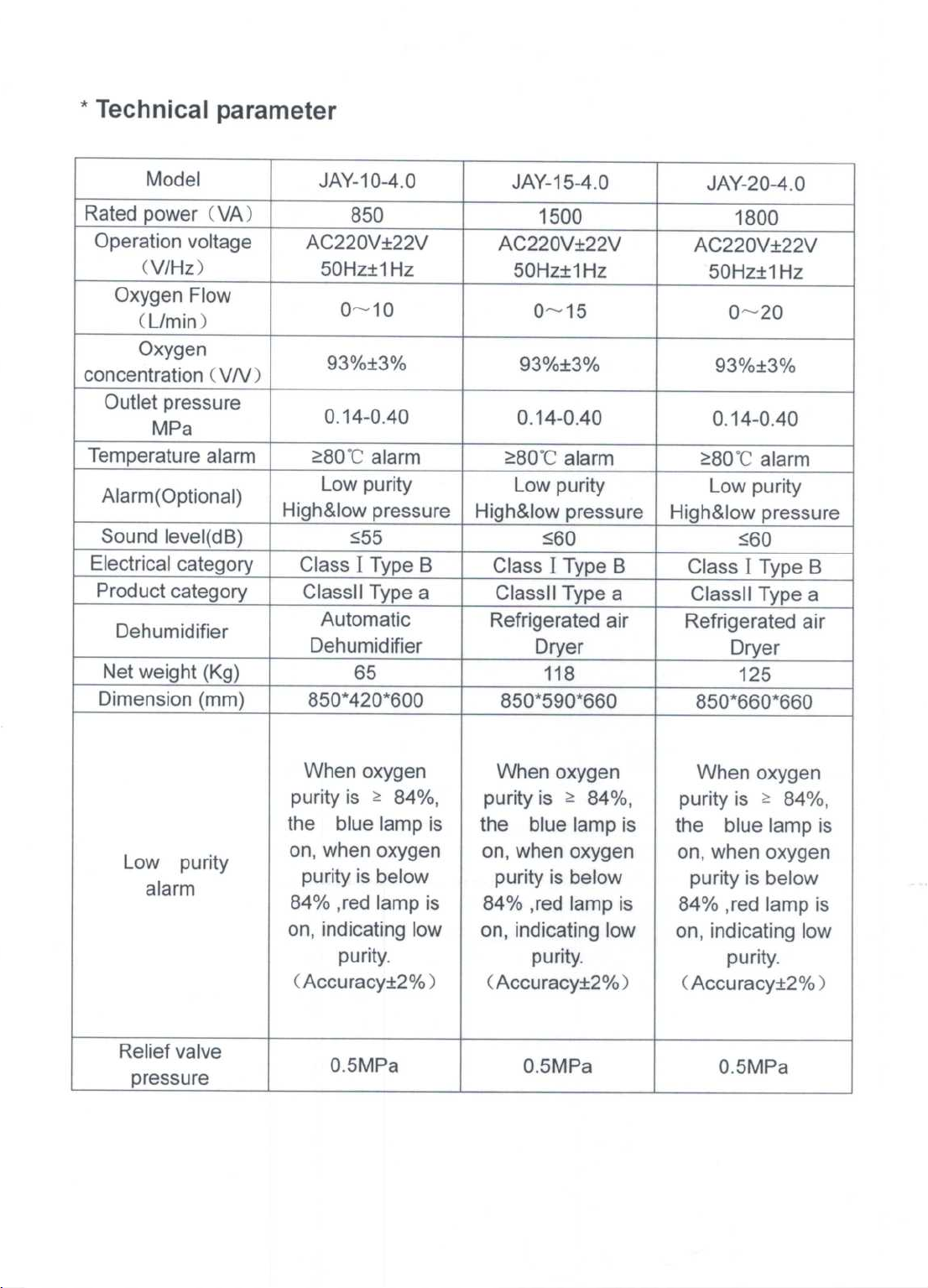

*

Technica!

parameter

Model

Rated

power

Operation

voltage

(Vl{z)

Oxygen

(

Oxygen

concentration

Outlet

Temperature

Alarm(Optional)

Sound level(dB)

Electrical

Product

Dehumidifier

Net weisht

Dimension

Flow

L/min

pressure

MPa

category

category

(VA)

)

(VA/)

alarm

(Ks)

(mm)

JAY-10-4.0

850

AC220Vt22V

50Hz+1Hz

0- 10

93o/ot3o/o

0.14-0.40

>80C

purity

Low

High&low

s55

Class

Classll Type

I

Automatic

Dehumidifier

65

850.420.600

alarm

pressure

Type B

a

JAY-15-4.0

1

500

AC220Vr22V

50Hz+1 Hz

0-

93%t3%

0.14-0.40

>80C

purity

Low

High&low

<60

Class

ClassllType

Refrigerated

I Type B

Dryer

118

850.590.660

15

alarm

pressure

a

air

JAY-20-4.0

1

800

AC220Yt22V

50Hz+1Hz

0-20

93o/ot3oh

0.14-0.40

>80C

purity

Low

High&low

<60

Class

ClassllType

Refrigerated

I

Dryer

125

850.660.660

alarm

pressure

Type B

a

air

Low

Relief valve

purity

alarm

pressure

When oxygen

purity

is

>

84%,

the blue lamp

on, when

purity

84o/o

on, indicating

(Accuracyx2%)

oxygen

is below

lamp

,red

purity.

0.5MPa

low

When

purity

is

the blue

on, when

purity

is

84o/o

on, indicating

(Accuracyt2o/o)

oxygen

>

is

lamp is

oxygen

is

below

lamp is

,red

purity.

0.5MPa

84%,

low

When

purity

oxygen

>

is

84%,

the blue lamp

on, when

purity

84o/o

on, indicating

(Accuracyx2%)

oxygen

is below

lamp

,rad

purity.

0.5MPa

low

is

is

*

Name

and

function

JAY-1

1.

General

0-4.0.

JAY-1

appearance

5-4.0.

JAY-20-4.0

of

oxygen

model

generator

oxygen

generator

W

construction

I

See

as above

panel,

2. Top

2.1

1)

2)

3)

4)

5)

6)

7)

front

view

JAY-10-4.0

Output regulator

Oxygen

LCD

display

Oxygen

Third

Second

Cooling

air filter

8) Reducing

9)

Oxygen

10)

Electric

1 1) A

12) B

13)

14) Fourth

15)

16)

adsorption

adsorption

C adsorption

Cooler

Cooling fan

condenser

air filter

JAY-10-4.0

picture,

plate,

pressure

tank

air filter

fan

back

of

Oxygen

(

compressor

valve

sensor

(cooler

oxygen

panel,

generator

valve

gauge

(

For

cooling

generator

head

cooling

oxygen

cover, left

sensor)

use)

is mainly

)

composed

side

door,

JAY- 1

5-4.

0/JAY-20-4.

right

by

main

side

door,

JAY-10-4.0

0

unit

case, front

trundles.

2.2

JAY-15-4.0

1

)

Output

2)

Oxygen

3) LCD

4)

Oxygen

5)

Cooling

6)

Electric

7)

Second

8)

Refrigerated

9)

A adsorption

10)

B

adsorption

11)

C

adsorption

12)

Cooler

13)

Cooling

14)

Fourth

pressure

15)

regulator

pressure

display

tank

fan

condenser

air

fan

air

gauge

valve

gauge

(compressor

filter

air

Dryer

(cooler

filter

cooling

(compressed

cooling)

use)

air

pressure)

JAY-15-4.0

2.3

JAY-20-4.0

1

) Output

2

) Oxygen

3) LCD

4)

5)

display

Oxygen

Cooling

6) Electric

7) Two

position

8) Second

9)

Single

10) Fourth

11)

C adsorption

12)

B

adsorption

13

) A

adsorption

14)

Fan

15)

Refrigerated

regulator

pressure

tank

(compressor

fan

condenser

three

air filter

way

valve

airfilter

air Dryer

valve

gauge

way

cooling)

electromagnetic

I

valve

JAY-20-4.0

3.

Oxygen generator

3.1

JAY-10-4.0

1)

Flowmeter

2)

LCD

display

3) Power

4)

LED

(Machine

on

indicating

Audio

relevant

6)

Oxygen

7)

Pressure

8)

Sequence

9)

Main

10)

Power

11

) Line

(Turn

display

works

alarm'

audio

pressure

Regulator

control

bank

(display

to

left,power

and

relevant

When

alarm

valve

board

positive

operation

alarms

situation)

machine

will

be

heared

gauge

valve

side

on)

in

different

works

view

parameters)

color

LED

unnormally,

.

light

i

ul

r.

,l

i;.

I

7

3.2

JAY-

1

5-4.0/JAY-20-4.0

1

) Flowmeter

2)

LCD

display:

3) Power:

4)

LED

light

(Machine

light

5)

Audio

relevant

6)

Oxygen

7)

Pressure

8)

Sequence

9) Main

10)

11)

12)

13)

14)

works

on

indicating

alarm:

audio

control

Power

Line

bank

Oxygen

Reducing

First

air

(display

(Turn

pressure

filter

to left

indicator:

and

alarms

relevant

When

alarm

Regulatorvalve

valve

sensor

valve

will

gauge

board

(oxygen

operation

,Power

in

different

situation)

machine

be

heard

sensor

parameters)

on)

works

.

use)

color

LED

abnormally,

JAY-10-4.0

/l

)l

,13

{

,4

/-

/c

v

JAY- 1 5-4.

0/JAY-20-4.0

4.

Right

4.1

1)

2

) Equalizing

3)

4)

5)

6

) Exhaust

7)

4.2

1)

2

) Empty

side

JAY-10-4.0

Oxygen

holder

Rubber

lnlet

tube

lntake

Empty

JAY-15-4.0

Pressure

3) Exhaust

view

of

tank

electromagnetic

(compressor)

tank

(compressor

Solenoid

silencer

valve

gauge

valve

silencer

valve

oxygen

(compressed

generator

valve

inlet)

and holder

and

JAY-10-4.0

air)

4)

Drainage

5) Drain

6) Pressure

7)

Pressure

outlet

valve

gauge

regulating

8) Refrigerated

9)

Oxygen

10)

Reducing

4.3

JAY-20-4.0

1)

Fan

2

Exhaust

)

3) Drain

4)

Drainage

5)

Refrigerated

6) Pressure

7)

Pressure

8)

Oxygen

9) Reducing

sensor

silencer

valve

outlet

gauge

regulating

sensor

valve(for

(oxygen)

air Dryer

valve(for

air Dryer

(oxygen)

valve

oxygen

valve

oxygen

sensor)

JAY-15-4.0

sensor)

JAY-20-4.0

5.

Left

side view

5.1

JAY-10-4.0

1) Axial

2)

3)

4)

5) Third

6)

7)

B)

flow

Fourth

Radiator

Adsorption

Equalizing

Rubber

Oxygen

air filter

air

filter

tank

tank

air

dryer

electromagnetic

(compressor)

9) Pressure gauge

10)

lntake

11)

Exhaust

12)

Breaker

5.2

JAY-15-4.0

1)

Adsorption

2)

Second

3)

Oxygen

4)

Rubber

5)

Equalizing

Solenoid

Solenoid

air

filter

tank

(compressor)

tank

electromagnetic

6) Radiator

7)

Axial

flow

air

dryer

8)

lntake

Solenoid

9) Breaker

10)

Exhaust

Solenoid

of

oxygen generator

(for

radiator)

valve

(compressed

valve

and holder

valve

and

valve

(for

radiator)

valve

and

valve

holder

and

and

air)

holder

JAY-10-4.0

and

holder

5.3

JAY-20-4.0

1) Adsorption

2) Second

3)

Third

4)

Oxygen

5) Rubber

6)

Equalizing

7)

lntake

air

tank

Solenoid

8) Breaker

9)

Exhaust

10)

Fourth

air filter

filter

tank

(compressor)

electromagnetic

valve

Solenoid

air filter

valve

and

and

valve

holder

holder

and

holder

JAY-15-4.0

JAY-20-4.0

h.,i

i/

tffi

,

6.

Back

side

6.1

JAY-10-4.0

1)

Oxygen

2

First

)

air

3) Automatic

4) Drain

5)

Power

6.2

JAY- 1

1)

Oxygen

2)

Waterspout

3)

Fan

4)

Power

valve

cord

5-4.0/JAY-20-4.0

outlet

cord

view

outlet

filter

dehydrator

of

oxygen

generator

JAY-10-4.0

7.

LED

indicating

1) P.O.:Power

2)

H.OZ:High

3) L.O2:Low

4)

L.P.:

Low

(oxygen

5)

H.P.:

High

(oxygen

6) H.T.:High

Remark'

JAY-10-4.0

light

On,

Green

oxygen

oxygen

Pressure

concentration

LED

on

concentration

indicate

light

pressure<0.25MPa,

pressure

light

pressure)0.45MPa,

temp

light

(

on

and

JAY-15-4.0

Rubber

(284o/o,

light

(<84o/o,

light

yellow

LED

Red LED

tank

temp>8Oc

Model:

light

light

Red

on)

Blue

on)

Red

,

JAY- 1

LED

LED

on)

on)

LED

5-4.

light

o/JAY-

on

)

20

-4.0

H.O2:High

oxygen

concentration

light

(>84o/o,

Blue

LED

on)

L.O2:Low

8. LCD

8.1 After

0.P.

0. T.

oxygen

SCreert:

turning

MPa:

C:

concentration

on

the

machine,

0.Time:0000:00

Acc.

O.P.:

O.T.:

O.Time:

Time:

oxygen

case

temp

Operating

output

of

compressor

time

0000000

pressure(normal

(hour:

(<g4o/o,

light

LCD

0.000

00.0

scope:

(normal

minute)

display

SCope

Red

LED

on,

follow

0.35Mpa-

sgOC

:

)"

on)

information

0.43Mpa).

will

be

shown

:

Acc.Time:

8.2

Adjustment

be

entered

8.3

Adjustment

display

will

Accumulative

interface

T1:

T3:

T5:0.00

TTz

of interface

be entered

T9:

operating

l,

When

0.00

0.00

0.00

ll,

0.00

(

time

pressing

<-

When

+

hour)

selected

T2:0.00

T4z

T6:0.00

T8:

pressing

button

0.00

0.00

selected

once,

button

following

nine

times,

display

follow

will

T10:

T11:

Tl2z

0.00

0.00

0.00

F:

000

T1-T12:

The

setting

time for

inlet.

exhaust.

Equalizing

solenoid

valve

which

works

F:

The

setting

in

every

humidity

long

*

Operation

1.

2.

LCD

3,

4.

5'

60

season

interval

Let

oxygen generator

Turn

on

screen,

Open

Turn

knob

After

the

unit:

minutes;

time),

circuit

red

the

knob

left

system

second"

interval

user

this

unit:

steps

breaker

LED

of flow

to

is

time

for

should

valve

open

minute

power

switch

indicator

meter.

"ON"

on

oxygen

,

and

drain

set

in

cord

of

for

low

empty

valve

it

starting

according

shorter

plugs

the

access

oxygen

oxygen

generator

valve

start

(

Factory

to actual

interval properly;

mains.

generator,

will

be

began

for

10

environment.

and

on.

to

work.

seconds

set

to start

conversely,

green

which

LED

guarantee

for

10

ln high

it

will

indicator,

seconds

open

the

in

compressor

6.

Oxygen

JAY-20-4.0

7.

after

3

greater

pressure

will

8.

9' lf

in

10.

When

When

than

stop).

oxygen

not

circuit

Oxygen

oxygen

oxygen

regulating

continuously

breaker

(the

start

generator's

above

minutes

the

purity

standard

switch)

purity

0. 35Mpa.

of

should

alarm

purity <

purity

valve

outlet

operation,

flow

valve,

but

be

be used,

and

function:

84o/o,

2

84o/o,

for

normally

pressure

flow

value.

not more

above

unplugged.

error+

error+

90%

please

after

2o/o, "L.o2"

2o/o, "H.O2',

open valve)

after

meter

Oxygen

than

after

shut

off the

ten

60

seconds:

should

output

the rated

operating

power

minutes

red

blue

JAY-10-4.0.

be adjusted

pressure

pressure

10 minutes.

(disconnect

it

will reach

LED

light,

LED

light.

JAy-15-4.0.

to required

can

be

flow.

adjusted

value(when>0.45

oxygen

the

normal.

show

low

oxygen

but

not

by

the

Mpa

generator

purity.

11'

lf

starting

the

system

Now

check

because

fifteen

operation

position

if

too much

minutes

is

of

flow

and

unnormal.

pressure

the

in

the oxygen

the

low

oxygen

reducing

sensor

concentration

valve

can

make

for

output

oxygen

purity

light "L.O2"

sensors

of

oxygen

is

still red,

normal,

generator

insufficient.

By

adjusting

pressure

the

reducing

valve

(oxygen

sensor

with)

make

make

pressure

12. Drain

of water

13.

stop

*

'1

a few

month.

2.

(see

Methods:

then

its

flow

blue

LED

reducing

valve

should

when

work.

Turning

after

Maintenance

Please

'

clean

cleaning

risen

cut off

cleaner,

primary

the case

with

meet

the

requirements,

light,:

be

60

valve,

starts

properly

off

seconds

the

with

for

(rotary

instructions

power

the

wipe

external

filter

is an

requirements

should

dry

cloth

twice

oxygen

5

seconds

sensor

reference

handled,

switch

supply,

casing

important

table)

be cleaned

every

or

close

concentration

should

to the

according

such

as

drainage

"oFF"),

to

the

external

everywhere,

step

of the

with

cleanser

month.

be checked

((maintenance

to interval

axial

casing

then dry

dairy maintenance

or

fan,

use

towel

setting

container

and

clean

Thoroughly

light

of the

for

adjustment

instructions)

(note:

time

collection).

cooling

soft

drying

wet

cleaning,

and

valve

towel

1

-

also

can't

with

in

item

discharge

device

touchs

2

times

six .

a

3. Change

3.1

JAY-10-4.0,

Open

filter

(figure

first

3.2 JAY-15-4.0

Open

if the

the

4.

4.1

Open

tube

filter

the oxygen

remove

place,and

the oxygen

secondary

new filter.

Clean

JAY-10-4.0.

the oxygen

on

cotton.

second

2),

on

third inlet

the top

at the

filter

filter(see

JAY-20-4.0

generator

cotton,

the inside,

rotation

model:

generator

filter

became

filter(see

JAY-20-4.0

generator

of third

same

the most

make

use.

side

side door,

filter,

time

cleaning

Model

side door,

black,

(change

outside

originally

door

and

if

cleaning

Model

turn on

clean filter's

(change

the

requirements

filter

open

the secondary

piece

a

the

second

check

yes,

change

requirements

the filter

Unplug

third filter

the

cavity.

table)

cotton)

of

change

piece

table)

in

the

cotton),

silicone rubber

and change

the

first filter

Second

Second

filter

filter

Third

air

filter

4.2

JAY-15-4.0

open

lnternal

open

same

5.

Open

the

changed,unscrew

the

case

the

black

time

Replace

the

oxygen

oxygen

model

oxygen

side

case,

clean

fourth

outlet

(change

generator

board,

replace

filter

cavity.

filter

generator

position,

filter

and

filter

left

side

unscrew

the

side

door,

check

change

element),

door,

the

third

internal

the fourth

the

filter

ln

element.

upload

filter

panel

the

firter's

compressor

fastening

core,

and

near

color,

screw,

at the

if

color

,.fl

*

Third

air filter

6,

Use

reducing

Reducing

othenryise

lead

because

purity

much

tube

(as

every

the

reducing

7.

Compressor

Compressor positioning

valve

,Oxygen

to loss

too

pressure

and

amount

to the

shown

a

second,

oxygen

composition,

happened

offset,

Compressor

wiring.

valve

is used

pressure

of

much

of oxygen

picture)

in

it

will

valve

need

lt

can

external

should

maintain

sensor

oxygen

of

sensor

be

show

check

to

of

oxygen

check

is

supplied

the oxygen

to

oxygen

the outlet.

to the

output

and if

one

oK. lf

be

adjusted

is

made

clear

forces

every

sensor

whether

more

ouflet,

sensor

The

best

oxygen

and

bubble

more

sensor

put

will

continuous

to its

positioning

of a

positioning

need

to

year,

blowing

oxygen

oxygen,

flow

will reducing

way

to check

is

this

tube

appear

best

screw

put

to

compressor

purity

reducing,

is normal.

it

will

how

to connect

to the

bubbles

condition

screw,

and

the dust

water

in

the water

damping

bottom

on

the

a

appears,

friction

in

the right

the

surface

spring

sound

Fourth

and

stator

when

position.

and

check

air

filter

9i-r

-

M;+-w,

W,&W

W

8.

Control

M

ffitr*it$IffiE

JAY-1

board

0-4.0.

JAY_20_4.0

@M#

JAY-15-4.0

A

ffi

::,.

o*'Lg,#,,;mffi*;m#

1)

Axial

&

Refrigerated

horn

connector;

B)

Up

adjusting

temperature

alarm

A

valve

21)

tower

for fixing

dust

connector

tower intake

connector;

C tower vent

equalizing

Every

three

line,

on the

T

wi,tl*

24

5) LED

button;

sensor

valve

19

valve

valve

months

should

surface

:l

,'iif

rilil

',23

',22

air

connector

14)

drain valve

connector

) A tower

connector;

connector;

check

no

loose,

and

check

2t

dryer

lamp

g)

control;

connector;

LCD

;

17

;

vent

the fastness

every

the wiring.

2A

19

2) Compressor

display

pressure

12)

connector;

) B

tower intake

valve

22)

24)

year

connector

AB

AC

17

18

6) Down

connector;

SerSot;

tower

tower

for

binding

should

adjusting

15)

atmospheric

valve

20)

;

equalizing

equalizing

complete

16

15

control;

10)

DCSV

13

Turn

)

connector;

B

tower vent

valve

post,

use

maintenance,

14

3) DC24V

button

input

on/off

valve

valve

connector;

connector.

screwdriver

input;

7)

select

connector;

power

and

connector;

18

) C tower

valve

connector;

twist

blowing

4)

button;

11)

off

16)

intake

23) BC

screw

the

9.

Binding

1)

locating

2)

Axial

3)

axial

4)

Axial

5)

axial

6) compressor

7)

AC/DC

8)

Connect

9)

Compressor

post

flow

flow

flow

flow

switch

plate;

fan,

air

fan,

dryerAC220V-N;

fan,

air

fan,

dryer

AC220V-L,

power

electric

connect

dryerAC220V-N;

dryerAC220V-N;

AC22OV-L,

connect

connect

supply

electric

electric

AC22OV-L;

supply

connect

relay

relay

part;

supplyAC220V-L;

AC220V-N;

part;

10)AC/DCswitchpoWerconnectelectricsupplyAC220V-Nffi

1 1

Connect

)

10'

lf users

maintenance

electric

need

circuit

material,

supplyAC220V-N;

diagram,

manufacturers

components

will

list,

provide

diagram

necessary

note,

correction

drawing

material.

rules

and

*

Troubles

and

solutions

No.

1

2

3

4

Trouble

\o

operation

power

rfter

:onnected

No

oxygen

out or

outtake

No

sound

l-oo

tiny

flow

exhaust

noisy

:xhaustion

Causes

1.No

connection

of

oxygen

2.Capacitor

croken

3.Compressor

4.Switch

l.Change

pressure

2.Filter

connection

of

clogging,

3.Connection

air leakage

4.Too

much

reducing

valve

sensor

5.No

working

1. Air

control

2. Electrical

work

fallen

joint

off

of

1.The

2. Exhaustion

between

generator

of

compressor

broken

Relief valve

air inlet

pipeline

leakage

for

oxygen

of solenoid

valve

control

can not work

board

exhaustion

muffler

circuit

power

and

problem

setting

difficult

no

screw,

rate

of

valve

cannot

muffler

broken

Solution

l.Check

power

2. Replace

3.Change

line in

4.Check

l.Replace

2.Clean

3.Check

filter

4.Check

one

bubble

5.Check

l.Change

2.Change

l.Connect

2. Have

the

out

whether

good

start

capacitor

compressor

switch

pipeline

and

solenoid

connection

and

adjust

adjust

every

air

control

electrical

joint

the

muffler

switch,

connection.

relief

reducing

second

valve

and replace

valve

control

well

replaced

plug,

line

valve

valve for

board

1 .Compressor

5

Ioo noisy

ihake

rffset

2.Compressor positioning

column

l.Oxygen

6

7

8

Cxygen

alarm light

High/low

pressure

alarm

No light

LCD

purity

for

backlight

l.Pressure

2.lncorrect

3.Pipeline

l.Backlight

2.Backlight

the fault

fixing

deformation

purity

regulating

flow

air leakage

damage

burn

alarm

below

meter

out

because

position

84%

valve

outlet

offse

of

1.Move

compressor

2. Reshaping

replacement

l.Check

2.Check

3.Check

valve

compressor

oxygen

and adjust

if have

3.Air leakage

l.Check

valve

2.Adjust

3.Check

1. Replace

and

and replace

fastening

2. Reconnect

and

restart

light

the machine,

positioning

sensor

no

air outlet

for

oxygen

adjust

LCD

with main

in the fixed

screw

air system

pressure

generator

pressure

flow

meter

pipeline

power

backlight will

position

or

reducing

regulating

supply

*

Condition

for

transportation

and

storage

Environment

Comparative

pressure

Air

*

Accompany

1,

Air filter

2.

Nylon

.

Quality

The

whole

net 1

tube

Warrant

machine

temperature

humidity

scale,

scale,

700hpa-1060hpa

spare

unit

10*8*1

meter.

repair:

scale: -4OC-S5C

<gs%

parts

8*6*1

one

year

meter.

guarantee.

6*4*l

meter

After-sale

Add:

NO.369

Postcode:

Service

Fax:

service:

2F&3F,

Huiyang

071051

phone:

0086-312-5909515

East

0086-31

Longfian

Section,

street,

071051,Baoding,Hebei

2-5909505

Scitech

Building

Co.,

Ltd.

12, Power

valley

province,

pioneer

park,

China

Appendix

l:

Oxygen generator

connection

diagram

ACZZOY

ACZZOY

N

L

breaker

comprBs$0r

controlboard

breaker

Axial&Refrigeration

air

dryer

Appendix

ll:

oxygen

generator

control

board

connection

diagram

A.P.AC

A.P.BO

A,P.AB

Exhaust

Exhaustvalve

Exhaustvalve

valve

lnputvalve

lnputvalve

l;r

U

r

[t

t!

Electric

C

r

B

A

C

f-.1

l'J

E

r

B

l.l

t!

control

LCD

board

option

I

screen connector

PCB

[.]

L*l

t-J

l'l

[]

UPE

Downf

r

lll

lnputvalve A

Empty

Drainage

valve

H

E]

Start&Power

Temp

sensor

faliure alarm

[lu

[J

connector

connector

Loading...

Loading...