Lonfian Scitech Jay Oxygen Concentrator Service manual

Service Manual

-1-

LONGFIAN SCITECH CO., LTD

SERVICE MANUAL

FOR HIGH PRESSURE GENERATOR

No.401,4th Floor, Block 1, Building 1, College Tech. Zone, No.5699 North

Second Circle Road, Baoding, Hebei, 071051, China

Tel: +86-312-3169262 Fax: +86-312-3169301

www.longfian.com

Service Manual

-2-

Contents

▇ External Structure

..............................................................................................................

2

▇ Main Service Tools and Accessory Materials

.............................................................

2

▇ Internal Structure and Name of Major Components

...................................................

3

▇ Dismantling Method.......................................................................................................... 3

▇ Working Principle

..............................................................................................................

6

▇ Circuit Description

.............................................................................................................

7

▇ Key Indicator...................................................................................................................... 9

▇ Major Fault Phenomenon and Maintenance Method

.................................................

9

▇ Accessory

.........................................................................................................................

12

▇ Appendix

............................................................................................................................

13

Service Manual

-3-

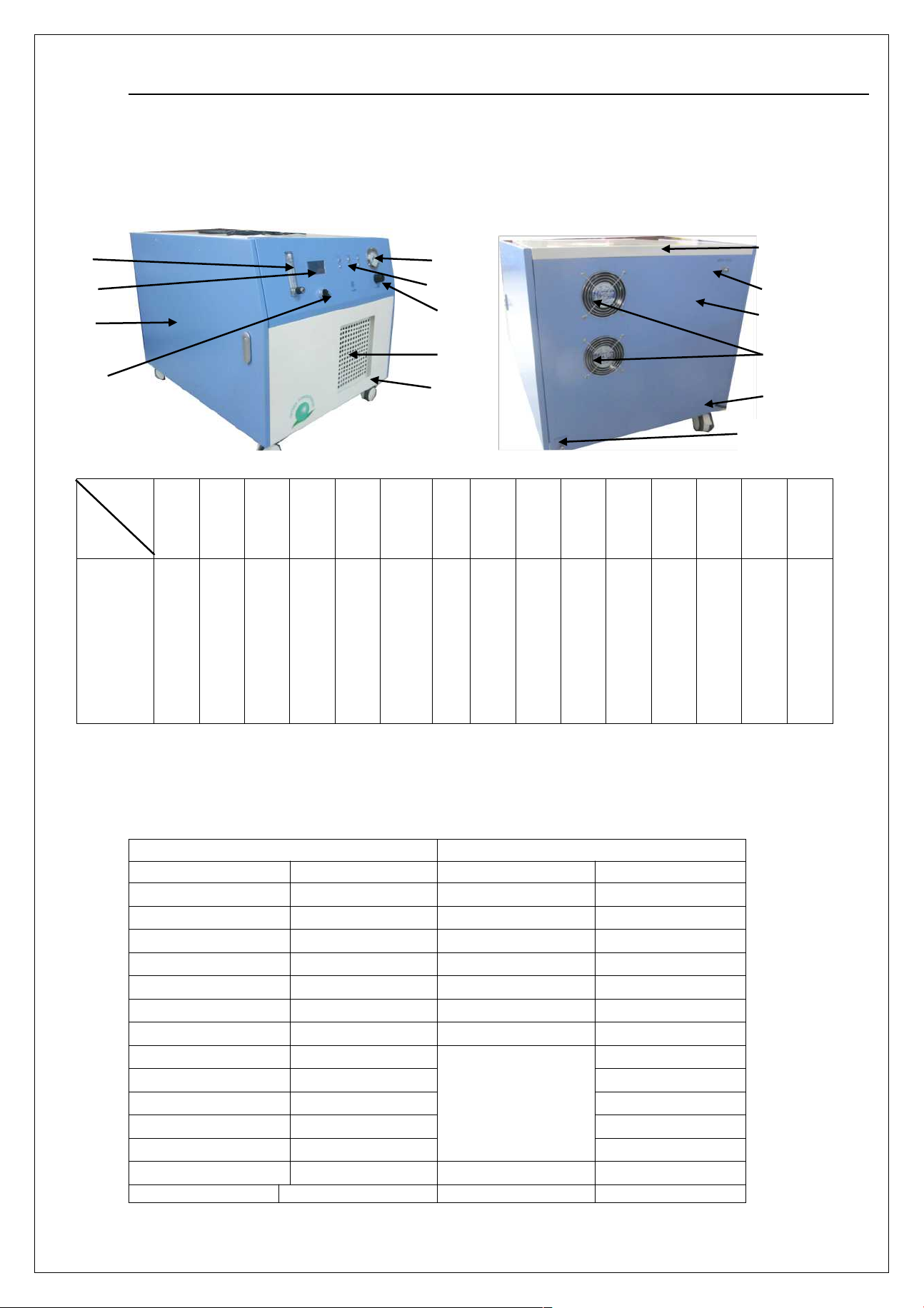

█ External Structure

External Structure :see figure 1&2,the parts :See table1

Figure 1 Figure 2

S/N

Name

123456789101112131415

flowmeter

LCD display

power switch

pressure gage

indicating lamp

pressure regulating

valve

side panel

Air filter

front panel

top panel

oxygen outlet

back panel

fan

power line

outfall

table1

█

Main Service Tools and Accessory Materials

Main Service Tools and Accessory Materials: see table 2

Tools

Accessory Materials

Name

Model

Name

Model

Phillips screwdriver

400mm, 200mm

704 silica gel

704

Slotted screwdriver

200mm

Impact wrench

6mm、9mm

8~10、12~14

13~15、14~17

19~22

Peeling pliers

Nipper pliers

PU tube

nylon tube

Φ12×10

Diagonal cutting pliers

φ10×8

Tube cutter

Φ8×6

Electric soldering iron

35W

Φ6×4

Avometer

FLUKE 17B

Oxygen density tester

handheld

Solder wire

0.6

Pressure gauge

0~0.4Mpa

7

3

1

2

4

5

6

8

9

11

12

13

14

15

10

Service Manual

-4-

Table 2

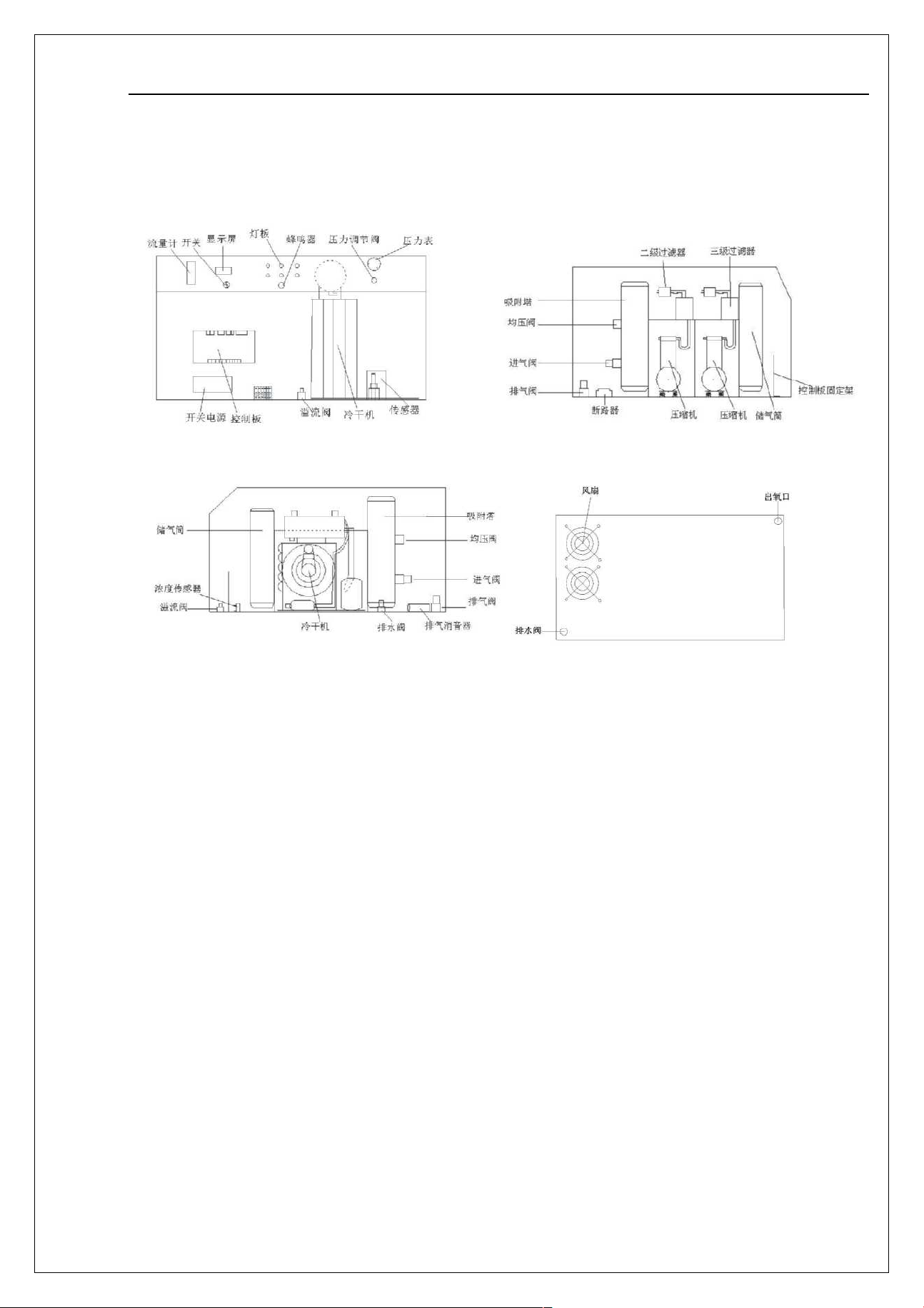

█

Internal Structure and Name of Major Components

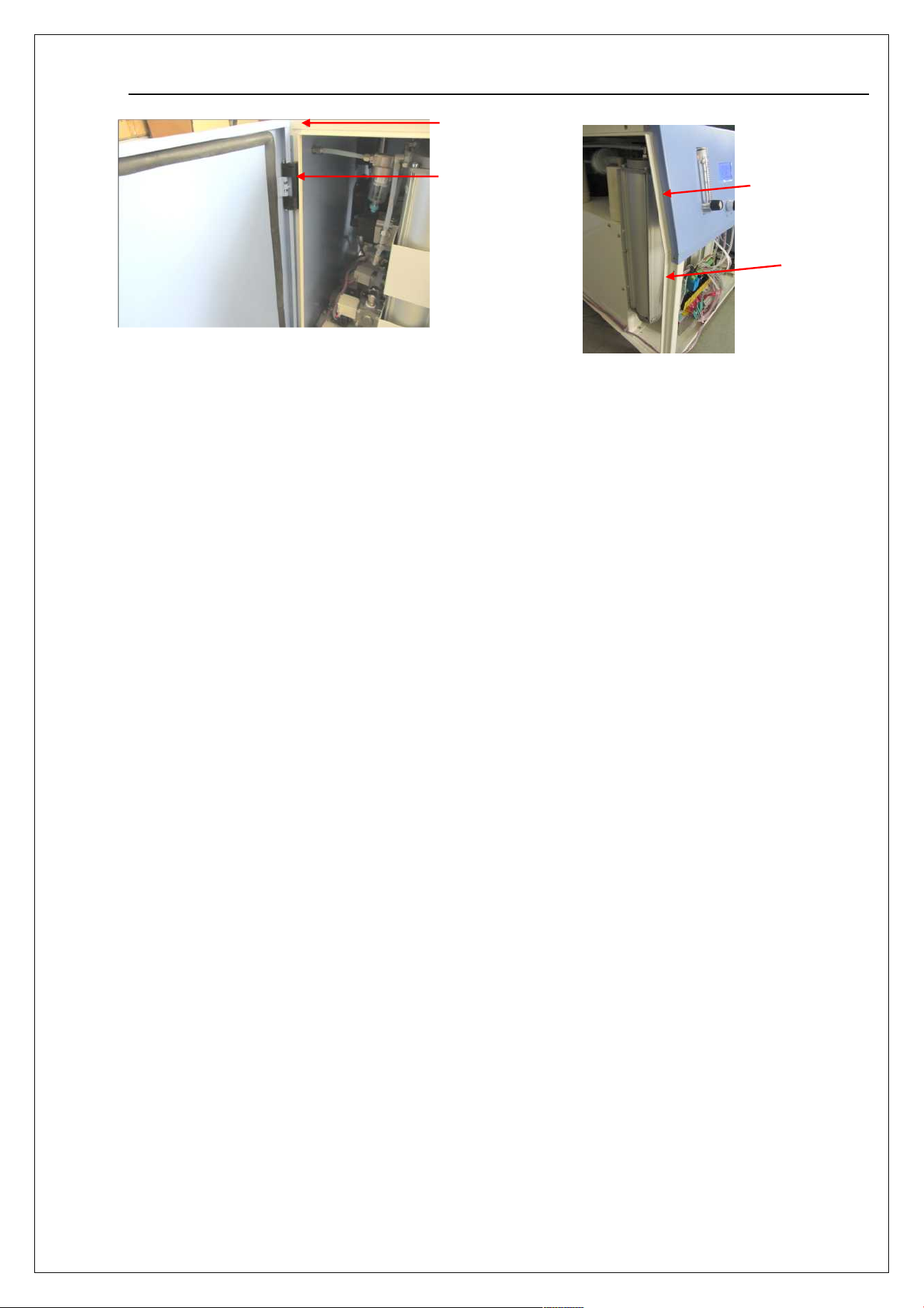

Front elevation : see figure 3;Left elevation: see figure 4;Right elevation :see figure 5;Back

elevation: see figure 6

Figure 3 Figure 4

Figure 5 Figure 6

█Dismantling Method

4.1 Dismantling the shell

4.1.1

Open the side panel,press/lift the hinges installed in the side panel(Two hinges),and then

remove the side panel(See figure 7)

4

.1.2 After removing the side panel, unscrew the retaining screw in the top panel, and then can

remove the top panel(See figure 7)

4.1.3Using Phillips screwdriver, unscrew the retaining screw in the front panel and then remove

the front panel(See figure 8

)

4.1.4 When removing the back panel,take down the fixed clamp of power line, take the power

line of fan apart installed in the back panel and unscrew the retaining screw .

Service Manual

-5-

Figure 7 Figure 8

4.2 Dismantling front panel

Take the tube apart that connect with pressure valve and flowmeter,take down the 3 pin

connector of LCD display, unscrew the retaining screw and then can remove the front panel

(See figure 8)

4.3

Dismantling

PCB board and power switch

After removing the front panel, the area of PCB board will be come into view. Take all the

connector apart installed in the board, it include: valve’s wiring (vent valve, inlet valve, balance

valve, drain valve), fan’s wiring, dryer’s wiring, compressor’s wiring, power switch’s wiring(24V),

7-pin connector of LCD display, 5-pin connector of lamp panel, 3-pin connector of temperature

sensor, power supply wiring of oxygen sensor (5V), 4-pin connector of power failure alarm, the

connecting tube of pressure sensor, the power line in the Wire terminal. Using Phillips

screwdriver, unscrew the retaining screw in the PCB board and switching power supply and then

can remove the PCB board and switching power supply(See Appendix 2)

4.4 Dismantling dryer, molecular sieve and oxygen tank

1、

unplug the connecting tube between dryer and compressor, dryer and inlet valve, dryer and

drain valve; Unscrew the retaining screw installed in dryer and then can remove the dryer by

using Impact wrench

2、

unplug the connecting tube between valves , zeolite sieve and oxygen tank. Unplug the

connecting tube between Exhaust valve and Intake valve using #19 wrench; Equalizing valve (#13

wrench); Using #13 wrench,uncrew the screws between molecular sieve and oxygen tank ,unplug

the tube, take the retaining screws down in the holder of Intake valve and equalizing valve,

remove the holder and then unscrew the retaining screws between the molecular sieve and

cabinet using Phillips screwdriver. The molecular sieve was taken off. (See figure 9)

Retaining screw

(top panel)

Retaining screw

(side panel)

Retaining screw

(front panel)

Retaining screw

(front panel)

Loading...

Loading...