Loncin G200FA, G420FDA, G420FA, G300FDA, G390FDA User Manual

...

Keep this owner's manual handy, so you can refer to it at any time.

This owner's manual is considered a permanent part of the engine and should remain with

the engine if resold.

The information and specifications included in this publication were in effect at the time of

approval for printing.

Only the D Type is equipped for both electric and manual starting.

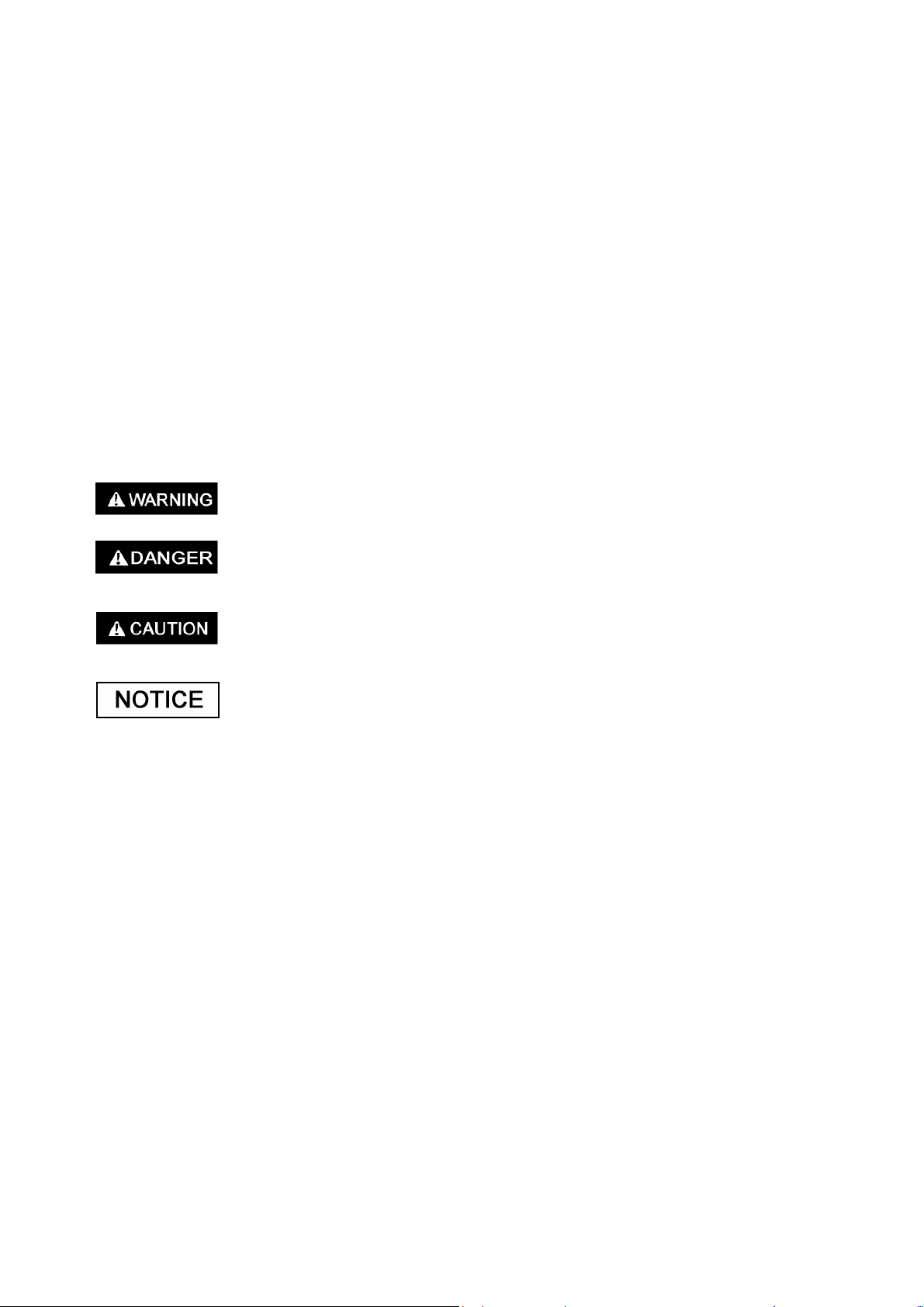

READ THIS OWNER’S MANUAL CAREFULLY. Pay special attention to these symbols

and any instructions that follow:

Indicates serious injury or death will result if instructions are not

followed.

Indicates a strong possibility that serious injury or death could

result if instructions are not followed.

Indicates a possibility that minor injury or an result if instructions

are not followed.

Indicates that equipment or property damage can result if

instructions are not followed.

NOTE: Gives helpful information.

If a problem should arise, or if you have any questions about your engine, consult your

engine dealer.

CONTENTS

CONTENTS

1. ENGINE SAFETY........................................................................................2

2. COMPONENTS & CONTROL LOCATIONS……………................................................3

3. CONTROLS...............................................................................................4

4. CHECK BEFORE OPERATION .............................................................................. 6

5. OPERATION............................................................................................ 7

6. MAINTENANCE ……………………….......................................................................11

7. STORAGE/TRANSPORTING ...................................................................................23

8. TROUBLESHOOTING………………………………………………................................26

9. TECHNICAL & CONSUMER INFORMATION ……..……………………………………27

10. SPECIFICATIONS ...................................................................................33

11. WIRING DIAGRAMS ...............................................................................35

12. OPTIONAL PARTS....................................................................................37

BATTERY.................................................................................................37

ENGINE SAFETY

1. ENGINE SAFETY

IMPORTANT SAFETY INFORMATION

Most accidents with engines can be prevented if you follow all instructions in this manual

and on the engine. Some of the most common hazards are discussed below, along with

the best way to protect yourself and others.

Owner Responsibilities

z The engines are designed to give safe and dependable service if operated according

to instructions. Read and understand this owner’s manual before operating the engine.

Failure to do so could result in personal injury or equipment damage.

z Know how to stop the engine quickly, and understand the operation of all controls.

Never permit anyone to operate the engine without proper instructions.

z Do not allow children to operate the engine. Keep children and pets away from the

area of operation.

Refuel With Care

Gasoline is extremely flammable, and gasoline vapor can explode. Refuel outdoors, in a

well-ventilated area, with the engine stopped. Never smoke near gasoline, and keep other

flames and sparks away. Always store gasoline in an approved container. If any fuel is

spilled, make sure the area is dry before starting the engine.

Hot Exhaust

z The muffler becomes very hot during operation and remains hot for a while after

stopping the engine. Be careful not to touch the muffler while it is hot. Let the engine

cool before storing it indoors.

z To prevent fire hazards and to provide adequate ventilation for stationary equipment

applications, keep the engine at least 3 feet (1 meter) away from building walls and

other equipment during operation. Do not place flammable objects close to the engine.

Carbon Monoxide Hazard

Exhaust gas contains poisonous carbon monoxide. Avoid inhalation of exhaust gas. Never

run the engine in a closed garage or confined area.

Other Equipment

Review the instructions provided with the equipment powered by this engine for any

additional safety precautions that should be observed in conjunction with engine startup,

shutdown, operation, or protective apparel that may be needed to operate the equipment.

2

COMPONENTS & CONTROL LOCATIONS

2. COMPONENTS & CONTROL LOCATIONS

MUFFLER

THROTTLE LEVER

SPARK PLUG

AIR CLEANER

FUEL VALVE LEVER

FUEL TANK

FUEL FILLER CAP

IGNITION SWITCH

STARTER GRIP

RECOIL STARTER

CHOKE LEVER

OIL DRAIN PLUG

OIL FILLER CAP/DIPSTICK

3

CHECK BEFORE OPERATION

3. CONTROLS

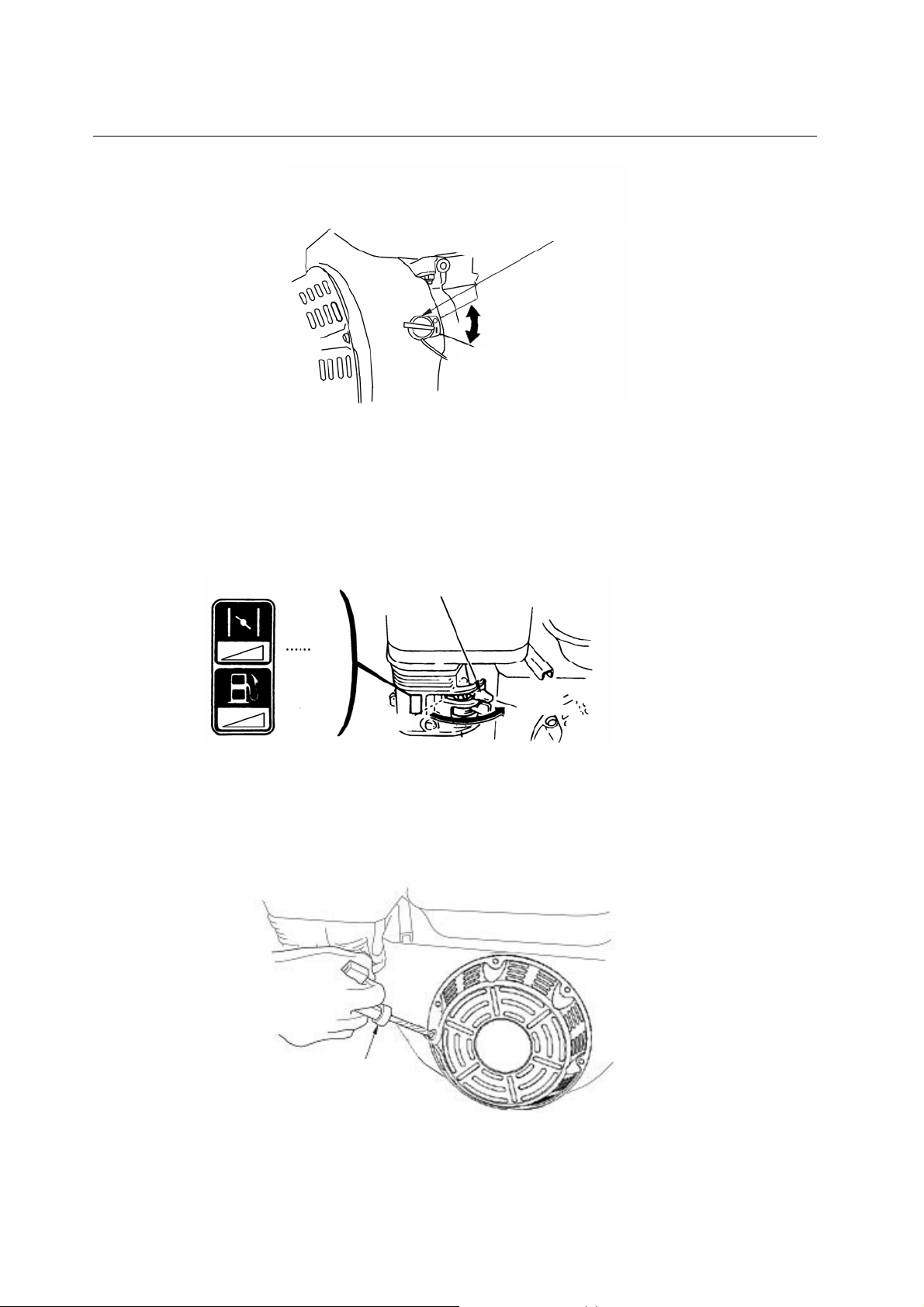

Fuel Valve Lever

The fuel valve opens and closes the passage between the fuel tank and the carburetor.

The fuel valve lever must be in the ON position for the engine to run.

When the engine is not in use, leave the fuel valve lever in the OFF position to prevent

carburetor flooding and to reduce the possibility of fuel leakage.

Throttle Lever

The throttle lever controls engine THROTTLE LEVER speed.

Moving the throttle lever in the directions shown makes the engine run faster or slower.

Engine Switch

The engine switch enables and disables the ignition system.

The engine switch must be in the ON position for the engine to run.

Turning the engine switch to the OFF position stops the engine.

OFF

FUEL

VALV E

LEVER

ON

OFF

THROTTLE

LEVER

SLOW

FAST

4

CHECK BEFORE OPERATION

ALL ENGINE EXCEPT D TYPE

ENGINE SWITCH

OFF

ON

Choke Lever

The choke lever opens and closes the choke valve in the carburetor.

The CLOSE position enriches the fuel mixture for starting a cold engine.

The OPEN position provides the correct fuel mixture for operation after starting, and for

restarting a warm engine.

Some engine applications use a remotely-mounted choke control rather than the

engine-mounted choke lever shown here.

CHOKE LEVER

OPEN

CLOSE

OPEN

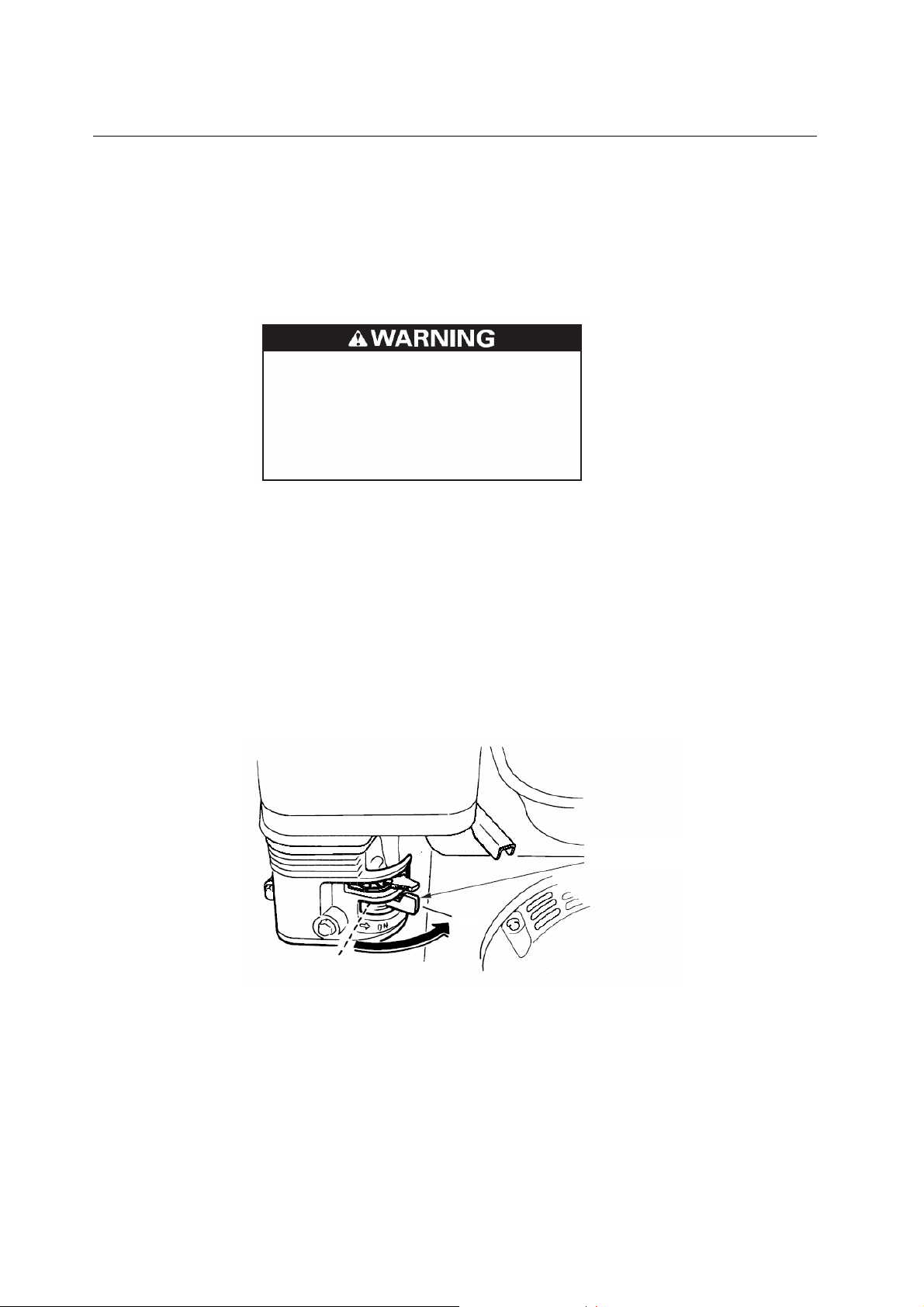

Recoil Starter Grip

Pulling the starter grip operates the recoil starter to crank the engine.

STARTER GRIP

5

CHECK BEFORE OPERATION

4. CHECK BEFORE OPERATION

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your equipment, it is very important to

take a few moments before you operate the engine to check its condition. Be sure to take

care of any problem you find, or have your servicing dealer correct it, before you operate

the engine.

Improperly maintaining this engine,

or failing to correct a problem

before operation, could cause a

malfunction in which you could be

seriously injured.

Always perform a preoperation

inspection before each operation,

and correct any problem.

Before beginning your preoperation checks, be sure the engine is level and the engine

switch is in the OFF position.

Check the General Condition of the Engine

z Look around and underneath the engine for signs of oil or gasoline leaks.

z Remove any excessive dirt or debris, especially around the muffler and recoil starter.

z Look for signs of damage.

z Check that all shields and covers are in place, and all nuts, bolts, and screws are

tightened.

Check the Engine

Check the engine oil level. Running the engine with a low oil level can cause engine

damage.

The Oil Alert system (applicable engine types) will automatically stop the engine before the

oil level falls below safe limits. However, to avoid the inconvenience of an unexpected

shutdown, always check the engine oil level before startup.

Check the air filter. A dirty air filter will restrict air flow to the carburetor, reducing engine

performance.

Check the fuel level. Starting with a full tank will help to eliminate or reduce operating

interruptions for refueling.

Check the Equipment Powered by This Engine

Review the instructions provided with the equipment powered by this engine for any

precautions and procedures that should be followed before engine startup.

6

OPERATION

5. OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the IMPORTANT SAFETY

INFORMATION and the chapter titled BEFORE OPERATION.

Carbon monoxide gas is toxic.

Breathing it can cause

unconsciousness and even kill you.

Avoid any areas or actions that

expose you to carbon monoxide.

Review the instructions provided with the equipment powered by this engine for any safety

precautions that should be observed in conjunction with engine startup, shutdown, or

operation.

STARTING THE ENGINE

1. Move the fuel valve lever to the ON position.

2. To start a cold engine, move the choke lever to the CLOSE position.

To restart a warm engine, leave the choke lever in the OPEN position.

Some engine applications use a remotely-mounted choke control rather than the

engine-mounted choke lever shown here.

ON

FUEL VALVE

LEVER

7

OPERATION

CHOKE LEVER

CLOSE

OPEN

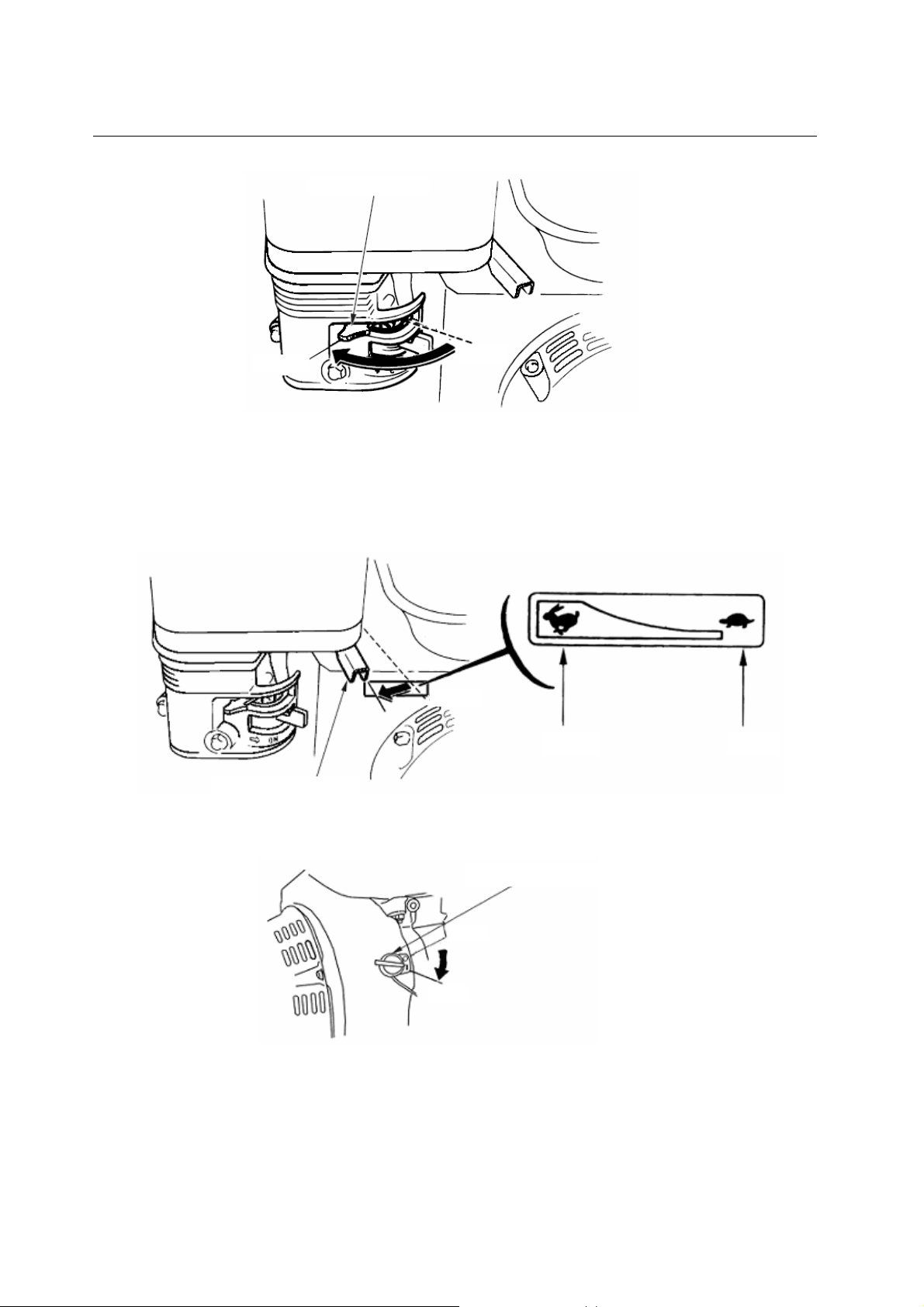

3. Move the throttle lever away from the SLOW position, about 1/3 of the way toward the

FAST position.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

THROTTLE LEVER

4. Turn the engine switch to the ON position.

5. Operate the starter.

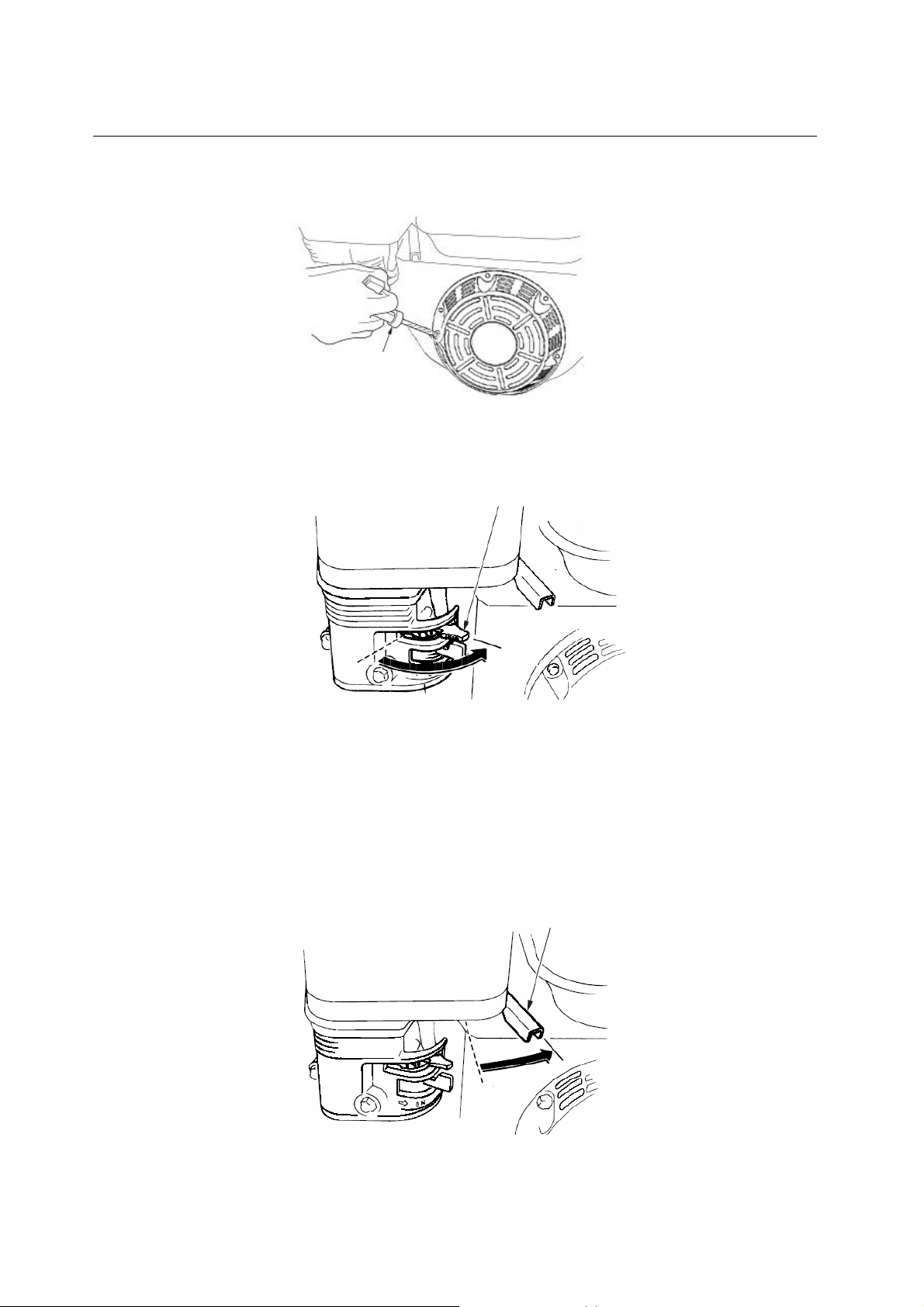

RECOIL STARTER (all engine types):

Pull the starter grip lightly until you feel resistance, then pull briskly.

SLOW

ENGINE SWITCH

OFF

ON

HIGH

LOW

8

OPERATION

Return the starter grip gently.

STARTER GRIP

6. If the choke lever has been moved to the CLOSE position to start the engine, gradually

move it to the OPEN position as the engine warms up.

STOPPING THE ENGINE

To stop the engine in an emergency, simply turn the engine switch to the OFF position.

Under normal conditions, use the following procedure.

1. Move the throttle lever to the SLOW position.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

CHOKE LEVER

OPEN

THROTTLE LEVER

SLOW

9

OPERATION

2. Turn the engine switch to the OFF position.

3. Turn the fuel valve lever to the OFF position.

FUEL VALVE

LEVER

OFF

SETTING ENGINE SPEED

Position the throttle lever for the desired engine speed.

Some engine applications use a remotely-mounted throttle control rather than the

engine-mounted throttle lever shown here.

For engine speed recommendations, refer to the instructions provided with the equipment

powered by this engine.

FAST

ENGINE SWITCH

OFF

ON

THROTTLE LEVER

SLOW

10

Loading...

Loading...