LogTag Recorders TRIX-8, TRIX-16, HAXO-8, SRIC-4, TREX-8 Quick Start Manual

...

is Quick-Start guide covers preparation, use and maintenance to

assist you in getting the best results from your LogTag®.

Products

LogTag® Recorders offer a variety of different models. The

product range is constantly being updated and new models added,

so visit

www.thermoworks.com/products/logger/logtag.html

to get the latest information and news

about upcoming product releases.

You can nd a list of the most common

models in table1. Using the LogTag®

most appropriate to your measuring

and monitoring task will ensure the

best results.

LogTag® recorder products have a number of features in common: a green OK

LED, a red ALERT LED, a START/

MARK button and a mounting lug.

GettinG started

All you need to use the LogTag® recording

system are a LogTag® interface, a PC running

Windows XP or later, the LogTag® Analyzer

PC application and the LogTag® recorder itself.

Don’t plug the interface into the computer just

yet, this will be done at the conclusion of the

software installation.

software installation

Before using a LogTag® recorder you will need to

download the LogTag® Analyzer software from

LogTag’s web site at

www.thermoworks.com/software/

. After

registering you will be e-mailed with a link, from

where you can download the latest version,

which supports multiple languages, including

those with special characters such as Chinese or

Greek.

Once downloaded, start the executable to initiate the installation

process; please note you will need local administrator rights to do

this.

Wait until nished before installing your interface.

interface installation

After the installation is complete, you will see a new icon

on your desktop. You can now plug your interface into

a USB port, or an RS232 port if you were supplied this

type of interface. For USB interfaces the drivers will now

install automatically. Your operating system will notify

you once the driver installation has succeeded. You can use

multiple interfaces on one computer and also mix RS232 and USB

interfaces.

When all interfaces are installed you are ready to proceed.

confiGurinG a loGtaG

You will need to congure a LogTag® if you

want to take readings with it. Insert the LogTag®

into the interface, contacts in rst and the

LED’s towards the interface label as shown in

the picture on the right.

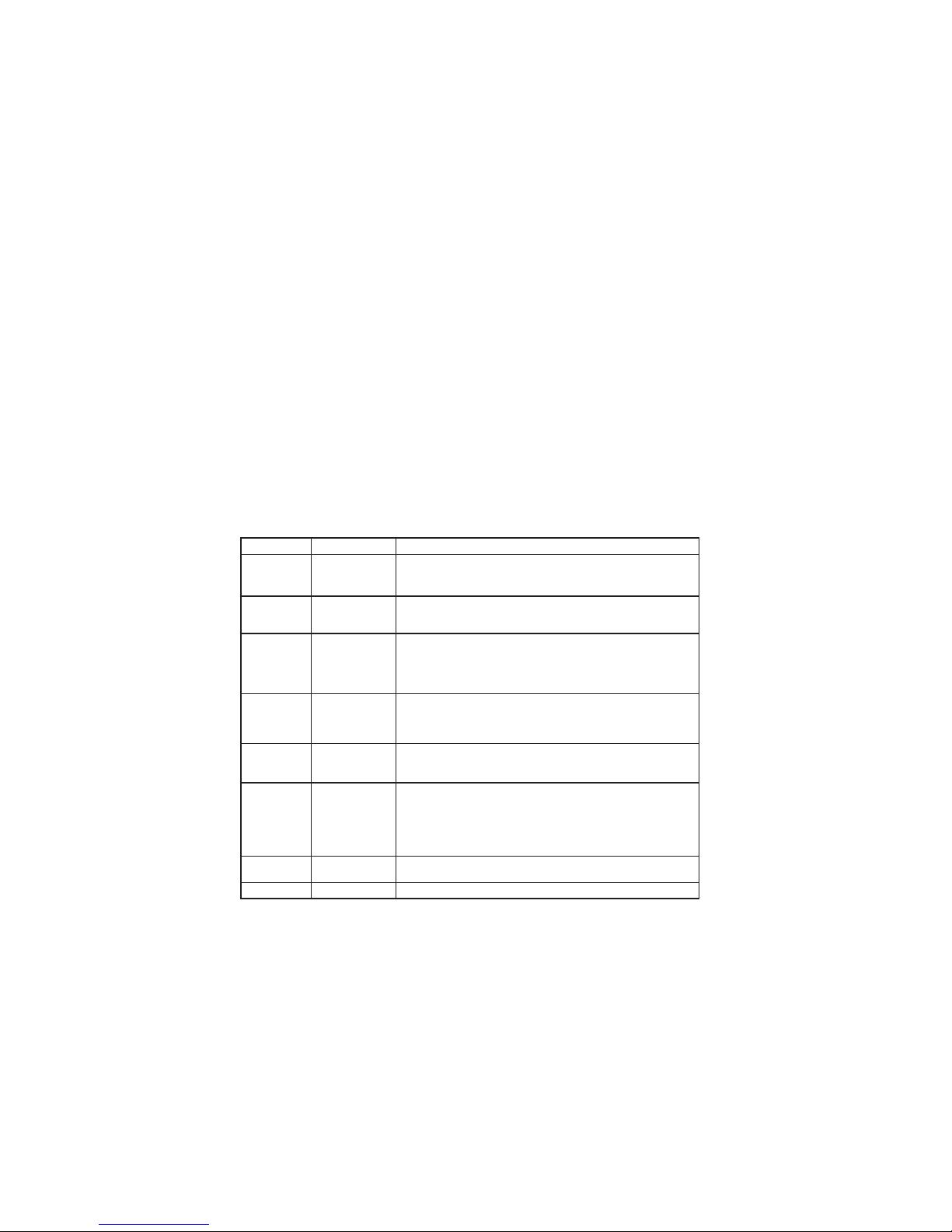

Start the software. e easiest way to

congure the LogTag® for a trip is the

use of the LogTag® Wizard by clicking

on the Wizard toolbar button or selecting

LogTag-Wizard from the menu.

e Wizard will

• Query all interfaces and any recorders inside them

• Download any data from recorders found and save them to les

• Allow you to enter parameters for a new trip, like shown in this

screen:

• Upload the new conguration to the recorders

You can enter parameters such as start method (push button or date/

time), logging interval (30 seconds to 18 hours), logging duration,

start delay, access passwords and not to forget Alert values, which

are used for the Alert LED activation and the reporting functions in

LogTag® Analyzer, and also add a description about your trip.

analysinG the results

Once loggers have completed a trip, you can use the LogTag®

Analyzer software to analyse and archive the data, to export them to

other programs such as MS Excel or to e-mail them and upload them

to an o-site server.

A number of controls and displays assist you in operating the software.

• Menu

• Toolbars

• Status

• Data window with graph, list, summary and averaging tabs

• Multichart windows and annotations for adding notes

• Context menus allowing quick access to the most used functions.

Quick Start Guide

Product

Type

Integrated

Temperature

Sensor

Integrated

Humidity

Sensor

Sensor

Probe

Display Recording

Temperature

Range

Memory

TRIX-8

-40ºC to 85ºC 8,000 samples

TRIX-16

-40ºC to 85ºC 16,000 samples

HAXO-8

-40ºC to 85ºC 8,000 samples

SRIC-4

-20ºC to 65ºC 4,000 samples

TREX-8

-40ºC to 99ºC 8,000 samples

TRIL-8

-80ºC to 40ºC 8,000 samples

TREL-8

-80ºC to 40ºC 8,000 samples

SRIL-8

-80ºC to 40ºC 8,000 samples

TRID30-7

-30ºC to 60ºC 7770 samples

TRED30-7

-40ºC to 99ºC 7770 samples

Table 1: LogTag Logger Models

LogTag

®

®

alert led

oK led

start/MarK Button

MountinG

luG

Signal Sequence Occurrence

LogTag® wake-up

signal

Sequence of four

alternate ashes of

green-red LED’s

• displayed after conguration has been successfully applied to the LogTag

®

• when a LogTag® is woken up from hibernation state

Not to be mixed up with...

LogTag

®

start-up

signal

Sequence of sixteen

alternate ashes of

green-red LED’s

• displayed when the LogTag® starts its recording cycle

Mark signal Sequence of ve

simultaneous ashes of

green and red LED’s

• displayed when pressing start/mark button while recording to indicate an inspection

mark in the software

• displayed directly after the start-up signal following a push button start where a

recording delay has been congured. In this instance the start-up signal is repeated

when the actual recording begins

Logging active, no

alert present

Single ash of green

LED every 4 seconds

(approx.)

• indicates LogTag® is recording

• is is not displayed when pre-start is active and the main logging cycle has not

yet started. It is also not displayed when the green LED has been turned o in the

conguration screen

Logging nished,

no alert present

Single ash of green

LED every 8 seconds

(approx.)

• indicates LogTag® has nished recording

• is is not displayed when the green LED has been turned o in the conguration

screen. Will also be displayed when unit has been woken up from hibernation

Alert condition

present

Single ash of red

LED every 4 seconds

• displayed when the LogTag® has detected an alert condition and the Alert LED has

been activated

If an alert is present you cannot determine if the unit is still logging or has nished its log cycle. If the Alert LED has not been activated during conguration,

in essence the visual indicators have been disabled, and the green LED will ash

every 4 or 8 seconds as above.

Communication e green LED will

ash occasionally

• during communication with the interface the green LED will ash occasionally; no

information is conveyed in this

Start button press red LED glows faintly

• is is by design but conveys no information

Table 2: Light Patterns

For a full list of features please see the LogTag® Analyzer User Guide,

which can be accessed through the Help Menu. You can also call up

on-line help information for all windows and dialogue buttons by

pressing the F1 key.

loGtaG indicator leds

e LogTag® recorder itself can give you important status information

by ashing its indicator LEDs in dierent patterns. Both the red ‘Alert’

LED and the green ‘OK’ LED convey information about conguration

and trip parameters, Alert status and give feedback when users interact

with the START/MARK button.

You will nd a summary of the LED patterns with a description about

their meaning in table 2 on the right.

start/MarK Button

Once a LogTag® has been congured, pressing the START/MARK button has a dierent outcome depending on what

the recorder is doing at the time the button is

pressed.

• If the recorder is congured for a push button start, pressing this button will activate

the main recording. ere is no need to be

concerned about any lost data if the user

forgets to press this button, as a pre-start

recording feature can be activated, logging

data even before the trip is started.

• Once the LogTag® has been started, pressing

the button will insert an inspection mark in

the data recordings, which is displayed when

viewing the data in the software.

• If congured, Alert Conditions can be reset

when this button is pressed.

custoMi;inG the software

The software allows you to customize many of

the features to your individual requirements.

Not only can you change some of the more

basic options like display language and

temperature units, but also adapt some of the

more advanced parameters for e-mail and FTP

functions, storage folder location, le name and

frequency for automatic software updates.

GettinG the riGht results

When you use the LogTag® units, please take a

moment to consider the application and how

to best approach the monitoring task. Allow the units to be located in

a place with good air movement, make sure HAXO units are not lying

at so water and dust cannot gather around the sensor lter and provide adequate insulation around access holes for sensors with probes.

certifications

LogTag® has achieved certication with a number of Authorities,

demonstrating the quality and suitability of the LogTag® Recorders for

applications where accuracy and consistency is required. Such certications have - amongst others- been issued by such organisations as the

FCC, CE, C-TICK, TÜV and the WHO.

fda title 21 cfr 11

Compliance to the FDA requirements is available to users via a special

server utility, available on request, which can log events and be used to

digitally sign data les.

Maintenance

LogTag® recorder products are rugged and need little maintenance,

it does pay however to observe some basic rules when handling the

recorders to maximize their use.

Battery rePlaceMent

Most LogTag® recorder products have a replaceable battery, some of

which may be soldered to the electronics to avoid contact issues that

exist with other branded loggers; for these you will need some soldering

expertise and a battery replacement kit from your distributor. Please

also note that the products do contain a non-rechargeable Lithium Battery, which must be disposed of in accordance with local regulations.

hiBernation

To prolong the life of your recorder you can hibernate it between trips

via LogTag® Analyzer when it is not being used for extended periods.

Please refer to the User Guide in the section about ‘Hibernation’

caliBration

All LogTag® recorders can be calibrated with special utility software, which will be made available

to calibration labs upon request. Re-calibrated

loggers can be identied and traced back to the

calibrating lab thus reducing the risk of fraudulent data tampering.

Basic trouBleshootinG

water inGress

Please carefully observe the IP rating for your unit

and remember that none of the LogTag® products

can be immersed into liquids.

contact cleaninG

Keep the three metal contacts at the back of the

recorder clean and free from tape residue, dirt

or other contaminants, as these usually result in

communications problems. If required, clean

them with a soft pencil eraser, but don’t use abrasive materials as you may permanently damage

them.

GettinG helP

If after studying the User Guide you still need

further information, please visit the Support section of the LogTag® Recorders website.

thanK you...

...for choosing LogTag® Recorders, we are looking

forward to working with you!

Loading...

Loading...