REEL ROTATOR

ELFRRM / ELFSRRM, ELFRRE / ELFSRRE

EU DECLARATION CONFORMANCE

Manufacturer: Logitrans A/S

Hillerupvej 35

DK-6760 Ribe

Denmark

It is hereby declared that:

Machine: Productgroup: Reel Rotator

Type: ELFRRE / ELFSRRE

Year of manufacture/

Serial No:

a) Has been manufactured in conformance with the stipulations of the:

• Directive no. 2006/42/EC

• Directive no. 2004/108/EC

• Directive no. 2006/95/EC

ELFRRM / ELFSRRM

b) Has been manufactured in conformance with the stipulations of the standard:

• EN 3691-5

Name: Gitte K. Berg

Position: CEO

Company: Logitrans A/S

Product type declaration of:

Signature:

Distributor:

16.02.2016

D179-1

Contents

1.0 Before the first lift... ............................................................................................. 4

2.0 Functions and identifications .......................................................................... 5

3.0 How to operate the Reel Rotator ................................................................... 7

3.1 Handling of reels.................................................................................................................. 7

3.2 Use of the Reel Rotator ....................................................................................................... 7

3.3 Clamping of reels................................................................................................................. 8

3.4 Extra support ..................................................................................................................... 10

3.5 Manual rotation (ELFRRM/ELFSRRM) ..............................................................................11

3.6 Electric rotation (ELFRRE/ELFSRRE)............................................................................... 12

3.7 Adjusting of rotation stop (ELFRRE/ELFSRRE) ................................................................ 13

3.8 Setting the speed (ELFRRE/ELFSRRE) ........................................................................... 13

3.9 Reset (ELFRRRE/ELFSRRE) ........................................................................................... 13

4.0 Optimum safety ..........................................................................................14

4.1 Rotation range ................................................................................................................... 14

4.2 Safety regulations .............................................................................................................. 15

4.3 Driving loaded.................................................................................................................... 16

4.3 Rotation range ................................................................................................................... 16

4.4 Rotation with load .............................................................................................................. 16

4.5 Emergency braking and Emergency stop.......................................................................... 16

5.0 There must be a current supply... ................................................................17

5.1 Fuses - replacement .......................................................................................................... 17

5.2 Wiring connections ............................................................................................................ 17

6.0 Long live Reel Rotator ........................................................................................ 18

6.1 Lubrication and hydraulic oil .............................................................................................. 18

6.2 Oil change ......................................................................................................................... 18

6.3 Adjustment of reel carriage ................................................................................................ 19

6.4 Adjustment of lifting chain .................................................................................................. 19

6.5 Adjustment of steering wheel chains ................................................................................. 20

6.6 The hydraulic pump and gear motor .................................................................................. 20

6.7 Cleaning ............................................................................................................................ 20

6.8 Adjustment of side play...................................................................................................... 21

7.0 Adjusting the Reel Rotator .............................................................................. 22

7.1 Tensioning the chains ........................................................................................................ 22

7.2 Adjusting the switch ........................................................................................................... 23

7.3 Lubrication ......................................................................................................................... 23

8.0 Fault location key ................................................................................................. 24

9.0 Good service after purchase ......................................................................... 26

9.1 Ordering spare parts.......................................................................................................... 26

9.2 Warranty/Compensation .................................................................................................... 26

9.3 Service and repair ............................................................................................................. 26

9.4 Warranty ............................................................................................................................ 26

9.5 Liability exemption ............................................................................................................. 26

3

1.0 Before the first lift...

The Reel Rotator is manufactured in accordance with safety directives.

Among the subjects dealt with in this Instruction Manual are:

- Proper application

- Physical limitations of the product

- Risks with improper use

- Therefore please read this Instruction Manual carefully!

4

2.0 Functions and identifications

Released position

Lifting/Lowering

Emergency stop

To release the brake:

1. Pull

2. Push

Braked position

Instrument board

- Battery indicator

- Type plate

- Charging plug

(internal or external charger)

- Plug for extra equipment,

12V maximum 20 Amp

5

2.0 Functions and indentifications

Clockwise/

counterclockwise

Remote control for rotation (ELFRRE/ELFSRRE)

The remote control is used when:

• Rotating the reel carriage

• Setting tilt stop in both directions: See paragraph 3.7.

• Setting rotation speed: See paragraph 3.8.

Remote control for clamping (all models)

The remote control is used when:

• Clamping/fastening

• Opening/releasing

6

3.0 How to operate Reel Rotator

3.1 Handling of reels

ELFSRRM & ELFSRRE

Handling of reels on closed pallets

- Use the Reel Rotator with straddle legs!

ELFRRM & ELFRRE

3.2 Use of the Reel Rotator (ELFRRE/ELFSRRE)

Conditions for rotation: Center of the gripping arms is lifted at least:

ELFRRE: 825 mm

ELFSRRE: 750 mm

ELFRRE/ELFSRRE:

side

.

Note: The rotation stops automatically, when the gripping arms are placed

horizontally/in position 0°.

To continue the rotation function from 0°, the rotation switch has

to be released and activated again in the requested rotation direction.

To lower the reel carriage fully, the reel carriage has to be placed in position 0°.

Soft acceleration / deceleration

The Reel Rotator has soft acceleration / deceleration with the following benets:

The load can be rotated 355º with one adjustable stop in every

• The reel rotation stops precisely.

• The gear is protected, because sudden start / stop are minimised.

7

3.0 How to operate the Reel Rotator

3.3 Clamping of reels

3

8

3.0 How to operate the Reel Rotator

Clamping:

(o)

Press until the lamp lightens

green.

When red lamp lightens, the

clamping force is not sufficient.

Releasing:

(o)

Press both buttons at the same

time to open the gripping arms.

Note: As a safety precaution,

the gripping arms can only be

opened, when the lifting system

is without pressure.

9

3.0 How to operate the Reel Rotator

3.4 Extra support

For reels from Ø800mm to Ø1270mm it is possible to use three-points clamping.

By adjusting the shown supporting plate, so that it supports the reel, it can be

prevented that the reel moves between the two plates that primarily fasten the reel.

The supporting plate can also be set as stop for a certain reel diameter.

Supporting plate

10

3.0 How to operate the Reel Rotator3.0 How to operate the Reel Rotator

3.5 Manual rotation (ELFRRM/ELFSRRM)

ATTENTION

Check that the load is placed in the load center before rotating.

Press the handle to position

”Release”

The reel carriage can now

be rotated by the gripping

handle.

Note: The reel carriage can be locked for each 90°.

Conditions for rotation: Center of the gripping arms is lifted at least:

ELFRRM: 825 mm

ELFSRRM: 750 mm

11

3.0 How to operate the Reel Rotator

3.6 Electric rotation (ELFRRE/ELFSRRE)

ATTENTION

Check that the load is placed in the load center before rotating.

Use the remote control for the rotation:

A

B

Press “A” to rotate clockwise (seen from position behind the

handle).

Press “B” to rotate counterclockwise (seen from position behind

the handle).

From the factory the rotation is preset to stop 90° to each side.

The load can as maximum be rotated 355º with one adjustable

stop in every side.

Note: The load has to be placed in position 0°, before the load

can be lowered fully.

12

3.0 How to operate the Reel Rotator

3.7 Adjusting of rotation stop (ELFRRE/ELFSRRE)

The reel carriage is factory-set to stop in 90º. If another setting is required, it can be

set electronically to stop in different angles.

1) The reel carriage is placed in position 0°.

2) Short pressure on the switch A activates the setting

procedure. The controller gives a signal (one beep).

3) The reel carriage is placed in the requested angle.

4) When the reel carriage has reached the requested

angle, the controller will give signal after three

seconds (one beep), when the position has been

stored.

The procedure is repeated to set the stop in the other

side.

A

3.8 Setting the speed (ELFRRE/ELFSRRE)

1) The reel carriage is placed in position 0°.

2) The switch (A) is pressed three seconds, and two

short beeps will be given. The switch is released

and the speed is set by activating the remote

control.

Plug from

remote control

Clockwise: Increasing the speed

Counter-clockwise: Reducing the speed

Note: Maximum rotation speed (0-355º): 30 sec.

3) 3 seconds after releasing the switch on the remote

control, the controller will give signal (two beeps),

indicating that the requested speed has been

stored.

Switch A

Signal

3.9 Reset the settings (ELFRRE/ELFSRRE)

1) The reel carriage is placed in position 0°.

2) Press switch (A), until ve beeps are given. The switch is released and the

controller is set to maximum speed and stops at 45°.

13

4.0 Optimum safety

4.3 Rotation range

Standard version

The load can be rotated, when the turning point of the reel carriage is raised more

than 750 mm (ELFSRRM/ELFSRRE) and more than 825 mm (ELFRRM/ELFRRE).

Below this range, it is only possible to raise/lower the reel carriage in position 0°.

Bottom stop (ELFRRE/ELFSRRE)

Adjusted with the following turning point above

the floor:

ELFSRRE: 750 mm

ELFRRE: 825 mm

14

4.0 Optimum safety

4.2 Safety regulations

• Never walk under a raised load!

• Never stand between the gripping arms!

ATTENTION

Moving parts

• Before lowering the reel carriage, make certain that no foreign

elements can hinder the free lowering of the reel carriage

• The Reel Rotator is designed for use on an even

and level oor

• During transport the reel carriage shall be raised as little as possible

• Transport with raised reel carriage should be made over the shortest

possible distances and at low speed

• Check that the chains lift equally. They shall be equally tight when the reel

carriage is loaded

• Chains and chain bolts must not be damaged. Chains that have become

permanently stretched (max. 2 % of original length) must be scrapped.

15

5

4.0 Optimum safety

4.3 Driving loaded

The Reel Rotator is designed for use on even and level oor. During transport the

reel carriage shall be raised as little as possible. Transport with raised reel carriage

should be made over the shortest possible distances and at low speed.

4.4 Rotation with load

NOTE! Rotation is only allowed to take place, if the Reel Rotater is placed on an

equal oor.

When rotating reels, the operator needs a full

overview of the whole working area, so that the

rotation movement can be stopped before the

reel touches the oor, the items or persons in the

working area.

4.5 Emergency braking and Emergency stop

The Reel Rotator has an emergency stop. When activating the

emergency stop, the main current supply is switched off.

The movement of the reel carriage stops immediately when

activating the emergency stop.

16

5.0 There must be a current supply...

5.1 Fuses - replacement

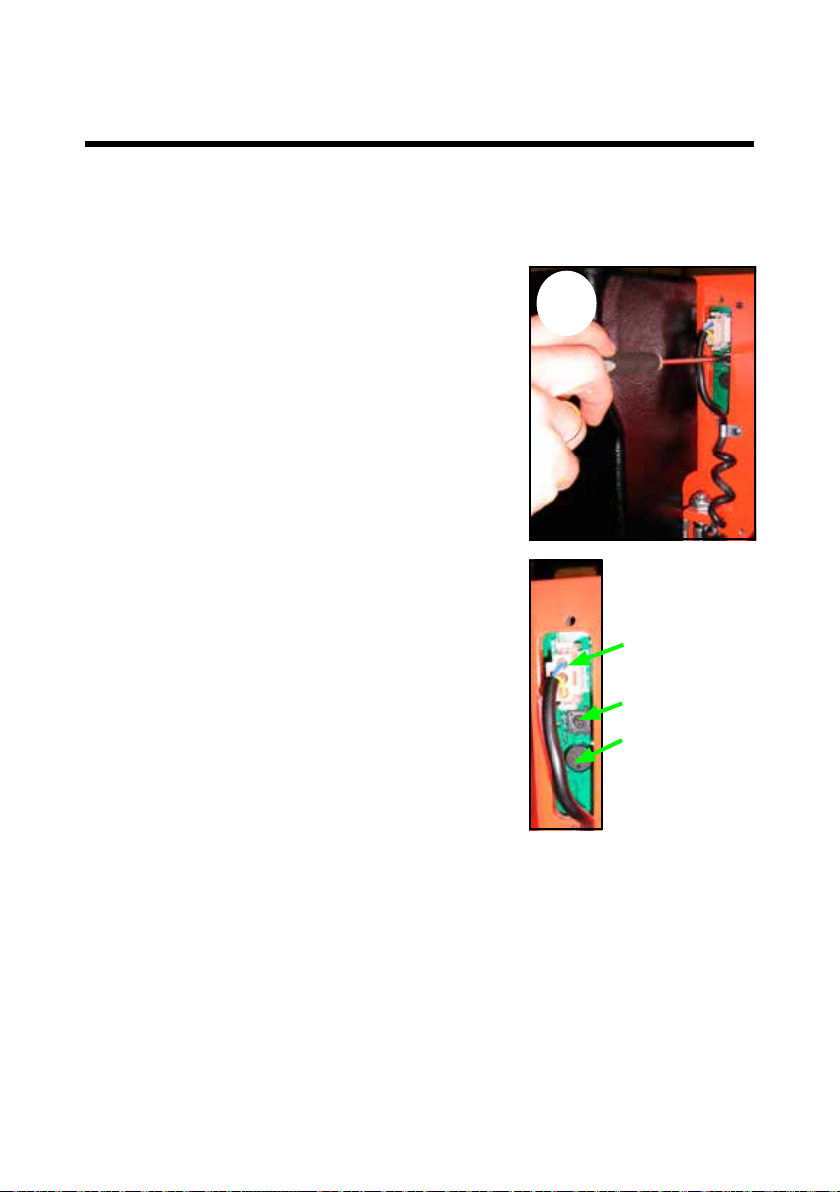

There are five fuses in the electrical circuit:

100 Amp fuse in the main supply from battery

10 Amp fuse in the control current circuit

20 Amp fuse (plug for extra equipment on the instrument board)

20 Amp fuse for built-in charger

40 Amp fuse for rotation

40A

10A 20A 20A

Replacement:

The old fuse is to be removed and replaced by a new one of the same size.

Find out why the fuses blow!

100A

5.2 Wirring connections

Many operational disturbances are caused by bad

connections in the elctrical circuit. Make sure that the

connections are in order.

Check connections regularly for damage at insulating caps or

bad connections at plugs etc. Verdigris must be removed from

cable plugs. Keep all screw/nut connections tight.

17

6.0 Long live Reel Rotator

Regular inspection and the replacement of worn or defective parts in good time will

prolong the life of the Reel Rotator. “Prevention is better than repair”, therefore ensure:

• That the battery is fully charged every time

• Correct usage

• Regular cleaning

• Periodic safety and service inspection

• For safety reasons please check the below every 3 month:

- Tighten loose screw and nuts

- Check that there are no cracks, fractures and deformations in

the bearing construction

- Wearing parts, such as brakes, wheels and bearings, are adjusted and

exchanged continuously

6.1 Lubrication and hydraulic oil

Under normal operation conditions the Reel Rotator requires no

lubrication. All ball bearings are sealed and lubricated for life, and

moving parts have self-lubricating bearings or are treated with grease.

The hydraulic system is lled with hydraulic oil of viscosity class

ISO VG 15. An additive is added to the oil. The concentrate reduces friction and wear

and protects against corrosion. Pre-mixed hydraulic oil with additive is available from

the dealer. The oil is suitable for use in the temperature range -10 to +50° C. A thinner

oil is recommended for temperatures lower than -10° C (if necessary, contact your

dealer).

6.2 Oil change

Draining the oil:

1. Bring the unloaded reel carriage down to the lowest position.

2. Most of the oil can be drained by loosening the hydraulic hose union and briey

activating the hydraulic pump with the switch.

3. The remaining oil can be drained from the oil tank by removing the tank.

Oil lling:

4. Fill oil through the lling hole on the tank.

5. Oil quantity: ELFRRM 1750 & ELFSRRM 1750 approx 3 liter

ELFRRE 1750 & ELFSRRE 1750 approx 3 liter

6. Ret the lling cap and bleed the system (6.6).

18

6.0 Longe live Reel Rotator

6.3 Reel carriage adjustment

Two of the rollers on the reel carriage are

mounted on eccentric pins, so that they can be

adjusted. The adjustable rollers are at the top.

1. Loosen screw (pos. 91) (key width 5 mm).

2. Eccentric pins (pos. 56) (key width 8 mm)

can now be turned to give the necessary

reel carriage adjustment.

3. Adjustment must be made on both sides

to ensure uniform loading of the rollers.

6.4 Adjustment of lifting chain

The chains shall be adjusted so that

• they lift equally

• they are equally tight

• The lifting movement has to stop in the cylinder,

before the mast rolls touch the top stop.

The nuts (pos. 18) are to be adjusted

(nut M12, key width 19 mm).

18

19

6.0 Longe live Reel Rotator

6.5 Adjustment of steering wheel

chains

- Set the handle in its middle position.

- Adjust the nuts (1, 2, 3 and 4) and bring

the wheels into parallel.

6.6 The hydraulic pump and the gear motor

The hydraulic pump has a S3 “periodic intermittent duty” of 10%. This means that

the pump in total is allowed to operate 1 minute for a period of 10 minutes.

Note! If the pump operates more than 10%, the motor will be damaged due to

superheating.

Bleeding the hydraulic system

With a load of 50-100 kg, the reel carriage must be raised and lowered to top and

bottom position 2-3 times.

Gear motor of the Reel Rotator

The gear motor has a ”short time under constant load” of 10 minutes

(S2=10 minutes). This means that the motor is allowed to operate with the

maximum load for 10 minutes. Hereafter it has to be cooled down to normal

temperature.

Note! The motor will be damaged by superheating, if it operates for a longer time

or if it is not cooled down.

6.7 Cleaning

When cleaning the Reel Rotator, do not direct the jet onto bearings

and seals. Otherwise the grease will be washed out and the life of the

equipment shortened.

Cleaning of the plastic screen (polycarbonate)

The screen is to be washed with slightly warm water added a neutral cleaning

material, and afterwards washed with clean water.

Use a soft sponge, a woollen cloth or a wash leather.

Never use sharp objects or

solvent cleaners when cleaning.

20

C

6.0 Longe live Reel Rotator

6.8 Adjustment of side play

1. Loosen counter nut B. Screw (A) is loosened counter-clockwise,

until resistance disappears.

2. Turn the screw clockwise, until resistance appears. The following

1.5 to 2.5 turns of the screw will be a tightening of the spring (C).

3. When a larger resistance appears, make 0.25 turn counter clockwise, and the counter nut (B) will be tightened.

4. Pump the reel carriage to its top position, and when lowering it has

to slide to the bottom. If this is not the case, loosen screw A, make

c. 0.5 turn counter-clockwise and repeat point 4.

Mast roll

Reel

carriage

C prol (mast)

21

7.0 Adjusting the Reel Rotator

7.1 Tensioning the chains (only ELFRRE & ELFSRRE)

When the unloaded reel carriage can be tilted manually approx. 2 cm, measured at

the rear carriage, the chains should be tensioned.

This is done by:

1) Removing the cover from the reel carriage.

2) Loosening the gear motor (A1)

3) Loosening chain wheel (B1)

4) Turning the nut (B2), so that the large chain is tensioned, until the slack

is about 5 mm.

5) Tightening the chain wheel (B1)

6) Tightening the nuts for the gear motor (A2), so that the chain is tensioned, until

the slack is about 2-3 mm. Tighten the nuts (A1) again.

7) Replace the cover.

NOTE!

Check the location of the inductive switch (see 7.2) and check that the large chain is

tighened correctly in the whole rotation area after adjusting the chains.

A2

Axle for gear

motor

22

Max. 2-3 mm

A1

Axle for chain

wheel

B1

B2

7.0 Justering af Rotator

7.2 Adjusting the switch (ELFRRE/ELFSRRE)

The location of the reel carriage is decided by two inductive switches.

A) Inductive switch on thrust ring indicates when the

reel carriage is in position 0°.

A

When the reel carriage is in position 0°, the

inductive switch has to be placed right above the

indication pin on the thrust ring in a distance of

2-4 mm.

B) Inductive switch on the teeth of the little toothed

wheel. The number of the impulses indicates the

angle of the reel carriage.

The distance from the

inductive switch to the

tooth has to be 2-4 mm.

Inductive

switch

2-4 mm

B

7.3 Lubrication

Support bolts

To support the thrust ring, two support bolts are

placed behind the ring.

The bolts must only just touch the ring, and the

back of the ring has to be lubricated with grease,

so that the bolts slide smoothly.

Chains

The chains of the Reel Rotator have to be

lubricated at the yearly service check.

23

8.0 Fault location key

When the Reel Rotator is used every day, adjustments and the replacement of worn

parts might be necessary.

Adjustments and minor repair can easily be made on the spot. Major repairs should,

however, be carried through by the dealer who has a well-trained staff and the

necessary special tools.

Before asking the dealer for assistence...

...try the fault location key!

SYMPTOMS AND OBSERVATIONS

A Pump does not run when the UP button is pressed

B Truck does not lift when the UP button is pressed

C Truck does not lift to max. height

D The reel carriage lowers after being raised

E The reel carriage does not not lower when DOWN button is pressed

F The reel carriage cannot be lowered fully

G Truck is unable to lift the max. load

H Truck lifts slowly

I The reel carriage does not lift horizontally

J Steering wheel does not drive evenly

Cause Mending

A

B

C

D

E

Oil deficiency

Battery discharged

Fuse blown

10 Amp or 100 Amp

Cables defective

Max. load exceeded

Air in hydraulic system

Pressure relief valve

incorrectly adjusted

Leakage in hydraulic system

Visible oil leakage

Reel carriage needs

adjustment

Solenoid or check valve

defective

Defective valves

in pump

Steering wheel out

of adjustment

Defective

solenoid valve

See point 6.1/6.2

See separate

instruction

See point 5.1

See point 5.2

See point 4.1

See point 6.6

Contact

the dealer

Contact

the dealer

See point

6.3/6.4/6.8

Contact

the dealer

Contact

the dealer

See point 6.5

Contact

the dealer

F

G

H

I

J

If the problem cannot be

solved by using the fault

location key...

...please contact

your dealer!

25

9.0 Good service after purchase

9.1 Ordering spare parts

The correct spare parts are obtainable from your dealer.

When ordering, please state:

• Serial number of the product

• Type and width/length of the product

• Spare part no. Please nd spare part no. on www.logitrans.com

9.2 Warranty/Compensation

Spare parts delivered during the warranty period will be invoiced. A credit note will

be sent immediately after we have received and tested the defective parts and

found that the warranty conditions have been met.

9.3 Service and repair

You should be able to make adjustments and perform minor repairs on the spot.

However, major repairs should be left to the dealer who has well-trained personnel

and the necessary special tools.

9.4 Warranty

The warranty covers material and assembly defects which, subject to inspection by

us or our representative, are deemed to be faults or deciencies that prevent normal

use of the parts concerned. Such affected parts shall be sent to your Logitrans

dealer carriage paid within the warranty period in force at the time in question,

together with a copy of the documentation for the service performed

(B284 - see the back page). The warranty does not cover normal wear and

adjustments. The warranty period is based on singleshift working.

The warranty shall no longer apply if

• the product has been used incorrectly,

• the product is used in environments for which it was not designed,

• the product has been overloaded,

• replacements of parts have been made incorrectly or original parts have not been

used and consequential damages have arisen,

• if the product is changed or accessories, not being approved by Logitrans, are used.

• it can not be proved that a qualied technician has performed the service check

according to the requirements stated in the instruction manual (see the back page).

9.5 Liability exemption

The manufacturer accepts no responsibility for personal injury or material damage

arising from deciencies, defects or improper usage. The manufacturer accepts

no responsibility for lost earnings, operating losses, lost time, lost prots or similar

indirect losses incurred by the purchaser or a third party.

26

27

Periodic service and safety inspection

Service check is required once each year.

Safety inspection should be performed by the dealer or other qualied

persons at least once each year, unless local regulations state

otherwise.

The safety inspection to be performed on the basis of form no. B0342

and proved on form no. B284. Forms and instructions for the safety

inspection are available at your dealer.

S 995

ELRR-L-EN

16022016

28

Loading...

Loading...