HTR

TEMPERATURE RECORDER

(0 ÷ 300°C)

Code 0KLC50BA

Rev.1 dated 16-06-2014

INSTALLATION AND USE MANUAL

1

INDEX

Technical features page 3

Accessories supplied page 3

Accessories on request page 3

Caution page 4

Electrical drawing page 5

Programming page 6

Messages and alarm codes page 11

Enabling the device to record page 12

Download data page 13

Cleaning the device page 14

Disposal page 14

Warranty page 14

Edition list page 14

CE Declaration page 15

Rev.1 dated 16-06-2014

2

TECHNICAL FEATURES

• Power supply: 230 V ~ ± 15 % - 50/60Hz

• Consumption: ~ 25 mA

• Protection degree:

IP64 for the frontal panel

IP20 for the other parts

• Working temperature: -5 ÷ +50°C with 90% RH non condensing

• Storage temperature: -20 ÷ +60°C

• Box material: black-grey ABS auto-extinguishing (V0)

• Connections: via terminal block to wires

• Nr. 6 key buttons

• Nr.2 inputs for PT 1000 temperature probes, working range: 0 ÷ +300°C, precision

± 3°C

• Nr.1 USB Host output for downloading flash memory driver USB

• Visualization through back-light graph LCD (128 x 64 dots)

• Nr.1 time-keeper, precision 0,1%, buffer battery non rechargeable electrical life over

10 years

• Capacity flash memory: (loop buffer: last data overwrite on the first one):

• ∼170.000 records by 1 sensor connected

• ∼ 85.000 records by 2 sensors connected

• Nr.1 input for detection door micro-switch open (free contact)

• Nr.1 relay 1 A- 250V~ with free contacts for remote alarm

• Nr.1 input for buffer battery to grant continuous recording over 12 hours in case of

power off (see technical features on electrical drawing page 5).

• Nr.1 serial port RS232 for connection to Logika GSM module or Modbus

Attention: when the recorder is powered by buffer battery, download data is

not allowed

• Settable parameters:

1. year – month – day – hour – minutes

2. language: Italian, English, French, German, Spanish, Greek, Portuguese

3. User company title

4. ID recorder

5. Analogue inputs

6. Records interval: 1÷ 240 minutes

7. Positive and negative alarm for each analogue channel

8. Delay alarm: 1÷ 60 minutes

Weight: ~ 1.200 g

Accessories supplied:

Nr.1 “USB Flash Drive” including instruction manual and Windows™ application for data

processing as graphic and/or statistics.

Accessories on request:

- Temperature probes PT1000 code BSTW0015

- Buffer battery code 0KLC946A

- GSM module code 0JLC5L5B

Rev.1 dated 16-06-2014

3

4

Integrated version

Fixing hole

CAUTIONS

Logika Control informs every modification or tampering on HTR and/or operations in

disagreement with the manual void both the warranty and the original CE declaration.

Remember: the technical data are related to HTR (

drawing/pictures and any other document are property of Logika Control s.r.l. which

reserves all rights; before the installation, the user is obliged to check the electrical plant is

in accordance to the nominal power supply of HTR (

The product is developed in environment with pollution degree 2.

The product can not be used as safety device.

HTR is not intended for use in potentially explosive atmospheres.

Only qualified LOGIKA personnel may carry out technical support on this product.

SEE TECHNICAL FEATURES – PAGE 3

SEE TECHNICAL FEATURES – PAGE 3

), the

).

Overall dimensions of the device (mm)

Versione integrata

The electrical connection must be carried out by authorized personnel according

the electrical drawing below and related legend and in power off status, so pay

attention the isolator switch that HTR depends on the power supply is in OFF

position.

ATTENTION: the connection to the electrical grid must be carried out as last

operation.

Rev.1 dated 16-06-2014

5

ATTENTION

ELECTRICAL DRAWING

LEGEND

Terminal M1

poles 1-2 = power supply 230V~

Terminal M2 (serial port RS232)

pole 1= GND

pole 2 = TX

pole 3 = RX

pole 4 = out Vdc = 4,7 V

Terminal M3

pole 1 (negative) – pole 2 (positive) = buffer battery

Terminal M4

poles 1-2 = temperature probe – zone 1

poles 3-4 = temperature probe – zone 2

Terminal M5

poles 1- 2 = door micro-switch

Terminal M6

Alarm relay poles 1, 2: max. current 1A - 250Vac. with free contacts; pay attention alarm

status comes when relay’s coil de-excited, it means on poles 1 and 2 (C – NC).

For the connection to GSM module (code 0KLC5L5B), use a shielded 3 poles cable AWG22

with max. length no more than 2 m (see connection drawing below).

In case of power off during records in progress, the following events could happen:

1 – If the buffer battery is not connected: the recording stop, the alarm relay start to signal the alert event

2 – If the buffer battery is connected: it starts working granting the recording for around 12 hours time, the

back-light switches off and the download data is not allowed.

Rev.1 dated 16-06-2014

6

PROGRAMMING

To program HTR and enable the recording, follow the instruction reported below.

Once HTR is powered, the LCD visualizes the following message for few seconds:

HTR

by Logika Control

V. 00x (firmware release)

and then visualize the picture nr. 1 below.

NOTE: after 3 minutes from the last pushing of a button, the back-light of the LCD switches

off to switch on again once any button is pushed again (energy saving).

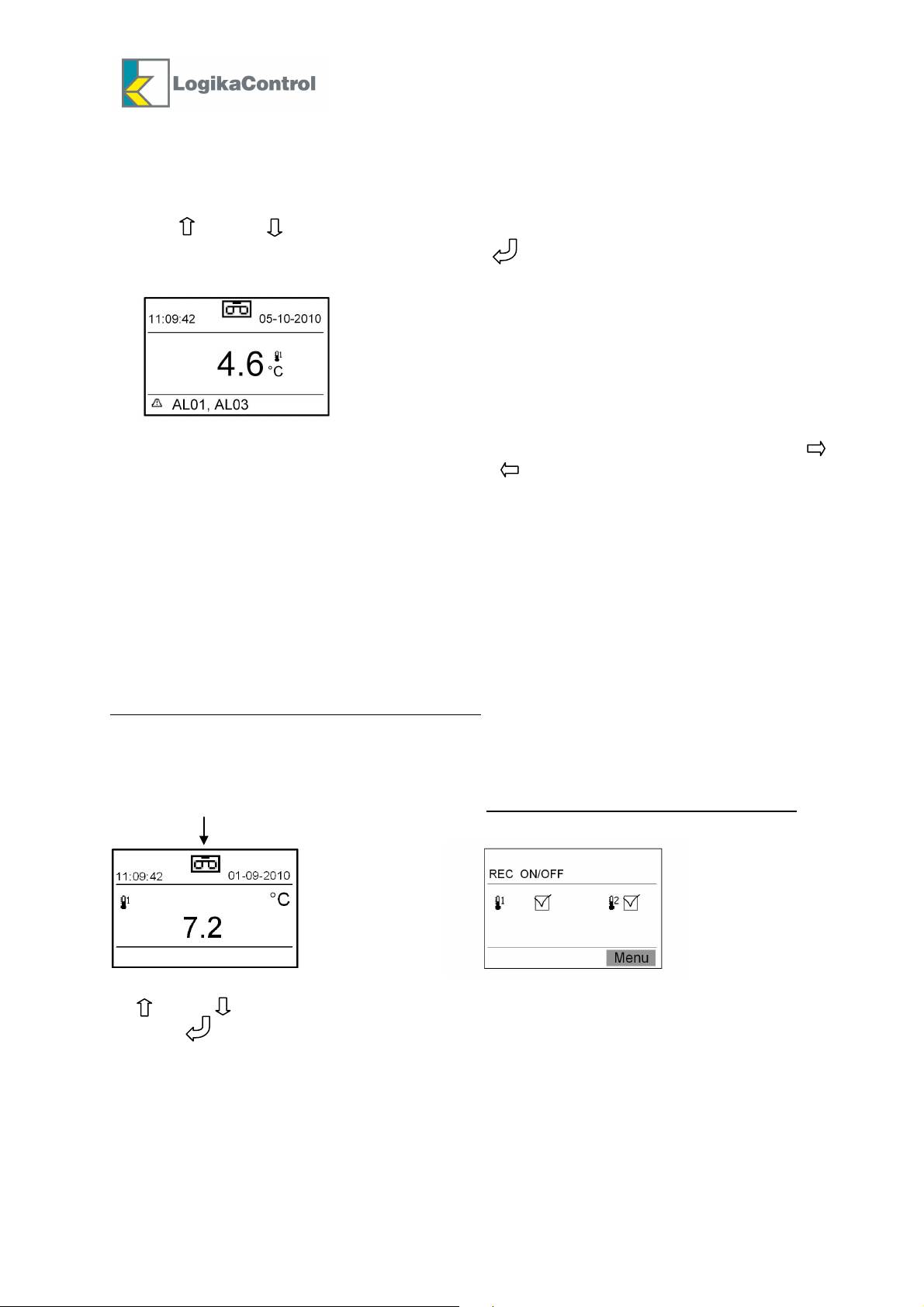

Picture nr.1: visualization with one temperature probe selected

On upper corners of the LCD are visualized the time (left) and the date (right)

Pushing (Menu) you enter into the programming device and visualization of the different

functions: flow up/down the functions through and ; once the function is selected,

confirm by .

After 3 minutes inactivity on the key buttons the visualization shift back to the

main menu automatically.

Programming functions

1. Visualizations

2. Setting

3. Records

4. Reset

5. Info

6. Communication

Rev.1 dated 16-06-2014

7

10:23 Thu 12/07/2007

°C

Visualizations 1-1

Visualizations 1-1

Italian

DST/Standard time = YES

By the buttoons and/or select the function to set and it will be visualized as reverse

(from positive to negative):

= language: Italian, English, French, German, Spanish, Greek, Portuguese –

default English

= temperature scale: °C / °F – default °C

= display contrast according ambient light where the recorder is installed

= time and date setting with possibility to switch between DLS and Standard time

where:

YES: the recorder updates the time automatically

NO: the updating DLS/Standard time is not operated

Once the function is selected by pushing the setting is enabled and the function starts

blinking: by the buttons and/or set the new data and confirm by (the function

stops blinking); after last setting the visualization shift back to the previous one.

Setting 1- 2

By the buttons and/or select the function to set and confirm by : the square on the

right starts blinking; till by and/or set the new value and confirm by ; push ESC

to shift back to the main visualization.

P01 – Company title: in the square on the right, name reported on the printing data); max.

15 alphanumerical characters; setting comes through and/or for each letter or number

(keep on pushing for fast-forward) and confirm by (the square moves on the right); at

the end of setting pushing twice (two white spaces enter) to confirm the name and quit;

in case of wrong typing, pushing ESC the cursor shift back to the previous character; keep

on pushing for about 2 seconds to cancel all the characters on the right and confirm the

last one entered.

P02 – ID Recorder (for example: cell name): in the square in the right set the code/name

will identify the recorder (name reported in the printing data); max. 15 alphanumerical

characters and the setting procedure is the same for company title as well.

P03 – Record interval (time to pass between a recording and next one): in the square on

the right is possible to change the default value (30 minutes): setting range 1 ÷ 240

minutes.

NOTE: the parameters P1-P2-P3 is required to be configured otherwise the records

can’t be downloaded to the PC through the software application.

P04 – Enabling the probes connected: in the square n the right is possible to change the

default value: T means temperature probe

1= probe T1 – default

2= T1+T2 – visualization of the parameter P07 and P08

P05 – High temperature alarm related to the probe T1: in the square on the right is

possible to change the default value 300 °C (alarm disabled): setting range 0 ÷ +300 °C.

P06 –Low temperature alarm related to the probe T1: in the square in the right is possible

to change the default value 0 °C (alarm disabled): setting range 0 ÷ +300 °C.

Rev.1 dated 16-06-2014

8

P07 – High temperature alarm related to the probe T2: in the square on the right is

possible to change the default value 300 °C (alarm disabled): setting range 0 ÷ 300 °C.

P08 – Low temperature alarm related to the probe T2: in the square in the right is possible

to change the default value 0 °C (alarm disabled): setting range 0 ÷ +300 °C.

NOTE: when temperature rise up or goes down the setting value, the timer related to

parameter P09 starts; once it’s over if the temperature is still over (up or down) the setting

value, the LCD visualizes the related alarm code and the alarm relay de-excites.

P09 – Alarm (positive/negative) delay: in the square on the right is possible to change the

default value 30 minutes: setting range 1 ÷ 60 minutes.

P10 – “Door open” alarm delay: once this time is over if the door input is still open, the

LCD visualizes the code alarm and the alarm relay de-excites; in the square on the right is

possible to change the default value 0 minutes (alarm disabled): setting range 0 ÷ 60

minutes.

NOTE:

1) If you need to set one or more parameter P05 ÷ P08, they have to be enabled once the

refrigerator reaches the working temperature only.

2) If you enter into the setting, try to change any parameter but the memory keep data not

downloaded yet, the LCD visualizes the message “DONWLOAD MEMORY”: in this case, stop

the recording and change the setting value once you’ve downloaded the memory only.

Records 1- 3

Visualization and/or print of the records stored into the memory for a defined period.

From: day – month – year

To: day – month – year

By the buttons and/or set the start/end date: every date must be confirmed by ;

after last data the LCD visualizes the followings:

1 – Visualization (see example of visualization)

2 – Download (it’s shown when the USB key is IN only)

By the buttons and/or select the function needed and confirm by .

If “Visualization” has been selected, the LCD visualizes all the records, eventual alarms

detected and the changes of any parameters (if any) with related date; flow up/down by

and/or ; by shift back to the main visualization.

If “Download” has been selected, push the related data for starting download data.

Example of “Visualizations”

The first page reports the date of the event on the upper left corner and the data of the

event in the next one.

1) example of visualization of the records with three analogue channels enabled

12/11/10 T1[°C] T2[°C]

12:15 14.5 3.5

2) visualization of the events

12:00 START REC T1-T2 (start recording)

12:00 STOP REC T1-T2 (stop recording)

12:45 AL05: Probe T1 failure (alarm activation time with related code and sliding

description for limited space)

13:08 P05 150°C (modification time of a parameter with new value)

13:18

17:52 12/11/10 (change of date and time)

Rev.1 dated 16-06-2014

9

Reset 1-4

This function allows to enable the following reset (protected by password max. 4 numbers –

default 0000):

Confirm the function by and the LCD visualizes:

Enter Password

by the buttons and/or enter the first number and confirm by to shift to the next

one (the number just entered is changed into the symbol *); after the fourth numer and

the password is right the LCD visualizes the following messages:

Setting – Records – Change Password

In case of wrong typing by pushing simultaneously it’s possible to shift back to the

previous number; if the password is wrong the LCD visualizes for few seconds the blinking

message “Password Wrong” and shift back the visualize “RESET”.

1 – Setting = the recorder returns to factory setting, before the installation; this function is

allowed if there is not any data into the memory only; in case of data into the memory the

LCD visualizes the message “DONWLOAD MEMORY”.

2 – Records = erase the records memory; this function is allowed if there is not any data

into the memory and no recording in progress only; in case of data into the memory the

LCD visualizes the message “DONWLOAD MEMORY”.

Select the function needed and confirm by : the LCD visualizes the message:

“Are you sure ?” and “NO”(visualized as reverse) / “YES”

If “YES” is confirmed by the blinking message “Resetting” is visualized to indicate reset

in progress; once reset is finished the LCD shift back to the previous visualization.

If “NO” is confirmed by the LCD shift back to the previous visualization.

3 – Change password

Confirming by the password setting is shown again: enter the new password according

the same procedure and the new password will be typed once requested into the Reset

function.

NOTE: it’s advisable to change the default password number in case the device is used by

personnel not authorized to this function.

PASSWORD MISSED?

In case of password missed/forgotten, take power off; supply power again keeping the

buttons and simultaneously pushed for 5 seconds while the LCD visualizes the blinking

message “D.P.L.” (loading default password).

To enter into the Reset menu now you have to enter the default password “0000”.

----

Rev.1 dated 16-06-2014

10

PIN

Info 1-5

Into this function you can read:

- firmware version

- company title and ID recorder (setting data)

- buffer memory status (%)

Communication 1-6

By the buttons and/or select the desired function and confirm by .

Communication allows to visualize/change the following parameters:

P20 - Mode: MODBUS default) or GSM

a) When MODBUS is selected, the parameter P21 is visualized only

b) If GSM is selected (the display visualizes “GSM = 00000” where you have to enter

the SIM number placed into the module – just as reminder) the display visualizes the

parameters P22÷P26.

P21 - 1 ÷ 32 (default 1): Modbus address of each unit in the net.

P22 - GSM phone number = 000000000

P23 - PIN code = 0000: if pin code is not enabled, leave 0000 (see alarm)

P24 - SMS Dest. 1 = 000000000: enter the phone number of the 1st cell phone

P25 - SMS Dest. 2 = 000000000: enter the phone number of the 2nd cell phone

P26 - SMS Dest. 3 = 000000000: enter the phone number of the 3rd cell phone

NOTE:

GSM selected

a) When an alarm is detected by the recorder, the GSM will send an SMS to the cell phones

set with the following information:

Company title – Recorder ID – probes selected – Alarm codes detected.

In case of power off and recorder powered by buffer battery, the GSM will send the

information above further to the message “ON BATTERY”; once the main power is restored

the GSM will send another SMS with the message “POWER OK”.

b) By sending from an SMS with word “STATUS” (it doesn’t matter capital letter or note)

from any cell phone to the GSM module, the GSM will reply automatically with the message

“NO ALARMS”, in case of no alarm detected or related codes in case of alarm detection.

Symbols reported on the right low corner of the display of HTR connected to a GSM module:

Antenna: the GSM is connected.

Net coverage: if this symbol is blinking, it means there is not net coverage so the

GSM module has to be placed in another position.

Max. distance between HTR and GSM module no longer than 3 meters.

It blinks in case you enter a wrong pin code: in this case quit the programming,

switch off and then switch on the HTR, enter the pin code again to avoid after 3rd

wrong attempt the SIM card lock and you have to enter the puk code to unlock.

General error: replace the GSM module.

Modbus selected

in this case it is possible both monitor the temperature and download data recorded by the

several HTR connected in the net.

Rev.1 dated 16-06-2014

It blinks when the SIM card is not in.

: units connected as serial net and software application installed on the PC;

11

Visualization with two temperature probes

MESSAGES AND ALARM CODES

Messages

“Download data” due to:

a) memory full (loop memory: once it’s full overwriting starts; last data erase the first one).

b) change a parameter while data to download into the memory: disable recording and

download the data before to modify any data.

“Push button download data”: when the USB key is IN.

“Download data” (with progress bar and related %: download data in progress.

“Drive USB key – Completed” (blinking): download data over.

“Drive USB key – Error” (blinking): download data not succeed; check if the USB key is

failure or full.

“Change time DLS/Standard time”: informs about change time.

Alarm codes

AL.00 = flash memory error: the LCD visualizes the message OFF; replace the recorder.

AL.01 = timekeeper failure: after download data the LCD visualizes the OFF; replace the

recorder. The printing data reports the message “timekeeper failure”.

AL.02 = Power OFF (missing power): the printing data reports the time when power off

comes; this alarm is detected if the buffer battery is connected and the recordings are in

progress only.

AL.03 = Power ON (restore power): the time when the power is restored is recorded into

the memory; the alarm is detected with recordings in progress only.

AL.04 = Door open: door input is open over the time set in the parameter P10: close the

door; the alarm is detected with recordings in progress only.

AL.05 = Temperature probe T1 failure: the printing data reports the related alarm code;

replace the probe.

AL.06 = temperature probe T2 failure: the printing data reports the related alarm code;

replace the probe.

AL.07 = high temperature alarm: temperature detected by T1 is over set P05; alarm

detected once timer P09 is over and recordings in progress only.

AL.08 = low temperature alarm: temperature detected by T1 is below set P06; alarm

detected once timer P09 is over and recordings in progress only.

AL.09 = high temperature alarm: temperature detected by T2 is over set P07; alarm

detected once timer P09 is over and recordings in progress only.

AL.10 = low temperature alarm: temperature detected by T2 is below set P08; alarm

detected once timer P09 is over and recordings in progress only.

AL.11 = Overwriting records due to memory full; download data.

Rev.1 dated 16-06-2014

12

R

ecord

s in progress

If one or more alarms are detected, the LCD visualizes the delta icon (generic alarm

symbol) and related code; the relay contact closes between the poles 1-2 of the terminal

M3.

Pushing and/or enter the alarm active list and you can flow up and down by the same

arrow buttons; it’s possible to reset the alarm by if the cause has been solved only.

Every alarm reports date and detection time.

All the alarms are reported in the printing data with related detection date ( )

and date the related casue has been solved ( )

In case of power off and buffer battery connected, the battery icon starts blinking;

in this status the download data is not allowed (automatically disabled).

ENABLING THE DEVICE TO RECORD

Once the programming is complete, the device is ready to record according the

following way:

Temperature probe T1 connected and selected:

By the button REC. you can enable and disable the recordings; when the recording is

enabled the LCD visualizes the temperature detected and the symbol for record in progress;

when the recording is disabled the LCD visualizes the OFF.

Probes T1+T2 connected and selected:

By the button REC. the LCD visualizes

By and/or select the zone you need to enable or disable (square blinking) the recording

and push to activate (election flag is shown) or deactivate it (selection flag disappear).

Push REC to confirm and the LCD visualizes the temperature of the zone enabled for the

recording with the related recording symbol or message OFF in case it’s disabled.

Rev.1 dated 16-06-2014

13

Complete

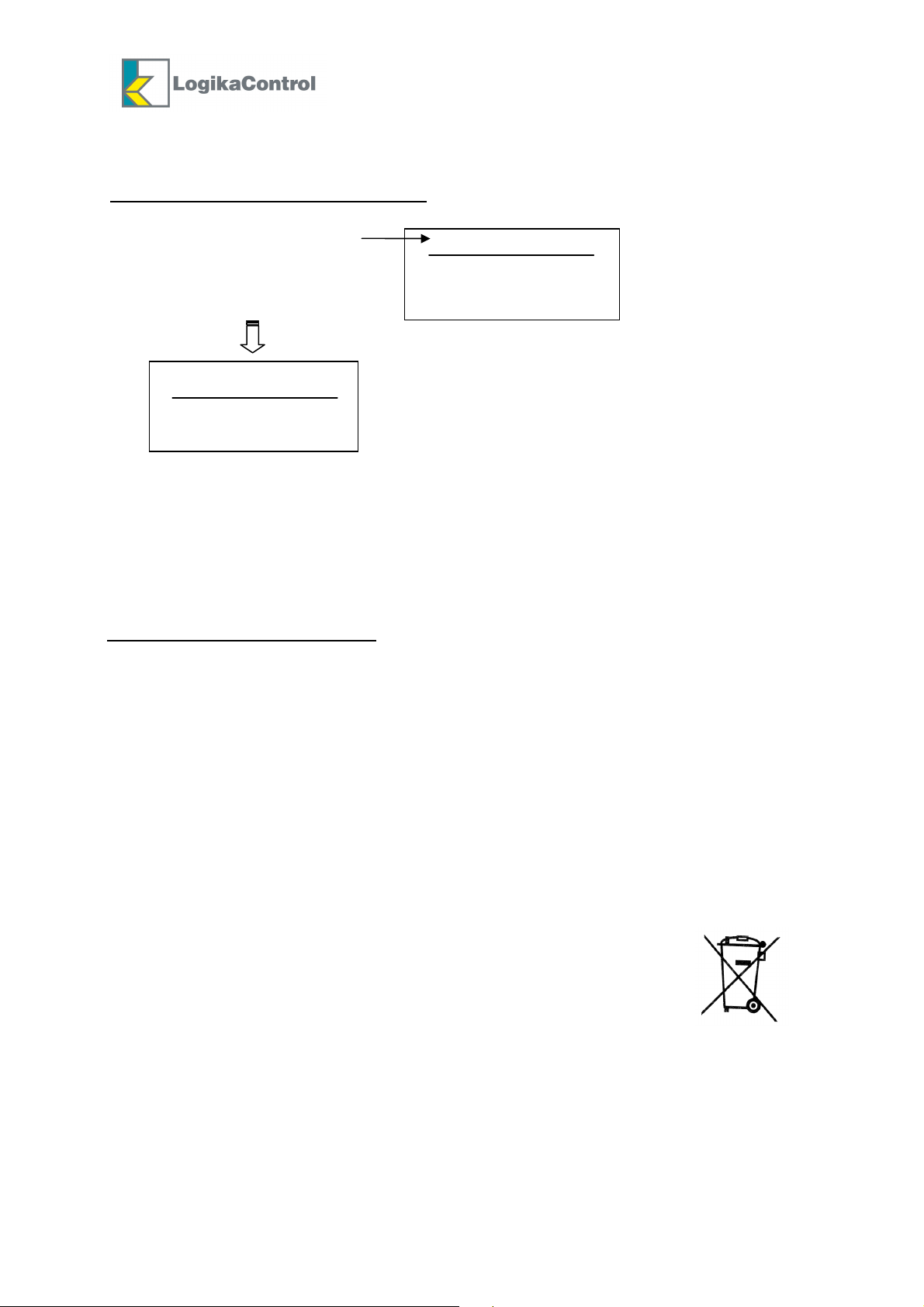

DOWNLOAD DATA

Operation allows by the main menu only

Insert USB key in the proper housing after you remove the cover cap (D).

The LCD visualizes the message

Push the button (near USB key) and LCD visualizes the message

Drive USB key

Push button

download data

Download

Drive USB key

Under the message “Drive USB key” is a bar indicating the download progress (%); at the

end of download the bar change into the message “Complete” (blinking).

Take the USB key out and remember to cover the housing with the proper cap to keep IP

protection of the device.

The file into the USB key is converted into a non changeable format by the PC to

avoid any tampering; original data are the ones into the flash memory of the

recorder.

USB FLASH DRIVE SUPPORTED

Flash drive USB supported: class 0x08 (Mass Storage Class), subclass 0x06 (SCSI

transparent command set) and protocol 0x50 (Bulk-Only Transport), formatted FAT16 o

FAT32 with sector dimensions 512 byte (windows default)

Different File system (example NTFS or different sector dimensions, example 1024byte)

CLEANING THE DEVICE

The plastic box cab be cleaned by no aggressive detergent while the front panel by a cloth

moistened with water and soap.

DISPOSAL

The HTR is composed by plastic, cables, printed circuit and electrical

components; for this reason it has not to be disposal in the

environment.

For a right disposal ask for specialized companies.

WARRANTY

HTR temperature recorders are covered by a 24-months warranty against all manufacturing

defects as from the production date printed on the label of the device identifying the year

by the first 4 characters, the week by the second 2 characters and the progressive serial

number with the last 5 characters.

Rev.1 dated 16-06-2014

14

In case you need to use the service assistance during the warranty period, the product must

be send back to the distributor you bought it paying attention it must be intact and packed

into its original package.

Customers are entitled to have defective products repaired, spare parts and labour included.

Transport expenses and risk shall be met entirely by the Customer.

Repairs carried out under warranty do not prolong or renew the warranty expiration date.

The Warranty does not cover the following cases:

- Damages resulting from tampering, impact or improper installation.

- Behaviour inconsistent with Manufacturer’s prescriptions and instructions.

- Damages caused by repairs made by unauthorized personnel.

In all above cases repair costs shall be charged fully to the Customer.

The Manufacturer cannot be held liable for any direct or indirect damages to animals, people

or things as a result of failure to observe all the instructions/information in the user manual,

especially instructions concerning installation, use and maintenance of the device.

For all matters not expressly indicated, the warranty is subject to the regulations contained

in the Italian Civil Code art. 1512.

The competent court for any controversies is acknowledged to be the “Foro Monza”.

Logika s.r.l. cannot be held liable for possible errors or inaccuracies written in this manual

as a result of printing or transcription errors.

Logika s.r.l. reserves the right to modify its products without prior notice as it deems

necessary without altering their main characteristics.

Each new release of Logika Control user manual replaces the previous ones.

EDITION LIST

Rev.0: 1st edition 02-02-2011

Rev.1: Modified electrical drawing due to mistake in the previous one 16-06-2014

Rev.1 dated 16-06-2014

Loading...

Loading...