Model PMP-716 Handheld Pyrometer

Operator’s Manual

Rev 1.2

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Contents

1. Introduction ...................................................................................................................... 2

2. Description ........................................................................................................................ 2

2.1 Operating Principle ................................................................................................. 2

2.2 Specifications .......................................................................................................... 4

3. Location ............................................................................................................................ 5

3.1 Sensor Location ....................................................................................................... 5

3.2 Sensor Aiming ......................................................................................................... 6

3.3 One-Color Mode ..................................................................................................... 6

3.4 Two-Color Mode ..................................................................................................... 7

4. Utility Connections ............................................................................................................ 7

5. Operation .......................................................................................................................... 9

5.1 Controls .................................................................................................................. 9

5.2 Set Parameters ...................................................................................................... 11

5.3 Status Information ................................................................................................ 14

5.4 Calibration ............................................................................................................ 14

5.5 Communication ..................................................................................................... 16

6. Notes .............................................................................................................................. 17

6.1 Environmental Temperature and Humidity ............................................................ 17

6.2 Maximum, Average and Minimum Sampling ......................................................... 17

6.3 Emissivity of Materials .......................................................................................... 19

6.4 Two-Color Slope Coefficient .................................................................................. 20

7. Maintenance ................................................................................................................... 21

7.1 Regular Maintenance ............................................................................................ 21

7.2 Returns of the PMP-716 ........................................................................................ 21

8. Dimensions ..................................................................................................................... 22

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 1

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

1. Introduction

The Logika Technologies Two-Color Handheld Pyrometer, Model PMP-716, is primarily used in

the metallurgical industry to measure the temperature of high speed wire rod, hot rolled steel,

molten metal and slabs/billets. Pyrometers are able to “look” into a process and measure the

target temperature from a distance, thus providing an accurate reading while eliminating

problems associated with contact measurements. Dual wavelength Infrared pyrometers are

able to overcome application challenges such as targets with a small cross-section, variable

emissivity, dust, water or other interfering media between the target and the pyrometer.

Accurate temperatures can be obtained even when the target is 90% obstructed.

The PMP-716 uses a visible laser to assist in aiming and a microprocessor to set up parameters

like emissivity, slope, response time, sampling mode etc. It also has an interior ambient

temperature compensation unit, which allows the instrument to work in temperatures of

0~50°C (32~122°F).

PM-716 is operated by a 9V 6LR61 battery. It also has real time data storage capacity which

can save up to 1000 data points.

2. Description

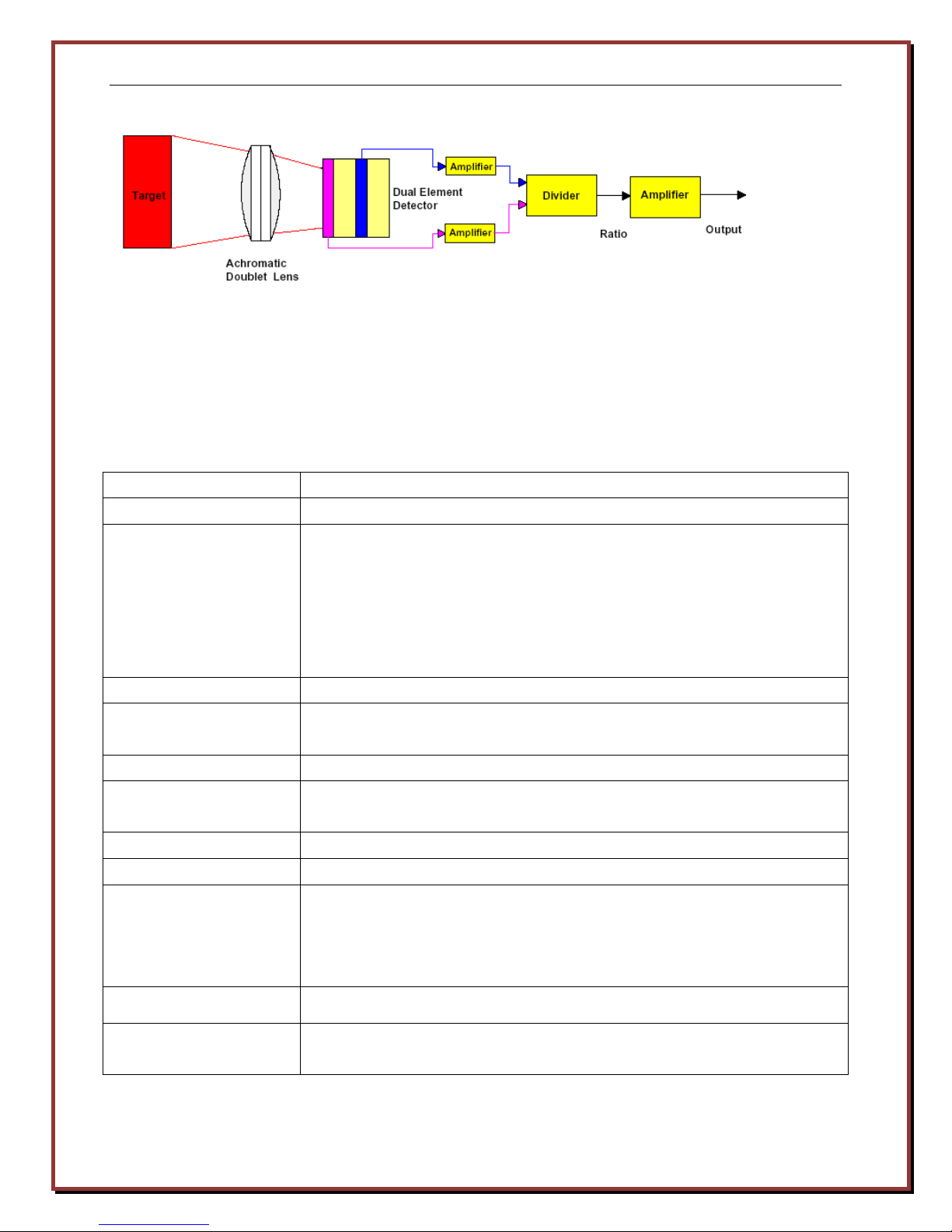

2.1 Operating Principle

This two-color (colorimetric) infrared pyrometer senses two adjacent infrared wavelengths

emitted by the target using a laminated photosensitive detector. By measuring the infrared

energy emitted from the target, the pyrometer calculates the ratio of these wavelengths to

determine the target temperature.

The primary advantage of Logika’s Two-Color Infrared Pyrometer over thermocouple

temperature measurements is that the pyrometer directly and instantaneously measures the

target temperature rather than inferring it based on the temperature of the atmosphere

surrounding the target.

The advantages of the Logika PMP716 two-color pyrometer vs. a single color pyrometer include:

• Overcomes optical fouling or interfering media between the target and the detector,

such as dust, dirt, smoke, and water vapor to yield accurate temperatures.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 2

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

absolute temperature.

• Automatically compensates for changes in target emissivity or varying distance from the

target to detector.

• The target does not need to fill the detector’s field of view to accurately measure the

target temperature, allowing flexibility of pyrometer location and target position

variability. An accurate measurement may be made with as little as 10% of the

pyrometer field of view used.

Notes:

• The energy from spectral radiation

increases with higher temperature.

• These curves do not intersect. The

spectral radiation has higher energy

at all wavelengths.

• Each curve has one peak, and these

peaks move towards shorter

wavelengths as the temperature

increases. (Color shift)

• In blackbody radiation, the emitted

energy is only dependent on

In one-color pyrometer, a single reading is taken and the temperature is derived from the

radiation energy. This works under the following conditions:

• If the emissivity is known and constant

• The object fills the entire field of view

• There is no interference from smoke or dust.

Two color systems measure the ratio of two readings and calculate the temperature from the

ratio rather than the absolute value of readings. This minimizes the effects of emissivity,

optical interference and partial views of the target.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 3

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

If the object remains at a stable temperature, the ratio of the radiation energy remains constant.

When the target temperature varies, the two wavelength ratio will remain the same. However,

the slope of the ratio change differs when measuring different objects (like metal and

non-metal), so a two-color slope coefficient is needed for correction.

2.2 Specifications

Measured range 700oC - 1600oC (1292oF - 2912oF)

Sensor Two-color laminated silicon infrared photocell

Field of View One-color mode: D/S=90:1

D is the distance between pyrometer and the target

S is the target diameter. See Figure 3.1 for more details.

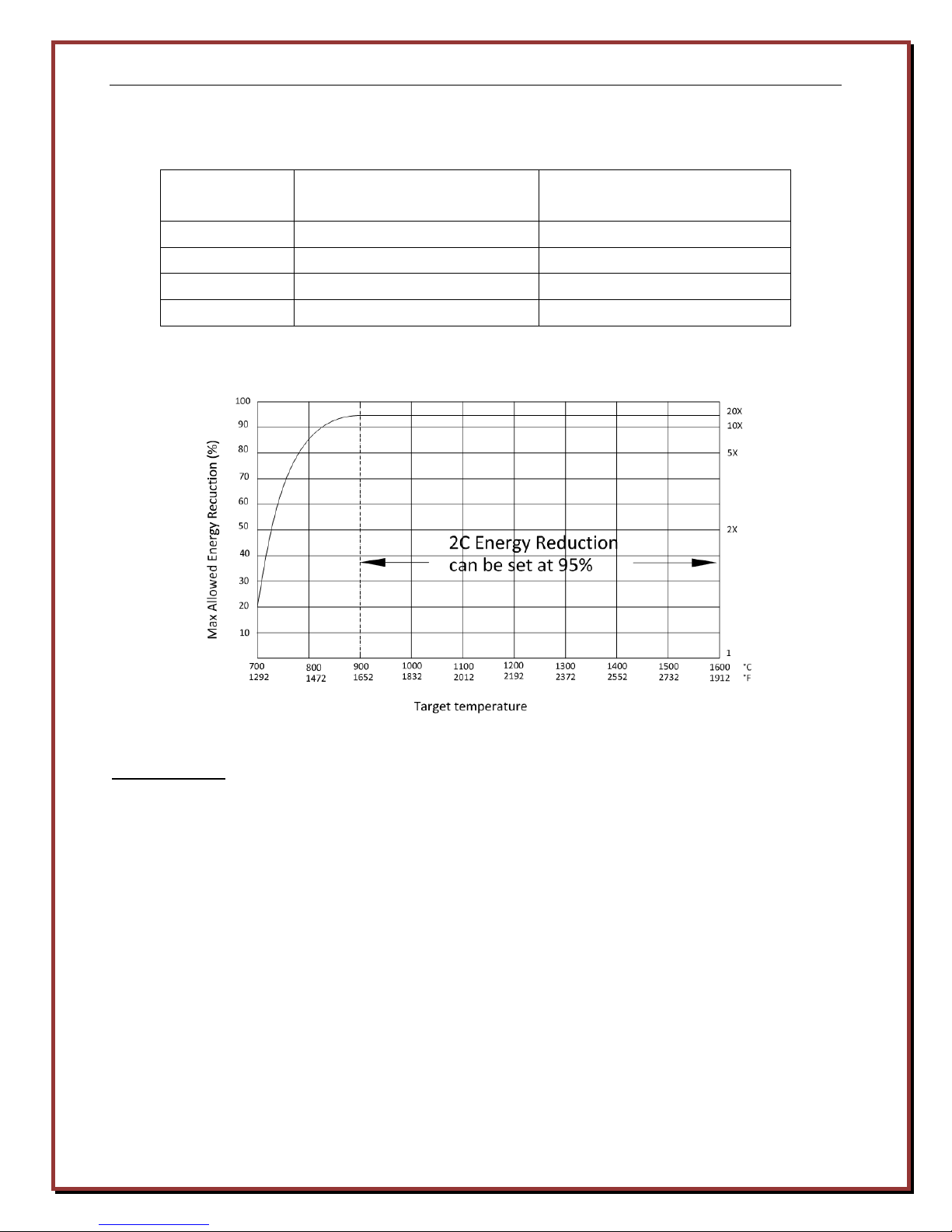

Two-color mode: No restriction for field of view. The target size can

be much smaller. If temperature is greater than 900°C, the

maximum signal attenuation ratio can be 95%.

Focal Range 0.5m to ∞

Accuracy ±0.75% full scale at ambient 23°C ±5% (73°F ±9%) and humidity of

35% to 75%

Repeatability ±2°C (±3°F)

Wavelengths One-Color: 0.75 ~ 1.1µm

Two-Color: 0.75 ~ 1.1µm/1.1 µm

Response time 100 ms

Display: LCD with backlight

Modes: Real-Time: 0.1 ~ 1.0s. At 1.0s it will average over a second

Maximum (Peak): 0 ~ 999.9s

Minimum(Valley): 0 ~ 999.9s

Average: 0 ~ 60.0s

Output: RS232: 9600, N, 8, 1

Power Input: One 9V 6LR61 battery

AC/DC adaptor, DC input range 9-24V

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 4

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Alarms: Adjustable high or low temperature alarm shows on display and

output via RS232

Ambient: Operation temperature 0 ~ 50°C (32 ~ 122°F)

Humidity 10 ~ 95%, no condensation

Deviation to reading at 23°C by ambient temperature:

-Two-Color Mode: ≤6°C(11°F)

-One Color Mode: ≤3 °C(5 °F)

Aiming Laser: Visible red 650 nm <3mW Class IIa

Internal Clock: Lithium battery up to 5 years life

Memory: 1000 Data points, historical data checkable

Storage temperature -20 ~ 50°C (-4 ~ 122°F)

Housing: Cast aluminum enclosure

Size: Enclosure: 230 mm L x 200 mm H x 70 mm W (9”L x 8”H x 2.75W)

Weight: 1.4 kg (3lbs)

3. Location

3.1 Sensor Location

The Logika PMP-716 Pyrometer should not be used above a heat source for extended periods of

time. Avoid direct exposure to water vapor or excessive dust or smoke

The Logika PMP-716 should be used close enough to the target to allow enough infrared energy

to reach the detector in order to provide a strong signal, but far enough from the target to

minimize the amount of heat that reaches the enclosure’s electronics.

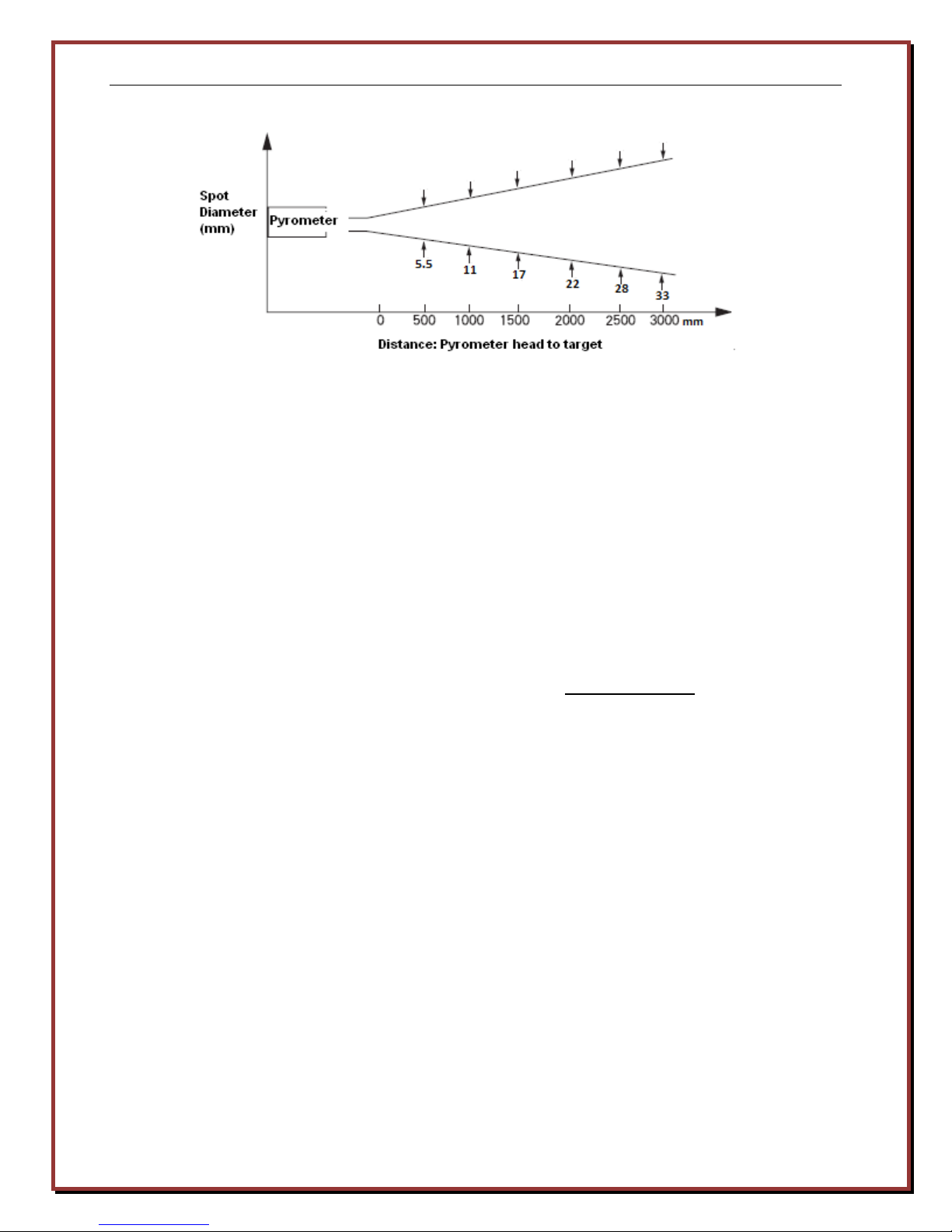

Use Figure 3.1 to determine the PMP-716 Pyrometer’s field of view based on its distance from

the target. Only the intended target should be seen inside the field of view. Other infrared

energy sources such as rolls, other wire or billets could interfere with accurate readings.

Example: The pyrometer measures the temperature of a 5 mm steel wire with adjacent wires

5 mm on each side of the target. Use Figure 3.1 to determine that the pyrometer may be

centered on the target wire and placed up to 1500 mm away from the target wire line (15 mm

total clearance from interference from other target wire lines).

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 5

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Figure 3.1: Pyrometer Distance Graph

3.2 Sensor Aiming

Use the pyrometer’s visible aiming laser to properly align the PMP-716 with the target.

Typically, the pyrometer should be centered on the target. At the same time, adjust the

detection spot by aiming laser to avoid interfering sources of infrared energy, including

reflection of hot metal or sunlight.

3.3 One-Color Mode

One-Color mode can be used to measure the average temperature in an area. The focal range of

the instrument is 0.5m ~ ∞ and the distance can be infinite as long as the measured area is large

enough. When selecting one-color mode, the object should completely cover the visual field;

usually 20% larger than the visual field.

This mode can be used for objects with level surfaces (no bending), with a viewing angle within

30° to the target’s surface. This surface should be physically and chemically stable (not in the

process of oxidation, gasifying or liquefying). The view to the object must also be free of

airborne particles and obstacles. When the background temperature is higher than the

measured temperature, One-Color mode can be used as long as the target fills the entire field of

view.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 6

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Figure3.2 One Color Mode Temperature Accuracy

3.4 Two-Color Mode

Utilized when:

• Measuring small objects

• Dust, vapor or fog in the environment

• Measuring distance changes

• Part of the object is obscured.

Two-Color temperature measuring mode measures the max temperature in an area regardless

of the size of target. Since the two sampled signals will vary at the same rate, the ratio

between the two signals will not change.

Two-Color mode permits the measurement angle to be smaller than 45°. When the background

temperature is higher than the target temperature, Two-Color mode is not recommended.

4. Utility Connections

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 7

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

DC Power Plug

RS-232 Plug

The unit uses a 9V non-rechargeable 6LR61 battery. Remove batteries if the unit is inactive for

an extended period of time.

It can also be operated with a 9-24VDC, >200mA power supply with polarity protection and

instantaneous over-voltage protection. When supplied from an external source, the unit

automatically disconnects the battery and runs continuously in External Power Mode.

The Communications plug allows the user to upload readings to a computer.

Battery compartment

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 8

Battery Compartment

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Time HH:MM:SS

Blank=No Alarms

“Recall” is Data

1C=One Color

5. Operation

5.1 Controls

The PMP-716 Pyrometer’s Control Panel is located at the rear of the enclosure.

Battery Status:

Black means OK.

White means Replace.

Date MM/DD/YY

“Scan” is Scan Mode

Real Time Temperature

in °C/°F

2C=Two-Color

LAL=Low Alarm Limit

HAL=High Alarm Limit

“Slope 1.00” means

Slope=1.0 in Two-Color

Mode

“ε=0.99” is emissivity in

“Average=1200” is

average value of

Temperature.

MAX is Maximum,

MIN is Minimum

Button function:

- “Laser”: turns the aiming laser ON/OFF.

- “Sys”

Press once: system information

Press twice: instrument calibration setup

-“Recall”: toggles between SCAN mode (running) and DATA Mode (replay) when pressed. It is

also used as an exit when modifying numerical parameters

-“Enter”: confirms the selection while in the parameter list. If pressed while in SCAN mode, it

stores the current reading. If pressed while in RECALL, it will display the most recently saved

reading. Pressing it a second time gives the option of deleting all saved readings or returning

to SCAN mode.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 9

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

-“Set”: steps through five pages of setup parameters. While on a parameter page, use the UP

and DOWN arrow keys to select a parameter, press “Enter” button to change it if it is a toggle

type parameter or “Recall” if it is a numerical parameter. Continue to click the “Set” button till

the RUN screen is again displayed. The changes will then be saved to the EEPROM.

-“▲ ” button moves the cursor up or increases the selected value

-“▼”” button moves the cursor down or decreases the selected value. In SCAN Mode, this

button will toggle between 1C (One-Color Mode) and 2C (Two-Color Mode). The instrument

will return to its default mode as selected in the parameters when power is cycled.

-“Power” button turns the pyrometer on and off .

Scan mode

Recall mode

Press “Recall”, toggle SCAN/RECALL

In “SCAN” mode, press “ENTER” can save

the data.

Data N0-N999, total saved 1000 data

After 1000 data, Save function is disabled,

all data must be erased to restore this

function.

In “SCAN” mode, press ▼ to switch 1C/2C

Press “Recall”, change to “RECALL”

mode. Now the time is still changing, it

is in RECALL idle mode. Press ”ENTER”

and change to RECALL run mode.

Press “▲ ” and “▼”” to look up the

number of saved data.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 10

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Recall mode changes to SCAN mode

In Recall mode press “ENTER”

Press “▲ ” and “▼”” to adjust

the cursor location, either select

delete all the data or EXIT

Press “ENTER” to exit

5.2 Set Parameters

Press “Set” button, enter parameters setup menu.

Press “▲ ” and “▼”” to adjust the cursor location

Press “ENTER” to select the parameter, and use “▲ ” and “▼”” to adjust the setup value

Press” RECALL” to EXIT

Parameter 1 - One-Color/Two-Color Operation: Toggles between 1 Color and 2 Color

measurement. Also changes by pressing “▼””

Parameter 2 - Emissivity: Only applies to One-Color Operation. See chart for typical

emissivity settings. Emissivity coefficient ↑0.01, Reading ↓1°C.

Parameter 3- Slope Coefficient: Only applies to Two Color Operation. Range from

0.800-1.200, increments 0.001. Slope ↑ 0.001, Reading↓ 1.2 °C.

Parameter 4 - Display: Toggles between Celsius and Fahrenheit.

Parameter 5 - Sample Mode: Choose between Max, Average and Min.

Parameter 6 - Sample Time: Max temperature: set the time 0.1~999.9s

Min temperature: set the time 0.1~999.9s

Average value temperature: set the time 0.1~60.0s,

The response time for average value is the time which the signal rises to 95%. Default is =1.0s.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 11

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Parameter 7 - Real Time Display Interval: The internal sample time is 0.1s. The setup range

for the real time display is from 0.1 to 1.0s. If set to 1.0s, the displayed value is the average

over the last ten readings (0.1s each).

Parameter 8 - Power Off Time: Default power off time is 10 minutes.

Parameter 9 - Light On/Off: LCD Backlight ON/OFF. Setup takes effect after the power is

OFF/ON.

Parameter 10 - Upper Alarm: HAL (High Alarm Limit) will be seen on the LCD display if the

temperature reading is higher than the setup value. Default is 1600°C.

Parameter 11 - Lower Alarm: LAL (Low Alarm Limit) will be seen on the LCD display if

the temperature reading is lower than the setup value. Default is 700°C.

Parameter 12 - 2C Energy Reduction: Allowed signal reduction value in two-color mode.

Setting range is 0~95%. When value >95%, it shows “OFF”, and the function is off. Default

is=95%. See chart below.

2C Energy Reduction is a threshold for verifying the validation of the measured temperature.

After the target temperature is calculated by the pyrometer, it calculates each wavelength’s

emissivity at this temperature. For each wavelength, the 2C energy reduction (100% –

Emissivity value) should not be lower than the set value. If either one is higher than the set

value, the LEDs display the lower limit temperature of the pyrometer.

This function is only used in two-color mode. The setup range is 20%-100% and the default

setup value is 95%. If the attenuation ratio is set greater than 95%, this function will shut

down; and again, the lower limit temperature will be displayed. For example, if the pyrometer

is used to detect the temperature of tungsten filament of a light bar, usually the temperature is

higher than 1500°C (2732°F). The tungsten filament (target) diameter is very small at 2mm, so

the emissivity would be very low. According to Figure 5.6, if the temperature is greater than

900°C and target size is 2mm, the 2C energy reduction should be set to 95%. This means that

as long as the emissivity value for each wavelength signal is not less than 5%, the calculated

temperature is valid. In this case, the two-color mode, can still accurately calculate the

temperature. In single color mode, it would be very hard to get an accurate target

temperature in this situation.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 12

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Target size

(Diameter)

Accurate measurement with

Energy Reduction value

Simplified measurement

with Energy Reduction value

2mm-10mm 95% 95%

10mm-30mm 90% 95%

30mm-100mm 80% 95%

>100 mm 70% 70%

Parameter 13 - Real Time Clock/Calendar:

Hour = 0 ~ 23

Minute = 0 ~ 59

Year = 2002 ~ 2099

Month = 01 ~ 12

Date and Day 01 ~ 31, “Mon” ~ “Sun”

Press “Enter”, then “▼”” to “Update Time” to save new settings.

The clock is maintained by a high capacity Lithium battery:

BR2330H2A, 3V, 255mAh

Under normal working conditions, the battery should last more than five years.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 13

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

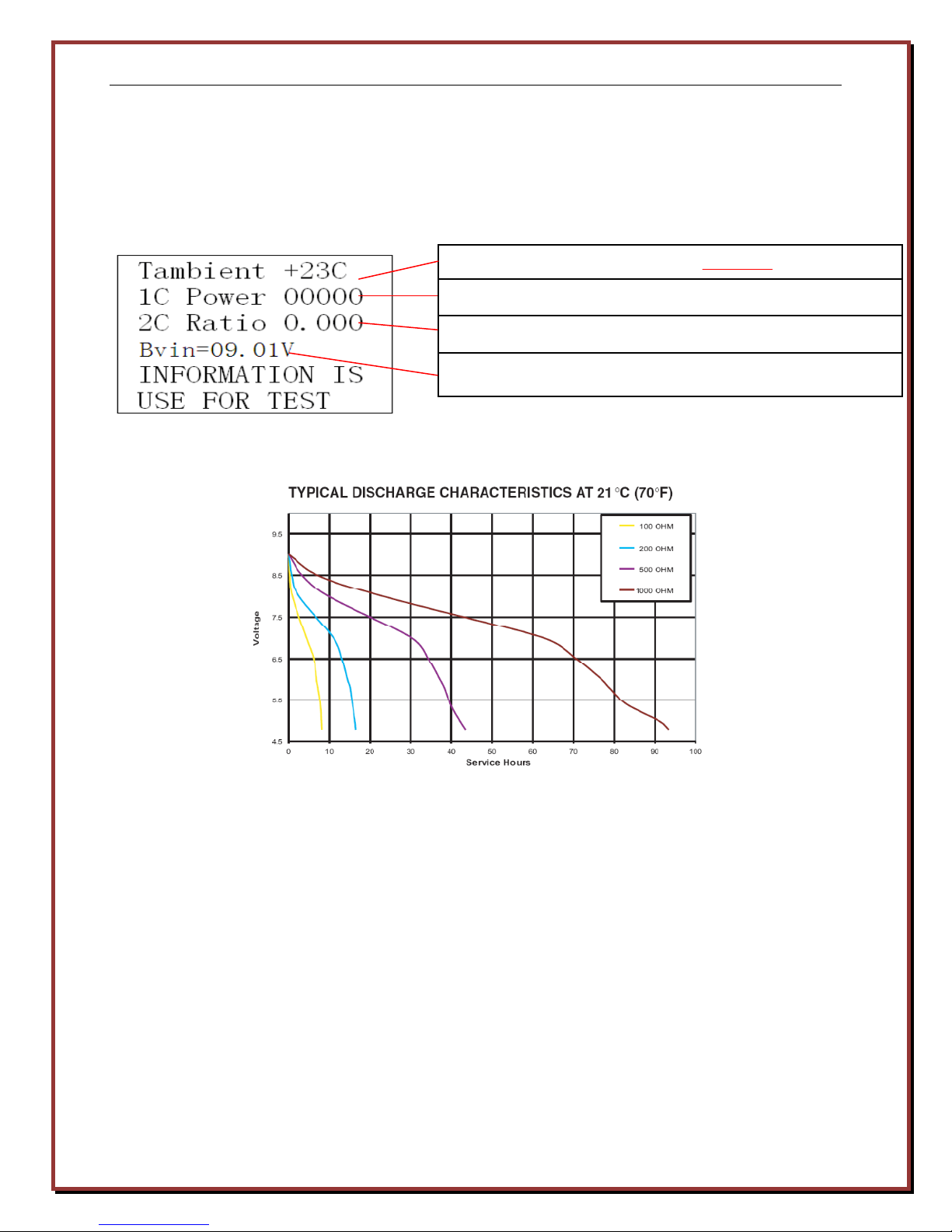

Ambient Temperature: C=

˚C, F=˚F

5.3 Status Information

Press “Sys” button once and it will display system information

One-Color signal energy from 16-bit A/D

Two-Color Signal Ratio

Battery voltage

9V Battery life and replacement

Battery life is determined by the status of the pyrometer. If the laser and backlight is on, the

pyrometer can work continuously for about 10 hours. When the power is OFF, the current

leakage is 1uA. When the battery voltage is low, the battery symbol changes to empty. In this

situation, all the parameters in EEPROM are locked and can’t be set until the battery is replaced.

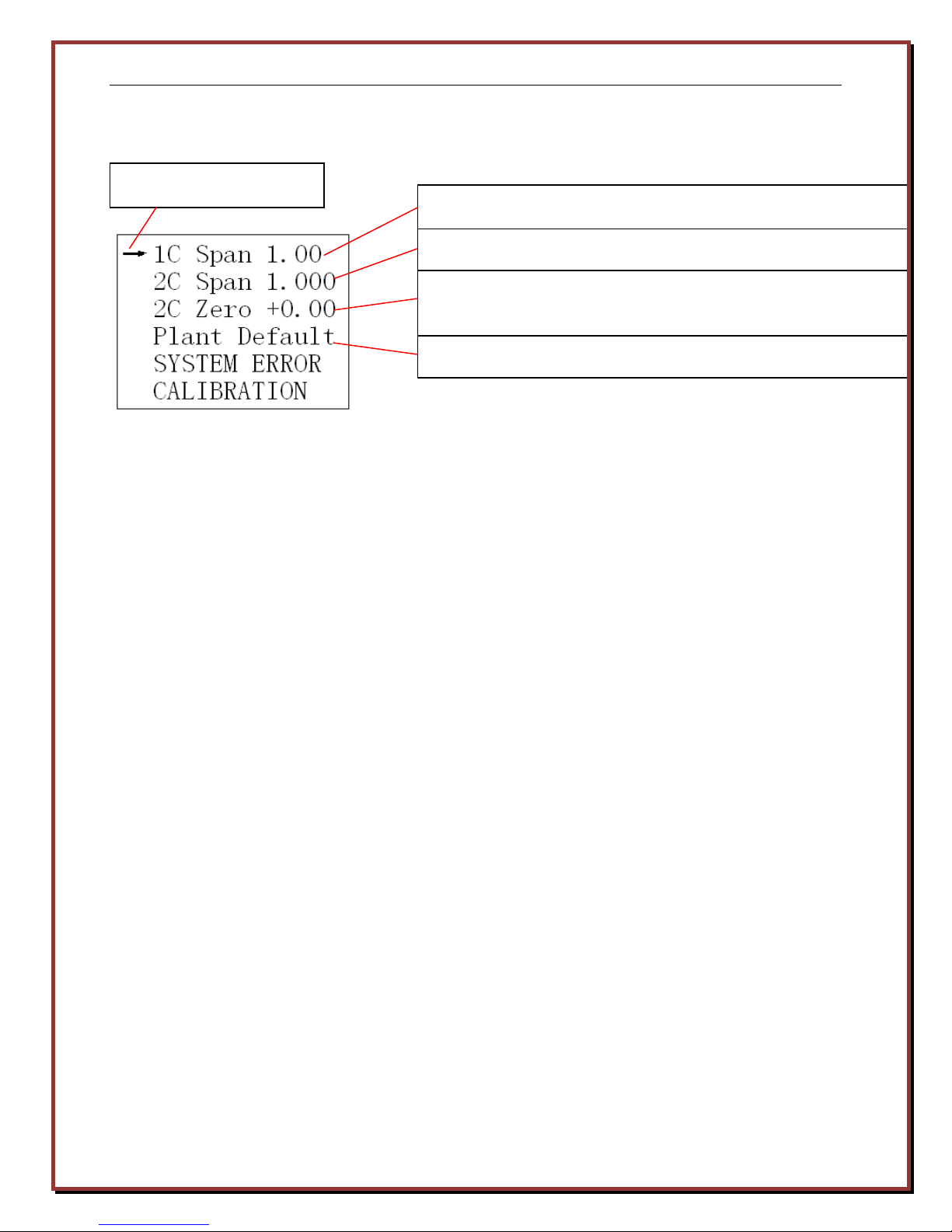

5.4 Calibration

The instrument arrives calibrated to a “Black Body Standard” that is traceable to NIST (National

Institute of Standards and Technology). The user may re-calibrate it to own in-house standards.

Press “Sys” twice, it will display next calibration menu

Press “Recall” to exit.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 14

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Location Cursor

One-Color Span Coefficient. Range 0.20 to 2.0. Default=0.30

Two-Color Span Coefficient. Range 0.500 to 1.300

Two-color zero-point compensation coefficient, setting range

-1.00 ~ +1.00 and default is < ±0.10.

Restores all three above to their factory defaults.

Manufacturer Test environment and conditions

Ambient temperature 23±5°C (41±9°F)

Relative humidity 35 ~ 75%

Atmospheric pressure 86kPa ~ 106kPa (12.5 PSI ~ 15.4 PSI)

Blackbody

Temperature range 500°C ~ 1600°C (932 ~ 2912°F)

Emissivity coefficient ≥0.995

Diameter 50mm

Measurements taken at 1m distance from the blackbody

The instrument should be recalibrated annually. During calibration, the surface temperature

of the blackbody is required to be stable and the blackbody oven tested by a Type B platinum

rhodium 30 / platinum rhodium 6 thermocouple or other standard thermocouple. Set the

one-color emissivity coefficient at 0.99-1.00, two-color slope at 1.000 as follows:

• One-Color span coefficient

Setting range 0.20~2.00, default =1.00, adjustment step 0.01, if coefficient ↑0.01,

temperature displayed ↓1°C. Calibration is done at above 2/3 of the instrument

measurement range, like 1200°C(2192°F). Adjust the blackbody to 1200°C, set PM716 to

one-color mode and compare the actual temperature of the blackbody with the displayed

temperature, adjust one-color span coefficient and make them equivalent.

• Two-Color Span Coefficient

Setting range 0.500 ~ 1.300, default =1.000, adjustment increments 0.001, if coefficient ↑0.001,

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 15

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

temperature displayed ↓1.4°C (2°F). Calibration is done at more than 2/3 of the instrument

measurement range, like 1400°C(2552°F). Adjust the blackbody to 1400°C, set PM716 to

two-color mode and compare the temperature of the blackbody with the displayed

temperature. Adjust two-color span coefficient and make them equivalent.

• Two-Color Zero-Point Compensation Coefficient

Setting range is -1.00 ~ +1.00, default <±0.10. Set the Two-Color span coefficient first.

Two-Color zero-point compensation coefficient is applicable for the instrument’s lower limit

temperature measuring section, such as 710°C (1310°F). Set the instrument to Two-Color mode

and compare the temperature of the blackbody with the displayed temperature value. Adjust

Two-Color zero-point compensation coefficient and make them equivalent.

5.5 Communication

Digital output: Format: ASCII, RS232, 9600 baud, 8 data bits, one stop bit and no parity check.

Data Transmitting Format

11:25:55 Space 07/10/12 Space

R1200C Space

Real-time

HH:MM:SS

MM/DD/YY

temperature,

Use C for“°C”,

Use F for“°F”

No.1 ~ 8 No.9 No.10 ~ 17 No.18

No.19 ~ 24 No.25

Space AVG1200 Space S1.00 Space

Average value 1200°C,

“S1.00” Two-Color

the unit is the same as

slope coefficient,

real-time temp.

“AVG” Average value,

“E0.95” One-Color

emissivity coefficient

“MAX” Max value,

“MIN” Min value.

No.2

No.30 ~ 36 No.37

No.38 ~ 42 No.43

9

2C

“2C”= Two-Color

mode, “1C”=

One-Color mode

No.26 ~ 28

NAL

“NAL” =No alarm

“HAL”=Hi alarm

“LAL”=Lo alarm

No.44 ~ 46

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 16

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Space

Name of internal instrument

No.47

PMP-716 Space

Serial number of instrument

No.48 ~ 54 No.55

6. Notes

6.1 Environmental Temperature and Humidity

Operating ambient temperature 0 ~ 50°C (32 ~ 122°F)

Humidity 10 ~ 95%, no condensation

Built in temperature compensation 0~50°C (32 ~ 122°F)

Deviation for readings at 23°C:

• One-color mode <3° C (5°F)

• Two-color mode <6°C (11°F)

SN1000 CR LF

No.56 ~ 61 No.62 No.63

6.2 Maximum, Average and Minimum Sampling

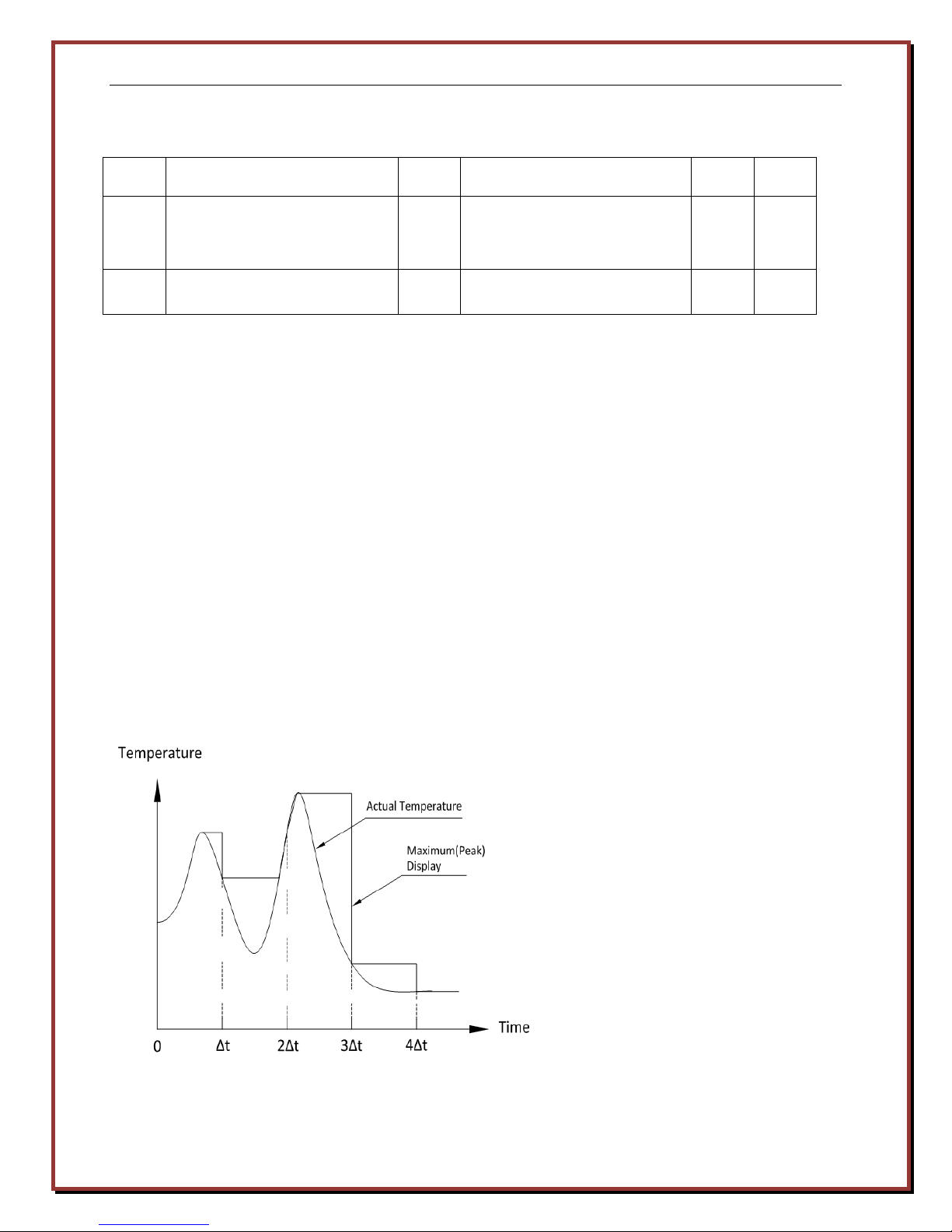

Maximum (Peak) Value Temperature Measuring Method

The holding time of a Maximum value can

be set through the buttons on the back of

the unit. The instrument will hold and

display the Max value of varying real-time

value in a selected time interval Δt.

Application: For measuring moving targets

(such as steel plate or steel wire).

Examples: The steel wire is vibrating; or

liquid metals when highest temperature is

required.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 17

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

lowest temperature is required.

Average value temperature measuring method

The average time duration can be set

through the controls on the back of

the unit. The instrument will calculate

and display the average value of the

varying real-time value in a selected

time interval Δt. This first-order RC

calculation can reduce the variation of

temperature.

Application: Ideal for most field

applications or if there is scale or

oxidation present.

Minimum (Valley) Value Temperature Measuring Method

The sampling period of Minimum

value can be set through the buttons

on the back of the unit. This

method functions similarly to the

Maximum Method, but holds the

minimum value instead.

Application: Measuring surface

temperature of liquid metals when

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 18

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Material and Status

Temperature Scope

(℃) Emissivity(about

1μm)

Steel:

Liquid state

0.35~0.45

Cast iron:

Liquid state

0.35~0.4

Stainless steel:

Oxidized through a temperature over

800℃

0.85

Copper:

Liquid state

0.15~0.21

Uranium

0.5~0.55

Hydrargyrum

(

liquid state)

0.2~0.25

Cobalt:

Roughened

with serious oxidation

0.7~0.75

Nickel

and its plate:

Roughened

with serious oxidation

0.8~0.9

0.8~0.9

Bismuth

0.34

Silver and Silver Plate P

late:

Roughened

with slight oxidation

0.15~0.35

Tungsten

(tungsten ribbon lamp)

1500

3000

0.3~0.39

0.3~0.36

Magnesium:

Roughened

without oxidation

0.1~0.2

Roughened

with serious oxidation

6.3 Emissivity of Materials

Material Emissivity Table

Polished without oxidation

Polished with slight oxidation

Roughened without oxidation

Roughened with slight oxidation

Serious oxidation

Polished without oxidation

Polished with slight oxidation

Roughened without oxidation

Roughened with slight oxidation

Serious oxidation

Smooth surface

Smooth slight oxidation

Serious oxidation

Iridium

Polished without oxidation

Polished with slight oxidation

Polished with serious oxidation

Roughened without oxidation

Roughened with slight oxidation

100~1200

100~1200

room temperature~800

100~1000

100~1000

100~1000

0.05~0.1

0.45

0.25~0.35

0.5~0.6

0.8~0.95

0.3

0.5

0.5

0.75

0.8~0.95

0.2~0.25

0.5

0.8

0.25~0.3

0.25

0.5

0.7

0.35

0.55~0.6

Polished without oxidation

Polished with slight oxidation

Polished with serious oxidation

Roughened without oxidation

Roughened with slight oxidation

Black nickel oxide 500~1000

Roughened without oxidation

Belt roughened without oxidation

Platinum:

Polished without oxidation

Polished with slight oxidation

Polished with serious oxidation

Roughened without oxidation

Roughened with slight oxidation

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 19

100~1000

100~900

2000

50~1000

0.25

0.8~0.9

0.35

0.1~0.25

0.3~0.37

0.25

0.4~0.5

0.4

0.5

0.3

0.4

0.3

0.4

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Platinum black

0.95

Tantalum:

Roughened

with serious oxidation

0.75~0.85

Palladium

0.33

Stibium

0.5~0.65

Beryllium:

Smooth oxidation

0.3~0.4

Brick

Silicon dioxide brick

1000

0.5~0.6

Alumina

Granularity

10~100 micron

1000~1500

Economet

:

Roughened

with serious oxidation

0.8~0.9

Carbon

Graphite

0~1500

0~1500

0.8~0.85

0.8

Polished without oxidation

Polished with slight oxidation

Polished with serious oxidation

Roughened without oxidation

Roughened with slight oxidation

White firebrick

Illinium

Granularity 1~2 micron

(Kermode)

Polished without oxidation

Polished with slight oxidation

Polished with serious oxidation

Roughened without oxidation

Roughened with slight oxidation

Carbon black]

100~1000

100~1000

200~1000

0~1000

0~1500

0.2

0.45

0.75~0.85

0.3

0.6

0.3

0.3~0.35

0.2~0.4

0.3

0.4

0.8~0.9

0.35~0.4

0.6

0.95

6.4 Two-Color Slope Coefficient

The slope is the ratio of the radiant energy from two adjacent wavelengths. Since the radiant

energy of both wavelengths will change in unison with emissivity, the emissivity factor is

eliminated.

The following slopes are approximations and will vary with the alloy material and surface finish:

For measuring the following oxidized surface metal materials, the slope is approximately 1.0.

Cobalt Stainless steel Nickel Iron Steel

For measuring the following metal materials with smooth, clean and non-oxidized surface, the

slope is approximately 1.03.

Cobalt Stainless Steel Nickel Rhodium Cast Iron

Tungsten Molybdenum Steel Tantalum Platinum

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 20

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

Unknown slope: To measure the temperature of other articles or materials, the slope can be set

according to the following steps:

• Use a trusted contact pyrometer or temperature probe to measure the temperature of

the target surface.

• Use average value mode of the pyrometer to measure the temperature on several

locations of the target.

• Adjust the slope of the pyrometer until the reading value equals the temperature of the

measured object.

7. Maintenance

7.1 Regular Maintenance

Regular attention to the following will ensure steady operation of the sensor:

Lens Cleaning- Routinely check the PMP-716 lens glass for dust or oil residue. When necessary,

clean the glass with alcohol and lens paper or soft cloth.

Calibration- Occasional calibration (see Section 5.4) will ensure that the accuracy of the

PMP-716 Pyrometer is maintained.

7.2 Returns of the PMP-716

Contact us at 1-888-856-4452 (1-888-8LOGIKA ) with the Serial Number of your pyrometer

before you return the product. If we are unable to solve the problem by phone or email, we

will then provide you with a return authorization number.

Do not return the PMP-716 without an authorization number.

If the product is out of warranty, we will provide a repair estimate and then complete the

repairs after your approval.

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 21

Logika Technologies Inc. Model PMP-716 Operator’s Manual Rev 1.2 Aug-13

8. Dimensions

Web: www.logikatech.com Phone: 905-829-5841 Fax: 905-829-8787 Email: info@logikatech.com

P a g e | 22

Loading...

Loading...