RTCU AX9i eco

Technical Manual

Version 1.01

RTCU AX9i eco Technical Manual V1.01

Introduction

This manual contains technical documentation which allows for easy installation and use of the

RTCU AX9i eco product. For information on the programming and software configuration of the

product please refer to the RTCU IDE documentation.

The RTCU AX9i eco has been designed from the ground up for professional wireless industrial

applications with its strong on-board I/O capabilities and multiple communication interfaces such

as: 1-Wire, RS232 and USB. For world-wide usage in any network environment the RTCU AX9i eco

offers a full quad-band GSM engine with a switchable dual antenna design supporting both an onboard as well as an external GSM antenna.

The RTCU AX9i eco is based on the X32 Execution Architecture offering high performance and a

large memory capacity for both program and data - meeting the requirements of today’s most

demanding and sophisticated M2M/IoT applications.

The RTCU AX9i eco rests on the RTCU M2M Platform that brings all the necessary tools together

to develop, implement and maintain today’s sophisticated M2M/IoT applications.

The development task is supported by the free RTCU IDE development environment

complimented by a large and comprehensive documentation and application example library.

The RTCU Gateway 2 is the corner-stone of the communication infrastructure ensuring reliable

two-way device communication in any network environment.

Deploying and maintaining new application and firmware versions for devices in the field are

handled by the powerful RTCU Deployment Server.

For detailed information on the powerful RTCU M2M Platform, please refer to the

RTCU M2M Platform datasheet.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 2 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

The technical highlights of the RTCU AX9i eco:

Based on the RTCU M2M Platform1

X32 execution architecture.

o RTCU IDE development tool with a full featured device simulator.

o Huge standard API with more than 800+ functions.

o Comprehensive protocol support, including:

TCP-UDP/IP, FTP, SMTP, RACP, MQTT.

World-wide Quad-band GSM engine.

Internal and external antenna connector. Selectable from application.

Internal SIM-card reader.

Digitized audio can be played over GSM.

DTMF support for implementation of Interactive Voice Response applications.

Large data-flash/logger memory with a capacity of 4.5 MB.

Internal 4 MB FAT32 flash drive.

1 x RS232 channel.

2 x analog inputs with 0..10 volt / 0..20 mA with 12 bit precision.

5 x digital inputs and 4 x high-power relays.

Up to 4 digital inputs can be configured as IEC62053-31 Class A compliant.

1-Wire bus for accessories such as ID-button reader, temperature sensors, etc.

Wide AC/DC power operating range from 85..265VAC / 8..36 VDC.

On-board Li-Ion battery.

Advanced power-management with wake-up on a wide range of events.

High-speed USB programming connector.

Housed in a ruggedized plastic encapsulation with cable glands.

IP65 water protected for outdoor usage.

Fully supported by the RTCU Gateway 2 and the RTCU Deployment Server

.

1 Please see “The RTCU M2M Platform” data sheet for more information.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 3 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

* * * * THIS PAGE IS INTENTIONALLY LEFT BLANK * * *

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 4 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Table of Contents

Introduction......................................................................................................................................................2

The technical highlights of the RTCU AX9i eco:.........................................................................................3

Graphical view.................................................................................................................................................6

Connection Overview.................................................................................................................................7

Power supply .................................................................................................................................................10

DC Supply ..................................................................................................................................................11

AC Supply..................................................................................................................................................12

Digital I/O .......................................................................................................................................................14

Relay outputs.............................................................................................................................................14

Load Noise .................................................................................................................................................14

Digital inputs / S0 inputs / wakeup (ignition) input.............................................................................15

Analog input ..................................................................................................................................................17

USB programming port ................................................................................................................................18

RS232 communication ports (EIA/TIA-232 and V.28/V.24 compatible) ................................................18

RS232 port 1 ...............................................................................................................................................18

1-Wire bus.......................................................................................................................................................19

LED Indicators ...............................................................................................................................................19

User LED A and B .....................................................................................................................................19

System LED S1 and S2..............................................................................................................................20

Switches ..........................................................................................................................................................21

DIP-Switch..................................................................................................................................................21

System switch (RST)..................................................................................................................................21

Internal Li-Ion battery...................................................................................................................................22

GSM .................................................................................................................................................................23

GSM Antenna ............................................................................................................................................23

SIM-Card.........................................................................................................................................................24

Barcode / unit type ........................................................................................................................................24

Power consumption ......................................................................................................................................25

External DC supply...................................................................................................................................25

Internal battery ..........................................................................................................................................25

External AC supply...................................................................................................................................26

Appendix A – Unit configuration guide ....................................................................................................27

Appendix B – Installing the SIM card.........................................................................................................29

RTCU AX9i eco Specifications.....................................................................................................................30

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 5 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

System LED

s

Graphical view

On the front of the RTCU AX9i eco are four user controlled LED’s and three system LED’s for

simple information and status.

The external GSM antenna connector is located at the side of the device as shown below:

User Controlled

LEDs

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 6 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

VAC terminal

Fuse

LED’s

USB-B

Angl

ed

and blinds

Connection Overview

Connections to external equipment are done via large and easy-to-use screw terminal blocks which

are accessible when the lid is removed. The placement of the terminals makes installation easy

using the PG glands and thereby maintaining the IP-67 protection.

The RTCU AX9i eco is delivered with three PG11 glands and additional two PG9 blind plugs that

can be replaced with PG9 glands if additional cable entry capacity should be required.

PG Glands

Internal GSM

Antenna

External SMA

GSM Antenna

connector

Stacked

Terminals

Configuration

Jumpers

Terminals

DIP

Switches

SIM card

reader

The stacked terminals contain connections for: digital inputs/outputs, analog inputs and DC power

input.

The angled terminals contain connections for the communication interfaces: RS232 Port 1 and 1Wire.

Also located inside the RTCU AX9i eco are the SIM card reader, DIP switches and a USB-B highspeed programming connector.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 7 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Stacked terminal overview

Terminal Name

Description

TOP row BOT row

R1A

Contact set for relay output 1

R1B

R2A

Contact set for relay output 2

R2B

R3A

Contact set for relay output 3

R3B

R4A

Contact set for relay output 4

R4B

N.C Not connected

PE Protective Earth terminal for AC supply.

DCIN DC power supply, positive (+) connection

XGND DC power ground, negative (-) connection

DCOUT12 Internally not connected

GND Signal ground

DI1 Digital input 1 / S0 input 1

DI2 Digital input 2 / S0 input 2

DI3 Digital input 3 / S0 input 3

DI4 Digital input 4 / S0 input 4

DI5 Digital input 5 / Wakeup (ignition) input

GND Signal ground

AI1 Analog input 1

AI2 Analog input 2

AGND Analog ground

AGND Analog ground

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 8 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Angled terminal front row overview

Terminal Name Description

SER1_TXD Transmit data from serial port 1, RS232 compatible

SER1_RXD Receive data for serial port 1, RS232 compatible

DEV_DET Reserved for accessories.

SGND Signal ground

1Wire 1-Wire bus for ID-Button / Temperature sensor

1Wire-LED 1-Wire ID-Button LED output

VAC terminal overview

Terminal Name Description

N

N

P

P

85-265VAC (50/60Hz) Null input

(internally connected)

85-265VAC (50/60Hz) Phase input

(internally connected)

USB-B connector

This is a standard USB-B connector and is used for communicating with the RTCU IDE (or other

RACP compliant application).

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 9 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Power supply

The RTCU AX9i eco unit can be supplied with either 85-265VAC (50/60Hz) or 8-36VDC or both

supply types simultaneously.

The RTCU AX9i eco also contains an internal low capacity backup battery, which will supply the

RTCU if the external power should fail or be disconnected. By default the RTCU AX9i eco is

powered down when a power fail occur. This setting however can be changed. Please consult the

RTCU-IDE on-line help for more information.

When the wakeup/ignition input is activated with a logical high, the RTCU AX9i eco unit will

wake up if it was in power down mode.

There are five different ground labels: External Ground (XGND), Signal Ground (SGND), Digital

Ground (GND), Analog Ground (AGND) and AC power ground (PE). The signal, digital and

analog grounds are filtered from the power ground. The signal, digital and analog grounds are

filtered from the power ground. External ground must only be used as DC power supply return

path. The digital ground is used as ground reference for digital I/O’s, signal ground is used as

ground reference for serial interfaces, and the analog ground is used as a low noise analog ground

reference for the analog inputs.

Dual Supply Note:

The RTCU AX9i eco unit can be supplied with both VAC and VDC at the same time. The unit will

run on the VAC supply if the VDC supply voltage is < +16VDC. If the VDC supply voltage is

higher it will run on the VDC supply.

Please refer to the RTCU on-line help for information on how to check the supply type from within

an application.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 10 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

DC Supply

The RTCU AX9i eco unit can be supplied with 8-36VDC from an external DC power source.

Positive power is applied to the DCIN pin and ground is connected to the XGND pin.

The DC supply of the RTCU AX9i eco is protected against wrong polarity. If a system ground are

connected to either SGND or AGND a wrong polarity on the supply lines will destroy the internal

GND connection.

Please Note:

Minimum 16VDC supply is necessary for digital inputs 1-4 to work as S0 compliant inputs.

VDC Supply terminals

Terminal Name Description

DCIN Power supply, positive (+) connection

XGND Power ground, negative (-) connection

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 11 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

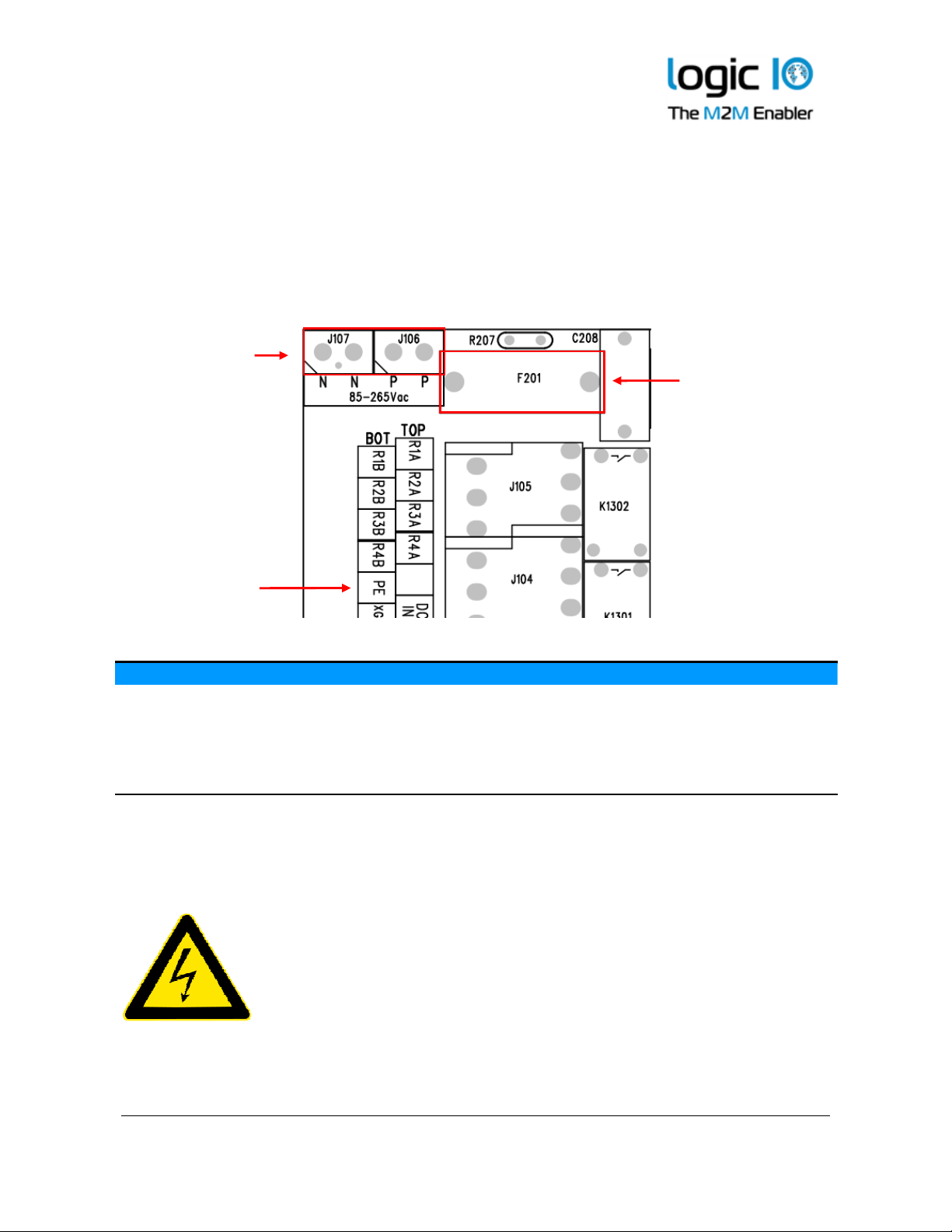

AC Supply

The RTCU AX9i eco unit can be supplied with 85-265VAC (50/60Hz) from a standard wall plug or

any other high-voltage VAC power rail. The AC supply of the RTCU AX9i eco is a high-efficient

switch mode power supply and the AC input is protected with a 1A/250V Fast Acting fuse.

The AC must be applied between the N and P on the separate located screw terminals. A

Protective Earth (PE) connection exists on the bottom row of the stacked terminals.

VAC terminal

1A/250V Fast

Acting fuse

Protective Earth

terminal

VAC Supply terminals

Terminal Name Description

N

N

P

P

85-265VAC (50/60Hz) Null input

(internally connected)

85-265VAC (50/60Hz) Phase input

(internally connected)

PE Protective Earth connector

Please Note:

The two pairs of N and P terminals are internally connected.

There is high voltage on certain areas of the PCB (Printed Circuit Board) when supplied with AC

mains. There is risk of electrical hazard, avoid touching the PCB and the

components during operation.

Be aware that the supply filter contains capacitors that may remain charged

after the equipment is disconnected from the supply. Although the stored

energy is within the approved safety requirements, a slight shock may be felt if

the plug pins are touched immediately after removal.

Refer all servicing and handling to qualified personnel.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 12 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Please Note:

The DC ground of the AX9 series is isolated from the AC ground because of the nature of AC-toDC converting. As these two grounds are not tied together anywhere in the AX9, the DC ground

may appear as "floating ground" to the outside if the AX9 ground is not connected to the same

reference as the outside, and a potential difference may occur. This difference can interrupt the

behavior of the unit, and in worst case can damage the part of the unit. This must be taken in

consideration when the AX9 series are supplied with AC supply. When the AX9 is supplied with

DC voltage this "potential difference" issue may not be observed, as the DC power supply has

usually the same potential as the rest of the system.

In order to avoid the potential difference the Earth connection on the AC supply rail can be

connected to the terminal that has been labeled “PE”.

For circuitry in situations where significant Earth ground currents can flow isolating the DC

ground from Earth grounds may be desired. In this case the DC ground may be tied together with

the Earth ground through a high impedance connection.

In other situations where a common reference needed the best EMI performance and ESD

immunity can be achieved connecting the DC ground and Earth ground with a low-inductance

connection.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 13 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Digital I/O

The RTCU AX9i eco unit has five digital inputs and four normally-open relay outputs.

The outputs are high performance relays with good current handling capabilities.

Digital input 1-4 offers several operation modes. Please refer to the digital input section for

additional information.

Relay outputs

The digital outputs control four relays and they act like a normally-open contact, where one side

must be connected to a source that needs switching and the other contact terminal is the output.

The source can be either VAC or VDC but the maximum switchable voltage and current must not

be exceeded, please refer to specification page.

There are no internal connections to the relay outputs and therefore a source must always be

connected to one of the relay terminals for the output to work. If power is removed or a power-fail

occurs on the RTCU AX9i eco will switch to normally-open.

The RTCU AX9i eco unit offers a very advanced power management, which makes it possible to

have one or more outputs enabled while the RTCU is in low power mode. Please consult the RTCU

IDE on-line help for more information.

Relay output terminals

Terminal Name Description

R1A

R1B

R2A

R2B

R3A

R3B

R4A

R4B

Contact set for relay output 1

Contact set for relay output 2

Contact set for relay output 3

Contact set for relay output 4

Load Noise

If highly inductive loads (such as high power contactors) are connected to the relays it is

recommended to externally connect a clamping diode in parallel with each inductive DC load or

connect an RC snubber circuit in parallel with each inductive AC load.

For DC applications Vishay UF5405-E3/54 or similar is recommended and for AC applications

AMPOHM FE-SP-HDR23-47/100 (47nF/100 ohm) or similar is recommended.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 14 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Digital inputs / S0 inputs / wakeup (ignition) input

The five digital inputs are all low-pass filtered (450kHz) and transient-protected. To activate the

inputs, connect a positive voltage between the corresponding input (DINx) and SGND.

Digital input 1-4 can be configured individually as S0 input (IEC62053-31, Class A) and DIN5 can

work as a wakeup (ignition) input.

As default the digital inputs are configured as normal inputs. For placement and configuration of

the hardware jumpers inside the unit, please refer to the configuration guide in Appendix A.

S0 compliant inputs (IEC62053-31, Class A compatible)

In S0 configuration the relevant RTCU AX9i eco input will act as a ‘pulse input device’, and a

current is supplied into the input connector so that a simple switch between SGND and the

appropriate input will activate it. This is used in most electricity metering equipment.

Please note: The RTCU AX9i eco unit must be supplied with a minimum of 16 VDC or AC power

for the S0 mode to work correctly.

S0 is enabled by default and may be disabled by the application to save power.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 15 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Wakeup (ignition) input

The DIN5 / wakeup (ignition) input is a special input in that it also functions as the wakeup input.

If the input is activated with a logical high or low (Wait For Event mode only) when the RTCU

AX9i eco is in low-power mode it will wake-up the unit. A power apply will also wake the unit up

if it is in power-down mode or in Wait For Event mode with power Apply and/or ignition selected

for wakeup. The input is de-bounced with a period between 1-2 ms when used as a digital input.

So any logical level applied to this input must be greater than 2 ms to be valid.

The power management allows for the possibility of configuring a wakeup on one or more digital

inputs with individually configured falling- or rising edge detection. Please consult the RTCU IDE

on-line help for more information.

Digital input terminals

Terminal Name Description Jumper Setting

DI1 Digital input 1 or

S0 input 1

DI2 Digital input 2 or

S0 input 2

DI3 Digital input 3 or

S0 input 3

DI4 Digital input 4 or

S0 input 4

DI5 Digital input 5 and

JPDI1 in position N (default)

JPDI1 in position S

JPDI2 in position N (default)

JPDI2 in position S

JPDI3 in position N (default)

JPDI3 in position S

JPDI4 in position N (default)

JPDI4 in position S

Wakeup (ignition) input

GND Digital Ground

For placement and configuration of the hardware jumpers inside the unit, please refer to the unit

configuration guide in Appendix A.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 16 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Analog input

The RTCU AX9i eco unit has two analog inputs which can be configured individually to work

either as voltage or current measurement inputs by using the configuration jumper. The range in

voltage mode is 0-10VDC and in current mode it is 0-20mA.

The conversion resolution is 12 bit.

By default the analog inputs are configured as voltage inputs, and are converted to a digital value

with a resolution of 10-bit before being presented to the application (0..1023). The application can

change the resolution to the full 12 bit (0..4095). Please consult the RTCU IDE for further details.

The input signal is connected between AINx and AGND. AGND must be connected to the

reference of the connected equipment. Please be aware that deviations may occur, as the system is

very noise sensitive. Avoid long, unshielded wires and high current, fast changing signals routed

parallel to the analog signals.

Analog input terminals

Terminal Name Description Jumper Setting

AI1 Analog input 1 – Voltage

Analog input 1 – Current

AI2 Analog input 2 – Voltage

Analog input 2 – Current

AGND Analog ground

AGND Analog ground

Specification for each analog input (voltage mode)

Min. Typ. Max. Unit

0

Resolution

- -

Precision -1.5

Cut-off frequency

Input impedance

-

-

-

-

4.5

40

10 VDC

12 Bit

1.5 %FSR

-

-

kHz

kΩ

Specification for each analog input (current mode)

Min. Typ. Max. Unit

0

Resolution

- -

Precision -1.5

Cut-off frequency

Input impedance

-

-

-

-

4.5

504

20 mA

12 Bit

1.5 %FSR

-

-

kHz

Ω

For placement and configuration of the hardware jumpers inside the unit, please refer to the unit

configuration guide in Appendix A.

JPAI1 not installed (default)

JPAI1 installed

JPAI2 not installed (default)

JPAI2 installed

Protected against transients and

low-pass filtered

Precision is based on

measurements @ 25 ˚C

Protected against transients and

low-pass filtered

Precision is based on

measurements @ 25 ˚C

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 17 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

USB programming port

The USB port is for programming and communicating with the RTCU IDE (or other RACP

compliant application). A standard USB cable can be used between the unit and the PC.

RS232 communication ports (EIA/TIA-232 and V.28/V.24 compatible)

One general purpose RS232 ports available on the RTCU AX9i eco unit. The serial input is

compliant with the EIA/TIA-232 standard.

RS232 port 1

This port is a general-purpose RS232 serial port and does not support handshaking.

The signals are available on the angled front row terminals.

SER1 terminals

Terminal Name Description

SER1_TXD Transmit data from serial port 1, RS232 compatible

SER1_RXD Receive data for serial port 1, RS232 compatible

SGND Signal ground

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 18 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

1-Wire bus

The 1-Wire bus is available on the angled front row terminals. All 1-Wire communication goes

through a single connection, and all 1-Wire devices connected to this connection retrieves its

power directly from the bus (called parasitic power). For this only two wires are needed – the 1wire signal and the ground reference – allowing minimal cable installations.

For 1-Wire ID-Button readers, which include a built-in LED, a dedicated output is available for this

purpose. Please consult the RTCU IDE documentation for further information.

For further information regarding modular 1-wire concept, please refer to the document “Modular

1-Wire Concept Technical Manual” on the Logic IO webpage.

1-Wire terminals

Name Description

1Wire 1-Wire bus

1Wire-LED 1-Wire ID-Button LED output

SGND Signal ground

LED Indicators

Three bi-colored (red and green) and a single yellow LED indicators are present on the front of the

unit (see graphical view section).

Two bi-colored LED’s (A and B) are available to the user and the remaining two LED’s (S1 and S2)

are indicating the status and possible errors of the RTCU unit.

User LED A and B

LED A and B are composed of four individually controllable LEDs:

• LED named A on the front consists of LED 1 (green) and LED 2 (red).

• LED named B on the front consists of LED 3 (green) and LED 4 (red).

They are easily accessed from within the application program, and it is possible to mix the LED’s

to obtain a third color: yellow. Please consult the RTCU IDE documentation for more information.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 19 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

System LED S1 and S2

The RTCU is equipped with two system LED’s which shows the status and possible errors of the

RTCU unit.

The different patterns are listed in the table below. If the color of the system LED S1 is yellow, the

unit is actively communicating with the RTCU IDE (or another program, supporting the RTCU

RACP protocol).

The single yellow LED is signaling either the GSM module activity, or if all other LED’s are off,

that the RTCU is in the “wait for event” low power state.

S1: System LED1 pattern overview

Pattern Description

Fastest blinking, green The unit is initializing, preparing to start the application.

Fast blinking, green2 The unit has been forced into recovery mode with the use of

the system switch. The application is not executing.

500ms On / 500ms Off green2 The unit is executing the application program

1.5s On / 0.5s Off. green2 The unit is executing the application program, while

charging the internal back-up battery.

Fast blinking, red2 A runtime error has been detected in the program.

Use the RTCU IDE to obtain the fault log.

Alternating Fast/Slow, red2 The unit has lost its firmware! This can only happen if,

during a firmware upgrade, the RTCU unit loses power or

the communication is lost completely. In this case, simply

upload the firmware to the unit again.

75ms On / 925ms Off, green Execution speed is different from full-speed.

S2: System LED2 pattern overview (GSM activity and “Wait For Event”)

Pattern Operating Status

Off The GSM module is turned off

600 ms On / 600 ms Off Missing SIM card or PIN code.

Network search and logon in progress.

75 ms On / 3 s Off Logged on to the network.

75 ms On / 75 ms Off /

A GPRS session is active.

75 ms On / 3 s OFF

Flashing Indicates GPRS data transfer.

On A voice or CSD session is active.

8 s OFF / 10 ms ON

The RTCU unit is in low-power “Wait For Event” state.

(and all other LED’s OFF)

2 Or yellow when communicating with the RTCU IDE or another program, supporting the RTCU RACP protocol).

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 20 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

DIP switch

Switches

DIP-Switch

The RTCU AX9i eco unit contains four dipswitches, where three of them are available for the

application to use (fourth dipswitch is reserved for GSM antenna switching.) The dipswitches are

located inside the unit (see drawing below or graphical view)

System switch (RST)

The RTCU AX9i eco unit contains a combined reset/diagnostic switch. This switch is accessible

from the inside of the unit (see drawing below or graphical view) It's necessary to use a small object,

for example the tip of a pencil.

By activating the switch shortly the RTCU unit will do a complete reset, as if the power was

removed and reapplied.

If the reset switch is held down for approx. 3 seconds3 the unit will enter recovery mode4 where the

application will not be started. In recovery mode the system will automatically turn on the GSM

module to establish a connection to the GSM network and RTCU Gateway (if configured). This

method will also activate the unit when the unit is in power-down mode.

System switch

3 System LED S2 will flash three times when this state is entered.

4 System LED S1 will indicates this state by fast blinking green or yellow.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 21 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Internal Li-Ion battery

The RTCU contains an internal Li-Ion battery for operation even when the external power is absent

making it possible to report power loss etc. Please note that when external power is removed, the

unit will be powered down by default. This setting can be changed as documented in the RTCU

IDE documentation.

The relay outputs will be disabled when a power fail occurs as the internal battery cannot provide

the supply voltage needed.

The battery charging is completely automated and handled internally by the RTCU unit – leaving

no need for user interaction. Different kinds of functions (Battery low, Charger enable, Charging

status, etc.) are available to the user application.

The charge current is relatively high, for a shorter charge time, as specified in the technical

specification. Make sure both power supply and cables can handle the high current.

The battery will be charged whenever a power fail has occurred to establish the capacity thus

making the battery ready for the next power fail. A maintenance charge will start every 20 days

after the last charge. This is to compensate for the battery self-discharge etc.

By default the battery cannot be charged above 45°C or below 0°C. The RTCU offers charging

down to -10 ˚C using a specialized algorithm to protect the battery.

If the temperature is above 45°C the charging will not start and will be postponed until it is below

this threshold.

The temperature has a very high influence on the battery capacity. At 0°C the capacity has

dropped to 60% of the initial capacity and it falls dramatically at lower temperatures.

The battery cycle (numbers of charges and discharges) also influences the capacity. After 300

cycles the capacity has dropped to approximately 80% of the initial capacity.

Warning

Misusing the RTCU unit may cause the built-in battery security circuit to be damaged.

• Do not place the RTCU unit in high temperature locations such as in direct sunlight or near

engines. Using the RTCU unit in this environment may result in loss of battery performance and a

shortened life expectancy.

• Do not expose the unit to water, salt water or allow the battery to get wet.

• Avoid strong impacts and shocks.

For more information regarding the environmental limitations, see “Specifications for RTCU AX9i

eco” below or consult the RTCU AX9i eco datasheet.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 22 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

GSM

For GSM and GPRS communication an industry leading QUAD band (850/900/1800/ 1900MHz)

GSM module is used.

The RTCU AX9i eco supports:

• Digitized voice

• SMS (Text and PDU)

• GPRS Multislot class 10. Support for simultaneous Voice and GPRS (suspended)

• CSD (Datacall)

GSM Antenna

The RTCU AX9i eco offers support for both an on-board internal GSM antenna and a user supplied

external antenna connected to the SMA female connector at the top of the encapsulation.

The active antenna can be selected by the application using the gsmSetAntennaMode function or

alternatively with a DIP switch. By default when the unit is delivered the active antenna can be

selected by DIP switch 4 and is set for external antenna.

Location of the internal/external GSM antenna and the DIP-switch 4:

Internal

Antenna

DIPswitch 4

External

Antenna

SMA

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 23 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

GSM antenna selection

gsmAntennaMode DIP-switch 4 GSM Antenna

1 Ignored Internal antenna

2 Ignored External antenna

3

On Internal antenna

Off External antenna

Please refer to the RTCU IDE online help for further information on gsmSetAntennaMode.

When installing the RTCU AX9i eco please make sure that the antenna is not in close proximity of

metallic parts or anything else that can influence the efficiency of the GSM antenna.

SIM-Card

The RTCU AX9i eco unit contains a standard SIM card reader which is located inside the unit (see

graphical view) and is easily accessed. The SIM card reader is lid based with a mechanical lock

system for secure installation of the SIM card. Please refer to Appendix B for SIM card installation

guide.

Barcode / unit type

The barcode label found on the RTCU AX9i eco unit contains the serial number.

The first three digits in the serial-number identify the unit type, as follows:

• 268: RTCU AX9i eco

The barcode format used: 2/5 Interleaved with Check Digit

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 24 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Power consumption

Detailed information on the maximum power consumption of the RTCU AX9i eco unit in different

states and different supply types is listed below.

Please Note: Values marked with (*) is average and should be considered as guidelines as they

may vary depending on the GSM signal strength.

External DC supply

When the RTCU AX9i eco unit is powered from an external DC power source the power

consumptions will be as follows.

Maximum power consumption

8V 12V 30V

Unit active 65 50 20 mA

Unit active with GSM on* 80 60 25 mA GSM idle @ -67dBm*

Unit active RF sending 65 55 20 mA

Unit active while charging 870 530 290 mA

Unit in power-down 1.3 0.8 0.4 mA Restart on DIN5, RTC

Unit in “wait for event” 1.3 0.8 0.4 mA Resume on DIN, RTC

Unit in “wait for event” 10 6 3 mA Resume on RS232

Unit in “wait for event” 26 20 8 mA Resume on GSM activity

Internal battery

If the external power source is removed and the internal battery is enabled the power consumption

from the battery will be as listed below.

Maximum power consumption

BAT

Unit active 85 mA

Unit active with GSM on* 105 mA GSM idle @ -67dBm*

Unit in power-down 1.5 mA Restart on DIN5, RTC

Unit in “wait for event” 1.5 mA Resume on DIN, RTC

Unit in “wait for event” 12 mA Resume on RS232

Unit in “wait for event” 35 mA Resume on GSM activity

Note: Power consumption from a fully charged battery.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 25 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

External AC supply

When the RTCU AX9i eco unit is powered from an external AC the power consumptions will be as

follows:

Maximum power consumption

220VAC

Unit active 8 VA

Unit active with GSM on* 8.5 VA GSM idle @ -67dBm*

Unit active RF sending 8.3 VA

Unit active while charging 17.2 VA

Unit in power-down 6.6 VA Restart on DIN5, RTC

Unit in “wait for event” 6.6 VA Resume on DIN, RTC

Unit in “wait for event” 7 VA Resume on RS232

Unit in “wait for event” 7 VA Resume on GSM activity

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 26 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Appendix A – Unit configuration guide

The RTCU AX9i eco has many features and some of them require configuration by using hardware

jumpers inside the unit. A brief overview over the jumper settings can be found on the following

table:

Feature Jumper State Default state

Analog input

Digital input

JPAI1 Installed

Not installed

JPAI2 Installed

Not installed

JPDI1 Position S

Position N

JPDI2 Position S

Position N

JPDI3 Position S

Position N

JPDI4 Position S

Position N

AI1 current measurement

AI1 voltage measurement (default)

AI2 current measurement

AI2 voltage measurement (default)

DI1 S0

DI1 normal (default)

DI2 S0

DI2 normal (default)

DI3 S0

DI3 normal (default)

DI4 S0

DI4 normal (default)

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 27 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

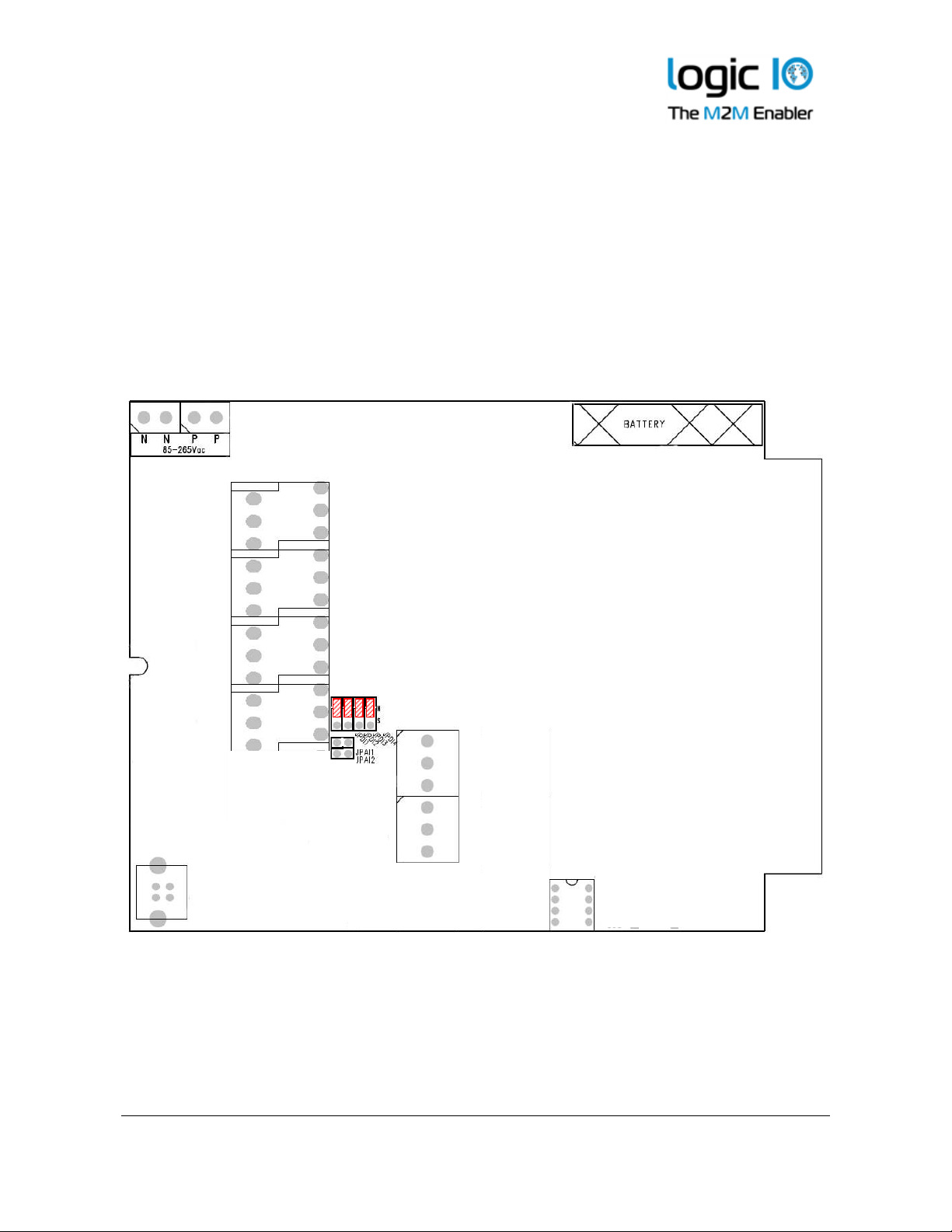

JPAI1 and JPAI2

These jumpers are used to select between current and voltage input. With a jumper installed on the

relevant analog input it will measure current between 0-20mA.

JPDI1, JPDI2, JPDI3 and JPDI4

These select either normal or Class A S0 input for DIN1-4. With the relevant jumper installed in

position “S” the input is configured to S0, when installed in position “N” the input is a normal

digital input.

The following figure shows the location of the jumpers when the lid of the unit is removed. Red

lined boxes show default state of the jumpers.

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 28 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Lock

Open

Appendix B – Installing the SIM card

The SIM card reader is a lid based type with a mechanical lock for secure installation of the SIM

card.

Open the hinged lid of the SIM card reader, orientate the card as showed below, and insert it into

the lid of the card reader. Close the lid, and slide the metal locking mechanism to the locked

position as shown with an arrow and text on the lid, until a click is heard.

To remove the card slide the metal locking mechanism to the unlocked position as shown with an

arrow and text on the lid, and open the lid. The SIM card can now be removed.

SIM card orientation.

SIM inserted and locked

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 29 of 30 Email: support@logicio.com

Denmark www.logicio.com

RTCU AX9i eco Technical Manual V1.01

Technical data are subject to changes.

RTCU AX9i eco Specifications

Processor and Main-memory

•

Powerful 32-bit ST ARM7 processor.

•

1088 KB fast execution RAM.

•

2304 KB Flash for firmware/application.

Electrical Specification.

•

Supply operating range:

8 to 36 VDC.

85 to 265 VAC.

•

Short and reverse power protected.

Internal Interfaces.

•

Screw-terminals for:

Power and I/O.

•

Angled screw-terminals for:

RS232 and 1-Wire.

Storage

•

3.5 MB persistent data flash.

•

4 MB internal FAT32 flash drive.

•

1 MB circular automatic datalogger.

•

8 KB FRAM with fast access /

unlimited write endurance.

GSM

•

Quad-band GSM engine.

850/900/1800/1900 MHz.

•

GPRS Class B, Multislot 10.

•

CSD with up to 19 Kbps.

•

SMS / PDU.

•

DTMF decoding / transmission.

•

Digitized voice playback / IVR.

•

Micro-SIM 1.8/3 volt.

•

Internal SIM card-reader.

•

Internal quad-band GSM antenna.

•

External or internal antenna selectable

by DIP-switch or user application.

•

Optional Gemalto SIM-on-chip.

User Interaction

•

3 x bi-colour LED.

•

Yellow status LED.

•

DIP-switches.

•

Reset/recovery switch.

•

Antenna selection dip-switch.

•

Configuration jumpers.

•

USB-B for service port.

Battery and Charger

•

On-board 1Ah (nominal) Li-Ion battery.

•

Intelligent charger with temperature

throttle and sub-zero degrees support.

Digital/Analog Interface

•

4 x relay output.

Max. 5A @ 250VAC / 30 VDC

•

5 x digital inputs.

Logic high: 6 to 40 VDC.

Logic low: -5 to 3 VDC.

•

4 x IEC62053-31 Class A input.

•

Digital input #5 can be used as ignition.

•

2 x analog inputs.

Range is 0..10VDC or 0..20 mA

Resolution: 12 bit

Precision: ±1.5% FSR @ 25°C

•

Protected against transients and lowpass filtered.

Communication

•

1 x RS232.

•

1-Wire bus.

Power Management

•

5 execution speeds.

•

Wait for Event: Timer, Digital input,

RS232, GSM, power change state.

•

Wait for event, from: 600 uA@12V.

•

Supervision of supply voltage / type.

* * * * END OF DOCUMENT * * * *

External Interfaces.

•

SMA Female connector for external

GSM antenna.

•

3 x PG11 cable glands.

•

2 x PG9 blind plugs.

Physical Characteristics

•

Encapsulation:

Durable Polycarbonate plastic.

•

Approx. 640 gram without accessories.

•

W 130 x H 180 x D 60 mm.

(wihout SMA and PG connectors.

Environmental Specification

•

Operating temperature: -30 to 60°C.

•

Battery charge temperature:

-10 to 45 °C

•

Recommended storage temperature:

0 to 45°C.

•

Humidity: 5..90% (non condensing).

•

Ingress Protection: IP65.

Approvals

•

CE. EU EMC directive 2004/108/EU.

•

Applied R&TTE directive.

•

GSM engine: CE/GCF/FCC/PTCRB.

Warranty

•

Two-years return to factory parts and

labor.

•

Optional warranty up to 5 years.

(restrictions apply).

Logic IO ApS. Ph: (+45) 7625 0210

Holmboes Allé 14 Fax: (+45) 7625 0211

8700 Horsens Page 30 of 30 Email: support@logicio.com

Denmark www.logicio.com

Loading...

Loading...