Page 1

1

WM1

-

TRM120

TRM120

T

R

M

–

ROT

ARY MOWERS

OPERATORS MANUAL

Page 2

2

TRM120

Serial Number:

Date of Purchase:

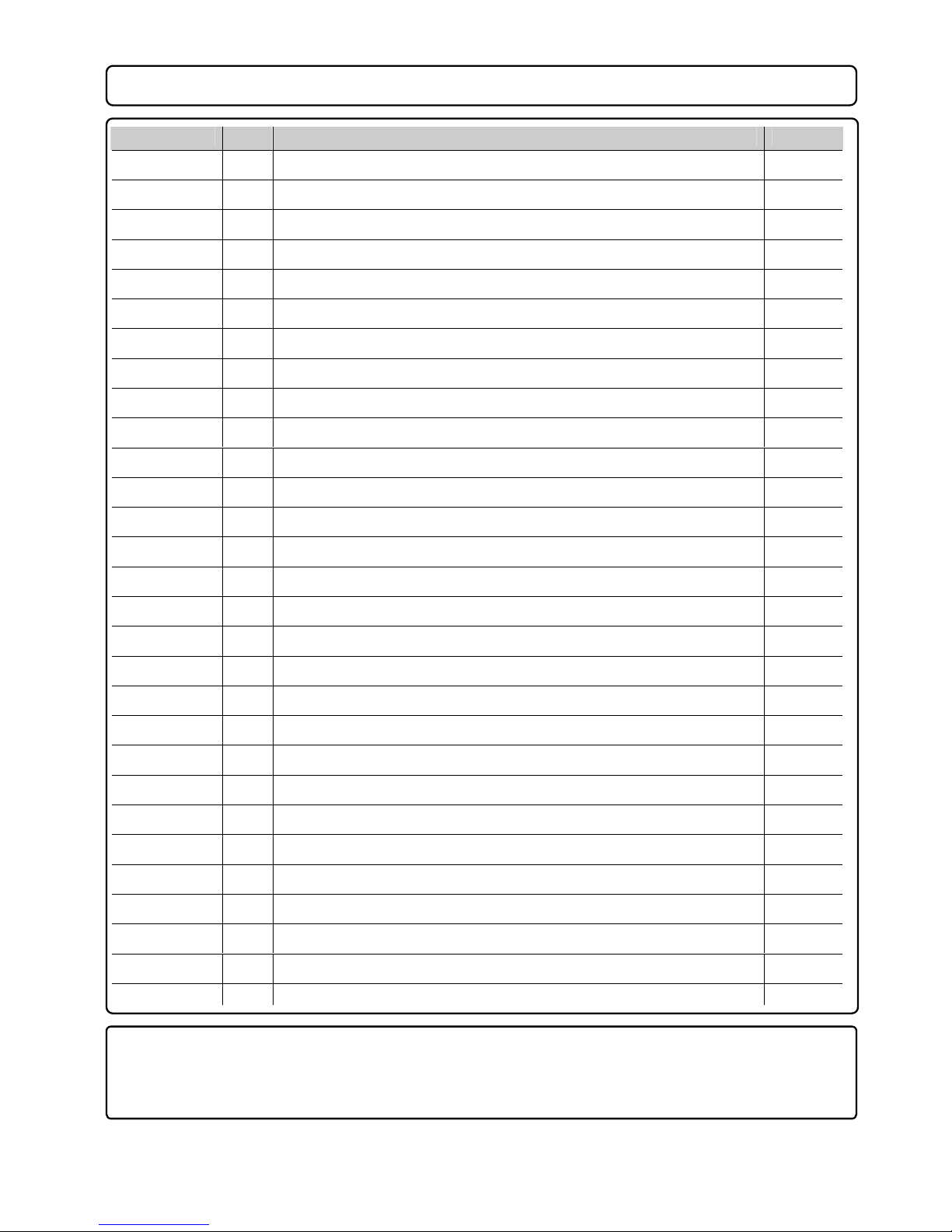

SECTION:

DESCRIPTION

PAGE

1 Introduction 3

HSE Information Sheet 4 - 7

2 In the interest of safety: DO NOT 8

3 In the interest of safety: DO 9

4 Instruction & Warning Decals 10

5 Transporting and lifting 11

6 Operating principles 11

7 Settings and adjustments

7.1 Before use inspection 12

7.2 Attachment to towing vehicle 12

7.3 Adjusting the mower 12

Drawbar pitch adjustment 12

Drawbar offset 13

Mowing cutting height 13

Starting the engine 14

Electric start 14

Remote throttle control 14

Throttle park 15

Stopping the engine 15

Transport position 15

8 Maintenance

Maintenance schedule 16

Maintenance history 16

Maintenance procedures 17 - 20

Specifications 20

9 Parts diagram 21

Parts list 22 - 24

10 Guarantee 24

Declaration of conformity 25

IN

DEX

Page 3

3

With the purchase of your LOGIC TRM - ROTARY MOWER you have made an excellent

choice.

This machine should give first class service for a long time, if used correctly, and maintained as

described in this manual.

Fitted with an easy to start engine it has been designed to cope with a wide range of conditions.

The Logic TRM - Rotary mower incorporates easy height adjustment, range of engine options

and three grass cutter blades for maximum life and durability. The Cutter blades have built in

deflectors to clean the blade and create a sucking action, all resulting in a better cutting finish

The mower incorporates a clutch to ensure the engine is protected and that the drive belts have

a longer life.

The mower deck is constructed from 4mm steel for added strength; all fittings are of high quality

to ensure years of trouble free use.

There are different wheel options available for the TRM - Rotary Mower

Engines used may vary, but all are accompanied by the maker’s usual warranty.

If after reading this manual there are any queries, please get in touch as we will be pleased to

help.

NORTH & EXPORT SOUTH

LOGIC MANUFACTURING LTD LOGIC MH LTD - New Whiteway Works,

Foundry Industrial Estate Fossecross Industrial Estate

Bridge End, Hexham Chedworth. Cheltenham

Northumberland NE46 4JL Gloucestershire GL54 4NW

Tel: 01434 606661 Fax: 01434 608143 Tel: 01285 720930 Fax:01285 720840

E-mail: sales@logic.gb.com E-mail: sales@logic.gb.com

www.logic.gb.com

www.logic.gb.com

INTRODUCTION

1

Page 4

4

Page 5

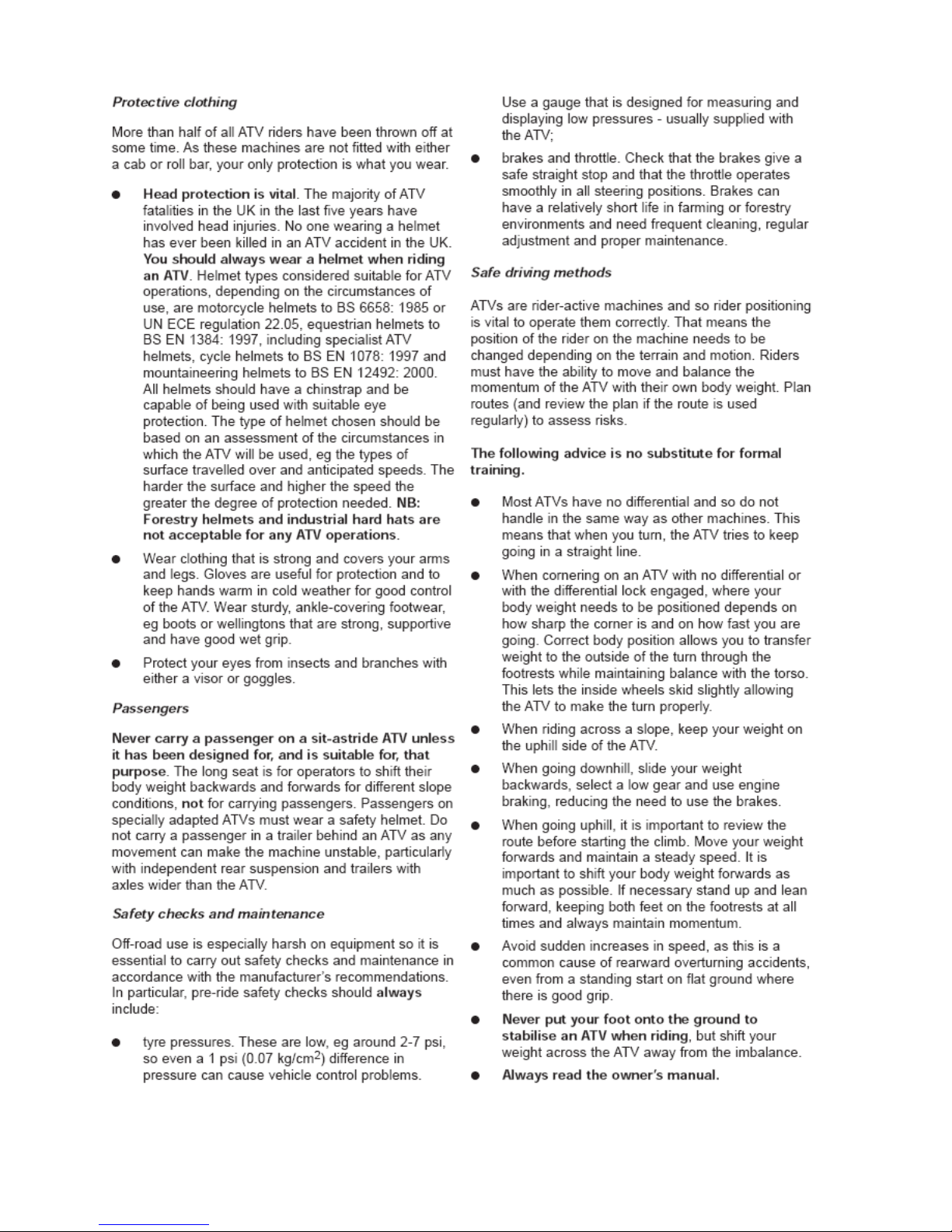

5

Page 6

6

Page 7

7

Page 8

8

1. DO NOT – Operate the mower without all the correct guards fitted.

2. DO NOT - Tamper with engine unless stated by Engine manufacturer.

3. DO NOT – Touch any moving or rotating parts during working conditions

4. DO NOT – Stop the engine immediately after heavy use, ensure engine is run at idle for

a short period to allow drive belts and engine to cool down, this will reduce wear.

5. DO NOT – Operate the mower without suitable ear and eye protection

6. DO NOT – Allow passengers.

7. DO NOT – Leave machine un-attended while operating

8. DO NOT – Run the engine in an enclosed area, exhaust gases contain Carbon

Monoxide and are fatal if inhaled.

9. DO NOT – Operate the mower on excessively steep slopes.

10. DO NOT – Operate the mower unless all safety features are fitted to the mower and are

used correctly

11. DO NOT – Operate the mower until you have read and understood the entire operators

manual

12. DO NOT – Wear loose fitting clothing, to avoid catching on parts of the machine

13. DO NOT – Try to remove blockages while the engine is running. Ensure engine is

stopped and blades have stopped rotating before any servicing/repairs are carried out.

14. DO NOT – Operated the mower in Dark conditions unless suitable artificial light is used.

15. DO NOT – Operate if excessive vibration occurs, stop the machine immediately and view

maintenance chart.

16. DO NOT – Climb on the mower.

2

IN THE INTEREST OF SAFETY:

DO NOT

This symbol means WARNING or CAUTION Personal safety or damage will be at

risk if these instructions are ignored. Most accidents are caused by neglect or

carelessness; Avoid needless accidents by following the safety precautions

listed below.

Page 9

9

1. DO – Follow Engine manufactures guidelines.

2. DO – Ensure all spectators are a safe distance away when operating.

3. DO – Carry out regular servicing and checks before use.

4. DO – Clear cutting area from potential damaging components e.g. stones etc.

5. DO – Reduce speeds when working on hillsides or rough terrain

6. DO – Be aware components can be hot after operation

7. DO – Follow any towing guidelines stated by towing vehicle manufacturer.

8. DO – Show some caution when filling the tank with petrol, especially if engine

components are hot.

9. DO – Ensure all safety decals are in good condition, replace any that are damaged.

10. DO – Keep hands and feet away from rotating blades

11. DO – Ensure mower is in transport position before transporting to and from the workplace

3

IN THE INTEREST OF SAF

ETY:

DO

Page 10

10

INSTRUCTION / WARNING DECALS

4

The above decals should be located on your TRM120. If any of the above decals

are not located on your TRM120 or are damaged in any way contact Logic for some

replacement decals before use.

Page 11

11

Ensure the vehicle used to lift and transport the TRM120 has the necessary lifting and loading

capacity. Follow all vehicle manufactures guidelines for lifting. Unladen weights are clearly

marked on the Manufactures plate attached to the TRM120 deck. Check the lifting weight

complies with the vehicle lifting limits

When lifting the TRM120 for transporting / delivery purposes always ensure to locate the lifting

straps on each of the four corners ensuring the straps/chains are all the same length before

lifting, or if using forklift tines ensure the mower is secure on the tines before lifting.

The LOGIC TRM ROTARY MOWER is designed to give safe and dependable service if

operated according to instructions and intended use.

Read and understand this manual before operating the mower, as failure to do so could result in

personal injury or equipment damage.

The amount of grass or weeds to be cut dictates the forward speed; slow forward speeds give

better results in most cases. Ensure you follow the procedure below.

NORMAL FORWARD SPEED (1 kph - very heavy use - 10 kp

h - very light use)

Start off in the slowest speed possible; ensure the mower is working efficiently with the engine

set at maximum RPM and not labouring. (If this is not possible due to very heavy cutting

conditions, raise cutting height of blades and be prepared to go over twice with machine set

lower on 2nd pass, leave at least 24 hours in between 1st and 2nd cut to allow grass to dry out)

Increase forward speed until the RPM of the engine starts to slow down (This is working the

engine too hard for conditions) - slow down, let the engine regain full RPM and go through the

same process but stop short of speed which made engine labour previously. It is important

always to listen to note of engine to ensure engine and mower are working efficiently, slow

down or stop once engine starts to labour.

FAILURE TO DO THIS WILL RESULT IN CLUTCH SLIP AND

ULTIMATELY SEVERE DAMAGE TO THE CLUTCH AND DRIVE BELTS.

TRANSPORTING & LIFTING

5

OPERATING PRINCIPLES

6

When moving from normal working conditions to heavier cutting, it may be evident that

the engine dies down and loses revs. SLOW DOWN IMMEDIATELY to allow the engine revs

to build up again to normal working speed if engine does not recover stop the engine

immediately by using the kill switch cord remove the blockage and follow all engine staring

procedures. Follow the procedure detailed above in “Normal Forward Speed”. Expected

forward speed will be much lower in heavy conditions.

Page 12

12

7.1 – BEFORE USE INSPECTION:

Ensure that all nuts, bolts and fittings are secure before using the TRM120.

Ensure the tyres are in good condition and have the correct pressures.

Ensure the swivel hitch is in good condition; replace any worn or damaged parts.

7.2 – ATTACHMENT TO TOWING VEHICLE

Any suitable vehicle can tow the Logic TRM120 normally by its 50mm swivel hitch coupling.

Ensure the hitch is securely attached to the towing vehicle and the handle indicator points to

“OK” before moving the vehicle.

Use the raise and lower levers to lift the TRM120 clear of the ground. Drive around for a short

period of time in a wide open space to ensure you become familiar with the operating width and

handling of the machine.

7.3 – ADJUSTING THE MOWER

MOWER ENGINE MUST BE SWITCHED OFF WHEN ADJUSTING THE MOWER!

DRAWBAR PITCH ADJUSTMENT

The hitch attachment height of the towing vehicle can vary. To accommodate this adjustment, a

screw link is located on the drawbar. This should be lengthened or shortened so that the cutting

deck is horizontal to level ground. (This ensures a better cutting efficiency)

1. Unlock the locking nut (A)

2. Lengthen the link to lower the front of the deck or shorten to raise the deck, by turning

handle (B).

3. Once the deck is level, re-tighten locking nut (A).

SETTINGS &

ADJUSTMENTS

7

A

B

Page 13

13

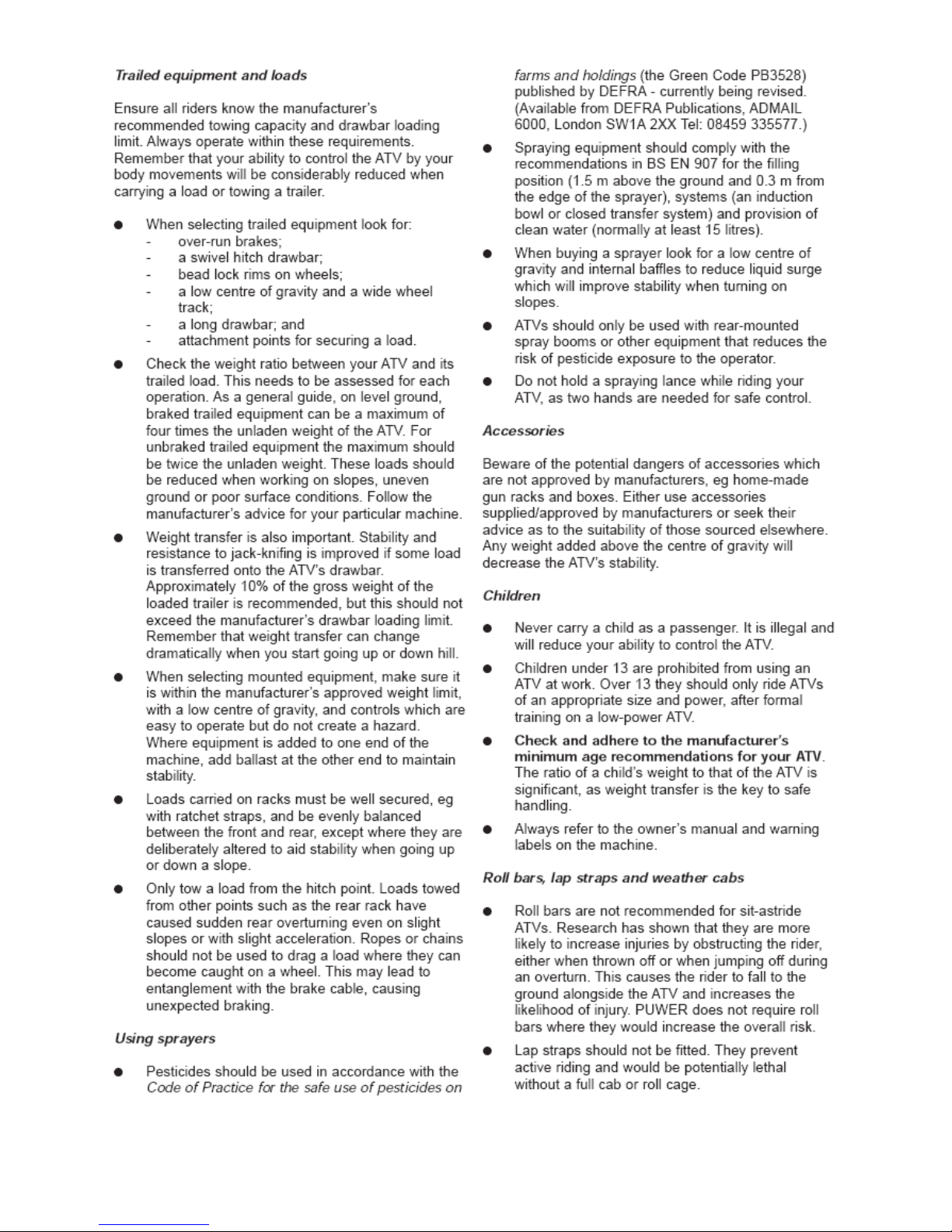

QUICK OFFSET DRAWBAR

Remove the ‘R’ clip and locking pin; slide the drawbar to the desired position and reposition the

locking pin into the securing hole as shown below. There are 4 hole positions as shown below

that allow the mower to move to an ‘Off set’ position. Hole position 1 (Zero offset) would mean

the mower would follow the towing vehicle straight behind, if the position was then changed to

hole 4 this would mean the mower would move by approx 700mm to the right hand side (Based

on the below image)

MOWER CUTTING HEIGHT

The main cutting height adjustment is achieved by using the spring assisted handles on either

side of the deck.

There are 5 cutting heights available, including transport position (See below diagram)

1. Remove ‘R’ clip and pin (A)

2. Raise or lower the spring assisted lever to the new cutting height replace the pin in the

correct hole (Ensure both height adjusters are on the same setting, never operate the mower

with different height settings) Ensure the deck runs parallel to the ground see drawbar

adjustment section in this manual.

3. Replace ‘R’ clip and pin (A)

A

Locking Pi

n

& ‘R’

clip

Hole Settings

(4 positions)

Transport position

1 4 3 2

Example: Setting number 4 is used the mower will be

700mm ‘Offset’ to the right

Page 14

14

STARTING THE ENGINE

READ AND UNDERSTAND THE ENGINE OPERATORS MANUAL BEFORE USE

OBSERVE ALL SAFETY PRECAUTIONS; KEEP HANDS AND FEET AWAY FROM

THE ROTOR AND OTHER MOVING PARTS.

KEEP SPECTATORS AT A SAFE DISTANCE

1. Make sure there is a gap between the blades and the ground / crop

2. Select an area clear of loose debris.

3. Set the engine choke (if necessary) and suitable idling speed with the throttle.

4. Place one foot on top of the deck body to give a firm and balanced position. Pull the starter

cord firmly, allowing the cord to return to the housing slowly (one or two strong pulls should

start the engine).

5. After a few seconds warming up at idling speed, move the throttle to the factory pre-set max

engine RPM.

ELECTRIC START

Push button electric start engine options can be supplied if required. Simply hitch up the

mower, connect the electrical supply plug to the ATV socket and press the ignition button to

start the mower. Observing all the precautions mentioned above in ‘Starting the mower’.

REMOTE THROTTLE CONTROL

When a remote throttle control option is fitted, normally to the rear carrier frame of an ATV or

other suitable position on the towing vehicle, it gives the operator the facility of controlling the

mower engine from the operating position.

If the throttle is altered to increase the engine R.P.M beyond the recommended level, the

guarantee will become invalid. In addition to this, cutting efficiency will be reduced, fuel

consumption will increase and excessive vibration could be caused, resulting in a potential

danger to personnel and damage to components.

Page 15

15

THROTTLE PARK

The mower deck is fitted with a throttle park. To use the throttle park clip the throttle to the

bracket as shown below.

DO NOT USE THE THROTTLE PARK DURING OPERATION. THE THROTTLE

SHOULD BE POSITIONED NEAR THE OPERATOR DURING WORKING CONDITIONS.

THROTTLE PARK IS FOR STORAGE WHEN THE MOWER IS NOT IN USE ONLY

STOPPING THE ENGINE

When stopping the mower after a period of heavy use. Run the machine at half working speed

in a stationary position for at least 4 minutes to allow the drive belts/clutch to cool down.

Shut the throttle down to lowest RPM and switch off engine.

1. Show caution to hot parts e.g. engine exhaust, belts etc after engine is switched off.

2. When the mower has cooled down (Min1hr after last used) Ensure all grass has been

removed from engine cooling fins, drive belt area and rotors before operating again.

TRANSPORT POSITION

When the mower is being moved from one site to another it is advisable to raise the deck to the

highest position (See section called ‘mower cutting height’)

The engine must be stopped and the blades at a standstill before adjusting to the transport

position. (Transport position is the highest deck setting available).

Remove any crop particles from the deck before leaving the field. Never move from one site to

another with the engine running. Ensure the mower drawbar has been adjusted to allow the

mower to run directly behind the towing vehicle and is not in an offset position

NB: TRM – Rotary mower is not road legal, and should not be used on public roadways.

If you have any specific questions regarding mowing or adjusting the TRM120 to suit your

conditions please contact Logic

Page 16

16

All servicing should be carried out by qualified mechanics. Contact your Local dealer for more

details.

MAINTENANCE

8

Maintenance Schedule

Maintenance Operation:

Hourly Daily Weekly Seasonal

Engine (See Engine manufacturer’s manual)

SEE ENGINE MANUFACTURES MANUAL

Remove excess crop gathered on deck

Remove excess crop wrapped around rotors

Visual check to ensure nothings loose

Grease Drive Pulleys

Grease Height Adjuster

Grease Rear Roller

Grease Rotor Bearings

Drive belt tension

Tyre Pressures

Rotor Bearing inspection

Wheel Bearing Inspection

Oil coupling

Coupling Bush Wear

Check All Fasteners are tight and intact

Safety projectile deflectors front/rear (inspection)

Safety Decals intact

Safety Guards Intact

Sharpen Rotor Blades

Check Metal Fatigue

Clutch Wear / Function

Maintenance History

Service Date: Service Performed: By:

Page 17

17

ENGINE MAINTENANCE

Refer to engine manufacturer’s manual, for servicing and maintenance of the engine.

EXCESS CROP BUILD UP

Remove all crop deposits from the deck and engine area. Build up of crop deposits could result

in heat build and fires. NB: Disconnect the spark plug lead.

Remove any crop that is wrapped around the rotors on the underside of the deck, as shown

below. Raise the deck to its max height to assist access to the rotor shafts.

VISUAL CHECK

Make a visual check around the mower, check for missing / loose parts or damaged / worn

components. All faults must be either repaired or replaced.

DRIVE BELT ADJUSTMENT

1. Remove drive belt covers by removing the 3x mounting bolts on each guard.

2. Slacken 4 x engine mounting plate bolts, so the plate is free to move (A) See figure 8.1

3. Tighten the tensioner bolt (B) until the tension on the belt allows one and a half the belts

thickness in deflection ether side of the belt centreline (C). Belt deflection should always

be tested on the longest and central part of the belt.

4. Replace drive belt covers.

NB: New drive belts stretch a little after the first f

ew hours of use; so be sure too check belt

tension after the first few hours of use. (DO NOT OVER TIGHTEN DRIVE BELTS)

Replace any worn or cracked drive belts. Only use Logic specified drive belts as

replacements.

Always stop and switch off the engine and wait for the rotor blade movement to

stop before carrying out any inspection or adjustment. CAUTION some Drive belts /

Drive pulleys could be hot after use

Page 18

18

TYRE / PRESSURES

DO NOT EXCEED RECOMMENDED TYRE PRESSURES

1. Remember that temperature affects pressures: in cold weather the pressure needs to be

higher than in hotter temperatures.

2. Never adjust the pressure immediately after driving because driving heats up the tyres.

There are many individual causes of tyre troubles. However, the three abuses which will cause

most problems and the greatest costs are under-inflation, overloading and speeding. When you

check the tyre pressures also look for bumps and bulges in the side of the tyre or tread. Check

the tyres for cuts, slits or cracks, nails or foreign objects embedded in the side of the tyre or

tread. Check the tread for excess wear. Replace or repair any defect or fault with tyres before

use.

ROTOR BEARING INSPECTION

NB: Disconnect the spark plug lead.

Rotate each rotor shaft by hand and feel for any roughness in the bearings. Also try to pull the

shaft from side to side if any movement is found check all mounting and blade bolts are tight

and repeat the test. If symptoms persist strip down the rotor-housing unit and inspect bearings.

C

B

A

A

Figure 8.1

WHEEL/TYRE TYPE

RECOMMENDED PRESSURE

CARLISLE AT 20 x 7 – 8 7 - 10 PSI

KINGSTYRE 16 x 6.50

- 8

28 PSI (Max)

Page 19

19

WHEEL BEARING INSPECTION

Jack one side of the mower body up, so the wheel is just off the ground. Rotate the wheel by

hand, and check the wheel alignment. To check the bearings, try to move the wheel from left to

right and feel for any play in the bearings (A), ensure the wheel-locating bolt is tight before you

start and follow any jacking procedures. If any play is found remove the wheel and inspect

bearings. Replace any faulty bearings.

OIL COUPLING / COUPLING BUSH WEAR

Check coupling for signs of damage or wear, swivel the coupling 360 degrees and check that

the yellow bushes aren’t to worn. Replace any warn or damaged parts. Oil the coupling regularly

GENERAL INSPECTION

Check the mower to ensure all fasteners are tight and all safety guards / chains are intact and

fitted securely. Check all safety-warning decals, Replace any defected guards or decals.

SHARPEN ROTOR BLADES

To remove the individual blades:

1. Disconnect the spark plug.

2. Block the blade to prevent it from rotating by using a block of wood. (A)

A

B

A

Page 20

20

3. Remove the blade bolt (B)

4. Remove the blade, replace or sharpen the blade.

5. Reinstall the blade ensure the blade-securing bolt has a torque setting of 60ft/lbs.

6. Inspect any fasteners before re-assembly, replace if necessary.

7. Reconnect spark plug.

SPECIFICATIONS

TRM120B12*** TRM120H13***

Max machine width

(CARLISLE) :1790mm

(KINGSTYRE) : 1770mm

Max machine height

(CARLISLE): 730mm

(KINGSTYRE): 690mm

Max machine length

2190mm

Max cutting width

1200mm

Cutting range

(CARLISLE): 20mm – 160mm

(KINGSTYRE): 20mm – 120mm

Weight

(CARLISLE): 168kg

(KINGSTYRE): 166kg

(CARLISLE): 173kg

(KINGSTYRE): 171kg

Hitch:

50mm swivel coupling

Drawbar

Adjustable and Offset facility (approx 700mm Offset)

Raise / Lower

Manual spring assisted lift handles

Wheel / Tyres

(CARLISLE AT 20 x 7 – 8): 4-10 Psi

(KINGSTYRE 16 x 6.50

–

8):

28 Psi

FOR REPAIRS BEYOND THE MINOR ADJUSTMENTS LISTED ABOVE CONTACT

YOUR LOCAL DEALER

Page 21

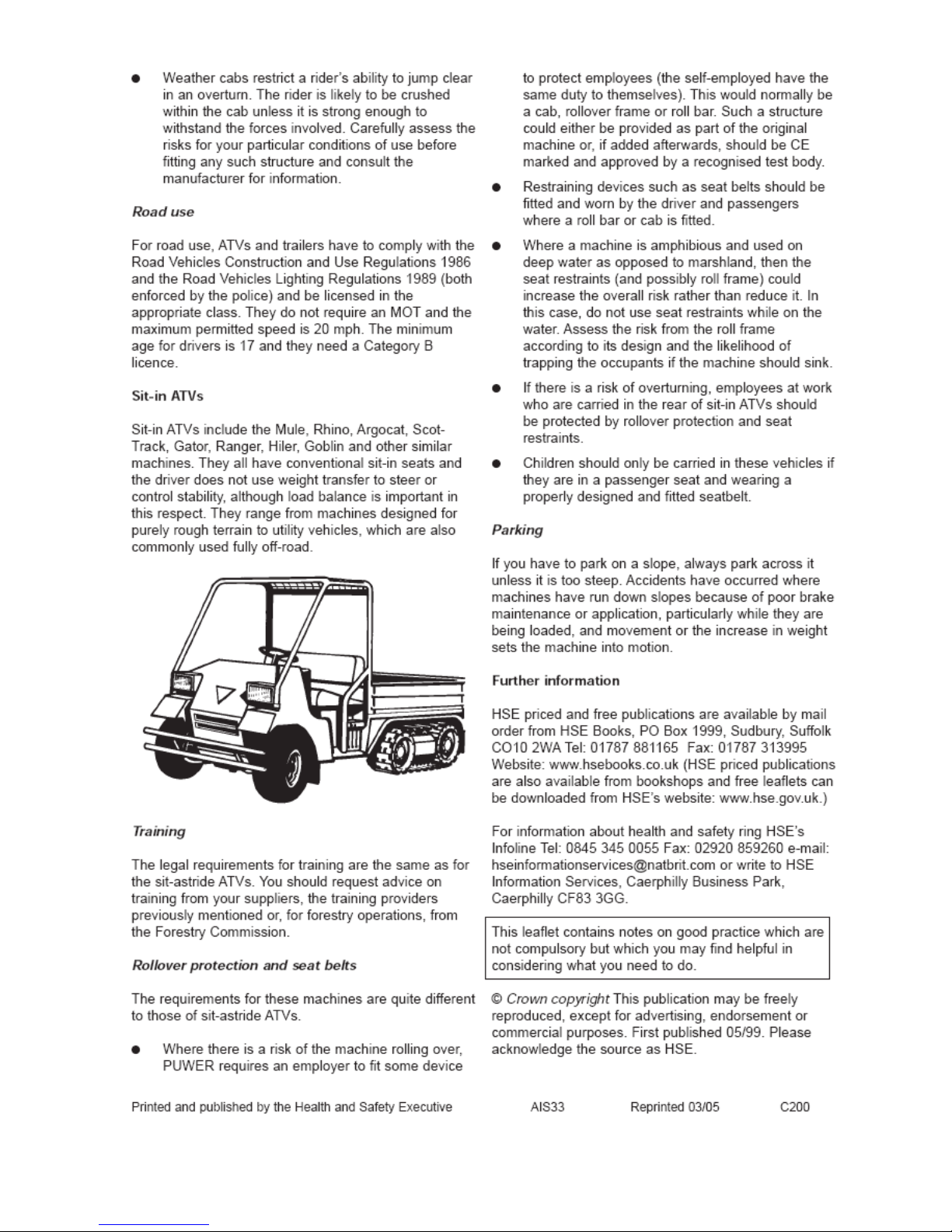

21

9:

PARTS DIAGRAM

Page 22

22

Item

Part Number

Description

01

TRM120-01A Mower Deck

02

TRM120-14 Rear Deflector Flap

03

FRP06014 Rivet Mono 6.5mm X 14mm (2mm X 9.5mm Panel)

04

FSH12035 S/Screw Hex Head M12 X 35

05

-09L Rear Discharge Deflector L/H

05

TRM120-09R Rear Discharge Deflector R/H

06

-22 Rear Clamping Plate

07

S216-1013 Self Locking Nut

08

S216-1012 Blade (Lg412)

09

S216-1026 Spindle

10

LRM120-41 Key Outer Pulley

11

S216-1025 Bearing Cover

12

FSH10030,FWF10,FNN10 S/Screw M10 X 30, Flat Washers, Nyloc Nut

13

MF120-1048 Bearing

14

TA102-03 Grease Nipple

15

S216-1024 Hub

16

S216-1023 Spacer

17

FSH10025,FWF10,FNN10 S/Screw M10 X 25, Flat Washers, Nyloc Nut

18

TRM120-23 Clamp plate front Outer

19

TRM120-12 Deflector front Flap: End

20

TRM120-13 Deflector front Flap: Centre

21

TRM120-24 Clamp plate front Centre

22

FSH08025,FWF08,FNN08 S/Screw M8 X 25, Flat Washers, Nyloc Nut

23

WP05,FRP03010 Manufacturers Plate Universal, Rivet Pop 1/8 X 3/8

24

WS01 Sticker: Logic – 240 X 75 MM

25

WS146 Sticker: Mower Hazard Sticker

26

WS147 Sticker: TRM120

27

S215-096 Sprocket Spacer Bush 2 MM

28

S215-091 Castor Bottom Collar 12 MM

29

S215-092 Castor Bush 6 MM

30

LRM120-38 Pulley Single V ‘B; Section 4”

31

S216-1027 Washer

32

S216-1015 Self Locking Ring Nut

33

FBH716200 Bolt Hex Head 7/16 UNF X 2”

34

LRM123-01 Top Hat Washer

35

TRM120-39 2 Vee Centrifugal Clutch (Purple Springs)

36

LRM123-04 Clutch Spacer 12 MM

37

LRM120-39 Pulley Double V ‘B’ Section 4”

38

WS36 Sticker: Design Right

39

Sticker: Ser No: N/Plate 50.4 X 19.1

40

-1054 Dust Cap

41

10

S/Screw M10 X 25, Spring Washer, Repair –

Washer

42

-1048 Outer Wheel Bearing

43

WT142 WL/TY 16 X 650 – 8 Kingstyre

Page 23

23

Item

Part Number

Description

43

WL/TY 20 X 700 – 8 Carlisle/Max 4

44

MF120-1063 Spacer

45

TRM120-20A Guard Rail

46

FSH08030,FWF08,FNN08 S/Screw M8 X 30, Flat Washers, Nyloc Nut

47

TRM120-37 Spring Tension 5.38 MM Dia

48

-25LA Axle L/H

48

-25RA Axle R/H

49

TRM120-10 Wheel Arm Locking Pin

50

-S100 Sleeve Flat Grey 31.75 MM X 9.5

51

FSH12035,FWF12,FNN12 S/Screw M12 X 35, Flat Washers, Nyloc Nut

52

TRM120-02LA Height Adjuster Bracket Assembly L/H

52

TRM120-02RA Height Adjuster Bracket Assembly R/H

53

FCG03064 Clip R3 X 64 MM

54

FNN20 Nut Nyloc M20

55

LRM123-05 Belt V BX49

56

FBH16090,FWF16,FNN16 Bolt M16 X 90, Flat Washers, Nyloc Nut

57

TRM120-05A Drawbar Mounting Assembly

58

MFG104-15 Turnbuckle

59

TRM120-03A Drawbar Offset

60

WS82 Sticker: Mfg300 Warning

61

CM100-04 Drawtube

62

CM100-03A Bush Nylon

63

TRM120-16A Drawbar Assembly

64

CM100-01A Thrust Washer

65

C900 Coupling 50 MM H/D Winterhoff

66

FBH12065,FNN12 Bolt M12 X 65, Nyloc Nut

67

FBH12070,FNN12 Bolt M12 X 70, Nyloc Nut

68

TRM120-11 Drawbar Locking Pin

69

FBH16065,FWF16,FNN16 Bolt M16 X 65, Flat Washers, Nyloc Nut

70

LRM120-02A Engine Mounting Stool

71

TRM120-07L Transmission Guard L/H

71

TRM120-07R Transmission Guard R/H

72

WS118 Sticker: Grease Symbol

73

FSH08015,FWF08 S/Screw M8 X 15, Flat Washer

74

WS103 Sticker: Keep Wheel Nuts Tight

75

WS11 Sticker: Mow General Warning

76

FSH08010,FWS08,FWF08 S/Screw M8 X 10, Washer Spring, Washer Flat

77

LRM120-37 Plastic Plug-Kill Switch Mounting

78

LRM126-01A Kill Switch Assembly

79

-013A Engine Mounting Plate

80

S/Screw M10 X 60, Flat Washers, Nyloc Nut

81

LRM123-03 Key Engine Pulley

Page 24

24

This Logic Manufacturing product is guaranteed against faulty workmanship and materials for a

period of 6 months from the date of purchase.

On Engine-Powered equipment, the engine manufacturer’s guarantee will apply, any claims

being subject to their terms and conditions.

All claims must be made in writing within 28 days of the alleged failure.

All claims must be made through the dealer who originally supplied the machine.

Any defective parts must be kept for inspection and if requested, sent to the factory or dealer.

The customer must bring equipment for repair to the dealer.

This guarantee becomes void if unauthorised modifications have been made, or if parts not

manufactured, supplied or approved by Logic Manufacturing have been fitted to the machine.

We accept no liability for normal wear and tear, misuse or abuse, or where recommended

maintenance has not been carried out.

All guarantee work must be authorised by Logic manufacturing prior to any work being done.

Work carried out without our consent may not be reimbursed.

LOGIC MANUFACTURING PR

ODUCTS OWNER

10

Item

Part Number

Description

82

FCF06 Clip Fix Rubber Lined 6.0mm

83

FSH06020,FWF06 S/Screw M6 X 20, Flat Washer

84

S216-048 Durite Heavy Duty Terminal

85

S216-047 Stadium Clip 21 MM OD

86

FSH06035,FWF06 S/Screw M6 X 35, Flat Washer

87

MFG109-04 Clip Base Plate

88

LRM123-03 Cable Clip

BRIGGS & STRATTON:

89

ME-S034 Switch Rocker On/Off 12v 6A B/S

90

FSC08035,FWF08,FNN08 Screw C/Sunk M8 X 35,Flat Washers, Nyloc Nut X2

91

EBV121 Engine B+S 12.5hp Recoil Start

92

TRM127-01 Throttle Control 2.7mt Fast/Slow Only

HONDA:

93

FSC516100,FWF08 Screw C/Sunk Sckt 5/16 X 1”, Flat Washer

90

Screw C/Sunk M8 X 35, Flat Washers, Nyloc Nut

91

EHV131 Engine Honda 13hp Electric Start

91

EHV132 Engine Honda 13hp Recoil Start

92

LRM127-01 Throttle Control 2.7metre

S216-060A Battery Lead ATV End (Electric Start Only)

Page 25

25

DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITYDECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

93 / 44 EEC

93 / 44 EEC93 / 44 EEC

93 / 44 EEC

LOGIC MANUFACTURING LTD

Foundry Industrial Estate

Bridge End

HEXHAM

Northumberland

Product Type: TRM120 – ROTARY MOWER RANGE

C

overed By Technical File Number: CE – LRM120

Serial Number:

Standards and Regulations Used:

The Supply of Machinery (Safety) Regulations 1992

HSE Guide Lines on ATV Equipment (Agric Sheet No. 11)

HSE Guide lines On Agricultural Mowers (Agric Sheet No.25)

Place of Issue: United Kingdom

Name of Authorised Representative: P. G. RIDLEY

Position of Authorised Representative: RESEARCH & DEVELOPMENT MANAGER

D

eclaration,

I declare that as the authorised representative, the above information in relation to the

Supply / manufacture of this product, is in conformity with the stated standards and other related

documents following the provisions of 93/68EEC directives

Signature of Authorised Representative

Date: 02/04/07

Loading...

Loading...