Datasheet LF48908QC25, LF48908JC50, LF48908JC25, LF48908QC31, LF48908JC31 Datasheet (LOGIC)

DEVICES INCORPORATED

1

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

❑❑

❑❑

❑ 40 MHz Data and Computation

Rate

❑❑

❑❑

❑ Nine Multiplier Array with 8-bit

Data and 8-bit Coefficient Inputs

❑❑

❑❑

❑ Separate Cascade Input and Output

Ports

❑❑

❑❑

❑ On-board Programmable Row

Buffers

❑❑

❑❑

❑ Two Coefficient Mask Registers

❑❑

❑❑

❑ On-board 8-bit ALU

❑❑

❑❑

❑ Two’s Complement or Unsigned

Operands

❑❑

❑❑

❑ Replaces Harris HSP48908

❑❑

❑❑

❑ DECC SMD No. 5962-93007

❑❑

❑❑

❑ Package Styles Available:

• 84-pin Plastic LCC, J-Lead

• 100-pin Plastic Quad Flatpack

FEATURES DESCRIPTION

LF48908

Two Dimensional Convolver

DEVICES INCORPORATED

The LF48908 is a high-speed two

dimensional convolver that implements a 3 x 3 kernel convolution at

real-time video rates. Programmable

row buffers are located on-chip,

eliminating the need for external data

storage. Each row buffer can store up

to 1024 pixels. Two internal register

banks are provided allowing two

separate sets of filter coefficients to be

stored simultaneously. Adaptive filter

operations are possible when both

register banks are used. An on-chip

ALU is provided, allowing real-time

arithmetic and logical pixel point

operations to be performed on the

image data. The 3 x 3 convolver

comprises nine 8 x 8-bit multipliers,

various pipeline registers, and summers. A complete sum-of-products

operation is performed every clock

cycle. The FRAME signal resets all

data registers without affecting the

control and coefficient registers.

Pixel and coefficient input data are

both 8-bits and can be either signed or

unsigned integers. Image data should

be in a raster scan non-interlaced

format. The LF48908 can internally

store images as wide as 1024 pixels for

the 3 x 3 convolution. By using

external row buffers and multiple

LF48908s, longer pixel rows can be

used and convolutions with larger

kernel sizes can be performed. Output data is 20-bits and this guarantees

no overflow for kernel sizes up to 4 x 4.

A separate cascade input is used as

the data input for summing results

from multiple LF48908s. It can also

function as the data input path when

external line buffers are used.

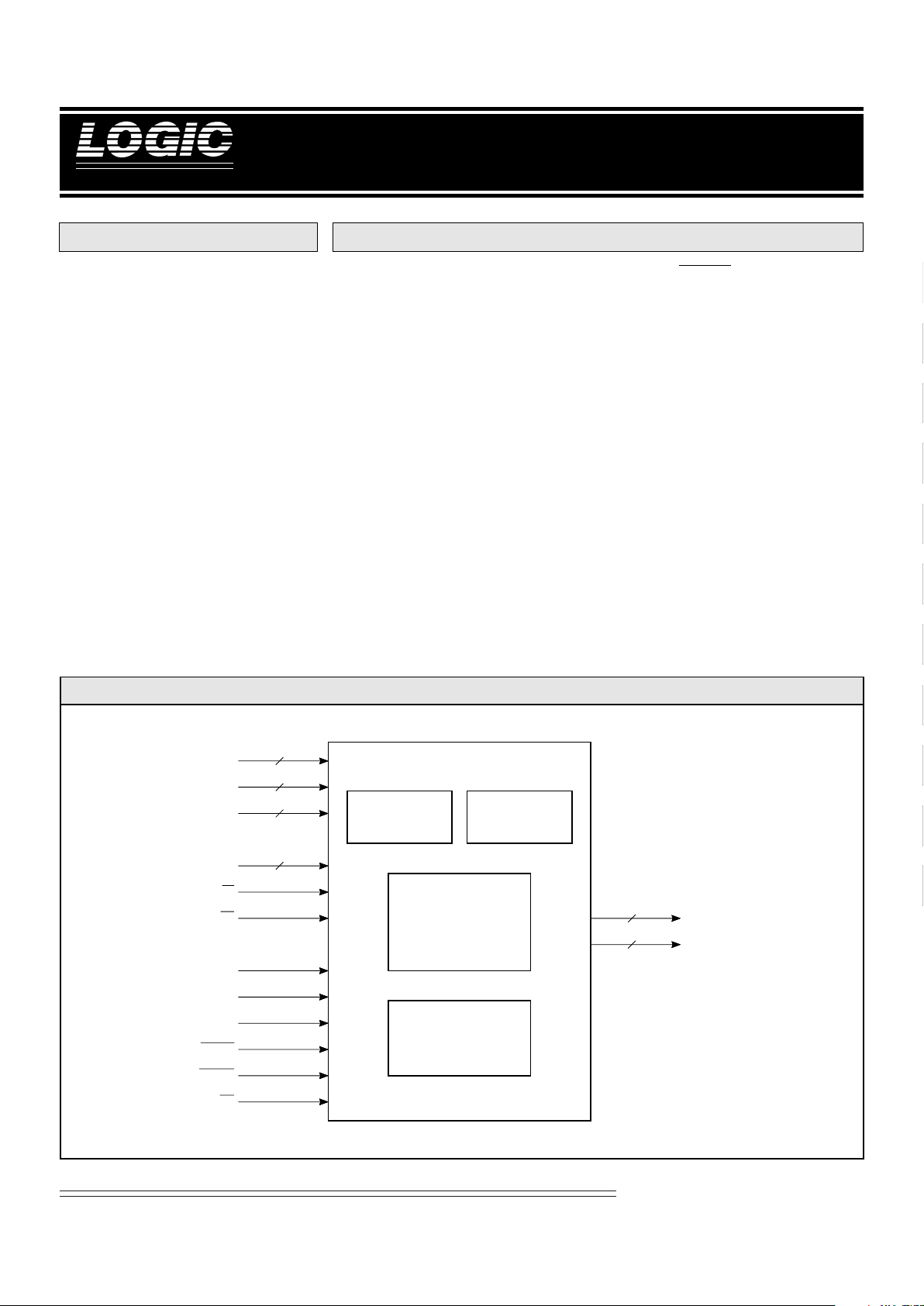

FIGURE 1. LF48908 BLOCK DIAGRAM

DIN

7-0

CIN

9-0

CASO

7-0

A

2-0

LD

CS

CASI

15-0

CLK

HOLD

FRAME

RESET

OE

DOUT

19-0

16

3

8

8

20

8

EALU

3 x 3

CONVOLVER

ALU

ROW

BUFFERS

CONTROL

LOGIC

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

2

Video Imaging Products

08/9/2000–LDS.48908-J

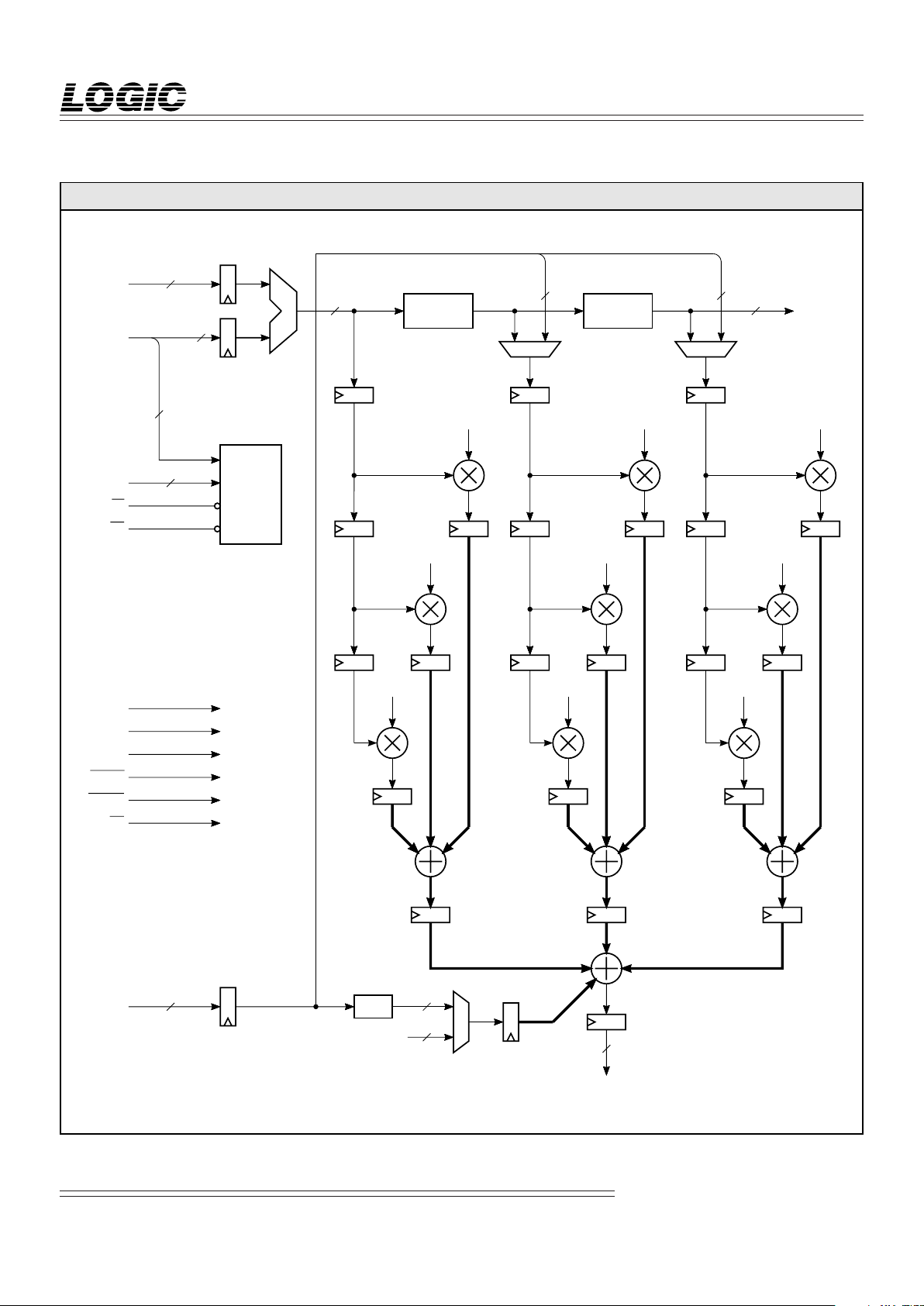

FIGURE 2. LF48908 FUNCTIONAL BLOCK DIAGRAM

DIN

7-0

1-4

CIN

9-0

2:1 2:1

ROW

BUFFER

ROW

BUFFER

CASO

7-0

7-0 15-8

A

2-0

LD

CS

CONTROL

LOGIC

CASI

15-0

2:1

SHIFT

0

CLK

HOLD

FRAME

RESET

OE

DOUT

19-0

I

H

G

F

E

D

C

B

A

ALU

REGISTER

ALU

20

20

16

3

8

8

10

20

8 8

8 8

7-0

EALU

NOTE: NUMBERS IN REGISTER INDICATE

NUMBER OF PIPELINE DELAYS.

DEVICES INCORPORATED

3

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

A2-0 — Control Logic Address Lines

A2-0 determines which Control Logic

Register will receive the CIN9-0 data.

CS — Chip Select

When CS is LOW, data can be loaded

into the Control Logic Registers.

When CS is HIGH, data can not be

loaded and the register contents will

not be changed.

LD — Load Strobe

If CS and LD are LOW, the data

present on CIN9-0 will be latched into

the Control Logic Register addressed

by A2-0 on the rising edge of LD.

FUNCTIONAL DESCRIPTION

The LF48908, a two-dimensional

convolver, executes convolutions using

internal row buffers to reduce design

complexity and board space requirements. 8-bit image data, in raster scan,

non-interlace format, is convolved with

one of two internal, 3 x 3 userprogramable filter kernels. Two 1024 x 8bit row buffers provide the data delay

needed to perform two-dimensional

convolutions on a single chip. The result

output of 20-bits allows for word growth

during the convolution operation.

The input data path (DIN7-0) provides

access to an 8-bit ALU. This allows

point operations to be performed on

the incoming data stream before

reaching the row buffers and the

convolver. The length of these buffers

is programmable for use in various

video formats without the need for

additional external delay.

This device is configured by loading

the coefficent data (filter kernels) and

row buffer length through the

coefficent data path (CIN7-0). Internal

registers are addressed using the A2-0

address lines. Chip Select (CS) and

Load Strobe (LD) complete the

configuration interface which may be

controlled by standard microprocessors without additional external logic.

SIGNAL DEFINITIONS

Power

VCC and GND

+5 V power supply. All pins must be

connected.

Clock

CLK — Master Clock

The rising edge of CLK strobes all

enabled registers except for the

Control Logic Registers.

Inputs

DIN7-0 — Pixel Data Input

DIN7-0 is the 8-bit registered pixel

data input port. Data is latched on the

rising edge of CLK.

CIN9-0 — Coefficient and Control Logic

Register Input

CIN7-0 is used to load the Coefficient

Registers or can be used to provide a

second operand input to the ALU.

CIN8-0 is used to load the Initialization Register. CIN9-0 is used to load

the ALU Microcode and Row Buffer

Length Registers. The Control Register Address Lines, A2-0, determine

which register will receive the CIN

data. The CIN data is loaded into the

addressed register by using the CS

and LD control inputs.

CASI15-0 — Cascade Input

The cascade input is used when

multiple LF48908s are cascaded

together or when external row buffers

are needed. This allows convolutions

of larger kernels or longer row sizes.

Outputs

DOUT19-0 — Data Output

DOUT19-0 is the 20-bit registered data

output port.

CASO7-0 — Cascade Output

The data presented on CASO7-0 is the

internal ALU output delayed by twice

the programmed internal row buffer

length.

Controls

RESET — Reset Control

When RESET is LOW, all internal

circuitry is reset, all outputs are forced

LOW, all Control Logic Registers are

loaded with their default values

(which is 0 for each one except the

ALU Microcode Register which has a

default value of “0000011000”), and all

other internal registers are loaded

with a “0”.

FRAME — New Frame Input Control

When asserted, FRAME signals the

start of a new frame. When FRAME is

LOW, all internal circuitry is reset

except for the ALU Microcode, Row

Length, Initialization, Coefficient, and

ALU Registers.

EALU — Enable ALU Register Input

When HIGH, data on CIN7-0 is latched

into the ALU Register on the next

rising edge of CLK. When LOW, data

on CIN7-0 will not be latched into the

ALU Register and the register contents will not be changed.

HOLD — Hold Control

The HOLD input is used to disable

CLK from all of the internal circuitry.

HOLD is latched on the rising edge of

CLK and takes effect on the next rising

edge of CLK. When HOLD is HIGH,

CLK will have no effect on the

LF48908 and all internal data will

remain unchanged.

OE — Output Enable

When OE is LOW, DOUT19-0 is

enabled for output. When OE is

HIGH, DOUT19-0 is placed in a highimpedance state.

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

4

Video Imaging Products

08/9/2000–LDS.48908-J

The filtered image data is output on

the Data Output bus (DOUT19-0). This

bus is registered with three-state

drivers to facilatate use on a standard

microprocessor system bus.

Data Input

Image data is input to the 3 x 3

convolver using DIN7-0. Data present

on DIN7-0 is latched into a programmable pipeline delay on the rising

edge of CLK. The programmable

pipeline delay (1 to 4 clock cycles)

allows for synchronization of input

data when multiple LF48908s are

cascaded together to perform larger

convolutions. This delay is programed via the Initialization Register

(see Table 3). The image data format,

unsigned or two’s complement, is also

controlled by this register.

Coefficient data is input to the 3 x 3

convolver using either of two Coefficient Registers (CREG0 or CREG1).

The Coefficient Registers are loaded

through CIN7-0 using the A2-0, CS, and

LD controls. The coefficient data

format, unsigned or two’s complement, is determined by the Initialization Register.

Arithmetic Logic Unit

The input data path ALU with shifter

allows pixel point operations to be

performed on the incoming image.

These operations include arithmetic

functions, logical masking, and left/

right shifts. The 10-bit ALU Microcode Register controls the various

operations. The three upper bits

control the shift amount and direction

while the seven lower bits determine

the arithmetic or logical operation.

The shift operation is performed on

the output of the ALU. This shift

operation is independent of the

arithmetic or logical operation of the

ALU.

Tables 1 and 2 show the operations of

the ALU Microcode Register. The “A”

operand comes from the DIN input

data path, while the “B” operand is

taken from the ALU Register. The

ALU Register is loaded using CIN7-0

and EALU. With EALU HIGH, data

from CIN7-0 is loaded into the ALU

Register on the rising edge of CLK.

With EALU LOW, the data is held in

the ALU Register. Since CIN7-0 is also

used to load the Control Logic Registers, it is possible to overwrite data in

those registers if CS and LD are active

when loading the ALU Register.

Therefore, special care must be taken

to ensure that CS and LD are not

active when writing to the ALU

Register.

Programmable Row Buffers

The two internal row buffers provide

the delay needed to perform the twodimensional convolution. The row

buffers function like 8-bit serial shift

registers with a user-programmable

delay from 1 to 1024 stages (it is

possible to select delay stages of 1 or

2, but this leads to meaningless results

for a 3 x 3 kernel convolution). The

row buffer length is set via the Row

Length Register (see Row Length

Register Section). The row buffers are

connected in series to provide the

proper pixel information to the

multiplier array. The Cascade Output

(CASO7-0) provides a 2X row delay of

the input data allowing for cascading

of LF48908s to handle larger frames

and/or kernel sizes. If more than 1024

delay stages are needed, it is possible

to use external row buffers and bypass

the internal row buffers. Bit 0 of the

Initialization Register determines if

internal or external row buffers are

used. If Bit 0 is a “0”, the internal row

buffers are used. If Bit 0 is a “1”, the

internal row buffers are bypassed and

external row buffers may be used.

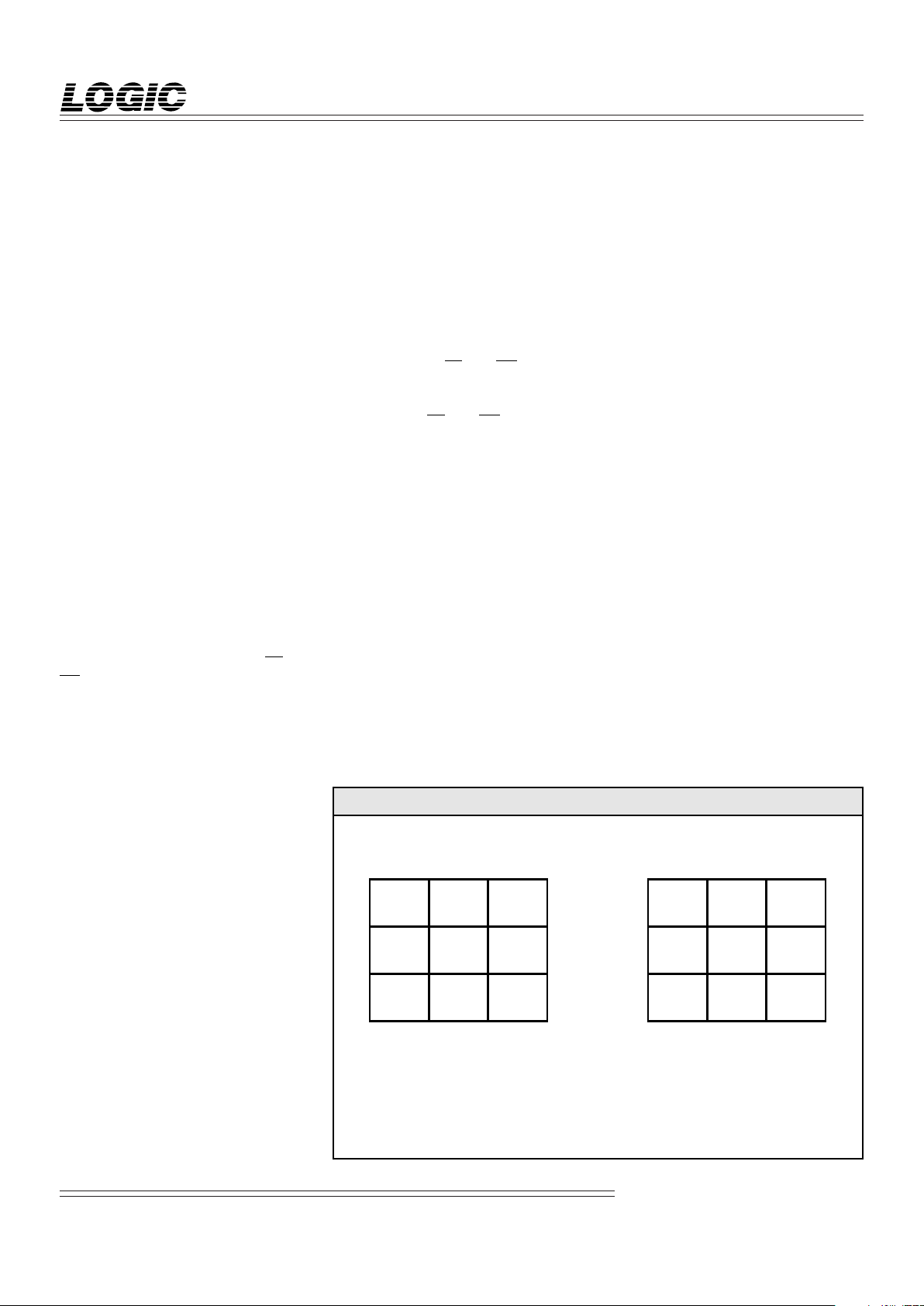

3 x 3 Multiplier Array

The multiplier array comprises nine

8 x 8-bit multipliers. The active

Coefficient Register supplies the

coefficents to each of the multipliers,

while the pixel data comes from the

data input path and row buffers. The

array forms a sum-of-products result

as defined by the equation listed in

Figure 3.

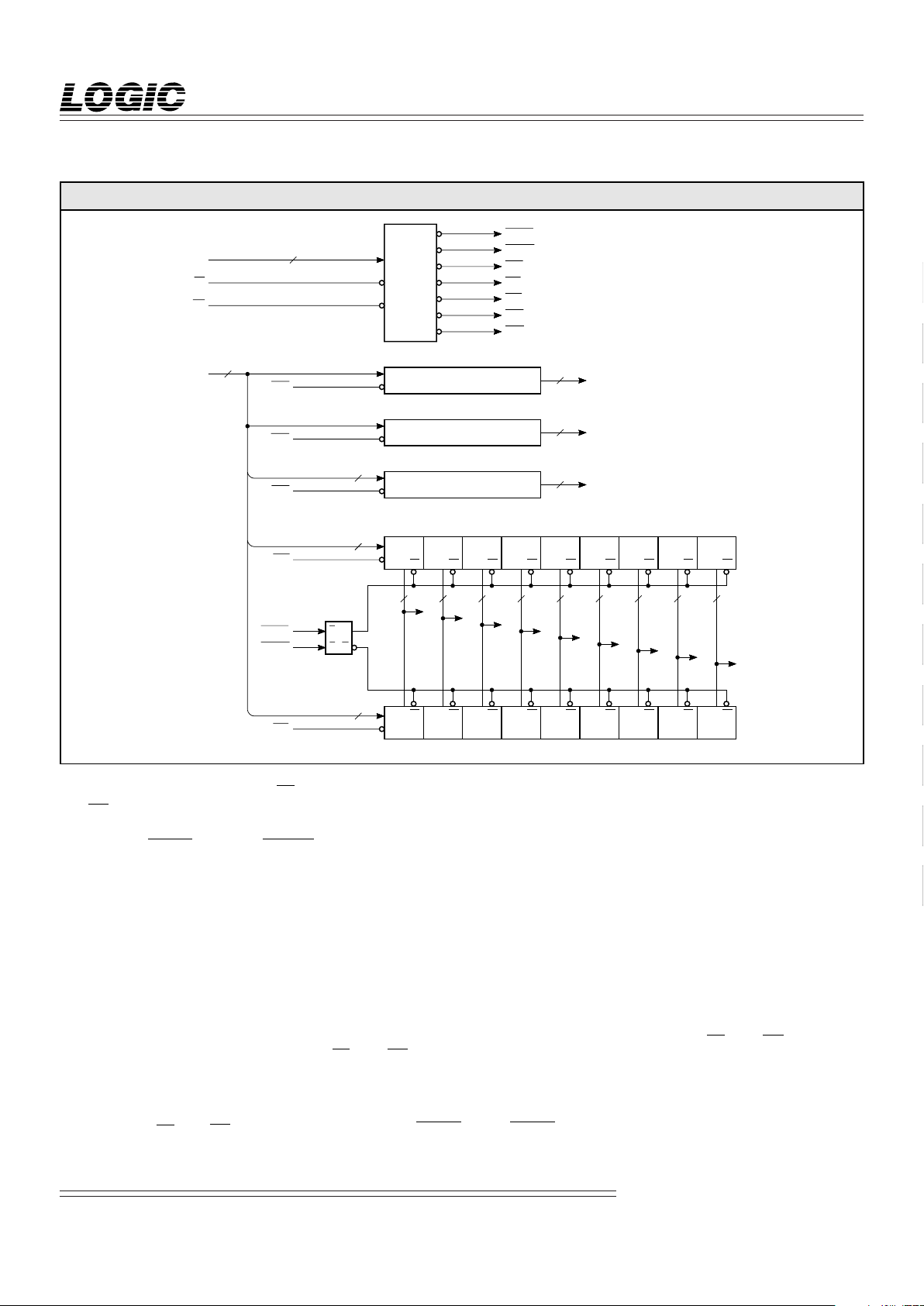

CONTROL LOGIC

Four sets of registers, the ALU Microcode, Row Length, Initialization, and

Coefficient, define the Control Logic

section. These registers are updated

FIGURE 3. MULTIPLIER ARRAY OUTPUT

P1 P2 P3

P4 P5 P6

P7 P8 P9

ABC

DEF

GH I

PIXEL INPUT DATA

FILTER KERNEL

MULTIPLIER ARRAY OUTPUT A(P1)=

+ D(P4)

+ G(P7)

+

+

+

B(P2)

E(P5)

H(P8)

+

+

+

C(P3)

F(P6)

I(P9)

DEVICES INCORPORATED

5

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

Row Length Register

The value stored in the Row Length

Register determines the number of

delay stages for each row buffer. The

number of delay stages should be set

equal to the row length of the input

image. The Row Length Register may

be loaded with the values 0 through

1023 (0 represents 1024 delay stages).

It is possible to program the row

buffers to have 1 or 2 delay stages, but

this will lead to meaningless results

for a 3 x 3 convolution. This register is

loaded through CIN9-0 using the A2-0,

CS, and LD controls. Once the Row

Length Register has been loaded, a

new value can not be loaded until the

LF48908 has been reset. This is done

by asserting RESET. After RESET goes

HIGH, the Row Length Register must

be loaded within 1024 CLK cycles. If

the Row Length Register is not loaded

within 1024 CLK cycles, the register

will automatically be loaded with a “0”.

Initialization Register

The Initialization Register configures

various functions of the device

including: input data delay, input

data format, coefficent data format,

output rounding, cascade mode, and

cascade input shift (see Table 3). This

register is loaded through CIN8-0

using the A2-0, CS, and LD controls.

Coefficient Registers - CREG0, CREG1

The Coefficient Registers are used to

store the filter coefficients for the

multiplier array. Each Coefficient

through the CIN bus using A2-0, CS,

and LD (see Figure 4). All the Control

Logic Registers are set to their default

values when RESET is active. FRAME

does not affect the values in these

registers.

ALU Microcode Register

Operation of the ALU and shifter are

determined by the value stored in the

ALU Microcode Register. This 10-bit

instruction word is divided into two

fields. The lower seven bits define the

arithmetic and logical operations of the

ALU. The upper three bits specify shift

distance and direction. Tables 1 and 2

detail the various instruction words.

This register is loaded through CIN9-0

using the A2-0, CS, and LD controls.

Also see Arithmetic Logic Unit section.

FIGURE 4. LF48908 CONTROL LOGIC BLOCK DIAGRAM

A2-0

LD

CS

ADDRESS

DECODE

3

ENCR1

ENCR0

CAS

CR1

CR0

LMC

EOR

CIN9-0

10

ALU MICROCODE REGISTER

LMC

ALU MICROCODE

10

ROW LENGTH REGISTER

EOR

ROW LENGTH

10

INITIALIZATION REGISTER

CAS

INITIALIZATION DATA

9

8-0

I

0 H0 G0 F0 E0 D0 C0 B0 A0

CR0

CR1

SRQ

Q

OE OE OE OE OE OE OE OE OE

I1 H1 G1 F1 E1 D1 C1 B1 A1

OE

OE OE OE OE OE OE OE OE

ENCR1

ENCR0

I

H

G

F

E

D

C

B

A

8 8 8 8 8 8 8 8 8

COEFFICIENT REGISTER 0

COEFFICIENT REGISTER 1

9

7-0

8

7-0

8

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

6

Video Imaging Products

08/9/2000–LDS.48908-J

loaded is determined by the data on

A2-0 during the load operation. If

CREG0 is to be loaded, “010” must be

placed on A2-0 during the load operation. If CREG1 is to be loaded, “011”

must be placed on A2-0. If desired, the

Coefficient Register that is not being

used to send data to the multiplier

array can be loaded with coefficient

data while the LF48908 is in active

operation.

Address Decoder

The Address Decoder is used to load

the Control Logic Registers and to

determine which Coefficient Register

sends data to the multiplier array. To

load a Control Logic Register, the

address of the register must be placed

on A2-0, the data to be written must be

placed on the CIN bus, and CS and

LD must be asserted. The data is

TABLE 2. ALU LOGICAL AND ARITHMETIC OPERATIONSTABLE 1. ALU SHIFT OPERATIONS

ALU MICROCODE REGISTER

REGISTER BIT

9 8 7 OPERATION

0 0 0 No Shift (Default)

0 0 1 Shift Right 1

0 1 0 Shift Right 2

0 1 1 Shift Right 3

1 0 0 Shift Left 1

1 0 1 Shift Left 2

1 1 0 Shift Left 3

1 1 1 Not Valid

Register can hold nine 8-bit values.

This allows two different 3 x 3 filter

kernels to be stored simultaneously on

the LF48908. The outputs of CREG0

and CREG1 are connected to the

coefficient inputs of the multiplier

array (A through I). The register used

to supply the coefficient data is

determined by the address written to

the Address Decoder. If a “101” is

written to the Address Decoder,

CREG0 will provide the coefficient

data. If a “110” is written to the

Address Decoder, CREG1 will be used.

It is possible to switch between the

two Coefficient Registers in real time.

This facilitates adaptive filtering

operations. It is important to remember to meet the tLCS timing specification when switching the Coefficient

Registers. When a Coefficient Register

is selected to supply data to the

multiplier array (one of the registers is

always selected), all of its outputs are

enabled simultaneously. When RESET

is asserted, CREG0 is the default

register selected to supply the coefficient data.

CREG0 and CREG1 are loaded

through CIN7-0 using the A2-0, CS, and

LD controls. The nine coefficient

values are presented on CIN7-0 one by

one, in order from A to I. As each

value is placed on CIN7-0, it is latched

into the selected Coefficient Register

using CS and LD. The register to be

latched into the addressed register

when LD goes HIGH. To select a

Coefficient Register (CREG0 or

CREG1) to send data to the multiplier

array, the appropriate address must be

placed on A2-0, and CS and LD must

be asserted. When LD goes HIGH, the

addressed register will begin supplying coefficient data to the multiplier

array. Table 4 lists all of the register

addresses.

The Control Logic Registers can be

modified during active operation of

the LF48908. If this is done, it is very

important to meet the tLCS timing

specification. This is to ensure that the

outputs of the Control Logic Registers

have enough time to change before the

next rising edge of CLK. If tLCS is not

met, unexpected results may occur on

DOUT19-0 for one clock cycle. There

are two situations in which tLCS may

ALU MICROCODE REGISTER

REGISTER BIT

6 5 4 3 2 1 0 OPERATION

0 0 0 0 0 0 0 Logical (00000000)

1 1 1 1 0 0 0 Logical (11111111)

0 0 1 1 0 0 0 Logical (A) (Default)

0 1 0 1 0 0 0 Logical (B)

1 1 0 0 0 0 0 Logical (A)

1 0 1 0 0 0 0 Logical (B)

0 1 1 0 0 0 1 Arithmetic (A + B)

1 0 0 1 0 1 0 Arithmetic (A – B)

1 0 0 1 1 0 0 Arithmetic (B – A)

0 0 0 1 0 0 0 Logical (A AND B)

0 0 1 0 0 0 0 Logical (A AND B)

0 1 0 0 0 0 0 Logical (A AND B)

0 1 1 1 0 0 0 Logical (A OR B)

1 0 1 1 0 0 0 Logical (A OR B)

1 1 0 1 0 0 0 Logical (A OR B)

1 1 1 0 0 0 0 Logical (A NAND B)

1 0 0 0 0 0 0 Logical (A NOR B)

0 1 1 0 0 0 0 Logical (A XOR B)

1 0 0 1 0 0 0 Logical (A XNOR B)

DEVICES INCORPORATED

7

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

be ignored. If the LF48908 is not in

active operation or if the innactive

Coefficient Register is being written to

during active operation.

Cascade Operation

The Cascade Input lines (CASI15-0)

and Cascade Output lines (CASO7-0)

are used to allow convolutions of

kernel sizes larger than 3 x 3. The

Cascade Input lines are also used to

allow convolutions on row lengths

longer than 1024 pixels. The Cascade

Mode Bit (Bit 0) of the Initialization

Register determines the function of

the Cascade Input lines. If the Cascade Mode Bit is a “0”, then the

Cascade Input lines are to be used to

cascade multiple LF48908s together to

perform convolutions of larger kernel

sizes. CASI15-0 will be left shifted (by

an amount determined by bits 7 and 8

of the Initialization Register) and then

added to DOUT19-0. Cascading is

accomplished by connecting CASO7-0

and DOUT19-0 of one LF48908 to

DIN7-0 and CASI15-0 respectively of

another LF48908. If the Cascade

Mode Bit is a “1”, then the Cascade

Input lines are to be used with external row buffers to allow for longer

row lengths. In this mode, the Cascade Input lines are split into two 8-bit

data busses (CASI15-8 and CASI7-0)

which are fed directly into the multiplier array.

TABLE 3. INITIALIZATION REGISTER

BIT FUNCTION

0 CASCADE MODE

0 Multiplier input from internal row buffers

1 Multiplier input from external buffers

2 1 INPUT DATA DELAY

0 0 No data delay registers used

0 1 One data delay register used

1 0 Two data delay registers used

1 1 Three data delay registers used

3 INPUT DATA FORMAT

0 Unsigned integer format

1 Two’s complement format

4 COEFFICIENT DATA FORMAT

0 Unsigned integer format

1 Two’s complement format

6 5 OUTPUT ROUNDING

0 0 No rounding

0 1 Round to 16 bits (i.e. DOUT19-4)

1 0 Round to 8 bits (i.e. DOUT19-12)

1 1 Not valid

8 7 CASI15-0 INPUT SHIFT

0 0 No shift

0 1 Shift CASI15-0 left two

1 0 Shift CASI15-0 left four

1 1 Shift CASI15-0 left eight

A2-0 FUNCTION

000 Load Row Buffer Length

Register

001 Load ALU Microcode Register

010 Load Coefficient Register 0

011 Load Coefficient Register 1

100 Load Initialization Register

101 Select Coefficient Register 0

for Internal Processing

110 Select Coefficient Register 1

for Internal Processing

111 No Operation

TABLE 4. CONTROL LOGIC

ADDRESS MAP

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

8

Video Imaging Products

08/9/2000–LDS.48908-J

Symbol Parameter Test Condition Min Typ Max Unit

VOH Output High Voltage VCC = Min., IOH = –400 µA 2.8 V

VOL Output Low Voltage VCC = Min., IOL = 2.0 mA 0.4 V

VIH Input High Voltage 2.0 VCC V

V IL Input Low Voltage (Note 3) 0.0 0.8 V

IIX Input Current Ground ≤ VIN ≤ VCC (Note 12) ±10 µA

IOZ Output Leakage Current Ground ≤ VOUT ≤ VCC (Note 12) ±10 µA

ICC1 VCC Current, Dynamic (Notes 5, 6) 110 mA

ICC2 VCC Current, Quiescent (Note 7) 500 µA

CIN Input Capacitance TA = 25°C, f = 1 MHz 10 pF

COUT Output Capacitance TA = 25°C, f = 1 MHz 12 pF

OPERATING CONDITIONS

To meet specified electrical and switching characteristics

ELECTRICAL CHARACTERISTICS

Over Operating Conditions (Note 4)

Mode Temperature Range (Ambient) Supply Voltage

Active Operation, Commercial 0°C to +70°C 4.75 V ≤ VCC ≤ 5.25 V

Active Operation, Military –55°C to +125°C 4.50 V ≤ VCC ≤ 5.50V

Storage temperature ........................................................................................................... –65°C to +150°C

Operating ambient temperature........................................................................................... –55°C to +125°C

VCC supply voltage with respect to ground............................................................................ –0.5 V to +7.0V

Input signal with respect to ground ............................................................................... –0.5 V to VCC + 0.5 V

Signal applied to high impedance output ...................................................................... –0.5 V to VCC + 0.5 V

Output current into low outputs............................................................................................................. 25 mA

Latchup current ............................................................................................................................... > 400 mA

MAXIMUM RATINGS

Above which useful life may be impaired (Notes 1, 2, 3, 8)

DEVICES INCORPORATED

9

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

LF48908–

50 31 25

Symbol Parameter Min Max Min Max Min Max

tCYC Cycle Time 50 31 25

tPWH Clock Pulse Width High 20 12 8

tPWL Clock Pulse Width Low 20 13 8

tDS Data Input Setup Time 14 13 8

tDH Data Input Hold Time 0 0 0

tCS CIN7-0 Setup Time 16 14 10

tCH CIN7-0 Hold Time 0 0 0

tES EALU Setup Time 14 12 10

tEH EALU Hold Time 0 0 0

tD Output Delay 22 16 15

tENA Three-State Output Enable Delay (Note 11) 22 16 15

tDIS Three-State Output Disable Delay (Note 11) 32 28 8

COMMERCIAL OPERATING RANGE (0°C to +70°C)

Notes 9, 10 (ns)

SWITCHING CHARACTERISTICS

SWITCHING WAVEFORMS:CONVOLVER DATA I/O

CLK

tCYC

tPWL tPWH

DIN7-0

CASI15-0

tDS tDH

DOUT19-0

CASO7-0

tD

CIN7-0

tCS tCH

EALU

tES tEH

(ALU REG DATA)

OE

tD

tDIS tENA

HIGH IMPEDANCE

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

10

Video Imaging Products

08/9/2000–LDS.48908-J

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

234567890123456789012345678901212345678901234

5

LF48908–

50

*

37

*

25

*

Symbol Parameter Min Max Min Max Min Max

tCYC Cycle Time 50 37 25

tPWH Clock Pulse Width High 20 15 8

tPWL Clock Pulse Width Low 20 15 8

tDS Data Input Setup Time 17 16 8

tDH Data Input Hold Time 0 0 0

tCS CIN7-0 Setup Time 20 17 10

tCH CIN7-0 Hold Time 0 0 0

tES EALU Setup Time 17 15 10

tEH EALU Hold Time 0 0 0

tD Output Delay 28 19 15

tENA Three-State Output Enable Delay (Note 11) 28 19 15

tDIS Three-State Output Disable Delay (Note 11) 40 35 8

MILITARY OPERATING RANGE (–55°C to +125°C)

Notes 9, 10 (ns)

SWITCHING WAVEFORMS:CONVOLVER DATA I/O

CLK

tCYC

tPWL tPWH

DIN7-0

CASI15-0

tDS tDH

DOUT19-0

CASO7-0

tD

CIN7-0

tCS tCH

EALU

tES tEH

(ALU REG DATA)

OE

tD

tDIS tENA

HIGH IMPEDANCE

2345678901234567890123

4

2345678901234567890123

4

*DISCONTINUED SPEED GRADE

DEVICES INCORPORATED

11

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

1234567890123456789012345678901212345678901234

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1234567890123456789012345678901212345678901234

COMMERCIAL OPERATING RANGE (0°C to +70°C)

Notes 9, 10 (ns)

LF48908–

50

*

37

*

25

*

Symbol Parameter Min Max Min Max Min Max

tLPW LD Pulse Width 20 15 8

tLCS LD Setup Time (Applies only during active operation) 37 30 15

tCDS Configuration Data Setup Time 20 17 10

tCDH Configuration Data Hold Time 0 0 0

tAS Address Setup Time 15 15 10

tAH Address Hold Time 0 0 0

tCSS CS Setup Time 0 0 0

tCSH CS Hold Time 0 0 0

MILITARY OPERATING RANGE (–55°C to +125°C)

Notes 9, 10 (ns)

SWITCHING WAVEFORMS:CONFIGURATION DATA

LD

CS

A

2-0

CIN

9-0

t

CDS

t

CDH

t

CSS

t

LPW

t

CSH

t

AS

t

AH

CLK

t

LCS

*

*applies only when the LF48908 is in active operation.

LF48908–

50 31 25

Symbol Parameter Min Max Min Max Min Max

tLPW LD Pulse Width 20 12 8

tLCS LD Setup Time (Applies only during active operation) 30 25 15

tCDS Configuration Data Setup Time 16 14 10

tCDH Configuration Data Hold Time 0 0 0

tAS Address Setup Time 13 13 10

tAH Address Hold Time 0 0 0

tCSS CS Setup Time 0 0 0

tCSH CS Hold Time 0 0 0

2345678901234567890123

4

2345678901234567890123

4

*DISCONTINUED SPEED GRADE

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

12

Video Imaging Products

08/9/2000–LDS.48908-J

1234567890123456789012345678901212345678901234

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1

23456789012345678901234567890121234567890123

4

1234567890123456789012345678901212345678901234

LF48908–

50

*

37

*

25

*

Symbol Parameter Min Max Min Max Min Max

tHS HOLD Setup Time 14 13 9

tHH HOLD Hold Time 2 2 0

tFPW FRAME Pulse Width 50 37 8

tFS FRAME Setup Time 30 25 20

tRPW RESET Pulse Width 50 37 8

LF48908–

50 31 25

Symbol Parameter Min Max Min Max Min Max

tHS HOLD Setup Time 12 11 9

tHH HOLD Hold Time 1 1 0

tFPW FRAME Pulse Width 50 31 8

tFS FRAME Setup Time 25 21 20

tRPW RESET Pulse Width 50 31 8

COMMERCIAL OPERATING RANGE (0°C to +70°C)

Notes 9, 10 (ns)

MILITARY OPERATING RANGE (–55°C to +125°C)

Notes 9, 10 (ns)

SWITCHING WAVEFORMS:CONTROL SIGNALS

CLK

HOLD

t

HS

t

HH

RESET

t

RPW

FRAME

t

HS

t

FPW

t

FS

2345678901234567890123

4

2345678901234567890123

4

*DISCONTINUED SPEED GRADE

DEVICES INCORPORATED

13

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

1. Maximum Ratings indicate stress

specifications only. Functional operation of these products at values beyond

those indicated in the Operating Conditions table is not implied. Exposure to

maximum rating conditions for extended periods may affect reliability.

2. The products described by this specification include internal circuitry designed to protect the chip from damaging substrate injection currents and accumulations of static charge. Nevertheless, conventional precautions should

be observed during storage, handling,

and use of these circuits in order to

avoid exposure to excessive electrical

stress values.

3. This device provides hard clamping of

transient undershoot and overshoot. Input levels below ground or above VCC

will be clamped beginning at –0.6 V and

VCC + 0.6 V. The device can withstand

indefinite operation with inputs in the

range of –0.5 V to +7.0 V. Device operation will not be adversely affected, however, input current levels will be well in

excess of 100 mA.

4. Actual test conditions may vary from

those designated but operation is guaranteed as specified.

5. Supply current for a given application can be accurately approximated by:

where

N = total number of device outputs

C = capacitive load per output

V = supply voltage

F = clock frequency

6. Tested with all outputs changing every cycle and no load, at a 20 MHz clock

rate.

7. Tested with all inputs within 0.1 V of

VCC or Ground, no load.

8. These parameters are guaranteed

but not 100% tested.

NCV F

4

2

NOTES

9. AC specifications are tested with

input transition times less than 3 ns,

output reference levels of 1.5 V (except

tDIS test), and input levels of nominally

0 to 3.0 V. Output loading may be a

resistive divider which provides for

specified IOH and IOL at an output

voltage of VOH min and VOL max

respectively. Alternatively, a diode

bridge with upper and lower current

sources of IOH and IOL respectively,

and a balancing voltage of 1.5 V may be

used. Parasitic capacitance is 30 pF

minimum, and may be distributed.

This device has high-speed outputs capable of large instantaneous current

pulses and fast turn-on/turn-off times.

As a result, care must be exercised in the

testing of this device. The following

measures are recommended:

a. A 0.1 µF ceramic capacitor should be

installed between VCC and Ground

leads as close to the Device Under Test

(DUT) as possible. Similar capacitors

should be installed between device VCC

and the tester common, and device

ground and tester common.

b. Ground and VCC supply planes

must be brought directly to the DUT

socket or contactor fingers.

c. Input voltages should be adjusted to

compensate for inductive ground and VCC

noise to maintain required DUT input

levels relative to the DUT ground pin.

10. Each parameter is shown as a minimum or maximum value. Input requirements are specified from the point

of view of the external system driving

the chip. Setup time, for example, is

specified as a minimum since the external system must supply at least that

much time to meet the worst-case requirements of all parts. Responses from

the internal circuitry are specified from

the point of view of the device. Output

delay, for example, is specified as a

maximum since worst-case operation of

any device always provides data within

that time.

11. For the tENA test, the transition is

measured to the 1.5 V crossing point

with datasheet loads. For the tDIS test,

the transition is measured to the

±200mV level from the measured

steady-state output voltage with

±10mA loads. The balancing voltage, VTH, is set at 3.5 V for Z-to-0

and 0-to-Z tests, and set at 0 V for Zto-1 and 1-to-Z tests.

12. These parameters are only tested at

the high temperature extreme, which is

the worst case for leakage current.

S1

I

OH

I

OL

V

TH

C

L

DUT

OE

0.2 V

t

DIS

t

ENA

0.2 V

1.5 V 1.5 V

3.5V Vth

1

Z

0

Z

Z

1

Z

0

1.5 V

1.5 V

0V Vth

VOL*

V

OH

*

V

OL

*

V

OH

*

Measured V

OL

with IOH = –10mA and IOL = 10mA

Measured V

OH

with IOH = –10mA and IOL = 10mA

FIGURE B. THRESHOLD LEVELS

FIGURE A. OUTPUT LOADING CIRCUIT

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

14

Video Imaging Products

08/9/2000–LDS.48908-J

Plastic J-Lead Chip Carrier

(J3)

LF48908JC50

LF48908JC31

LF48908JC25

ORDERING INFORMATION

0°C to +70°C — COMMERCIAL SCREENING

Speed

50 ns

31 ns

25 ns

84-pin

1234567

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

84 83 82 81 80 79

4443 45 46 47 493837 39 40 41 42

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

48

Top

View

891011 78 77 76 75

36353433 50 51 52 53

CIN3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

GND

CLK

V

CC

HOLD

LD

CS

A

2

A1

A0

EALU

CASI

15

CASI14

CASI13

CASI12

CASO6

CASO7

DOUT0

DOUT1

DOUT2

GND

DOUT

3

DOUT4

DOUT5

DOUT6

DOUT7

VCC

DOUT8

GND

DOUT

9

DOUT10

DOUT11

DOUT12

DOUT13

DOUT14

GND

CASI11

CASI10

CASI9

CASI8

CASI7

CASI6

CASI5

CASI4

CASI3

VCC

CASI2

CASI1

CASI0

FRAME

RESET

GND

DOUT

19

DOUT18

DOUT17

DOUT16

DOUT15

CIN2

CIN1

CIN0

DIN7

DIN6

DIN5

DIN4

DIN3

DIN2

DIN1

DIN0

VCCOEGND

CASO0CASO1

CASO2

CASO3

CASO4

GND

CASO

5

–40°C to +85°C — COMMERCIAL SCREENING

DEVICES INCORPORATED

15

LF48908

Two Dimensional Convolver

1

2

3

4

5

6

7

8

9

10

11

08/9/2000–LDS.48908-J

Video Imaging Products

Plastic Quad Flatpack

(Q2)

LF48908QC31

LF48908QC25

ORDERING INFORMATION

0°C to +70°C — COMMERCIAL SCREENING

Speed

31 ns

25 ns

100-pin

CIN1

CIN2

NC

NC

CIN

3

CIN4

CIN5

CIN6

CIN7

CIN8

CIN9

GND

GND

CLK

V

CC

VCC

HOLD

LD

CS

A

2

A1

A0

EALU

CASI

15

CASI14

CASI13

CASI12

NC

NC

CASI

11

CIN0

DIN7

DIN6

DIN5

DIN6

DIN3

DIN2

DIN1

DIN0

VCC

VCCOEGND

GND

CASO0CASO1

CASO2

CASO3

CASO4

GND

GND

CASO

5

NC

CASO

6

CASO7

DOUT0

DOUT1

DOUT2

GND

GND

DOUT

3

DOUT4

DOUT5

DOUT6

DOUT7

VCC

VCC

DOUT

8

GND

GND

DOUT

9

DOUT10

DOUT11

DOUT12

DOUT13

DOUT14

GND

GND

DOUT

15

DOUT16

CASI10

CASI9

CASI8

CASI7

CASI6

CASI5

CASI4

CASI3

VCC

VCC

CASI2

CASI1

CASI0

FRAME

RESET

GND

GND

DOUT

19

DOUT18

DOUT17

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

Top

View

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31323334353637383940414243444546474849

50

100

99989796959493929190898887868584838281

–40°C to +85°C — COMMERCIAL SCREENING

DEVICES INCORPORATED

LF48908

Two Dimensional Convolver

16

Video Imaging Products

08/9/2000–LDS.48908-J

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

23456789012345678901234567890121234567890123456789012345678901212345678901234567890123456789012

1

Ceramic Pin Grid Array

(G6)

ORDERING INFORMATION

0°C to +70°C — COMMERCIAL SCREENING

Speed

–55°C to +125°C — MIL-STD-883 COMPLIANT

–55°C to +125°C — COMMERCIAL SCREENING

84-pin

A

B

C

D

E

F

G

H

J

K

L

Top View

Through Package

(i.e., Component Side Pinout)

12345

6

7 8 9 10 11

CIN

0

CIN

3

CIN

4

CIN

7

GND

V

CC

A

2

EALU

CASI

13

CASI

11

CASI

9

DIN

7

CIN

1

CIN

9

HOLD

LD

CASI

10

CASI

8

DIN

5

DIN

6

CASI

7

CASI

6

DIN

2

DIN

3

DIN

4

CASI

5

CASI

4

CASI

3

DIN

1

CASO

0

DIN

0

CASI

2

V

CC

RESET

OE

GND

V

CC

CASI

1

FRAME

CASI

0

CASO

1

CASO

2

DOUT

19

GND

CIN

2

CIN

5

CIN

6

CIN

8

CLK

A

1

CS

A

0

CASI

15

CASI

14

CASI

12

CASO

3

GND

DOUT

3

DOUT

7

V

CC

DOUT

16

DOUT

18

CASO

4

CASO

5

CASO

7

DOUT

2

DOUT

4

DOUT

9

GND

DOUT

11

DOUT

14

GND

DOUT

17

CASO

6

DOUT

0

DOUT

1

GND

DOUT

5

DOUT

6

DOUT

8

DOUT

10

DOUT

12

DOUT

13

DOUT

15

Discontinued Package

Loading...

Loading...