Page 1

LDS120/120DS/240/360/700

OPERATORS MANUAL

WM1

-

LDS120

LDS – GROUND

DRIVE SPREADER

Page 2

LD

S Serial Number:

Date of Purchase:

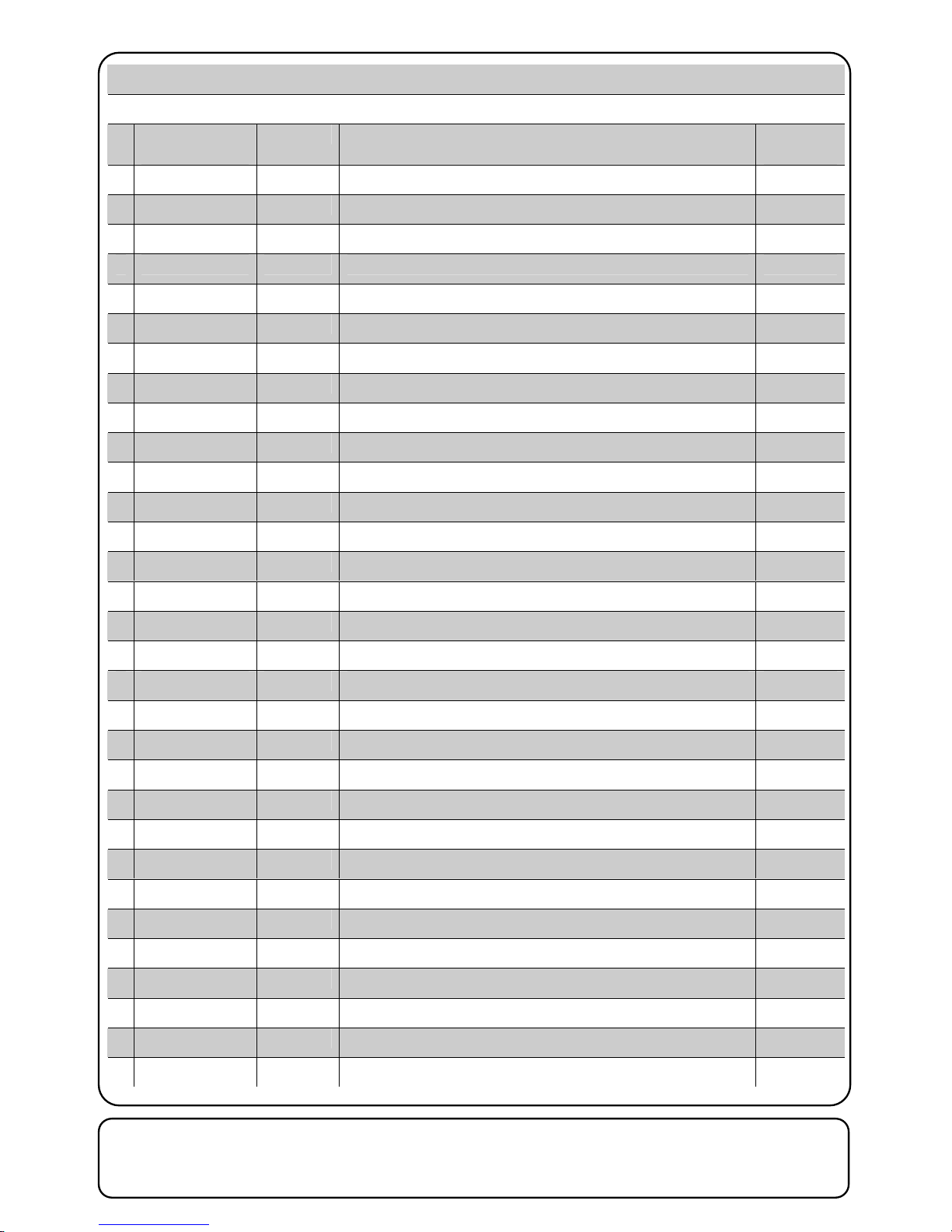

INDEX

Section:

Description: Page

No:

1 Introduction 1

HSE Information Sheet 2

HSE Information Sheet 3

2 In the interest of safety: DO NOT 4

3 In the interest of safety: DO 5

4 Instruction & Warning Decals 6

5 Transporting and lifting the LDS 7

6 Operating instructions and adjustments

6.1 Before use check the following 8

6.2 Distribution 9

6.3 Vane regulation / adjustment 10

6.4 Calibration 10

6.5 Calibration charts LDS120/240/360/700 11

6.6 Calibration charts LDS120DS 12

7 Maintenance

7.1 Daily maintenance 14

7.2 Seasonal 15

8 Exploded Parts Diagram

8.1 Main frame LDS120/DS

16

8.2 Main frame Parts list LDS120/DS 17

8.3 Spinner and Hopper LDS120/DS

18

8.4 Main frame LDS240/360

19

8.5 Main frame Parts list LDS240/360 20

8.6 Spinner and Hopper LDS240/360

21

8.7 Drive Assembly LDS700

22

8.8 Main frame LDS700

22

8.9 Wheels & Tyres LDS700 23

8.10 Spinner & Agitator LDS700

23

8.11 Parts list LDS700 24

9 Owner Guarantee 25

Declaration of conformity 26

Page 3

1

W

ith the purchase of your LOGIC LDS – GROUND DRIVE SPREADER you have made an

excellent choice.

This machine should give first class service for a long time, if used correctly, and maintained as

described in this manual.

The Ground Drive Spreader range is capable of spreading fertiliser as well as salt depending on

which model you have, it is ideal for small holdings or similar smaller areas where a general

approach to spreading is required.

The hopper capacities range from, 120 - 700lt. being land driven it is essential to maintain a

constant forward speed if accurate spread patterns and accurate quantities are to be achieved,

therefore an accurate speedometer may be required.

The Ground Drive Spreader has a mild steel framework with a galvanised finish to add extra

protection from corrosion and harsh working environments.

If, after reading this manual there are any queries, please get in touch, we will be pleased to

help.

NORTH & EXPORT SOUTH

L

OGIC MANUFACTURING LTD LOGIC MH LTD - New Whiteway Works,

Foundry Industrial Estate Fossecross Industrial Estate

Bridge End, Hexham Chedworth. Cheltenham

Northumberland NE46 4JL Gloucestershire GL54 4NW

Tel: 01434 606661 Fax: 01434 608143 Tel: 01285 720930 Fax:01285 720840

E-mail: sales@logic.gb.com E-mail: sales@logic.gb.com

www.logic.gb.com

www.logic.gb.com

INTRODUCTION

1

Page 4

2

Introduction

This information sheet gives advice to users on how

to use All Terrain Vehicles (ATVs) safely with towed

and mounted equipment.

Plan the use of an ATV carefully and take particular

note of ground conditions and slopes, as these may

vary considerably, depending on the terrain, weather

conditions, ground surface and the crop under the

wheels.

Towed equipment

Choose equipment which matches your ATV.

Stability of towed equipment is affected by:

Weight ratios

The safe ratio between the trailed laden maximum

weight and unladen weight of the ATV must be

assessed for each operation.

Always take note of information given in the

manufacturer’s handbook when making this

assessment.

As a guide research shows that on level ground, 4 x

unladen weight of the ATV for braked trailed

equipment and 2 x unladen weight of the ATV for

unbraked trailed equipment are the appropriate

maximum ratios.

Note: For work on slopes or uneven ground the ratio

will need to be reduced.

Braking

Fit:

Brakes to trailed equipment. This helps prevent jackknifing when braking or travelling downhill;

Over-run brakes which come into action whenever

the ATV brakes are applied;

Agriculture Sheet No 11

Centre of gravity

Stability of the ATV is improved if there is:

A low centre of gravity which is within the wheel

base;

A wide wheel base;

A long draw-bar;

Means for holding detachable equipment in position.

Hitching and loads

Stability is also improved if:

Some weight is transferred from the trailer onto the

ATV draw-bar;

The draw-bar has a swivel hitch and the ATV a ball

hitch having a large head to neck ratio. This makes it

easier for the draw-bar hitch to swivel and cope with

undulating ground;

The load is positioned as near to the centre of the

trailer as possible.

Tyres and wheels

Check tyre pressures regularly with a pressure

gauge capable of reading low pressures accurately;

Check tyre pressures regularly for damage and

wear;

Select equipment which has tyres and wheels that

can cope with speeds over 20 mph and occasional

higher speeds;

Use wheels with bead locks on the rims if the main

use is going to be on sloping ground. This prevents

tyre run-off on side slopes.

Maximum towed weight

Follow the advice given by manufacturers on the

maximum trailed weight. This will be found on the

equipment or in the instruction handbook.

Note: Universal road going trailers will normally have

the maximum gross weight stated on a separate

notice.

Selecting and using equipment for All

Terrain Vehicles (ATVs)

HSE information sheet

Page 5

3

Mounted Equipment

ATVs using mounted equipment are safer if the

equipment has:

A low centre of gravity. This improves stability;

A gross weight within the limits the limits approved

by the ATV manufacturer;

No dangerous projections to enquire the operator or

bystanders;

No forward projections which stop head protection

being worn;

Controls which are easy to work and which do not

create a hazard to the operator;

Working speeds less than 16hp.

Instructions for the mounted and trailed

equipment

Take note of the manufacturers instructions on:

Operating on slopes;

Where to place loads so as to give fore/aft and

lateral stability;

The risks of using equipment with negative drawbar

nose weight, i.e. loss of traction;

The maximum operating speed;

The effect that equipment carried on front and/or

rear racks will have on longitudinal and lateral

stability;

Securing loads;

The use of ballast, if any to improve stability;

The need to select and use safe routes.

Using an ATV

Read the manufactures instruction book and take

note of the safety advice given;

Choose an ATV with enough power for the work you

want it to do. Four wheel drive will give better

traction and mobility and may provide a margin of

safety;

Choose a safe route;

Be aware that increased speed greatly increases the

risk of instability and the risk of an overturn.

Printed and published by HSE

Training

Train everyone who has to use an ATV whether with

mounted or trailed equipment or as a solo machine.

The training should emphasise the factors affecting

stability, the need for care and concentration, and

how to recognise the conditions, which may affect

the safety of operation. It is important for trainees to

familiarise themselves with the handling and control

of the machine on level open ground before tackling

rough hill terrain.

Suitable training courses are run by such bodies as

ATB Landbase and Forestry Authority.

Helmets

Wear head protection, which protects the head and

neck. Helmets to BS 6658:1985 (specification for

protective helmets for vehicle users) are suitable.

Some users find open faced helmets more suitable

than full face helmets.

Use of ATV’s for Spraying

A separate information sheet No 10 ATV’s fitted with

spray equipment is available from the Crop and

Pesticides National Interest Group (see address

below)to cover the use of mounted or trailed ATV

sprayers.

Further information

HSE Contract Research Report No52/1993 braking

and overturning stability of all terrain vehicles with

trailed or mounted loads and review of guidelines

1993 ISBN 011 882149 0

HSE safeguarding agricultural machinery: moving

parts HS (G) 89 1992 ISBN 011 882051 6. This

provides further information on the design of

machinery.

These publications are available from HSE books,

PO Box 1999, Sudbury, Suffolk, CO10 6FS

(Tel: 0787 881165; fax: 0787 313995).

If you need information please contact your local

HSE office.

Further copies of this information may be obtained

from the crop and pesticides national interest group,

HSE, Bareback house, Trinity Square, Nottingham

NG1 4AU: tel: 0602 470712

This publication may be freely reproduced, except for

advertising, endorsement or sale purposes. The

information it contains is current at 7/94. Please

acknowledge the source as HSE.

NIS/13/11 C100

Page 6

4

1

. DO NOT – Operate the LDS without all the correct guards fitted.

2. DO NOT – Touch any moving or rotating parts, during working conditions

3. DO NOT – Operate the LDS without suitable ear and eye protection

4. DO NOT – Allow passengers.

5. DO NOT – Operate the LDS on excessively steep slopes.

6. DO NOT– Operate the LDS unless all safety features are fitted, and are used

correctly

7. DO NOT – Operate the LDS until you have read and understood the entire operators

manual

8. DO NOT – Wear loose fitting clothing, to avoid catching on parts of the machine

9. DO NOT – Operate the LDS in Dark conditions unless suitable artificial light is used.

10. DO NOT – Climb on the LDS.

11. DO NOT – Travel at speeds in excess of 20 Mph (32Kph) when travelling to and from

the spreading area.

12. DO NOT – Exceed 10 Mph (16 Kph) in working conditions

13. DO NOT – Engage or disengage the disc drive whilst the machine is running.

14. DO NOT – Tow the LDS with an unsuitable vehicle, check vehicle-towing limits before

operation. Never overload the LDS.

15. DO NOT – Use the spreader for any other task other than the one it was designed

for.

16. DO NOT – Use the LDS120 for spreading salt, only use the LDS120DS model.

17. DO NOT – Use the spreaders on public roads. The spreaders are not road legal.

2

IN THE INTEREST OF SAFETY:

DO NOT

This symbol means WARNING or CAUTION Personal safety or damage will be

at risk if these instructions are ignored. Most accidents are caused by neglect

or carelessness; Avoid needless accidents by following the safety

precautions listed below.

Page 7

5

1

. DO – Follow all manufactures guidelines.

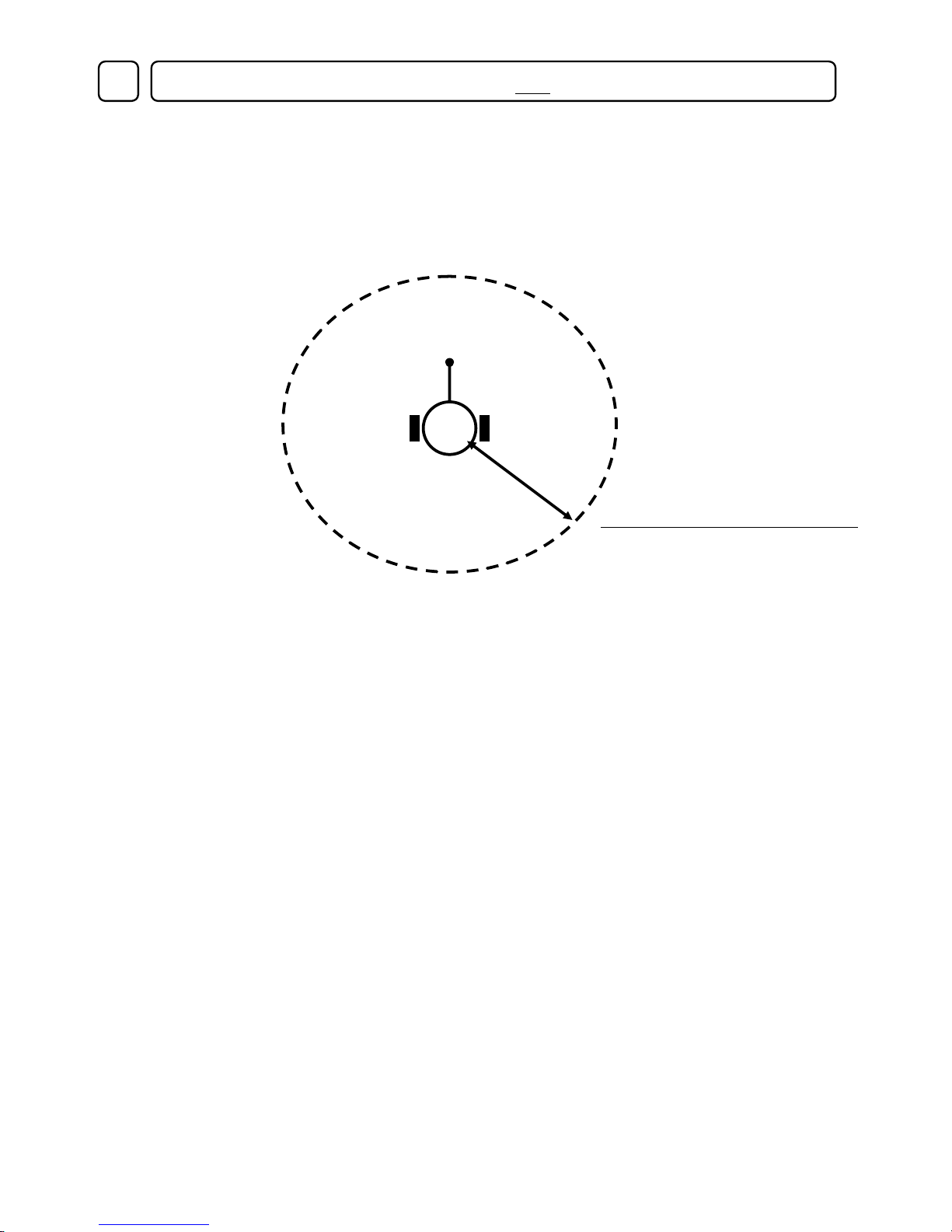

2. DO – Ensure all spectators are a min of 15 metres distance away when operating the

spreader. The operator must continually check the working area, to avoid harming such

third parties.

3. DO – Carry out regular servicing and checks before use.

4. DO – Clear spreading area from potential damaging or restricting components.

5. DO – Reduce speeds when turning corners, working on hillsides or rough terrain

6. DO – Be aware components can be hot after operation e.g.: Gearbox

7. DO – Follow any towing guidelines stated by ATV / Vehicle manufacturer.

8. DO – Follow suitable lifting regulations when filling the hopper.

9. DO – Ensure all safety decals are in good condition, replace any that are damaged.

10. DO – Keep hands and feet away from rotating parts

11. DO – Ensure LDS disc drive is disengaged before transporting from workplace.

12. DO - Ensure the spreader tow hitch is in good repair and fit for towing.

13. DO – Wear protective gloves and boots / facemask when handling fertiliser or salt.

14. DO – Ensure the hopper is empty and the machine is washed down after daily use.

3

IN THE INTEREST OF SAFETY:

DO

SAFETY ZONE 15 METRES MINIMUM

Page 8

6

INSTRUCTION

/ WARNING DECALS

4

The above decals should be located on your LDS – Ground Drive Spreader. If any of

the above decals are not located on your LDS or are damaged in any way contact Logic for

some replacement decals before use.

Page 9

7

1. Check to see if the vehicle transporting the spreader can legally carry its weight (See

m

anufactures plate on spreader for unladen weights)

2. Ensure the vehicle used to lift and transport the LDS has the necessary lifting and

loading capacity. Follow all vehicle manufactures guidelines for lifting.

2. When lifting the LDS for transporting / delivery purposes always ensure to locate lifting

straps where you see the lifting symbol as shown on the below diagram. Never lift the

spreaders with material in the hopper. And ensure pedestrians are clear from danger

3. Ensure all straps are the same length and comply with EN1492-1

4. All LDS unladen weights are clearly marked on the Manufacture’s plate attached to the

LDS framework. Check the lifting weight complies with the vehicle lifting limits.

LDS120/120DS: Only lift the LDS from the correct lifting points as shown below.

LDS240 / LDS700:

TRAN

SPORTING & LIFTING

5

The above decals

should be located on your

LDS – Ground Drive

Spreader. If any of the above

decals are not located on your

LDS or are damaged in any

way contact Logic for some

replacement decals.

Page 10

8

6.1 – BEFORE USE CHECK THE FOLLOWING:

1

. Ensure the tow ball on the vehicle is compatible with the spreader.

2. Check the operation of all controls (A).

3. Ensure the ride height is correctly set for the ATV towing the spreader (B). Remove the

fixing bolt and adjust the angle of the spreader to ensure the spreader disc is running

horizontal to the ground. Replace the fixing bolt in the nearest hole available. (The

spreader disc must run horizontally to the ground to ensure the correct spreading width

and overlap is achieved)

4. Check that the tyre pressure (C) 10psi minimum to 25psi maximum dependant on load

size. Check the condition of the tyres. Look for signs of wear, cuts and impact damage.

5. Check the free operation for the shutter aperture (D).

6. Check the condition of the hopper and lid (E, If fitted).

7. Check that all grease points have been greased, and are operating freely.

8. Check the gearbox for oil leaks, if an oil leak is evident do not use the spreader and carry

out repairs immediately.

Check that the agitator (G) is free from debris and well greased.

9. Before filling the hopper, set the flow from the hopper by moving the pointer (A) to the

setting required (B) and locking in place with the lock nut (C).See figure 11.1

OPERATING INS

TRUCTIONS AND ADJUSTMENTS

6

Page 11

9

1

0. Place the flow lever (D) in the zero position and fill the hopper with the material to be

spread. Ensure that a suitable towing vehicle has been hooked up to the spreader before

filling and that the handbrake has been applied. Do not overfill the hopper; this could

result in fertilizer being spilt or component failure. Ensure there are no foreign bodies in

the hopper e.g. stones or rocks. Wear suitable protective clothing and face protection.

11. Drive to the area requiring the fertiliser, move the drive lever (E) to the IN position (F)

gently moving forward at the same time.

Figure 11.1

6.

2 – DISTRIBUTION OF THE FERTILISER/SALT:

The operator must ensure that the towing vehicle travels at a constant speed in order to obtain

an even distribution of material, the operator should use the following overlap technique as

illustrated below:

Spread width is dependable on forward speed and the type of material being spread.

6 Mtr

6 Mtr

1.5 Mtr

Overlap

1.5 Mtr

Overlap

Diagram shows three bout marks and the

desired overlap.

1 2 3

Page 12

10

6.

3 – VANE REGULATION / ADJUSTMENT:

Should the distribution prove to be uneven, the operator can remedy this by regulating the angle

of all the vanes by adjusting the vanes to the different holes on the spreader disc.

6.

4 – CALIBRATION (FERTILISER)

To precisely calibrate the spreader carefully read and perform the following instructions:

1. Place a measured amount of fertiliser in the hopper e.g. 10kg

2. Choose an aperture setting to suit the rate required for the type of fertiliser being used,

e.g. Setting 6

3. Obtain the desired travel speed (12 to 20kpH) and open the aperture to preset setting 6,

e.g. 200 metres. (NOTE: Maintain a constant speed)

4. Check the effective spread coverage width, e.g. 12 metres (D).

5. Measure the amount of fertiliser left in the hopper, e.g. 4kg (E).

Then perform the following calculations: -

Measured amount of fertiliser initially loaded in hopper (A): 10kg

Deduct any remaining fertiliser (e): 4kg

Balance used (B): 6kg

Multiply width of spread (D) by the metres travelled (C): 12 x 200 Mtr = 2400 Mtr²

Divide 10,000 (1hectare) by the answer (2,400): 10,000

2400 = 4.1

Multiply the sum (4.1) by the test quantity balance used (B, 6Kg): 4.1 x 6 = 24.6 kg/Ha

The figure achieved is the sowing rate per hectare at the constant speed selected for the test.

Due to the variations of seeds and fertiliser types, it is recommended the test be carried out for

each product being used. Adjust the machine accordingly until the desired application rate is

achieved.

Record all results to ensure accurate speed rates for future reference, use the chart provided on

page 13).

Vane adjusting holes

LDS120 / 240

LDS700

Page 13

11

6.

5 – CALIBRATION CHARTS

LDS120:

Calibrated at a speed of 15kpH (kg/ha)

Setting 1 2 3 4 5 6

Urea - 11.00 27.50 482.50 63.30 82.50

Super - 19.30 44.00 77.00 112.80 140.30

DAP - 19.30 35.80 57.80 79.80 104.50

Calibrated at a speed of 20kpH (kg/ha)

Setting 1 2 3 4 5 6

Urea - 7.50 20.00 32.50 50.00 62.50

Super - 20.00 42.50 62.50 82.50 102.50

DAP - 10.00 25.00 40.00 60.00 75.00

LDS240:

Calibrated at a speed of 15kpH (kg/ha)

Setting 1 2 3 4 5 6

Urea - 11.00 29.70 41.50 52.50 67.50

Super - 19.30 44.00 93.50 107.30 140.30

DAP - 11.00 33.00 55.00 74.50 99.00

Calibrated at a speed of 20kpH (kg/ha)

Setting 1 2 3 4 5 6

Urea - 7.50 17.50 30.00 47.50 67.50

Super - 15.00 30.00 55.00 87.50 102.50

DAP - 8.80 25.00 40.00 55.00 70.00

LDS700:

Calibrated at a speed of 15 KPH (kg/ha)

S

etting 1 2 3 4 5 6 7 8 9 10 11

Urea - - 9.40 25.00 50.00 84.40 118.80 162.50 200.00 250.00 275.00

Super - - 15.60 53.10 103.10 143.80 200.00 268.70 337.50 412.50 425.00

DAP - - 12.50 37.50 62.50 100.00 162.50 193.80 250.00 325.00 337.50

Calibrated at a speed of 20KPH (kg/ha)

Setting 1 2 3 4 5 6 7 8 9 10 11

Urea - - 9.40 25.00 40.60 75.00 100.00 137.50 162.50 200.00 237.50

Super - - 15.60 43.80 81.30 131.30 167.50 225.00 262.50 300.00 312.50

DAP - - 9.40 28.10 50.00 81.30 125.00 156.30 200.00 250.00 275.00

NOTE The calibration charts above are a guide only and should be checked to confirm

accuracy.

Page 14

12

6.6 - LDS120DS – CALIBRATION (SALT)

The L

ogic LDS120DS is capable of spreading dry white bagged de-icing salt only.

All materials will vary slightly, depending on density and moisture, etc, even in bags, the same

batch can vary.

The following steps are intended as a guide only, and it is highly recommended that simple test

runs are carried out in the filling area before setting out, to check that the spreading quantity

and pattern are satisfactory.

The main controlling factor is forward speed, which dictates the spreading width. The

application rate will then be controlled by the feed gate setting.

The recommended minimum working forward speed is 3 mph (5 kph). This would be used in

confined spaces, or where a minimum spreading width is required. At this speed the spreading

width will be approx. 8mtrs. Recommended maximum working speed is 12 mph (19 kph)

which will result in a spreading width of approx 12mtrs suitable for car parks and roads, etc.

The feed gate setting at the front of the hopper controls the material flow and therefore the

application rate (grams per sq metre). Our recommendation would be to use setting 6 for

spreading salt; the aperture needs to be open enough to prevent the salt bridging in the hopper.

For transporting max / min operating speeds see page 4.

CALIBRATION STAGES

1. Decide what spread width is required in relation to a safe working speed.

2. Select the feed gate setting to achieve the desired application rate.

This will depend on trials carried out with materials to be spread at the time.

3. Check the accuracy of the settings, try a few trial runs over a clean area of concrete or

road surface, at the correct forward speed. Check the spread width, which may vary due

to bouncing material if it is very dry.

Check the application rate by visually looking at your test run and ensure a suitable

amount of salt is spread evenly. To change the application rate alter the forward speed

or aperture setting accordingly to ensure the correct amount of salt you require is applied

4. Write down results for future reference in the table provided (See next page).

Page 15

13

LDS -SPREADER SETTINGS CHART

MATERIAL

TOWING VEHICLE

OPERATING

SPEED

(mph)

SPREAD

WIDTH (m)

FEED

GATE

SETTING

Page 16

14

Always empty the hopper before any maintenance is carried out

7.1 - DAILY

1. Check the condition of the engagement mechanism and grease daily. Use the following

procedure, firstly engage the drive, and then pump grease into the nipple.

2. Check the condition of the spreader, if any parts need replacing this should be carried

out before operating the machine.

3. Check tyre pressures before use.

4. Check all nuts and bolts are secure before operating.

5. Check the condition of the swivel hitch bushes and replace if damaged or worn

excessively.

6. Check the tension on drive chain and lubricate when necessary (LDS700 Only)

7. Always wash the spreader thoroughly after use, spray a CORROSION INHIBITOR over

the spreader disc and axle components to prevent corrosion. (LDS120DS version, see parts

list)

MAINTENANCE

7

Page 17

15

7.

2 - SEASONAL

1. Check the condition of the drive engagement lever and the plastic tube liner.

2. Check the wheel bearings for play and pack with grease every six months

3. Open the aperture and clean around the aperture blades and holes.

4. Periodically remove the agitator by removing the retaining pin located under the hopper.

5. Lift the agitator, clear of the shaft and remove any residue. Grease and replace the

agitator. Ensure the retaining pin is re-fitted and held in place by the spring clip.

6. Check the oil level in the gearbox. To check, turn the spreader on its side, remove the

filler plug located in the base, check that the oil is level with the rim of the hole, top up if

necessary.

Change the gearbox oil (EP 90) every six months with normal use, or every three months

under extreme conditions. The quantity of oil required is 300ml.

Maintenance should be undertaken regularly, good maintenance extends the

life of the spreader.

Clean aperture and

aperture blades

Remove pin

Remove agitator and

remove residue

Page 18

16

8.1 – MAIN FRAME AND PARTS

PARTS LIST: LDS120 / LDS120DS

8

Page 19

17

8.

2 - PARTS LIST MAIN FRAME: LDS120 / LDS120DS

Item Part Number Description Qty

1 LDS120-1001 FRAME 1

2 LDS120-1002 DRIVE AXLE 1

3 LDS120-1003 EASYLOCK HUB 1

4 LDS120-1004 DRIVE COUPLING 1

5 LDS120-1005 BEARING HOUSING 1

6 LDS120-1006 DRIVE AXLE BEARINGS 2

7 LDS120-1007 KEY 1

8 LDS120-1008 DRIVING WHEEL 1

9 LDS120-1009 NON DRIVING WHEEL 1

10 LDS120-1010 WHEEL BEARINGS 4

11 LDS120-1011 BEARING SPACER 2

12 LDS120-1012 WHEEL NUT 2

13 LDS120-1013 DUST CAP 2

14 LDS120-1014 TYRE 2

15 LDS120-1015 POINTER 1

16 LDS120-1016 STAR NUT 1

17 LDS120-1017 SHUTTER LEVER 1

18 LDS120-1018 DRIVE LEVER 1

19 LDS120-1019 DRIVE OPERATING LEVER 1

20 LDS120-1020 HAND GRIP 2

21 LDS120-1021 SHAFT GUARD 2

22 LDS120-1022 PLASTIC BUSH 1

23 LDS120-1023 TOW BAR 1

24 LDS120-1024 TOW BAR STAY 1

25 LDS120-1025 TOW BAR BOLT 1

26 LDS120-1026 SPINNER GUARD 1

27 LDS120-1027 GEARBOX 1

Page 20

18

8.3 – SPINNER AND HOPPER DETAILS: LDS120 / LDS120DS

Item Part Number Description Qty

1 LDS120-1028 LID - LDS120 1

2 LDS120-1029 HOPPER – LDS120 1

3 LDS120-1030 AGITATOR 1

4 LDS120-1031 AGITATOR BUSH 1

5 LDS120-1032 LOWER SHUTTER PLATE 1

6 LDS120-1033 CIRCLIP 1

7 LDS120-1034 SPINNER PLATE 1

8 LDS120-1035 SPINNER FIN 4

9 LDS120-1036 BLOWER FIN 4

10 LDS120-1027 GEARBOX 1

11 LDS120-1038 PIN 1

MLU-021 CORROSION INHIBITOR (LDS120DS) 1 (Can)

Page 21

19

8.4 – MAIN FRAME AND PARTS

PARTS LIST: LDS 240/360

8

Page 22

20

8.

5 - PARTS LIST MAIN FRAME: LDS240/360

Item Part Number Description Qty

1 LDS240-1001 FRAME 1

2 LDS120-1002 DRIVE AXLE 1

3 LDS120-1003 EASYLOCK HUB 1

4 LDS120-1004 DRIVE COUPLING 1

5 LDS120-1005 BEARING HOUSING 1

6 LDS120-1006 DRIVE AXLE BEARINGS 2

7 LDS120-1007 KEY 1

8 LDS240-1002 DRIVING WHEEL 1

9 LDS240-1003 NON DRIVING WHEEL 1

10 LDS120-1010 WHEEL BEARINGS 4

11 LDS120-1011 BEARING SPACER 2

12 LDS120-1012 WHEEL NUT 2

13 LDS120-1013 DUST CAP 2

14 LDS240-1004 TYRE 2

15 LDS120-1015 POINTER 1

16 LDS120-1016 STAR NUT 1

17 LDS120-1017 SHUTTER LEVER 1

18 LDS120-1018 DRIVE LEVER 1

19 LDS120-1019 DRIVE OPERATING LEVER 1

20 LDS120-1020 HAND GRIP 2

21 LDS120-1021 SHAFT GUARD 2

22 LDS120-1022 PLASTIC BUSH 1

23 LDS120-1023 TOW BAR 1

24 LDS120-1024 TOW BAR STAY 1

25 LDS120-1025 TOW BAR BOLT 1

26 LDS120-1026 SPINNER GUARD 1

27 LDS120-1027 GEARBOX 1

Page 23

21

8.6 – SPINNER AND HOPPER DETAILS

PARTS LIST: L

DS240/360

8

Item Part Number Description Qty

1 LDS240-1005 LID – LDS240 1

2 LDS240-1006 HOPPER – LDS240 1

2 LDS240-1006 HOPPER – LDS360 1

LDS360-1001 HOPPER EXTENSION – LDS360 (Not Shown) 1

LDS360-1002 HOPPER FIXING BOLT C/W NUT & WASHER 6

3 LDS120-1030 AGITATOR 1

4 LDS120-1031 AGITATOR BUSH 1

5 LDS120-1032 LOWER SHUTTER PLATE 1

6 LDS120-1033 CIRCLIP 1

7 LDS120-1034 SPINNER PLATE 1

8 LDS120-1035 SPINNER FIN 4

9 LDS120-1036 BLOWER FIN 4

10 LDS120-1027 GEARBOX 1

11 LDS240-1038 PIN 1

Page 24

22

8.7– DRIVE ASSEMBLY: LDS700

8.8- MAIN FRAME: LDS700

8

7

6

9

11

12 13 14 1 2

3

4

5

20

19 18

17

16

24

15

21

22

23

10

PARTS LIST: LDS700

8

Page 25

23

8.

9 – WHEELS AND TYRES: LDS700

8.10 – SPINNER AND AGITATOR: LDS700

29

28

27

26

25

33

32

31

30

35

34

36

38

39

40

41

42

43

Page 26

24

8.

11 - PARTS LIST: LDS700

Item Part Number Description Qty

1 LDS700-1001 DRIVE AXLE 1

2 LDS120-1003 EASYLOCK HUB 1

3 LDS120-1004 DRIVE COUPLING 1

4 LDS120-1027 GEARBOX 1

5 LDS120-1019 DRIVE OPERATING LEVER 1

6 LDS700-1002 BEARING HOUSING 1

7 LDS700-1003 DRIVEN SPROCKET 1

8 LDS700-1004 TENSIONER 1

9 LDS700-1005 DRIVING WHEEL RIM ONLY 1

10 LDS700-1006 DRIVE AXLE CARRIER 1

11 LDS700-1007 DRIVE CHAIN 1

12 LDS700-1008 DRIVING SPROCKET 1

13 LDS700-1009 DRIVE WHEEL AXLE 1

14 LDS120-1006 DRIVE AXLE BEARINGS 2

15 LDS700-1010 DRAWBAR 1

16 LDS120-1025 DRAWBAR FIXING BOLT 1

17 LDS700-1011 MAIN FRAME 1

18 LDS700-1012 DRIVE ENGAGEMENT LEVER 1

19 LDS700-1013 SHUTTER OFF LEVER 1

20 LDS120-1020 HAND GRIP 2

21 LDS700-1014 POINTER 1

22 LDS120-1016 STAR NUT 1

23 LDS700-1015 DRAWBAR STAY 1

24 LDS700-1016 PROP STAND 1

25 LDS700-1017 WHEEL RIM ONLY 1

26 LDS120-1011 BEARING SPACER 2

27

LDS120-1010

WHEEL BEARINGS 2

28

LDS700-1018

SPINNER GUARD 1

29

LDS700-1019

HOPPER 700LT 2

30

LDS120-1022

PLASTIC BUSH 1

31

LDS700-1020

TYRE 2

32

LDS700-1021

CHAIN GUARD 1

33

LDS120-1021

SHAFT GUARD 2

34

LDS120-1013

DUST CAP 1

35

LDS700-1022

HUB NUT 1

36

LDS700-1023

WHEEL NUT 4

37

LDS700-1024 AGITATOR 1

38

LDS120-1031 AGITATOR BUSH 1

39

LDS700-1025 LOWER SHUTTER PLATE 1

40

LDS120-1033 CIRCLIP 1

41

LDS700-1026 SPINNER PLATE 1

42

LDS700-1027 SPINNER FIN 4

43

LDS120

-

1038

PIN 1

Page 27

25

This Logic Manufacturing product is guaranteed against faulty workmanship and materials for a

p

eriod of 6 months from the date of purchase.

On Engine-Powered equipment, the engine manufactures guarantee will apply, any claims

being subject to their terms and conditions.

All claims must be made in writing within 28 days of the alleged failure.

All claims must be made through the dealer who originally supplied the machine.

Any defective parts must be kept for inspection and if requested, sent to the factory or dealer.

The customer must bring equipment for repair to the dealer.

This guarantee becomes void if unauthorised modifications have been made, or if parts not

manufactured, supplied or approved by Logic Manufacturing have been fitted to the machine.

We accept no liability for normal wear and tear, misuse or abuse, or where recommended

maintenance has not been carried out.

All guarantee work must be authorised by Logic Manufacturing prior to any work being done.

Work carried out without our consent may not be reimbursed.

LOGIC MANUFACTURING PRODUCTS OWNER GUARANTEE

9

Page 28

26

DECLARATION OF CONFORMITY

93 / 44 EEC

LOGIC MANUFACTURING LTD

Foundry Industrial Estate

Bridge End

HEXHAM

Northumberland

Product Type: LDS100 – VOGAL GROUND DRIVE SPREADER

Covered By Technical File Number: CE – LDS100

Serial Number:

Standards And Regulations Used:

The Supply Of Machinery (Safety) Regulations 1992

HSE Guide Lines On ATV Equipment (Agric Sheet No. 11)

Place Of Issue: United Kingdom

Name Of Authorised Representative: P. G. RIDLEY

Position Of Authorised Representative: RESEARCH & DEVELOPMENT MANAGER

Declaration,

I declare that as the authorised representative, the above information in relation to the

Supply / manufacture of this product, is in conformity with the stated standards and other

related documents following the provisions of 93/68EEC directives

Signature Of Authorised Representative

Date: 10/03/05

Loading...

Loading...