Logan Graphic Products 550-1, 560-1 User Manual

INSTRUCTION MANUAL

SIMPLEX CLASSIC

MAT CUTTER

INSTRUCTIONS AND OPERATION MANUAL

40 in (101 cm) mat cutting system with

bevel & straight cutters, production stops,

MODEL 550-1 / 560-1

27 in (68 cm) squaring arm & stop.

View How-To Videos Online

at LoganGraphic.com/videos

For best results use only

authentic Logan blades

Uses Logan Replacement

Blade #270

LoganGraphic.com

Purchase Date

ID Number (on bottom of board)

Date (on bottom of board)

L759DN4 8/11

Instruction Manual

Simplex Classic Mat Cutter

Model 550-1/560-1

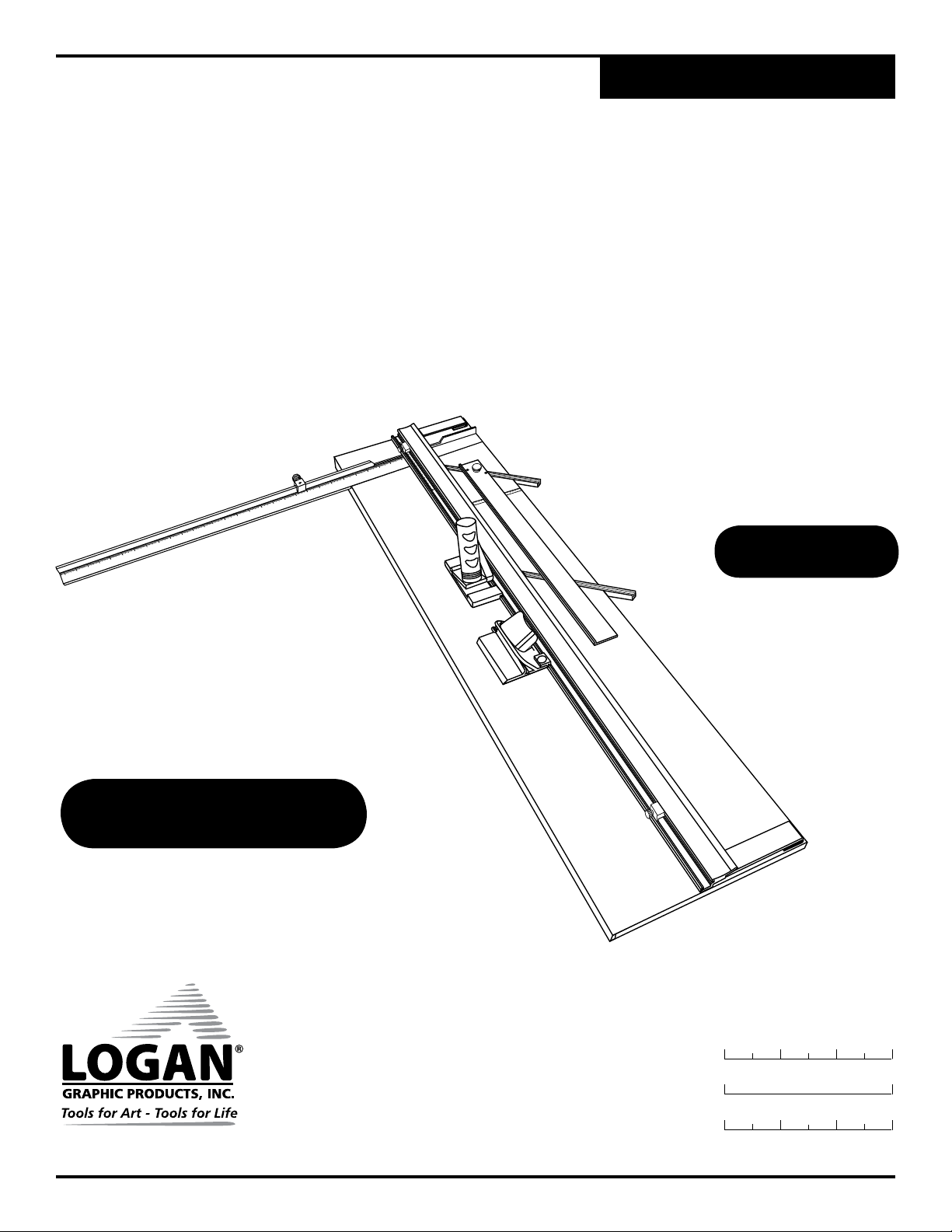

Fig. 1

Orientation

The procedures detailed in the

following instructions refer to the

right & left sides and top & bottom

of the machine as shown (Fig. 1).

Top

Left Right

Bottom

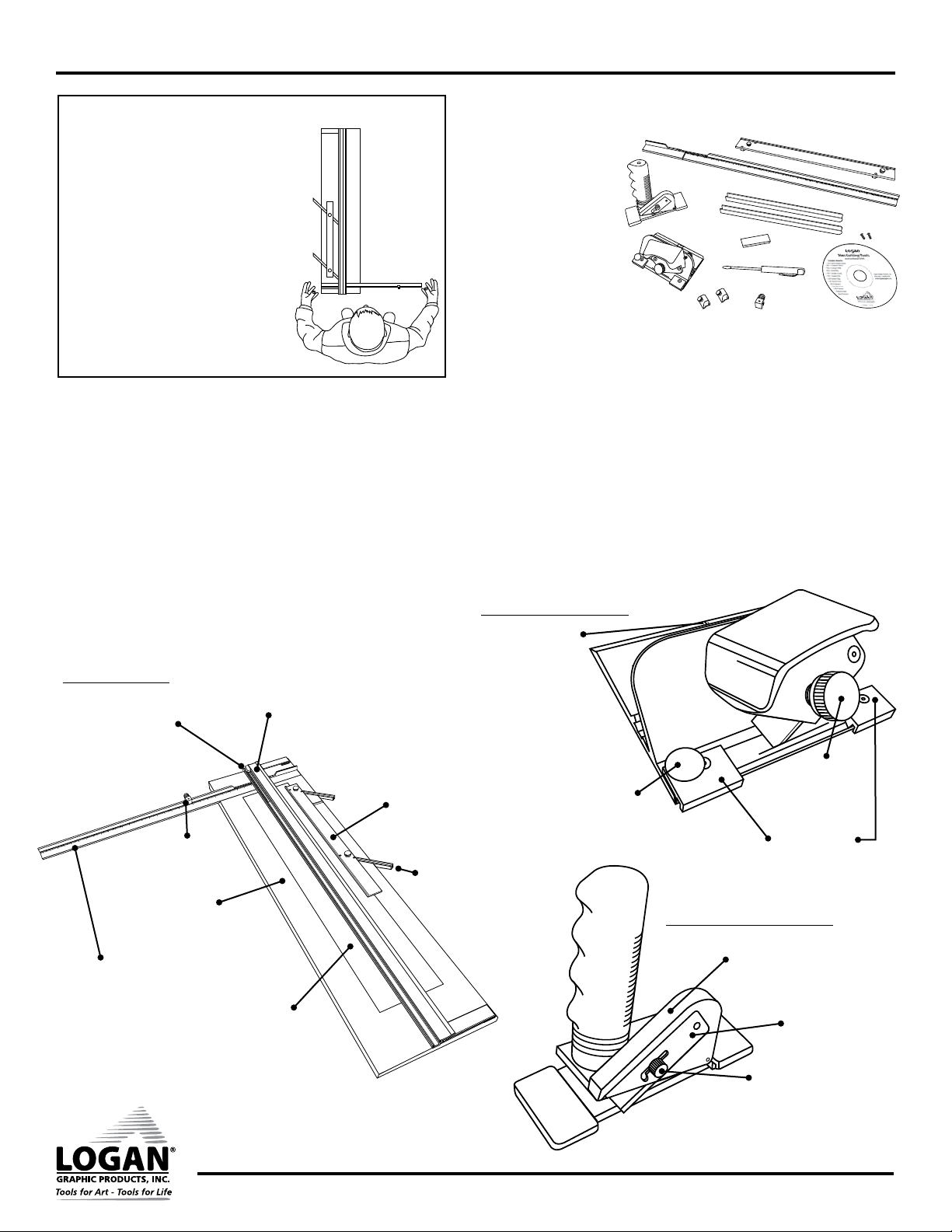

Carton Contents

1. Straight Cutter

2. Bevel Cutter

3. Squaring Arm

4. Squaring Arm Stop

5. Mat Guide

6. Mat Guide Channels (2)

7. Channel Screws (2)

8. Screwdriver

9. Rail Stops

10. Blade Pack

3

1

6

10

2

9

8

4

5

7

11

11. DVD

Congratulations on your purchase of the Logan Simplex Classic Mat Cutter.

The Simplex Classic is a well-designed mat cutter, combining the best of what Logan mat cutters have to offer. Features like heavy duty pull style

bevel cutter with anti-crawl pin, pivot & pull straight cutter, production stops, squaring arm, parallel mat guide, plus the flexibility to add additional

accessories like the glass cutter or surface V-groovers make the Simplex Classic a cost effective and useful tool for artists, crafters, photographers

and framers. This instruction manual is written to familiarize you with the product. Please take some time to review the instructions before cutting.

You will find that the time taken will be well worth it, and you will be cutting professional mats in no time.

PRODUCT DESCRIPTION

550-1 / 560-1 Simplex Classic- 40 in vinyl covered cutting board with mat guide in aluminum channels, two production stops, 27 in squaring arm,

straight and bevel cutting heads, slip sheet, screwdriver, DVD and one 5-pack of Logan #270 blades.

Identification of Machine Components

Cutting Board

Rail Stop

Squaring Arm Stop

Cutting Board

Vinyl covered base

board of machine

Squaring Arm

27 in board mounted

90° bar used to hold

mats square when

straight cutting and as a

stop when bevel cutting

Guide Rail

Used to guide cutting

heads while in use

Slip Sheet

A Slip Sheet is a piece of

scrap mat board that is

placed beneath the mat

when bevel cutting

Bevel Cutting Head

Start and Stop Indicator

(not visible in this drawing located on opposite side) Line

which shows where to begin

and end cut

Mat Guide

Used to set the border

width of a mat and

keep the mat in position

Mat Guide Channel

Anti-Crawl Pin

Prevents cutting head

from creeping forward when

insterting blade into mat

Blade Screw

Holds blade in

place for cutting

Nylon Guides

Guides which allow Bevel

Cutting Head to hook

onto Guide Rail

Straight Cutting Head

Blade Holder

Block which holds blade in place

while cutting. Has three separate

depth settings.

Blade Cover

Covers blade

on Blade Holder

Blade Screw

Holds blade in

place inside

Blade Holder

Lo g a n G r aphic Produc t s I n c ., 1 1 0 0 B rown Street, Wa u conda, IL 60084 847-52 6 - 5 515

2

Lo ganGraphic. com

Instruction Manual

Simplex Classic Mat Cutter

Model 550-1/560-1

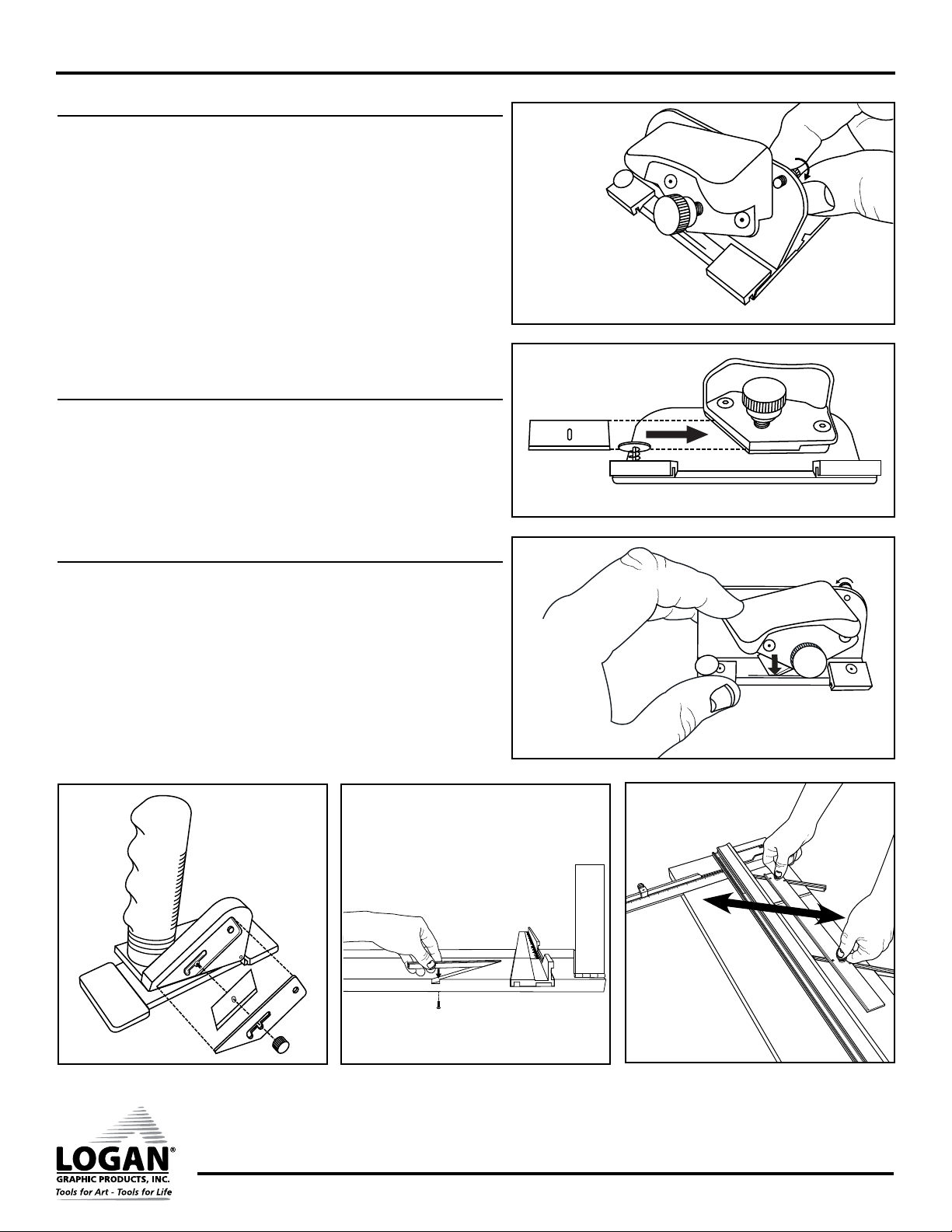

Blade Installation

1. Loosen blade retaining screw enough to allow blade holder to tilt back

(Fig. 2). Loosen the blade holding knob.

2. Remove one blade from the package of five.

NOTE: Because the blades are packed with a small amount of oil, they may stick

together. Be certain that only one blade is being inserted into the blade slot.

3. Slide blade, sharp edge down, fully into blade holder (Fig. 3).

NOTE: The hole in the blade is not designed to line up with the blade screw.

4. Tighten blade screw.

5. Tilt blade holder down, allowing tip of blade to enter into the blade slot

and retighten retaining screw (Fig. 4).

Blade Installation - Model 701-1 Straight Cutter Elite

1. Remove blade knob and blade cover.

2. Align blade hole over thread. Be sure sharp edge of blade is facing down.

3. Reassemble blade cover and blade knob (Fig. 5).

NOTE: Adjust blade to foamboard (fully extended), standard 4-ply mat board

(middle setting) or safety (fully retracted).

Mat Guide Assembly

Fig. 2

Fig. 3

Fig. 4

1. Press each Mat Guide Channel into board slots with rounded end towards

guiderail. (Fig. 6).

2. Insert two channel screws from the UNDERSIDE of board and tighten (Fig. 6).

3. Loosen each mat guide knob three full turns.

4. Hold mat guide at ends with your thumbs on the loosened knobs with

raised edge facing guiderail and evenly drop mat guide into channels.

5. Slide to adjust and tighten knobs to lock mat guide (Fig. 7).

Fig. 5

Fig. 6

Fig. 7

Lo g a n G r aphic Produc t s I n c ., 1 1 0 0 B rown Street, Wa u conda, IL 60084 847-52 6 - 5 515

3

Lo ganGraphic. com

Loading...

Loading...