Model F500-4

Instruction Manual

PICTURE FRAMING

www.logangraphic.com

Air-Matic

Dual Drive Point Driver

Description

The model F500-4 Air-Matic

Dual Drive Point Driver is

designed to quickly drive either

rigid or flexible points

pneumatically using a common

air compressor at 52 psi.

Contents

Air-Matic Dual Drive x 1

Rigid points x 100

Flexible points x 100

Supplies needed-

Any air compressor producing between 50 and 100 psi

Air hose with 1/4” standard NPT male plug fittings or quick

release coupler

Regulator/lubricator (optional)

Only Use Logan Points

F53 Flex point 600 pc pack

F54 Rigid point 600 pc pack

F55 Flex point 2,500 pc pack

F56 Rigid point 2,500 pc pack

L502 09/18

Instruction Manual

Supplies needed-

Any air compressor producing between 50 and 100 psi

Air hose with 1/4” standard NPT male plug fittings or quick

release coupler

Regulator/lubricator (optional)

Contents

Air-Matic Dual Drive x 1

Rigid points x 100

Flexible points x 100

F500-4 Air-Matic Dual Drive Point Driver

Trigger lock

Trigger

Model F500-4

Handle grip

Drive guide

Air line connection

Point magazine

Magazine release lever

Before you use your F500-4 Air-Matic Dual Drive Point Driver.......

Always use safety glasses when operating the Air-Matic Dual Drive.

Keep children away from air tools.

Never point the Air-Matic at yourself or anyone.

Do not operate the trigger when there are no points in the magazine.

Always use clean, dry air only. Do not use compressed gases of any kind.

Always use a regulator usually found on the air compressor at roughly 50 psi.

Do not exceed maximum psi or permanent damage to the tool can occur.

Engage the trigger lock mechanism anytime the tool is attached to an airline but not being used.

Always disconnect the air line before performing any maintenance or when loading more points.

Only use Logan replacement points.

Instruction Manual

F500-4 Air-Matic Dual Drive Point Driver

Operating Instructions

Loading Points before attaching the air line

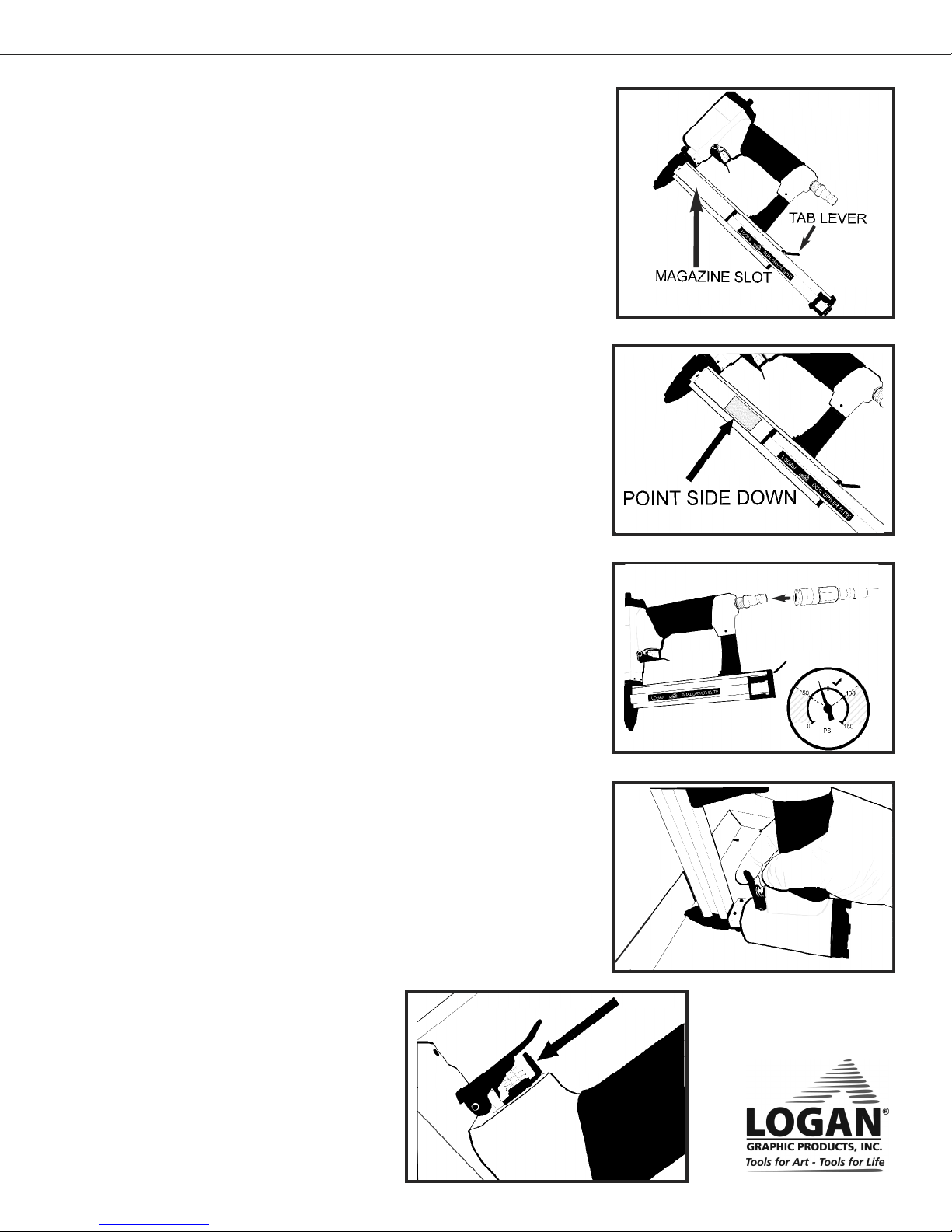

1. Use the metal tab lever at the rear of the magazine to

release and open the magazine loading slot. (Fig 1)

2. Insert full stacks of Logan points with the point side down.

(Fig 2)

3. Slide the magazine back until it locks and is properly closed.

Attach the air line

Connect a suitable air line (not included) to the air supply nipple using a

quick release attachment. (Fig 3)

See that the compressor you are using has its regulator set to 50 psi (3.5

bar) for use on soft woods. Hardwood may require more air pressure but

do not exceed 100 psi (7 bar).

Model F500-4

Fig 1

Using the Air-Matic Dual Drive

Always wear safety glasses when using the Air-Matic Dual Drive

1. Place the framed art face down on a flat surface.

See that the frame is braced in position so it cannot slide.

NEVER PLACE YOUR HAND NEAR THE NOSE OF THE

TOOL TO HOLD THE FRAME IN PLACE

2. Rest the nose of the tool against the rabbet of frame with the

tool inverted as shown. (Fig 4)

3. Pull the trigger to fire a single point. Immediately release the

trigger after each point.

NOTE

The drive of the point is dependent on the psi of the

compressor.

Increase psi to drive deeper into harder woods.

DO NOT EXCEED 100 PSI (7 bar)

Fig 2

Fig 3

Trigger Lock

Engage the safety trigger lock when not in use but

connected to an air line.(Fig 5)

Fig 4

Fig 5

Instruction Manual

F500-4 Air-Matic Dual Drive Point Driver

Model F500-4

Maintenance

Always disconnect the Air-Matic Dual Drive from its air source when not in use.

If you are not using a lubricator on your compressor, add a single drop of air tool lubricant or 3 in

1 oil into the air line nipple once daily before each use. Do not exceed a single drop of oil. Do not use

detergent oil. Safely test fire the tool after lubricating to move the oil through pneunmatic system.

If a point gets stuck or jammed then first disconnect the air supply, take off the cover plate and

remove any jammed points. Re-install the cover plate.

Troubleshooting

Problem

Air leak or excessive

hissing sound.

Driver does not fire or

does not fire points deep

enough.

Points jamming

Points not inserting far

enough into harder

woods

Trigger will not move

Possible Cause

Loose body screws or bad

airline connection.

Inadequate air pressure or

lubrication

Not using authentic Logan

points, loose body screws on

the tool, foreign debris in the

magazine

Insufficient psi from

compressor

Trigger lock engaged

Correction

Check and tighten any loose screws

on the body assembly

Check all connections, check for

proper compressor psi, add single

drop of oil into the air line nipple

Insure you are using authentic

Logan points. Tighten any loose

screws on the body assembly.

Disconnect air and inspect the inside

of the magazine for bent or jammed

points or debris

Gradually increase compressor psi

for desired insertion. Do not exceed

100 psi

Disengage trigger lock

Only Use Logan Replacement Points

F53 Flex point 600 pc pack

F54 Rigid point 600 pc pack

F55 Flex point 2,500 pc pack

F56 Rigid point 2,500 pc pack

Logan Graphic Products, Inc. 1100 Brown Street Wauconda, IL 60084 847-526-5515

800-331-6232 www.logangraphic.com

Loading...

Loading...