85-Ton Open Loop Power Swivel

Contents

Overview................................................................................2

Uses ......................................................................................2

Important Safety Information .................................................2

Construction ..........................................................................3

Power Swivel

Control Units ......................................................................3

Basic Power System ..........................................................4

Hydraulic System ...............................................................4

Power Unit .........................................................................4

Trailer-Mounted Unit .......................................................4

Skid-Mounted Unit ..........................................................4

Installation .............................................................................4

Rig Up ................................................................................4

Pre-operation Start-up Procedure ......................................5

Operation ...........................................................................6

General Rules ....................................................................

Air Controls ........................................................................6

Electric Controls .................................................................

Maintenance ......................................................................7

Power Swivel Maintenance ................................................7

Lubrication ......................................................................

Breaking-In .....................................................................7

Storage ...........................................................................7

Replacing the Floating Washpipe Assembly

and Packing

Power Unit Maintenance ....................................................7

Swivel Disassembly .............................................................10

Swivel Reassembly .............................................................16

Troubleshooting ...................................................................18

Specications ......................................................................19

Assembly .....................................................3

..............................................................7 – 8

6

6

7

Drawings and Schematics

Floating Washpipe Assembly ................................................8

Swivel Head Assembly:

Front V

iew ........................................................................12

Side View .........................................................................13

Top View ..........................................................................14

Section A-A – Through Gear Train) ..................................

Swivel Head Dimensions .................................................

Bumper Pull Trailer-Mounted Unit .......................................22

Skid-Mounted Unit ...............................................................23

Hydraulic System and Controls ...........................................24

Torque Controller (for Air and Electric Controls) ..................25

Assembly and Replacement Parts Lists

Floating Washpipe .................................................................8

Power Swivel .......................................................................11

Power Unit ...........................................................................21

Torque Controller .................................................................25

1 • Logan 85-ton Open Loop Power swivel

15

20

Logan 85-Ton Open Loop Power Swivel

OVERVIEW

The newly engineered, hydraulic motordriven, Logan 85-Ton Open Loop Power

Swivel provides smooth, shock-free

torque. It is rated to support tensile pipe

loads of 85 tons at zero rpm and 45

tons of dynamic load at 100 rpm. The

compact, swivel-head design weighs

only 1,163 lbs and ts into most drilling

or work-over masts.

The design incorporates a reliable,

custom drive train with hardened steel

gears. For most applications, the Logan

85-Ton Open Loop Power Swivel eliminates the use of dangerous spinning

chains, tongs, and kelly spinners. The

Power Swivel facilitates drilling with

longer drill string lengths before the rig

must be shut down to add pipe. Stops

and start-ups are thereby reduced

— improving rig efciency and reducing wear on the pump, drawworks, and

other rig equipment.

The Logan 85-Ton Open Loop Power

Swivel uses an open loop hydraulic

system with variable displacement,

reversible over center pumps, and air or

electric remote controls. Speed control

is continuously variable over the entire

operating range. Pressure compensating-type torque control overrides the

speed control to maintain maximum

torque. The power unit’s torque limits

can be set, thereby eliminating the

potential danger of twist-offs or swollen boxes in the drill string. An integral

rotary swivel bearing, oating washpipe

assembly, and gooseneck connection eliminates the need for a separate

rotary swivel.

A 2-1/2" bore gooseneck and washpipe

assembly allows circulation through the

2" I.D. stem while rotating or in static

mode. An access plug allows wireline

to be run through the unit.

Features include:

•

Smooth, shock-free torque reduces

drill string damage

• Fits most drilling and work over masts

• Allows use of longer drill string lengths

• Power unit torque limits can be set

• Separate rotary swivel is unnecessary

• Choice of diesel engines

• Increased environmental safety

features on skids and trailers

• Easy to service

Extra cost options include:

• Air- or hydro-start engine

• Special hydraulic motor

• Lifting frame

• Electric or hydraulic loading winch

• Dimetcote coating

(inorganic zinc primer)

• Control can be operated remotely

or from the power unit

Cold weather package

•

The complete Logan 85-Ton Open Loop

Power Swivel package includes an

elevator-type bail; a unitized washpipe

packing box assembly; a xed displacement, piston-type, hydraulic motor rated

at 5,000 psi; a torque rein assembly;

safety cable; and 1-inch swivel joints.

The components are available either

trailer- or skid-mounted with powered

hose reels to form a rugged unit. A

swivel carrying stand is standard.

CAUTION:

procedure outlined on page 4 before

installing the Logan 85-Ton Open

Loop Power Swivel on a rig. Failure

to install the Power Swivel properly

can result in injury to the operator

and/or rig floor personnel. Read I portant Safety Information below.

USES

The Logan 85-Ton Open Loop Power

Swivel is ideally suited for use in shing

and workover operations — such as

the internal or external cutting of casing,

tubing, or drill pipe; drilling out plugs,

packers, or cement; milling operations;

or scraping casing — whenever shockfree, controlled torque is essential to

eliminating the potential danger of twistoffs or damage to cutting tools.

The compact, lightweight swivel-head

design also makes it extremely effective

for light to medium drilling applications

including water wells, pilings for piers

and foundations, in addition to oil and

gas wells. Suspending the swivel from

a boom or crane eliminates a great deal

of set-up time or shifts to additional

locations.

The Logan 85-Ton Open Loop Power

Swivel is also ideal for coring operations. Any length of core may be taken.

Accurate and smooth torque ensures

against damage to core tools or strings.

IMPORTANT

SAFETY INFORMATION

Before operating the Logan 85-Ton

Open Loop Power Swivel, users are

advised of the following important safety

precautions and procedures:

1.

Verify the strength of the derrick

structure and torque rein guide cable

to ensure they are strong enough to

withstand the loads imposed by the

Power Swivel.

Refer to the installation

Logan 85-Ton Open Loop Power Swivel • 2

Logan 85-Ton Open Loop Power Swivel

2. A Logan Safety Cable (provided as

standard equipment on the Logan 85Ton Open Loop Power Swivel) should

be used for torque rein and should

be utilized at all times. Attach one

end of the safety cable to the torque

rein and secure the other end to the

swivel. In the event of torque rein

assembly failure, the safety cable will

prevent the assembly from falling to

the rig oor.

3. Carefully check the full range of

travel in the derrick or mast before

beginning operations. With the guide

cable as nearly vertical as possible,

ensure that the swivel can move

freely up and down under full torque

in either direction. Angles exceeding

5% can cause side loads on the

swivel.

4. Although Logan bails are not as

dangerous as “stepped” bails, tubing

elevators should not be used with

Power Swivel bails. Besides being

a potentially dangerous practice, the

use of an upset elevator reduces

the contact between the elevator and

bail, and accelerates wear.

5. Inspect elevators and bails for excessive wear according to guidelines

published in API RP-8B.

WARNING:

Failure to comply with

these safety procedures may cause

physical injury to the operator and/or

rig floor personnel

CONSTRUCTION

Power Swivel Assembly

The Logan 85-Ton Open Loop Power

Swivel is powered by a xed displacement, piston-type, hydraulic motor rated

at 5,000 psi. The motor is mounted

on the underside of the swivel and is

protected by a steel frame.

Lightweight, compact swivel-head design

fits most drilling or workover masts

Two high pressure hydraulic hoses and

the motor drain hose exit from the bottom of the assembly. The high pressure

hydraulic hoses connect to the motor

with swivel joints. The motor drain hose

is tted with a self-sealing quick dis-

connect coupling.

The one-piece gooseneck is construc-

ted of cast steel. A 2-inch I.D. NPT access plug located in the top allows passage of wireline and small tools through

the swivel for downhole operations.

The gooseneck and swivel packing are

hydrostatically tested and rated at 5,000

psi circulating pressure.

The oating washpipe assembly and

packing are self-aligning. Friction bearing surfaces of the washpipe (areas that

contact the packing) are hard-surfaced

for wear-resistance.

The elevator bail is machined or ame

cut from forged, heat-treated alloy

steel for maximum strength. The bail,

bail pins, and body are tested to API

guidelines.

The design incorporates a reliable,

custom drive train with hardened steel

gears consisting of: a motor drive gear,

reduction drive gear, an intermediate

gear, and the main drive gear. Roller

bearings keep the gears in close alignment.

A magnetic drain plug is located on the

lower cover plate of the swivel assembly. A tell-tale hole in the lower plate

indicates hydraulic oil leakage past the

motor shaft seal or lubricating gear oil

past the input pinion shaft. A ller/relief

plug is located on the upper cover plate.

The gear housing is equipped with an

oil level sight glass so the operator may

check oil level with a quick glance.

To protect the main stem oil seal from

dirt, an excluder seal is installed below

the packing nut.

Control Units

Control assemblies for the Logan

85-Ton Open Loop Power Swivel are

either air or electric. They can be operated remotely (extra cost option) for

operator convenience and safety, or

from the power unit. Remote control

assemblies are pedestal mounted. The

control assembly is lightweight and the

pedestal base is removable for easy

storage on the trailer or skid. A new

wireless remote with an operating range

of 150 feet is also available.

Air controls consist of an air compressor

and tank, an air lter/regulator/lubricator

unit, manual torque control, and a pedestal mounted control panel with extra

lines tted with quick disconnect coup-

lers. A lever-operated air valve controls

the engine speed. Another single-lever

air valve controls the direction and

speed of the Power Swivel. A torque

gauge, calibrated in ft-lbs, indicates

torque.

3 • Logan 85-Ton Open Loop Power Swivel

Logan 85-Ton Open Loop Power Swivel

The electric control panel consists of

a joy stick for controlling swivel direction and speed, an engine rpm control

switch, a torque gauge, and a master

kill switch. An emergency kill switch is

available for hazardous locations.

Torque limits can be easily and accurately set on both air and electric control

units. A torque control unit mounted

on the fuel tank can be preset to the

desired torque limit with the turn of

a knob. Torque will be indicated on the

control panel dial in ft-lbs.

Basic Power System

The Logan 85-Ton Open Loop Power

Swivel is equipped with a diesel engine

to pro-vide power. The engine is sized

to provide sufcient horsepower to

operate the swivel to full torque and rpm

limits. Control systems may be either air

or electric.

On units equipped with air control systems, an air compressor rated at 7.4

cfm, a three-gallon receiver tank, and

an air lter-lubricator are also provided.

A torque gauge, calibrated in ft-lbs, is

located on the remote control panel.

Hydraulic System

The hydraulic system includes a direct

driven, variable displacement hydraulic

pump that is mounted directly on the

engine ywheel housing. All piping,

valves, ttings, reservoirs, and other

components required to complete the

system are included. The hydraulic

system is designed and rated at 5,000

psi working pressure.

All hydraulic hoses are reel-mounted

on the power unit. They are connected

to the power swivel hydraulic motor with

swivel joints and quick disconnects.

A swivel carrying rack allows the swivel

to be loaded and unloaded without

breaking the hose connections.

Power Unit

The compact, easily transportable

Power Swivel units may be mounted on

a trailer or skid. All units consist of an

engine with a hydraulic pump, hydrau-

lic piping, a hydraulic uid reservoir, a

hose reel assembly and hoses necessary for supplying hydraulic power to

the power swivel motor. Brackets to

hold and transport the swivel and the

control panel are included.

Trailer-Mounted Unit

The compact, four-wheel trailer units

meet all ICC regulations and are

equipped with heavy-duty springs and

electric brakes. The trailer is equipped

with a gooseneck or bumper pull.

Tongue weight is designed to ensure

on-road stability and eliminate shtailing. Diamond-patterned deck plate

provides solid, skid resistant ooring

over the all welded, steel frame.

Skid-Mounted Unit

Skid units are rugged and made of

heavy-duty structural tubing with welded construction. Both ends are rounded

for easy skidding. Ends are tted with

an integral pipe that may be used to

attach boom lines or hoist slings. These

pipes are ush with the sides of the

skid. Main runners, running the length

of the skid, are strengthened by crossmembers for additional rigidity. The

entire frame is covered with diamondpatterned deck plate to provide a solid,

skid resistant oor.

To meet environmental regulations,

both trailer- and skid-mounted units are

equipped with skirts to eliminate uid

spills.

INSTALLATION

Rig Up

Check all components to ensure that

all accessory items (especially the portable control panel) and spare parts

are packed, and that all equipment is

in serviceable condition. If time permits, the operator should run the power

swivel for a short time to check control

indicators, lter, and response of con-

trols, etc. before leaving for the job site.

The hydraulic reservoir is designed to

dissipate heat and is adequately sized

to disperse foam that may be generated

during operation. A 10-micron suction

lter and high pressure loop lters provide continuous ltration of the hydraulic

uid. Visual registers on the suction

lter and high pressure loop lters indi-

cate when these elements need to be

replaced.

Gooseneck Trailer-Mounted Unit, Side View

Logan 85-Ton Open Loop Power Swivel • 4

Logan 85-Ton Open Loop Power Swivel

Be sure to have an ample supply of fuel

and that the hydraulic reservoir is full.

Upon arriving at the job site, the power

unit should be placed in a level position

a safe distance from the well head and

other hazards. All corners of skid units

should be supported. On trailer units,

wheel chocks should be set in front and

in back of the wheels and the jack lowered to level the trailer bed.

Using a catline or derrick line, lift the

swivel unit from the rack. Suspend

the swivel over the well head from the

drilling hook or elevators. Be sure the

elevator is the correct size for the elevator bail. Carefully inspect the elevator

for excessive wear (refer to API RP-8B

for guidelines).

Remove the control cable or air control

hoses and the pressure gauge hose

from their storage hangers on the skid

or trailer. Connect them to their respective connections on the power unit and

control panel.

Power Swivel Electric Control Panel

Pre-Operation Start-up Procedures

Electric Controls

1.

Move the engine throttle handle to

full “decrease” position.

2. Move the swivel control handle to

neutral position (center).

3. Start the engine:

a. Turn the engine ignition switch

to “on.”

b. Hold the engine throttle control in

“decrease” for 15 to 20 seconds.

c. Hold the engine ignition in “start.”

Release the switch when the en-

gine starts and allow it to return

to the “on” position.

4. Adjust the engine throttle to 800 to

1,000 rpm.

5. Check condition of suction lter. The

lter indicator is located on top of

the hydraulic reservoir. Replace the

lter if the suction gauge reads more

than 5" Hg.

6. Check the suction vacuum gauge

mounted near the pump. It should

not read over 5" Hg.

7. Set the torque control to the desired

maximum torque. The adjustment

knob and torque indicator gauge are

calibrated in ft-lbs. Turn the adjust-

ment knob until the desired maxi mum torque is indicated on the

gauge.

8. Move the swivel control handle

to the “forward” position.

9. Increase engine throttle until the

desired swivel rpm is attained and

the engine runs smoothly.

10. Check the high pressure lter.

Charge pressure should be 100

to 200 psi.

NOTE:

promptly, reset the trip lever on the

air intake manifold located inside

the right-hand engine panel if it has

been tripped.

If the engine fails to start

Air Controls

1.

Move the engine throttle control

lever to neutral position (center).

2. Move the swivel control lever to

neutral position (center).

3. Press and release the start button

on the power unit engine

NOTE:

promptly, reset the trip lever on the

air intake manifold located inside

the right-hand engine panel if it has

been tripped.

If the engine fails to start

4.

Adjust the engine throttle to 800

to 1,000 rpm.

5. Check condition of suction lter.

The lter indicator is located on top

of the hydraulic reservoir. Replace

the lter if the suction gauge reads

more than 5" Hg.

6. Check the suction vacuum gauge

mounted near the pump. It should

not read over 5" Hg.

5 • Logan 85-Ton Open Loop Power Swivel

Logan 85-Ton Open Loop Power Swivel

Power Swivel Air Control Panel

7. Check the air lter/regulator/

lubricator unit. Air pressure should

read 100 psi or more. Lubricator

should be full of oil. Filter should be

free of water. If water is present,

open the drain valve on the bottom

of air reservoir to drain the water.

Close the drain valve.

8. Set the torque control to the desired

maximum torque. The torque control system is mounted adjacent to

the pump. The adjustment knob and

torque indicator gauge are cali-

brated in ft-lbs. Turn the adjustment

knob until the desired maximum

torque is indicated on the gauge.

9. Move the swivel control handle to

the “forward” position.

10. Increase engine throttle until the

desired swivel rpm is attained and

the engine runs smoothly.

11. Check the high pressure lter.

Charge pressure should be 100 to

200 psi.

The Logan 85-Ton Open Loop Power

Swivel is now ready for operation.

OPERATION

General Rules

Logan Oil Tools recommends the following rules be observed when operating

the Power Swivel. These operational

rules apply to all power swivel units,

whether they are equipped with air or

electric controls.

1.

The pump displacement control

should always be used to change

the speed of the swivel. Setting the

engine at the rated rpm will prolong

engine and pump life, burn less oil,

and result in fuel economy.

2. Set the speed control at minimum

and allow the engine to idle before

changing the direction of rotation.

Allow the swivel to completely stop in

neutral before switching to reverse.

3. Filters should be checked on a daily

basis.

4. The hydraulic uid level should be

checked weekly. If the level is below

the sight gauge, add hydraulic uid.

5. Charge pressure and suction gauges

should be monitored daily.

NOTE:

Fluid (Part No. 06206) or approved

equivalent when adding or changing

hydraulic fluid.

Air Controls

The air control system utilizes a single

lever-type control valve that is mounted

on the remote control panel. This control provides variable air pressure from

0 to 100 psi to the actuator positioner

to control both engine speed and the

direction of swivel rotation.

When this lever is in the center position,

the pump is in neutral and the Power

Swivel is not rotating.

Electric Controls

Diesel engine speed is controlled by

the lever labeled “Engine Throttle” on

the control panel.

Swivel rotation is controlled by the lever

labeled “Swivel Control.” It utilizes a

forward/neutral/reverse switch to control

rotation direction. Moving the lever to

the “forward” position will cause the

Power Swivel to move in a right-hand

(clockwise) direction.

Push the “Engine Throttle” lever forward

until the desired speed is attained.

Increase the engine speed if the engine

begins to overload or if a higher swivel

rpm is required.

Pressure compensating-type torque

control overrides the speed control to

automatically maintain the maximum

pre-established torque limit. This is

accomplished by reducing the pump

stroke while maintaining engine speed.

If the engine speed continues to be

overridden, the engine speed should be

reduced until identical torque and speed

conditions exist at full pump stroke.

Use only Logan Hydraulic

6. Do not permit hydraulic oil temperature to exceed 190°F for extended

periods.

Logan 85-Ton Open Loop Power Swivel • 6

Logan 85-Ton Open Loop Power Swivel

MAINTENANCE

The following guidelines are intended

to ensure maximum life of the Logan

85-Ton Open Loop Power Swivel.

These are recommendations only.

Extreme peak load usage, temperature,

and other variables will affect suggested

service intervals.

Power Swivel Maintenance

Lubrication

1.

Check the gear lubricating oil prior

to service. The oil level should be

maintained at the oil level plug level

at all times. If necessary, bring oil to

the proper operating level by adding

Logan Gear Lubricant (Part No.

G14085-001). Some lubricating oil

may leak out when the oil level plug

near the top cover plate is removed.

If oil does not leak out, gear lubricating oil of proper type and grade

should be added to the correct operating level.

2. Gear lubricating oil should be

changed after the rst 100 hours of

initial operation. Check the magnetic

drain plug for metal lings when

changing the gear lubricating oil.

NOTE:

Ton Power Swivel is eight (8) quarts.

3. After the initial break-in period (rst

4. Regularly subject the elevator bail,

Oil capacity of the Logan 85-

100 hours of operation), the gear

lubricating oil should be changed

after each 1,000 hours of operation

thereafter, or if the unit has been out

of service for an extended period.

Always check the magnetic drain

plug for metal lings when changing

the gear lubricating oil.

stem, and saver subs to magnetic

particle inspection.

Breaking-In

During initial break-in, or after a long

period of idleness, run the Power Swivel

with a reduced load at slower speed

until it reaches normal operating temperature ranging between 120 – 200°F.

A somewhat higher operating temperature is permissible in very hot climates,

provided that it increases gradually.

Storage

If the Logan 85-Ton Open Loop Power

Swivel must be stored, it should be

completely lled with gear lubricating oil

to prevent oxi-dation. Thread protectors

or lift plugs should be installed on stems

or saver subs to prevent damage to the

threads. Grease or dope the threads

before installing the thread protectors or

lift plugs.

Open gear housings, ports, and removed motors should be covered with

clean drop cloths to prevent dirt and

trash from entering internal mechanisms. Before shipping parts for service,

all openings should be sealed and parts

wrapped in clean, heavy kraft paper.

Replacing the Floating Washpipe

Assembly and Packing

The entire Floating Washpipe Assembly,

including the upper and lower packing

nuts, can be removed from the swivel

without removing the gooseneck or

bonnet.

Remove the four retainers and retaining screws from the lower packing nut.

Loosen the lower packing nut by turning

it in a clockwise direction until it turns

freely. Secure the upper stem to keep

it from rotating while loosening and

removing the lower packing nut. Use

the same procedure to loosen and

remove the upper packing nut from the

gooseneck.

Remove the washpipe and packing

assemblies. Press the washpipe out

of the lower packing nut and slide the

upper nut off. Remove the three upper

packing locking pins and press the upper packing off the washpipe. Replace

the washpipe if it shows any signs of

wear (i.e., scoring or surface abrasion).

The average life expectancy of the

packing is 200 – 250 hours. Remove

the old packing from the packing nuts.

Thoroughly clean the inside of both

nuts. Using the drawing on page 8 as

a reference, install the new packing.

Assemble the packing and oating

washpipe assembly in reverse of assembly procedure. Tighten the packing

nuts securely, locking them in place with

the retaining screws and retainers.

Power Unit Maintenance

The Power Unit includes the engine,

piping, lters, reservoir, hoses, hose

reels, cables, electrical components,

and gauges.

Engine

Please refer to the specic engine man-

ufacturer’s maintenance instructions

included with your documentation.

Hydraulic Oil and Filters

The hydraulic uid reservoir (Logan

Part No. PS06206) should be maintained at the proper level at all times.

The oil level should be visible in the

sight gauge when cold.

Filters

The return lter located at the top of the

reservoir should be replaced when the

pointer indicates that it needs cleaning.

The indicator registers when the engine

is running.

The high pressure lter in the pressure line should be serviced when the

condition indicator displays red. Green

indicates that the lter is in satisfactory

condition. The lter indicator operates

when the swivel is rotating to the right.

7 • Logan 85-Ton Open Loop Power Swivel

Floating Washpipe Assembly

Gooseneck Pipe

PS77322

2" NPT

1

3

2

4

5

6

7

Plug

2-1/2 API

LINE PIPE

15

16

8

9

10

11

12

1413

Body

PS54075

FLOATING WAShPIPE ASSEMbLY (PS49028-001) REPLACEMENT PARTS

Item Logan Part no. Qty DescrIPtIon

1 PS09028 1 Gooseneck

2 ACSA8-500-13-150 4 1/2"

- 13 x 1-1/2" Socket Head Cap Screw

3 LKWA-500 4 1/2" Lock Washer

4 PS19028 1 Bonnet

5 568-236 2 O-Ring

6 PS79028 1 Upper Packing Nut Ring

7 PS50732-003 8 1/2" - 13 NC x 3/4 Socket Set Screw

8 PS20128 8 Washpipe Packing Nut Screw Retainer

9 PS99028 3 Washpipe Locking Pin

10 568-010 3 O-Ring

Item Logan Part no. Qty DescrIPtIon

11 PS72327 1 Packing Set

12 PS39028 1 Upper Packing Nut

13 ACSA8-625-13-150 4 5/8" - 13 x 1-1/2" Socket Head Cap Screw

14 LKWA-625 4 5/8" Lock Washer

15 PS49028 1 Washpipe

16 PS69028 1 Spacer

17 PS63672 1 Packing Nut Grease Fitting

18 PS62327 1 Plain Spacer Ring

19 PS42327 1 Packing Bottom Ring

20 PS29028 1 Lower Packing Nut

17

18

11

19

8

7

20

5

and Lantern Ring

Logan 85-Ton Open Loop Power Swivel • 8

Logan 85-Ton Open Loop Power Swivel

Hoses

Lubricate the hose reel swivel joints

with automotive chassis grease

monthly.

Inspect the torque control mechanism

every six months and coat all moving

parts with automotive chassis grease.

Avoid contaminating the hydraulic uid

and hydraulic system, including the

hoses and couplings, with dust, water,

or other foreign matter. Introduction of

foreign materials into the system will

damage the machinery.

Torque gauge hose end connections should be kept clean at all times

through the use of dust covers or by

wrapping them with a clean cloth when

not in use. Open, loose ends, especially

those that have been dropped on the

ground, should be thoroughly cleaned

inside and out, and ushed prior to use.

Extend the life of the hoses by never

allowing them to become twisted or

kinked, or unnecessarily stretched. Do

not allow any sharp or heavy objects

to drop or lay on the hoses. Doing so

may cut or crush them.

Thoroughly clean the power unit when

the job has been completed. Replenish

the engine fuel and hydraulic oil supplies. Make any necessary repairs at

this time. Hoses should be reeled after

cleaning and the hose ends covered.

Power Units with Air Controls

Expel water condensate from the tank

daily by opening the drain valve on the

bottom of the air receiver. Pressurize

the tank before opening the valve.

Visually inspect the lter/lubricator valve

twice a day. Drain any water that has

collected in the lter bowl and maintain

the lubricating oil at the proper operating level with SAE 10W motor oil.

Always keep the pump stroke cylinder

rod, rod bearing, and clevis coated with

chassis grease.

Power Units with Electric Controls

The electrical cable should be coiled

and stored on the cable bracket when

not in use. Cover the open end with

the provided dust cap. Avoid kinking

or placing undue tension on the cable.

Do not allow equipment to run over the

cable.

Open the relay cabinet at least once

a year (more often in humid climates)

for cleaning. All exposed terminals and

metal parts should be cleaned, dried,

and sprayed with silicone or varnish.

Power Swivel

Power Swivels should not be started

or operated in freezing weather until

the hydraulic system has been properly

prepared for cold weather service by:

1.

Charge the hydraulic system with

hydraulic oil rated for cold weather.

2. Prepare the engine according to the

manufacturer's recommendations.

3. Ensure the hydraulic system is

moisture-free.

Never allow the power unit to vibrate.

Vibration indicates mechanical misalignment or that the unit is not properly supported. The power unit should

be shutdown until the cause can be

determined and eliminated. Continued

excessive vibration will cause severe

damage to the hydraulic pump and

other components.

Machinery and hoses should not be

allowed to remain outdoors when not

in use.

In cold climates, it is particularly important to keep the hydraulic system free

of moisture caused by condensation or

water contaminated hydraulic uid. Any

moisture in the system may freeze and

cause severe damage, especially to the

pump and valves.

Power Unit

Inspect trailer-mounted units prior to

use to ensure that it is safe and roadworthy. Pay particular attention when

inspecting the following items:

1. Trailer hitch and safety chain

2. Brakes and tires

3. Tail and brake lights, and turn signals

4. Reserve fuel supply

5. Trailer tongue jack and supports

9 • Logan 85-Ton Open Loop Power Swivel

Gooseneck Trailer-Mounted Unit, Rear View

Logan 85-Ton Open Loop Power Swivel

SWIVEL DISASSEMbLY

Care should be taken to ensure that

no foreign material enters the interior

machinery of the swivel. All disassembly

and major repairs should be conducted

in a clean, well-equipped shop.

1. Remove all hydraulic hoses from the

swivel. Hose ends should be covered

to help prevent foreign matter from

entering the interior.

NOTE:

lic hoses should be reeled up to

prevent kinking and other damage.

Damaged hoses may cause blockage

or other interference that the unit

may not function properly.

2. Place the swivel on a suitable rack

3. Remove the hydraulic motor guard.

4. Place an open container under the

5. Remove the four retaining screws

6. Press the washpipe out of the lower

When not in use, all hydrau-

(similar to the bracket on the skid or

trailer) that supports the swivel on its

bail pins.

magnetic drain plug and remove

the plug. Check the drain plug and

drained hydraulic uid for metal lings

and other foreign matter.

and their retainers from the lower

packing nut. Secure the lower stem

of the swivel to keep the upper stem

from turning while loosening the lower

packing nut. Turn the lower packing

nut in a clockwise direction until it

turns freely. Back the lower packing

nut completely off the upper stem.

Repeat the above procedure to

remove the upper packing nut and

back it completely off the gooseneck.

Remove the oating washpipe and

packing assembly.

packing nut and slide the upper nut

off. Remove the three upper packing

locking pins and press the upper

packing off the washpipe. Replace

the washpipe if it shows any signs of

wear (scoring or surface abrasion).

7. Remove the packing assembly parts

from inside both nuts. (The lower

packing assembly consists of an

o-ring, packing bottom ring, plain

spacer ring, spacer and lantern ring,

and three packing rings. The upper

packing assembly consists of an

o-ring, upper packing nut ring, and

one packing ring.) When replacing

the packing, it is important that both

packing nuts are clean and free of all

old packing residue. Make sure both

packing nuts are clean and free of

foreign matter.

8. Remove and set aside the goose

neck and bonnet.

9. Turn the swivel upside down. Remove the hydraulic motor and set it

aside.

NOTE:

draulic motor. If trouble with the motor is known or suspected, carefully

plug the ports and return the motor

to Logan Oil Tools for inspection and

repair.

10. Remove the piping that runs from

11.Remove the lower bearing retainer

12. Remove the seal retainer snap ring

13. Turn the swivel upright and remove

14. Remove the cap screws from the

15. Remove the upper gear cover shim

Do not disassemble the hy-

the oil ller plug opening in the top

plate to the side of the swivel body

next to the rst reduction gear.

screws. Set the retainer aside and

remove the gasket.

from the bearing retainer and the

two lower oil seals.

the upper seal protector from the top

of the stem.

top cover plate. A rubber mallet may

be used to break the gasket seal

if necessary. Lift off the top cover

plate.

and gasket. A putty knife or other

thin tool may be used for prying and

cleaning.

16. Remove the oil seal from the upper

cover plate. Using the inside bearing

puller, pull the outer track of the

stem upper bearing from the top

cover plate. This will free the stem

for removal.

17. The inner tracks of the stem’s upper

and lower bearings and seal wear

ring at the bottom of the stem may

be removed with a bearing puller.

The nal reduction gear is removed

by rst removing the six ring groove

pins and then forcing the gear off the

main stem.

18. Remove the screws from the lower

gear cover plate. Tap the cover plate

gently with a rubber mallet to break

the seal if necessary. Scrape off

remaining residue with a putty knife.

19. Remove the rst reduction pinion

bearing spacer and the rst reduc-

tion pinion lower bearing from the

swivel body.

20. Lift out the nal reduction pinion,

main thrust bearing, second reduc-

tion pinion, and rst reduction

pinion. The gears may require

rotation to facilitate removal.

21. Remove the remaining roller bearings, second reduction lower bear-

ing with its retainer ring, and rst

reduction pinion upper bearing. As

with all bearings, exercise caution

when handling to guard against

possible damage.

NOTE:

oughly cleaned (with steam or a high

pressure washer for metal parts, or

with a good grade solvent applied

with a clean brush) as it is removed.

Check parts for repair or replacement as they are cleaned. Dry all

cleaned parts with compressed air

or a clean, soft cloth. Coat all clean,

dry parts with a thin coat of lubricating oil. Never leave parts exposed

overnight without a coating of protective oil.

Each part should be thor-

Logan 85-Ton Open Loop Power Swivel • 10

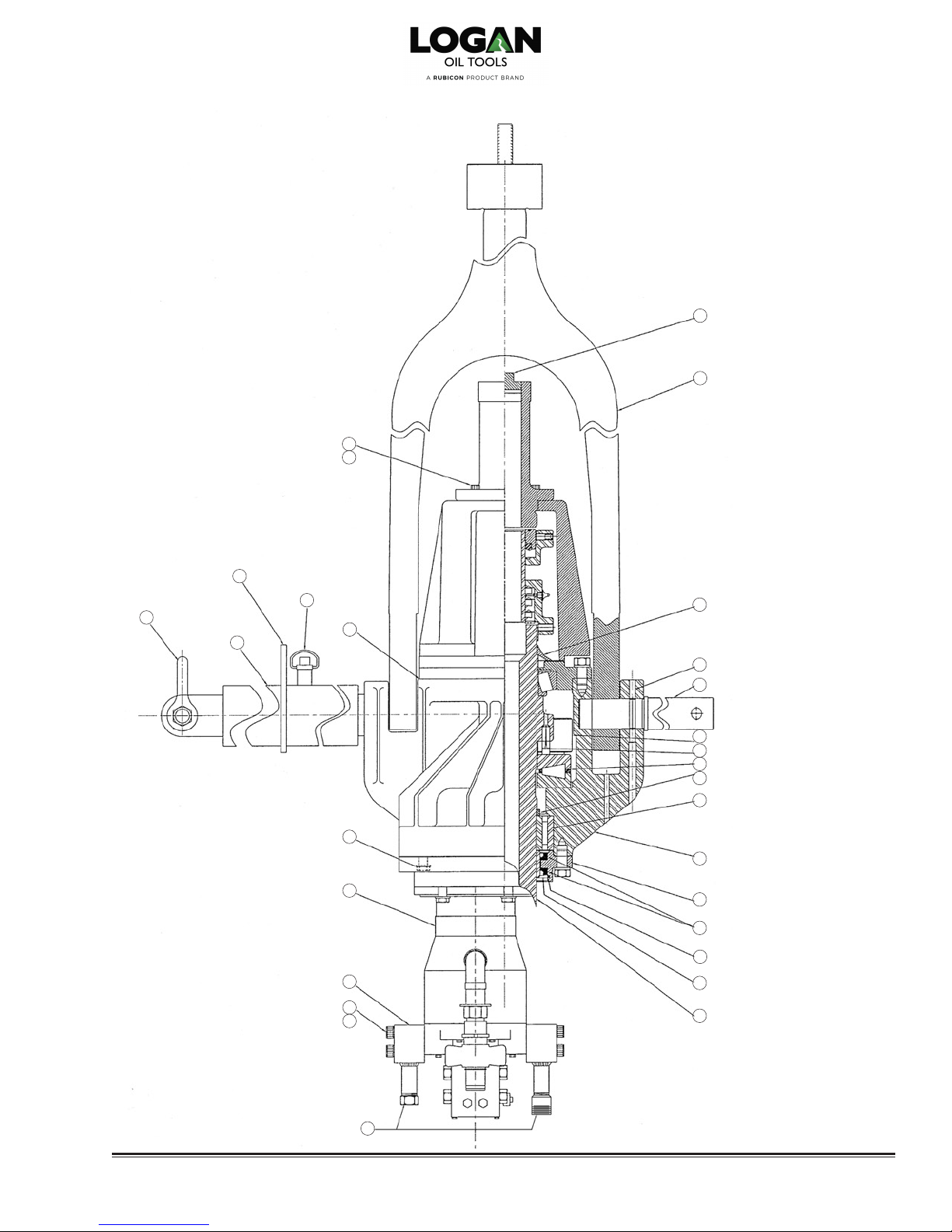

Swivel head Parts List

Item numbers refer to drawing callouts on pages 12 – 15

Item Part no. Qty. DescrIPtIon

1 PS09028 1 Gooseneck

2 ACSA8-500-13-150 14

3 LKWA-500 16 1/2" Lockwasher

4 PS19028 1 Bonnet

5 568236 2 O-Ring

6 PS79028 1 Upper Packing Nut Ring

7 PS50732-003 8 1/2" - 13 NC x 3/4" Long, Socket Set Screw

8 PS20128 8 Washpipe Packing Nut Screw Retainer

9 PS99028 3 Washpipe Locking Pin with 56810 O-Ring

10 568010 3 O-Ring

11 PS72327 1 Set Packing

12 PS39028 1 Upper Packing Nut

13 ACSA8-625-13-150 4

14 LKWA-625 4 5/8" Lockwasher

15 PS49028 1 Washpipe

16 PS69028 1 Spacer and Lantern Ring

17 PS63672 1 Packing Nut Grease Fitting

18 PS62327 1 Plain Spacer Ring

19 PS42327 1 Packing Bottom Ring

20 PS29028 1 Lower Packing Nut

21 HCSA8-625-13-150 9 5/8" - 13 x 1-1/2" Long, Hex Head Cap Screw

22 PS44322 2 Dowel Pin

23 AHSS-625-11-625 4 5/8" - 11 x 5/8" Long, Allen Head Set Screw

24 PS77122 1 Filler Plug Relief Fitting

25 PS98352 1 Oil Filler Plug

26 PS72602 1 Magnetic Drain Plug

30 PS78103 1 1" Wing Nut Quick Disconnect

31 PS22196 1 1-1/4" Quick Disconnect Set

33 PS55164 1 Lower Bearing Retainer Gasket

34 HCSA8-625-11-175 6 5/8" - 11 x 1-3/4" Long, Hex Head Cap Screw

35 PS50602 1 Saver Sub

36 HCSA8-500-13-150 4 1/2" - 13 x 1-1/2" Long, Hex Head Cap Screw

37 PS91764 4 1/2" Special Flat Washer

38 PS93456 2 1-1/4" Swivel Joint

39 PS55115-003 1 Shackle

40 PS55115-003 1 Torque Rein Assembly

41 PS697702 1 Torque Rein Eye

42 PS21415 1 Torque Rein Pull Pin

43 PS91875 1 Upper Gear Cover Shim

44 PS85-OL-KM40.109 1 Hydraulic Motor (Open Loop Gear)

45 PS65895-OL 2 Hydraulic Motor Manifold Assembly

47 ACSA8-375-13-275 8

48 LKWA-375 8 3/8" Lockwasher

1/2" - 13 x 1-1/2" Long, Socket Head Cap Screw

with Brass Point

5/8" - 11 x 1-1/2" Long, Socket Head Cap Screw

3/8" - 13 x 2-3/4" Long, Socket Head Cap Screw

Item Part no. Qty. DescrIPtIon

49 PS77322 1 Gooseneck Pipe Plug

50 PS20213 1 Elevator Bail

51 PS28444 1 Seal Protector

52 PS34813-001 1 Bolt and Nut for Bail Pin

53 PS65115 1 Bail Pin

54 PS12965 1 Final Reduction Gear

55 PS64702 6 Ring Gear Groove Pin

56 PS98402 1 Main Thrust Bearing

57 PS04685 1 Lower Stem Bearing Spacer

58 PS70602 1 Lower Stem Bearing

59 PS54075 1 Body

60 PS14685 1 Lower Stem Bearing Retainer

61 PS22602 2 Lower Oil Seal

62 PS16303 1 Seal Retainer Snap Ring

63 PS51602 1 Lower Seal Wear Ring

64 PS18444-001 1 Stem

65 PS64165 1 Second Reduction Pinion

66 PS05775 1 Second Reduction Gear Key

67 PS15165 1 First Reduction Pinion Upper Bearing

68 PS37965 1 First Reduction Pinion Upper Gear

69 PS05165 1 First Reduction Pinion Lower Bearing

70 PS44685 1 First Reduction Pinion Bearing Spacer

71 PS12685 1 Lower Gear Cover Gasket

72 PS25165 1 First Reduction Pinion Oil Seal

73 PS62516 1 Hydraulic Motor Adapter

74 PS08327 1 Retainer Ring

75 PS97327 1 Motor Adapter Sleeve

76 PS45165 1 Retainer Ring

77 PS85152 1 Second Reduction Shaft Lower Bearing

78 PS65165 1 Reduction Gear Key

79 PS95675 1 Lower Gear Cover Plate

80 PS27965 1 First Reduction Gear

81 PS84165 3 Roller Bearing

82 PS55935 1 Oil Seal Grease Fitting

83 PS90137 1 Oil Level Indicator Plug

84 PS88402 1 Upper Stem Bearing

85 PS02685 1 Upper Oil Seal

86 PS12165 1 Second Reduction Gear

87 PS53775 1 Upper Gear Cover Plate

88 PS03165 1 Final Reduction Pinion

89 PS95516-001 1 Motor Guard

90 PSWB3 3 Hose Safety Cable

91 G14085-001 2.5 Gal HD-85W-140 Gear Lube

11 • Logan 85-Ton Open Loop Power Swivel

Swivel head – Front View

Refer to Parts List on page 11 for part numbers and descriptions

49

50

2

3

41

42

39

40

43

2

44

45

47

48

51

52

53

54

55

56

57

58

59

60

61

62

63

64

31

Logan 85-Ton Open Loop Power Swivel • 12

Swivel head – Side View

Refer to Parts List on page 11 for part numbers and descriptions

24

25

33

26

3 13

36 14

37

30

38

2

3

13

34

64

35

13 • Logan 85-Ton Open Loop Power Swivel

(See page 15 for Section A-A)

A

Swivel head – Top View

Refer to Parts List on page 11 for part numbers and descriptions

13 14

A

(See page 15 for Section A-A)

24 25

13 21

22

23

Logan 85-Ton Open Loop Power Swivel • 14

Section A-A – Through Gear Train

Refer to Parts List on page 11 for part numbers and descriptions

23

85

84

83

64

33

86 87

88 81

43

65

66

67

68

69

70

82

80

81

78

79

76

77

75

74

73

71

72

15 • Logan 85-Ton Open Loop Power Swivel

Logan 85-Ton Open Loop Power Swivel

22. Remove the bail only when absolutely necessary. Lay the bail and

swivel body down so the holes at

the bottom of the bail pockets in the

body can be reached. Set a 10inch-long dowel rod with a diameter

slightly smaller than the bail pocket

holes against the pin. Strike the

dowel with a hammer. Once the

grooved pin has been removed,

insert a rod in the pull pin hole. Use

a rubber mallet to loosen the bail

pin by tapping it in alternate direc-

tions. Pour penetrating oil around

the pin to aid the loosening process.

While pulling on the pin, repeat the

loosening process until the pin is

removed. Lift out the bail.

NOTE:

tors, hoses, or similar items are to be

stored or shipped for repair, all ports

and openings should be carefully

sealed to prevent foreign matter from

entering interior parts.

SWIVEL REASSEM

Care should be taken to ensure that

no foreign material enters the interior machinery of the swivel.

repairs and reassembly should be conducted in a clean, well-equipped shop.

In the event hydraulic motors, hoses, or

similar items are to be stored or shipped

for repair, all ports and openings should

be carefully sealed to prevent foreign

matter from entering.

NOTE:

ly cleaned, dried, oiled, and in good

operating condition. Never reuse the

gear lubricating oil drained from the

swivel. Always use new, fresh oil of

the recommended type and grade.

O-rings should never be reused. It is

also recommended that all oil seals

be replaced.

In the event hydraulic mo-

bLY

All major

All parts should be thorough-

1. Place the swivel on a suitable rack

(similar to the bracket on the skid

or trailer) that supports the swivel

on its bail pins.

2. Install component parts on the

stem:

a. Press nal reduction gear back

on the stem and install groove

pin.

b. Press on upper stem bearing.

c. Install main thrust bearing.

d. Install stem lower bearing spacer.

e. Press on lower stem bearing

inner race.

f. Press on lower seal wear ring.

3. Install component parts onto shafts:

a. Install key and second reduction

gear onto nal reduction pinion.

b. Press roller bearings onto each

end of nal reduction pinion.

c. Press roller bearing on upper end

of second reduction pinion.

d. Press rst reduction pinion lower

bearing onto rst reduction

pinion.

4. With the stem lower bearing in

place, set the main stem through

the stem lower bearing into position

in the body.

5. Check the top face of the body,

making sure that the surface is

clean and free of burrs. Place a

gasket on the face of the body.

6. Place a set of three shims (one

each in thicknesses of .005", .007",

and .020") on the body face.

7. With the upper cover plate upright,

press the upper oil seal into position. Press the outer race of the

stem upper bearing into the top

cover plate.

8. Position the upper cover plate over

the stem and into place on the

body. Insert cap screws with lock

washers into the upper plate and

tighten.

9. Place a small hydraulic jack under

the lower end of the stem and a

micrometer against the top of the

stem to detect and measure any

vertical movement (end-play). Apply

lift to the stem with the jack and

note any movement shown on the

micrometer.

10. Remove the jack, micrometer, and

the top cover plate. Remove the

shims and replace them with a

combination of shims that will allow

a sufcient total amount of end-play

between .004" and .005".

NOTE:

plate without sufficient shims or

over-tighten the upper plate cover

screws. Doing so will cause the bearings to bind.

1

12. Set the rst reduction pinion, rst

13. Remove the top cover plate and

14. Turn the swivel upside down. Check

Do not tighten the cover

1. Press the second reduction pinion

lower bearing into the lower cover

plate. Set the retainer ring into position above the bearing and press

the rst pinion upper bearing into

place in the body.

reduction gear, and rst reduction

pinion bearing spacer into place in

the swivel body.

set the nal and second reduction

pinion into place. Rotate the shafts

in order to mesh the gears. Reinstall the top cover plate and tighten

the screws.

the bottom surface of the body for

burrs and atness. Lay the lower

cover gasket on the face. Position

the lower cover plate on the body

and insert the cap screws with lock

washers. Tighten the screws.

Logan 85-Ton Open Loop Power Swivel • 16

Logan 85-Ton Open Loop Power Swivel

15. Place the two lower stem oil seals

into position on the stem’s lower

bearing retainer. Set the seal retainer snap ring on the bearing retainer.

When properly assembled, the lips

of the oil seals should point upward.

Exercise caution when assembling

the oil seals over the wear ring,

being careful not to tear or turn

back the lips of the oil seals or

cause other damage to the seals.

Dam

aged seals will cause leakage.

Set the lower bearing retainer over

the stem and in place on the body.

Insert the six lower bearing retainer

cap screws with lock washers.

Tighten the screws.

16. Insert the rst reduction pinion oil

seal. Place the hydraulic motor

with the hydraulic motor adapter

attached into position. Insert the

eight cap screws with lock washers.

Tighten the screws. Attach the

hydraulic motor guard.

17. Turn the body upright.

18. Grease the upper oil seal and place

the upper seal protector in position

on the stem. Make sure the seal

protector is right-side up with the lip

against the upper cover plate.

19. Assemble the bonnet to the upper

cover plate and bolt the gooseneck

to the bonnet. Insert the gooseneck

pipe plug and tighten.

20. Coat the packing elements (o-rings,

upper packing nut ring, packing,

spacer and lantern ring, plain

spacer ring, and packing bottom

ring) generously with Logan packing

lubricant and install them into their

respective packing nuts. Reassem-

ble the oating washpipe assembly

and packing in reverse of the dis-

assembly procedure outlined on

page 7. Reinstall the packing nuts,

retainers, and retainer screws, tight ening and locking the packing nuts

securely.

Securely tighten the packing nuts

and lock into place with their re

spective retainers and retainer

screws.

21. Lay the unit at on a workbench

and insert the bail into the bail

pockets of the body. Align the bail

pins with the lock pin holes in the

body. Secure the bail by driving

the bails pins into place with a rubber mallet. As the lock pins come

into alignment, drop a drift punch

through them, driving lightly to

laterally align them.

22. Drop the bail pin grooves into place

and snug-up with a hammer. Hang

up the swivel by the bail and support the underside of the swivel.

Using a medium weight (2-1/2 lbs)

sledge hammer, drive the pins in

straight through until the heads are

ush with the top of the bail pock-

ets.

17 • Logan 85-Ton Open Loop Power Swivel

23. Reattach all piping to the hydraulic

motors before reattaching the motor

guard.

Logan 85-Ton Open Loop Power Swivel

TROUbLEShOOTING

GENERAL

Loss of charge pressure — Charge pressure gauge registers zero. Gauge may be defective. Remove charge

pump in neutral. pump and inspect for broken parts.

Loss of charge pressure — Vacuum gauge reading is high Suction strainer may be clogged.

pump in neutral. (10" Hg or more). Replace lter.

Loss of charge pressure — Charge pressure is less than 60 psi when Pump or motor may be defective. Close

pump on stroke. power swivel is rotating at full rpm. the ball valve in the high pressure line.

Put pump stroke on stroke. If charge pressure is normal, the motor is defective.

Replace valve and bearing plates.

If charge pressure is not normal, the pump

is defective. Replace valve and bearing

plates in the pump.

Hydraulic oil overheats Temperature gauge registers 190°F Hydraulic oil has been aerated (a milky ap-

or higher. pearance indicates presence of air in the oil).

Check suction connections on charge pump.

Check oil level in reservoir.

AIR CONTROL SYSTEM

Unable to control speed Power Swivel has low rpm Low air pressure.

Adjust air pressure to 100 psi.

Sticky air cylinder.

Clean and lubricate air cylinder on pump.

Defective air control valve.

Replace valve section of pump control.

Swivel rotates when control is Visual Air cylinder rod is out of adjustment.

in neutral position (air controls) Remove bolt and allow rod to center.

Adjust rod end to match.

ELECTRIC CONTROL SYSTEM

Loss of speed control Visual Defective rheostat. Voltage to control valve

should be zero to 9 volts DC. Replace con

trol valve if defective.

Dirty or defective control valve. Free the

sticky spool by rapidly moving the lever on

the valve back and forth.

Loose electrical connection at control valve

or pressure safety switch. Clean and tighten

connections.

Loss of direction control Visual Defective forward/reverse switch. If no volt-

age to pump control valve. Replace with new

switch.

Swivel rotates when control Visual Control valve on pump is not properly cen-

is in neutral position (electric controls) tered. Loosen lock nut on hex bolt located on

the front of the control. Turn bolt in one direction until the swivel turns. Turn the bolt in the

opposite direction, counting the turns until

the swivel turns in the opposite direction.

Turn the bolt to midpoint and fasten the lock

nut.

Displacement control adjustment is not

centered. Consult hydro-transmission

manual.

Logan 85-Ton Open Loop Power Swivel • 18

Specications

POWER SWIVEL SPECIFICATIONS

MODEL NO. PS85-OL

NOMINAL LOAD RATING (tons) 85

DYNAMIC LOAD RATING @ 100 RPM (tons) 45

MAXIMUM TORQUE (ft-lbs) 3,356

MAXIMUM SPEED (rpm) 150

MAXIMUM CIRCULATING PRESSURE 5,000

STANDARD STEM CONNECTION 2-7/8 IF

GOOSENECK CONNECTION 2-1/2 NPT

SWIVEL HEAD ASSEMBLY WEIGHT (lbs) 1,163

POWER UNIT & CONTROL SPECIFICATIONS

MODEL NO. PS85-OL

DIESEL ENGINE * 4BTA

ENGINE CONT HP @ 2000 RPM 83

HYDRAULIC OUTPUT (max gpm/max psi) 60.7/3,000

* Choice of Cummins, Caterpillar/Perkins, or John Deere

CAUTION:

Before installing a Logan 85-Ton Open Loop Power Swivel on a rig,

refer to the installation procedure on page 4. Failure to install the Power Swivel

properly can result in injury to the operator and rig floor personnel

19 • Logan 85-Ton Open Loop Power Swivel

2" NPT PLUG

Swivel head – Dimensions

5

Ø

2-7/8

Ø

20-17/32

18-1/2

16-5/32

2-7/8 API IF

4-1/32

23-5/32

20-15/16

53-15/16

32-7/16

2-1/2 API

LINE PIPE

13-23/32

19-1/2

41-7/32 CLOSED

58-17/32 OPEN

Logan 85-Ton Open Loop Power Swivel • 20

Power Unit Parts List

PS85-OL POWER UNIT PARTS LIST

LOGAN PART NO. QTY DESCRIPTION

PS911712 1 14 ft Gooseneck Trailer

PS811712 1 14 ft Bumper Pull Trailer

PS81795 1 14 ft Skid

ENGINES

PS290412-007 1 Cummins T-II with Compressor

PS290413-003 1 Caterpillar T-II with Compressor

PS290414-001 1 John Deere T-II with Compressor

PS290412-001 1 Perkins T-II with Compressor

PS290412-005 1 Cummins T-II without Compressor

PS290414-002 1 John Deere T-II without Compressor

PS290412-005 1 Perkins T-II without Compressor

HYDRAULIC PUMP

PS85-OL-KP40/KP20 1 Hydraulic Pump for Air Controls

PS85-OL-Main Valve 1 Control Valve

PS255002 1 Pump Motor Adapter

HYDRAULIC RESERVOIR

PS89046-OL-Assy. 1 125 gal Hydraulic Tank Reservoir

Consisting of:

PS780412 1 Hydraulic Suction Strainer

PS754T08N 1 Hydraulic Suction 2" Ball Valve

PS099612 1 Hydraulic Return Filter Assembly

PS099612-001 1 Hydraulic Return Filter Element Only

PS80602 1 Hydraulic Vacuum Gauge

PS02311 1 Filler Breather Cap

PS30795-002 1 Oil Level Gauge with Temperature

PS89046-OL 1 Hydraulic Reservoir Only

PS233612 1 Relief Back Pressure Orice

FUEL TANK

PS96892-001 1 60 gal Fuel Tank Assembly

Consisting of:

PS96892 1 Fuel Tank Only

PS96892-2 2 Fuel Sight Tube

PS94626 1 1-1/4" High Pressure Ball Valve

PS61648 2 High Pressure Filter Assemblies

Consisting of:

PS921512-001 2 High Pressure Filter Element Lng

PS921412-002 2 High Pressure Filter Housing

PS921412-003 2 High Pressure Filter Head

PS02311 1 Filler Breather Cap

PS811412 1 Fuel Suction Tube

PS811412-A 1 Fuel Return Tube

PS96892 1 Fuel Tank Weldment

MISCELLANEOUS

PSMM9000-002 1 Electric Winch

PS558612-001 1 Hydraulic Winch

PSBattery Box 1 Battery Box

PSTool Box 1 Tool Box

PS211412 1 Power Swivel Stand

LOGAN PART NO. QTY DESCRIPTION

HOSE REEL

PS670712-OL 1 Hose Reel Assembly with Hydraulic Winch

PS97556 1 100 ft High Pressure Hose Assembly

PS24376 1 100 ft, 3/4" Case Drain Hose

PS195412 1 Hydraulic Valve for Reel

PS85-OL-HR/HW Valve 1 Hydraulic Valve for Reel with Hydraulic Winch

PS220712 1 Hydraulic Motor Hose Reel

PS89638-002 1 Flow Control Hose Reel

PS490412 1 Three-Port Coupling Hub

PS120712 1 Torque Hub

AIR TORQUE SET PANEL

PS223612-OL 1 Torque Set Panel Assembly

PS22236-OL 1 0 – 3,356 ft/lbs Torque Gauge

PS98126 1 Torque Set Relief Valve

PS220512 1 Torque Set Air Override Valve

AIR CONTROL PANEL

PS09966-003 1 Pump Control Valve

PS29966 1 Engine Throttle Control Valve

PS22236-OL 1 0 – 3,356 ft/lbs Torque Gauge

PS220512 1 Engine Kill Valve

PS80345-003 5 1/4" Quick Disconnect, Air Male x Male Pipe

PS70345 1 1/4" Quick Disconnect, Hydraulic Male x Male Pipe

PS217752 1 Control Umbilical Bundle

PS70345-001 5 1/4" Quick Disconnect, Air Female

PS80345-003 1 1/4" Quick Disconnect, Hydraulic Female

AIR PREPARATION PACKAGE

PS81455-002 1 Air Preparation Package

PS81455 1 3 Gallon Air Receiver

PS24695 1 Gauge

PS73585 1 Safety Pop-Off Valve

PS93646-001 1 Filter Regulator/Lubricator

PS81455-003 1 Tank Guard

PS57196-OL 1 Heat Exchanger

FILTERS

PS290412-009A 1 Cummins Oil Filter

PS290412-009B 1 Cummins Fuel Filter

PSAF1640 1 Cummins Primary Air Filter

PSAF1641 1 Cummins Secondary Air Filter

PS2654407 1 Caterpillar Oil Filter

PS26560201 1 Caterpillar Fuel Filter

PS26510380 1 Caterpillar Primary Air Filter

PS26510381 1 Caterpillar Secondary Air Filter

PSP550779 1 John Deere Oil Filter

PSP550759 1 John Deere Fuel Filter

PSAF1640 1 John Deere Primary Air Filter

21 • Logan 85-Ton Open Loop Power Swivel

bumper Pull Trailer-Mounted Unit

97-3/4"

232-1/2"

The hydraulic system has been omitted from the drawing for clarity.

Please refer to the hydraulic schematic on page 24.

79-1/2"

Logan 85-Ton Open Loop Power Swivel • 22

Skid-Mounted Unit

87"

74"

The hydraulic system has been omitted from the drawing for clarity.

Please refer to the hydraulic schematic on page 24.

23 • Logan 85-Ton Open Loop Power Swivel

79-1/2"

187"

hydraulic Schematic

Logan 85-Ton Open Loop Power Swivel • 24

Torque Controller

For Air and Electric Controls

PUMP STROKE

psi

ft lbs of Torque

TORQUE SET

TORQUE CONTROLLER ASSEMbLY (PS223612-OL) REPLACEMENT PARTS

Item Logan Part no. Qty DescrIPtIon

1 PS22236-OL 1 0 - 3,356 ft/lbs Torque Gauge

2 PS223612-001 1 Torque Set Panel

3 PS220512 1 Air Valve Push Button

4 PS98126 1 Torque Release Valve

5 PS2501-04-02 1 1/4" Male x 1/8" Male 90 Degree

Item Logan Part no. Qty DescrIPtIon

6 PS2405-04-08 1 1/4" Male x 1/2" Female Bushing

7 PS2501-04-04 1 1/4" Male x 1/4" Male 90 Degree

8 PS2404-04-02 1 1/4" Male x 1/8" Male Connector

9 LKWA-625 1 1/4" MT x 1/4" MT x 1/4" MP Tee

25 • Logan 85-Ton Open Loop Power Swivel

notes

Logan 85-ton Open Loop Power swivel • 26

Loading...

Loading...