Framer's Edge Elite 60"

Professional Mat Cutter

from Logan Graphics - 660-1

Instruction Manual

INSTRUCTION MANUAL

MODEL 650-1 / 655-1 / 660-1

FRAMER’S EDGE ELITE

MAT CUTTER

INSTRUCTIONS AND OPERATION MANUAL

Professional Series mat cutting system with laminate board surface,

ball bearing guided cutting head, production stops, 9” & 32”

squaring arms, plus dual straight & bevel cutting heads

Model 650-1 Framer’s Edge Elite - 40” mat cutter

Model 655-1 Framer’s Edge Elite - 48” mat cutter

Model 660-1 Framer’s Edge Elite - 60” mat cutter

CAUTION!!

MAT CUTTING BLADES ARE SHARP

Mat border calculator

Mobile app

For best results use only

authentic Logan blades

Uses Logan Replacement

Blade #269 Blade #268

LoganGraphic.com

Purchase Date

ID Number (on bottom of board)

Date (on bottom of board)

L618DN4 Rev.2 10-13

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Congratulations on your purchase of the Logan Professional Series, Framer’s Edge Elite Mat Cutter.

The Framer’s Edge Elite Mat Cutter is a well-designed mat cutter, combining the best of what Logan mat cutters have to offer. It’s designed specifically with the framer in mind.

All materials are heavy-duty to withstand the rigors of professional mat cutting and to provide the accuracy framers demand. Features which Logan introduced to the industry

years ago include squaring arm, mat guide, movable production stop, high-tech aluminum cutting bar, simple blade change and precision adjustment of the blade to maintain

straight cuts with no overcuts. In addition, the cutting head is ball bearing guided for smooth operation. We are confident that the quality, accuracy and dependability of the

Framer’s Edge Elite will be everything you expect in a professional mat cutter. This instructional manual is written to acquaint you thoroughly with this product. Referred to at

the outset, it will answer many questions that may arise during use. You will find that the time taken will be well worth it and you will be cutting top quality mats in no time.

Top

Work Surface

and Orientation

The work surface must be flat and

smooth. Any dips or warps in a table

top can cause the base board of the

mat cutter to also warp. Never lean the

mat cutter against a wall when not in

use. Always store flat. The procedure

detailed in the following instructions refer

to the right and left side and the top and

bottom of the mat cutter as shown.

Left Right

Bottom

Carton Contents

1. Squaring Arm Stop (1)

2. 32” Squaring Arm (1)

3. Logan Screwdriver (1)

4. Five pack of Logan #269 blades (2)

5. Five pack of Logan #268 blades (1)

6. Channel screws (2)

7. Mat guide channels (2)

8. Top production stop (1)

9. Mat Guide (1)

10. 9” Squaring Arm (1)

11. Allen Wrench (1)

9

2

10

7

8

6

1

11

4

3

5

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

2

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Identification of Machine Components

Cutting Board

Squaring Arm

Right angle back stop

necessary to hold material

square to Cutting Bar

Bevel Cutting Head

Squaring Arm Stop

Aluminum stop that slides onto

either end of the Squaring Arm

and tightens into position

Cutting Board

3/4” thick laminate

surface Cutting Board

Cutting Bar

Heavy-duty extruded Cutting

Bar with non-stick coating

and polished surface

Bottom Production Stop

Production Stop tightens to the Cutting Bar Rod and stops the

cutting head at the location determined by the scale setting

Cutting Bar Scales

Dual inch/metric scale recessed into cutting bar to

be used together with the bottom production stop

Mat Guide

Movable, parallel guide bar

used to set border width of

the mat being cut

Handle Bar

Square shaped handle used to raise

Cutting Bar to vertical position

Slip Sheet

A piece of scrap matboard

that is placed beneath the

mat when bevel cutting

Top

Production Stop

Movable stop which

connects to cutting

head. Allows fast

production cutting

of mat board

Top Overcut

Adjustment

For adjusting overcut

at the top of the mat

Indicator Plate

Metal outrigger with green and

red arrow used to accurately

start and stop on marked lines

resulting in minimal overcuts

Depth Adjustment Screw

Adjustment screw used to

set bevel cutting head to cut

various thickness matboard.

Bottom Overcut

Adjustment

For adjusting overcut at

the bottom of the mat

Cutting Head

Mounting block that

glides on cutting bar

and contains both bevel

and straight cutting

blade holders

Lock-Down Pin

Pin for locking Straight

Cutter in down position

Depth

Adjustment Knob

Knob adjusts to 3

depth settings

Straight Cutting Head

Blade Holding Screw

Screw for tightening

blade in head

3

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Set-Up

MAT CUTTING BLADES ARE SHARP

CAUTION!!

Bevel Blade Installation

NOTE: There are two blades from which to choose... #269 (Green tape) blades are used

for bevel cutting standard thickness matboard and have two beveled edges. #268 (Blue

tape) blades are used for bevel cutting 8-Ply thickness matboard and have one beveled

edge. (Fig. 1)

#269 (GREEN TAPE) DOUBLE BEVEL BLADE (STANDARD THICKNESS MATBOARD)

1. Using the handle bar, lift the cutting bar to full upright position.

2. Loosen blade screw.

3. Remove one blade from pack of five.

4. Slide blade, sharp edge down, fully into blade holder. (Fig. 2)

5. Tighten blade screw.

#268 (BLUE TAPE) SINGLE BEVEL BLADE (8-PLY THICKNESS MATBOARD)

NOTE: Only one corner of the #268 blade can be used.

1. Using the handle bar, lift the cutting bar to full upright position.

2. Loosen blade screw.

3. Remove one blade from pack of five.

4. Slide blade, sharp edge down, bevel edge visible, fully into blade holder. (Fig. 2)

5. Tighten blade screw.

Straight Blade Installation

1. Set cutting bar in down position on cutting board.

2. Pull out lock down pin & rotate blade holder as far back as it will go. (Fig. 3)

3. Loosen blade screw.

4. Determine desired depth setting using blade depth settings chart. (Fig. 4)

5. Rotate depth adjustment knob to desired setting. (Fig. 5)

6. Slide blade into slot under “blade” label. (Fig. 6)

NOTE: Only use blade #269 (Green tape) for straight cutting.

7. Tighten blade screw.

8. Rotate blade holder back until lock down pin “pops” into safety position. (Fig. 7)

Straight Blade Removal

1. Set cutting bar in down position on cutting board.

2. Pull out lock down pin & rotate blade holder as far back as it will go. (Fig. 3)

3. Loosen blade screw.

4. Rotate depth adjustment knob to setting 3.

5. Remove blade.

Mat Guide Assembly

1. Press each Mat Guide Channel into board slots with rounded end towards guiderail.

2.

Insert channel screw from the UNDERSIDE of board and tighten with Logan screwdriver. (Fig. 8)

3. Loosen each mat guide knob three full turns.

4. Hold mat guide at ends with your thumbs on the loosened knobs with raised edge facing

guiderail and evenly drop mat guide into channels.

5. Slide to adjust and tighten knobs to lock mat guide. (Fig. 9)

Fig. 1

Fig. 2

Fig. 3

Fig. 4

#269

#268

Fig. 5

Fig. 6 Fig. 7 Fig. 8

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

Fig. 9

E

L

A

C

S

T

E

S

LoganGraphic.com

4

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

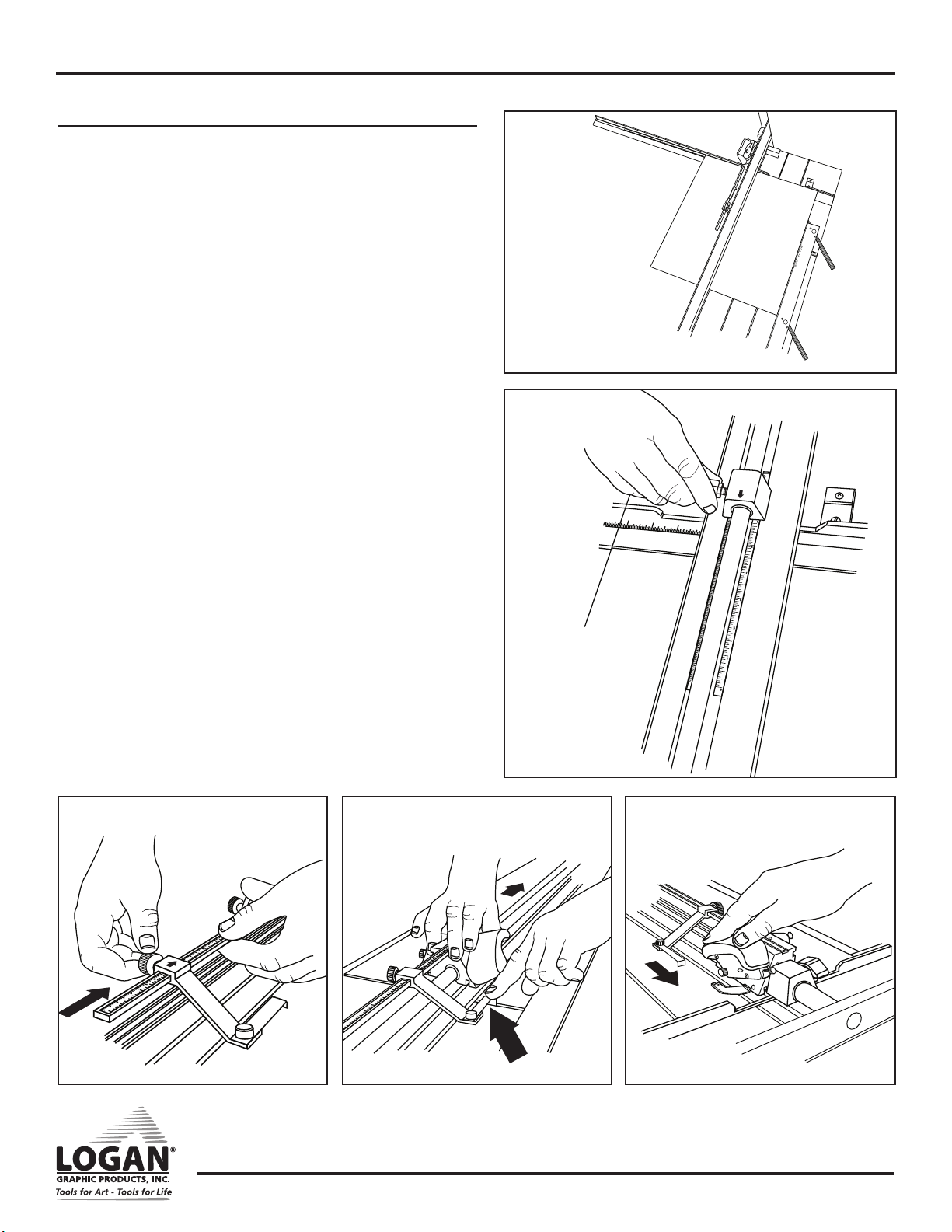

Squaring Arm Assembly

NOTE: There are two squaring arms from which to choose. The 32” arm is used for straight

cutting. The 9” is an option if straight cutting is unnecessary or saving space is required.

1. Line up squaring arm along side of slot, ensuring the bottom of the v-groove is

underneath screw. (Fig. 10)

2. Slide into the slot.

3. Align slots and tighten screw. (Fig. 11)

4. Slide stop onto squaring arm. (Fig. 12)

Top Production Stop Assembly

1. Slide top production stop onto measuring bar. (Fig. 13)

2. Tighten knob.

Straight Cutting Board to Size Using 32” Squaring Arm

1. Remove mat guide and slip sheet.

2. Loosen bottom production stop and move to bottom of cutting bar. (Fig. 14)

3. Lift Handle bar into up position.

4. Set squaring arm stop to dimension of cut. Place mat (color side down) against

squaring arm and stop. (Fig. 15)

5. Lower handle bar into down position so cutting bar rests on mat.

6. Slide cutting head past far end of mat.

7. Rotate straight cut blade holder down until lock down pin “pops” into lock slot.

(Fig. 16)

8. Holding the cutting head as shown (Fig. 17), pull the cutting head until the board is

completely cut.

NOTE: Do not apply downward pressure on blade holder. The lock down pin is holding blade

at proper depth.

9. IMPORTANT: After finishing the cut, pull lock down pin out and rotate blade holder to

safety position. (Fig. 18)

NOTE: It is dangerous to leave the blade set in the “cut” position.

Fig. 10

Fig. 11

Fig. 12

Fig. 13

Fig. 16

Fig. 14

Fig. 17

Fig. 15

3

2

1

Fig. 18

5

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

LoganGraphic.com

Instruction Manual

Fig. 22

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Bevel Cutting Mat Openings

Using Line to Line Method

1. Install mat guide and set to desired border width. Tighten black knobs.

2. Loosen bottom production stop and move to bottom of cutting bar. (Fig.19)

3. Lift handle bar and replace/install slip sheet.

NOTE: For best results ALWAYS use a slip sheet when bevel cutting. A slip sheet is a scrap piece

of matboard which is at least as long as the mat you are cutting and at least 4” wide. Your first slip

sheet is included. The slip sheet will need to be changed periodically. Move the slip sheet slightly

after each cut to avoid cutting into previous scores that may cause the blade to flare out, causing a

curve in your cut.

3. Place the mat (color side down) against the squaring arm and against the mat guide. (Fig. 20)

4. Lower the handle bar. With a pencil, draw a line on the back of the matboard using the left side

of the cutting bar as a guide. Do this for the remaining three sides of the mat. (Fig. 21)

5. Slide the cutting head into position so that the edge of the metal near the green arrow on the

indicator plate is directly over the top marked line. (Fig. 22)

6. Rotate the bevel blade holder down completely to seat the blade into the mat.

NOTE: Press your finger against the side of the indicator and the mat firmly enough to not allow cut-

ting head to “creep forward” when inserting blade, which can cause an overcut. (Fig. 23)

7. Maintaining downward pressure, pull the cutting head toward yourself until edge of the metal

near the red arrow on the indicator plate is directly over the bottom marked line. (Fig. 24)

NOTE: Do not push down on the handle bar when cutting, as this will flex the cutting bar upwards

and prevent the blade from cutting through the matboard.

8. Rotate the bevel blade holder up to the neutral position and lift the handle bar to an upright position.

9. Turn the mat 1/4 turn to the right and make sure that the mat is down against the squaring arm

and against the mat guide on the left.

10. Continue steps 5 through 8 until all four sides are cut.

Fig. 19

Fig. 20

3

2

1

E

L

A

C

S

T

E

S

Fig. 21

Fig. 23

Fig. 24

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

6

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Using Production Stops

1. Install mat guide and set to desired border width. Tighten black knobs.

2. Lift handle bar and replace/install slip sheet.

NOTE: For best results ALWAYS use a slip sheet when bevel cutting. A slip

sheet is a scrap piece of matboard which is at least as long as the mat you

are cutting and at least 4” wide. Your first slip sheet is included. The slip

sheet will need to be changed periodically. Move the slip sheet slightly after

each cut to avoid cutting into previous scores that may cause the blade to

flare out, causing a curve in your cut.

3. Place the mat (color side down) against the squaring arm and against

the mat guide. (Fig. 25)

4. Slide the bottom production stop up to the increment on the scale of

the border size you wish to cut. (Fig. 26)

5. Slide the top movable stop up to the increment on the scale of the

border size you wish to cut. (Fig. 27)

6. Slide the cutting head into position in front of the top edge of the

matboard. As the movable stop approaches the edge of the matboard,

press down on the stop foot with your left index finger until it gently

makes contact with the top edge of the mat. (Fig. 28)

7. Holding the stop foot in place with your finger, rotate the blade holder

down to enter the blade into the mat.

Fig. 25

Fig. 26

E

L

A

C

S

T

E

S

3

2

1

8. Release the stop foot with your finger, so that it raises above the edge

of the mat board and pull the cutting head towards yourself until it

makes gentle contact with the bottom production stop. (Fig. 29)

9. Turn the mat 1/4 turn to the right and make sure that the mat is down

against the squaring arm and against the mat guide on the left.

10. Continue steps 6 through 9 until all four sides are cut.

Fig. 27

Fig. 28 Fig. 29

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

7

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Adjustments

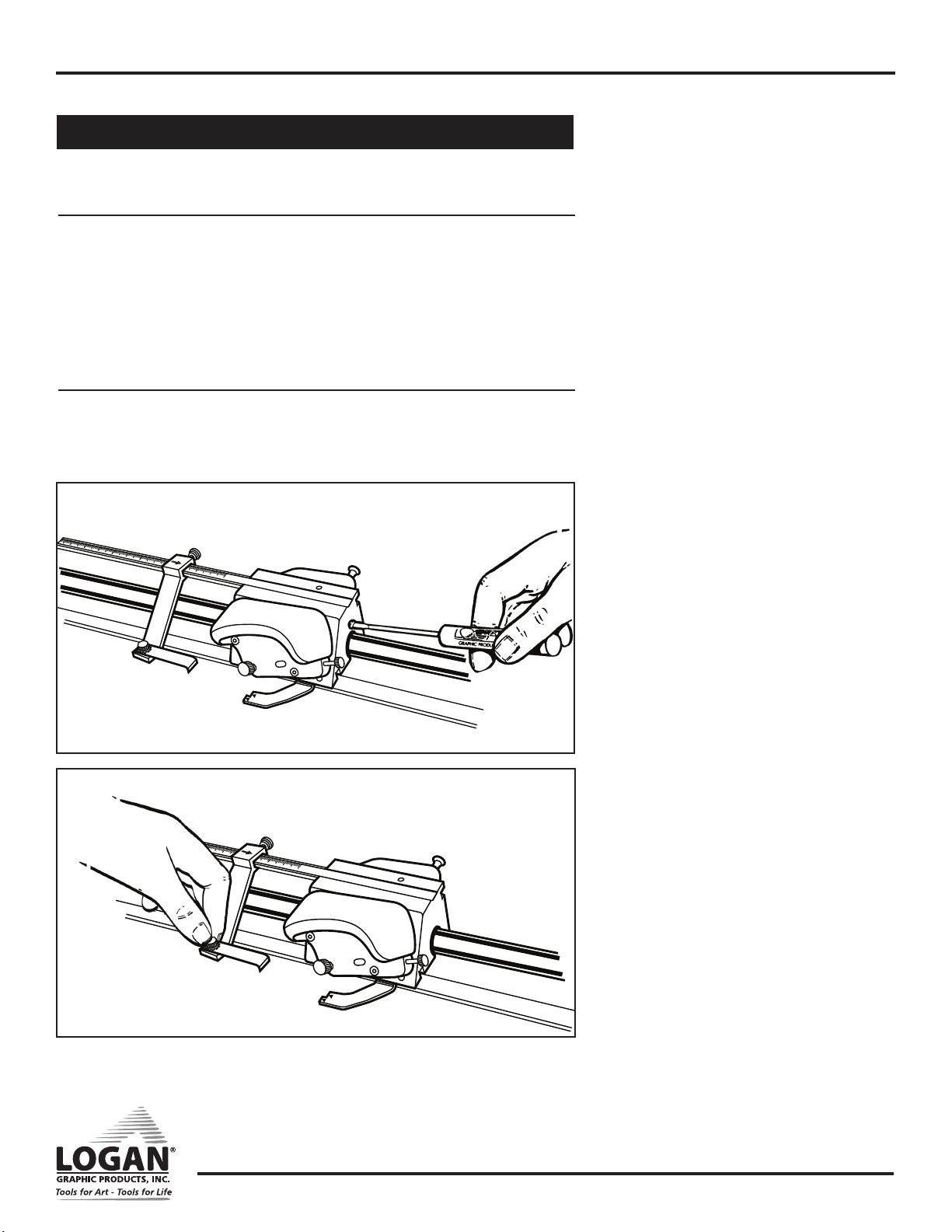

Bevel blade depth adjustment

1. Turn depth adjustment screw clockwise to increase depth or coun-

terclockwise to decrease depth. (Fig. 30)

NOTE: Use the blade window to reference various blade depths.

NOTE: It is always ideal to have just enough blade depth to slice through

the mat you are cutting and score slightly into the slip sheet. Extra blade

depth can allow the blade to flex, resulting in hooks or curves in the cut.

Extra blade depth can also cause the blade to start its cut sooner and

stop its cut later than needed, resulting in overcuts.

Cutting Head Slide Adjustment

If cutting head is too loose, wobbles up and down OR rocks side to

side, you will need to adjust the cutting head.

Bushing Adjustment

1. To eliminate side to side rocking, tighten each adjustment screw

a very small amount using Allen Wrench. (Fig. 32)

Fig. 30

Fig. 31

2. Test rocking and readjust until rock is eliminated and sliding

motion is smooth.

Bearing Adjustment

1. To eliminate wobble up and down, tighten adjustment screw a

very small amount using Allen Wrench. (Fig. 31)

2. Test wobble and readjust until wobble is eliminated and sliding

motion is smooth.

Fig. 32

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

8

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Overcut Screw Adjustments

NOTE: These adjustments are only needed when production stops are being used.

Bottom Overcut Adjustment

1. If over or under cuts appear at the BOTTOM of the cut when using the production

stops even after a blade depth adjustment, use the Logan screwdriver provided to

make slight adjustments on the overcut adjustment screw on the back of the cutting

head. This screw will fine tune the BOTTOM over/under cut only when using the

production stop.

2. To adjust, use Logan screwdriver to turn screw in (clockwise) to increase overcut or

turn screw out (counterclockwise) to decrease overcut. (Fig. 33)

Top Overcut Adjustment

1. Loosen knob to allow leg to slide. Slide leg away from cutting head to decrease

overcut or toward cuting head to increase overcut. Tighten knob to lock leg into

position. (Fig. 34)

Fig. 33

Model 650-1 / 655-1 / 660-1

Fig. 34

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

9

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Cutting Board Adjustments

Fig. 35

Fig. 36

PLACE

SQUARE HERE

Re-Squaring the Squaring Arm

Tools needed: Screwdriver, Carpenter’s Square

Before making any adjustments to the squaring arm, make sure that the machine is truly

out of square, not the mat board, by using the squareness test.

ATTENTION: It is common for 32” x 40” sheets of mat board to be un-square when

bought. Take this into account before making any adjustments to the squaring arm.

Squareness Test

1. Place the carpenter’s square against the right hand side of the guide rail and

down against the squaring arm. (Fig. 35) Lock to see if there are any gaps

between the framing square and the squaring arm. If so, the squaring arm needs

to be adjusted.

To Re-Square

1. By looking at where the gap is, you can determine which way the squaring arm needs

to go, in order to be square again.

2. Remove the squaring arm and locate the two screws inside of the slot.

3. To adjust, you must turn screws A & B in equal but opposite directions. To move the

far right end of the squaring arm towards the top end of the machine, turn adjustment screw B inward (clockwise) about a quarter turn, and turn adjustment screw A

outward (counter-clockwise) a quarter turn. (Fig. 36)

4. Re-install the squaring arm and check for square. This is a trial and error method.

In some cases more than a quarter turn is needed, in some cases, less.

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

10

LoganGraphic.com

Instruction Manual

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

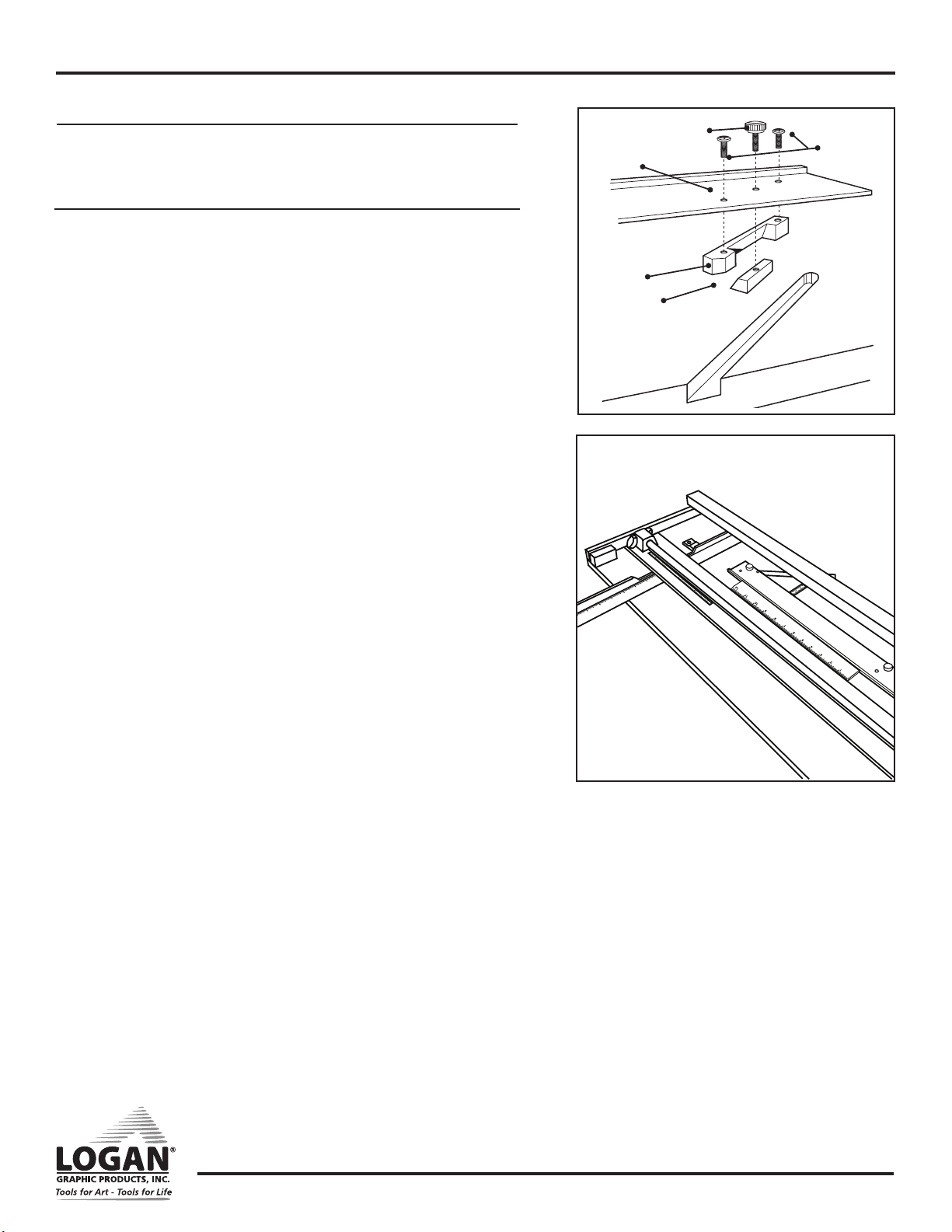

Mat Guide Assembly

If mat guide wedge becomes unscrewed from mat guide, reassemble making sure

angle of wedge is aligned correctly. (Fig. 37)

Re-parallel Mat Guide

Tools Needed: Phillips Screwdriver, Ruler

To re-parallel the Mat Guide, first determine that the Mat Guide is out of parallel by

doing a parallel test.

Parallel Test:

1. Lock the Mat Guide at the 2” mark on the scale.

2. Place a scrap piece of matboard under the Guide Rail and up against the Mat

Guide at the far end of the machine.

3. Using a pencil, mark a line across the matboard.

4. Slide the mat all the way down near where you are standing keeping under the

Guide Rail.

5. Mark another line across the matboard.

6. The piece of matboard should now appear to only have one single line across it.

If the two lines drawn do not line up with each other, the Mat Guide needs to be

re-paralleled.

To Re-parallel:

1. Release the Mat Guide.

2. Use a Phillips head screwdriver to loosen the four screws on either side of the

black knobs one turn.

Fig. 37

Mat Guide

#602 Slide

#603 Wedge

Fig. 38

#112N Mat

Guide Knob

#604 Mat

Guide

Screws (2)

3. Place a ruler or straight edge between the Mat Guide and the Guide Rail. (Fig. 38)

4. Slide the Mat Guide against the straight edge and the Guide Rail. Make sure

both the Mat Guide and the Guide Rail are making solid contact on both

sides of the straight edge.

5. Re-tighten the Black Knobs first.

6. Then re-tighten the four screws. Do another parallel test to ensure that the Mat

Guide is now parallel.

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

11

LoganGraphic.com

Instruction Manual

Troubleshooting

Problem Solution

•

Hooks or Curves

Overcut on Top Cut

Overcut on Bottom Cut

Mat Borders Uneven

Ragged Bevel Cut

Not Cutting Through

Blade depth set too deep.

•

Blade is dull.

•

Blade is catching on previous cut in Slip Sheet.

•

Uneven pressure being applied to

Cutting Head during cut.

•

Blade depth set too deep.

•

If too small - align start and stop indicator slightly below

pencil line and cut.

•

If too big - align start and stop indicator slightly above

pencil line and cut.

•

Mat Guide not parallel.

•

Cutting without a Slip Sheet.

•

Slip Sheet is worn out.

•

Not changing the blade often enough.

•

Machine not on a level surface.

•

Not using a Slip Sheet as least as long as the

mat you are cutting.

•

Blade depth set too shallow.

Framer’s Edge Elite Mat Cutter

Model 650-1 / 655-1 / 660-1

Helpful Hints

Avoid Board Warp - Always store your Mat Cutter flat.

Clean Guide Rail - Only use evaporative solvents such as lighter fluid or alcohol. Do not lubricate the Guide Rail.

Cutting a Border Less Than 3/4” - Mark mat (back side) using a pencil and do not use Mat Guide.

Blade Life - Use only authentic Logan blades to ensure best results. No two blades last the same amount of time. Size of mats and differences in

mat board effect blade life. It is best practice to use a new blade whenever starting a new project.

Warranty

Logan Graphic Products, Inc. (“Logan”) warrants the model 650-1 / 655-1 / 660-1 FRAMER’S EDGE ELITE to be free from defects in parts

and workmanship for a period of two years from the date of original purchase. Logan warrants that it will either repair or replace, in its sole

discretion, any necessary replacement parts found to be defective. Should the product need to be returned to Logan for repair or replacement

parts, authorization for any return must come from Logan in writing. Costs of returning the product to Logan, including insurances, shall be

borne by the purchaser. Logan shall not be liable for any damages or losses, incidental or consequential, direct or indirect, arising from the

use of this product. This warranty extends only to the original purchaser and is not assignable or transferable. This warranty is in lieu of all

other warranties, expressed or implied. Be advised that any Logan products purchased as “new” from an unauthorized dealer, such as an

online auction site or similar, may be void of their warranty.

Logan Graphic Products, Inc.

1100 Brown Street Wauconda, IL 60084

800/331-6232 847/526-5515

Logan Graphic Products Inc., 1100 Brown St, Wauconda, IL 60084 847-526-5515 cs@logangraphic.com

12

LoganGraphic.com

Loading...

Loading...