Page 1

GAS-FIRED FURNACE

DOWN FLOW & DIRECT VENT (SEALED COMBUSTION)

MODELS: GMD1-80N

INSTALLATION AND SERVICE MANUAL

For installation in:

1. Manufactured Homes

2. Modular Homes/Buildings

3. Site Constructed—Residential (Single Story Dwellings)

:

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

: If the information in these instructions is not followed exactly, a fire or explosion may

result causing property damage, personal injury, or loss of life.

: Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this manual. For assistance or additional information, consult

a qualified installer, service agency, or fuel supplier.

: Do not use this appliance if any part has been underwater. Immediately call a

qualified service technician to inspect the appliance and to replace any part of the electrical or

control system that has been underwater.

PLEASE READ THESE INSTRUCTIONS PRIOR TO INSTALLATION, INITIAL FIRING, AND BEFORE

PERFORMING ANY SERVICE OR MAINTENANCE. THESE INSTRUCTIONS MUST BE LEFT WITH THE USER

AND SHOULD BE RETAINED FOR FUTURE REFERENCE BY QUALIFIED SERVICE PERSONNEL.

THERMO PRODUCTS, LLC.

POST OFFICE BOX 217

NORTH JUDSON, IN 46366

PHONE: (574) 896-2133

MG-505

ECN 4501-MA

MADE IN USA

Page 2

All installations and services must be performed by qualified service personnel.

I. SAFETY SECTION

This page and the following two pages contain various warnings and cautions

found throughout this furnace Service and Installation Manual. Please read and

comply with the statements on the cover and the statements below.

: This furnace is not to be used as a construction heater.

: When testing electrical equipment, always follow standard electrical

procedures and precautions.

: The area around the furnace should be kept free and clear of

combustible materials, especially papers and rags.

: This furnace uses an automatic hot surface ignition control. NEVER

try to ignite gas manually.

: If the temperature rise exceeds 85°F, the heat exchanger may fail

voiding the heat exchanger warranty resulting in property damage, personal

injury or loss of life.

: Burner adjustments must be confirmed by instrumentation. Failure to

use accurate or calibrated instrumentation to setup the burner may result in

reduced efficiency, sooting, and/or the production of hazardous carbon

monoxide gas.

: Any attempt to relocate safety controls or replace safety controls with

a control that is not approved or incompatible, may result in personal injury,

substantial property damage or death.

: If you do not follow these instructions exactly, a fire or explosion may

result causing personal injury, loss of life or property damage.

: HAZARD OF ASPHYXIATION: Negative pressure inside the closet with

closet door closed and the furnace blower operating shall be no more negative

than minus 0.05 inch water column.

: Do not obstruct any return air openings, including the return grille on

the furnace. To do so may cause the furnace to activate the high limit and shut

down or it may cause asphyxiation.

: Because of the potential of odorant fade, a gas leak may not be

detected by smell. If this furnace is installed below grade, contact your gas

supplier for a gas detector.

: All gas pipe connections must be leak tested using a strong soap and

water solution (with the gas turned on). Any leaks must be repaired immediately

1

Page 3

All installations and services must be performed by qualified service personnel.

after turning off the gas supply. A final test for gas leakage must be made after

purging the gas line.

: DO NOT wet electronic components during the leak test. Wetting

electronic components may damage circuitry and cause a hazardous situation.

Dry moisture from all leads and terminals if wetting occurs. Wait at least 24

hours for the circuit to fully dry before energizing the system.

: The furnace and its gas valve must be disconnected from the gas

supply during pressure testing of the gas supply system at pressures in excess

of 1/2 PSIG or 14.0 inches W.G. The furnace can be isolated from the gas supply

by closing its manual shut off valve at test pressures equal to or less than 1/2

PSIG or 14.0 inches W.G.

: Copper and brass tubing and fittings (except tin lined) shall not be

used if the gas contains more than a trace (0.3 grains per 100 cubic ft.) of

hydrogen sulfide gas. Check with your gas supplier.

: If you suspect there is a problem with the furnace, the venting system

or any other related problem, immediately contact a qualified service agency. If a

service agency is not available, contact your fuel supplier.

: Personal injury, or property damage, could result from major repair or

service of this furnace by anyone other than a qualified contractor. Only the

routine maintenance described in the user section of this manual should be

performed by the user.

: Do not block or obstruct air openings on the furnace or air openings

communicating with the area in which the furnace is installed.

: Do not allow the outside air intake to be blocked or obstructed by

vegetation, ice, snow or any other materials.

: Do not use this furnace if any part has been underwater. Immediately

call a qualified service agency to inspect the furnace and to replace any part of

the electrical or control system, which has been underwater.

: Should overheating occur or the gas supply fail to shut off, shut off the

manual gas supply valve to the furnace before shutting off the electrical supply.

2

Page 4

All installations and services must be performed by qualified service personnel.

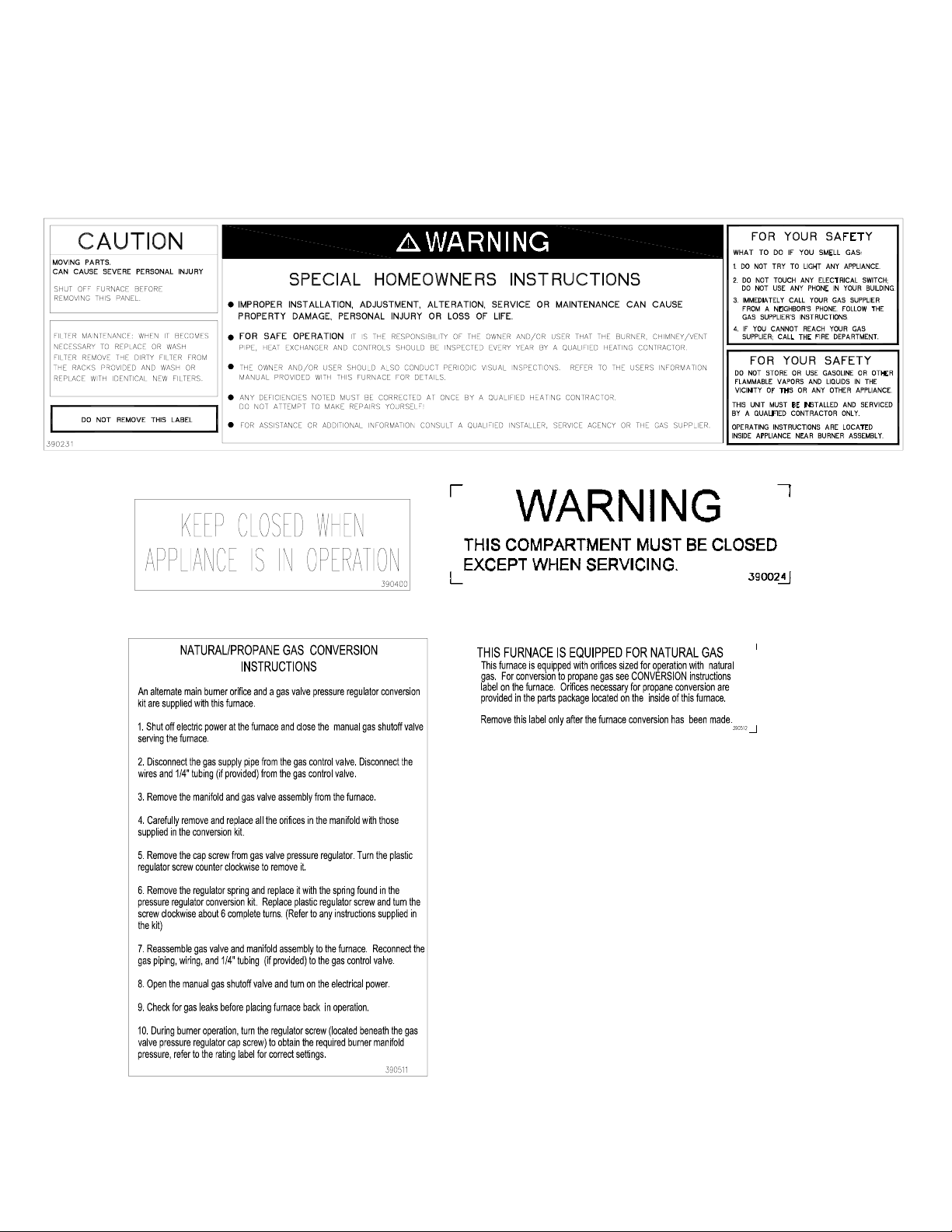

This page and the following page contain reproductions of the various warning

and instruction labels placed on the Thermo Pride Gas Furnace. Please read and

comply with the contents of these labels.

3

Page 5

All installations and services must be performed by qualified service personnel.

4

Page 6

All installations and services must be performed by qualified service personnel.

TABLE OF CONTENTS

SECTION BEGINNING PAGE

I. SAFETY SECTION 1

II. GENERAL INSTRUCTIONS AND CLEARANCES 6

III. FURNACE SPECIFICATIONS 8

IV. INSTALLATION 10

A. ROOF JACK 10

B. STANDARD CHIMNEY 10

C. FURNACE LOCATION 10

D. BASE INSTALLATION 12

1. Combustible Floor Base Model: 70-BASE 12

2. Cottage Base Model: 01COT-BASE 13

E. ALCOVE INSTALLATION 14

F. CLOSET INSTALLATION 15

G. COMBUSTION AIR 16

H. GAS PIPING 18

I. ELECTRICAL WIRING 19

J. PROPANE CONVERSION 21

K. INITIAL START UP 24

L. ADJUSTMENT OF BTU INPUT RATE 24

M. BURNER ADJUSTMENT 26

N. SETTING TEMPERATURE RISE 27

O. FURNACE CHECKOUT PROCEDURE 27

V. INSTALLER’S INSTRUCTIONS TO USER 29

VI. STARTING THE UNIT 30

A. SEQUENCE OF OPERATIONS 30

VII. TROUBLESHOOTING 32

VIII. DEALER MAINTENANCE 38

A. ELECTRICAL 38

B. BURNERS 38

C. INDUCER BLOWER ASSEMBLY 38

D. INSPECTING THE VENTING SYSTEM 39

E. GASKETS/SEALING MATERIALS 39

F. HEAT EXCHANGER 39

G. HOUSE AIR BLOWER 39

H. EXTENDED SHUTDOWN 39

IX. USERS INFORMATION SECTION 41

A. WARNINGS & CAUTIONS 41

B. COMPONENT LOCATIONS 42

C. INSPECTION AREAS 42

D. FILTER LOCATION AND CLEANING 43

APPENDIX A - REPLACEMENT PARTS LIST 44

APPENDIX B – WIRING DIAGRAM 46

5

Page 7

All installations and services must be performed by qualified service personnel.

II. GENERAL INSTRUCTIONS AND CLEARANCES

NOTE: READ THIS SECTION BEFORE STARTING INSTALLATION

1. This furnace is equipped with orifices for operation with natural gas. For

conversion to propane gas, see instructions in Gas Conversion Section of this

manual.

2. Any reference to L.P. or Propane gas in this manual, any other labels, or

markings on this furnace is to be construed to be propane HD-5. A commercial

grade of liquefied petroleum gases composed of a minimum of 90 percent liquid

propane (C8H8).

3. The selection of a furnace heating capacity for a proposed installation should be

based on a heat loss calculation made according to the manuals provided by the

Air Conditioning Contractors of America (ACCA) or the American Society of

Heating, Refrigeration and Air Conditioning Engineers, Inc. (ASHRAE).

4. The installer shall be familiar with and comply with all codes and regulations

applicable to the installation of these heating appliances and related equipment.

In lieu of local codes, the installation shall be in accordance with the current

provisions of one or more of the following standards.

a. Federal Manufactured Home Constructions & Safety Standard (HUD Total 24,

Part 280).

b. American National Standard (ANSI-119.2/NFPA-501C), for installations of all

recreational vehicles.

c. American National Standard (ANSI-Z223.1/NFPA-54), for installation of all gas-

fired furnaces.

d. American National Standard Electric Code (ANSI-C1/NFPA-70), for installation of

all electrical field wiring.

The gas-fired furnace has been investigated under the ANSI Z 21.47-CAN/CGA 22.32001 CENTRAL FURNACE test standard. This gas fired unit is listed by Intertek

Testing Services and described as, “For installation as central furnace special type for

single story dwelling.”

: The area around the furnace must be kept free and clear of

combustible materials, especially papers and rags.

: This furnace is not to be used as a construction heater.

6

Page 8

All installations and services must be performed by qualified service personnel.

5. Definitions of "combustible" and "non-combustible" materials as presented in the

1999 version of the National Fuel Gas Code, ANSI Z223.1-1999/NFPA 70-1999, are

as follows:

a. Combustible material:

“...materials made of or surfaced with wood, compressed

paper, plant fibers, or other materials that are capable of

being ignited and burned. Such material shall be

considered combustible even though flame proofed, fireretardant treated, or plastered.”

b. Non-combustible material:

“...material that is not capable of being ignited and

burned; such as material consisting entirely of, or a

combination of, steel, iron, brick, tiles, concrete,

slate, asbestos, glass, and plaster.”

This heating appliance must be installed with clearances to combustible material

surfaces of not less than the minimum distances given below. Also, allow ample

clearances for servicing the furnace for easy access to the air filter, blower assembly,

burner assembly, controls, and vent connections.

MODELS GMD1-80N

FRONT

BACK

SIDES

ROOF JACK

VENT CONNECTOR

TOP

PLENUM SIDES

TOP AND SIDES OF DUCT

BOTTOM OF DUCT

CLOSET ALCOVE

6”

0”

0”

0”

6”

1”

1”

1”

1”

18”

0”

0”

0”

6”

1”

1”

1”

1”

7

Page 9

All installations and services must be performed by qualified service personnel.

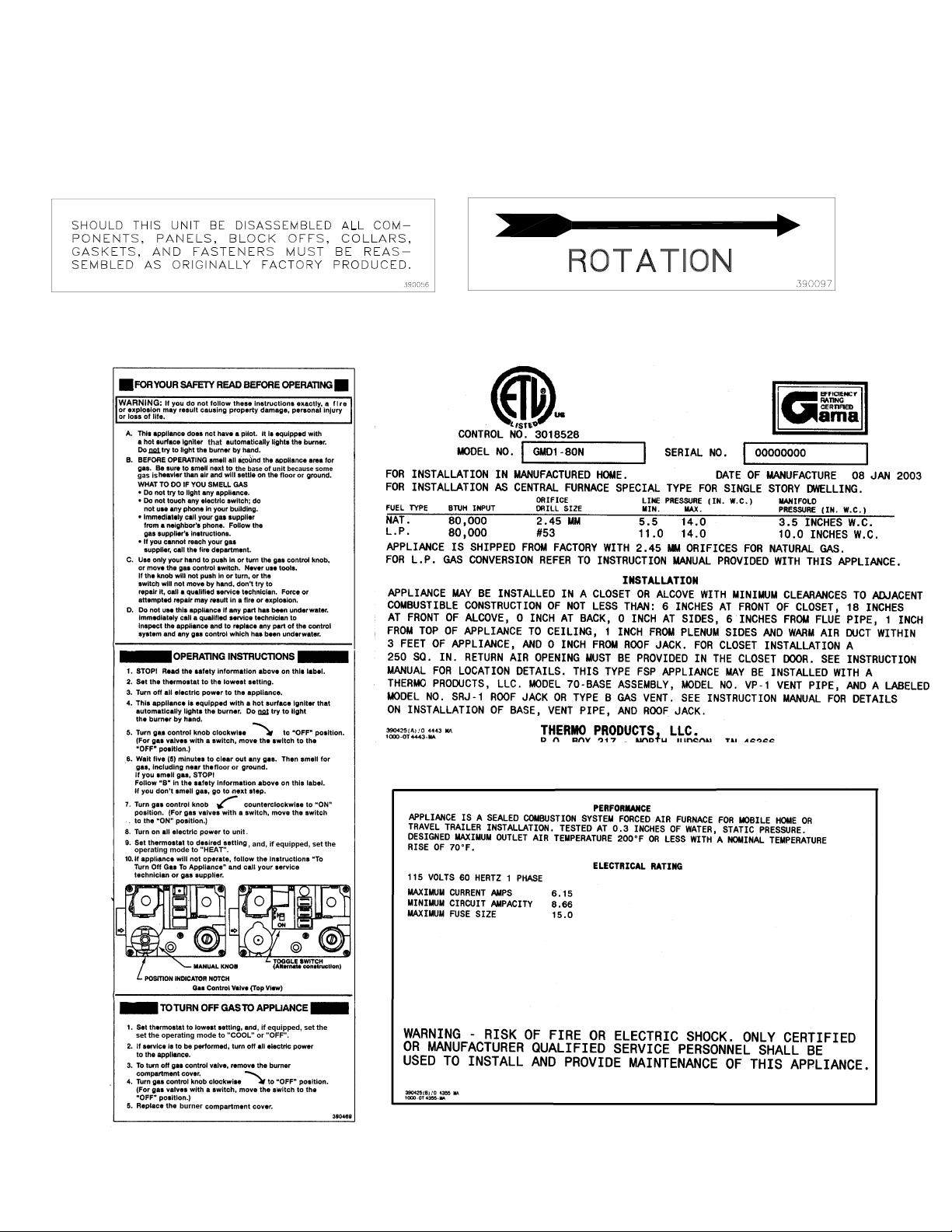

III. FURNACE SPECIFICATIONS

MODEL GMD1-80

HEAT INPUT RATE (BTUH) 80,000

HEATING CAPACITY (BTUH) 65,000

BURNER ORIFICE-NAT. GAS (MM) 2.45

BURNER ORIFICE-PROP. GAS (DMS) #53

GAS SUPPLY PRESSURE (IN.W.G.)

MINIMUM REQUIRED

PROPANE 11

NATURAL 5.5

MAXIMUM ALLOWED

PROPANE 14.0

NATURAL 14.0

GAS MANIFOLD PRESSURE (IN. W.G.)

PROPANE 10 + 0.3

NATURAL 3.5 + 0.3

VENT PIPE SIZE (INCHES) 4

DESIGN TEMPERATURE RISE (°F) 70

SEASONAL EFFICIENCY

(AFUE*, %) 81

*AFUE - INCLUDES STEADY STATE THERMAL EFFICIENCY AND OFF CYCLE

LOSSES.

ELECTRICAL RATINGS AND SETTINGS:

ELECTRICAL SUPPLY: 115 VAC / 60HZ / 1 PHASE

MAXIMUM TIME DELAY TYPE FUSE OR HACR BREAKER RATING: 15 AMPS

TOTAL RATED CURRENT (AMPS): 7.15 (GMD1)

NOMINAL HEAT ANTICIPATOR SETTING -- 0.8 mA (GMD1)

DIMENSIONS & WEIGHTS:

CABINET: WIDTH - 18 IN., DEPTH – 25-1/2 IN., HEIGHT - 57 IN.

NO.70 MOBILE HOME BASE: WIDTH - 18-5/16 IN., DEPTH - 24¼ IN., HEIGHT - 4 IN.

WARM AIR DUCT: WIDTH – 12 IN., DEPTH – 12 IN.

COTTAGE BASE: WIDTH – 18-3/16 IN., DEPTH - 24¼ IN., HEIGHT – 14 IN.

FILTER QUANTITY & SIZE: 1 – 18” x 24 “

APPROXIMATE SHIPPING WEIGHT: 165 LBS.

PRODUCT LISTED UNDER ETL FILE NUMBER –

8

Page 10

All installations and services must be performed by qualified service personnel.

BLOWER DATA

MANUFACTURER: MORRISON PRODUCTS, INC.

BLOWER MODEL: 10-9, DIRECT DRIVE

NOMINAL MOTOR POWER OUTPUT (HORSEPOWER): 1/3

TYPICAL AIRFLOW @ SPECIFIED EXTERNAL

STATIC PRESSURES (SCFM @. IN.W.G.):

ESP (IN W.C.) 0.2 0.5

LOW SPEED: 712 640

MEDIUM LOW

SPEED:

MEDIUM HIGH

SPEED:

870 760

1100 886

HIGH SPEED: 1258 1003

ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

9

Page 11

All installations and services must be performed by qualified service personnel.

IV. INSTALLATION

A. ROOF JACK

The roof jack assembly and accessories must be listed by a nationally recognized

testing agency for the appropriate heating fuel.

The roof jack assembly must be installed according to the vent manufacturer’s

instructions prior to the furnace installation. (Refer to Figure 2 for flue location on

furnace.) Adapters for pitched roofs as well as extended barrel length roof jacks are

available from other suppliers.

All vent seams and connections must be sealed with high temperature silicone caulk.

B. STANDARD CHIMNEY

When installed as a central furnace special type for single story dwelling, venting into a

metal vent system approved by a nationally recognized testing agency for the

appropriate heating fuel type is permitted. Lined masonry chimneys are acceptable

when sized appropriately. The minimum chimney size should equivalent to the inside

free area of the 4-inch diameter vent collar exiting the furnace, or 12.5 square inches.

Maximum chimney sizes and acceptable installation practices are referenced in the

following publication. When installing the GMD1-80N, refer to Appendix G of the latest

edition of the installation standard NFPA 54, National Fuel Gas Code.

C. FURNACE LOCATION

1. For best performance, locate the furnace so that it is centralized with respect to the

duct system.

2. This furnace is only intended for installation with free air return through the furnace

door louvers. ?

?CAUTION: DO NOT connect a ducted return air system directly to

??

the furnace. Improper installation may create a fire hazard and damage internal

equipment, as well as void all manufacturers’ warranties.

3. This furnace may be installed on combustible flooring when utilizing either the No. 70

counterflow floor base, for below the floor duct systems, or with the cottage base, for

floor level air distribution. See Figures 1A and 1B for depictions of the No. 70 and

the cottage bases.

4. This furnace is listed for closet, alcove, or freestanding applications. All applications

must comply with the requirements of this manual.

10

Page 12

All installations and services must be performed by qualified service personnel.

Combustible Floor Base

Model: 70-BASE

Figure 1A

Cottage Base

Model: 01COT-BASE

Figure 1B

Coil Cabinet

Model: CE111S

Figure 1C

11

Page 13

All installations and services must be performed by qualified service personnel.

D. BASE INSTALLATION

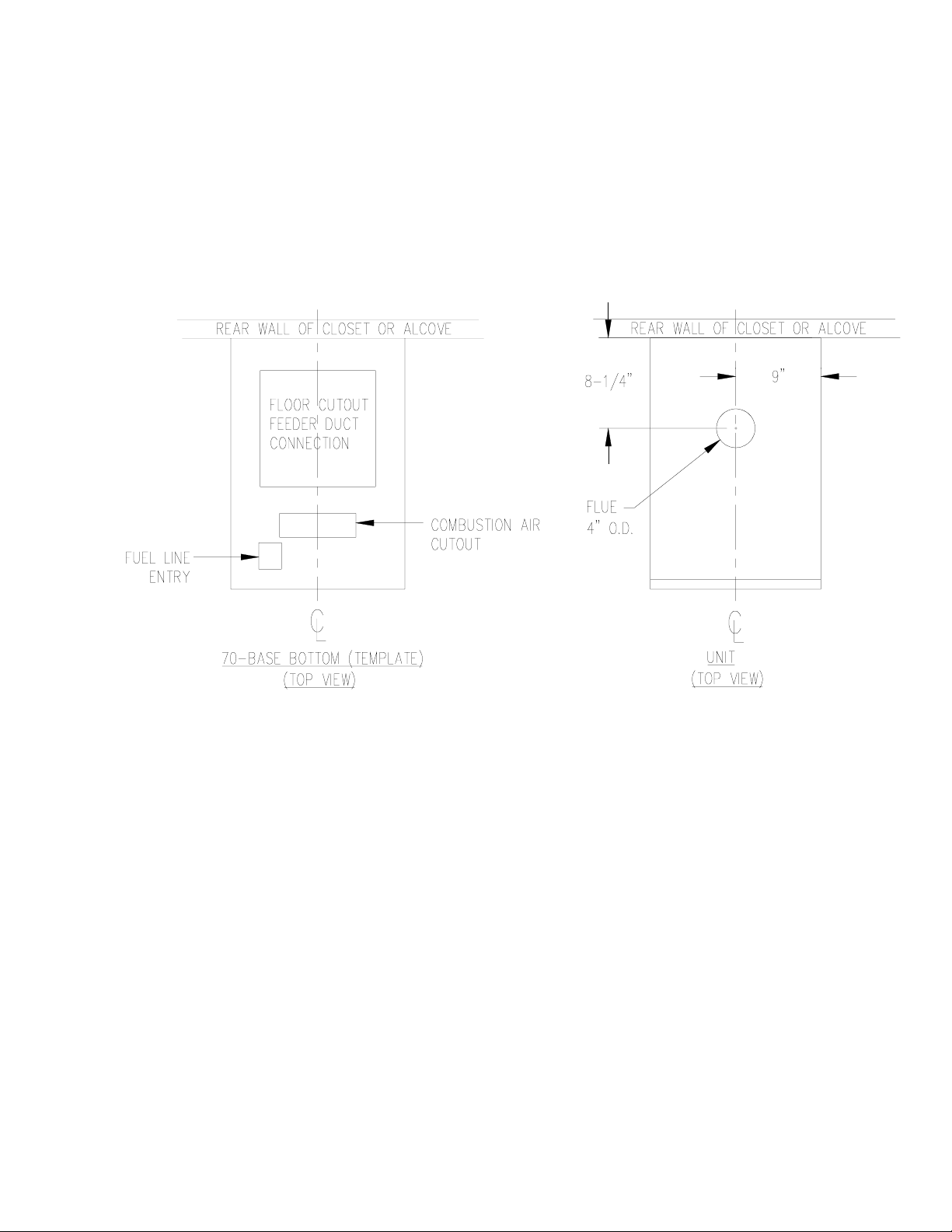

1. Combustible Floor Base Model: 70-BASE

Referring to Figure 1A, for applications using a combustion air channel and a supply

air duct, use the base as a template to mark the floor opening locations. See Figure

2 for cutout locations. Cut a square opening in the floor for the supply air duct. Cut

the opening 1-inch larger than the square template opening. Cut the combustion air

duct opening. See Figure 1A for cutout sizes.

Figure 2

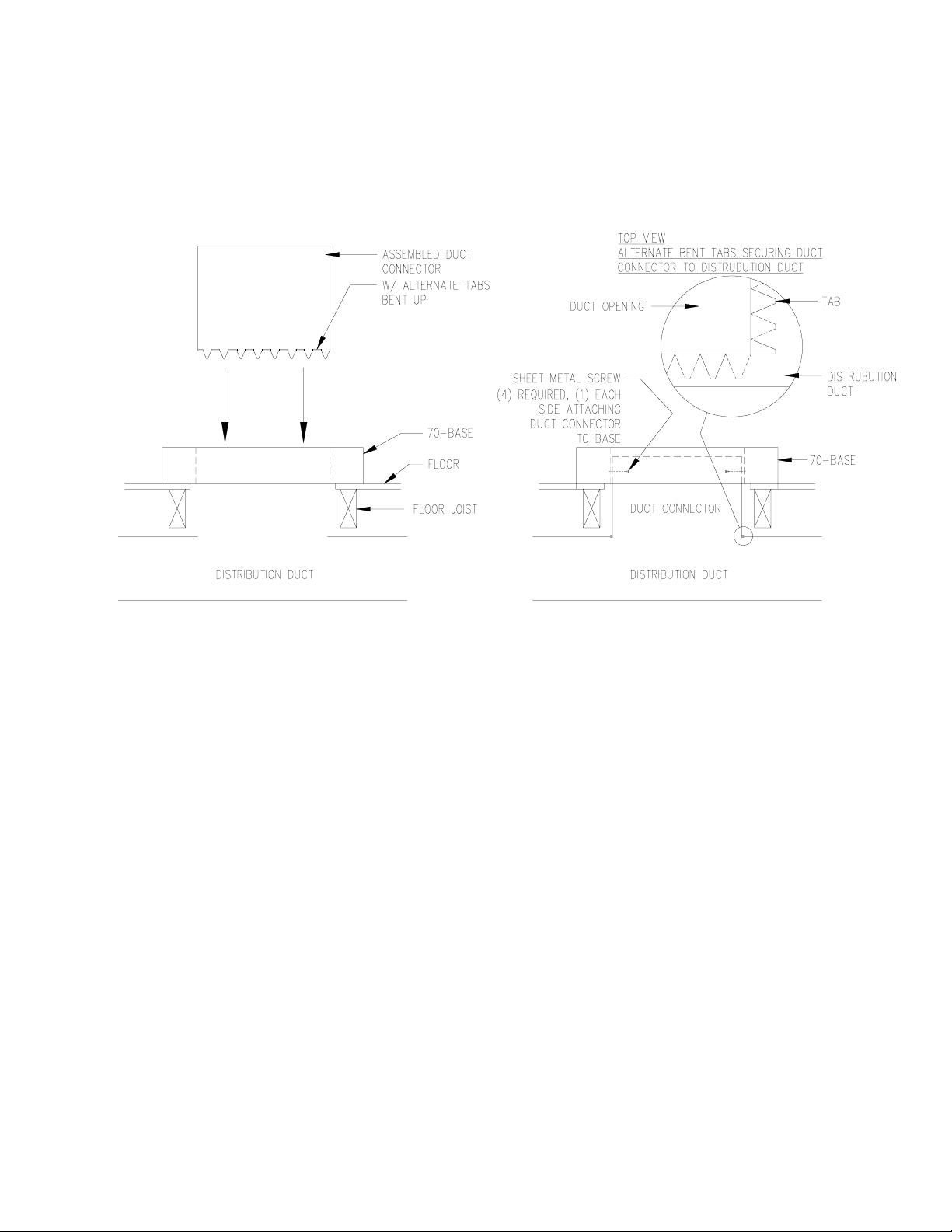

Place the bottom base panel in position. Mark the square opening location on the

distribution duct at the connection point of feeder duct. Remove the bottom panel.

Cut an opening in the duct slightly larger than the feeder duct. Cut the feeder duct to

length. (Refer to Figure 3 for location of this cut.) Install the feeder duct. Bend over

each tab. Insure an airtight seal by using high temperature sealant or tape on the

joint. Reinstall the bottom panel over the feeder duct. Insert and secure the

combustion air duct. Put the top panel in place.

?

?CAUTION: A combustion air duct must be used. If the underside of the mobile

??

home is skirted or enclosed (e.g. enclosed in a crawlspace), the combustion air

intake should exit through the skirting, or enclosure, if at all possible. All joints

and seams of supply ducts and combustion air ducts must be closed with a

sealing method suitable to the application conditions and temperatures (e.g. high

temperature silicone caulk and/or aluminum tape).

12

Page 14

All installations and services must be performed by qualified service personnel.

If the combustion air passageway cannot terminate outside of the skirting or

enclosure, a permanent opening with a minimum of 50 square inches of

unobstructed infiltration (free area) for ventilation air must be provided for

adequate combustion. This permanent opening must be located no less than 12

inches from the bottom of the enclosure or skirting.

Figure 3

Slit the corners of feeder duct down to the top of the top panel. If metal projects

more than 1 inch above the top panel, trim the flanges down to 1 inch. While pulling

the top of the distribution duct up with one hand, bend down each side of the feeder

duct tightly to the top panel with the other hand. This assures a tight connection

between the top panel and the feeder duct and that the distribution duct will be full

size. Use high temperature tape and/or high temperature silicone caulking on all

joints and seams to minimize air leakage. Secure the top panel to the floor with two

screws in the front flange.

2. Cottage Base Model: O1COT-BASE

The O1COT-BASE cottage base (Figure 1B) is required for a freestanding cottage

base installation. The cottage base is designed to permit the installation of a 6-inch x

14-inch register in each of the two side panels and the front panel.

13

Page 15

All installations and services must be performed by qualified service personnel.

?

?CAUTION: A permanent opening with a minimum of 50 square inches of

??

unobstructed infiltration (free area) for ventilation and combustion air must be

provided to the interior of the structure. Additional make-up air may need to be

supplied to the interior of the structure to compensate for exhaust fans,

appliances, or vents, which consume air from the interior of the structure.

Refer to the assembly installation instructions included with OM1COT-BASE cottage

base for additional information.

3. Coil Cabinet: CE111S

The CE111S coil cabinet (figure 1C) is for applications requiring air conditioning.

The coil cabinet is designed to have the combustion air brought in from the bottom

thru a duct, supplied with the cabinet. Refer to section G Combustion air of this

manual for further instructions on the combustion air termination and connections.

For additional information refer instructions provided with the CE111S coil cabinet.

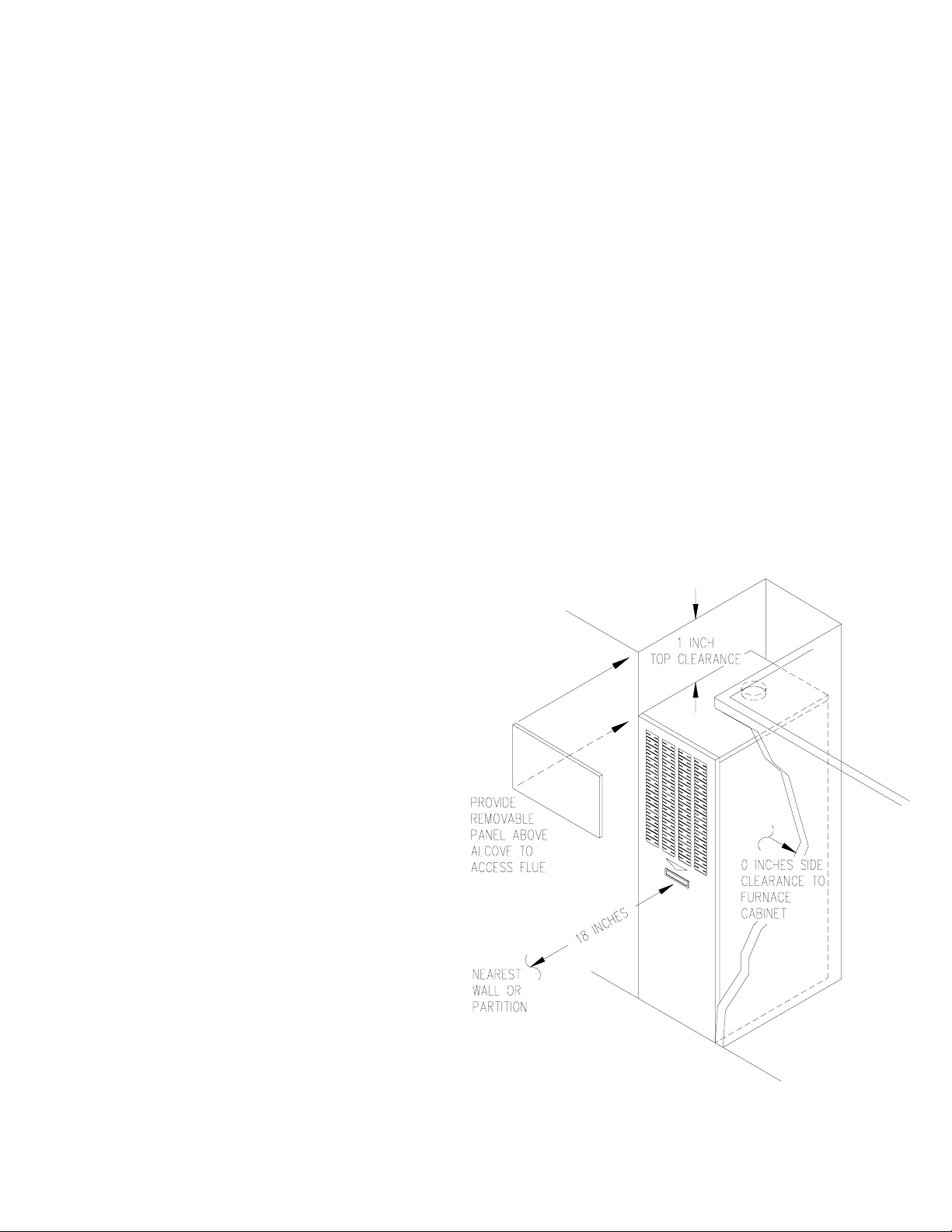

E. ALCOVE INSTALLATION

In this application, a minimum of 18

inches of clearance must be provided

to the front of the unit. Refer to Figure

4.

Alcove installations must use the No.

70 mobile home base.

Refer to section

G. COMBUSTION AIR for additional

combustion air requirements.

Figure 4

14

Page 16

All installations and services must be performed by qualified service personnel.

F. CLOSET INSTALLATION

WARNING: HAZARD OF

????

ASPHYXIATION: A suction

effect will occur when the

furnace is operating inside the

closet with the closet door

closed. For proper operation,

the furnace blower shall create

no more than a 0.05-inch water

column pressure differential

between the closet and the

adjoining space.

Figure 5

1. The return air opening into the closet is to have a minimum free area of 250 square

inches, (refer to Figure 5).

2. The return air opening may be located in the top, the center or (ideally) the bottom of

the closet door, or sidewall.

: Do not obstruct any return air openings, including the return grille on

the furnace. To do so may cause the furnace to activate the high temperature

limit and shutdown, or it may cause asphyxiation.

3. The cross-sectional area of the return air grille leading into the closet (when located

in the floor or ceiling) shall not be less than 250 square inches.

15

Page 17

All installations and services must be performed by qualified service personnel.

4. The total free area of openings in the floor or ceiling registers serving the return air

system must be at least 350 square inches. At least one register must be located

where it is not likely to be covered by carpeting, boxes, furniture, or any other

objects.

5. Materials located in the return air system must have a flame spread classification of

200 or less.

6. Wiring materials located in the return air duct system must conform to Article 300-22

of the latest edition of the National Electrical Code, NFPA 70.

7. Gas piping shall not be located in, or extend through, the return air duct system.

8. Refer to section G. COMBUSTION AIR for additional combustion air requirements.

G. COMBUSTION AIR

The furnace requires the proper amount of combustion airflow through the combustion

air intake to combust the fuel cleanly and efficiently. An inadequate combustion air

supply can result in unsafe and erratic operation of the burner, sooting of the

combustion chamber and the heat exchanger, and possibly, offensive fuel odors. Refer

to chapter 5.3 of the National Fuel Gas Code, ANSI Z223.1 / NFPA 54-1999, or latest

edition for application specific combustion air requirements.

The preferred location of the outside combustion air intake terminal (e.g. an optional

stainless steel intake hood, part no.370183) is through the side of the structure, skirting,

or enclosure. An acceptable alternate location is under the structure in the skirted or

crawlspace area providing a minimum of 50 square inches of free area exists around

the perimeter for outside combustion air to be drawn through. The opening of the

termination must be at least 7 inches below the top of the floor.

The 70-base/coil cabinet is shipped with a combustion air duct that must be installed in

the bottom of the base enclosure, before the furnace is installed. This 2-inch by 7-inch

duct is shipped in two pieces. High temperature silicone sealant should be applied to

both vertical seams, before it is snapped together with all four flanges on the same end.

High temperature silicone must be applied to the flanges. The combustion air duct can

then be inserted through the opening in the floor base model no.70. When the

combustion air duct has been inserted completely, secure the duct to the combustion

adapter with self-tapping sheet metal screws, refer to Figure 6. Make certain that the

flanges, duct, and adapter are completely sealed to the burner enclosure base with high

temperature silicone caulk. A 3-inch round to 7-inch x 2-1/4 inch rectangular adapter

plate is supplied with the furnace for adapting the 3-inch round flex combustion air duct

to the 2-inch x 7-inch combustion air duct.

16

Page 18

All installations and services must be performed by qualified service personnel.

Recommended materials for the combustion air duct are smooth, round, galvanized

steel duct or schedule 20 PVC pipe. The maximum intake duct length allowed is

equivalent to 40-feet of straight duct. Reduce this length by 6-feet for the intake hood

and each 90-degree elbow used, and by 3-feet for each 45-degree elbow used the

combustion air duct. ???? CAUTION: Flexible, spiral, or corrugated duct is not

recommended, due to the relatively high-pressure drop associated with air movement

through this type of passageway.

Optional combustion air- a 4” round duct may be used by connecting a 3 x 4 reducer to

the 3” flex duct supplied with the furnace.

Figure 6

17

Page 19

All installations and services must be performed by qualified service personnel.

H. GAS PIPING

: Because of the potential of the odorant to fade, a gas leak may not be

detected by smell. If this furnace is installed below grade, contact your gas

supplier for a gas detector.

: With the gas piping pressurized, all gas piping connections must be

leak tested using a strong soap and water solution. Any leaks must be repaired

immediately after turning off the gas supply. A final test for gas leakage must be

made after purging the gas line.

: DO NOT wet electronic components during the leak test. Wetting

electronic components may damage circuitry and cause a hazardous situation.

Dry moisture from all leads and terminals if wetting occurs. Wait at least 24

hours for the circuit to fully dry before energizing the system.

: The furnace and its gas valve must be disconnected from the gas

supply during pressure testing of the gas supply system at pressures in excess

of 1/2 PSIG (13.9 inches W.G.). The furnace can be isolated from the gas supply

by closing the manual gas shutoff valve serving the appliance at test pressures

equal to, or less than, 1/2 PSIG or (13.9 inches W.G.).

: Copper and brass tubing and fittings (except tin lined) shall not be

used if the gas contains more than a trace (0.3 grains per 100 cubic ft.) of

hydrogen sulfide gas. Check with your gas supplier.

Sizing and installation of fuel lines must be in accordance with federal, state, and local

regulations.

A qualified installer or service person must install all gas piping and perform all required

testing.

Piping from the natural gas meter to the furnace shall be in accordance with

requirements of the local gas utility. Piping from the propane tank to the furnace must

follow the recommendations of the gas supplier. In the absence of local codes

governing gas piping selection and installation, follow the National Fuel Gas Code,

ANSI Z223.1 / NFPA 54-1999, or latest edition.

A readily accessible, manual gas shutoff valve (design-certified for the applicable gas)

with a non-displaceable rotor member shall be installed within six (6) feet of the

furnace.

A pipe union, or flanged connection, shall be provided directly up stream of the burner

to allow burner removal. Unions must be of a ground joint type or flange-jointed type

using a gasket resistant to the corrosive effects of LP gases. Pipe dope or sealant

18

Page 20

All installations and services must be performed by qualified service personnel.

design-certified to be resistant to the action of the LP gases should be used on all

threaded joints.

The burner is setup to be piped to the gas supply through the left-hand side of the

furnace. For service purposes, it is recommended the gas union be located inside the

furnace.

A drip leg must be used on both propane and natural gas installations immediately

upstream of the furnace in order to trap oil, condensate, and other impurities which

might otherwise lodge in the gas valve, or plug the main burner orifice. A drip leg shall

be provided at the outlet of the gas meter when there is excessive condensation

between the gas meter and the furnace.

Failure to install drip leg(s) may void the manufacturer’s limited warranty on the furnace.

For natural gas, the maximum supply pressure is 14.0 in. W.G. and the minimum

supply pressure, for purposes of input adjustment, is 5.5 in. W.G.

For propane gas, the maximum supply pressure is 14.0 in. W.G. and the minimum

supply pressure, for purposes of input adjustment, is 11.0 in. W.G.

I. ELECTRICAL WIRING

: When testing electrical equipment, always follow standard electrical

procedures and precautions.

All electrical wiring must be installed in strict accordance with local ordinances and

codes. In the absence of local ordinances and codes, all electrical wiring must conform

to the requirements of the National Electric Code, ANSI/NFPA 70-1999, or latest

edition.

1. Electrical Branch Supply Circuit

Route all electrical wiring to the left side of the furnace. The power supply circuit to

the furnace must be installed and grounded in accordance with the provisions of the

National Electrical Code, ANSI/NFPA-70-1999, or latest edition, and all local codes

having jurisdiction.

2. Connection Of Power Supply Wires

a. Remove the cover from junction box.

b. Insert 115 VAC wires through the strain relief bushing (or conduit connection as

applicable) on the left side of the furnace junction box.

c. Connect the “hot” wire to the black wire

.

d. Connect the “neutral” wire to the white wire.

e. Connect the “ground” wire to the green wire.

19

Page 21

All installations and services must be performed by qualified service personnel.

f. Reinstall and secure the junction box cover with the original mounting screws.

3. Connection Of Room Thermostat Wires

NOTE: Class 1 thermostat wire must be used inside the furnace burner

compartment.

a. Insert 24 VAC wires through the plastic grommet on the left side of the furnace

casing.

b. Connect the thermostat wires to the W/R 50A65-143 control (refer to the wiring

diagram).

c. Connect the thermostat wires to the room thermostat.

IMPORTANT: The room thermostat should be installed 4 to 5 feet above the floor

on an interior wall which is relatively free from direct sources of heat (sunlight or

supply airflow) or exposure to cold (drafts from open windows and doors). The

nominal anticipator setting is 0.8 amperes, for the GMD (refer to the thermostat

literature for additional information).

Five-conductor thermostat wire is recommended for 24 VAC, low-voltage, control

circuit wiring. How ever only 2 wires are required for the furnace (a heating

application only).

Electrical Wire Diameter

Maximum Recommended

Thermostat Wire Length

(AWG)

(Feet)

24 55

22 90

20 140

18 225

Once the furnace is installed, check the thermostat anticipator for proper nominal

setting.

1. Connect a multimeter, capable of reading milliamps (mA), in series

with the low voltage wires to the thermostat.

1. Increase the thermostat setting, or create a “call for heat”.

2. Read the value of the thermostat current, in milliamps.

3. Adjust the heat anticipator of the thermostat to the value read by the

multimeter.

If the heat anticipator is set too high, the furnace may delay activation of a heating

cycle for too long. If the heat anticipator is set too low, the furnace may cycle too

frequently. Either condition may not provide optimal comfort to the homeowner.

20

Page 22

All installations and services must be performed by qualified service personnel.

J. PROPANE CONVERSION

Parts are included with this furnace to convert from natural to propane gas. See

table 1

This conversion kit shall be installed by a qualified service agency in accordance

with the manufacturer's instructions and all applicable codes and requirements

of the authority having jurisdiction. If the information in these instructions is not

followed exactly, a fire or explosion may result causing property damage,

personal injury, or loss of life. The qualified service agency performing this work

assumes responsibility for the proper conversion of this furnace with this kit."

The installation of this conversion kit must be done only by qualified service personnel.

These instructions must be read in their entirety before converting the furnace. Follow

the start-up and operation section of this manual for instructions on the test fire

subsequent to this conversion. The following instructions will outline the procedure for

converting the existing burner from natural to propane gas.

When making a gas conversion, it is necessary to replace and/or modify several

of the existing components. Table 1, shown below, describes these components

and shows the correct model or size for each type of gas, propane, or natural.

Table 1: Contents of the Thermo Pride Gas Conversion Kits

CONTENTS QUANTITY

Main Burner Orifice Diameter 3

Gas Valve Pressure Regulator

Kit

(White-Rodgers Part No.)

21

(NAT. TO

PROPANE)

#53 DMS

(0.0595in)

1 92-0659

Page 23

All installations and services must be performed by qualified service personnel.

MANIFOLD REMOVAL AND ORIFICE CHANGE

: Make sure that pipe dope or sealant certified to be resistant to the action of

liquefied petroleum gases is used on all threaded joints.

: The gas supply shall be shut off prior to disconnecting the electrical power

before proceeding with the conversion.

1. Shut off gas to the furnace at the main manual gas shut off valve and power to the

furnace at the disconnect switch.

2. Disconnect the furnace from the gas supply system at the pipe union.

3. Remove the burner box cover by removing the outer row of screws holding the

cover.

Figure 8

22

Page 24

All installations and services must be performed by qualified service personnel.

4. Remove the four screws securing the manifold in the burner box. Pull the manifold

far enough out of the burner box to access the burner orifices. (See figure 8)

5. Remove the main burner orifices from the manifold using a 1/2-inch wrench.

Replace the existing main burner orifices with conversion orifices as indicated in

table 1.

6. Refer to the instructions provided in the gas valve conversion kit for regulator spring

change out instructions.

7. Reinstall the manifold into the burner box. Make sure that all orifices go into their

respective burners and the groove of the rubber grommet on the manifold lines up

on the edge of the burner box to seal around the manifold. Secure it with four

screws. (See figure 8).

8. Inspect the seal on the burner box cover and if damaged replace it. Install and

secure the burner box cover. Make sure all the fastening screws are used.

9. Check to make sure that the electrical connections to the gas valve are tight.

10. Check that the plastic hose from the pressure switch is attached securely to the

hose barb at the outlet of the gas valve without being kinked.

: The regulator of the gas valve will not function properly if this hose

connection is not made.

11. Reconnect the furnace to the gas supply.

12. Refer to initial start-up and operating instructions for test fire and burner

adjustments.

23

Page 25

All installations and services must be performed by qualified service personnel.

K. INITIAL START UP:

This furnace does not have a pilot. It is equipped with a hot surface igniter, which

automatically lights the burner. Do not attempt to light the burner by hand. Check the

following items before the initial start-up.

1. Check all wiring for proper hook up. Tighten any loose connections.

2. Using a soap solution, leak test gas piping connections.

3. Check all tubing connections to the pressure switch, inducer, burner box, and gas

valve and make sure they are connected firmly at all their connection points.

4. Check flue pipe, combustion air inlet, and all joints for tightness and to make sure

there is no blockage.

5. Make sure air filter is in place.

6. Make sure the outside vent and air intakes are installed according to instructions

and are free from blockage.

OPERATING INSTRUCTIONS:

: Turn off power to furnace before it is placed into service. The gas

piping system must have been leak tested by a qualified heating contractor. (See

Section IV, H, of these instructions on the installation of gas piping).

: It may be necessary to purge the air out of the gas line for initial startup of the furnace after installation. A qualified heating contractor should do this.

If excessive gas escapes when purging the gas supply at the union, allow the

area to ventilate for at least 15 minutes before attempting to start the furnace.

Propane gas is especially dangerous because the specific gravity of propane gas

allows it to accumulate at floor level at a dangerous concentration.

: Heat exchanger oil will burn off on initial firing creating an unpleasant

odor. To prevent this odor from occurring more than once, it is suggested that:

1. A window(s) be opened.

2. The thermostat be set at highest setting.

3. The furnace remains running at conditions 1&2 for 30 minutes or until odor

has dissipated.

L. ADJUSTMENT OF HEAT INPUT RATE:

The orifices for this furnace were sized: 1) for natural gas having a heating value of

1025 BTU per cubic foot and a specific gravity of .65, or 2) for liquefied propane gas

with a heating value of 2500 BTU per cubic foot and a specific gravity of 1.55. The

rating label inside the furnace vestibule will specify which gas your furnace is orificed

for. If the furnace is installed at an altitude that is more than 2,000 feet above sea level,

24

Page 26

All installations and services must be performed by qualified service personnel.

it is mandatory the input to the burner be reduced 4.0% for every 1,000 feet that it is

above sea level. If the furnace is installed at an elevation of 5,000 feet, its input must

be reduced 20.0%. Example: a furnace rated at 80,000

BTU at sea level must be reduced to a firing rate of 64,000 (80,000 x .80 = 64,000) at

an elevation of 5,000 feet. If the furnace is installed at an elevation of 2,000 feet or

less, no reduction in input is required. Your gas supplier may supply you with the

correct orifice sizing information.

To check the heat input rate of your natural gas furnace, allow the unit to operate for 10

to 15 minutes and proceed as follows:

a. Call your gas supplier and ask for the BTU content (heating value) of one cubic foot

of the gas, supplied to the installation area. An alternate approach is to assume a value

of 1025 BTU/Cu Ft, which is the national average.

b. With all other gas appliances turned off and using a stopwatch, clock the time

required for the (small) dial on the gas meter to make one full revolution. The meter

dial will state the cubic feet of flow for one revolution usually one, two or five.

FORMULA: BTU/Cu Ft x Number of Cu Ft x 3600 Seconds = Input BTU/hr

Seconds for one revolution

EXAMPLE: 1025 BTU/Cu Ft x 2 Cu Ft x 3600 = 78,678 BTU Input

93.80 Seconds

Check the model number of the furnace, the input rate, the type of gas, and the

manifold pressure on the rating label located in the burner vestibule. If using the above

example, the furnace is a GMD1-80N model and the input rate is 78,678 BTU/hr. The

input rate would be acceptable because it was within + 2% of the listed input of 80,000.

c. Make sure that the gas supply pressure to the furnace is within the allowable range of

5.5" to 14" WC pressure on natural gas and 11.0" to 14.0" WC on propane gas. The

pressure to the furnace must be checked while the furnace burner and any other gas

appliances on the same supply system are operating, using the 1/8 in. NPT manifold

pressure tap shown in figure 8.

GAS PRESSURE CHART FOR ALL GMD1-80 MODEL FURNACES

SUPPLY PRESSURE MANIFOLD PRESSURE

NAT

PROPANE

25

MAX 14” WC

MIN 5.5” WC

MAX 14” WC

MIN 11” WC

3.5 + .3” WC

10.0” + .3” WC

Page 27

All installations and services must be performed by qualified service personnel.

TABLE 2

This gas furnace is equipped with a fixed orifice sized for the manifold pressure shown

on the rating label. The input can only be increased, or decreased, by adjusting the

manifold pressure. Remove the 1/8" threaded pipe plug located on the gas manifold.

Use a U tube manometer or recently calibrated pressure gage to measure the pressure.

To adjust the pressure, remove the screw cap from the regulator on the gas valve and

using the adjustment screw. Decrease the pressure by turning the screw

counterclockwise or increase it by turning the screw clockwise.

???? CAUTION: ADJUSTMENTS TO THE LISTED PRESSURE MUST NOT EXCEED

0.3" WC A 0.3" WC adjustment will increase or decrease the input approximately 4.0%.

Replace screw (cap) when adjustment is complete.

The correct input can be assumed if the furnace manifold pressure is the same as that

shown on the rating label if a gas meter is not available for natural gas or the unit is

installed on an unmetered propane gas supply.

Shut off the gas supply to the furnace. Remove the pressure gage and re-install the

pipe plug using a thread compound resistant to the action of LP gases.

If the rated input cannot be obtained with the present orifice at the correct pressure,

your local gas supplier may assist in sizing the proper orifice. Thermo Products

Engineering Department will gladly assist in sizing the orifice if you provide them with

the heating value in BTU per cubic foot and the specific gravity of the fuel gas.

M. BURNER ADJUSTMENT

: The GMD1-80N furnace model utilizes an in-shot burner design that

does not require an air shutter adjustment (air shutters are not used) for proper

flame characteristics. Burner box access cover must always be secured with all

screws in place and tightened before operating furnace.

This unit is designed to not require any burner adjustment. The flames should be

checked by looking through the sight glass located on the burner box. Burner flames

should be clear, blue, and almost transparent in color. (See Figure 9). NOTE: It is not

unusual to have mostly blue flames with yellow or orange tips visible in the tube for

propane gas.

26

Page 28

All installations and services must be performed by qualified service personnel.

Figure 9

N. SETTING TEMPERATURE RISE

The GMD1-80N is designed and wired at the factory for a heating blower speed that

should result in an approximate temperature rise of 70°F. The blower motor is wired on

medium low speed for heating mode. The temperature rise through the furnace may

vary depending on the duct system, elevation, heating value, etc. for each installation.

After 10 to 15 minutes of continuous operation, the temperature rise through the

furnace must fall within a range of 55°F to 85°F. If the outlet or supply duct

temperature is too high, check to make sure the return air filter is clean, the return air

registers are free from obstruction, the outlet registers are properly adjusted and clear,

and the supply and return air ducts are open.

The circulating air blower is not moving enough air if the supply air temperature is still

too high. Before proceeding further, turn off the power supply to the furnace and

remove the blower door. The speed of the blower must be increased by changing the

speed tap from the motor (see wiring diagram). This is accomplished by locating the

control panel attached to the blower housing and switching blue (med. low) blower lead,

which should be connected to the “Heat” terminal on the White-Rodgers 50A65-143

control, with one of the higher speed blower leads attached to a terminal marked “Park”.

Be sure to attach any unused blower leads to a terminal marked “Park”. Replace the

blower door and turn on the power supply.

O. FURNACE CHECKOUT PROCEDURE

Before any system of gas piping is finally put into service, it shall be carefully tested to

assure that it is gas tight as indicated in section IV. H. Gas Piping of this manual.

27

Page 29

All installations and services must be performed by qualified service personnel.

NOTICE: All controls on the unit should be checked for proper functioning prior to the

qualified service personnel leaving the job site. Specifically the following should be

checked:

With furnace in normal heating operation, check to make certain blower will start and

stop automatically under control of integrated fan control.

1. Check safety limit control as follows:

a. Shut off incoming power.

b. Block return air opening or disconnect blower motor leads.

c. Restore power to furnace.

d. Set thermostat above room temperature calling for heat.

e. When high air temperatures are reached in furnace at limit control setting with

blower out of operation, burner should shut off.

f. Shut off electrical power.

IMPORTANT: Remove blockage or reconnect blower motor and restore power.

2. Make certain thermostat will automatically start and stop furnace.

3. Block the flue pipe outlet gradually until the pressure switch functions shutting off

the main burners.

4. Block the inlet gradually until pressure switch functions shutting off the main burners.

IMPORTANT: Remove flue or air inlet blockages when done.

28

Page 30

All installations and services must be performed by qualified service personnel.

V. INSTALLER'S INSTRUCTIONS TO USER:

After completing the installation, the installer shall inform and/or demonstrate to the

homeowner:

1. The location of all the instructions in the furnace must be kept along with

instructions for any accessories in the plastic pouch near the furnace.

2. The location and use of the manual gas shut off valve and furnace electrical

disconnect switch. Instruct user to always shut off gas before shutting off electric

power.

3. The sequence of operation of the furnace.

4. The correct operation and maintenance of the appliance as outlined in the Users

Information section of this manual.

5. That failure to maintain and operate this furnace in accordance with these

instructions could result in hazardous conditions, bodily injury, and property

damage and may void the limited warranty on the furnace.

6. Review with and encourage the user to read the label reproductions and all

warnings and instructions outlined on the front cover and in sections I, II and III of

this manual and in the Users Information section of this manual.

7. Recommend the user has a qualified heating contractor inspect the furnace at the

start of each heating season. Inform the user of the frequency of inspection

required for reach item in the User Information Section of this manual.

29

Page 31

All installations and services must be performed by qualified service personnel.

VI. STARTING THE UNIT

A. SEQUENCE OF OPERATIONS

AT ANY TIME THE

GAS VALVE IS

NOT ENERGIZED

START

CONTINUOUS SAFE OPERATION CHECK IF FLAME

SIMULATION CONDITION PRESENT OR ROLL-OUT

SWITCH OPENS, SYSTEM ENERGIZES INDUCER

FAN FOR 15 SECONDS AND CIRCULATOR BLOWER

AT HEATING SPEED UNTIL SITUATION CORRECTION

THERMOSTAT CALLS FOR

HEAT, CONTACTS CLOSE

CONTROL BOARD ENERGIZED,

INDUCER ENERGIZED

PRESSURE SWITCH SENSES

ADEQUATE DIFFERENTIAL

PRESSURE CONTACTS CLOSE

START TRIAL

FOR IGNITION

POWER IS APPLIED TO

THE SILICON NITRIDE

IGNITOR. IGNITOR

WARM-UP IS 20 SECONDS

AFTER IGNITOR WARM-UP,

THE GAS VALVE IS

ENERGIZED TO OPEN

FLAME MUST BE

DETECTED WITHIN

4 SECONDS IF FLAME

IS DETECTED, THE

DELAY-TO-FAN-ON

TIME BEGINS (45 SECONDS)

POWER INTERRUPTION

SYSTEM SHUTS OFF,

RESTARTS WHEN

POWER IS RESTORED.

IF FLAME IS NOT

DETECTED, THE GAS VALVE

IS DE-ENERGIZED, THE

IGNITOR IS TURNED OFF AND

THE CONTROL BOARD CONTROL

GOES INTO "RETRY" SEQUENCE

30

Page 32

All installations and services must be performed by qualified service personnel.

MAIN

BURNER

OPERATION

CALL

FOR HEAT

SATISFIED

AFTER DELAY-TO-FAN--ON

PERIOD ENDS, CIRCULATING

AIR FAN IS ENERGIZED AT

HEATING SPEED. THE

(OPTIONAL) ELECTRONIC

AIR CLEANER AND

HUMIDIFIER ARE ENERGIZED.

WHEN THERMOSTAT IS

SATISFIED, CONTACTS

OPEN AND THE GAS

VALVE IS DE-ENERGIZED.

AFTER PROOF OF FLAME

LOSS, INDUCER STARTS

5 SECOND POST SURGE

AND (OPTIONAL) HUMIDIFIER

IS DE-ENERGIZED. THE

DELAY-TO-FAN-OFF PERIOD

BEGINS (180 SECONDS)

AFTER THE DELAY-TO-

FAN-OFF PERIOD ENDS,

THE CIRCULATING AIR

FAN AND (OPTIONAL)

ELECTRONIC AIR CLEANER

ARE DE-ENERGIZED.

THE RETRY SEQUENCE

PROVIDES A 60 SECOND

WAIT BEFORE IGNITION

RETRY. RETRY IS

ATTEMPTED WITH AN

ADDITIONAL 10 SECONDS

OF IGNITOR WARM-UP TIME.

IF IGNITION ATTEMPT IS

UNSUCCESSFUL, ONE

MORE RETRY WILL BE

MADE BEFORE THE

CONTROL BOARD GOES

INTO SYSTEM LOCKOUT.

IF FLAME IS DETECTED,

THEN LOST, THE CONTROL

BOARD WILL REPEAT THE

INITIAL IGNITION SEQUENCE

FOR A TOTAL OF SIX

RECYCLES. AFTER SIX

UNSUCCESSFUL RECYCLE

ATTEMPTS, THE CONTROL

WILL GO INTO SYSTEM

LOCKOUT.

END OF CYCLE

31

IF SYSTEM IS IN LOCKOUT, THE

MODULE WILL RESET ITSELF

AFTER 60 MINUTES OR MAY

BE MANUALLY RESET BY

INTERRUPTING THE POWER

TO THE FURNACE AT THE

DISCONNECT OR INTERRUPTING

THE CALL FOR HEAT AT THE

THERMOSTAT. IF THIS DOES

NOT RESTART THE SYSTEM,

REFER TO THE TROUBLESHOOTING

SECTION OF THIS MANUAL.

Page 33

All installations and services must be performed by qualified service personnel.

VII. TROUBLESHOOTING

THIS SECTION IS ONLY TO BE PERFORMED BY TRAINED, QUALIFIED SERVICE

PERSONNEL, AND NOT BY THE FURNACE OWNER.

NOTICE: BEFORE TROUBLESHOOTING, FAMILIARIZE YOURSELF WITH THE

START UP AND CHECKOUT PROCEDURE. ALL INSTALLATION AND

SERVICES MUST BE PERFORMED BY QUALIFIED HEATING CONTRACTORS

When testing electrical equipment, always follow standard electrical

procedures and precautions.

1. Check for line voltage (110-120VAC) to the furnace. If there is no line voltage

applied to the furnace, check that disconnecting switch is “on”, fuses or circuit

breakers have not blown or tripped.

2. Make sure thermostat is “calling for heat”.

3. Check for adequate fuel supply and pressure. Are all the fuel shutoff valves

open?

4. To assist you in troubleshooting this furnace, it is equipped with an integrated

ignition control with diagnostics. These diagnostics evaluate what malfunction

the control system has experienced and will activate a flashing light on the

control in different sequences to help pinpoint the failure.

32

Page 34

All installations and services must be performed by qualified service personnel.

DIAGNOSTIC FEATURES

: Power must be disconnected before servicing.

The 50A65-143 control continuously monitors its own operation and the operation of the

system. If a failure occurs, the LED will indicate a failure code as shown below. If the

failure is internal to the control, the light will stay on continuously. In this case,

the entire control should be replaced, as the control is not field-repairable.

If the sensed failure is in the system (external to the control), the LED will flash in the

following flash-pause sequences to indicate failure status (each flash will last

approximately 0.25 seconds, and each pause will last approximately 2 seconds).

1 flash, then pause System lockout

2 flashes, then pause Pressure switch stuck closed

3 flashes, then pause Pressure switch stuck open

4 flashes, then pause Open limit switch or rollout switch

6 flashes, then pause 115 Volt AC power reversed

7 flashes, then pause Low flame sense signal

8 flashes, then pause Check igniter or improper grounding

Continuous flashing Flame has been sensed when

(No pause) no flame should be present

(No call for heat)

The LED will also flash once at power-up.

33

Page 35

All installations and services must be performed by qualified service personnel.

THE SYSTEM IS STARTED BY SETTING THE THERMOSTAT TO CALL FOR

HEAT. THE FOLLOWING SHOULD HELP ESTABLISH THE TYPE OF

MALFUNCTION OR DEVIATION FROM THE NORMAL OPERATION.

TO USE THIS DIAGRAM, FOLLOW THE INSTRUCTIONS IN THE BOXES.

TURN THERMOSTAT TO CALL FOR HEAT

DOES THERMOSTAT MAKE CONTACT?

Yes

IS ROOM TEMPERATURE

BELOW THERMOSTAT

SETTING?

Yes

TROUBLESHOOTING GUIDE

No

IS ROOM

TEMPERATURE

ABOVE

90 DEGREES F?

Yes

COOL THE THERMOSTAT

NoNo

TURN T'STAT

SETTING ABOVE

ROOM TEMP.

IS THE TRANSFORMER

SUPPLYING 24 VOLTS

TO THE THERMOSTAT?

Yes Yes

REPLACE

THERMOSTAT

IS THE INDUCER

BLOWER OPERATING?

No No

ARE WIRES CONNECTED

PROPERLY?

IS INTERNAL DAMAGE

PRESENT ON THE

TRANSFORMER?

Yes

REPLACE TRANSFORMER

No No

IS THERE 24 VOLTS

ACROSS "TH" & "TR"

AT THE INTEGRATED

CONTROL?

YesYes

No

CORRECT WIRE

CONNECTIONS

CHECK INPUT

POWER, SERVICE

SWITCH AND FUSES

CHECK FOR

CONTINUITY

& PROPER

CONNECTIONS

34

Page 36

All installations and services must be performed by qualified service personnel.

Yes Yes

CHECK THE INTEGRATED

IS THERE LINE VOLTAGE

ACROSS INDUCER POWER

TERMINALS "IND" & "IND N"

AT THE INTEGRATED CONTROL?

Yes

CHECK WIRING TO INDUCER

AND IF OK, REPLACE

INDUCER ASSEMBLY.

No

CONTROL DIAGNOSTIC LED

LAMP. RESET BY INTERRUPTING

POWER TO CONTROL FOR MORE

THAN ONE SECOND. IF LED STAYS

ON CONTINUOUSLY, REPLACE

INTEGRATED CONTROL.

DOES THE HOT

SURFACE

IGNITOR ENERGIZE

AND GLOW?

Yes

AFTER HOT

SURFACE IGNITOR

WARM-UP, DOES

GAS VALVE OPEN?

IS THERE LINE VOLTAGE

No

No No

ACROSS HOT SURFACE

IGNITOR TERMINALS

"IGN" & "IGN N" AT THE

INTEGRATED CONTROL?

Yes

CHECK WIRING TO HOT

SURFACE IGNITOR AND

IF OK, REPLACE HOT

SURFACE IGNITOR ASSEMLBY.

CHECK ACROSS "MV"

TERMINALS ON INTEGRATED

CONTROL FOR 24 VOLTS DURING

THE 4 SECOND FLAME PROVING

PERIOD AFTER IGNITOR WARM-UP.

IS THERE 24 VOLTS?

Yes

No

CHECK THE INTEGRATED CONTROL

DIAGNOSTIC LED LAMP. RESET BY

INTERRUPTING POWER TO CONTROL

FOR MORE THAN ONE SECOND. IF

REPLACE INTEGRATED CONTROL.

LED STAYS ON CONTINUOUSLY

SAME AS ABOVE

Yes

CHECK WIRING TO GAS

VALVE AND IF OK,

REPLACE GAS VALVE.

35

Page 37

All installations and services must be performed by qualified service personnel.

Yes

AFTER GAS VALVE

OPENS, DO THE

BURNERS IGNITE?

Yes

DO BURNERS STAY

LIT PAST PROOF

OF FLAME CHECK?

No No

No

MEASURE MANIFOLD

PRESSURE. IS

PRESSURE ADEQUATE?

CHECK IGNITOR

VOLTAGE DURING

20 SECOND WARM-UP,

IT SHOULD BE AT

LEAST 105 VOLTS.

IS IGNITOR

POSITIONED

CORRECTLY?

CHECK FLAME

PROVING CIRCUIT

Yes

Yes

No

No

ADJUST TO 3.5" WC FOR

NATURAL GAS OR 10.0" WC

FOR PROPANE GAS

CORRECT LINE

VOLTAGE PROBLEM.

REPOSITION TO

CORRECT LOCATION.

Yes

DOES THE INTEGRATED

CONTROL ENERGIZE THE

CIRCULATING AIR

BLOWER AFTER THE 45

SECOND TIME DELAY?

Yes

DOES THE CIRCULATING

AIR FAN COME ON

WHEN ENERGIZED?

Yes

CHECK ACROSS THE

No No

No

WORKING PROPERLY?

CIRCULATING AIR

BLOWER TERMINALS

"CIR N" & "HEAT"

FOR PROPER VOLTAGE.

DOES BLOWER

SPIN FREELY?

Yes

IS CAPACITOR

No

REPLACE CAPACITOR

No

Yes

REPLACE THE

INTEGRATED CONTROL.

CONFIRM IF EITHER

BLOWER WHEEL IS

RUBBING AGAINST

HOUSING OR MOTOR

SHAFT IS SPINNING

FREELY AND REPAIR

OR REPLACE AS

NECESARRY.

REPLACE MOTOR

36

Page 38

All installations and services must be performed by qualified service personnel.

Yes

DOES SYSTEM RUN UNTIL

THERMOSTAT IS SATISFIED?

Yes

DOES BURNER SHUT OFF

WHEN THERMOSTAT IS

SATISFIED?

Yes

No No

No

IF LED FLASHES:

1 FLASH, THEN PAUSE SYSTEM LOCKOUT

2 FLASHES, THEN PAUSE PRESSURE SWITCH STUCK CLOSED

IS LED LIGHT

ON INTEGRATED

CONTROL FLASHING?

Yes

CHECK FOR SHORT IN

WIRE TO THERMOSTAT

AND CORRECT IF

NECESSARY.

CHECK ALL

WIRING FOR

LOOSE

CONNECTIONS

DOES THE CIRCULATING

AIR BLOWER TURN OFF

AFTER THERMOSTAT IS

SATISFIED WITHIN

120 SECONDS?

Yes

TROUBLESHOOTING COMPLETE.

3 FLASHES, THEN PAUSE PRESSURE SWITCH STUCK OPEN

4 FLASHES, THEN PAUSE OPEN LIMIT SWITCH OR ROLLOUT SWITCH

6 FLASHES, THEN PAUSE 115 VOLT AC POWER REVERSED

7 FLASHES, THEN PAUSE LOW FLAME SENSE SIGNAL

8 FLASHES, THEN PAUSE CHECK IGNITOR OR IMPROPER GROUNDING

CONTINUOUS FLASHING FLAME HAS BEEN SENSED WHEN NO FLAME

(NO PAUSE) SHOULD BE PRESENT (NO CALL FOR HEAT)

THE LED WILL ALSO FLASH ONCE AT POWER-UP.

CHECK COMPLETE SYSTEM OUT.

LED LIGHT STAYS ON CONTINUOUSLY,

COMPLETE FAILURE - REPLACE INTEGRATED CONTROL.

37

Page 39

All installations and services must be performed by qualified service personnel.

VIII. DEALER MAINTENANCE

A qualified heating contractor should perform the following maintenance

procedures at the beginning of each heating season. Correct any deficiencies at

once.

???? WARNING: Personal injury or property damage could result from repair or

service of this furnace by anyone other than a qualified heating contractor. Only

the homeowner/user routine maintenance described in the Users Information

Manual may be performed by the user.

???? WARNING: To avoid injury from moving parts, shut off the power to the

furnace before removing blower compartment door.

???? CAUTION: Label wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation.

A. ELECTRICAL:

1. Check all wiring for loose connections and any signs of damage or unusual wear.

2. Check for correct voltage at the furnace when operating.

3. Check amp-draw on blower motor and inducer motor to assure they are not

exceeding nameplate amp rating.

4. Check for correct operation and proper settings (if manually adjustable) of all

controls.

Shut off gas and disconnect power before continuing.

B. BURNERS

If it appears that material is accumulating in the burner box, the burner box cover can

be removed and the box and burners can be vacuumed. If necessary, the burners

assembly can be removed by taking out the two screws/one on each bracket on top of

burner box and removing the burner manifold assembly. Assembly must be pulled &

tilted down in order to remove from box. If necessary, the individual tubes can be

cleaned out using compressed air to blow out the individual tubes. Care must be taken

not to damage the igniter.

C. INDUCER BLOWER ASSEMBLY

Inspect the pressure switch and tubing connections and inspect the blower/assembly

for warpage, deterioration and carbon or other build-up. If necessary, clean the

accessible portions of the housing and blower with a damp cloth. Vacuum to remove

any lint or dust from the motor assembly.

38

Page 40

All installations and services must be performed by qualified service personnel.

D. INSPECTING THE VENTING SYSTEM

The venting system should be inspected during the annual maintenance check-up or

during each subsequent service call.

Check all vent pipes for restrictions due to soot, or carbon build-up, as well as foreign

matter, or any materials, that cause the venting system to restrict the proper venting of

combustion products. If a restriction is found, the flue vent must be cleaned or

replaced to ensure proper venting.

Vent pipes should also be inspected for any signs of corrosion, deterioration, or leakage

that may cause combustion by-products to infiltrate the home or indoor environment.

If signs of corrosion, deterioration, or leakage are evident, the vent pipe must be

replaced with a properly sized, agency-approved, vent pipe.

E. GASKETS/SEALING MATERIALS

Inspect all visible gaskets for signs of degradation, especially any seals which were

removed as part of the inspection. Replace any suspect gaskets.

F. HEAT EXCHANGER

Inspect for corrosion, pitting, warpage, deterioration, carbon build-up, and loose gaskets

in the flue pipe, burner box, and accessible areas of the heat exchanger.

G. HOUSE AIR BLOWER

Check and clean the blower wheel, housing, and compartment with a vacuum. Check

the motor nameplate and follow the motor manufacturers instructions for lubrication, if

required.

IMPORTANT:

Some motors are permanently lubricated and should not be oiled.

See motor nameplate for specific instructions.

H. EXTENDED SHUTDOWN

If this furnace is shut down or off for an extended period of time, several steps can be

taken to help insure a smooth and reliable start.

ON SHUT DOWN:

1. Close the gas supply shutoff valve(s).

2. Turn the furnace power switch “off” and disconnect electrical power to the unit.

39

Page 41

All installations and services must be performed by qualified service personnel.

ON START-UP:

8. Have the heating system (and furnace) inspected and started by a qualified

service person.

9. Set the room thermostat above room temperature.

10. Open all shutoff valves in the gas supply line.

4. Turn “on” the main power at the disconnecting switch and at the furnace power

switch to start the inducer.

5. Follow the “BURNER OPERATION AND ADJUSTMENT” procedure in Section L.

40

Page 42

All installations and services must be performed by qualified service personnel.

IX. USER INFORMATION SECTION

A. WARNINGS AND CAUTIONS:

: If you suspect there is a problem with the furnace, pertaining to the

venting system or any other related problem, immediately contact a qualified

service agency. If a service agency is not available, contact your fuel

supplier.

: Personal injury or property damage could result from major repair

or service of this furnace by anyone other than a qualified contractor. The

user should only perform the routine maintenance described in the user

section of this manual.

: The area around the furnace should be kept free and clear of

combustible materials, especially papers and rags.

: Do not block or obstruct air openings on the furnace casing. Do not

block or obstruct air openings communicating within the area in which the

furnace is installed.

: Do not allow the outside air intake to be blocked or obstructed by

vegetation, ice, snow, or any other materials.

: Do not use this furnace if any part has been underwater.

Immediately call a qualified service agency to inspect the furnace and to

replace any part of the electrical or control system, which has been

underwater.

: Should overheating occur or the fuel supply fail to shut off, shut off

the manual fuel supply valve to the furnace before shutting off the electrical

supply.

41

Page 43

All installations and services must be performed by qualified service personnel.

B. COMPONENT LOCATIONS

The following diagram shows a typical furnace installation and typical position of

the components referenced in these instructions.

Figure 10

C. INSPECTION AREAS

IMPORTANT: For safe operation it is the responsibility of the owner and/or user

that the burner, chimney/vent pipe, heat exchanger and controls should be

inspected every year by a qualified heating contractor.

42

Page 44

All installations and services must be performed by qualified service personnel.

1. VESTIBULE: The furnace vestibule areas or burner compartment should be

inspected by removing front door of the furnace and looking for signs of

excessive heat such as discoloration of components, materials damaged

from rust or corrosion, soot or carbon build-up.

2. EXTERIOR OF FURNACES: The furnace exterior should be inspected for

signs of excessive heat such as discoloration of materials or damage from

rust or corrosion.

3. VENT CONNECTOR: The furnace vent pipe should be inspected for signs of

rust, corrosion pitting, or holes in the pipe. Check for leakage around seams

in pipe indicated by soot or condensate streaks.

4. ROOF JACKS: The furnace roof jack should be inspected for signs of rust or

corrosion, pitting or holes, signs of excessive condensation or moisture

leaking from roof jack.

D. FILTER LOCATION AND CLEANING

???? CAUTION: To avoid injury from moving part, hot surfaces or electrical

shock, shut off the power to the furnace and allow the furnace to cool

before removing furnace access door to service filter.

The air filter should be inspected each month and cleaned when dirty. Clean the

filter by soaking it in water with a mild detergent and rinsing it with clean water.

Allow the filter to air dry before reinstalling it in the furnace. Cleaning the air filter

frequently may prevent airborne contaminants from going through the furnace

and depositing in the furnace, duct system, and interior of the building.

See Figure 10, in this section, for the location of the return air filter.

43

Page 45

All installations and services must be performed by qualified service personnel.

APPENDIX A. REPLACEMENT PARTS LIST

44

Page 46

All installations and services must be performed by qualified service personnel.

45

Page 47

All installations and services must be performed by qualified service personnel.

APPENDIX B – WIRING DIAGRAM

46

Loading...

Loading...