Loctite VoluDrop UV 97650 Operating Manual

Operating Manual

VoluDrop Dispenser UV

97650

Contents

English....................................................................................................................3 - 16

2

Contents

1 Please observe the following......................................................................................4

1.1 Emphasized Sections.....................................................................................................4

1.2 Items Supplied................................................................................................................4

1.3 For Your Safety..............................................................................................................5

1.4 Field of Application (Intended Usage)............................................................................5

2 Description....................................................................................................................6

2.1 Theory of Operation .......................................................................................................6

2.2 Operating Elements and Connections............................................................................6

3 Technical Data..............................................................................................................7

4 Installation ....................................................................................................................8

4.1 Connecting to the Product Reservoir .............................................................................8

4.2 Connecting to the Controller...........................................................................................8

4.3 Selection of the Required Dispensing Needle ..............................................................10

5 Dispensing..................................................................................................................11

5.1 Flushing........................................................................................................................11

5.2 Adjusting the Dispensing Quantity ...............................................................................12

5.3 Shutdown .....................................................................................................................12

5.4 Returning to Operation.................................................................................................12

6 Maintenance................................................................................................................13

7 Troubleshooting.........................................................................................................14

8 Annex ..........................................................................................................................15

8.1 Accessories and Spare Parts.......................................................................................15

8.2 Manufacturer’s Declaration ..........................................................................................16

8.3 Warranty (excluding Germany) ....................................................................................16

3

1 Please observe the following

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice

+

Gives recommendations for better handling of the unit during operation or adjustment as

well as for service activities.

The numbers printed in bold in the text refer to the corresponding position numbers in

the illustration on page 7.

• The point emphasizes an instruction

step.

Instruction steps in the illustrations are

indicated with arrows.

When several instruction steps are

indicated in an illustration, the shading of

the arrow has the following meaning:

Black arrow = 1

Grey arrow = 2

White arrow = 3

st

step

nd

rd

step

1.2 Items Supplied

– 1 VoluDrop Dispenser 97650

– 1 Needle Variety Kit 97262;

– 1 Product Feedline, length 2 m, including Valve Fitting ¼”

– 1 Instruction Manual 97650

– 1 Assembly Tool for Maintenance

– 1 Air Pressure Hose OD 4 mm calibrated, length 1 m

step

As a result of technical development, the illustrations and descriptions in this operating

+

4

manual can deviate in detail from the actual unit delivered.

1 Please observe the following

1.3 For Your Safety

For safe and successful operation of the unit, read these instructions completely.

If the instructions are not observed, the manufacturer can assume no responsibility.

Be sure to retain this manual for future reference.

When working with pressurized air, wear protective glasses!

Observe general safety regulations and manufacturer’s instructions for the

handling of chemicals.

If chemical products are not properly handled, damage to health can result!

Request a safety data sheet for the LOCTITE

®

1.4 Field of Application (Intended Usage)

The VoluDrop Dispenser is suitable only for the exact drop application of

LOCTITE UV acrylics up to a viscosity of 15,000 mPas.

It is not suitable to dispense UV acrylics with anaerobic component,

cyanoacrylates, abrasive adhesives and anaerobics.

Only drop dispensing is possible.

Up to a viscosity of 5,000 mPas the dispenser is able to spit adhesives.

Spitting is possible form 3 µl up to 15 µl, non-spitting from 0.8 µl up to 3 µl.

Within a distance of 50 mm a feed motion of the workpiece is not necessary. The

dispenser should be mounted with the dispensing needle downwards.

-adhesive used!

The dispenser is used as a stationary applicator unit. It is mounted directly at the

dispensing position. The free end of the product feedline is connected to the product

reservoir.

For product reservoirs, 0.5 l and 2 l versions are available.

The control of the dispenser is provided by a control unit of the LOCTITE equipment line.

5

2 Description

2.1 Theory of Operation

The LOCTITE adhesive is transported through a product feedline to the dispenser by the

dispensing pressure in the product reservoir. This feedline has a PTFE-liner to prevent

curing of adhesives in this area.

When the ejector piston moves back the dispensing chamber will be filled. The adhesive

is spat under high pressure by very fast movement of the piston. During dispensing a

non-return valve prevents back-flow of adhesive to the reservoir.

The amount of product dispensed is controlled by the volume of the dispensing chamber.

Via a stroke adjustment the amount can be limited between 0.8 µl to 15 µl per shot.

As a matter of principle, spitting is possible with each LOCTITE dispensing needle. An

exact spitting is only possible with the conical needles.

Generally, the size of the needle should be adapted to the required amount.

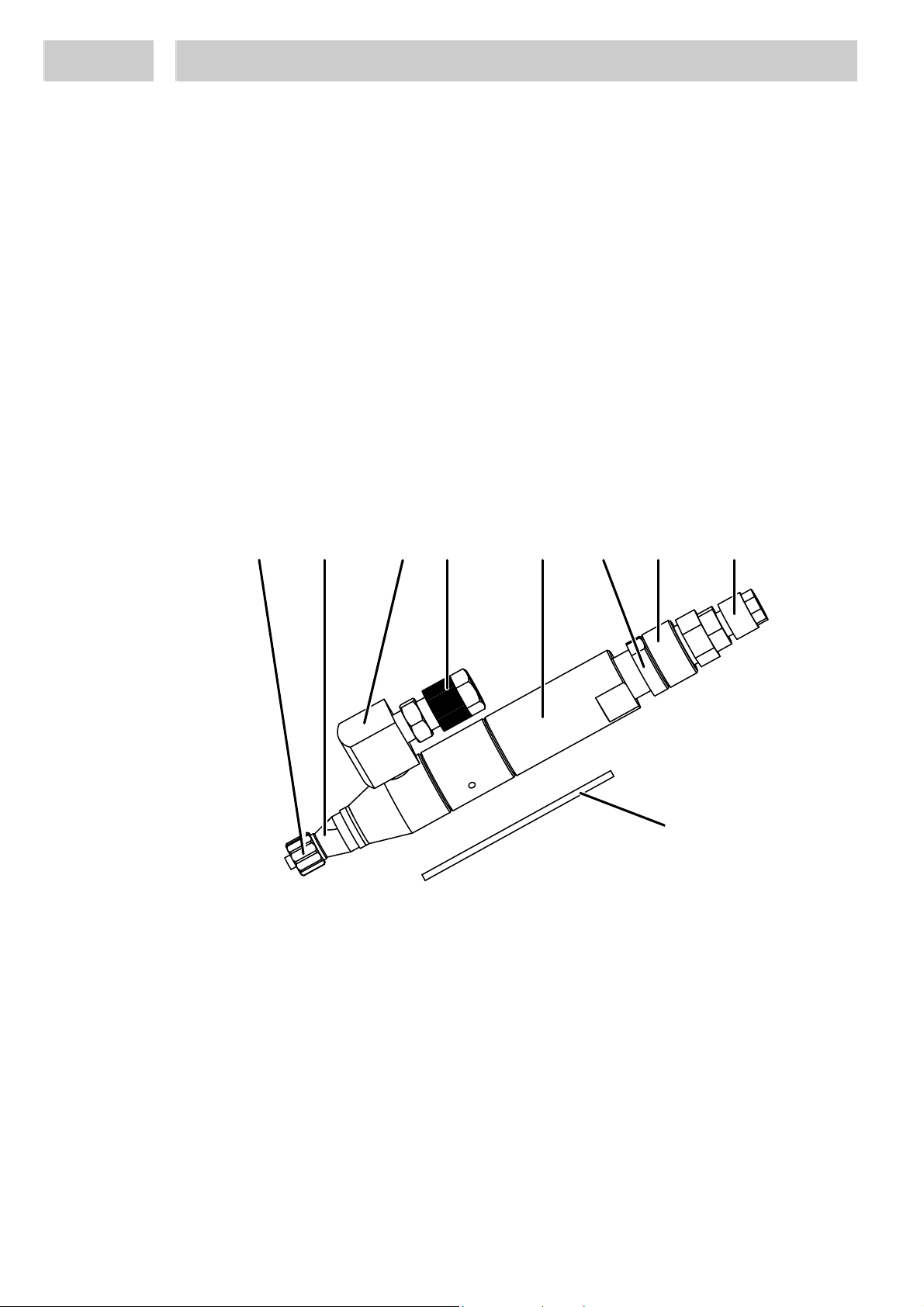

2.2 Operating Elements and Connections

2

13457

Luer-Lock Adapter to mount a dispensing needle.

1

Integrated Non-Return Valve prevents dripping of adhesive due to the

2

reservoir pressure.

6

8

9

6

Non-Return Valve to prevent back-flow of adhesive to the reservoir during

3

dispensing.

Feedline Connector to connect a feedline (OD 1/4" or 6 mm) to the reservoir.

4

5 Dispenser

Lock Nut to fix the stroke adjustment knob.

6

Stroke Adjustment Knob to reduce stroke and therewith the dispensed

7

quantity.

Compressed Air Connector, to connect pneumatic tube, OD see section 3.

8

Assembly Tool for maintenance, see section 6

9

Loading...

Loading...