Sliding Gate Operator

User's Manual

Model: L110C

www.Openers4Less.com

L110C/L110 SLIDING GATE OPERATOR

2

OUTLINE

1. Important safety information

…………………3

2. Main functions

…………………………………3

3. Technical parameters

…………………………3

4. Packing list

……………………………………3

5. Installation

……………………………………5

6. Connect the wires

……………………………9

7. Adjustment

……………………………………9

8. Maintenance

…………………………………10

L110C/L110 SLIDING GATE OPERATOR

3

1. Important safety information

Carefully read and follow all safety precaution and warnings before attempting to install and

use this operator, incorrect installation can lead to severe injury.

The gate operator should be installed by a qualified technician; otherwise, serious

personal injury or property damage may occur.

The automatic gate operator must be grounded.

When opening or closing the gate, do not attempt to walk or drive through the gate.

Children should not be allowed to play near or operate automatic gates.

Install the gate operator on the inside of the property, DO NOT install it on the outside of

the property where the public has access to it.

Be careful when in close proximity to moving parts where hands or fingers could be

pinched.

The operator should be switched off before repairing it or opening its cover.

2. Main functions

The gate operator is used to drive the sliding gate, it is capable of overwork in short time.

When overloading, it has electrical and mechanical double protections to ensure operating

safety. In case of power failure, a release key allows to loosen the clutch to move the gate

manually.

3. Technical parameters

Type L110C L110

Limit switch Magnetic limit switch Spring limit switch

Power supply AC1 10, 60Hz

Output torque (Max.)

15N·m

Motor speed 1650rpm

Reduction ratio 1:30

Environmental temperature -10ºC to +55ºC

4.Packing list

After receiving the product, you should make an unpack-in spectio n, in whi ch you sh ould check

whether the product was damaged. If you have any problem please contact dealer.

L1 10C gate operator packing list

No. Item Quantity

1 Gate operator 1

2 Release key 2

3 Operator base (spare accessory) 1

4 Tighten bar 2

5 Magnet bracket 2

6 Sprocket cover 1

7 Screw for mounting driven sprocket bracket (M8X16) 4

8 Anchor bolt with nut 4

9 Driven sprocket bracket (left side & right side) 2

10

Magnet

2

11

Anchor

4

Residential Sliding Gate

Operator

Tools you will need

During assembly and installation of your opener, the instructions will call for the use of

various tools shown below. Other tools may be required as needed for the installation of

the concrete pad and electrical connection.

Table 3 Required Tools for Installation

Screwdriver Tape Measure Electric Drill Level

File Wrenches Multimeter Pliers Allen Wrenches

Wire Strippers Wire Cutter Adjustable Wrench Socket Wrench

L110C/L110 SLIDING GATE OPERATOR

4

Fig.1 L1 10C accessories

L1 10 gate operator packing list

No. Item Quantity

1

Gate operator

1

2

Release key

2

3

Operator base (spare accessory)

1

4

Tighten bar

2

5

Block bracket

2

6

Sprocket cover

1

7

Screw for mounting driven sprocket bracket (M8X16)

4

8

Anchor bolt with nut

4

9

Driven sprocket bracket (left side & right side)

2

10

Block

2

11

Anchor

4

L110C/L110 SLIDING GATE OPERATOR

5

Fig.2 L1 10 accessories

5. Installation

The L110C/L110 Chain-driven Gate Operator operates by forcing a straight piece of chain.

This length of chain is extended between two chain brackets located at opposite ends of the

gate. The entire configuration is shown in the diagram below.

Fig.3 L110C

L110C/L110 SLIDING GATE OPERATOR

6

Fig.4 L1 10

Conduit

In order to protect the wires, conduit must be preset into the concrete when it is poured. Wires

within the conduit shall be located or protected so that no damage can result from contact with

any rough or sharp part.

Concrete pad

The base unit of the gate operator requires a concrete pad in order to maintain proper stability.

The concrete pad should be approximately 300mm x 260mm x1 20mm deep in order to p rovide

for adequate operation.

Anchors

You can use the anchor bolts, anchors, washers, and nuts. These ancho rs must be set i nto the

concrete when it is poured, or you can use wedge anchors.

Chain

Sprocket bracket

Installation 2

Installation 1

Anchor

Anchor bolt

Tighten bar

Conduit

Fig.5

L110C/L110 SLIDING GATE OPERATOR

7

Driven sprocket bracket

Fix the driven sprocket bracket on both sides of the operator.

Operator

In locations where ground freeze is possible, mount the gate operator as shown in Fig.5

installation 1 or installation 2. Check the operator and make sure it is lined up with the gate.

Chain Brackets

Use the appropriate bolts to attach the chain bracket to the frame of the gate. If the gate is of

square frame style, use the square bolts shown.

Spring washer (Φ8)

Plain washer (

Φ8)

"L" bracket

Square bolt

Nut (M8)

Chain bolt

Master link

Nut (M6)

Spring washer (

Φ6)

Plain washer (

Φ6)

Gate

Square frame

Fig.6

If the gate is of round frame style, use the round bolts shown.

Round bolt

"L" bracket

Plain washer (

Ф8)

Spring washer (

Ф8)

Nut (M8)

Chain bolt

Master link

Nut (M6)

Spring washer (

Ф6)

Plain washer (

Ф6)

Gate

Round frame

Fig.7

Chain

Close the gate and attach a chain bolt to the chain using enclosure master links. Tighten the

chain bolt to the bracket with washers and nuts. Pull the chain through the sprockets to the

other chain bracket at the opposite end of the gate see Fig.9. Connect the other end of the

chain and the chain bolt, and then tighten the chain bolt to the chain bracket. Thread up the

chain by adjusting the chain bolt. Cut the chain to length if necessary. Tighten the chain by

tightening the chain bolts at either end. See Fig.8.

Master link

Chain bolt

Chain

Fig.8

L110C/L110 SLIDING GATE OPERATOR

8

Drive sprocket

Driven sprocket

Driven sprocket

Fig.9

Sprocket cover

Mount the sprocket cover with screws.

Limit switch

L1 10C-Magnets for limit switch

(see Fig.10)

Install the magnet as shown in Fig.10 below. The magnet and limit switch are used to

control the position of the gate.

When the magnet is installed, release the gear clutch and pu sh the sliding gate manually to

pre-determine the position. Fix the magnet bracket to the gate and then tighten the gear

clutch. The lower bracket is for open position and upper bracket is for close position.

Finally adjust the magnet to the proper position by moving the gate with the motor. The

magnet should be 10~15mm away from the magnetic limit switch. If it is too far away, the

switch will fail to work. Adjust the position of the magnet until the positions of the opening

and closing meet the requirement.

Please note the position of two magnet brackets (fixed plate) are different: one is

upper and another is lower. Verify and if necessary exchange the two brackets

position. Also if necessary exchange the limit switch wires CL (close) and OP

(open).

Release key

Gate operator

Gate

Upper and lower Magnets

Sprocket cover

Drive sprocket

Magnet bracket

Fig.10 L1 10C

L110C/L110 SLIDING GATE OPERATOR

9

L1 10-Spring limit switch (see Fig.11)

To ensure safety, it is recommended to install limit devices at both ends of the gate to

prevent the gate from sliding out of the rails. The rails must be installed horizontally.

The spring limit switch and blocks are used to control the position of the gate.

When the block is installed, release the gear clutch with the key and push the sliding gate

manually to pre-determine the position, fix the block bracket to the gate and then tighten

the gear clutch with the key. Moving the gate electrically, adjust the block bracket to the

proper position until the position of the opening and closing meet the requirement.

Release key

Gate operator

Gate

Spring limit

switch and block

Block bracket

Fig.1 1 L110

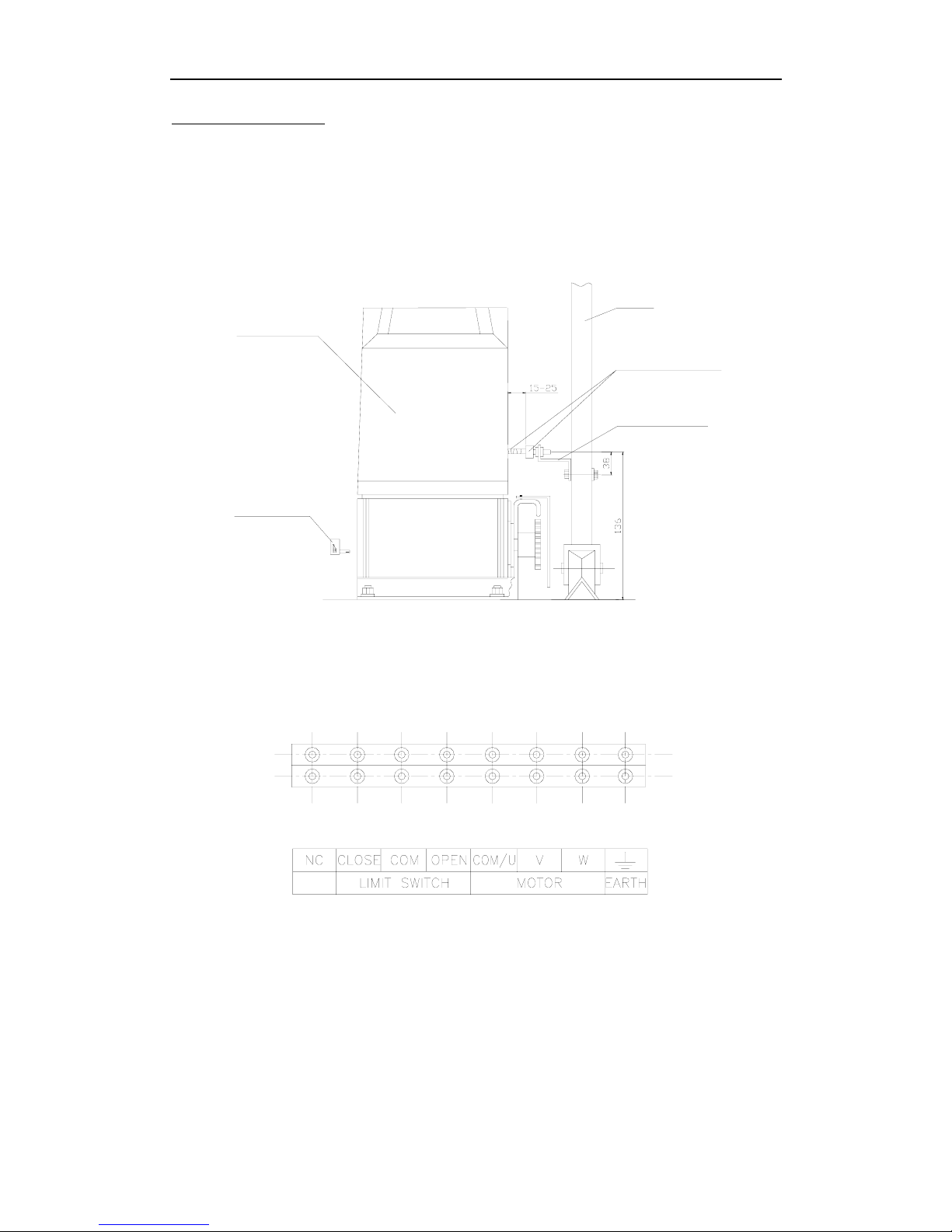

6. Connect the wires

Make sure that the power is OFF before making any electrical connections. Remove the cover

of the control box, perform the wiring and replace the cover again. (Refer to Fig.12)

Fig.12

7. Adjustment

Check the power supply, grounding and wiring before running the device.

Release the clutch with the key to determine whether or not the gate can be moved manually.

If everything is in good working order, engage the clutch with the key.

When engage the clutch with the key, be sure to close completely to prevent from damage.

Switch on the power and run the operator to ensure that the gate is sliding smoothly.

Adjust magnet or block position until the gate opened and closed properly at the limited

positions.

L110C/L110 SLIDING GATE OPERATOR

10

Tighten (or release) the force adjust bolt on the motor top to increase (or decrease) the output

torque (i.e. output force of the operator), and ensure the gate safely.

Adjust the output torque in the safety range before using the operator.

8. Maintenance

Ensure the power is switched off before removing the cover .

Loosen the oil screw on the motor to avoid leakage.

Ensure the operator is well earthed.

Regularly grease the wheels and axles to ensure the gate moves smoothly.

Keep opener clean at all times.

Step #2

Install the Control Board onto the Motor by mounting it on the

Step #3

Install the Receiver onto the Motor by mounting it on the small

(as shown

Step #1

Unscrew the Blue Cover from the Motor and set it aside.

Open the small white box & make sure that the contents include:

(1) - Receiver and (1) - Control Board

small white clips that are on the large Mounting Plate.

(as

shown below)

white clips that are on the small Mounting Plate.

below)

7

Step #4

Next, take the set of wires coming from the motor and connect the

red and black wires anywhere onto the plug.

Once you have connected those wires, you will then take that plug

and connect it to the Control Board on the section labeled:

MAKING THE CONNECTION

Now you will begin the installation by screwing the wires that are coming

from the small Receiver Board onto the Terminals (see Pic 1, right) from

the Control Board, in the following order:

Terminal 10 - GREEN WIRE

Terminal 11 - RED WIRE

Terminal 12 - YELLOW WIRE (any)

Terminal 13 - YELLOW & BLUE WIRE (any )

Terminal 14 - BLUE WIRE (any)

Step #5

(as shown on the pic, right)

Pic 1

"MOTOR"

(as shown on the pic, right)

8

Step #6

Find the plug with the Blue & Yellow wires on it. Connect the plug on

Step #7

Find the plug with the Red, White & Blue wires on it. Connect the plug

Step #8

Step #9

You are now ready to connect you power wires to your Gate

Opener!

to the Control Board on the section labeled:

"CAPACITOR"

(as shown on the pic, right)

on to the Control Board on the section labeled:

"LIMIT SWITCH"

(as shown on the pic, right)

Find the wire coming from the bottom of the Motor that is GREEN &

YELLOW. Screw the "Ground Wire" to Terminal #22 on the Control

Board

(as shown on the pic, right)

Terminal #1 - POWER

Terminal #2 - NEUTRAL

9

AC SLIDE GATE CONTROLLER

FEATURE SELECTOR

Limit Switch Type

ON: Normally Close

OFF: Normally Open

When using auto close features

DIP 1

10

Auto Close Feature

12.5 Seconds

25 Seconds

45 Seconds

only one

di

p sw

itch sh

ou

ld

b

e

ON. The other two dip switch

should be in the OFF posion for

the auto close feature to work

correctly.

DI P 2

DI P 3

DI P 4

Direcon of Gate

ON: Gate Opening to the le

OFF: Gate Opening to the Right

NOT USED

DI P 5

DI P 6

Receiver

Channel One (not used at this me)

Channel Two (not used at this me)

DI P 7

DI P 8

Transmitter/Remote Control (shown in Figure 9)

1. Yellow Button Channel

2. Blue Button Channel

3. Indicator Light

4. Yellow Button Channel – exposed

5. DIP Switch

6. Battery

7. Blue Button Channel – exposed

8. Back side cover

Figu

re 9

Receiver

1. Channel 1 DIP Switch (yellow

button

on remote control

transmitter)

2. Channel 2 Dip Switch

(Secondary, Multi-Code

co

mpatible, blue button on

remote control transmitter)

The

red and black wires are 24 volt

po

wer input. The two yellow are the

ch

annel 1, the two white are

ch

annel 2, and the black wire is the

antenna wire

Figure 10

Figure 10

Setting the Transmitter DIP Switches:

There

are a total of eight (8) transmitter DIP switches. Each one can be placed in three (3) different positions

(+,

0, -). DO NOT set all of the switches to the same position, for example: all +, all 0 or all -. Once the

DI

P switches have been set to a personal code, replace and close the cover.

11

Residential Sliding Gate Operator

13

Optional Equipment Installation Procedures

O

O

O

O

O

O

O

O

O

O

O

O

Blue

Brown

Black

White

Grey

Grey

Black

Black

Green

Brown

Red

Black

©2005-2009 LockMaster All Rights Reserved

sales@Openers4Less.com

www.Openers4Less.com

Loading...

Loading...