Lochinvar XPN399 User Manual

Commercial Pool Heating Applications

Outstanding Features

> Up to 97% efficiency

> Reduced pool heating costs

(as much as 20-25% in actual application)

> Small footprint

> Smart System operating control

> Condensing Boiler design with ASME construction

> Modulating burner matches input to demand

> Completely factory assembled and tested

> Easy to install

XLP

Pool Heater

Package

> Direct vent/sealed combustion isolates heater

from contaminated air within pool equipment room

> Lower installed costs with PVC/CPVC vent materials

> External Cupro-Nickel pool heat exchanger -

• Salt water approved

• Shell and tube design

• Pool water isolated from

combustion chamber

• Reduced maintenance requirements

Standard Features

Gas Inlet

Flue Connection

Copper Pipe

Pressure Reducing

Valve/Auto Fill Valve

System Sensor

Location

Current Hourly Cost Hourly Cost

Pool Heater at 78% at 97% Annual Savings Based on

Input Efficiency Efficiency Operating Hours per Day

4 8 12 18

1,000,000 $14 $11 $3,861 $7,721 $11,582 $17,373

2,000,000 $27 $22 $7,721 $15,443 $23,164 $34,746

4,000,000 $54 $43 $15,443 $30,886 $46,329 $69,493

Costs are based on a gas price of $1.35 per therm.

Air Inlet

Connection

Relief Valve

T&P Gauge

Flow Switch

Condensate Drain

Cupro-Nickel Pool

Heat Exchanger

Skid Mounted on

Steel Frame

Boiler Pump

399,000 to 800,000 BTUs

Expansion Tank

NOTE: Indoor applications only.

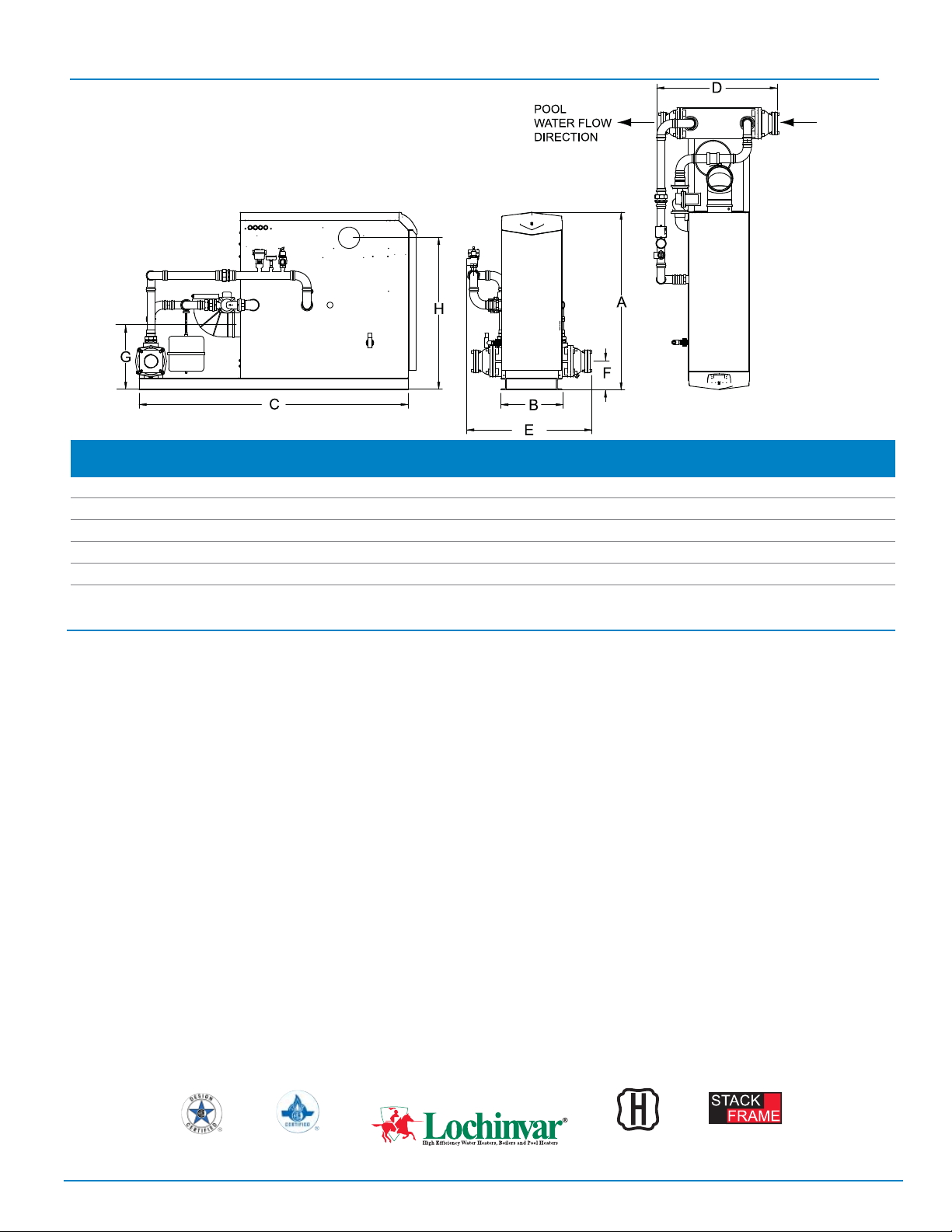

XLP Pool Heater Package Dimensions

Model Btu Water Gas Vent Air Pool Pressure Ship.

Number Output* A B C D E F G H Conn. Conn. Size Inlet Flow Drop Wt.

XPN399 372,038 45-1/2” 15-3/4” 53” 23-1/4” 23-1/2” 6-1/2” 16-3/4” 37” 2-1/2” 1” 4” 4” 93 0.73 465

XPN500 467,297 45-1/2” 15-3/4” 55” 23-1/4” 23-1/2” 6-1/2” 16-3/4” 38” 2-1/2” 1” 4” 4” 117 1.15 497

XPN600 567,364 45-1/2” 15-3/4” 63” 23-1/4” 23-1/2” 6-1/2” 16-3/4” 39” 2-1/2” 1-1/2” 4” 4” 142 1.72 534

XPN700 660,423 45-1/2” 15-3/4” 68” 30” 32-1/4” 7-1/4” 16-3/4” 39” 3” 1-1/2” 6” 4” 166 0.55 634

XPN800 773,268 45-1/2” 15-3/4” 69” 30” 32-1/4” 7-1/4” 16-3/4” 39” 3” 1-1/2” 6” 4” 194 0.80 671

Notes: Change ‘N’ to ‘L’ for L.P. Gas Model. No deration on L.P. models. Performance data based on manufacturer test results.

120 VAC /15 AMP circuit required. All dimensions shown in inches.

* BTU output based on 80 degree pool water and a delta t of 8 degrees across the pool heat exchanger

Standard Features

> Up to 97% Thermal Efficiency*

> Modulating Burner with 5:1 Turndown

> Direct-Spark Ignition

> Low NOx Operation

> Sealed Combustion

> Low Gas Pressure Operation

> Vertical & Horizontal Direct-Vent

> Category IV venting up to 100 feet

> PVC, CPVC or AL29-4C Venting up to 100 Feet

> Factory Supplied Sidewall Vent Termination

> Integral Boiler Heat Exchanger

> ASME Certified, ”H” Stamped

> 316L Stainless Steel

> Gasketless Heat Exchanger

> 160 psi Working Pressure

> Highly efficient, condensing design

> On/Off Switch

> Adjustable High Limit w/ Manual Reset

> Flow Switch

> Pool Temperature Sensor

> Inlet & Outlet Temperature Sensors

> Flue Temperature Sensor

> Low Air Pressure Switch

> 50 psi ASME Relief Valve

> Temperature & Pressure Gauge

> Cast Iron Pump

> Expansion Tank

> Pressure Reducing Valve/Auto Fill Valve

> Condensate Trap

> Zero Clearances to Combustible Material

> 10 Year Limited Warranty (See Warranty for Details)

> External Cupro-Nickel Pool Heat Exchanger

> Salt Water Ready

> Flanged Connections for Pool Water

> SMART SYSTEM Digital Operating Control

> 2 line, 16 Character Display

> Dual Level Password Security

> Built in Cascading Sequencer for up to 8 Heaters

> Building Management System Integration

with 0-10 VDC Input

> Low Water Flow Safety Control & Indication

> Pool Temperature Readout

> Inlet & Outlet Temperature Readout

> Freeze Protection

> Service Reminder

> Time Clock

> Data Logging

> Hours Running

> Ignition Attempts

> Last 10 Lockouts

> Low Voltage Terminal Strip

> 24 VAC Auxiliary Device Relay

> Auxiliary Proving Switch Contacts

> Flow Switch Contacts

> Alarm on Any Failure Contacts

> Runtime Contacts

> System Sensor Contacts

> Cascade Contacts

> 0-10 VDC BMS External Control Contact

Optional Equipment

> Alarm Bell on Any Failure

> Condensate Neutralization Kit

> High & Low Gas Pressure Switches w/ Manual

Reset (500-800)

> Low Water Cutoff w/Manual Reset & Test

> Stainless Steel Vent Kits (700-800)

> Stack Frame

> DHW Priority Piping

> Room Air Filter Kit

Firing Codes

> M9 Standard Construction

> M7 California Code

> M13 CSD1 / FM / GE Gap (500-800)

Patent # 7,506,617

NOTE: Indoor applications only.

* Thermal effi ciency based on 110°F

inlet water temperature to the boiler

and 75°F pool water temperature.

XPN-01

Applies to Boiler only

Applies to Boiler only

Applies to Boiler only

Lochinvar Corporation • 300 Maddox Simpson Pkwy • Lebanon, TN 37090 • 615-889-8900 / Fax: 615-547-1000

www.Lochinvar.com

©-4/10-Printed in the U.S.A.

Loading...

Loading...