Lochinvar TTW Series, TTW410, TTW580 Installation, Commissioning And Maintenance Instructions

1

TTW

FLOOR STANDING GAS FIRED CONDENSING

CIRCULATING TYPE WATER HEATER

Installation Commissioning and Maintenance

instructions

MODELS

TTW410

TTW580

Installation manual_TTW_December 2018

2

3

Table of Contents

1.0 INTRODUCTION ........................................................................................................................................................................................ 6

1.1 ANCILLARY OPTIONS: ......................................................................................................................................................................... 6

2.0 SAFETY GUIDELINES .............................................................................................................................................................................. 7

2.1 GENERAL DESCRIPTION OF SAFETY SYMBOLS USED.................................................................................................................. 7

2.2 WHAT TO DO IF YOU SMELL GAS ...................................................................................................................................................... 8

3.0 PRINCIPLE PARTS ................................................................................................................................................................................... 8

3.1 CASING .................................................................................................................................................................................................. 8

3.2 ELECTRICAL ......................................................................................................................................................................................... 9

3.3 GAS TRAIN AND AIR INLET ................................................................................................................................................................. 9

4.0 TECHNICAL DATA .................................................................................................................................................................................. 10

4.1.1 TECHNICAL DATA........................................................................................................................................................................... 10

5.0 DIMENSIONS AND CLEARANCE .......................................................................................................................................................... 11

5.1 DIMENSIONS ....................................................................................................................................................................................... 11

5.1.1 DIMENSIONS TTW410 .................................................................................................................................................................... 11

5.1.2 DIMENSIONS TTW580 .................................................................................................................................................................... 11

5.1.3 MINIMUM CLEARANCES ................................................................................................................................................................ 11

5.2 WATER HEATER CONNECTIONS ..................................................................................................................................................... 12

5.2.1 WATER HEATER CONNECTIONS ................................................................................................................................................. 12

5.2.2 CONNECTIONS AND CONNECTION SIZES ................................................................................................................................. 12

5.3 CONDENSATE DRAIN CONNECTION ............................................................................................................................................... 13

6.0 GENERAL REQUIREMENTS .................................................................................................................................................................. 14

6.1 RELATED DOCUMENTS ..................................................................................................................................................................... 15

7.0 WATER QUALITY ................................................................................................................................................................................... 16

7.1 WATER CHEMISTRY .......................................................................................................................................................................... 16

8.0 LOCATION ............................................................................................................................................................................................... 16

8.1 PLANT ROOM REQUIREMENTS ....................................................................................................................................................... 16

8.2 GENERAL REQUIREMENTS .............................................................................................................................................................. 16

8.3 UNPACKING AND LEVELLING THE WATER HEATER .................................................................................................................... 17

8.4 CLEARANCES ..................................................................................................................................................................................... 17

9.0 GAS SUPPLY .......................................................................................................................................................................................... 18

9.1 SERVICE PIPES .................................................................................................................................................................................. 18

9.2 METERS ............................................................................................................................................................................................... 18

9.3 GAS SUPPLY PIPES ........................................................................................................................................................................... 18

9.4 BOOSTED SUPPLIES ......................................................................................................................................................................... 18

9.5 PLANT-ROOM CONTROL VALVE ...................................................................................................................................................... 18

9.6 EQUIPMENT GAS SYSTEM LEAK CHECK ....................................................................................................................................... 18

10.0 FLUE SYSTEM ........................................................................................................................................................................................ 19

10.1 FLUE SYSTEM GENERAL REQUIREMENTS .................................................................................................................................... 19

10.2 FLUE TERMINAL POSITION ............................................................................................................................................................... 20

10.3 FLUE GAS AND AIR SUPPLY SYSTEM ............................................................................................................................................. 20

10.4 APPROVED FLUE SYSTEM ............................................................................................................................................................... 20

10.5 INSTALLATION PRECAUTIONS ......................................................................................................................................................... 20

10.6 WATER HEATER CATEGORIES - TYPES OF FLUE GAS SYSTEMS. ............................................................................................ 21

10.7 TYPE C63 CERTIFIED .......................................................................................................................................................................... 23

10.8 TTW AIR INLET / FLUE GAS OUTLET CALCULATION EXAMPLES ................................................................................................ 23

10.9 TYPE C53(TWIN PIPE) FLUE SYSTEMS ............................................................................................................................................ 24

10.9.1 EXAMPLE A: TWIN PIPE SYSTEM ................................................................................................................................................. 25

10.10 GENERAL TWIN-PIPE INSTALLATION GUIDELINES ....................................................................................................................... 26

10.11 TYPE B23 (CONVENTIONAL FLUE WITH FAN ASSISTANCE) ......................................................................................................... 29

10.11.1 EXAMPLE B: SINGLE PIPE SYSTEM FOR FLUE GAS OUTLET ONLY ...................................................................................... 30

10.12 SEPARATE AIR SUPPLY AND FLUE TERMINAL FOR A PITCHED ROOF ..................................................................................... 31

10.13 COMMON FLUE SYSTEMS ................................................................................................................................................................ 32

10.14 CONDENSATE DRAIN ........................................................................................................................................................................ 32

11.0 AIR SUPPLY ............................................................................................................................................................................................ 32

11.1 AIR SUPPLY THROUGH HUMID AREAS ........................................................................................................................................... 32

11.2 PIPE HEIGHTS AND MUTUAL DISTANCES ON A FLAT ROOF. ..................................................................................................... 32

11.3 COMBUSTION VENTILATION ............................................................................................................................................................ 33

11.4 COOLING VENTILATION .................................................................................................................................................................... 33

12.0 WATER CONNECTIONS ......................................................................................................................................................................... 34

12.1 GENERAL............................................................................................................................................................................................. 34

12.2 UNVENTED SYSTEM ARRANGEMENT............................................................................................................................................. 34

12.2.1 EXPANSION VESSEL SIZING ........................................................................................................................................................ 34

12.2.2 COEFFICIENT OF EXPANSION OF WATER AT 3.5 BAR INLET PRESSURE ............................................................................ 34

12.3 CIRCULATING PUMPS ....................................................................................................................................................................... 35

12.4 PRIMARY PIPEWORK LOOP SIZING ................................................................................................................................................ 35

12.4.1 CIRCULATION REQUIREMENTS ................................................................................................................................................... 35

12.4.2 PIPEWORK HEADER SIZES FOR COMMON INSTALLATIONS .................................................................................................. 36

12.4.3 PIPEWORK SCHEMATICS ............................................................................................................................................................. 36

12.5 PRESSURE RELIEF VALVE ............................................................................................................................................................... 37

12.6 ANTI-GRAVITY LOOP ......................................................................................................................................................................... 37

12.7 AUTOMATIC AIR VENT ....................................................................................................................................................................... 37

12.8 FROST PROTECTION ......................................................................................................................................................................... 37

12.9 SYSTEM FLUSHING............................................................................................................................................................................ 37

4

13.0 CONTROL OPTIONS/INSTALLATION ................................................................................................................................................... 38

13.1 VESSEL TEMPERATURE SENSOR SINGLE WATER HEATER INSTALLATION............................................................................ 38

13.1 location of flow temperature sensor (fs) on a single vessel installation ............................................................................................... 39

13.2 location of flow temperature sensor (fs) on a multiple vessel installation ............................................................................................ 39

13.3 SENSOR WIRING ................................................................................................................................................................................ 39

14.0 SCHEMATICS .......................................................................................................................................................................................... 40

14.1 SINGLE WATER HEATER WITH SINGLE STORAGE VESSEL INSTALLATION ............................................................................. 40

14.2 MULTIPLE WATER HEATERS WITH MULTIPLE STORAGE VESSELS NOT IN CASCADE .......................................................... 41

14.3 MULTIPLE WATER HEATERS WITH MULTIPLE STORAGE VESSELS IN CASCADE ................................................................... 41

15.0 ELECTRICAL INSTALLATION ............................................................................................................................................................... 42

15.1.1 ELECTRICAL SUPPLY REQUIREMENTS ...................................................................................................................................... 42

15.2 EXTERNAL CONTROLS ..................................................................................................................................................................... 42

15.3 WIRING CONNECTIONS .................................................................................................................................................................... 42

15.3.1 ACCESSING WIRING CONNECTIONS .......................................................................................................................................... 42

15.3.2 WIRING CONNECTIONS ................................................................................................................................................................ 43

15.3.3 WIRING TERMINALS ...................................................................................................................................................................... 43

15.3.4 WIRING TERMINALS ...................................................................................................................................................................... 44

15.4 MAINS SUPPLY CONNECTION – THREE-PHASE SUPPLY. ........................................................................................................... 45

15.4.1 3-PHASE ELECTRICAL SUPPLY CONNECTION .......................................................................................................................... 45

15.5 MAINS SUPPLY CONNECTION – SINGLE PHASE SUPPLY ........................................................................................................... 45

15.5.1 SINGLE PHASE ELECTRICAL SUPPLY CONNECTION ............................................................................................................... 45

15.6 FUSES .................................................................................................................................................................................................. 45

15.6.1 FUSES .............................................................................................................................................................................................. 45

15.7 WIRING DIAGRAMS ............................................................................................................................................................................ 46

15.7.1 UPPER BURNER WIRING DIAGRAM (PCB A, left) ....................................................................................................................... 47

15.7.2 UPPER BURNER CONTROL .......................................................................................................................................................... 47

15.7.3 LOWER BURNER WIRING DIAGRAM (PCB B, Right) ................................................................................................................... 49

15.7.4 LOWER BURNER CONTROL ......................................................................................................................................................... 49

15.8 SENSOR VALUES ............................................................................................................................................................................... 50

15.8.1 SENSOR VALUES ........................................................................................................................................................................... 50

16.0 CONTROL SYSTEM ................................................................................................................................................................................ 51

16.1 CONTROL PANEL ............................................................................................................................................................................... 51

16.2 CONTROL PANEL / MENU STRUCTURE .......................................................................................................................................... 52

16.3 DISPLAY DURING OPERATION ......................................................................................................................................................... 54

16.4 MONITOR SCREENS .......................................................................................................................................................................... 55

16.5 SERVICE FUNCTION .......................................................................................................................................................................... 57

16.6 SCHORNSTEINFEGER FUNCTION ................................................................................................................................................... 57

16.7 PROGRAMMING IN STANDBY MODE ............................................................................................................................................... 58

16.8 SETTING TIME & DATE ...................................................................................................................................................................... 58

16.9 SET POINTS ........................................................................................................................................................................................ 59

16.10 SETTING THE TIMER PROGRAMS ................................................................................................................................................... 59

16.10.1 STARTING THE TIMER PROGRAMS ............................................................................................................................................. 59

16.11 HOT WATER PROGRAM .................................................................................................................................................................... 60

16.12 ANTI LEGIONNAIRES’ DISEASE PROGRAM .................................................................................................................................... 61

16.13 CHECKING THE OPERATING HISTORY ........................................................................................................................................... 62

16.14 CHECKING THE FAULT HISTORY ..................................................................................................................................................... 63

16.15 SETTING THE MAINTENANCE SPECIFICATIONS ........................................................................................................................... 64

16.15.1 MAINTENANCE SETTINGS ............................................................................................................................................................ 64

16.16 SETTING THE USER LOCK ................................................................................................................................................................ 67

16.17 SETTING THE PARAMETERS BY THE DISPLAY MENU ................................................................................................................. 68

16.18 FAULT CODES DISPLAY .................................................................................................................................................................... 76

16.18.1 LOCK-OUT CODES ......................................................................................................................................................................... 76

16.18.2 BLOCKING CODES ......................................................................................................................................................................... 78

16.18.3 IMPORTANT MESSAGE ................................................................................................................................................................. 80

17.0 CONTROLLING OPTIONS AND SETTINGS .......................................................................................................................................... 80

17.1 GENERAL............................................................................................................................................................................................. 80

17.1.1 EXTRA WATER HEATER CONTROL ............................................................................................................................................. 80

17.1.2 MAX COOLING TIME ...................................................................................................................................................................... 80

17.1.3 TEMPERATURE DISPLAY ON/OFF ............................................................................................................................................... 80

17.1.4 GAS TYPE SELECTION .................................................................................................................................................................. 80

17.1.5 SOFT START OPTION .................................................................................................................................................................... 81

17.1.6 PUMP MODE (EC TECHNOLOGY) ................................................................................................................................................ 81

17.2 WATER HEATER OPTIONS................................................................................................................................................................ 82

17.2.1 0-10 VDC REMOTE FLOW TEMPERATURE SET POINT ............................................................................................................. 82

17.2.2 ANTI-LEGIONNAIRES’ DISEASE (PASTEURISATION) FUNCTION ............................................................................................ 82

17.2.3 TANK SENSOR SENSITIVITY......................................................................................................................................................... 83

17.3 CASCADE CONTROL ......................................................................................................................................................................... 84

17.3.1 PARAMETER SETTINGS FOR CASCADED WATER HEATERS .................................................................................................. 84

17.3.2 MONITOR SCREENS ...................................................................................................................................................................... 86

17.3.3 OUTPUT CONTROL AND BURNER SEQUENCE .......................................................................................................................... 86

18.0 COMMISSIONING THE WATER HEATER ............................................................................................................................................. 87

18.1 FIRST: FLUSHING THE WATER HEATER WITH WATER ................................................................................................................ 87

18.2 SECOND: FILLING & VENTING THE WATER HEATER AND THE SYSTEM ................................................................................... 87

18.3 THIRD: CHECK THE WATER FLOW .................................................................................................................................................. 87

18.4 FLOW MONITORING ........................................................................................................................................................................... 88

19.0 STARTING THE WATER HEATER ......................................................................................................................................................... 89

5

19.1 GENERAL............................................................................................................................................................................................. 89

19.2 FIRING FOR THE FIRST TIME ........................................................................................................................................................... 90

20.0 ADJUSTING AND SETTING THE BURNERS ........................................................................................................................................ 91

20.1 INTRODUCTION .................................................................................................................................................................................. 91

20.1.1 ADJUSTMENT TABLES .................................................................................................................................................................. 91

20.1.2 ADJUSTMENT VALUES .................................................................................................................................................................. 91

20.1.3 PRE ADJUSTMENT SETTINGS FOR GAS VALVES ..................................................................................................................... 93

20.1.4 GAS VALVE SETTING SCREWS: DRAWING ................................................................................................................................ 93

20.1.5 HOW TO REMOVE AND MOUNT THE FLUE PLUG: .................................................................................................................... 94

20.1.6 ADJUSTMENT ACTIONS: GENERAL SCHEME ............................................................................................................................ 95

20.1.7 NOTE: CO2 MEASURING POSITION.............................................................................................................................................. 96

20.2 ADJUSTING IN CASE OF A NEW WATER HEATER, OR AFTER MAINTENANCE (CASE A) ........................................................ 96

20.2.1 GENERAL REMARK ........................................................................................................................................................................ 96

20.2.2 CHECKING AND ADJUSTING THE TOP BURNER ....................................................................................................................... 96

20.2.3 CHECKING AND ADJUSTING THE BOTTOM BURNER ............................................................................................................... 97

20.2.4 CHECKING BOTH BURNERS ......................................................................................................................................................... 97

20.3 ADJUSTING AFTER GAS VALVE REPLACEMENT OR IN CASE OF GAS CONVERSION (CASE B) ........................................... 98

20.3.1 GENERAL REMARKS ..................................................................................................................................................................... 98

20.3.2 CASE B ADJUSTMENTS ................................................................................................................................................................. 98

21.0 PUTTING THE WATER HEATER OUT OF OPERATION ...................................................................................................................... 99

22.0 FAULT CODES, BLOCKING CODES................................................................................................................................................... 100

22.1 FAULT CODES .................................................................................................................................................................................. 100

22.1.1 LOCK-OUT CODES: ...................................................................................................................................................................... 100

22.1.2 BLOCKING CODES ....................................................................................................................................................................... 108

22.1.3 MAINTENANCE ATTENTION MESSAGE ..................................................................................................................................... 112

23.0 MAINTENANCE ..................................................................................................................................................................................... 113

23.1 GENERAL........................................................................................................................................................................................... 113

23.2 MAINTENANCE REMINDER FUNCTION. ........................................................................................................................................ 113

23.3 SERVICE INTERVALS ....................................................................................................................................................................... 113

23.4 INSPECTION & MAINTENANCE ....................................................................................................................................................... 113

23.4.1 CUSTOMER COMMENTS ............................................................................................................................................................. 113

23.4.2 SERVICE HISTORY ....................................................................................................................................................................... 113

23.4.3 FLUE GAS & AIR SUPPLY ............................................................................................................................................................ 114

23.4.4 GAS SUPPLY & SAFETIES ........................................................................................................................................................... 114

23.4.5 REMOVE THE BURNER UNIT ...................................................................................................................................................... 114

23.4.6 BURNER......................................................................................................................................................................................... 114

23.4.7 IGNITION / IONISATION ELECTRODE ........................................................................................................................................ 114

23.4.8 BURNER DOOR GASKETS .......................................................................................................................................................... 114

23.5 MOUNTING THE BURNER DOOR CORRECTLY BACK ONTO THE HEAT EXCHANGER: ......................................................... 114

23.5.1 NON RETURN VALVE ................................................................................................................................................................... 115

23.5.2 FAN ................................................................................................................................................................................................. 115

23.5.3 INSULATION .................................................................................................................................................................................. 115

23.5.4 SIPHON .......................................................................................................................................................................................... 115

23.5.5 HEAT EXCHANGER AND BURNER ROOM ................................................................................................................................. 116

23.5.6 GAS/AIR RATIO ............................................................................................................................................................................. 116

23.5.7 PUMP ............................................................................................................................................................................................. 116

24.0 ErP DATA TABLE ................................................................................................................................................................................. 116

25.0 USER INSTRUCTIONS ......................................................................................................................................................................... 116

26.0 WARRANTY ........................................................................................................................................................................................... 116

6

1.0 INTRODUCTION

The Lochinvar TTW is a floor standing gas-fired condensing water heater. The equipment comprises of

two stainless steel radial burner assemblies and a heat exchanger that permits fully condensing

operation.

The burners are initiated by cascaded electronic ignition sequence controls that incorporate spark

ignition and flame rectification devices for supervision of the flame.

The output from the water heater is regulated by two variable speed combustion fans and gas/air ratio

controls to maintain correct combustion at all levels of modulation. This configuration allows modulation

down to 12.5% of the rated output.

For the correct operation of the water heater, it is essential that a suitably sized pump is utilised to

maintain a constant water flow rate through the heat exchanger.

This equipment is intended for use on Group H Natural Gas (2

nd

Family) and LPG propane (3rd Family).

The information relating to propane firing is to be found in Section 15.3.This equipment MUST NOT use

gas other than that for which it has been designed and adjusted.

This equipment must be installed by a competent person, registered with a H.S.E. approved body. All

installations must conform to the relevant Gas Safety and Building Regulations. Health & Safety

requirements must also be taken into account when installing any equipment. Failure to comply with

the above may lead to prosecution.

If the equipment is to be connected to an unvented (pressurised) system, care must be taken to ensure

all extra safety requirements are satisfied should a high or low-pressure condition occur in the system.

The equipment is designed for direct connection to a flue system.

1.1 ANCILLARY OPTIONS:

Matched primary pump LM900149A

Twin pipe balanced flue assemblies Refer to TT Flueing Specification Document*.

Conventional flue assembly Refer to TT Flueing Specification Document*.

Condensate neutralisation kit LM900002

* Visit www.lochinvar.ltd.uk for additional technical documentation

7

2.0 SAFETY GUIDELINES

READ AND UNDERSTAND THE INSTRUCTIONS

Read and fully understand all instructions before attempting to operate maintain or install the

unit.

Keep these instructions near the water heater for quick reference.

This equipment must be installed by a competent person, registered with the H.S.E. approved body. All

installations must conform to the relevant Gas Safety and Building Regulations. Health & Safety requirements

must also be taken into account when installing any equipment. Failure to comply with the above may lead to

prosecution

Without written approval of the manufacturer the internals of the water heater may not be changed. When

changes are executed without approval, the water heater certification becomes invalid.

Commissioning, maintenance and repair must be done by a skilled installer/engineer, according to all applicable

standards and regulations.

2.1 GENERAL DESCRIPTION OF SAFETY SYMBOLS USED

BANNED

A black symbol inside a red circle with a red diagonal indicates an action that should not be

performed

WARNING

A black symbol added to a yellow triangle with black edges indicates danger

ACTION REQUIRED

A white symbol inserted in a blue circle indicates an action that must be taken to avoid risk

ELECTRICAL HAZARD

Observe all signs placed next to the pictogram. The symbol indicates components of the unit and

actions described in this manual that could create an electrical hazard.

HOT SURFACES

The symbol indicates those components with a high surface temperature that could create a risk.

This symbol shows essential information which is not safety related

Recover or recycle material

8

2.2 WHAT TO DO IF YOU SMELL GAS

Warning if you smell gas

No naked flames, no smoking!

Avoid causing sparks, do not switch on or off electrical equipment or lights

Open windows and doors

Shut off the main gas supply

Warn occupants and leave the building

After leaving the building alert the local gas supply company

Do not re-enter the building until it is safe to do so

Lochinvar Limited is not liable for any damage caused by inaccurately following these installation

instructions. Only original parts may be used when carrying out any repair or service work.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their

safety. Children should be supervised to ensure that they do not play with the appliance.

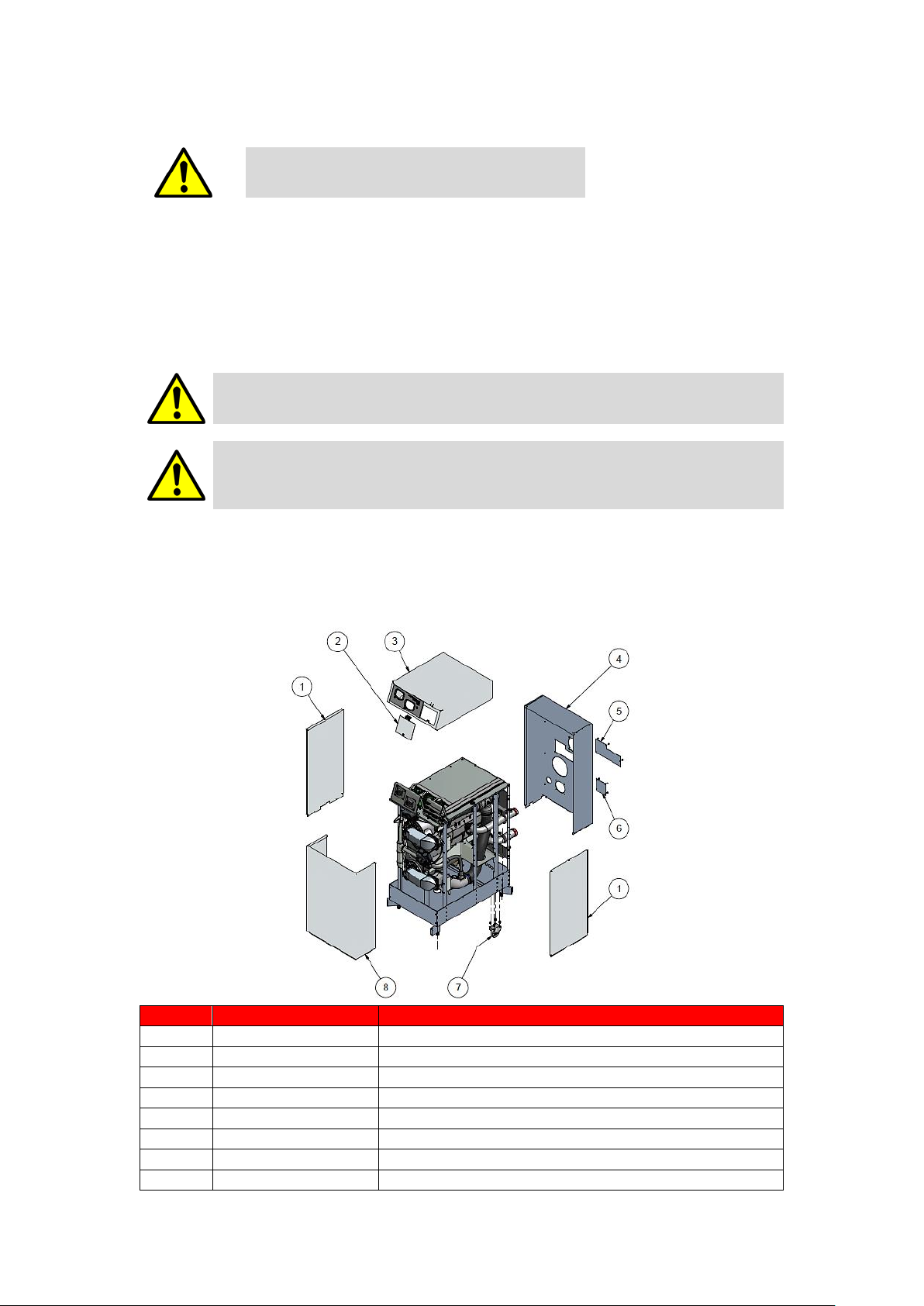

3.0 PRINCIPLE PARTS

3.1 CASING

No

Item No

Description 1 E01-000-124

SIDE PANEL 2 S01-000-337

ELECTRICAL COVER

3

S01-000-380

TOP COVER

4

E01-002-114

REAR COVER

5

E01-002-128

COVER UPPER LIMIT SWITCH

6

E01-002-129

COVER LOWER LIMIT SWITCH

7

S04-000-307

WHEEL ASSEMBLY

8

E01-000-215

FRONT PANEL

9

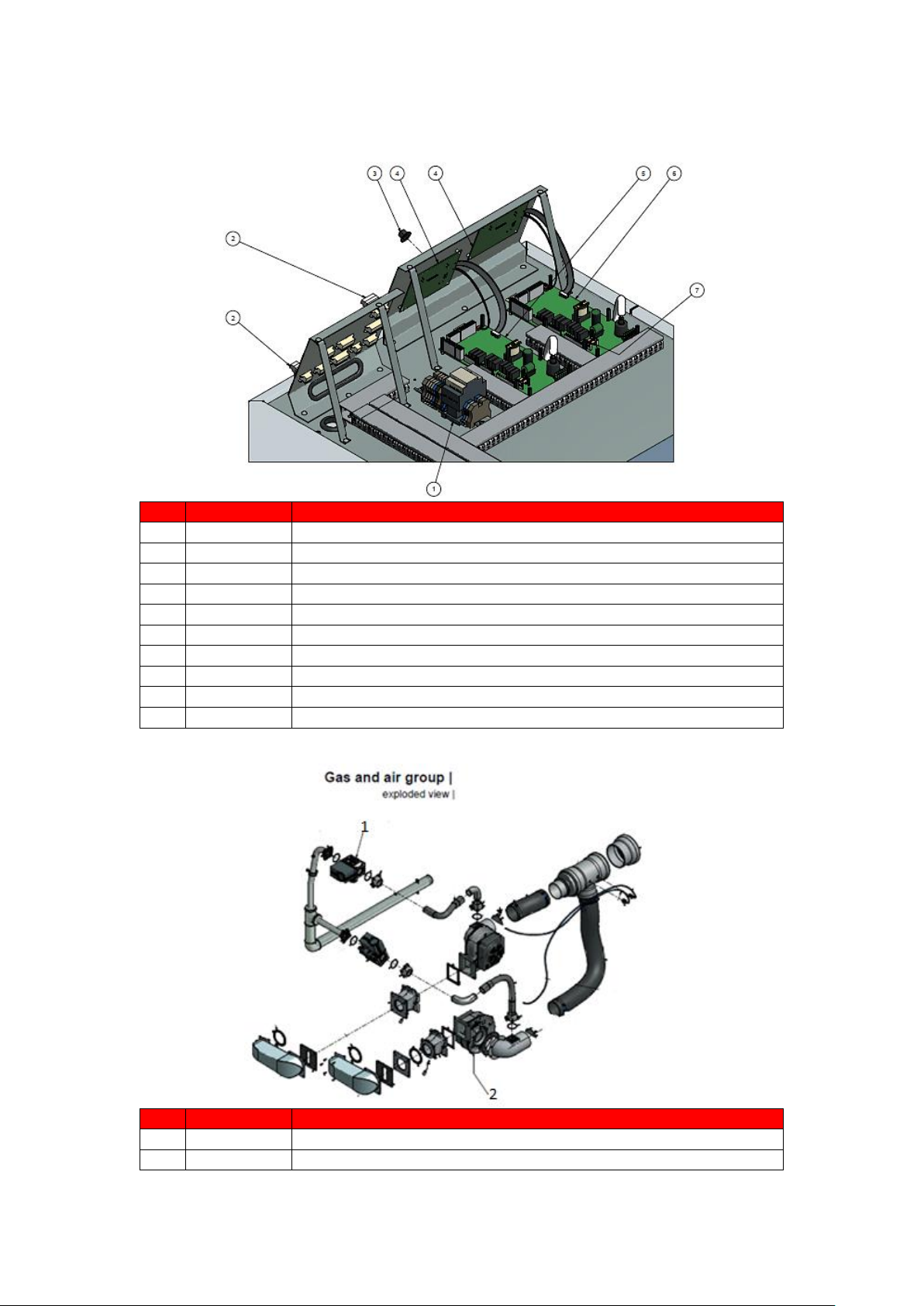

3.2 ELECTRICAL

No

Item No

Description

1

E04-016-425

RELAY LC1D09

2

E04-016-291

CONNECTOR PLUG 2 POLE

2

E04-016-292

CONNECTOR PLUG 3 POLE

2

E04-016-293

CONNECTOR PLUG 4 POLE

2

E04-016-295

CONNECTOR PLUG 6 POLE

3

E05-001-062

RUBBER PLUG 15mm

4

S04-000-310

REPLACEMENT KIT DISPLAY

5 WATER HEATER CONTROL SLAVE-STATE TYPE AND SERIAL NO

6 WATER HEATER CONTROL MASTER-STATE TYPE AND SERIAL NO

7

S04-016-582

FUSE SET x10

3.3 GAS TRAIN AND AIR INLET

No

Item No

Description

1

S04-000-199

GAS VALVE

2

S04-000-200

COMBUSTION FAN

10

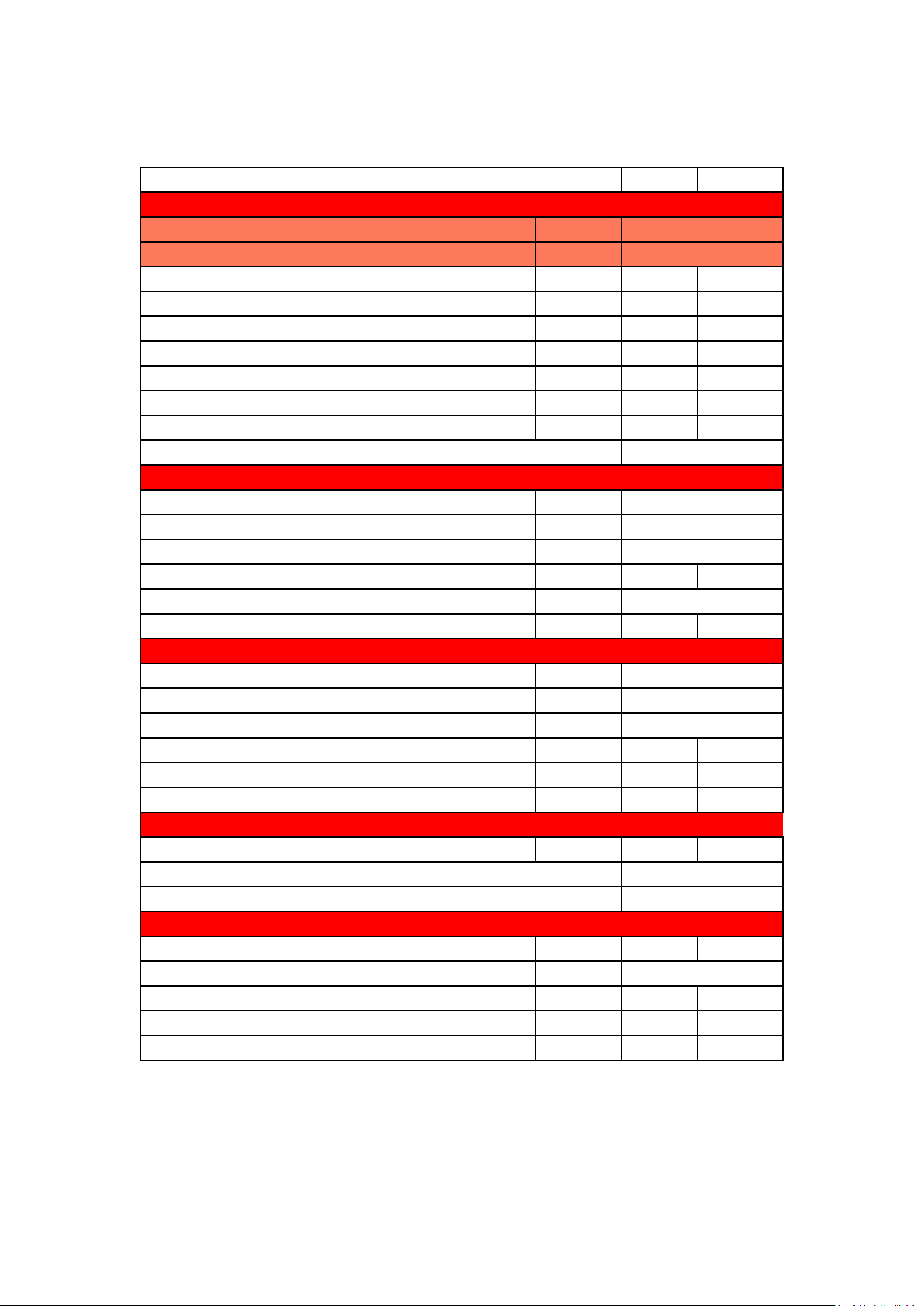

4.0 TECHNICAL DATA

Model Number

TTW410

TTW580

GENERAL DATA

Product I.D. Number

CE 0063BS3806

Classification II2H3B/P

Input (gross) min-max

kW

55.4 - 444

75.5 - 611

Input (net) min-max

kW

50 - 400

68 - 550

Recovery Rate (44° ΔT)

l/hr

8168

11263

Recovery Rate (50° ΔT)

l/hr

7188

9912

Heat generator seasonal efficiency

%

95.4

95.9

Shipping Weight

kg

400

450

NOX

mg/kWh

44

41

NOX Class

6

GAS DATA G20

Nominal gas inlet pressure

mbar

20

Maximum gas inlet pressure

mbar

25

Minimum gas inlet pressure

mbar

17.5

Gas flow rate – m3/hr

m3/hr

5.3 - 42.3

7.2 - 58.2

Flue gas mass rate (@ 9.0% CO2)

g/sec

24.1 - 207.8

Gas inlet connection size

“ BSP 2 2

GAS DATA G31

Nominal gas inlet pressure

mbar

37

Maximum gas inlet pressure

mbar

45

Minimum gas inlet pressure

mbar

27

Gas flow rate – m3/hr

m3/hr

16.8

23

Flue gas mass rate (@ 9.0% CO2)

g/sec

193

265

Gas inlet connection size

“ BSP 2 2

ELECTRICAL DATA

Power consumption

W

752

829

Power supply

Single phase 230v/50Hz

Protection class

IPX0B

WATER DATA

Water content

litres

30

43

Water connections (F & R)

“ BSP

2 ½

Max. water pressure

bar 8 8

Min. water pressure

bar 1 1

Maximum water temperature

°C

70

70

4.1.1 TECHNICAL DATA

11

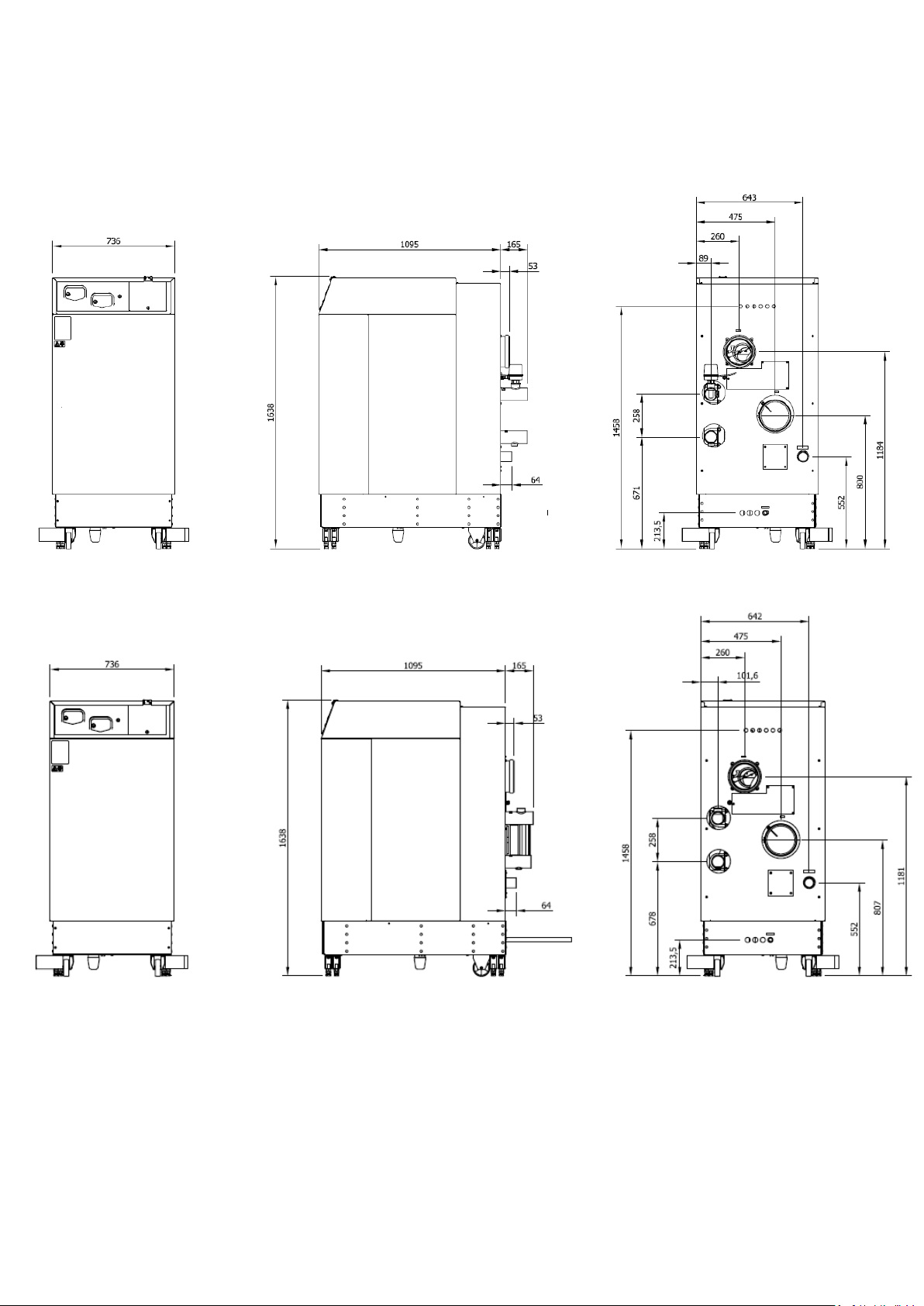

5.0 DIMENSIONS AND CLEARANCE

5.1 DIMENSIONS

5.1.1 DIMENSIONS TTW410

5.1.2 DIMENSIONS TTW580

Minimum Side Clearance of 500mm (Advised 1000mm)

Minimum Front Clearance of 800mm

Minimum Rear Clearance of 500mm

5.1.3 MINIMUM CLEARANCES

12

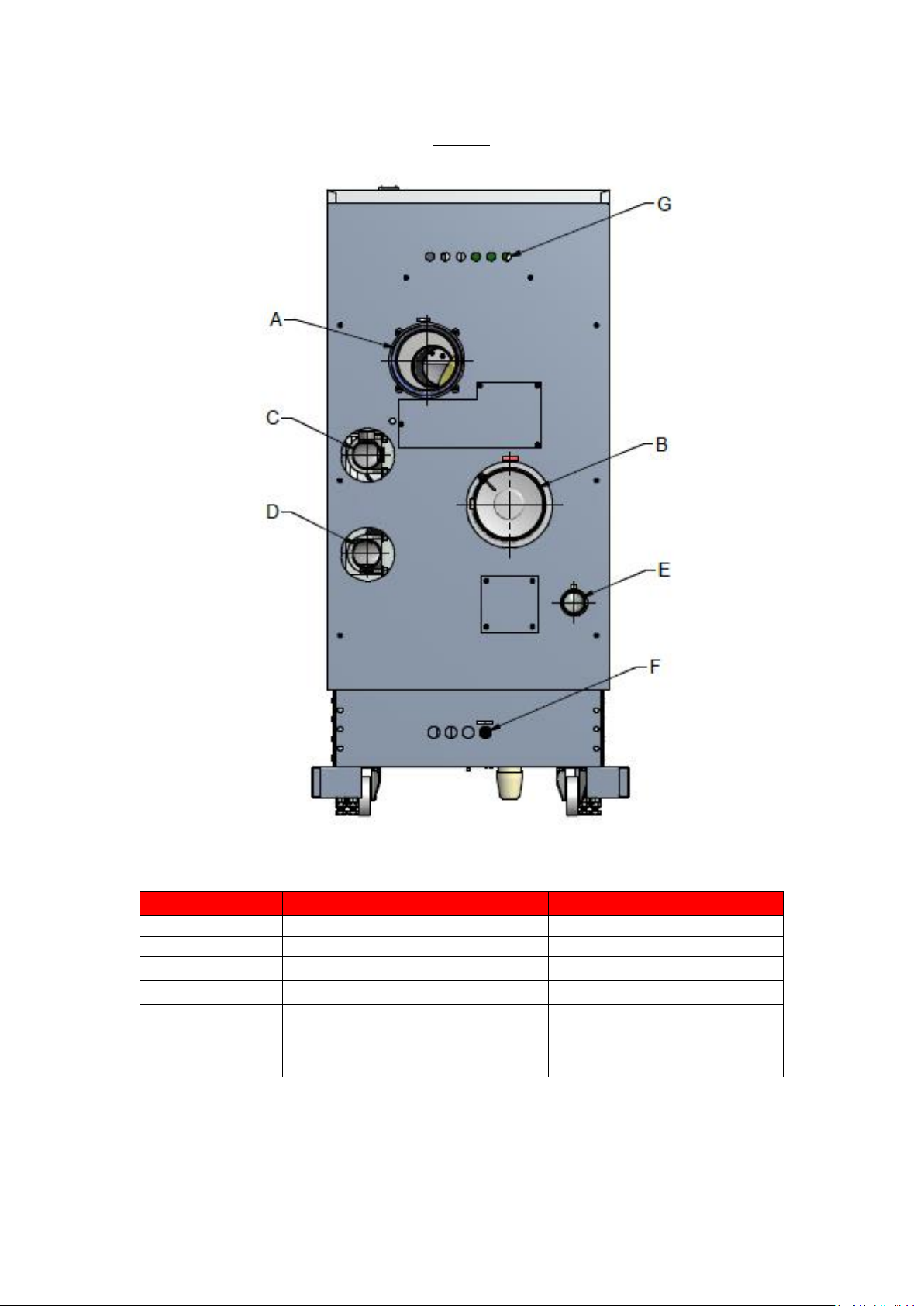

5.2 WATER HEATER CONNECTIONS

Rear view

5.2.1 WATER HEATER CONNECTIONS

Connection

Function

Diameter (inch/mm)

A

combustion air inlet

Ø 180 mm

B

flue outlet

Ø 180 mm

C

water flow (outlet)

R 2½ "

D

water return (inlet)

R 2½ "

E

gas connection

R 2 ”

F

condensate discharge hose

Ø 25 mm outer diameter

G

cable input

Ø 22.5 mm

5.2.2 CONNECTIONS AND CONNECTION SIZES

13

5.3 CONDENSATE DRAIN CONNECTION

The condensate drain is placed at the centre and at the bottom of the water heater and has a ¾ inch hose discharge.

Connect this flexible hose to a suitable drain point.

Use only plastic parts with the condensate drain.

Blockage of this drain may damage the water heater. The drain connection is correct when the condensate can be

seen flowing away.

Any damage caused by incorrectly installing the condensate drain WILL not be covered by

warranty.

There should be an open connection of the condensate hose into the drain. A possible under pressure in the

drainage system must never be allowed to cause drain water to pull into the water heater.

When mounting the bottom part of the siphon, before commissioning the water heater and/or

after maintenance, the siphon must ALWAYS be completely filled with water.

This is a safety measure: the water in the siphon keeps the flue gases from entering the plant

room by leaving the heat exchanger via the condensate drain.

FIGURE 3.2 CONDENSATION SIPHON

Turn LEFT to open

Turn RIGHT to close

Fill with water

to the edge

14

6.0 GENERAL REQUIREMENTS

The Lochinvar TTW comes with the following documents and accessories:

An installation, commissioning and maintenance instruction guide for the installer.

3 spare fuses and 3 spare nuts for the installation of the burner plate (this is attached to the front of the gas

valve).

Spare flue gas plugs

One gas conversion sticker

One Torx key T40

One allen key no. 3

Bottom part of Siphon

Lochinvar will supply a suitable shunt pump with every TTW water heater, this must be

installed with the TTW to maintain the correct flow

On delivery, immediately check that the water heater is complete and without any defects. Report any damage

immediately to Lochinvar Limited.

The Lochinvar TTW has been designed to operate trouble free for many years. These instructions should be

followed closely to obtain the maximum usage and efficiency of the equipment. PLEASE read the instructions fully

before installing or using the appliance.

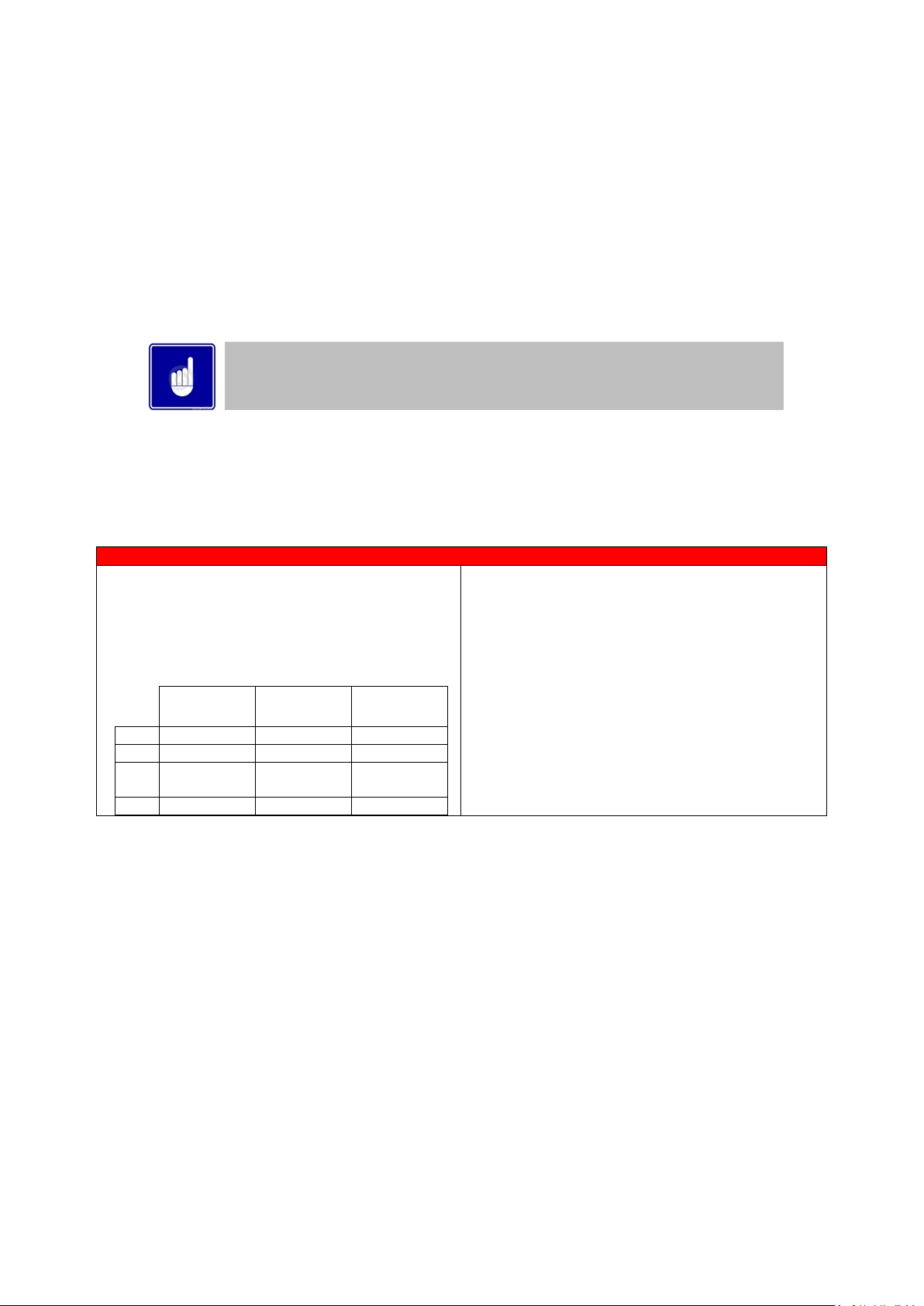

NOTES

1

All water heaters are supplied as twin pipe model.

2

Using propane, butane and B/P, maximum fan speed

needs to be reduced (parameter P4BD)

3

Below a table is given in which the min. and max. gas

supply pressures are listed according to EN437:

p nominal

[mbar]

p min

[mbar]

p max

[mbar]

G25

25

20

30

G20

20

17

25

G31

30

25

35 37

25

45

G30

50

43

57

4

Emissions measured during unit certification.

5

Maximum combined resistance of flue gas and air

supply piping at high fire.

6

230 Vac is necessary for the water heater to function.

If a 400 Vac water heater pump is applied, 400 Vac

must be connected to the appliance so the power

supply for the pump can be delivered by the system.

(An optional safety switch for the pump motor must be

added externally).

15

6.1 RELATED DOCUMENTS

It is law that all gas appliances are installed by competent persons, in accordance with The Gas Safety (Installation

and Use) Regulations 1998. Failure to install appliances correctly could lead to prosecution. It is in your own

interest, and that of safety, to ensure that this law is complied with.

The installation of the equipment MUST be in accordance with the relevant requirements of the Gas Safety

Regulations, Building Regulations, I.E.E. Regulations and the bylaws of the local water undertaking. The installation

should also be in accordance with any relevant requirements of the local gas distributor and local authority.

In addition the installation should follow the relevant guidance offered in the following documents. It is not

practical to list all relevant information but emphasis is placed on the following documents, as failure to comply

with the guidance given will almost certainly result in an unsatisfactory installation:

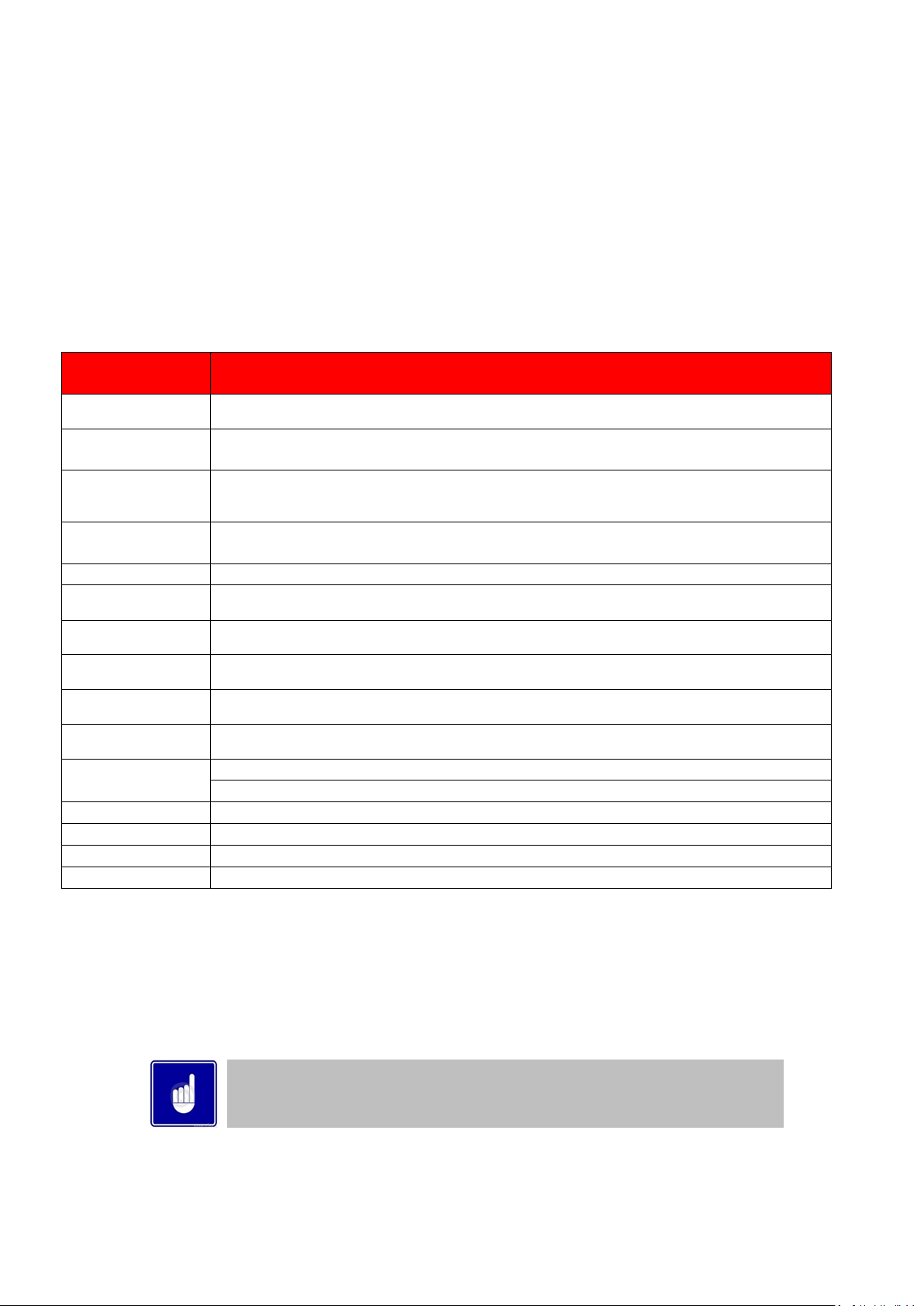

Regulation

Description

BS EN 1858: 2008 +

A1: 2011

Chimneys, Components. Concrete flue blocks.

BS 5440-1: 2008

Flueing and ventilation for gas appliances of rated input not exceeding 70 kW net (1st, 2nd and 3rd family

gases). Specification for installation of gas appliances to chimneys and for maintenance of chimneys.

BS 5440-2: 2009

Installation and maintenance of flues and ventilation for gas appliances of rated input not exceeding 70

kW net (1st, 2nd and 3rd family gases). Specification for installation and maintenance of ventilation for gas

appliances.

BS 6644: 2011

Specification for Installation of gas-fired hot water Heaters of rated inputs between 70 kW (net) and 1.8

MW (net) (2nd and 3rd family gases).

BS EN 806 1-5

Specifications for installations inside buildings conveying water for human consumption.

BS 7671 :2008 +

A3:2015

Code of practice for low temperature hot water systems of output greater than 45 kW.

BS 7074: 1989 Parts 1

and 2

Application, selection and installation of expansion vessels and ancillary equipment for sealed systems.

BS 7671: 2008 + A1:

2011

Requirements for electrical installations, I.E.E. wiring regulations seventeenth edition.

BS 7671: Amendment

2: August 2013

BS EN

12828:2012+A1:2014

Heating systems in buildings. Design for water-based heating systems.

CP 342 (Part 2 1974):

Code of practice for centralised hot water supply-buildings other than dwellings.

Institute of Gas Engineers and Managers (IGEM) Publications

IGE/UP/1 - Edition 2:

Installation pipework on industrial and commercial premises.

IGE/UP/2 – Edition 3

Gas installation pipework, boosters and compressors on industrial and commercial premises.

IGE/UP/4 - Edition 4

Commissioning of gas-fired plant on industrial and commercial premises.

IGE/UP/10 - Edition 4

Installation of flued gas appliances in industrial and commercial premises.

Gas Safety (Installation and Use) Regulations 1998 (England, Scotland & Wales)

CIBSE: Guide parts A, B and C

H.S.E. guidance Automatically controlled steam and hot water heaters note PM5:

Third edition of the 1956 Clean Air Act Memorandum on Chimney Heights

Manufacturer's notes must not be taken in any way as overriding statutory obligations.

16

7.0 WATER QUALITY

7.1 WATER CHEMISTRY

Water supply quality may adversely affect the efficiency performance and longevity of Water Heaters and Hot

Water systems. Hard water may cause the formation of limescale that will reduce operating efficiency and may

cause early product failure. Please note the following: -

Maximum allowed water hardness is 205 PPM or 205 mg/L CaCO3 (= 11.5°dH)

TDS (total dissolved solids) may not exceed 350 PPM

Water hardness and TDS together may not exceed 350 PPM

The pH value of the water may not be under 6.5 and not above 7.5 (measured cold)

If TDS alone or the combined value is higher than the abovementioned, the water should be heated by

means of an indirect water-heating appliance.

Minimum water hardness = 80 PPM or 80 mg/L CaCO3 (= 4.5°dH)

Minimum TDS = 100 PPM

Water that is under these minimum values normally has a pH value, which is aggressive and corrosive.

If these values are exceeded a water treatment specialist should be consulted. Water

Softeners and Water Conditioners may be considered, but whichever method is selected, it

should be suitable for installation with Direct Gas-fired Water Heaters. A maintenance

regime will also be required for such systems

The formation of limescale or other solids can cause a blockage within the heat exchanger,

which in turn may cause premature failure. Such instances are not regarded as defects in

manufacture and will not be covered under the product warranty

8.0 LOCATION

8.1 PLANT ROOM REQUIREMENTS

The Lochinvar TTW condensing water heater can only be installed in a room that complies with the appropriate

ventilation requirements.

The Lochinvar TTW can be used as a type C13, C33, C

43, C53,

or C83 appliance. Due to its room sealed design, ventilation

allowances for combustion air are not necessary; ventilation for cooling purposes however, must be fitted. For

further guidance, please refer to Section 9: AIR SUPPLY or to BS6644.

The Lochinvar TTW can also be used as a type B23 appliance. If such a configuration is to be used, then appropriate

ventilation for cooling and combustion must be provided. For further details, please refer to Section 9: AIR SUPPLY

or to BS6644.

8.2 GENERAL REQUIREMENTS

Corrosion of the heat exchanger and vent system may occur if air for combustion contains certain chemical

vapours. Such corrosion may result in poor combustion and create a risk of asphyxiation. Aerosol propellants,

cleaning solvents, refrigerator and air conditioning refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes and process chemicals are corrosive. Products of this sort should not be stored near the water

heater or outside by the air intake (if applicable). The fitting of this equipment in a situation where aerosols or

other chemicals may be entrained into the combustion air will invalidate the warranty.

The equipment must be installed on a level, non-combustible surface that is capable of adequately supporting its

weight (when filled with water) and any ancillary equipment. The operation of the equipment must not cause the

temperature of any combustible material in the vicinity of the equipment and its flue to exceed 65°C. If such a

situation is unavoidable, appropriate insulation should be provided.

Locate the equipment so that if the appliance or any connecting pipework should leak, water

damage will not occur. When such locations cannot be avoided, it is recommended that a suitable

drain pan be installed under the equipment. The pan should be adequately drained but must not

restrict the combustion or ventilation airflow.

17

8.3 UNPACKING AND LEVELLING THE WATER HEATER

The water heater is mounted on a pallet with a wooden support frame around it. The water heater is wrapped in

shrink wrap before the wooden support frame is mounted. After the frame is placed the whole pallet, water heater

and frame package is shrink wrapped again. Only remove the outer packaging once the water heater has been

positioned as close as possible to the place where it will be installed. After removing the wrapping and frame the

water heater can be taken off the pallet using a fork-lift truck or suitable lifting device. The water heater is fixed to

the pallet with screws; make sure these are removed before attempting to lift the water heater from the pallet.

Once the water heater is in its final position, the inner packaging can be removed.

The water heater will now be stood on 4 adjustment bolts; ensure the water heater is level in both directions by

using these 4 bolts. There are also four legs under the appliance that can be turned outward if a positive fixing to

the floor structure is required.

8.4 CLEARANCES

The location chosen for the equipment must permit the provision for a satisfactory flue system and, where

necessary, an adequate air supply. The location must also provide adequate space for servicing and air circulation

around each unit. This includes any electrical trunking laid across the floor and to the appliance.

See 5.1.3 for dimensions/clearances. Further details regarding locations are given in BS6644.

18

9.0 GAS SUPPLY

The Lochinvar TTW is suitable for use on second and third family gasses 2H - G20 - 20mbar and 3P - G31 - 37mbar.

Details relating to Natural Gas (2H) appear below; for details relating to Propane (3P) please refer to Section 17.1.4

GAS TYPE SELECTION.

9.1 SERVICE PIPES

The local gas distributor must be consulted at the installation planning stage in order to establish the availability

of an adequate supply of gas. An existing service pipe must not be used without prior consultation with the local

gas distributor.

9.2 METERS

The local gas distributor contractor will connect a new gas meter to the service pipe. An existing gas meter should

be checked, preferably by the gas distributor, to ensure that it is adequate to deal with the rate of gas supply

required.

9.3 GAS SUPPLY PIPES

Supply pipes must be fitted in accordance with IGE/UP/2. Pipework from the meter to the equipment must be of

adequate size. The complete installation must be purged and tested as described in IGE/UP/1. Refer to Section

17.1.4 GAS TYPE SELECTION for information on LPG installation guidance.

9.4 BOOSTED SUPPLIES

Where it is necessary to employ a gas pressure booster, the controls must include a low-pressure cut-off switch at

the booster inlet. The local gas distributor must be consulted before a gas pressure booster is fitted. For details

of how to connect a low-pressure cut-off switch, please refer to Section 15.0: ELECTRICAL INSTALLATION.

9.5 PLANT-ROOM CONTROL VALVE

A manual valve for plant-room isolation must be fitted in the gas supply line. It must be clearly identified and

readily accessible for operation, preferably by an exit.

9.6 EQUIPMENT GAS SYSTEM LEAK CHECK

An approved isolating valve and union should be installed for each unit in a convenient and

safe position and be clearly marked.

Ensure that the manual gas service valve is in the OFF position. Although the equipment receives a gas leak check

and gas train component integrity check prior to leaving the factory, transit and installation may cause disturbance

to unions, fittings and components. During commissioning, a further test for tightness should be carried out on

the equipment gas pipework and components.

Care must be taken not to allow leak detection fluid on or near any electrical parts or

connections.

19

10.0 FLUE SYSTEM

All versions of the TTW Condensing water heater can be installed as either type B23 (fan assisted open flue) C53

(room sealed) C63 (Flue not supplied by the appliance manufacturer) appliances. Only B23,C53 Flue systems are

covered in any detail within this document, further information can be found in the TTW Flue assemblies and

ancillaries guide available at www.lochinvar.ltd.uk See the relevant section for details of each flue type and

requirements.

10.1 FLUE SYSTEM GENERAL REQUIREMENTS

Install the horizontal flue components with an angle of 3° back in the direction of the water

heater (roughly equal to five centimetres for every linear meter). Failure to install the flue

correctly will result in a build-up of condense within the flue pipework that will cause early

component failure.

When using a wall terminal, there is the possible risk of ice building-up on surrounding

parts/structures, because the condensate will freeze. This risk should be taken into account

during the design phase of the heating installation.

TTW Water heaters will produce large condense clouds especially during cold weather,

consideration must be taken as to whether this will cause a nuisance to neighbouring properties

and if so alternative flue arrangements used.

TTW Water heaters can operate with very low flue temperatures; as such the flue system used

must be suitable for use with condensing appliances made from either Polypropylene or

stainless steel and have a temperature class of T120.

Aluminium flue pipe must not be used on this appliance as it may lead to premature failure of

the heat exchanger and will invalidate the warranty.

Before installation of any flue system read the installation manual carefully for both the

appliance and flue system to be used. Information on the flue system Supplied by Lochinvar can

be found within this manual.

MODEL NUMBER

TTW410

TTW580

FLUE DATA

Appliance category

B23, C13, C33, C43, C53, C83

Nominal flue diameter – mm

180

180

Maximum flue gas temp. – °C

90

90

20

10.2 FLUE TERMINAL POSITION

Any flue termination must be in such a position as will not cause a hazard to the health of persons who may be

nearby or a nuisance to other persons beyond the curtilage. The flue terminal must be positioned externally such

as to allow the dispersal of products of combustion and air intake. The terminal should be installed in a location

where it will not easily flood or be blocked by snow. Under certain operating and weather conditions, the TTW

may generate a plume at the terminal. Consideration should be given to the nuisance this may cause and the

terminal should be sited accordingly.

The flue terminal position is very important and must be in accordance with the recommendations found in BS6644

or IGE/UP/10. Once the terminal position has been determined the appropriate local authority should be advised

of the proposed installation. It is important that the appropriate local authority is consulted at an early stage in

the design in order to establish that the proposed flue discharge positions are acceptable and will not cause

significant local exceedances of air quality objectives.

Where agreement is reached with the local authority, this should be recorded in a reproducible format as

competent people involved at the latter stages of the project (i.e. the commissioning engineer) will ask for proof

before allowing products of combustion to be discharged in an apparently non-compliant position.

10.3 FLUE GAS AND AIR SUPPLY SYSTEM

The overall resistance of the air supply and exhaust ducts must not create a pressure drop exceeding 200 Pa. The

output of the water heater is influenced by the resistance of the air supply and discharge system therefore all flue

gas and air supply systems must be carefully considered or referred to a specialist flue design company.

Details of air inlet and exhaust locations and sizes can be found in 4.0 TECHNICAL DATA.

10.4 APPROVED FLUE SYSTEM

When used as a type C appliance, the approved, purpose designed adaptive flue system should be used. For further

details, please contact Lochinvar Limited.

When used as a Type B appliance, a suitable flue system constructed of Stainless Steel or Polypropylene with a

temperature rating in excess of 120C should be used.

10.5 INSTALLATION PRECAUTIONS

The water heater must not be operated unless the complete flue system is installed. This

includes the water heater connections, flue pipes, air ducts (if required) and terminals.

Due to the condensing nature of the water heater, long external runs should be avoided to

prevent the condensate freezing within the flue system.

During assembly, precaution should be taken to ensure that any sealing ring is seated

correctly

Due to the close tolerances in the flue system, it may be necessary to use a twisting action

to fit the joints together. No lubrication other than water should be used.

21

10.6 WATER HEATER CATEGORIES - TYPES OF FLUE GAS SYSTEMS.

Type according EN 15502-2-1: 2012

Performance

Description

B23(P)

Open

Air supply from

room

* Roof terminal

* Without draught diverter

* Water heater room air supply.

* P = overpressure systems

Be aware: The installation room has to have sufficient air

supply vents. These vents must be open and

may not be closed or blocked.

Requirements at NEN 3028 paragraph 6.5

Use table 10.11 to select the correct flue items.

C53 Closed

Air supply from

outside

*Separate air supply duct

*Separate flue gas discharge duct.

* Air supply inlet and flue gas outlet at different air

pressure zones. But not at opposite walls.

Use table 10.9 to select the correct flue items

Flue

Outlet

Air

Inlet

Flue

outlet

Air

inlet

Vented

area

22

C63 Closed

Air supply from

outside

* Appliance sold without flue/air-inlet ducts

* The flue gas parts are not part of the water heater. The

water heater is intended to be connected to a separately

approved and marketed system for the supply of

combustion air and discharge of combustion products.

Condensate is allowed to go to the water heater.

* Air supply inlet and flue gas outlet not at opposite walls

* Technical data:

nominal T

flue gas

85°C

nominal Q

fluegas

see 2.2

1)

maximum T

fluegas

95°C

min. load T

fluegas

35°C

min. load Q

fluegas

see 2.21)

nominal % CO2

see 2.21)

max. allowed draft

70Pa

max. pressure drop inlet-

outlet

200Pa

max T

air supply

40°C

max recirculation

10%

1) table technical specifications

See chapter: Accessories

- Fluegas and air supply parts

Flue outlet

Air inlet

23

10.7 TYPE C

63

CERTIFIED

In general, water heaters are certified with their own flue gas material. For type B23(P), C13, C33, C43, C53 and

C83 systems, only use flue gas and air supply parts approved for use with the appliance.

If a heater is C63 certified, no specific type flue gas material has been certified in combination with the water

heater. In this case the flue gas and air supply parts should comply with the applicable European standards

(EN14989).

So, for type C63 systems flue gas and air supply parts from other suppliers can be used. It must be able to handle

the condensate forming (W) and transport, overpressure (P1) and must have a minimum temperature class of

T120. Also, it has to meet the requirements in the following chapters "air supply" and "flue terminal".

CE string

flue gas

material

European standard

Temperature

class

Pressure class Resistance to

condensate

Corrosion

resistance class Metal: liner

specifications

Soot fire resis-tance class

Distance to

combustible

material

Plastics:

location Plastics: fire

behaviour

Plastics:

enclosure

min. req. PP

EN 14471

T120

P1 W 1 O

30

I of E

C/E

L

min. req. SS

EN 1856-1

T120

P1 W 1

L20040

O

40

A few examples of flue gas material suitable for TTB water heaters:

CE String for Plastic PPs: EN14471 T120 P1 W 2 O(30) I C/E L

CE String for Stainless Steel: EN1856-1 T250 P1 W V2-L50040 O (50)

When selecting flue gas systems, be aware that the minimum requirements are met. So only select flue gas

materials having the same or better properties than this table.

Never use aluminium containing flue gas pipes in these water heaters.

Connecting diameters and tolerances:

mat d

nom

D

outside

L

insert

d

inside

L

insert

d

wall thickness

RVS 180

180 ± 0,3

50 ± 1

181,2 ± 0,3

50 +0/ -2

0,6 ± 10%

RVS 200

200 ± 0,3

50 ± 1

201,2 ± 0,3

50 +0/ -2

0,6 ± 10%

PP 200

200 +1/ -0,6

50 +20/ -2

202 +0,6/ -1

50 +20/ -2

≥ 3,5

Multiple water heaters can be connected to a common duct. These flue gas systems for multiple water heater

installations must always be engineered as zero or negative pressure systems; so as to prevent the risk of

recirculation of the flue gases. Consult the flue gas supplier for detailed information and engineering.

If the combustion air is taken from the water heater room, the inlet air must be clean and free of water. Always

use a wire mesh to prevent debris being drawn into the air inlet

10.8 TTW AIR INLET / FLUE GAS OUTLET CALCULATION EXAMPLES

The load of the water heater is influenced by the resistance of the air supply and the discharge system. The

diameter and length of both air supply and flue gas pipes needs to be designed accurately to decrease the possible

power loss of the water heater.

Calculation examples

In the following, two calculation examples are given for determining the maximum length of the flue gas and air

supply pipes.

A: Twin pipe system with separate pipes for flue gas and air supply.

Air supply roof mounted.

B: Single pipe system for flue gas outlet only.

Air supply from water heater room.

24

10.9 TYPE C

53

(TWIN PIPE) FLUE SYSTEMS

Flue system specifications

MANUFACTURER MUELINK AND GROL (M&G)

TEMPERATURE CLASS T120

FLUE GAS MATERIAL PP

Each Twin-Pipe starter assembly includes the items shown in the tables below

TWIN-PIPE FLUE ASSEMBLY MODELS

TTW410,TTW580

COMPONENTS REQUIRED TO START INSTALLATION

VERTICAL FLUE

M70439

VERTICAL TERMINAL Ø200mm

1

LE400092

INCREASER Ø180mm TO Ø200mm FOR AIR INLET ONLY

1

LE400093

ECCENTRIC INCREASER Ø180mm - Ø200mm FOR EXHAUST

1

LE400096

VERTICAL TERMINALØ200mm (AIR INLET) - PP

1

Additional Flue Ancillary Items

Item No.

Description

Dimensions

LV310696

EXTENSION Ø200mm PP

500mm

M70402

EXTENSION Ø200mm PP

1000mm

M70404

EXTENSION Ø200mm PP

2000mm

M70411

ELBOW 90° Ø200mm PP

n/a

M70412

BEND 45° Ø200mm PP

n/a

LV310677

T PIECE WITH CONDENSATE CONNECTOR Ø200mm PP

n/a

M87198

WALL CLAMP Ø200mm

n/a

Do not reduce the pipe diameter relative to the water heater connection

25

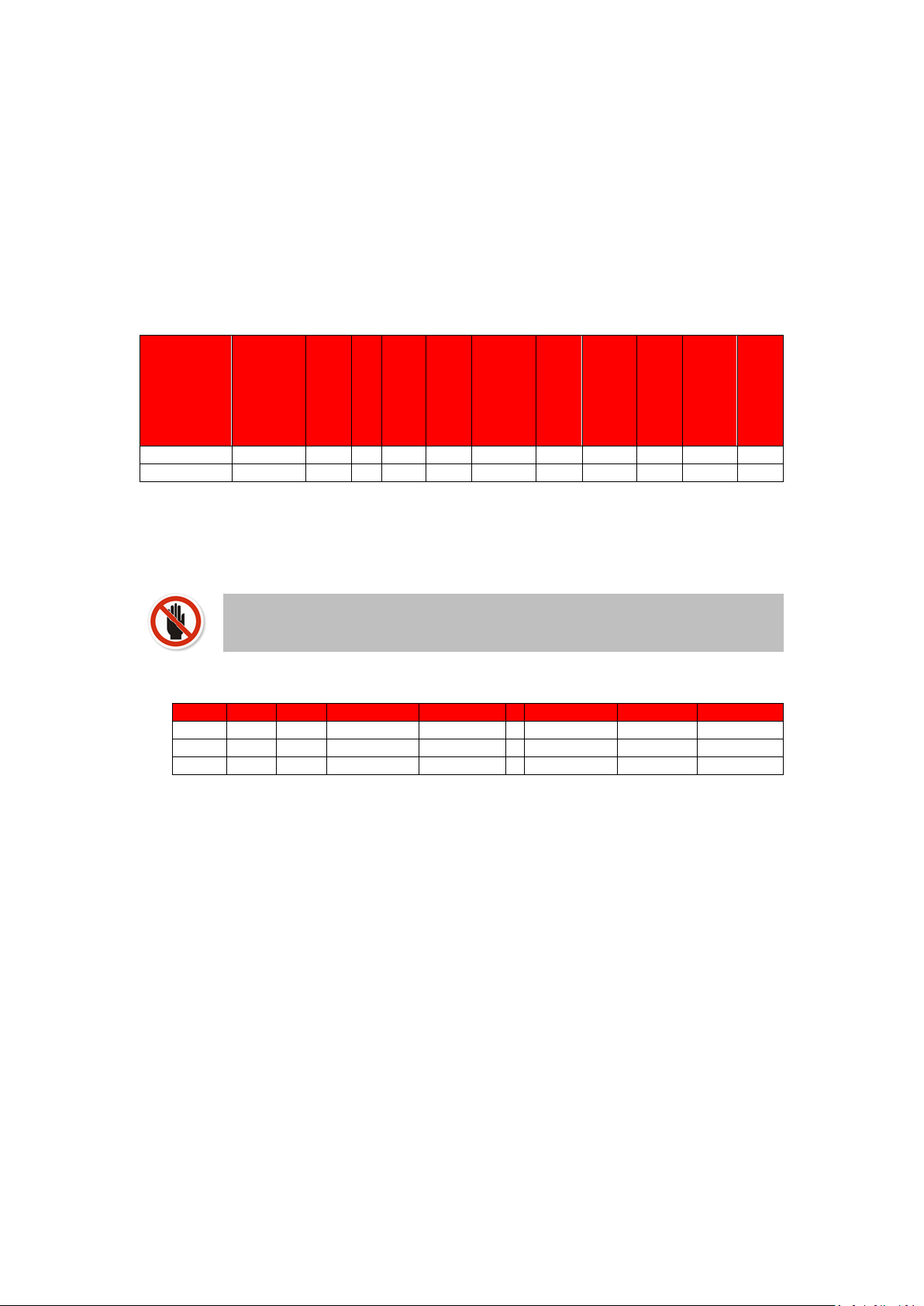

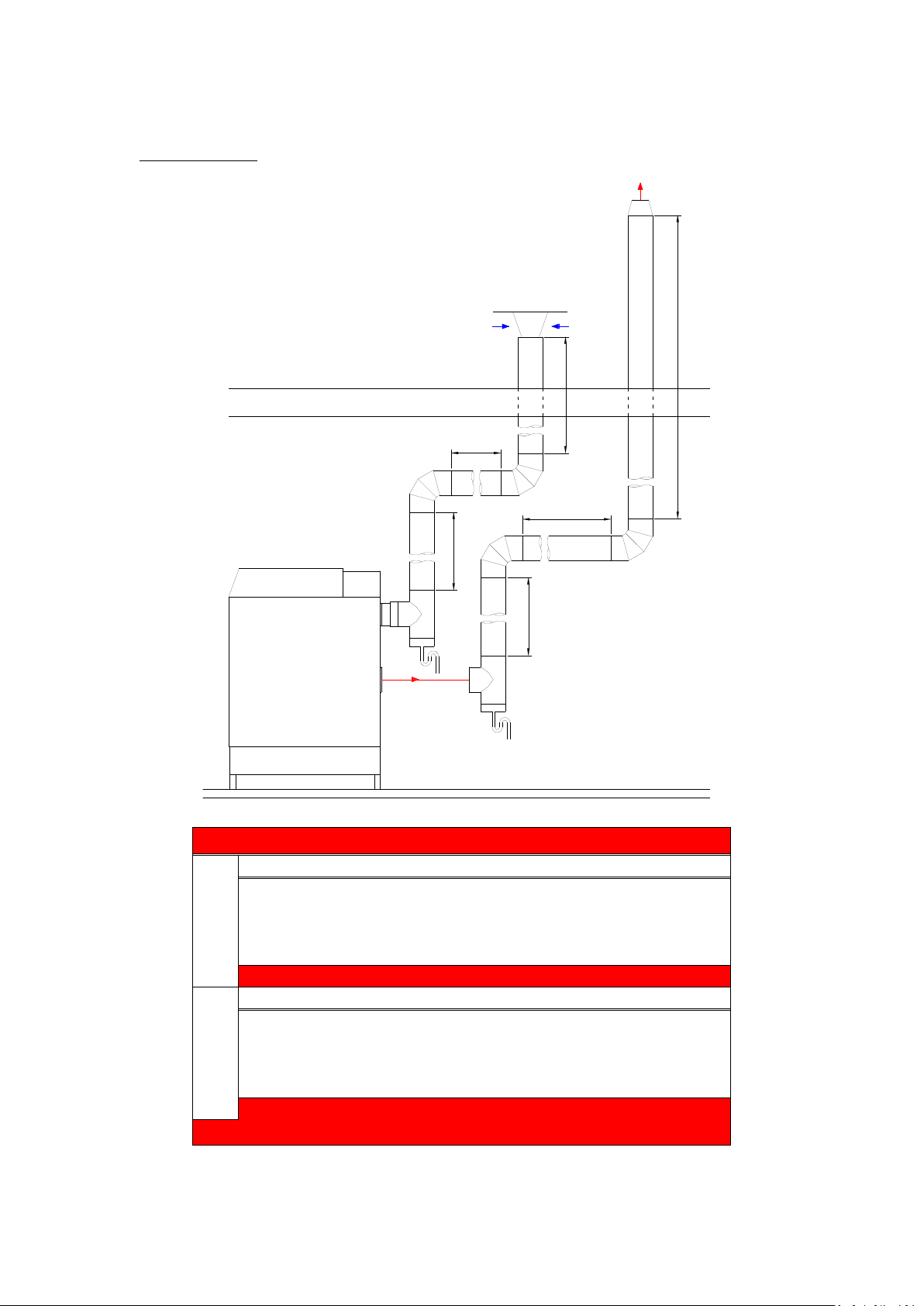

10.9.1 EXAMPLE A: TWIN PIPE SYSTEM

Calculation example:

The total resistance is less than 200 Pa, so this is acceptable.

Water heater type:

TTW410

Flue gas

Diameter: 200 mm.

Number

Pa

Pa total

Straight tube m¹

total

13

1,8

23,4

T-piece

outlet 1 16,7

16,7

Bend

90° 2 6,5

13

Flue outlet

Zeta=0,05

1

0,9

0,9

Total resistance flue gas outlet:

54,0

Air supply

Diameter: 200 mm.

Number

Pa

Pa total

Straight tube m¹

total 7 1,3

9,1

T-piece

inlet 1 17,5

17,5

Bend

90° 2 4,9

9,8

Air inlet

Zeta=1,0 1 14,0

14,0

Total resistance air supply:

50,4

Total resistance flue gas outlet and air supply:

104,4 Pa

INLET AIR MUST BE CLEAN

AND FREE OF WATER.

USE A WIRE MESH WHEN

THERE IS RISK OF DEBRIS

BEING DRAWN INTO THE

AIR INLET.

EXAMPLE A

8m

3m

1m

2m

2m

4m

INLET AIR MUST BE CLEAN

AND FREE OF WATER.

ALWAYS USE A WIRE MESH

TO PREVENT DEBRIS BEING

DRAWN INTO THE AIR INLET.

26

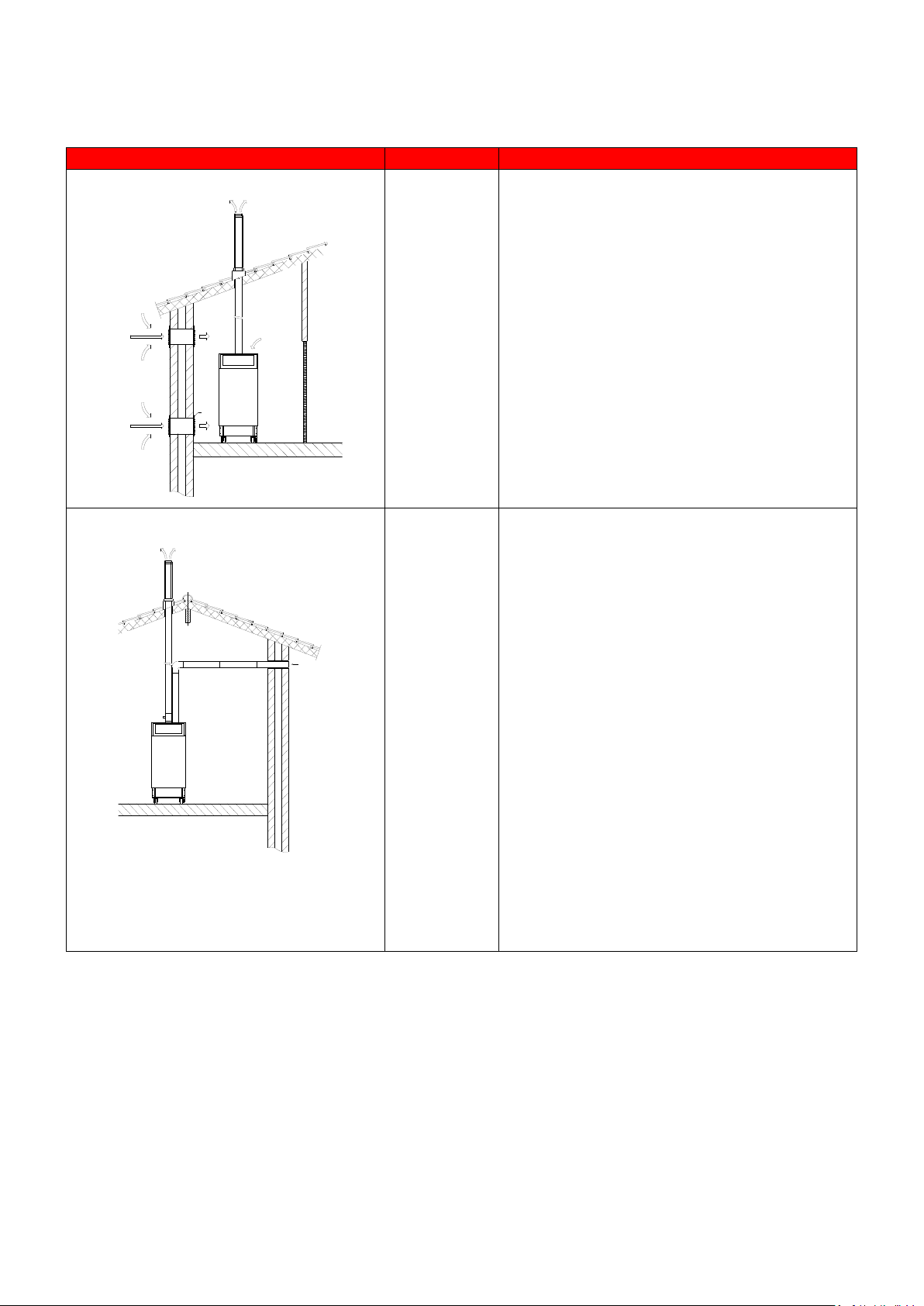

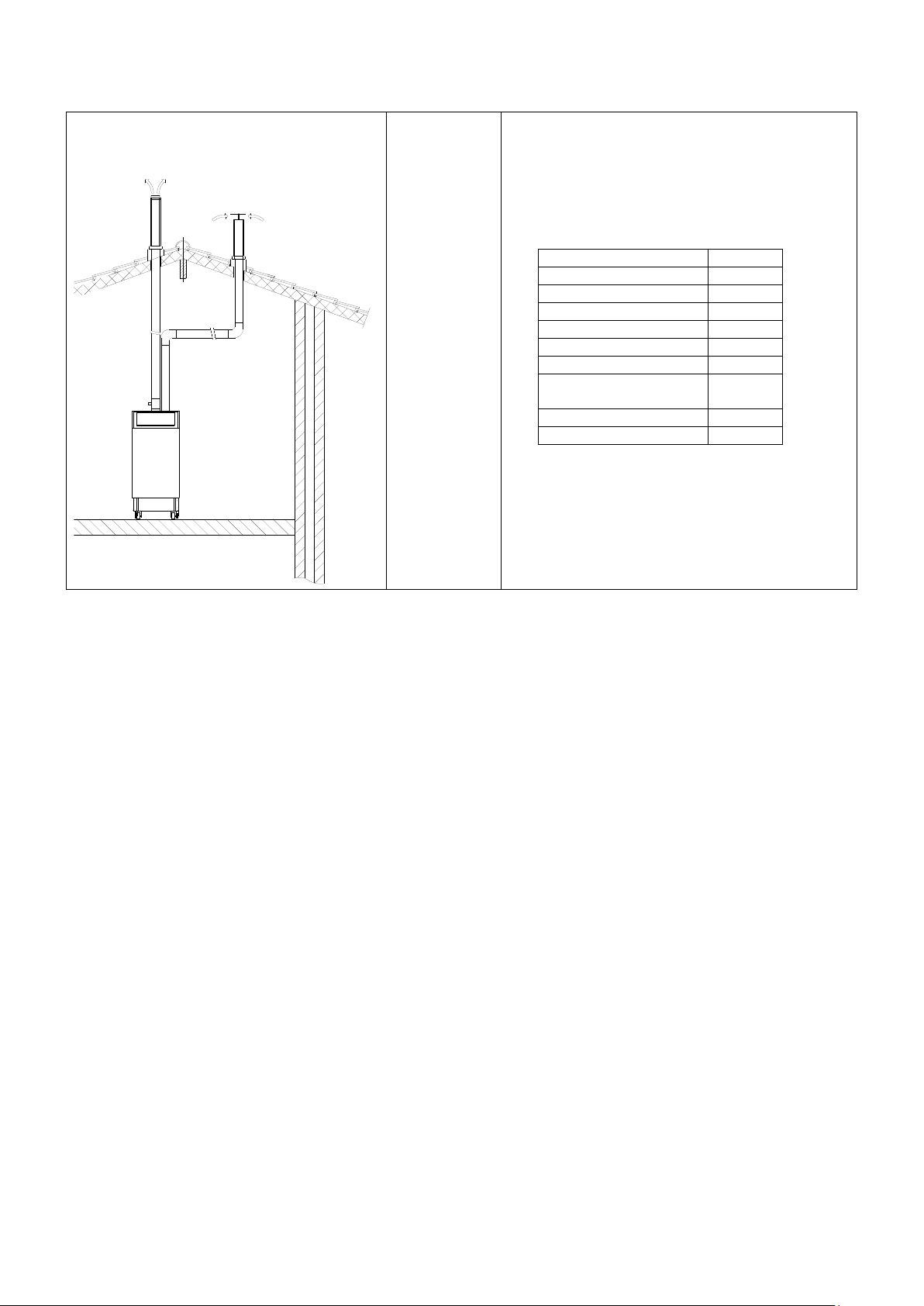

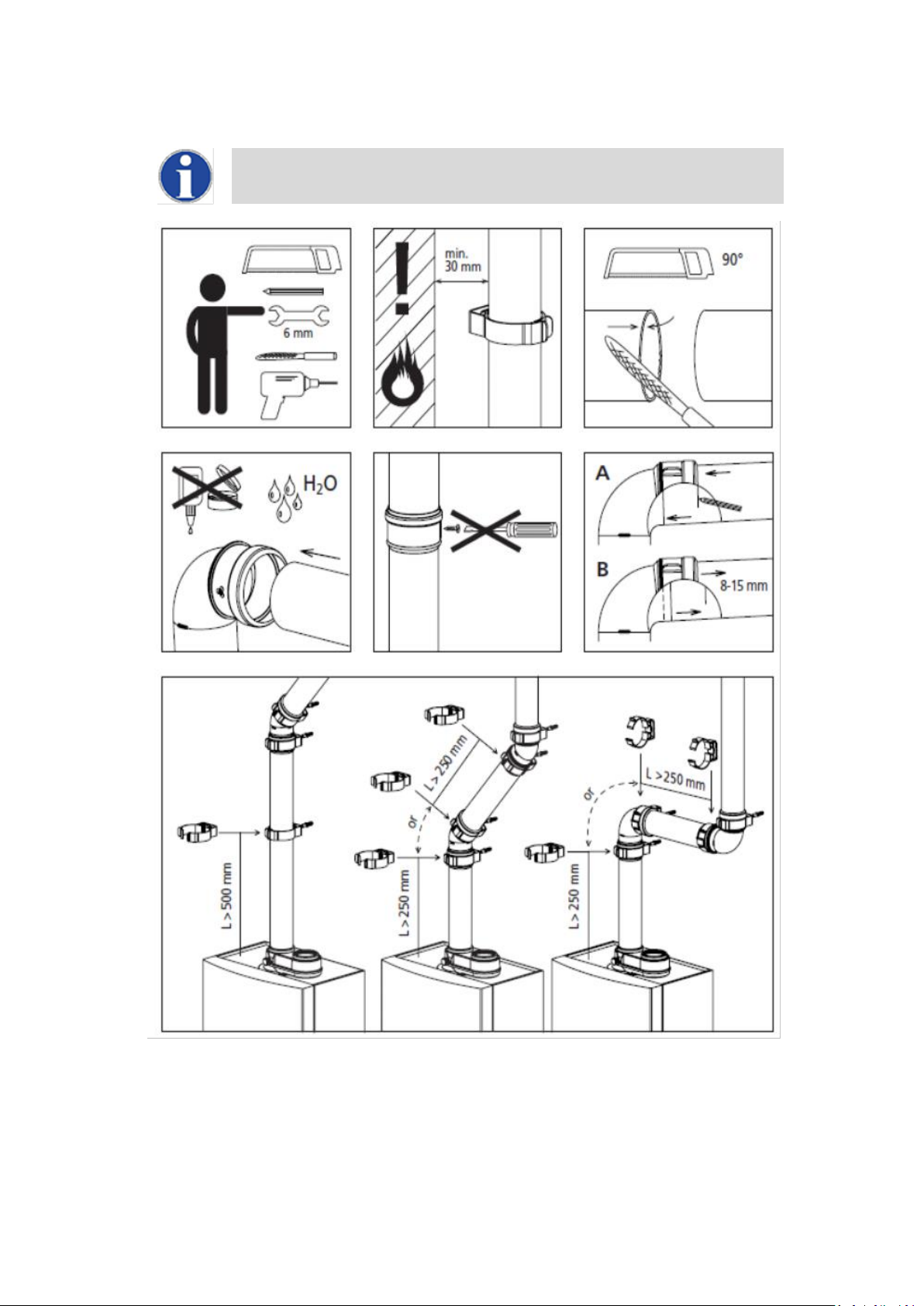

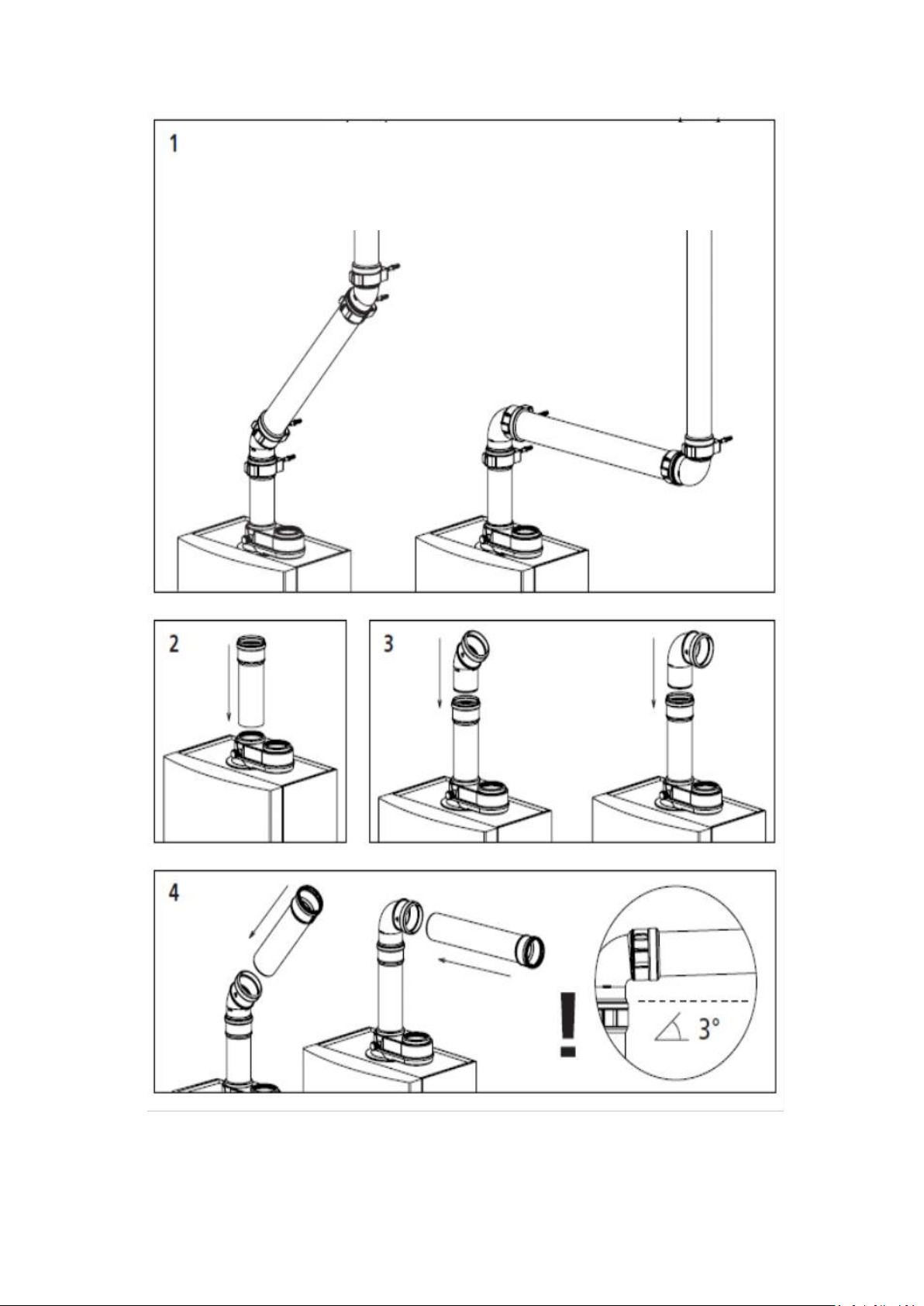

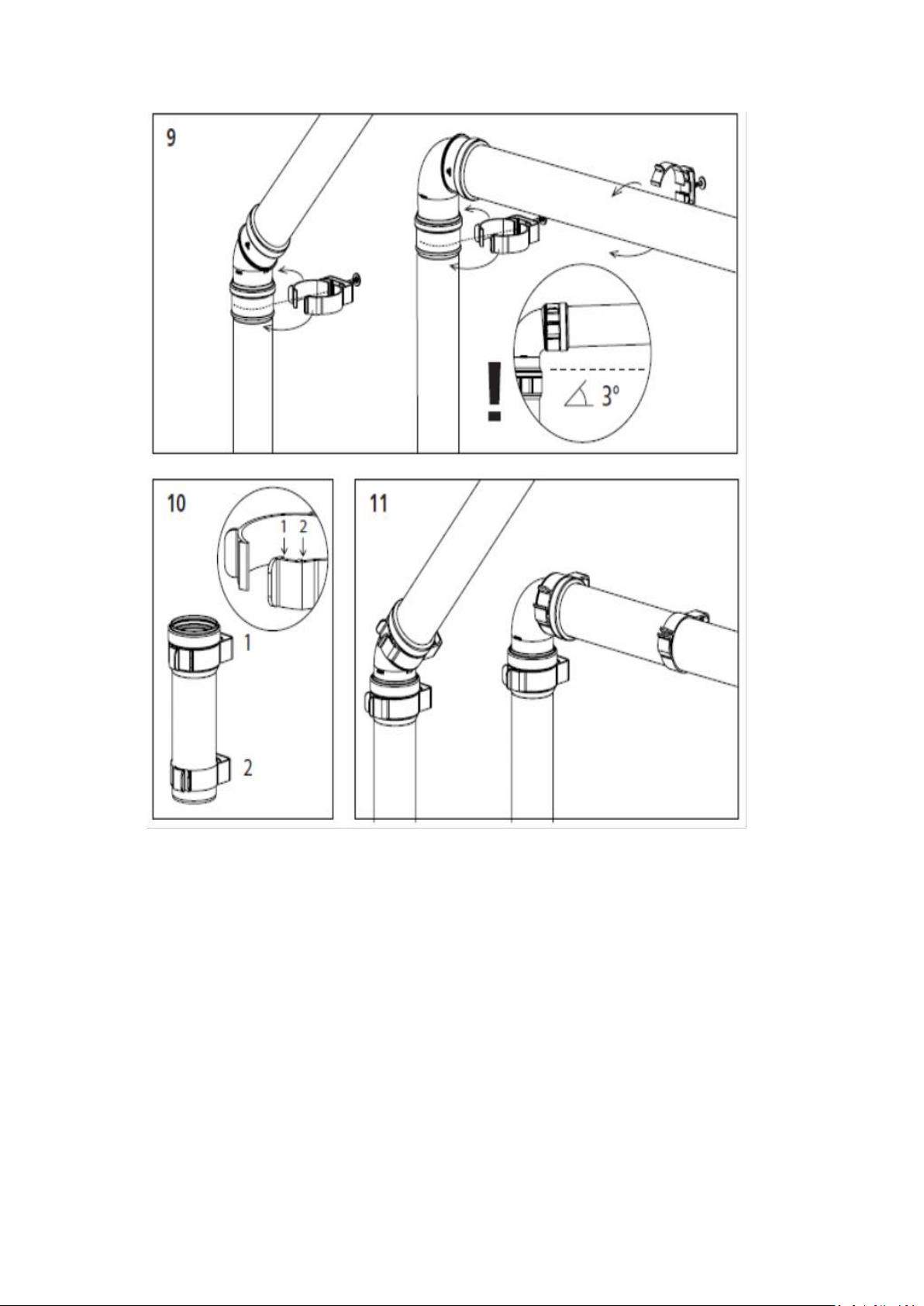

10.10 GENERAL TWIN-PIPE INSTALLATION GUIDELINES

The images shown below may not represent the equipment supplied, images and

instructions are for general guidance only

27

28

29

10.11 TYPE B

23

(CONVENTIONAL FLUE WITH FAN ASSISTANCE)

When the water heater is installed as a Type B23 appliance, the flue system should be installed in accordance with

the flue manufacturer’s specific instructions

CONVENTIONAL FLUE ASSEMBLY MODELS

TTW410,TTW580

COMPONENTS REQUIRED TO START INSTALLATION

Item No.

Description

Dimensions

M70439B

VERTICAL TERMINAL Ø200mm

1

LE400093B

ECCENTRIC INCREASER Ø180mm - Ø200mm FOR EXHAUST

1

LE400094B

AIR INLET SCREEN Ø160mm SS

1

Additional Flue Ancillary Items

Item No.

Description

Dimensions

LV310696

EXTENSION Ø200mm PP

500mm

M70402

EXTENSION Ø200mm PP

1000mm

M70404

EXTENSION Ø200mm PP

2000mm

M70411

ELBOW 90° Ø200mm PP

n/a

M70412

BEND 45° Ø200mm PP

n/a

LV310677

T PIECE WITH CONDENSATE CONNECTOR Ø200mm PP

n/a

M87198

WALL CLAMP Ø200mm

n/a

When using flue pipe supplied by Lochinvar the guidance given in section 10.10 is also applicable for B23

systems.

30

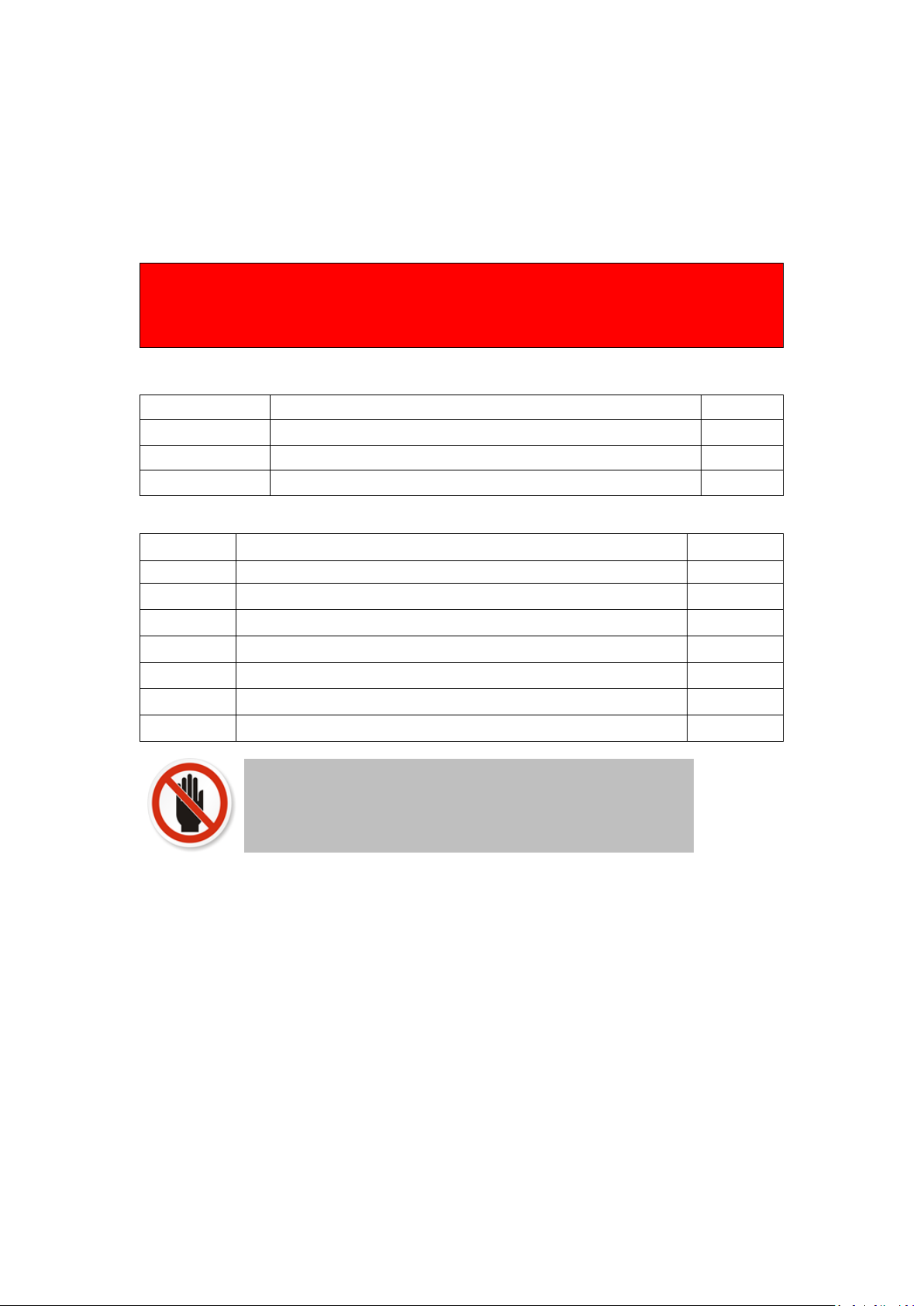

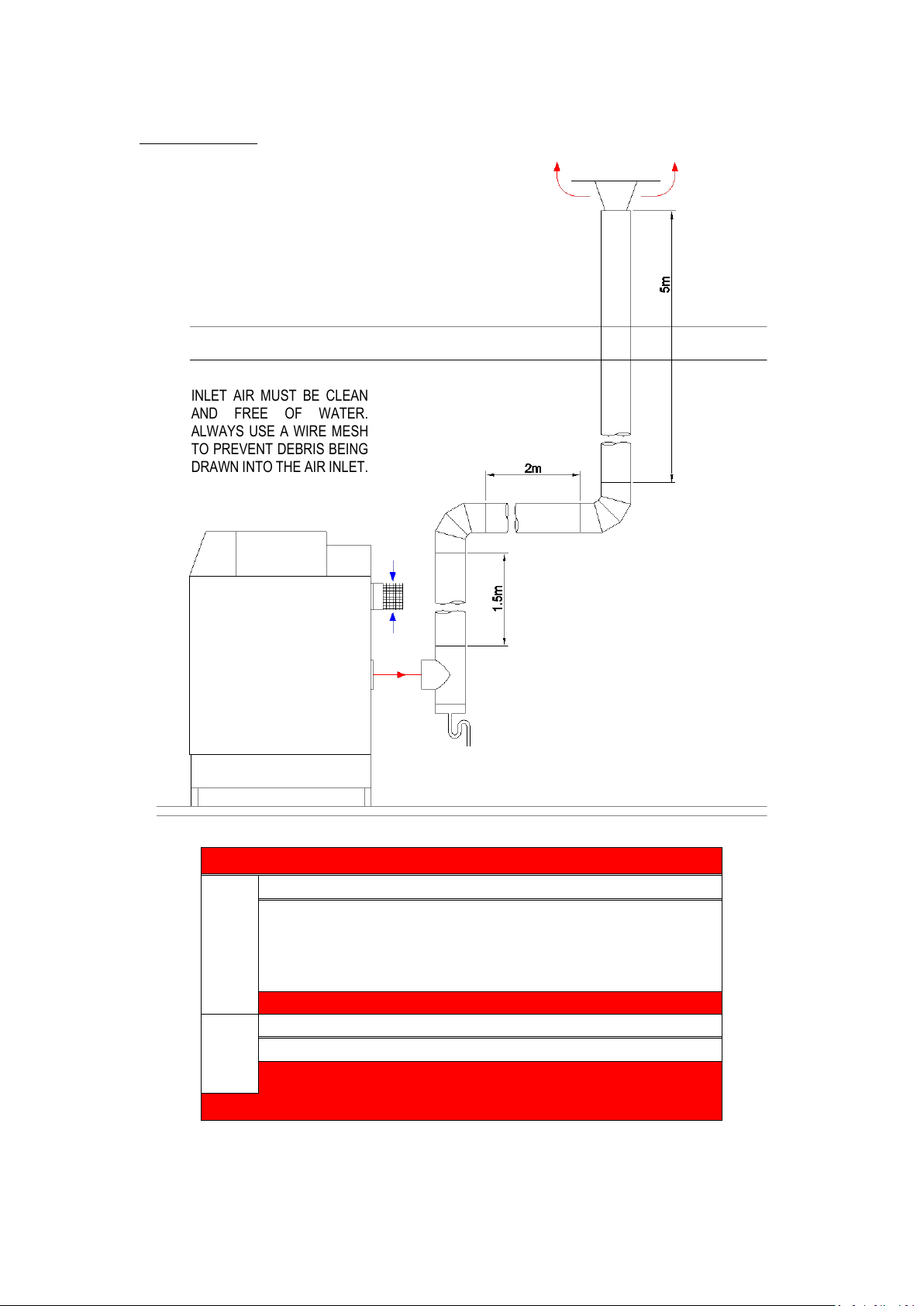

10.11.1 EXAMPLE B: SINGLE PIPE SYSTEM FOR FLUE GAS OUTLET ONLY

Calculation example:

The total resistance is less than 200 Pa, so this is acceptable.

Water heater type:

TTW410

Flue gas

Diameter: 180 mm.

Number

Pa

Pa total

Straight tube m¹

total

8,5

3,0

25,5

T-piece

outlet 1 25,5

25,5

Bend

90° 2 9,9

19,8

Flue outlet

Zeta=1,0

1

28,3

28,3

Total resistance flue gas outlet:

99,1

Air supply

Diameter: 180 mm.

Number

Pa

Pa total

Air inlet

Zeta=1,3

1

27,7

27,7

Total resistance air supply:

27,7

Total resistance flue gas outlet and air supply:

126,8 Pa

INLET AIR MUST BE CLEAN

AND FREE OF WATER.

ALWAYS USE A WIRE MESH

TO PREVENT DEBRIS BEING

DRAWN INTO THE AIR INLET.

Loading...

Loading...