Lochinvar SCH Installation Manual

SCH-I-O Rev A

Installation & Operation

Manual

SCH Collectors

WARNING:

This manual must only be used by a qualified heating

installer/service technician. Read all instructions

before installing. Perform steps in the order given.

Failure to comply could result in severe personal

injury, death, or substantial property damage.

Contents

HAZARD DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. LOCATION

Array Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Handling and Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What to Avoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. ROOF ATTACHMENT INSTALLATION

Roof Attachment Types . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Roof Attachment Quantities for SCH Collectors . . . . . . . 11

Roof Attachment Spacing Distance . . . . . . . . . . . . . . . . . 12

Installation of Roof Attachment Types . . . . . . . . . . . . 13-27

4. COLLECTION INSTALLATION

Horizontal Bar Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Spacing Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SCH Parallel Mounting Instructions . . . . . . . . . . . . . . 29-31

SCH Inclined / Non-South Facing Mounting Instructions 32-34

SCH Frame Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCH Mounting Hardware + Hydraulic Connection Kits . . 36

5. HYDRAULIC CONNECTIONS

SCH Connections Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Hydraulic Expansion Kits . . . . . . . . . . . . . . . . . . . . . . 37-38

Pressure Drop Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6. SYSTEM STARTUP

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Filling, Flushing and Bleeding . . . . . . . . . . . . . . . . . . . . . 40

Clamp Ring Screw Connections . . . . . . . . . . . . . . . . . . . 41

Flat Seal Screw Connections . . . . . . . . . . . . . . . . . . . . . . 41

Operation, Multi-function Ball Valve & Check Valve . . . . 41

7. MAINTENANCE

Fluid Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

System Design Considerations . . . . . . . . . . . . . . . . . . . . 42

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Solar Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pump / Control Function . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Revision Notes . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or

to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

2

1 Introduction

SCH Collectors Installation & Operation Manual

The SCH collector is suitable for parallel installations and inclined installations on pitched and flat roofs as well as freestanding

on the ground. It is available as a single-piece large collector in sizes ranging from 65 to 130 ft

2

with inlet and outlet connections of

.86" in diameter. Suitable mounting systems are available for various types of roofing. The SCH collector is delivered in standard

lengths of 9'-10" to 19'-7" and a height of 6'-7", resulting in gross surface areas between 65 and 130 ft².

Area of use: Parallel, inclined, on roof mounting, on tiles, plain tiles, slate, Spanish tiles, tin roofing, flat roofs, and as a

freestanding unit

Technical data

SCH Collector

Type SCH065 SCH090 SCH110 SCH130

Quantity of Glass Panels 3 4 5 6

Gross area 65.66 ft

Aperture surface area 58.45 ft

Absorber surface area 59.85 ft

External Dimensions (L x W)

1

6'-7" x 9'-10" 6'-7" x 13'-2" 6'-7" x 16'-4" 6'-7" x 19'-7"

2

2

2

87.19 ft

77.93 ft

79.76 ft

Weight Ratings 309 lbs. 411 lbs. 513 lbs. 614 lbs.

SCH mounting hardware + hydraulic connection kits

Part-number Description

Parallel installation:

SCA20001 Horizontal aluminum bar 10 ft 2

SCA20002 Horizontal aluminum bar 13 ft 2

SCA20003 Horizontal aluminum bar 16 ft 2

SCA20004 Horizontal aluminum bar 20 ft 2

SSK20004 End bracing kit 2222

SSK20005 Z-hook kit 2333

2

2

2

108.72 ft

97.95 ft

99.67 ft

2

2

2

Needed quantities for:

SCH065 SCH090 SCH110 SCH130

130.24 ft

116.90 ft

119.59 ft

2

2

2

Inclined (20°,40°,60°) installation:

SCA20001 Horizontal aluminum bar 10 ft 2

SCA20002 Horizontal aluminum bar 13 ft 2

SCA20003 Horizontal aluminum bar 16 ft 2

SCA20004 Horizontal aluminum bar 20 ft 2

SCA20005 Aluminum U-channel 10 ft 3

SCA20006 Aluminum U-channel 13 ft 3

SCA20007 Aluminum U-channel 16 ft 3

SCA20008 Aluminum U-channel 20 ft 3

SSK20001 A-frame 20° inclined 2334

SSK20002 A-frame 40° inclined 2334

SSK20003 A-frame 60° inclined 2334

Hydraulic connection kits: (1 array is max. 2 SCH’s!)

HYK20001 Hydr. conn. kit 2x 6.5' + plug + sensor well 1x per collector or array

HYK20002 Hydr. conn. kit 1x 6.5'/1x 13' + plug + sensor well 1x per collector or array

HYK20003 Serial hydr. exp. kit for stacked installation 1x per array

HYK20004 Parallel hydr. exp. kit for side by side installation 1x per array

HYK20005 Serial hydr. exp. kit for side by side installation 1x per array

Mechanical connection kits: (optional for installation!)

MCK20001 Mechanical conn. kit for side by side installation 1x per array

MCK20002 Mechanical conn. kit for stacked installation 1x per array

MCK20003 Cover for piping (for side by side installations) 1x per array

Gable bracing kits: (required for non-south facing installation!)

GBK20003 Bracing kit w/ diagonal support 1x per collector

3

1 Introduction

SCH Collectors Installation & Operation Manual

How it works...

1. Housing

Powder coated (RAL7016)aluminum frame structure with

PU rigid foam and an aluminum rear wall.

2. Cover

Prismatic solar safety glass, .15" thick, for maximum light

transmission.

3. Insulation

.76" heat resistant, special PU rigid foam and 1.57" mineral

wool with high pressure resistance, emission free, non flammable.

4. Absorber

Full surface absorber, laser welded with highly-selective PVD

coating (PVD = Physical Vapor Deposition), serpentine flow.

5. Collector seal

Aluminum profile system with double temperature and UV resistant silicone seals, emission free.

SCH Collector

7

1

6. Inlet connection

Copper pipes, .86" diameter.

7. Outlet connection

Copper pipes, .86" diameter.

8. Absorber coils

10 mm copper, serpentine arrangement.

9. Hydraulic connection kit

Connection set with stainless steel corrugated pipe. For connecting

the collector supply and return to the riser. The corrugated pipes

are available in kits with 2 x 6'-7" or 2 x 13'1" length including

sensor well and plug.

10. Sensor well

For measuring the collector outlet temperature directly in

the fluid. The sensor well can be installed on the outlet connection

as shown on the collector label. The sensor must be inserted up to

the end of the sensor well.

11. Plug

This plug is used on the end collector of each array to complete the

water flow path.

7

5

3

2

8

6

4

10

9

11

4

1 Introduction (continued)

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

Before getting started on your installation be sure to carefully

read the preparation instructions in this section.

WARNING

NOTICE

CAUTION

Installer – Read all instructions, including

this manual before installing. Perform

steps in the order given.

Have your collector(s) serviced/inspected

by a qualified service technician, at least

annually.

Failure to comply with the above could

result in severe personal injury, death or

substantial property damage.

When calling or writing about the collector

– Please have the collector model and

serial number.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with the

collector) does not apply to collectors

improperly installed or improperly

operated.

• You must comply with local

regulations, laws and standards of the

local governing authority.

• The frame must be capable of

withstanding the local snow and wind

loads and permit the correct

anchoring of the collectors in

accordance with all applicable local

regulations.

• The load bearing capacity of the

roofing and the frame shall be specially

checked or analyzed by a structural

engineer.

• The number of mounting brackets

specified by the Lochinvar/TiSun

manuals and parts sheets is based on

an average collector load bearing per

square foot. The maximum

permissible collector loading per

square foot may be calculated from the

number of mounting brackets, taking

into consideration the permissible

loading on the mounting brackets. If a

higher collector wind and snow loading

(including snow sliding off the roof)

per square foot is required, additional

mounting brackets will have to be

used. Roof pitches in excess of 30° also

represent increased loading; additional

mounting brackets must also be used

for this variant.

CAUTION

CAUTION

CAUTION

Lochinvar/TiSun Solar Thermal Collectors

are not specifically designed for drain back

installations. Consult the factory if drain

back utilization is necessary.

• The mounting substructure must be

capable of withstanding the local

snow and wind loads and permit

correct anchoring of the collectors.

• To avoid damage to the collectors

and mounting frames from snow

sliding off the roof, additional snow

guards must be placed in sufficient

numbers around the collectors and

above the collectors.

• The collectors must be linked with a

lightning arrester system and/or the

building’s ground system by a licensed

electrician.

• Hydraulic connection of the collectors

must be performed according to

Lochinvar/TiSun specifications.

• The collector connections must not be

damaged, soiled or misaligned. Take care

during transport, installation, and

connection of the modules. Do not

remove the header protection caps at the

top and bottom connections of the

collector until just before installation.

• When connecting the modules to the

riser, the Hydraulic Connection Kit

(corrugated pipe) supplied must be

installed. Otherwise, the warranty is

invalidated.

• Always connect the collector outlet and

inlet flow to each other diagonally,

please follow the connection

example (see FIG. 1-1 on page 6).

• Do not twist the headers when screwing

the connections together. Hold threaded

connection in the desired position and

tighten clamping ring union nut to

torque.

• Roof penetrations for solar piping must

be adequately sealed against water ingress.

• Use only the original sensor well

supplied.

• Use only high temperature and glycol

pipe sealing materials.

All piping should be properly insulated to

avoid freezing and/or burn potential.

5

1 Introduction

SCH Collectors Installation & Operation Manual

NOTICE

• Check the materials for any damage

sustained in transport and describe any

damage in writing on the packing slip

where necessary. This is important to

process any needed freight or delivery

damage claims.

• Carefully read through the relevant

installation instructions before

starting the installation and follow

each step.

• Use only the original mounting

components.

• Stainless steel screws may not be used

again once they have been removed

(because of the possibility of

breaking).

• Any conversion or modification of the

Lochinvar/TiSun product not

expressly approved in writing by the

manufacturer shall void the warranty.

• No liability can be accepted for damage

resulting from failure to observe the

installation instructions.

WARNING

WARNING

Figure 1-1 Connection Diagram

A properly sized expansion tank must be

used to avoid damage to the Solar Thermal

System.

If copper pipe is being used, all joints

MUST BE brazed, no soldering allowed.

WARNING

WARNING

WARNING

WARNING

WARNING

Dismantling and Disposal

• The units are dismantled in the reverse sequence of

installation.

• The roofing shall be properly sealed after the

mounting brackets have been removed.

• Materials shall be disposed of in an environmentally

conscious manner.

Only authorized solar companies familiar

with our products may handle them.

There is a risk of injury when handling

collectors and mounting accessories as

these have sharp edges.

The collector becomes very hot in the

sunlight. There is a risk of burn.

Comply with all safety regulations and

applicable OSHA requirements.

Check the load bearing capacity and

stability of the substructure onto which

the collector is to be installed and will

need to be accessed during the installation

process.

6

SCH Collectors Installation & Operation Manual

2 Location

Array options

For series and parallel connection of multiple collectors, it is advisable to calculate the pressure drop over the entire system with

the aid of the enclosed documents and to install an appropriate pump if necessary. The maximum collector area per collector

array connected in series is 260 ft2. Be aware of pressure drop, reference the array options (FIG.’s 2-1 and 2-2).

Figure 2-1 Array Piping

SERIES STACKED

SINGLE COLLECTOR

Figure 2-2 Multiple Array Piping

PARALLEL SIDE BY SIDE

PARALLEL WITH BALANCING VALVES

(ON ROOF ONLY)

SERIES SIDE BY SIDE

7

2 Location

Installation positions

SCH Collectors Installation & Operation Manual

Figure 2-3 SCH Parallel Installations

min. 15° - max. 70°

Figure 2-5 SCH Freestanding Installations

Figure 2-4 SCH Inclined Installations

20°/40°/60°

min. 15° - max. 70°

NOTICE

NOTICE

For best performance, it is recommended

that the collectors face true south.

It is not recommended for the collector

field to deviate any further than 45°

from true south.

min. 15° - max. 70°

NOTICE

NOTICE

Collector incline should be at least 15° and

no more than 70° for best performance.

Avoid installation in shaded areas. Shaded

areas will reduce the performance of the

solar collectors.

8

2 Location (continued)

Handling and storing

WARNING

CAUTION

NOTICE

• Installation of LOCHINVAR/TiSun

SCH collectors is only allowed for

professional staff.

• Local instructions, laws and standards

are to be kept.

• Collectors are to be located so

falling of snow and ice does not

endanger any person or property.

• Use personal protection equipment

(helmet, belt, security shoes) when on

the roof.

• Secure tools and materials against

falls.

• It is forbidden to stand under

hanging load.

• Danger area has to be closed.

• Put ladders up properly and check

stability.

• Check the under roof construction on

the building before installation.

SCH Collectors Installation & Operation Manual

WARNING

• Only loosen the crane connection

when the collectors are completely

fixed to the substructure.

• Pay special attention to roof-work

near an electric grid. If need be, the

constructor must take security

precautions such as isolation,

covering, etc.

• Inspect the roof surface in the area of

the installation for cracks, water

leakage, and roofing material quality

and uniformity. This is especially

important if the roof is more than 10

years old.

• Inspect the roof for sags and other

abnormalities. A sag or deep

depression in the roof may indicate a

structural weakness in the support

system that may require correction.

• Check that all rafters, trusses and

other materials are in good condition.

WARNING

• Avoid rotating movements of the

load through wind. Secure load

before lifting.

What to avoid

CAUTION

• Only move collectors on the given

fixing loops.

NOTICE

Figure 2-6 Crane Transportation Connection Points and Positioning

< 30°

6.5 ft.

• Collectors are to be located such that

eventual sliding of snow and ice does

not endanger any person.

• See FIG. 2-6 for crane transportation

connection points and positioning.

< 30°

6.5 ft.

< 30°

6.5 ft.

< 30°

8.5 ft.

9

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

3 Roof Attachment Installation

Roof attachment types

Table 3A Roof Fastenings - Parts

SOLAR ROOF MOUNTS

Part #

SRM20001

SRM20003

SRM20004

SRM20005

SRM20006 CLAMP, JOINT XX

Lochinvar

Name

BOLT,

DOUBLE

HANGER

ANCHOR,

RAFTER, STD

ROOF TILE

ANCHOR,

RAFTER, TALL

ROOF TILE

HOOK, FLAT

TILE

Installation Type

Parallel Inclined Free-

standing

XX X13

XX

XX

X

--

-

-

-

See

Page

15

15

16

18

Description

Stainless steel attachment for universal heavy duty

installations, on parallel and inclined roofs and

freestanding installations on sufficiently anchored

bases.

Stainless steel attachment for parallel and inclined

installations on various types of tiled roofs. Standard

installations for tile heights of up to 1.5". Package is

complete with fasteners and spacers.

Stainless steel attachment for parallel and inclined

installations on various types of tiled roofs. Standard

installations for tile heights of up to 2". Package is

complete with fasteners and spacers.

Stainless steel attachment for parallel installations on

plain tile, slate, and flat cement tiled roofs with pitches

in excess of 30 degrees.

Stainless steel attachment for parallel and inclined

installations on jointed tin, galvanized, or copper

roofs. Additional securing cables (Lochinvar Part #

SRM20012) are required for inclined installations.

SRM20007

SRM20008

SRM20009

SRM20010

SRM20012

SRM20013

SRM20014

SRM20015

10

PLATE,

FLANGE,

SHINGLE, STD.

PLATE,

FLANGE,

SHINGLE,

RAISED

BOLT,

ANCHOR,

CONCRETE W/

ADJ

BOLT,

ANCHOR,

CONCRETE

KIT, UNIV

CABLE

SECURING

ATTACHMENT,

ROOF CORR

METAL

ATTACHMENT,

WAVE ROOF SMXX

ATTACHMENT,

WAVE ROOF LGXX

XX X20

-

-

-

-

XX

XX22

XX26

XX26

X

Galvanized steel attachment for parallel, inclined and

freestanding installations on asphalt or elastomer

roofs.

Galvanized steel attachment for inclined and

freestanding installations on asphalt or elastomer

roofs. Also recommended for flat roofs.

Galvanized steel attachment for inclined or freestanding

installations with 2.75" height adjustment. For use in

applications with no more than a 5 degree inclination.

Galvanized steel attachment for inclined or

freestanding installations with no height adjustment.

For use in applications with no more than a 5 degree

inclination.

Stainless steel cable set for securing collectors on

inclined jointed roofs. Kit includes cable, turnbuckle,

-

-

-

-

19

hardware for attachment to frame, and joint clamp.

For inclined installations only.

Stainless steel attachment for parallel and inclined

23

installations on profiled and corrugated roofs.

Galvanized steel attachment for installations on

25

concrete corrugated roofs with 5 corrugations per

meter. For parallel and inclined installations.

Galvanized steel attachment for installations on

25

concrete corrugated roofs with 8 corrugations per

meter. For parallel and inclined installations.

10

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

3 Roof Attachment Installation (continued)

Roof attachment quantities for SCH collectors snow loading

Table 3B Parallel Installations

SRM: 20001, 20003, 20004, 20006, 20007,

20013, 20014, 20015

area load up to

32 lb/sq-ft

SCH065 610610

SCH090 812812

SCH110 814814

Parallel installation

SCH130 10 18 10 18

Table 3C Inclined (20°, 40°, and 60°) Installations

SRM: 20001, 20003, 20004, 20007, 20008,

20009, 20010, 20013, 20014, 20015

area load up to 32 lb/

sq-ft

area load up to

64 lb/sq-ft

area load up to 64 lb/

sq-ft

SRM: 20005

area load up to

16 lb/sq-ft

SRM: 20006 + 20012

area load up to 64 lb/sq-ft

area load up to

32 lb/sq-ft

SCH065 610122

installation

SCH090 812143

Inclined (20, 40°, 60°)

SCH110 814183

SCH130 10 18 22 4

11

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

3 Roof Attachment Installation

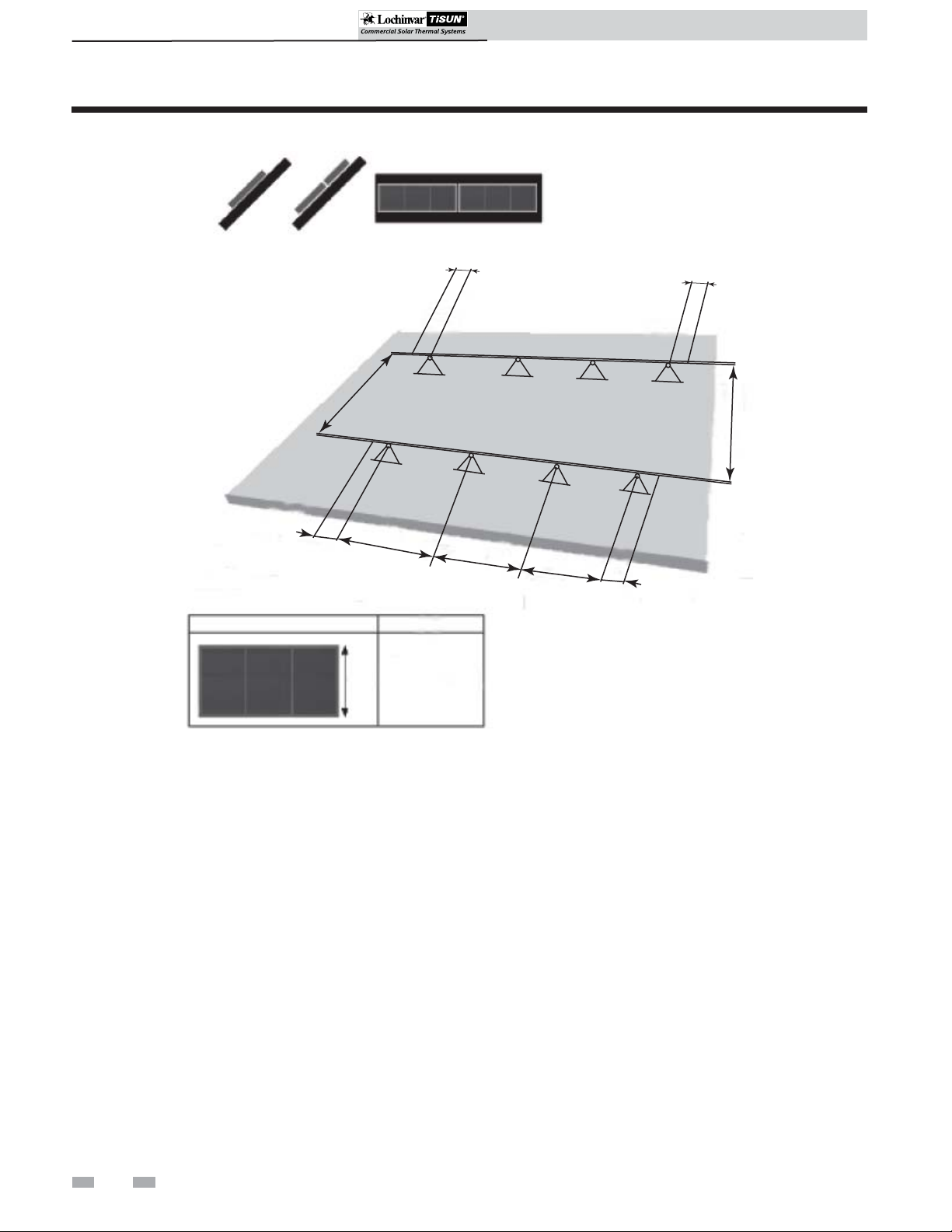

Figure 3-1 Spacing Distance

a = 2 - 10 in.

a

=

a

=

55 - 63 in.

=

X

=

a

a

x

Spacing Distance

Equally space the center roof attachments starting in the

middle, the two (2) end attachments will be spaced according

to the inner measurement (start in the middle and work

outwards). The remaining roof mounts should be equally

spaced in between the two (2) end roof attachments.

Note: For multiple collector installations reference the

Collector Mounting Section of this manual for spacing

between collectors.

12

Each collector will have its own independent substructure set.

Ensure there is ample room on the chosen roof area for the

number of collectors chosen.

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

3 Roof Attachment Installation (continued)

Installation of roof attachment types

The solar thermal collectors are capable of being mounted to several different types of roofing with a wide variety of

mounting hardware available from Lochinvar.

Double hanger bolt for universal fastening

#SRM20001

Universal fixture for parallel and inclined installation on

various roof types and freestanding installation on sufficiently

anchored frames. Two hanger bolts are to be installed on the

roof as vertically as possible with a spacing of 4 3/4" to 6 3/4".

The two are connected by an intermediate plate.

CAUTION

• The hanger bolt must be screwed

into a support capable of bearing

the required static load (generally

rafters).

• Install the hanger bolt using a field

supplied anchoring adapter.

• The roofing must be capable of

withstanding the pressure needed

to compress the gasket.

• Beware of linear expansion in sheet

metal that prevents a linear

expansion and can cause lifting of

the sheet.

Unpacking and checking parts

When unpacking the system, check the model names of the

components of each system and check to be sure you have the

correct number of parts (see FIG. 3-2).

Figure 3-2 Kit #SRM20001 - Double Hanger Bolt Kit

Components

Install double hanger bolt

1. Determine roof type. Inspect the structural integrity of

the roof and the durability of the roof materials.

2. Determine the number of collectors needed for the

installation and the number of required roof attachments

from Table 3B or 3C on page 11.

3. Determine collector connection points (spacing).

Measure the spacing of the rafters or trusses to confirm

the dimensions and prepare for the system layout

(reference the Roof Attachment Spacing Section on

page 12).

4. Pre-drill two 9mm holes, a minimum of 4 inches deep

into the roof substructure (see FIG. 3-3), perpendicular

to the roof with a spacing of 4 3/4" to 6 3/4".

5. Install the hanger bolts into the pre-drilled holes

until the threads are level with the roof’s surface.

Figure 3-3 Pre-Drill 9mm Holes Into Substructure

PRE-DRILL TWO (2) 9MM HOLES

PERPENDICULAR TO THE ROOF

(APPROX. 4 IN. DEEP)

INSTALL

HANGER

BOLT(S)

HANGER BOLT (M12) (2X)

WASHER (M12) (2X)

HANGER BOLT SEAL (2X)

HEX BOLT (M8) (1X)

WASHER (M8) (1X)

DOUBLE HANGER BOLT PLATE (1X)

HEX NUT W/FLANGE (M12) (6X)

SQUARE DISK (1X)

HEX NUT (M8) (1X)

6. Slide the hanger bolt seals over the machine threads until

the seal is touching the roof’s surface (FIG. 3-4A).

7. Slide the washer (M12) on top of the hanger bolt seal

(FIG. 3-4A).

8. Thread the hex nut with flange (flange side down) onto

the washer, compressing the washer and hanger bolt seal

to the roof (FIG. 3-4B).

9. Install the second hex nut with flange (flange side up)

until the hex nut reaches the desired substructure height

(FIG. 3-4B).

10. Slide the hanger bolt plate onto the flange of the hex nut

installed in Step 9 (FIG.’s 3-4A and 3-4B).

11. Install the remaining hex nut with flange (flange side

down) to the top of the double hanger bolt plate.

Tighten and secure both hex nuts (top and bottom) to

the double hanger bolt plate.

12. Make certain all double hanger bolt plates are facing the

same direction.

13

SCH Collectors Installation & Operation Manual

SCH Collectors Installation & Operation Manual

3 Roof Attachment Installation

Figure 3-4A Install Double Hanger Bolt Components

HEX NUT W/FLANGE

HANGER BOLT PLATE

HEX NUT W/FLANGE

WASHER (M12)

HANGER BOLT SEAL

HANGER BOLT

min.

4”

Figure 3-4B Compress Washer and Hanger Bolt Seal

DOUBLE HANGER BOLT PLATE

HEX NUT

FLANGE UP

Figure 3-5 Install Hex Bolt(s)

HEX BOLT

SQUARE DISK

DOUBLE HANGER

BOLT PLATE

NUT

WASHER

SEAL

13. Slide the square disk onto the hex bolt (see FIG. 3-5).

14. Install the hex bolt with square disk attached into the

opening of the double hanger bolt plate as shown in

FIG. 3-5.

Note: Do not tighten hex bolts until ready to install on the

collector substructure.

15. Thread the hex nut (M8) and washer (M8) onto the

bottom of the hex bolt installed in Step 14 (FIG. 3-5).

16. Repeat Steps 4 - 15 until installation is complete.

Install hex bolt onto collector substructure (reference Section

4 - Collector Installation)

14

Loading...

Loading...