Lochinvar Armor 151, Outdoor Knight 286, Armor 801, Outdoor Knight 151, Outdoor Knight XL 400 Instructions Manual

...

MODB-I-O_100161545_2000014822_Rev M

MODBUS AND BACNET

COMMUNICATION

INSTRUCTIONS

Models:

Knight 81 - 286, Knight XL 400 - 801,

Armor 151 - 801, Outdoor Knight 151

- 286, Outdoor Knight XL 400 - 801,

Outdoor Armor 151 - 801,

AQUAS 400 - 801, FTXL 400 - 850,

Wall Mount 51 - 211, Wall Hung 55 -

399, and Wall Mount Armor 125 - 200

WARNING

is manual must only be used by a

quali ed heating installer / service

technician. Read all instructions,

including this manual, the Installation

and Operation Manual, and the Service

Manual, before installing. Perform

steps in the order given. Failure to

comply could result in severe personal

injury, death, or substantial property

damage.

Save this manual for future reference.

Contents

1. INTRODUCTION

Defi nitions .................................................................... 2

Minimum System Requirements .................................. 2

2. INSTALLATION

Wall Mount, Armor, Knight and Knight XL, Outdoor

Armor, Outdoor Knight, and Outdoor Knight XL........ 3-4

FTXL ............................................................................ 5

Wall Hung .................................................................... 6

3. MODBUS CONFIGURATION

Addressing ................................................................... 7

Timing Specifi cations ................................................... 8

Parity ............................................................................ 8

Data Transmission Mode ............................................. 8

ModBus Board Diagnostics ......................................... 8

Internal Faults ......................................................... 8

ModBus Function Set .................................................. 9

ModBus Exception Codes ........................................... 10

4. MODBUS MEMORY MAP

Primary Data Tables .................................................... 11

Memory Map............................................................11-12

Input Registers .......................................................12

Holding Registers ................................................... 12

Confi guration Bits......................................................... 12

5. BACNET CONFIGURATION ....................................... 13

Addressing ................................................................... 13

Timing Specifi cations ...................................................14

Communication Board Diagnostics ............................. 14

Internal Faults ......................................................... 14

6. BACNET MEMORY MAP

Primary Data Tables .................................................... 15

Crest Boiler Memory Map........................................15-16

Input Registers ............................................................15

Holding Registers ................................................... 16

7. WIRING REQUIREMENTS

Physical Wiring ............................................................ 17

Control Inputs/Outputs............................................ 18-19

Control Location.......................................................20-21

Typical Boiler/Water Heater System Wiring................ 22

8. UNIT OPERATION

Unit Operation with ModBus

Communications ..................................................... 23-27

9. TROUBLESHOOTING ........................................... 28-29

10. DIAGRAMS

Ladder & Wiring Diagrams ..................................... 30-39

Revision Notes ................................................... Back Cover

1 Introduction

e information contained in this manual provides general guidelines for the implementation of ModBus and BACnet

communication with the Lochinvar Armor water heaters (151 - 801), Wall Mount Armor (125-200), Knight (81-286), Knight

XL (400 - 801), Outdoor Knight (151-286), Outdoor KnightXL (400-801), Outdoor Armor (151-801), Wall Mount (51 - 211),

and Wall Hung (55 - 399) boilers.

All ModBus networks are implemented utilizing a master-slave arrangement where all boilers/water heaters are slaves and

the master is a building automation system capable of communicating over a RS-485 half duplex serial connection. BACnet

networks are implemented using a token passing process where multiple masters and slaves share a common RS-485 bus. e

Lochinvar BACnet interface is a master only.

Defi nitions

Abbreviation or Acronym Meaning

ASCII American Standard Code for Information Interchange

BACnet A data communication protocol for Building Automation and Control Networks

BAS Building Automation System

Baud (Baud Rate) Number of data bits transmitted per second (bps)

EMS Energy Management System

FDX Full-Duplex

HDX Half-Duplex

Hex Hexadecimal Number (0 - 9, A - F)

I/O Box Input/Output (I/O)

LSB Least Signifi cant Byte

ModBus A serial, half-duplex data transmission protocol developed by AEG Modicon

MSB Most Signifi cant Byte

RS232

RS485 A standard for serial transmission of data based on the RS-485 Standard

RTU Remote Terminal Unit

A standard for serial, full-duplex (FDX) transmission of data based on the RS232

Standard

Minimum System Requirements

• BAS system or computer with a serial or USB port

with a converter to RS-485 half duplex.

• Unit equipped with communication board.

• Shielded twisted pair communication cable.

2 Installation

ModBus and BACnet Communication Instructions

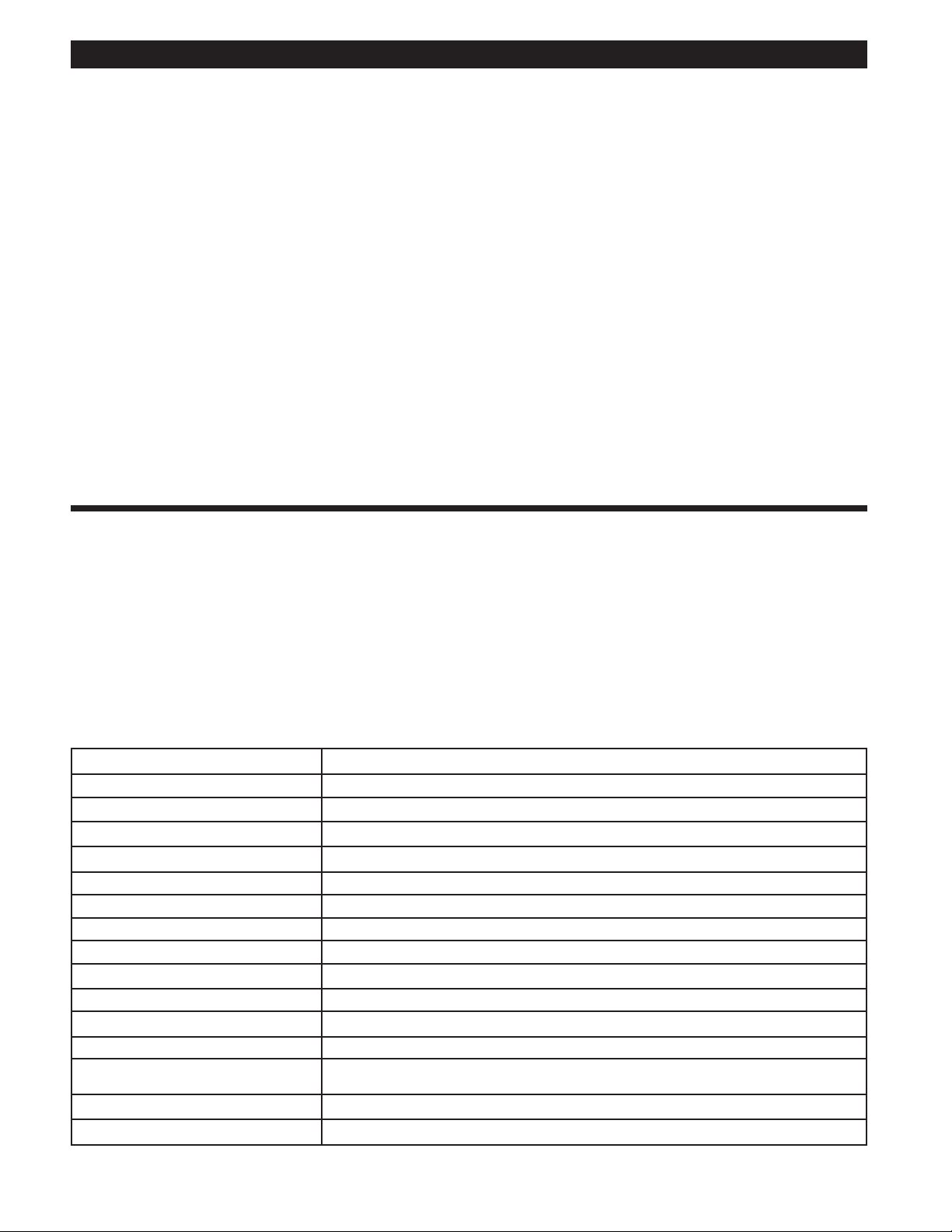

Installation procedure - for Models WB,

WA, AW, KB, OA, OK and KBX

1. Turn OFF the main electrical power to the appliance.

2. Turn OFF the main manual gas shuto to the appliance.

3. Assemble the communication control board to the sheet

metal base as shown in FIG. 2-1a and 2-1b, depending on

model.

4. Connect the power harness from the appliance to the

communication board through the sheet metal cover

hole (see FIG. 2-2a and 2-2b, depending on model).

5. Using the two (2) sheet metal screws provided in the kit,

attach the pre-painted sheet metal cover over the

Communication board for protection from line voltage

(FIG. 2-2a and 2-2b, depending on model).

6. Locate the pilot holes on the side of the jacket (le side if

AW/KB/KXL or right side if WB/WA), using the sheet

metal screws provided in the kit, mount the

communication board assembly to the appliance (FIG.

2-3a and 2-3b, depending on model).

Wiring

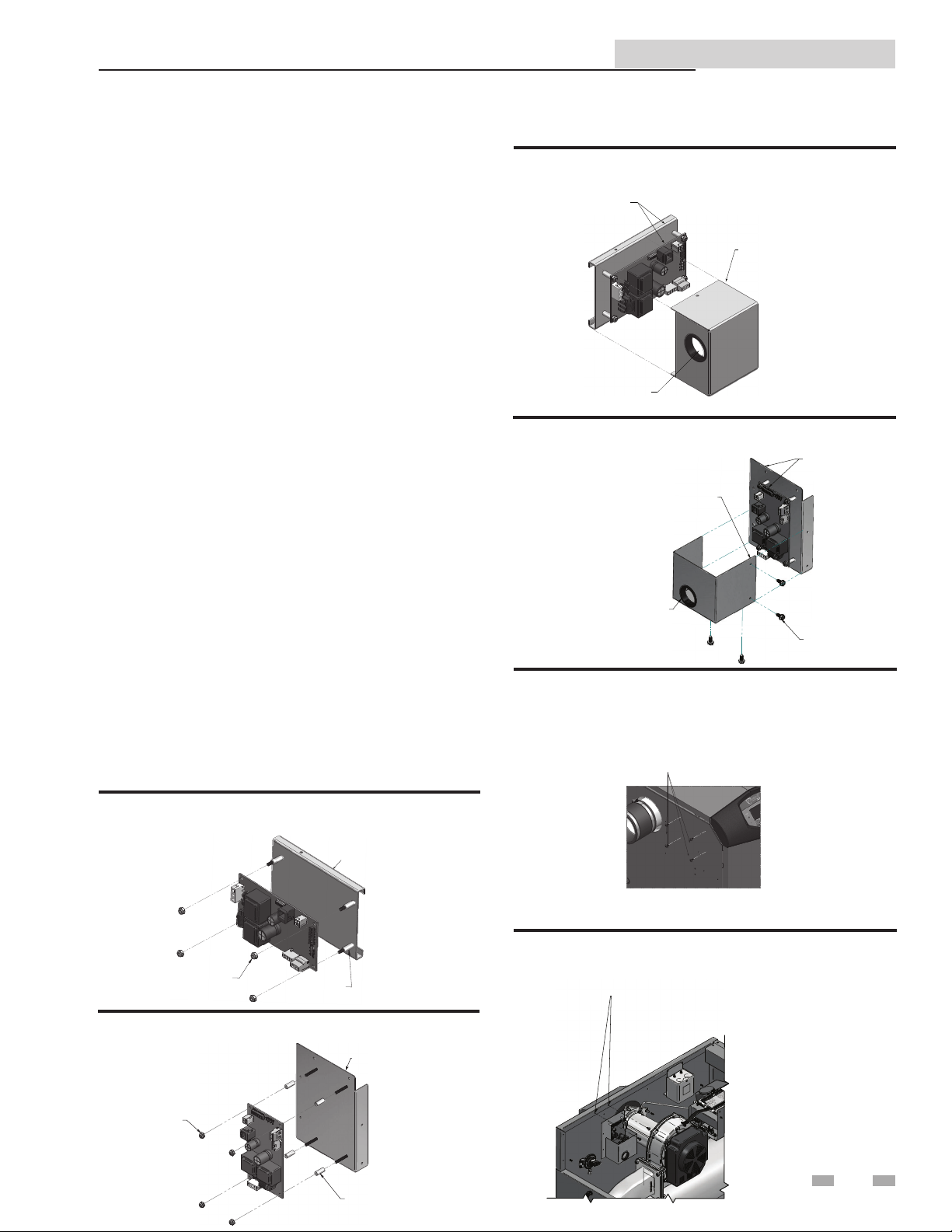

7. Disconnect power to the transformer by removing

connection “B”, see FIG. 2-4, page 4.

8. Connect A, C, D, and B (FIG. 2-4).

9. Connect the communication board to the control board

of the appliance (see FIG. 2-5 on page 4).

10. Turn on the main electrical power and the main manual

gas shuto to the appliance.

11. Con gure the control board and unit controls per this

manual and resume operation.

Figure 2-2a_Attach Cover to Communication Board for

Models WB, WA, AW, KB and KBX

MODBUS

ASSEMBLY

MOUNT PRE-PAINTED

SHEET METAL COVER

OVER THE MODBUS

ASSEMBLY FOR PROTECTION

FROM LINE VOLTAGE

ATTACH POWER HARNESS

TO MODBUS THROUGH

SHEET METAL COVER HOLE

Figure 2-2b_Attach Cover to Communication Board

for Models OA and OK

MOUNT PRE-PAINTED

SHEET METAL COVER OVER

THE MODBUS ASSEMBLY FOR

PROTECTION FROM LINE VOLTAGE

ATTACH POW ER HARNESS

TO MODBUS THROUGH

SHEET METAL COVER HOLE

MODBUS

ASSEMBLY

IMG00566

BLT7404 [X4]

Figure 2-3a_Mount Communication board to Unit for

Models WB, WA, AW, KB and KBX

- LOCATE THE PILOT HOLES

- USING THE 4 SHEET METAL SCREWS

PROVIDED IN THE KIT MOUNT THE MODBUS

ASSEMBLY TO THE UNIT

(SIDE DEPENDENT ON MODEL)

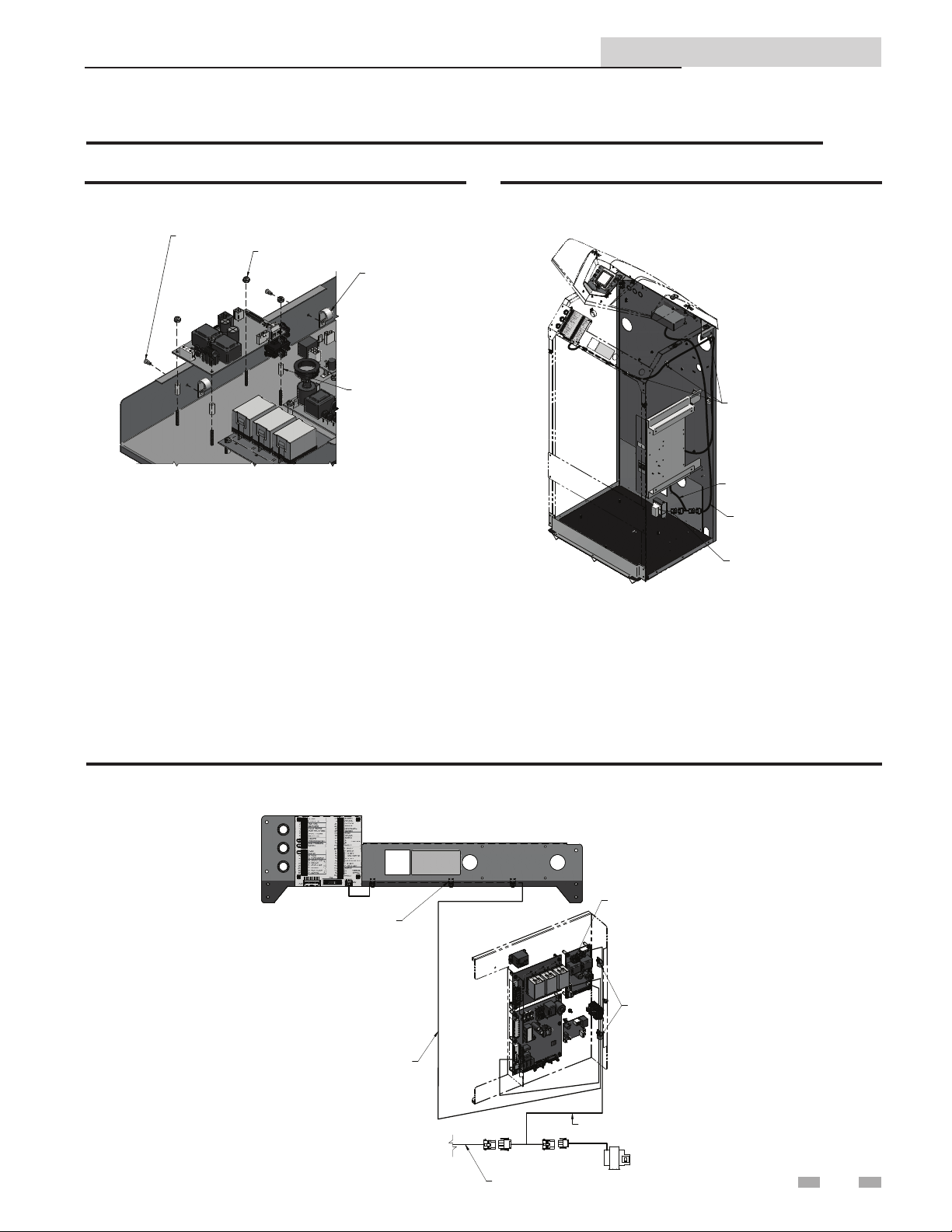

Figure 2-1a_Assemble Communication Board for

Models WB, WA, AW, KB and KBX

SHEET METAL BASE

JKB40095

BLT2007 [X4]

BLT7068 [X4]

Figure 2-1b_Assemble Communication Board for

Models OA and OK

BLT2007

[X4]

SHEET METAL

BASE (JKB40265)

IMG00565

BLT7068 [X4]

NOTE: KB/KXL/AW - MOUNT MODBUS ASSEMBLY TO THE LEFT SIDE OFTHE

JACKET. WB/WA - MOUNT MODBUS ASSEMBLY TO THE RIGHT SIDE OF THE JACKET.

Figure 2-3b_Mount Communication board to Unit for

Models OA and OK

- LOCATE THE PILOT HOLES

- USING THE (2) SHEET METAL SCREWS PROVIDED

IN THE KIT MOUNT THE MODBUS ASSEMBLY TO THE UNIT

(SIDE AND ORIENTATION DEPENDENT ON MODEL /

VERTICAL ORIENTATION SHOWN)

NOTE: OA/OK151 MOUNT MODBUS ASSEMBLY TO THE RIGHT SIDE JACKET FLANGE

OA/OK400-501 MOUNT MODBUS ASSEMBLY IN HORIZONTAL ORIENTATION

IMG00567

3

ModBus and BACnet Communication Instructions

2 Installation

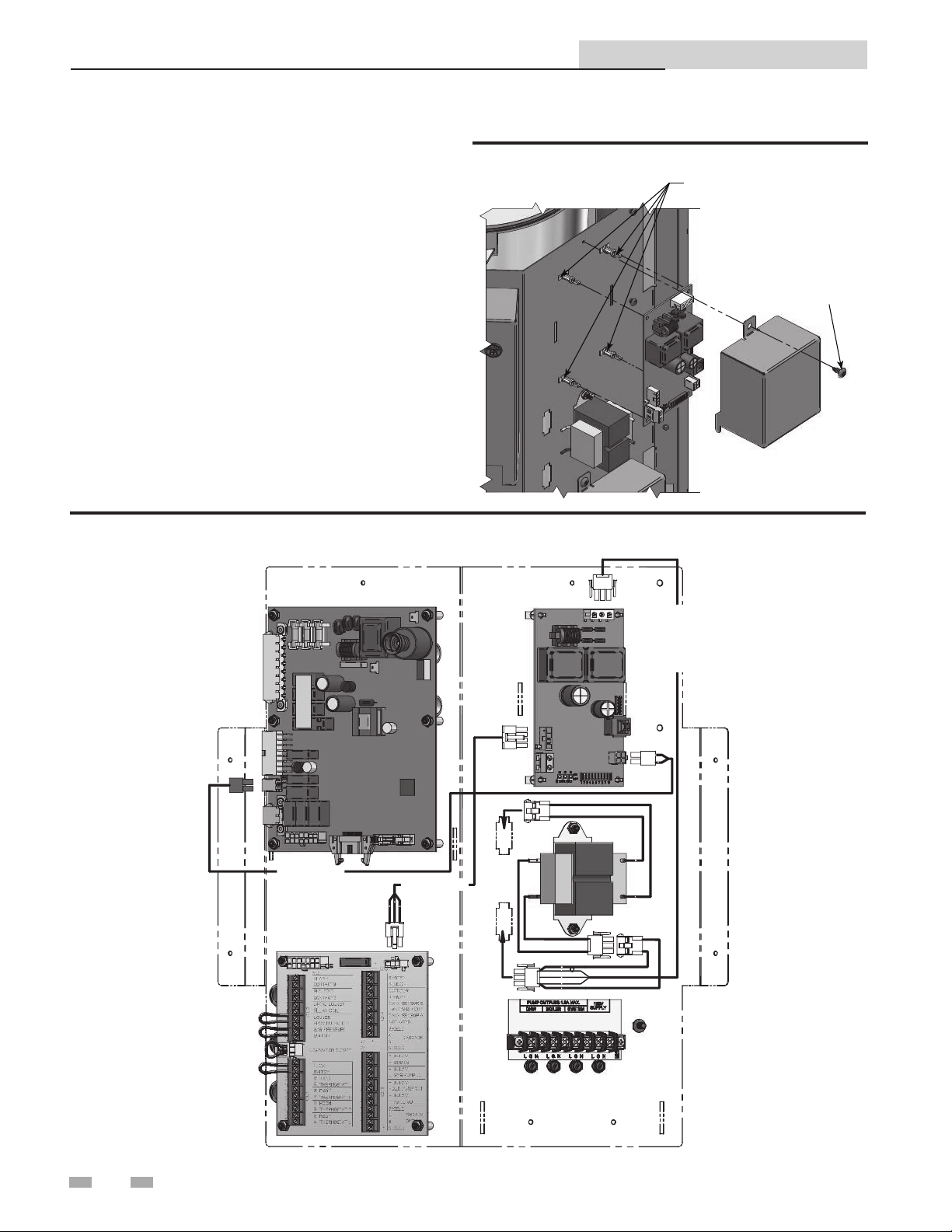

Figure 2-4_Harness Connections_WB, WA, AW, KB, KBX, OA, and OK models

FROM POWER

HARNESS

A

B

G

W

ROUTE THROUGH

JACKET HARNESS

CLIPS

USE SUPPLIED CABLE TIE

TO CONNECT MODBUS POWER

HARNESS TO BLOWER POWER

WIRES (RED, WHITE, GREEN)

TO TRANSFORMER

D

C

B

W

WGB

B

B

W

GY

G

R

BL

G

Figure 2-5_Connect Communication Board to Control Board

CONNECT TO

CONTROL BOARD

FROM COMMUNICATION

BOARD*

4

*HARNESSES CAN ONLY BE CONNECTED ONE WAY.

LOW VOLTAGE

CONNECTION BOARD

CONNECT TO

CONNECTION BOARD

FROM COMMUNICATION

BOARD*

2 Installation (continued)

ModBus installation procedure - for FTXL Models

ModBus and BACnet Communication Instructions

Figure 2-6a_Assemble ModBus Control Board for FTXL

2X RIVET

4X LOCKNUT

2X CLIP

4X ALUMINUM

SPACER

IMG01107

1. Turn OFF the main electrical power to the appliance.

2. Turn OFF the main manual gas shuto to the appliance.

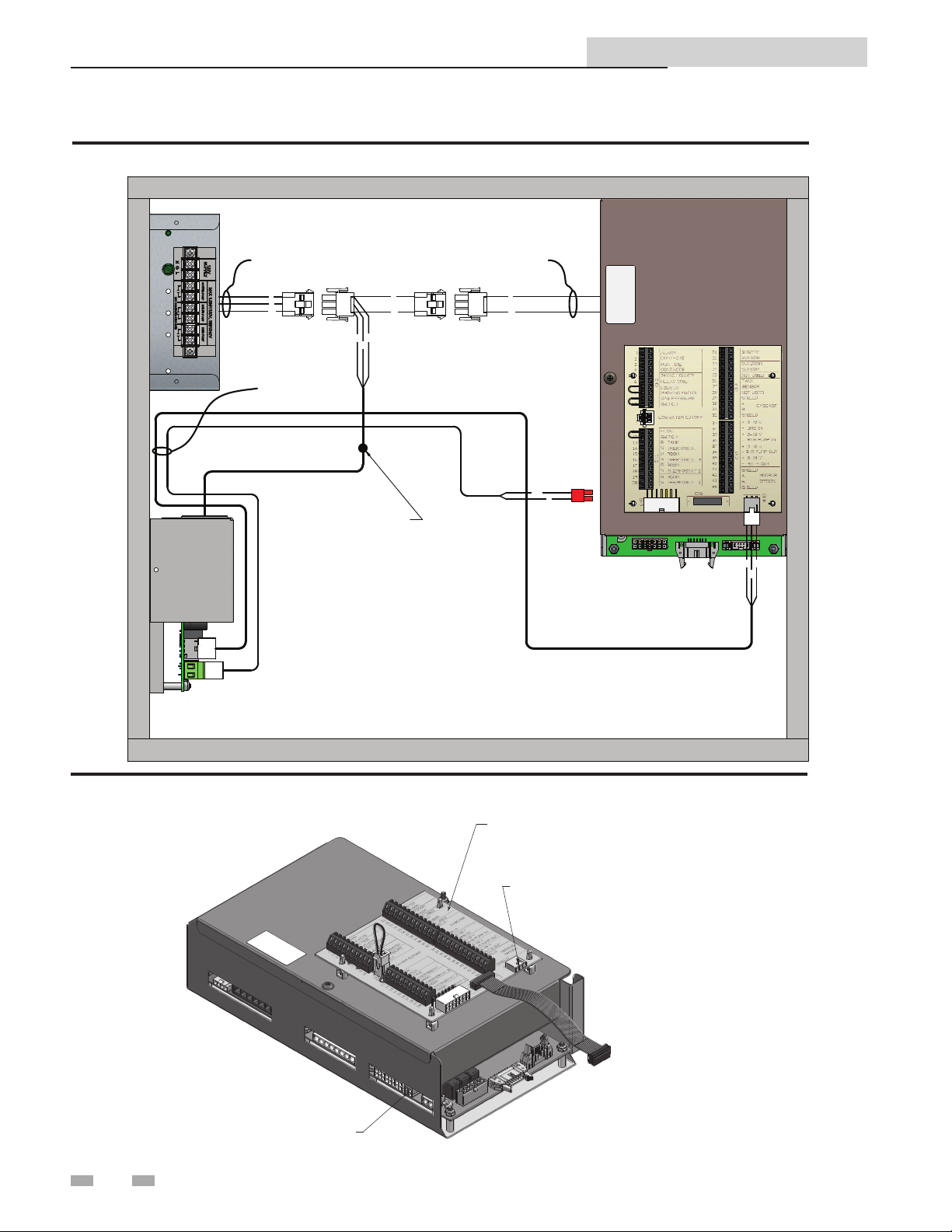

3. Assemble the ModBus control board and provided cable

clamps to the control panel as shown in FIG. 2-6a.

4. Connect the ModBus power, control board and

connection board wiring harnesses. Secure the wiring

with the provided cable clips and route it through the

bottom of the control panel. Perform the wiring

connections referencing FIG.’s 2-6b and 2-6c.

5. Turn ON the main electrical power to the appliance.

6. Con gure the control board and unit controls per this

manual and resume operation.

Figure 2-6b_Secure Control Board to FTXL Unit

SECURE CONNECTION

BOARD W/ 5X CLIPS

MODBUS

POWER HARNESS

UNIT

POWER HARNESS

TRANSFORMER

PRIMARY 120V

IMG01106

Figure 2-6c_Perform Wiring Connections for FTXL

LOW VOLTAGE CONNECTION BOARD

SECURE HARNESS

W/ 3X CLIPS

CONNECTION BOARD /

MODBUS HARNESS

MAIN CONTROL BOARD

UNIT POWER HARNESS

MODBUS

MODBUS

POWER HARNESS

PRIMARY

120V

SECURE HARNESS

W/ 2X CLIPS

IMG01105

5

2 Installation

ModBus and BACnet Communication Instructions

Installation Procedure - for WH Models

1. Turn OFF the main electrical power to the appliance.

2. Turn OFF the main manual gas shuto to the appliance.

3. To assemble the communication board to the sheet metal,

insert four (4) stando s into the front access panel

(FIG. 2-6).

4. Place the communication board onto the stando s

installed in Step 3. Use the screw (provided in kit) to

secure the control panel cover (FIG. 2-6).

5. Connect the wire harnesses (100172824 , 100172826 and

100172828) from the appliance to the communication

board following the diagram shown in FIG. 2-7.

6. Turn on the main electrical power and the main manual

gas shuto to the appliance.

7. Con gure the communication board and unit controls

per this manual and resume operation.

Figure 2-7_Harness Connections_WH

Figure 2-6_Assemble Communication Board_WH

INSERT

STANDOFFS

USE SCREW TO

SECURE COVER

TO FRONT PANEL

(WRE20075)

(WRE20073)

G

R

B

L

(WRE20077)

G

Y

G

W

B

W

W

G

B

B

6

ModBus and BACnet Communication Instructions

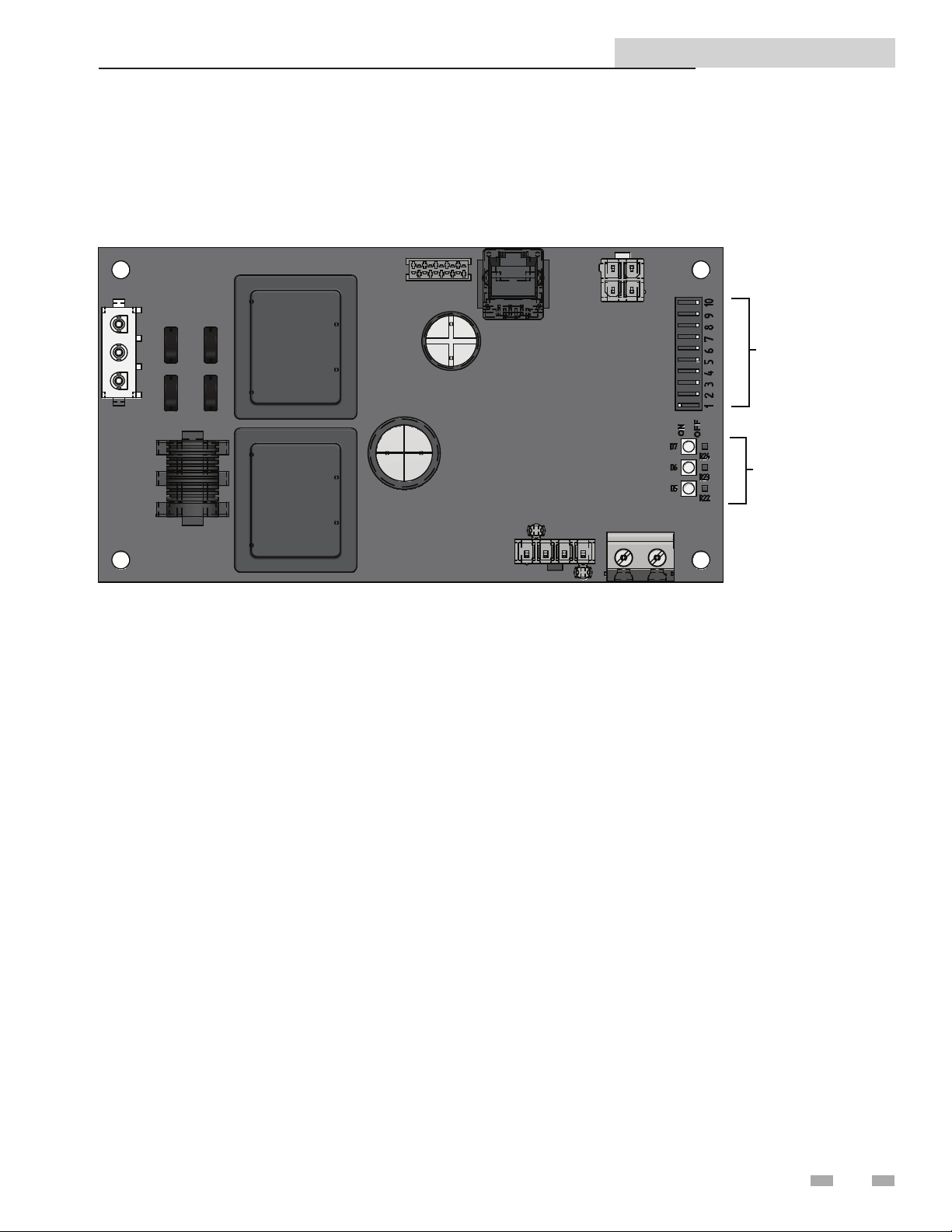

3 ModBus Confi guration

e ModBus communication board is equipped with a set of ten dip switches that are used to set the board con guration

(address, baud rate, and parity settings). e rst eight are used to set the address of each board. e ninth is baud rate. e

tenth is parity.

Figure 3-1_ModBus Communication Board

DIP SWITCHES

LED’S

Addressing

e ModBus addressing space is comprised of 256 di erent

addresses.

• 0 is reserved for broadcast messages from the master

device

• 1 - 247 are free to use for each unique device

• 248 - 255 are reserved

To set the ModBus address the dip switches can be set in

either the 0 position or the 1 position. For switches set to

the 1 position their value will be added together to determine

the address.

Each switch set to the 1 position has the following value:

Dip switch 1 = 1

Dip switch 2 = 2

Dip switch 3 = 4

Dip switch 4 = 8

Dip switch 5 = 16

Dip switch 6 = 32

Dip switch 7 = 64

Dip switch 8 = 128

Any dip switch set to 0 has a value equal to 0.

Example:

To set the address of the ModBus board to 50, dip switches 2, 5,

and 6 have to be set to the 1 position. e address is determined

by adding the values of all the dip switches together.

Address = Value of Dip switch 1 + Value of Dip switch 2 +

Value of Dip switch 3 + Value of Dip switch 4 + Value of Dip

switch 5 + Value of Dip switch 6 + Value of Dip switch 7 +

Value of Dip switch 8

In this example:

Address = 0 + 2 + 0 + 0 + 16 + 32 + 0 + 0 = 50

7

3 ModBus Confi guration

ModBus and BACnet Communication Instructions

Timing Specifi cations

e baud rate for the ModBus board is selectable with Dip

switch #9.

1 = 19200 bps

0 = 9600 bps

Each message is started by at least 3.5 character times of

silence. e maximum delay between frames is 1.5 character

times.

When the system temperature, tank temperature, and/or

0-10V BMS voltage is provided by the BAS to the boiler, it

is critical that the values be updated every few seconds. If

the boiler does not receive updated values within a timeout

period (installer adjustable), the control will revert to using its

own readings (if connected). e timeout is programmable

as follows:

NOTICE

1. Press and hold the LEFT SELECT [MENU] key for 5

seconds.

2. Enter installer code - 5309.

3. Scroll down and select [CONTROL MODES].

4. Scroll down and select [MODBUS T/O].

5. Scroll to desired time. Press the RIGHT SELECT [SAVE]

key.

Please note that the brackets ([]) denote

screen status.

Data Transmission Mode

Many ModBus bus master devices can be con gured to

transmit data in either ModBus RTU or ModBus ASCII modes.

Since RTU messages can be formatted to use fewer data bits and

are therefore more e cient, RTU has been chosen to be used

with all Lochinvar ModBus communication. Please ensure that

the master device is transmitting ModBus RTU.

ModBus Board Diagnostics

e ModBus board is equipped with three LED’s for visual

diagnostics: Two yellow LED’s and one green. One yellow LED

(D5) is used to indicate transmission of data. e other yellow

LED (D6) is used to indicate reception of data. e green LED

(D7) is used to show internal faults.

Internal Faults:

Normal Operation = 1 second bright, 1 second dim

Controller Fault = Continuously on

No Burner Control Communication = 0.5 seconds on, 1.5

seconds o

No ModBus Communication = 1.5 seconds on, 0.5 seconds

o

ModBus Communication

e ModBus communication commands and exception codes

that are supported by the ModBus communication board can

be found on pages 8 and 9 of this manual.

e timeout is adjustable between 5 and 120 seconds. e

default timeout is 10 seconds.

When the BAS is not providing any of these values, but

is still controlling the boiler (such as providing an enable

command), the BAS must refresh these commands at least

every 4 minutes. If the commands are not refreshed, the

boiler will revert to operating based on its own inputs.

Parity

Parity is set by the position of Dip switch #10.

0 = No Parity

1 = Even Parity

If No Parity is selected there will be two stop bits, otherwise

there will be one.

8

3 ModBus Confi guration (continued)

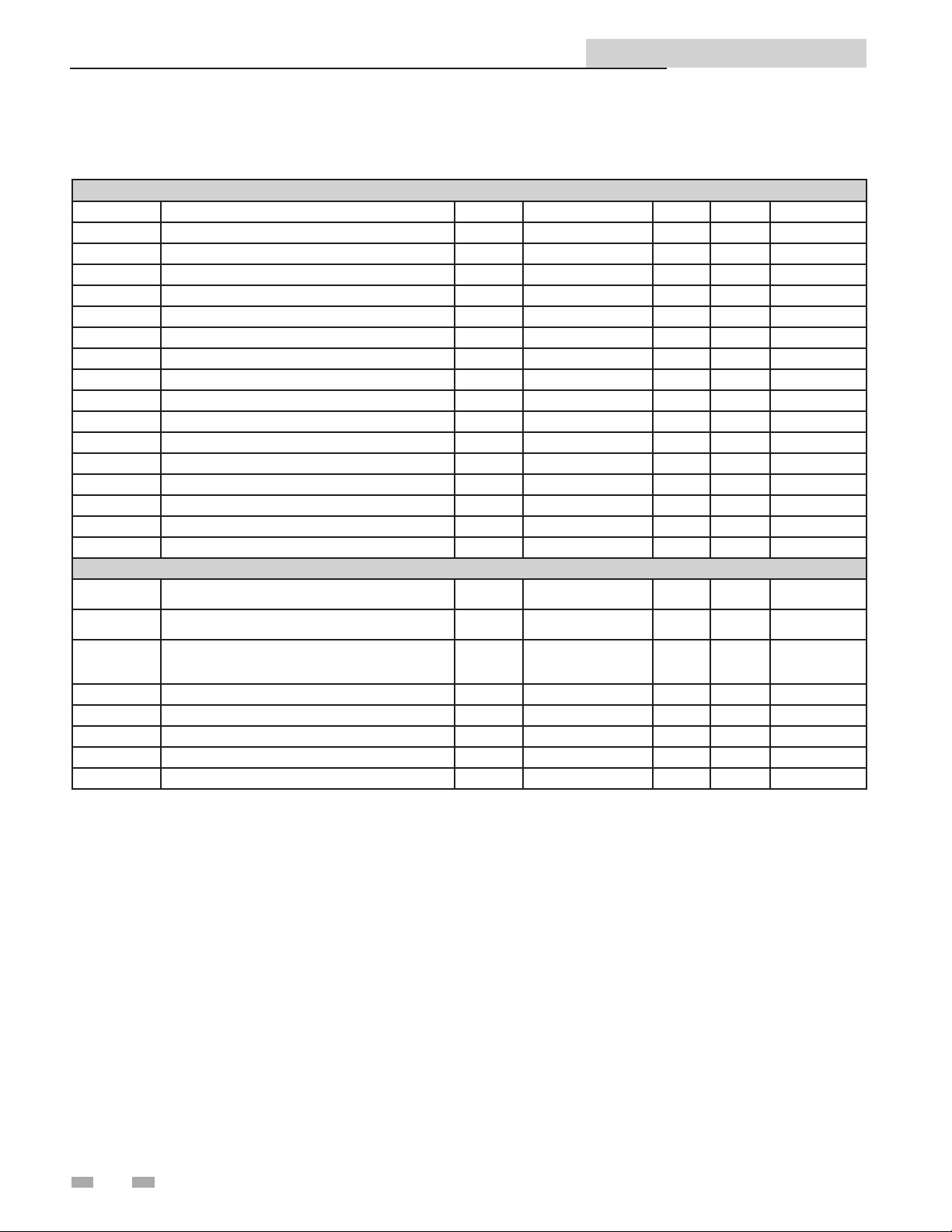

ModBus Function Set

ModBus and BACnet Communication Instructions

Function Sub Function

HEX Description

Dec HEX Dec

1 01 Read Coil Status

2 02 Read Input Status

3 03 Read Holding Registers

4 04 Read Input Registers

5 05 Force Single Coil

6 06 Preset Single Register

7 07 Read Exception Status

8 08 0 00 Diagnostic - Return Query Data

1 01 Diagnostic - Restart Communication

2 02 Diagnostic - Return Diagnostic Register

4 04 Diagnostic - Force Listen Mode

10 0A

11 0B Diagnostic - Return Bus Message Count

Diagnostic - Clear Counters and Diagnostic

Registers

12 0C Diagnostic - Bus Communication Error Count

13 0D Diagnostic - Bus Exception Error Count

14 0E Diagnostic - Return Slave Message Count

15 0F Diagnostic - Return Communication Error Count

16 10 Diagnostic - Return Slave NAK Count

17 11 Diagnostic - Return Slave Busy Count

18 12 Diagnostic - Return Bus Character Overrun Count

20 14 Diagnostic - Clear Overrun Counter and Flag

11 0B Get Communication Event Counter

12 0C Get Communication Event Log

15 0F Write Multiple Coils

16 10 Write Multiple Registers

17 11 Report Slave ID

23 17 Read / Write Multiple Registers

9

ModBus and BACnet Communication Instructions

3 ModBus Confi guration

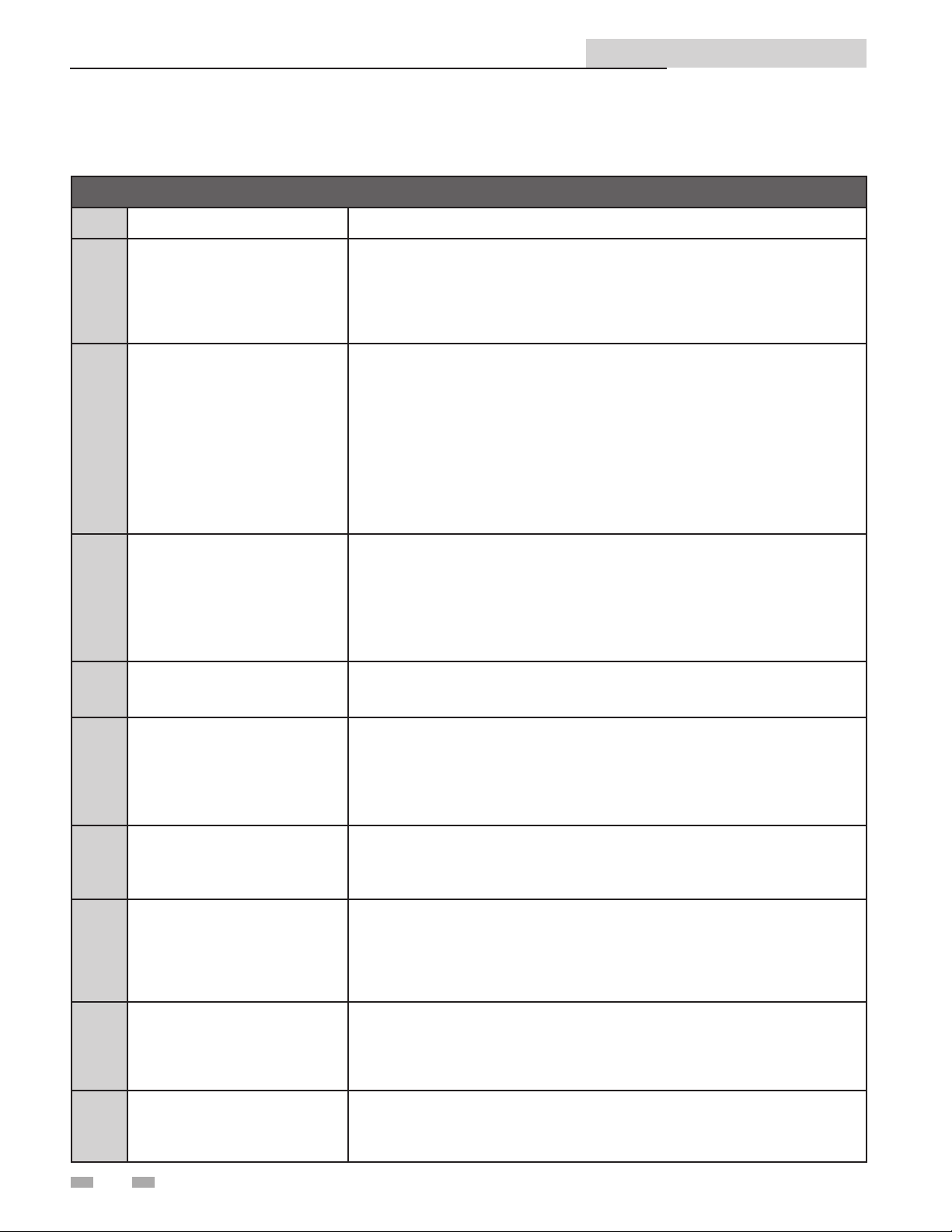

ModBus Exception Codes

MODBUS Exception Codes

Code Name Meaning

The function code received in the query is not an allowable action for the server

(or slave). This may be because the function code is only applicable to newer

01 ILLEGAL FUNCTION

02 ILLEGAL DATA ADDRESS

devices, and was not implemented in the unit selected. It could also indicate that

the server (or slave) is in the wrong state to process a request of this type, for

example because it is unconfi gured and is being asked to return register values.

The data address received in the query is not an allowable address for the

server (or slave). More specifi cally, the combination of reference number and

transfer length is invalid. For a controller with 100 registers, the PDU addresses

the fi rst register as 0, and the last one as 99. If a request is submitted with a

starting register address of 96 and a quantity of registers of 4, then this request

will successfully operate (address-wise at least) on registers 96, 97, 98, 99. If

a request is submitted with a starting register address of 96 and a quantity of

registers of 5, then this request will fail with Exception Code 0x02 “Illegal Data

Address” since it attempts to operate on registers 96, 97, 98, 99 and 100, and

there is no register with address 100.

03 ILLEGAL DATA VALUE

04 SLAVE DEVICE FAILURE

05 ACKNOWLEDGE

06 SLAVE DEVICE BUSY

08 MEMORY PARITY ERROR

A value contained in the query data fi eld is not an allowable value for server

(or slave). This indicates a fault in the structure of the remainder of a complex

request, such as that the implied length is incorrect. It specifi cally does NOT

mean that a data item submitted for storage in a register has a value outside the

expectation of the application program, since the MODBUS protocol is unaware of

the signifi cance of any particular value of any particular register.

An unrecoverable error occurred while the server (or slave) was attempting to

perform the requested action.

Specialized use in conjunction with programming commands. The server

(or slave) has accepted the request and is processing it, but a long duration of

time will be required to do so. This response is returned to prevent a timeout error

from occurring in the client (or master). The client (or master) can next issue a Poll

Program Complete message to determine if processing is completed.

Specialized use in conjunction with programming commands. The server

(or slave) is engaged in processing a long -- duration program command. The

client (or master) should re-transmit the message later when the server (or slave)

is free.

Specialized use in conjunction with function codes 20 and 21 and reference type

6, to indicate that the extended fi le area failed to pass a consistency check. The

server (or slave) attempted to read record fi le, but detected a parity error in the

memory. The client (or master) can retry the request, but service may be required

on the server (or slave) device.

0A GATEWAY PATH UNAVAILABLE

0B

GATEWAY TARGET DEVICE

FAILED TO RESPOND

10

Specialized use in conjunction with gateways, indicates that the gateway was

unable to allocate an internal communication path from the input port to the

output port for processing as the request. Usually means that the gateway is

misconfi gured or overloaded.

Specialized use in conjunction with gateways, indicates that no response was

obtained from the target device. Usually means that the device is not present on

the network.

ModBus and BACnet Communication Instructions

4 ModBus Memory Map

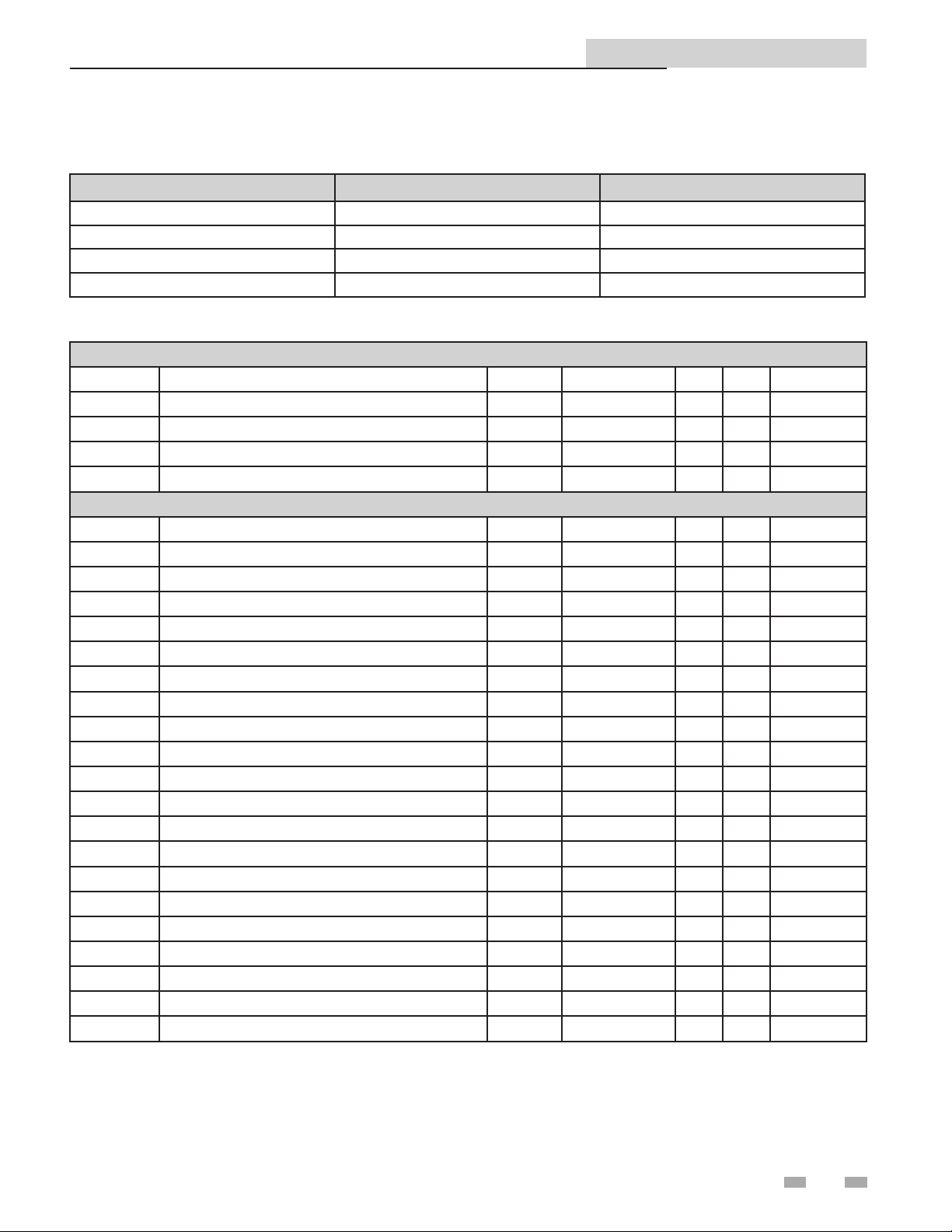

Primary Data Tables

Table Data Type Read / Write

Discrete Inputs Single Bit Read Only

Coils Single Bit Read / Write

Input Registers 16-Bit Word Read Only

Holding Registers 16 Bit Word Read / Write

Memory Map

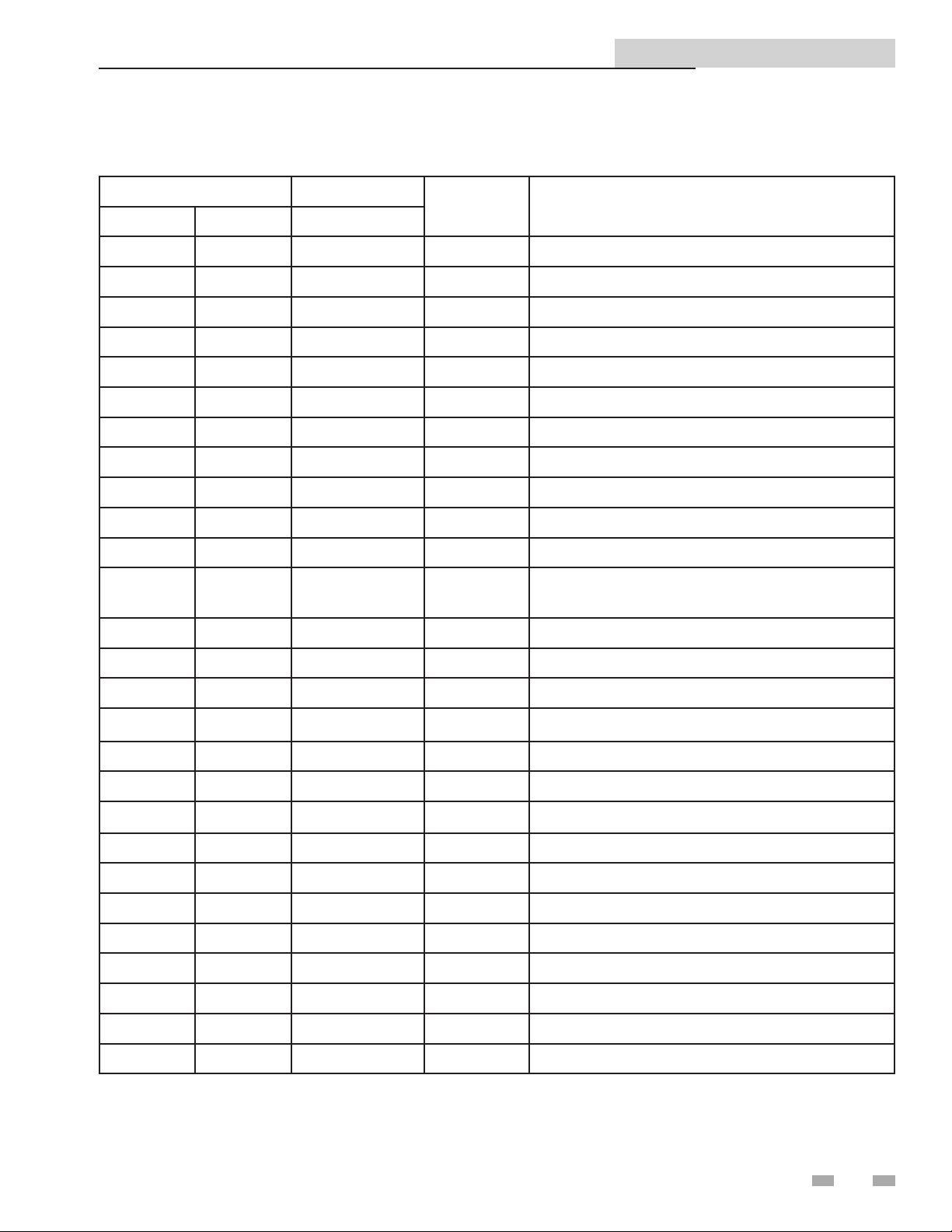

Coils

Address Description Default Unit Min. Max. Resolution

00001 Room Thermostat 1 0 1=ON / 0=OFF 0 1 1

00002 Room Thermostat 2 0 1=ON / 0=OFF 0 1 1

00003 Room Thermostat 3 0 1=ON / 0=OFF 0 1 1

00005 Tank Thermostat 0 1=ON / 0=OFF 0 1 1

Discrete Inputs

10002 Flow Switch 0 1=ON / 0=OFF 0 1 1

10003 Gas Pressure Switch 0 1=ON / 0=OFF 0 1 1

10004 Louver Proving Switch 0 1=ON / 0=OFF 0 1 1

10005 Air Pressure Switch 0 1=ON / 0=OFF 0 1 1

10006 Blocked Drain Switch 0 1=ON / 0=OFF 0 1 1

10007 Auto Reset High Limit 0 1=ON / 0=OFF 0 1 1

10008 Flame 0 1=ON / 0=OFF 0 1 1

10009 Room Thermostat 1 0 1=ON / 0=OFF 0 1 1

10010 Tank Thermostat 0 1=ON / 0=OFF 0 1 1

10024 Room Thermostat 2 0 1=ON / 0=OFF 0 1 1

10033 Run-time Contacts 0 1=ON / 0=OFF 0 1 1

10034 Alarm Contacts 0 1=ON / 0=OFF 0 1 1

10035 CH Pump 0 1=ON / 0=OFF 0 1 1

10036 DHW Pump 0 1=ON / 0=OFF 0 1 1

10037 Louver Relay 0 1=ON / 0=OFF 0 1 1

10038 Gas Valve 0 1=ON / 0=OFF 0 1 1

10039 System Pump 0 1=ON / 0=OFF 0 1 1

10044 DHW Recirculation Pump 0 1=ON / 0=OFF 0 1 1

11

ModBus and BACnet Communication Instructions

4 ModBus Memory Map

Memory Map

Input Registers

Address Description Default Unit Min. Max. Resolution

30001 Discrete Inputs 1 - 16 0 HEX 0 65535 1

30002 Discrete Inputs 17 - 32 0 HEX 0 65535 1

30003 Discrete Inputs 33 - 48 0 HEX 0 65535 1

30004 System / Cascade Setpoint 0 Degrees Celsius 0 130 0,5

30005 System Pump Speed 0 % 0 100 1

30006 Cascade Total Power 0 % 100 800 1

30007 Cascade Current Power 0 % 0 800 1

30008 Outlet Setpoint 0 Degrees Celsius 0 130 0,5

30009 Outlet Temperature 0 Degrees Celsius 0 130 0,1

30010 Inlet Temperature 0 Degrees Celsius -20 130 0,1

30011 Flue Temperature 0 Degrees Celsius -20 130 0,1

30012 Firing Rate 0 % 0 100 1

30013 Boiler Pump Speed 0 % 0 100 1

30014 Boiler Status Code 0 HEX 0 65535 1

30015 Boiler Blocking Code 0 HEX 0 65535 1

30016 Boiler Lockout Code 0 HEX 0 65535 1

Holding Registers

40001 Confi guration 0 NA 0 65535 1

40002 Coils 0 NA 0 65535 1

40003

40004 Tank Setpoint 0 Degrees Celsius 0 87,5 0,5

40005 Tank Temperature 0 Degrees Celsius -20 130 0,1

40006 Outdoor Temperature 0 Degrees Celsius -40 60 0,1

40007 System Supply Temperature 0 Degrees Celsius -20 130 0,1

40008 DHW Recirculation Temperature 0 Degrees Celsius -20 130 0,1

0-10 Volt Input / Rate Command / Setpoint

Command

0 % 0 100 1

Confi guration Bits

Address 40001 contains con guration bits sent from the BAS to the appliance. ese bits tell the boiler/water heater to use its

own internal inputs, or inputs from the BAS. When a bit is set to 1, the boiler/water heater will ignore the corresponding value

contained internally, and expect the BAS to write that value into the Holding Registers. e con guration bits are as follows:

Bit 0 (LSB): Boiler Enable

Bit 1: Tank ermostat

Bit 2: Rate Command / 10 - 10V Input / Setpoint Command

Bit 3: Tank Setpoint

Bit 4: System Supply Temperature

Bit 5: Outdoor Temperature

Bit 6: Tank Temperature

Bit 7: System Return Temperature

Bit 8 - 15: Not Used (Default = 0)

12

Loading...

Loading...